Page 1

Excavators Electric

Material Handlers

ER 934 C - ER 954 C

High RiseHigh Rise

ER 934 C Operating Weight: 56,200 - 56,600 kg

ER 944 C Operating Weight: 73,400 - 74,700 kg

ER 954 C Operating Weight: 95,800 - 97,000 kg

Page 2

ER 934 C

ER 944 C

Operating Weight: 56,200 - 56,600 kg

Engine Capacity: 160 kW / 218 PS

ER 954 C

Operating Weight: 95,800 - 97,000 kg

Engine Capacity: 250 kW / 340 PS

Operating Weight: 73,400 - 74,700 kg

Engine Capacity: 200 kW / 272 PS

ER 934 C - ER 944 C - ER 954 C High Rise

2

Page 3

Performance

These new electric Material Handlers have been designed

to meet the specific needs of industrial handling. A range

of equipment even wider for the High Rise and uppercarriages optimized for long working radius provide the ideal

answer to all the demands which arise in the industry.

The performance of the kinematic chain formed from components from our in-house production, combined with the

power of the electric motor, maximize the performance

of the machine when it comes to lifting power, precision,

and speed of operation. The equipment’s performance is

enhanced by the mobility provided by the crawler undercarriage as well as the height of work adapted to the industrial process.

Reliability

Backed by more than 30 years experience in the construction of electric excavators, Liebherr designed the

new ER 934 C, ER 944 C and ER 954 C High Rise with the

aim of providing top performance whatever the challenge

might be. The structure of the machine, using compo-

nents from our own manufacture for the electric drive,

has been completely rethought, and so moves away

from simply being an adaptation of a diesel-engine

machine. Being intended for key functions in the

organization of industrial sites, Liebherr electric

Material Handlers provide a very high level of

reliability. The service life of the hydraulic com-

ponents has also been increased, thanks to the

constant regime of the electric drive. The concept of the

single actuator (one single electric motor for all the hydraulic functions) allows all the low-voltage functions to

be concentrated in a single box.

Comfort

Helping the operator to concentrate on his work and get

the best out of his machine is achieved by providing a comfortable driving position, good panoramic visibility, and a

highly ergonomic layout of the controls. The new electric

Material Handlers offer the same level of comfort as on the

thermal excavators (arrangement of the controls, driver’s

seat, climate control, large window areas, etc.). The electric motor system adds a further layer of comfort thanks

to the low noise emissions and absence of vibration. For

Liebherr, comfort also means ease of daily maintenance of

the machine in terms of access to the service and inspection points, so as to minimize down time.

Economy

Investing in the acquisition of an electric Material Handler is a great long-term advantage. Constant increases

in the costs of conventional energy sources are pushing

up operating charges, and reducing profi t margins considerably. Environmental criteria, in particular CO2 emissions, are also playing a constantly greater part in the

choice of power systems and working methods. With the

electric drive, Liebherr offers an economical alternative

to conventional diesel-engine machines, and a solution

with real respect for the environment. Also, the excavator

is permanently available, with no need to refill. There are

no constraints (e.g. DPF or AdBlue). Mobility is added to

economy, through custom cable reels solutions.

ER 934 C - ER 944 C - ER 954 C High Rise

3

Page 4

Excavator electric at a glance

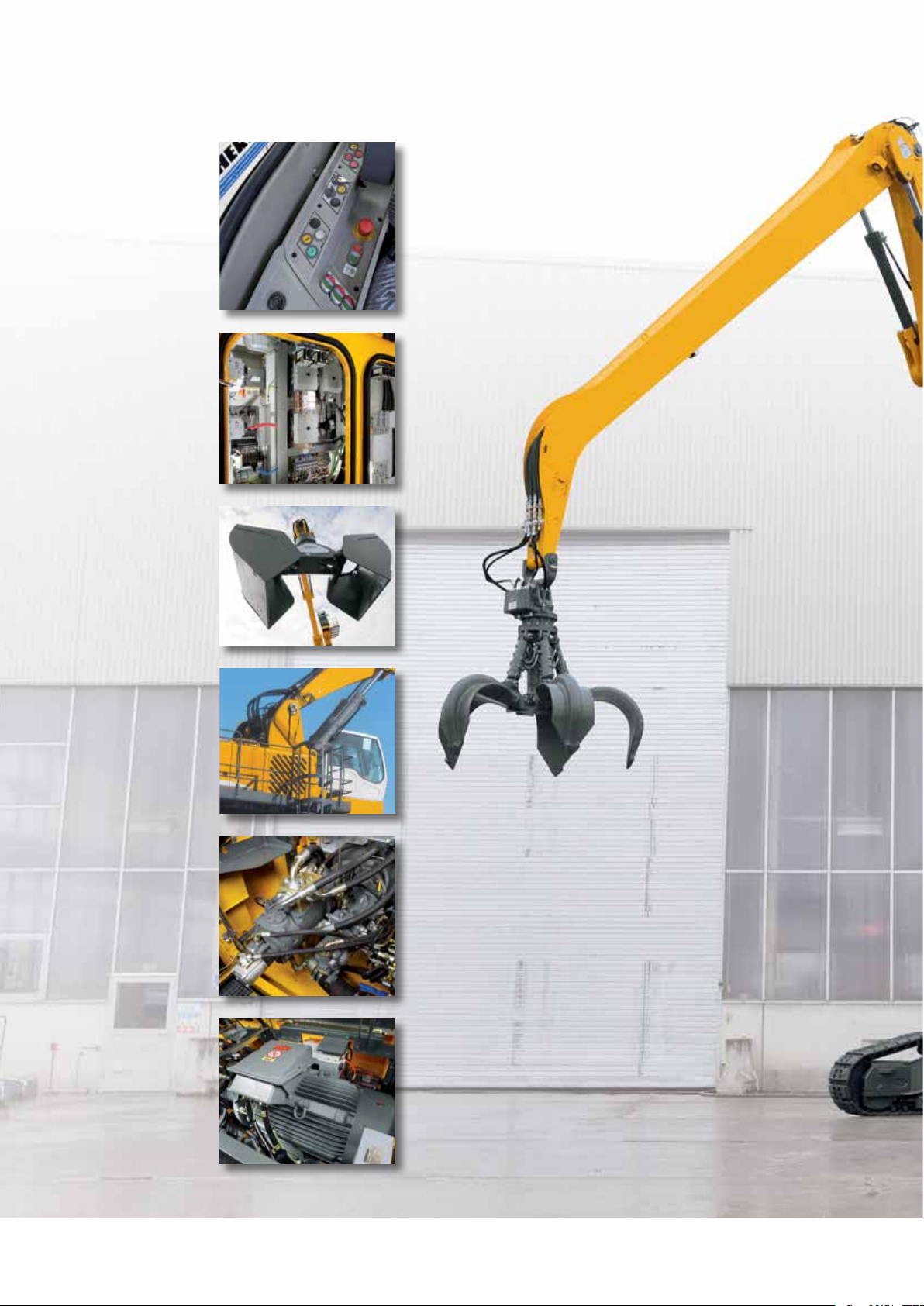

Cab with special

control panel

• Control power on/off

of the excavator

• Additional interface for

the cable reel option

Integrated electric cabinet

• Hard conditions

• Pressure relief system

to prevent the intrusion

of dust

• Closing with padlocks

• Robust

Wide range of tools,

including

• Grapples

• Shells for Loose Material

• Wood clamps

• Quick change adapter

Wide range of equipments

• Range of equipments from

the stationary excavators

for a moving machine

• Special adjustments on

demand

Kinematic chain Liebherr

• High work precision

• Immediate response

• Large power for

maximum productivity

Electric motor

• Hard conditions

• Constant regime

whatever the load

• Integrated sensors for

maximum availability

ER 934 C - ER 944 C - ER 954 C High Rise

4

Page 5

Cab elevation

• Wide range of rigid cab elevation

and adjustable hydraulically

• High visibility of the working

area and the site

Access

• As standard, safety and comfort

to access the work space

• Handrails, non-slip surfaces

Walkways

• Wide walkways and handrails

all around the excavator

• Can be tted with secure

trapdoors, wicket doors

Undercarriage

• Derived from thermal excavators,

specifically equipped for electric

excavators :

- cable entry

- power connector

- slip ring collector

• Stability for all operations

Cable entry

• In free-standing, cable left

entry as standard, right or rear

on demand

• Rear cable reel for a large radius

of action and movement facilities

• Side cable reel for in-line

processes

ER 934 C - ER 944 C - ER 954 C High Rise

5

Page 6

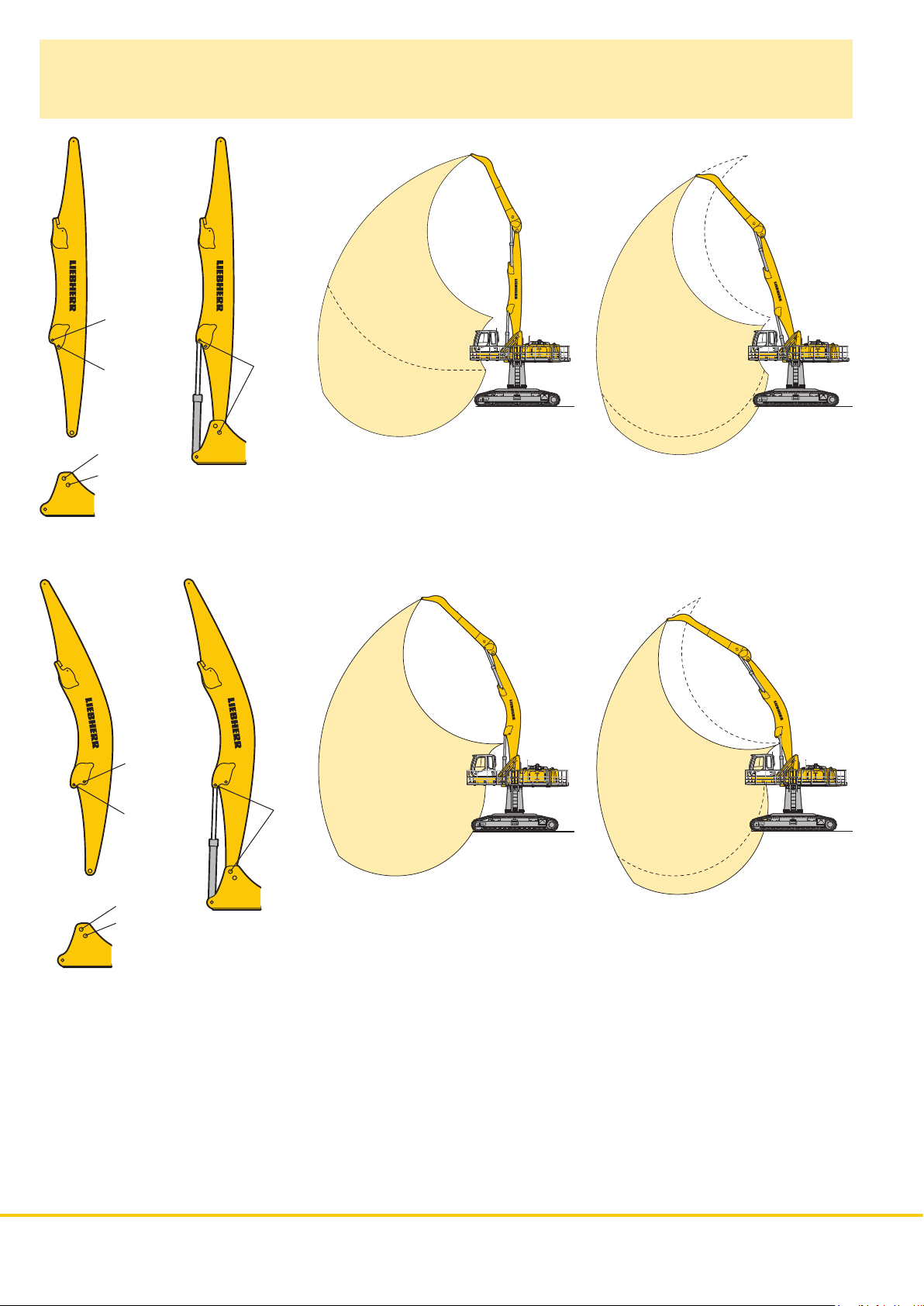

VarioLiftPlus

Variable Boom Mounting Positions for Optimized Lift Capacities

Hole A

Hole B

Hole 3

Hole 2

Version 2A

R0082

2A

with the same working range with a different working range

2A

3B

3B

R0082

3A

Kinematic variant 2A:

Increased lift capacities above ground level

Kinematic variant 3B:

Kinematic variant 3A:

Altered range curve with additional reach

depth, e.g. for unloading from ships

Increased lift capacities below ground level

and when working at large outreach

R0110

with a different working range

R0082

Hole C

Hole D

Hole 3

Hole 2

Version 3D

3D

3D

Kinematic variant 3D:

Increased lift capacities below ground level

and when working at large outreach

R0110

R0110

3C

Kinematic variant 3C:

Altered range curve with additional reach

depth, e.g. for unloading from ships

6 ER 934 C ER 944 C ER 954 C High Rise

Page 7

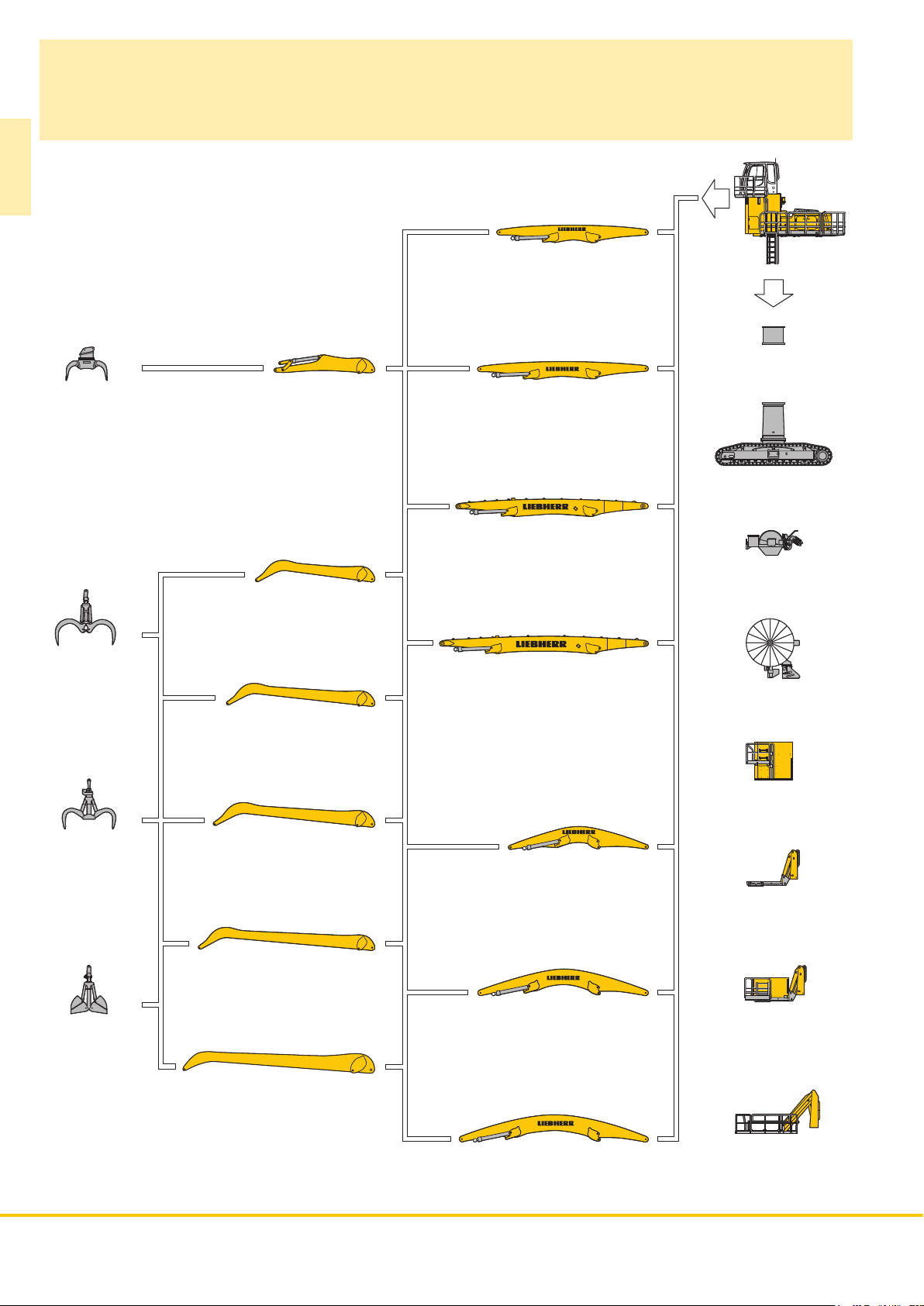

Technical Data

Electric Motor

������������������������������

Engine

934 944 954

Power rating

(as per CEI 34-1)

Rated voltage

Number of poles

Design type

Standard degree of protection

Insulation

Cooling

Heat protection for windings

Heat protection for bearings

Anti-condensation heating system resistors

������������������

���������������������

������������������

�����������������������

��������������������������

�����������������������������

induction motor dedicated definition Liebherr

160

kW (218 HP)

400 V – 50 Hz *

4

horizontal axle B35

axle height 315 mm

��

IP55

class F

IC06

200

kW (272 HP)

250

kW (340 HP)

Electric System

The 400 V electrical cabinet provides a degree of protection to IP55.

This houses the following components:

– Electrical cabinet – remote control inside the cab

– Star/delta starter for motor

– Outlets for supplying auxiliary elements: heating, climate control

– Overheat protection devices

– Integrated heating and ventilation

– Filtered booster

– Transformers – rectifier for 24 V control circuit

– Motor protection

– Auxiliary batteries: 2 x 135 Ah/12 V: secured functions: lighting for excavator/

attachment position (option)

– Connecting inside closed panel

– Equipment: slip ring collector

power connector

embedded cable reel

Swing Drive

����������������������������

Drive by

Transmission

Swing ring

934 944 954

Swing speed

Swing torque

Holding brake

Option

����������������������

�������������������������

����������������������

����������������������

���������������������

������������������������������

hydraulic swash plate motor with integrated

brake valves

Liebherr compact planetary reduction gear

Liebherr, sealed single race ball bearing swing

ring, internal teeth

0 – 9.4 RPM 0 – 7.9 RPM 0 – 5.6 RPM

stepless stepless stepless

81.07 kNm 119 kNm 167.23 kNm

oil-bath disk brake (negative action)

pedal controlled positioning brake

Operator’s Cab

���������������������������������

Cab

Operator’s seat

Controls

Monitoring

Climate control

Noise emission

2000/14/EC 934 944 954

L

WA

�������������������

����������������������������

�������������������������

�������������������

(surround noise)

single shell concept with shaped profiles, resil-

iently mounted, sound insulated, tinted windows.

Front window can be folded away under roof,

door with sliding window

shock absorbing suspension, adjustable to

operator’s weight, 6-way adjustable seat

integrated into adjustable seat consoles

menu driven digital display of current operating

conditions. Automatic monitoring, display, warn-

ing (audible and visual signal) and saving of

machine malfunction data, such as overheating

ofwindings, motor bearings, or low hydraulic

oillevel

standard climate control system, combined

cooler/heater, additional dust filter in the outside/

fresh air circuit

�������

101 dB(A) 103 dB(A) 105 dB(A)

ER 954 C ER 944 C ER 934 C

Hydraulic System

934 944 954

Hydraulic pump

for the attachment

Max. flow

Max. pressure

Pumpenansteuerung

Hydraulic pump

for the swing drive

Max. flow

Max. pressure

Hydraulic tank

Hydraulic system

���������������������������

Filtration

�����������������������������

Cooling

Tool Control

�����������������������

����������

���������������������

���������������

������������

����������

���������������������

���������������

��������������������

�����������������

two Liebherr swash plate pumps with variable

output

2 x 253 l/min. 2 x 305 l/min. 2 x 341 l/min.

350 bar

electro-hydraulic, with electronic regulation by

power limit, minimum pump flow at max. pres-

sure, distribution of oil to different receptor

components proportional to demand

reversible swash plate pump, in closed circuit

170 l/min. 205 l/min. 205 l/min.

370 bar

340 l 460 l 440 l

550 l 710 l 790 l

934: filter in the return circuit, with integrated fine

filter elements (5 μm)

944/954: 2 filters in the return circuit, with inte-

grated fine filter elements (5 μm)

radiator equipped with hydrostatic drive fan for

cooling the hydraulic oil and climate control

condenser

10 flow rates and pressures adjustable as option

for optional accessories

Hydraulic Controls

Power distribution

Flow summation

Closed-loop circuit

Control

Attachment and swing

Travel

Additional functions

����������������

������������

���������

�����

�������������������������

��������������

with the aid of hydraulic distributors with

integrated safety valves

to boom stick and stick

for uppercarriage swing drive mechanism

proportional by handling element in cross

operation

proportional by pedals or by lever

proportional by pedals or by toggle switch

Undercarriage

Version HR

��������������������������������

Drive

Transmission

934 944 954

Travel speed

Drawbar pull max.

Track components

Track rollers/Carrier rollers

Tracks

Track pads

Digging locks

Brake valves

����������������������

����������������������

����������������

���������������

������������������������������

������������������������

���������������������

����������������������

Liebherr swash plate motors with integrated

brake valves on both sides

Liebherr planetary reduction gears

2.6 km/h 2.6 km/h 2.5 km/h

318 kN 363 kN 397 kN

maintenance- maintenance- maintenance-

free free free

B 60 D 7 G D 8 K

�����

9/2 13/3 13/3

sealed and greased

triple grouser

wet multi-discs (spring applied, pressure

released)

integrated into travel motor

Attachment

��������������������������������

Type

Hydraulic cylinders

�������������������������������

Pivots

Lubrication

VarioLift

������������������������

�������������������������

Plus

���������������

high-strength steel for extreme stresses. Bearings

designed for optimum distribution of stresses

Liebherr cylinders with end-of-travel shock

absorbing, fitted with guide and sealing joints

sealed, low maintenance

centralised semi-automatic Liebherr lubrication

system

variable boom mounting positions for optimized

lift capacities

* Other voltages and frequencies possible on request.

ER 934 C ER 944 C ER 954 C High Rise 7

Page 8

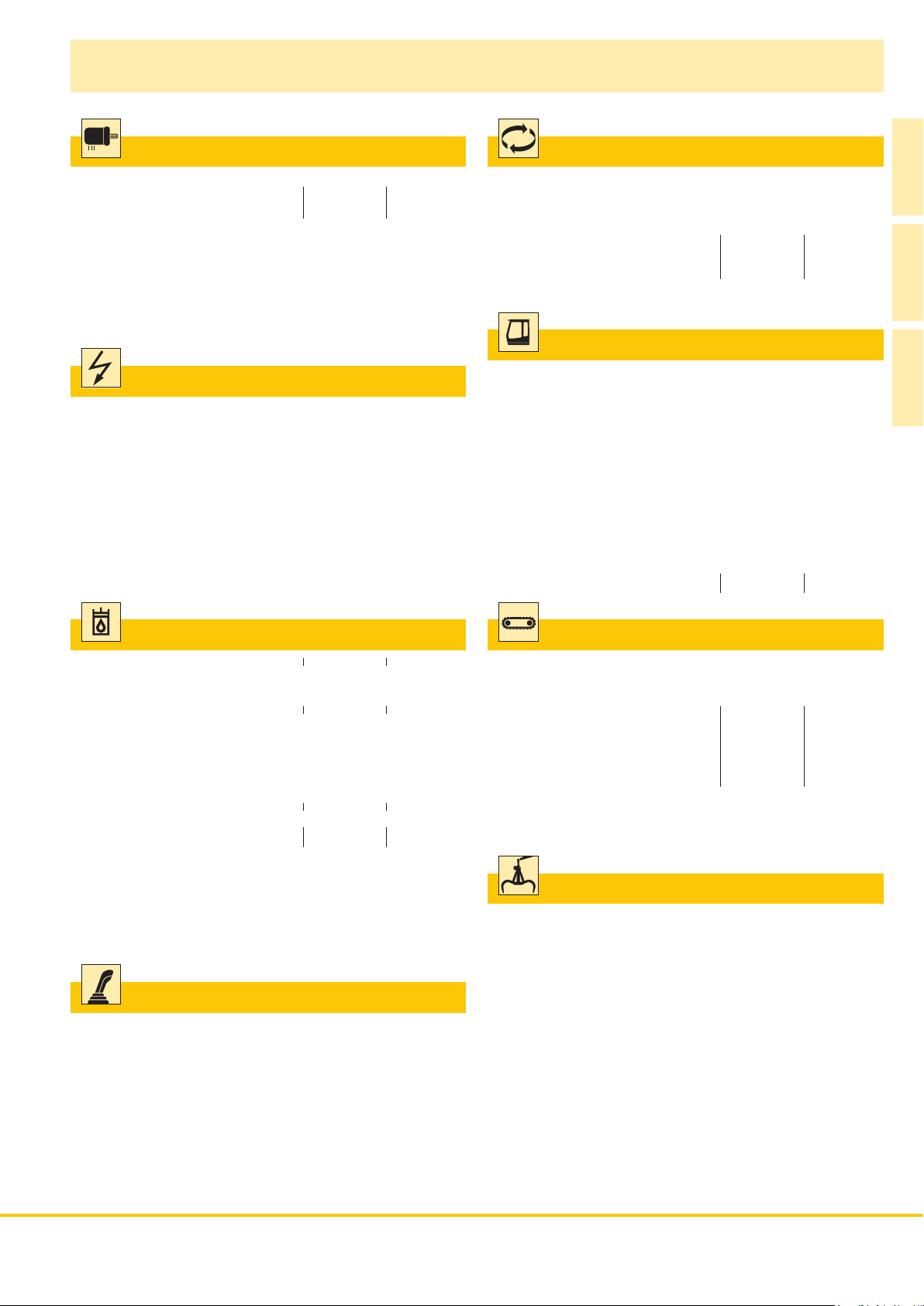

The Right Attachment

for Every Application

ER 934 C

Industrial-type straight mono boom 7.60 m

Sorting grapple

Stick 5.00 m

Industrial-type straight mono boom 8.60 m

Uppercarriage Elevation

Undercarriage

Wood grapple

Multi-tine grapple

Industrial-type straight mono boom 9.60 m*

Cylindrical cable reel

Industrial stick 6.00 m

Industrial-type straight mono boom 10.60 m*

Spiral cable reel

Industrial stick 7.50 m

Rigid cab elevation

Industrial stick 8.00 m

Industrial-type angled mono boom 7.60 m

Hydraulic Cab Elevation

Industrial stick 9.00 m*

Clamshell bucket

* presented configurations

8 ER 934 C ER 944 C ER 954 C High Rise

Industrial stick 9.00 m*

Industrial-type angled mono boom 8.60 m

Industrial-type angled mono boom 9.60 m*

Hydraulic Cab Elevation

+ Rigid cab elevation

Hydraulic Cab Elevation

+ Intermediate Piece

Page 9

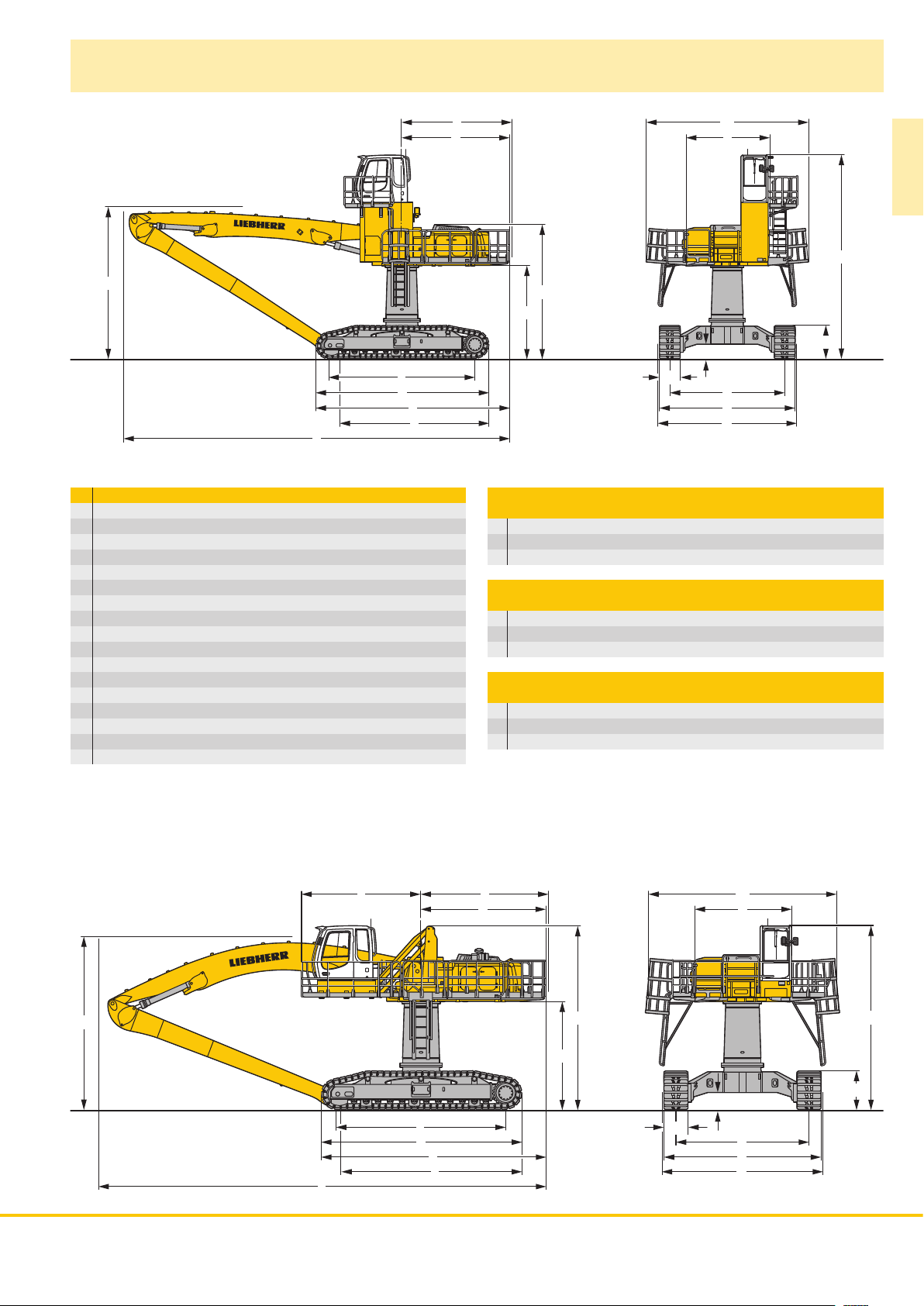

Dimensions

WW

LL

UU

ZZ

VV

XX

mm

A 3,225

A1 5,935

C 5,800

D 3,930

E 4,030

F 3,770

H 5,780

K 3,395

L 5,350

P 1,215

Q 530

S 4,200

U 6,320

N 750

B 4,950

G 5,060

Z 7,095

E = Tail radius

EE

DD

HH

KK

NN

A1A1

AA

QQ

SS

BB

GG

Industrial-Type Straight Mono Boom 9.60 m

and Industrial Stick m 9.00 10.00

V mm 5,800 5,450

W mm 4,850 5,550

X mm 14,100 14,100

Industrial-Type Straight Mono Boom 10.60 m

and Industrial Stick m 9.00 10.00

V mm 6,950 6,000

W mm 4,900 4,900

X mm 15,100 15,100

Industrial-Type Angled Mono Boom 9.60 m

and Industrial Stick m 9.00 10.00

V mm 5,700 5,500

W mm 5,450 6,500

X mm 14,100 14,100

ER 934 C

CC

PP

R0083

EEFF

DD

WW

LL

UU

ZZ

VV

XX

HH

KK

NN

A1A1

AA

CC

QQ

SS

BB

GG

PP

R0084

ER 934 C ER 944 C ER 954 C High Rise 9

Page 10

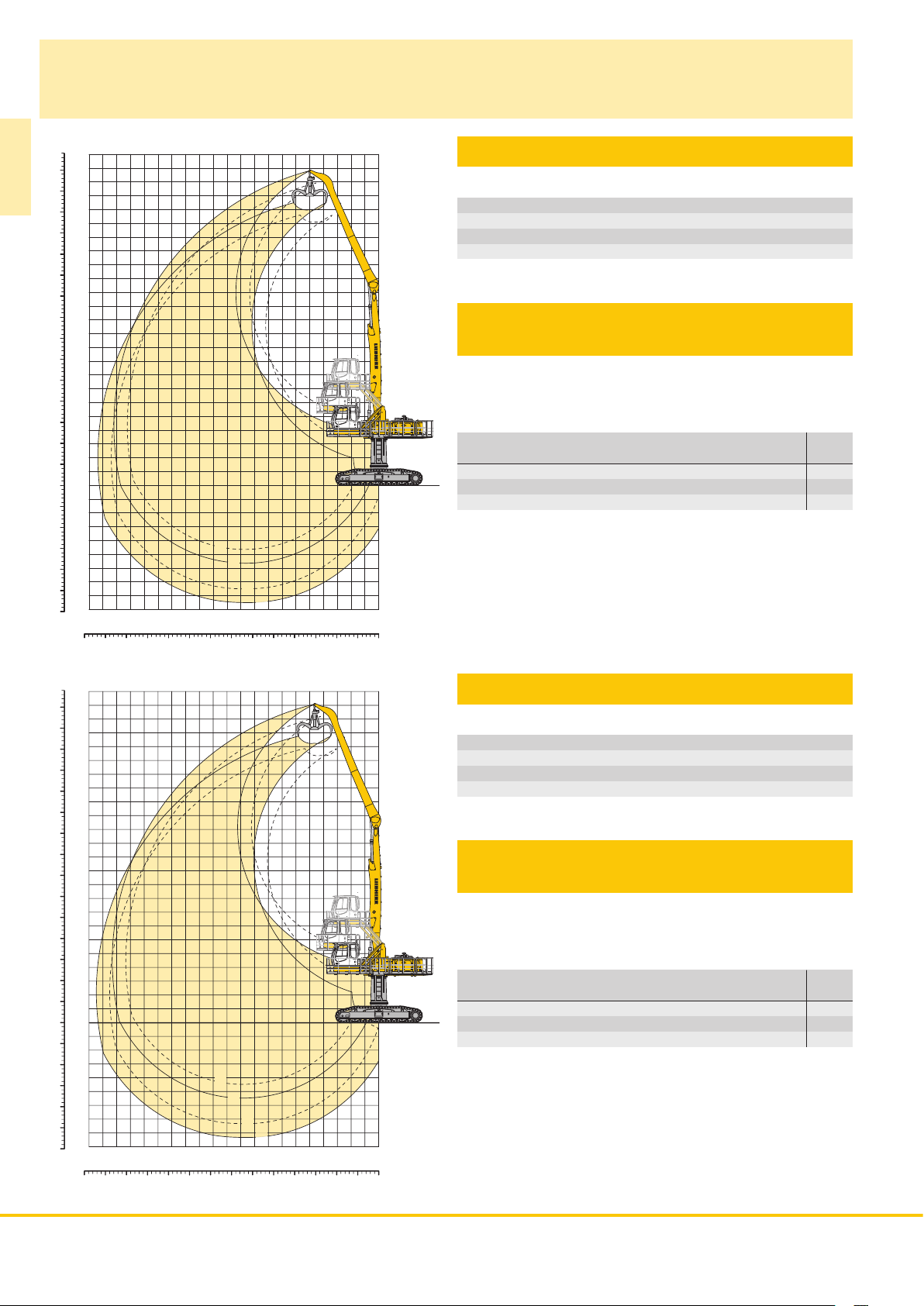

Industrial Attachment

with Industrial-Type Straight Mono Boom 9.60 m

m

ft

24

75

22

70

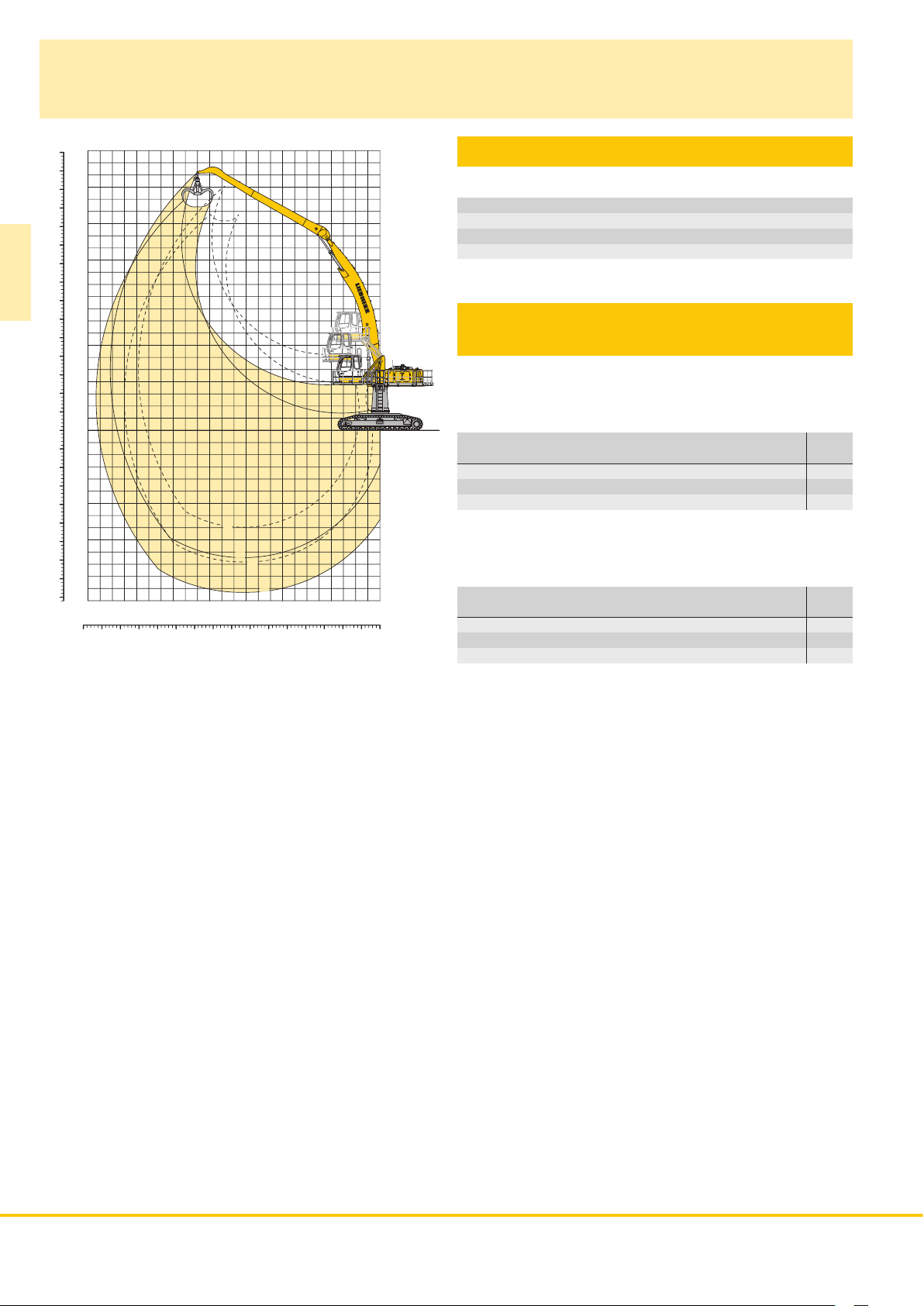

ER 934 C

20

65

60

18

55

16

50

14

45

40

12

35

10

30

8

25

20

6

15

4

10

2

5

0

0

-5

-2

-10

-15

-20

-25

-30

-4

-6

-8

16

18

20

1

3

2

4

6

8

10

12

14

R0100

Attachment Envelope

Kinematic variants 2A

1 with industrial stick 9.00 m

2 with industrial stick 9.00 m and grapple model GM 70C

3 with industrial stick 10.00 m

4 with industrial stick 10.00 m and grapple model GM 70C

Operating Weight

and Ground Pressure

Operating weight includes basic machine with hydraulic cab elevation

+ intermediate piece 0.5 m, counterweight 7.5 t, industrial-type

straight mono boom 9.60 m, industrial stick 9.00 m and grapple model

GM 70C with 5 semi-closed tines 0.80 m

Undercarriage HR

Pad width mm 750

Weight kg 56,200

Ground pressure kg/cm

0

2

4

3

(1,705 kg).

2

0.70

75

70

65

60

55

50

45

40

35

30

25

20

15

10

-10

-15

-20

-25

-30

ft

5

0

-5

70 65 60

m

24

22

20

18

16

14

12

10

8

6

4

2

0

-2

-4

-6

-8

20

18

55 50

16

0mft

5

15 10

25 20

30

35

40

54

R0101

Attachment Envelope

Kinematic variants 3B

1 with industrial stick 9.00 m

2 with industrial stick 9.00 m and grapple model GM 70C

3 with industrial stick 10.00 m

4 with industrial stick 10.00 m and grapple model GM 70C

Operating Weight

and Ground Pressure

Operating weight includes basic machine with hydraulic cab elevation

+ intermediate piece 0.5 m, counterweight 7.5 t, industrial-type

straight mono boom 9.60 m, industrial stick 10.00 m and grapple

model GM 70C with 5 semi-closed tines 0.80 m

Undercarriage HR

Pad width mm 750

Weight kg 56,400

Ground pressure kg/cm

1

3

2

4

0

2

4

6

8

10

12

14

3

(1,705 kg).

2

0.70

70 65 60

55 50

35

40

54

10 ER 934 C ER 944 C ER 954 C High Rise

30

25 20

15 10

0mft

5

Page 11

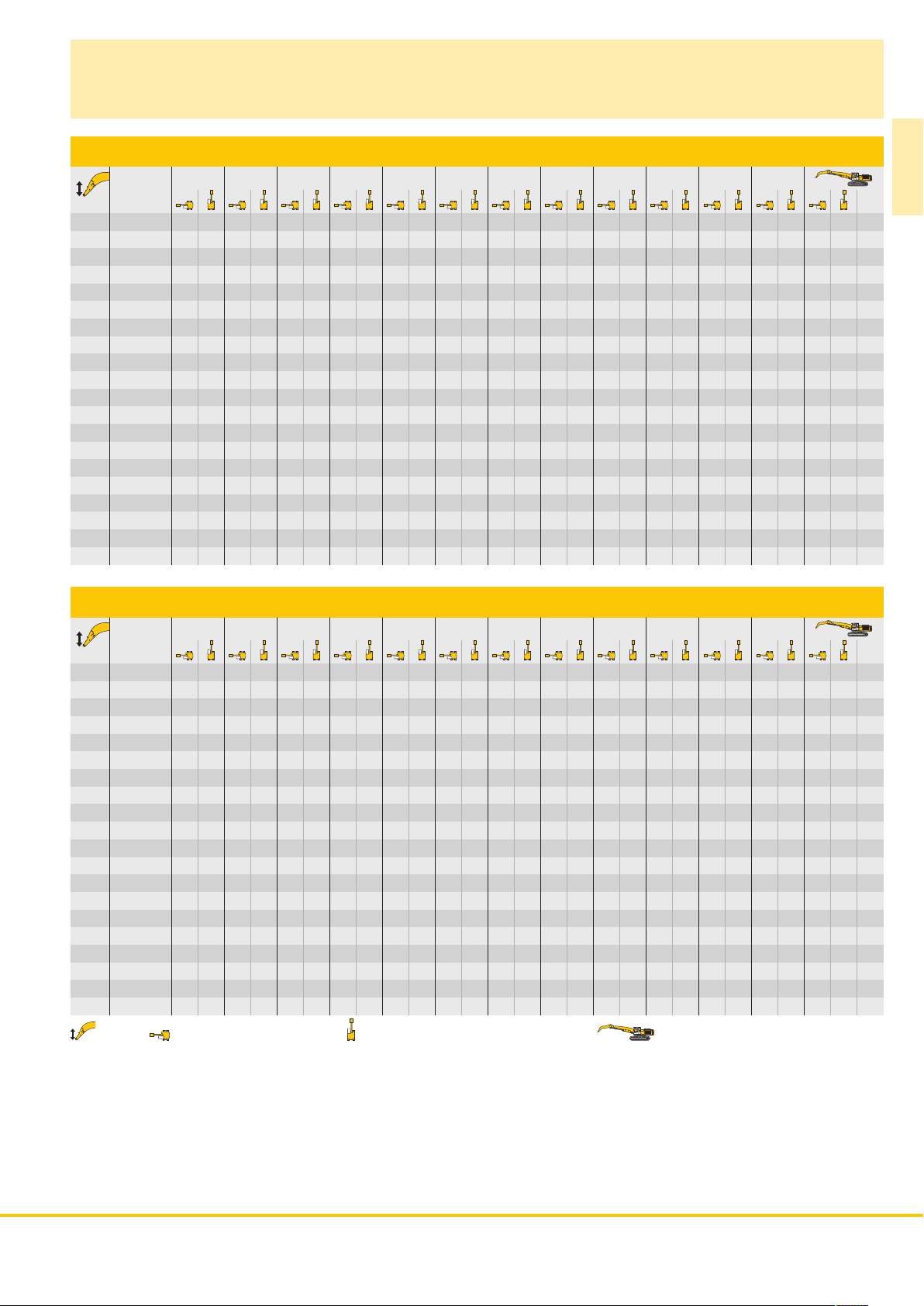

Lift Capacities

with Industrial-Type Straight Mono Boom 9.60 m

Industrial Stick 9.00 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m

Under m carriage m

24.0

HR

22.5

HR

21.0

19.5

18.0

16.5

15.0

13.5

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

0

– 1.5

– 3.0

– 4.5

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

6.6* 6.6* 5.3* 5.3* 7.2

6.4* 6.4* 5.4* 5.4* 4.3* 4.3* 10.0

6.2* 6.2* 5.3* 5.3* 3.8* 3.8* 3.7* 3.7* 12.0

6.5* 6.5* 5.9* 5.9* 5.1* 5.1* 3.5* 3.5* 3.4* 3.4* 13.5

6.1* 6.1* 5.5* 5.5* 4.8* 4.8* 3.2* 3.2* 14.8

6.1* 6.1* 5.5* 5.5* 5.0* 5.0* 4.2* 4.2* 3.1* 3.1* 15.7

6.1* 6.1* 5.5* 5.5* 5.0* 5.0* 4.5* 4.5* 3.0* 3.0* 3.0* 3.0* 16.5

6.9* 6.9* 6.2* 6.2* 5.6* 5.6* 5.0* 5.0* 4.5* 4.5* 4.0* 4.0* 2.9* 2.9* 17.1

7.1* 7.1* 6.3* 6.3* 5.6* 5.6* 5.0* 5.0* 4.5* 4.5* 4.0* 4.0* 2.9* 2.9* 17.6

7.8* 7.8* 7.4* 7.4* 6.5* 6.5* 5.7* 5.7* 5.1* 5.1* 4.5* 4.5* 3.9* 3.9* 2.9* 2.9* 17.9

8.6* 8.6* 9.1* 9.1* 7.7* 7.7* 6.6* 6.6* 5.8* 5.8* 5.1* 5.1* 4.4* 4.4* 3.9* 3.9* 3.1* 3.1* 2.9* 2.9* 18.1

16.0* 16.0* 11.9* 11.9* 9.5* 9.5* 7.9* 7.9* 6.7* 6.7* 5.8* 5.8* 5.0* 5.0* 4.4* 4.4* 3.7* 3.7* 3.0* 3.0* 2.8* 2.8* 18.2

1.6* 1.6* 9.4* 9.4* 12.3* 12.3* 9.7* 9.7* 7.9* 7.9* 6.7* 6.7* 5.7* 5.7* 4.9* 4.9* 4.2* 4.2* 3.5* 3.5* 2.7* 2.7* 2.5* 2.5* 18.2

1.7* 1.7* 4.8* 4.8* 12.1* 12.1* 9.5* 9.5* 7.8* 7.8* 6.5* 6.5* 5.6* 5.6* 4.7* 4.7* 4.0* 4.0* 3.3* 3.3* 2.3* 2.3* 18.0

2.3* 2.3* 4.4* 4.4* 9.4* 9.4* 9.1* 9.1* 7.4* 7.4* 6.2* 6.2* 5.3* 5.3* 4.4* 4.4* 3.7* 3.7* 2.8* 2.8* 2.0* 2.0* 17.6

3.0* 3.0* 4.8* 4.8* 8.4* 8.4* 8.2* 8.2* 6.8* 6.8* 5.7* 5.7* 4.8* 4.8* 4.0* 4.0* 3.2* 3.2* 2.2* 2.2* 2.2* 2.2* 16.5

8.4* 8.4* 7.0* 7.0* 5.9* 5.9* 4.9* 4.9* 4.1* 4.1* 3.3* 3.3* 2.5* 2.5* 14.9

4.7* 4.7* 3.9* 3.9* 3.5* 3.5* 11.3

ER 934 C

Industrial Stick 10.00 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m

Under m carriage m

24.0

HR

22.5

HR

21.0

HR

19.5

HR

18.0

HR

16.5

HR

15.0

HR

13.5

HR

12.0

HR

10.5

HR

9.0

HR

7.5

HR

6.0

HR

4.5

HR

3.0

HR

1.5

HR

0

HR

– 1.5

HR

– 3.0

HR

– 4.5

HR

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 750 mm track flat pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic

capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the

load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

5.6* 5.6* 5.5* 5.5* 6.1

5.7* 5.7* 4.6* 4.6* 4.0* 4.0* 9.5

5.5* 5.5* 4.6* 4.6* 3.4* 3.4* 11.8

5.3* 5.3* 4.5* 4.5* 3.1* 3.1* 13.5

5.6* 5.6* 5.1* 5.1* 4.2* 4.2* 2.8* 2.8* 14.9

5.8* 5.8* 5.2* 5.2* 4.8* 4.8* 3.8* 3.8* 2.7* 2.7* 16.0

5.7* 5.7* 5.2* 5.2* 4.8* 4.8* 4.4* 4.4* 3.1* 3.1* 2.6* 2.6* 16.9

5.8* 5.8* 5.2* 5.2* 4.8* 4.8* 4.3* 4.3* 3.9* 3.9* 2.5* 2.5* 17.6

5.9* 5.9* 5.3* 5.3* 4.8* 4.8* 4.3* 4.3* 3.9* 3.9* 2.8* 2.8* 2.4* 2.4* 18.2

6.0* 6.0* 5.4* 5.4* 4.8* 4.8* 4.4* 4.4* 3.9* 3.9* 3.4* 3.4* 2.4* 2.4* 18.6

6.8* 6.8* 6.2* 6.2* 5.5* 5.5* 4.9* 4.9* 4.4* 4.4* 3.9* 3.9* 3.4* 3.4* 2.4* 2.4* 19.0

7.1* 7.1* 7.3* 7.3* 6.3* 6.3* 5.6* 5.6* 4.9* 4.9* 4.4* 4.4* 3.8* 3.8* 3.3* 3.3* 2.4* 2.4* 19.1

6.3* 6.3* 8.7* 8.7* 9.1* 9.1* 7.6* 7.6* 6.5* 6.5* 5.6* 5.6* 4.9* 4.9* 4.3* 4.3* 3.8* 3.8* 3.2* 3.2* 2.5* 2.5* 19.2

4.6* 4.6* 16.2* 16.2* 11.9* 11.9* 9.4* 9.4* 7.7* 7.7* 6.5* 6.5* 5.6* 5.6* 4.9* 4.9* 4.2* 4.2* 3.6* 3.6* 3.0* 3.0* 2.3* 2.3* 19.2

2.0* 2.0* 6.9* 6.9* 12.1* 12.1* 9.5* 9.5* 7.7* 7.7* 6.5* 6.5* 5.5* 5.5* 4.8* 4.8* 4.1* 4.1* 3.4* 3.4* 2.7* 2.7* 2.0* 2.0* 19.0

2.2* 2.2* 4.9* 4.9* 11.7* 11.7* 9.2* 9.2* 7.5* 7.5* 6.3* 6.3* 5.3* 5.3* 4.5* 4.5* 3.8* 3.8* 3.1* 3.1* 2.3* 2.3* 1.7* 1.7* 18.7

2.8* 2.8* 4.7* 4.7* 9.1* 9.1* 8.6* 8.6* 7.1* 7.1* 5.9* 5.9* 5.0* 5.0* 4.2* 4.2* 3.4* 3.4* 2.7* 2.7* 1.9* 1.9* 17.8

3.4* 3.4* 5.1* 5.1* 8.5* 8.5* 7.7* 7.7* 6.4* 6.4* 5.3* 5.3* 4.4* 4.4* 3.7* 3.7* 2.9* 2.9* 2.1* 2.1* 16.5

7.6* 7.6* 6.4* 6.4* 5.4* 5.4* 4.5* 4.5* 3.7* 3.7* 2.9* 2.9* 2.5* 2.5* 14.3

ER 934 C ER 944 C ER 954 C High Rise 11

Page 12

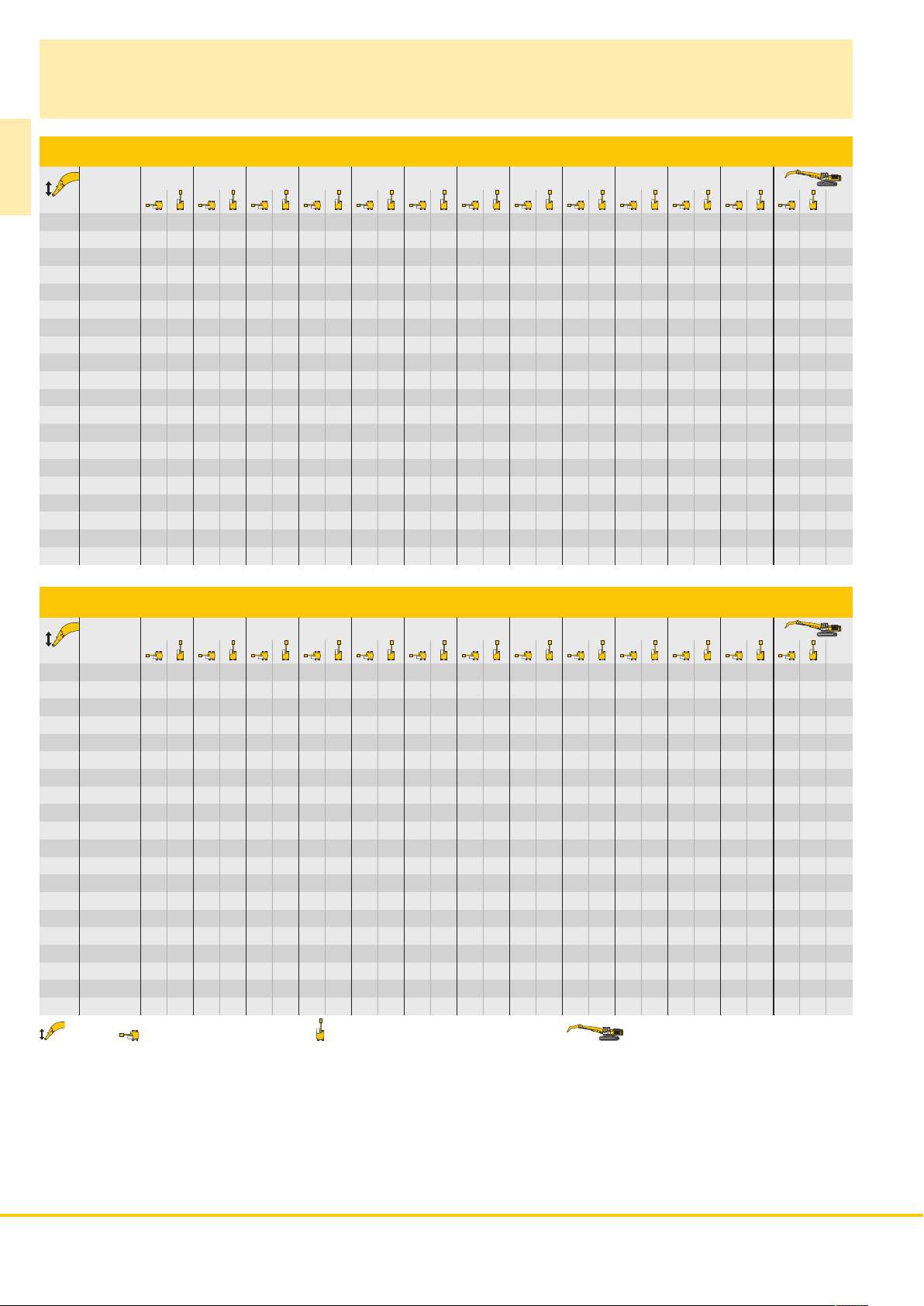

Lift Capacities

with Industrial-Type Straight Mono Boom 9.60 m

Industrial Stick 9.00 m (Variant 3B)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m

Under m carriage m

ER 934 C

24.0

HR

22.5

HR

21.0

19.5

18.0

16.5

15.0

13.5

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

0

– 1.5

– 3.0

– 4.5

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

5.4* 5.4* 5.2* 5.2* 7.7

6.4* 6.4* 5.6* 5.6* 4.2* 4.2* 10.4

5.4* 5.4* 5.1* 5.1* 4.1* 4.1* 3.7* 3.7* 12.3

5.2* 5.2* 4.9* 4.9* 4.7* 4.7* 3.9* 3.9* 3.4* 3.4* 13.8

4.8* 4.8* 4.5* 4.5* 4.4* 4.4* 3.2* 3.2* 15.0

4.7* 4.7* 4.5* 4.5* 4.3* 4.3* 4.1* 4.1* 3.1* 3.1* 15.9

5.1* 5.1* 4.8* 4.8* 4.5* 4.5* 4.3* 4.3* 4.1* 4.1* 3.4* 3.4* 3.0* 3.0* 16.7

5.3* 5.3* 5.0* 5.0* 4.6* 4.6* 4.4* 4.4* 4.1* 4.1* 3.9* 3.9* 2.9* 2.9* 17.3

5.6* 5.6* 5.2* 5.2* 4.8* 4.8* 4.5* 4.5* 4.2* 4.2* 3.9* 3.9* 2.9* 2.9* 17.8

6.8* 6.8* 6.1* 6.1* 5.5* 5.5* 5.0* 5.0* 4.6* 4.6* 4.3* 4.3* 4.0* 4.0* 3.1* 3.1* 2.9* 2.9* 18.1

6.5* 6.5* 8.9* 8.9* 7.6* 7.6* 6.5* 6.5* 5.8* 5.8* 5.2* 5.2* 4.7* 4.7* 4.3* 4.3* 4.0* 4.0* 3.5* 3.5* 2.9* 2.9* 18.3

14.0* 14.0* 10.4* 10.4* 8.4* 8.4* 7.0* 7.0* 6.1* 6.1* 5.4* 5.4* 4.9* 4.9* 4.4* 4.4* 4.0* 4.0* 3.6* 3.6* 3.0* 3.0* 18.3

1.3* 1.3* 7.3* 7.3* 11.5* 11.5* 9.1* 9.1* 7.5* 7.5* 6.4* 6.4* 5.6* 5.6* 5.0* 5.0* 4.5* 4.5* 4.1* 4.1* 3.6* 3.6* 3.1* 3.1* 18.3

1.6* 1.6* 4.3* 4.3* 12.3* 12.3* 9.6* 9.6* 7.8* 7.8* 6.6* 6.6* 5.8* 5.8* 5.1* 5.1* 4.5* 4.5* 4.0* 4.0* 3.4* 3.4* 3.2* 3.2* 18.1

2.2* 2.2* 4.2* 4.2* 8.7* 8.7* 9.8* 9.8* 8.0* 8.0* 6.8* 6.8* 5.8* 5.8* 5.1* 5.1* 4.5* 4.5* 3.9* 3.9* 3.4* 3.4* 17.6

4.6* 4.6* 8.0* 8.0* 9.8* 9.8* 8.0* 8.0* 6.8* 6.8* 5.8* 5.8* 5.0* 5.0* 4.4* 4.4* 3.7* 3.7* 3.7* 3.7* 16.5

8.2* 8.2* 9.5* 9.5* 7.8* 7.8* 6.6* 6.6* 5.6* 5.6* 4.8* 4.8* 4.2* 4.2* 14.8

Industrial Stick 10.00 m (Variant 3B)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m

Under m carriage m

24.0

HR

22.5

HR

21.0

HR

19.5

HR

18.0

HR

16.5

HR

15.0

HR

13.5

HR

12.0

HR

10.5

HR

9.0

HR

7.5

HR

6.0

HR

4.5

HR

3.0

HR

1.5

HR

0

HR

– 1.5

HR

– 3.0

HR

– 4.5

HR

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 750 mm track flat pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic

capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the

load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

5.9* 5.9* 5.3* 5.3* 6.7

5.8* 5.8* 4.8* 4.8* 4.0* 4.0* 9.9

5.2* 5.2* 4.8* 4.8* 3.5* 3.5* 3.4* 3.4* 12.1

4.6* 4.6* 4.4* 4.4* 3.4* 3.4* 3.0* 3.0* 13.8

4.4* 4.4* 4.2* 4.2* 4.1* 4.1* 3.0* 3.0* 2.8* 2.8* 15.1

4.3* 4.3* 4.1* 4.1* 4.0* 4.0* 3.9* 3.9* 2.7* 2.7* 16.2

4.3* 4.3* 4.1* 4.1* 3.9* 3.9* 3.8* 3.8* 3.4* 3.4* 2.6* 2.6* 17.1

4.4* 4.4* 4.2* 4.2* 4.0* 4.0* 3.8* 3.8* 3.6* 3.6* 2.5* 2.5* 17.8

4.5* 4.5* 4.3* 4.3* 4.0* 4.0* 3.8* 3.8* 3.6* 3.6* 3.1* 3.1* 2.4* 2.4* 18.4

5.1* 5.1* 4.7* 4.7* 4.4* 4.4* 4.1* 4.1* 3.9* 3.9* 3.7* 3.7* 3.5* 3.5* 2.4* 2.4* 18.8

5.5* 5.5* 5.0* 5.0* 4.6* 4.6* 4.3* 4.3* 4.0* 4.0* 3.7* 3.7* 3.5* 3.5* 2.4* 2.4* 19.1

6.8* 6.8* 6.0* 6.0* 5.4* 5.4* 4.8* 4.8* 4.4* 4.4* 4.1* 4.1* 3.8* 3.8* 3.5* 3.5* 2.4* 2.4* 19.3

6.9* 6.9* 9.3* 9.3* 7.6* 7.6* 6.5* 6.5* 5.7* 5.7* 5.1* 5.1* 4.6* 4.6* 4.2* 4.2* 3.9* 3.9* 3.5* 3.5* 2.5* 2.5* 19.3

3.0* 3.0* 14.6* 14.6* 10.6* 10.6* 8.4* 8.4* 7.0* 7.0* 6.0* 6.0* 5.3* 5.3* 4.8* 4.8* 4.3* 4.3* 3.9* 3.9* 3.5* 3.5* 2.5* 2.5* 19.3

1.8* 1.8* 5.9* 5.9* 11.6* 11.6* 9.1* 9.1* 7.5* 7.5* 6.3* 6.3* 5.5* 5.5* 4.9* 4.9* 4.4* 4.4* 3.9* 3.9* 3.5* 3.5* 2.6* 2.6* 19.1

2.1* 2.1* 4.5* 4.5* 10.7* 10.7* 9.5* 9.5* 7.7* 7.7* 6.5* 6.5* 5.6* 5.6* 4.9* 4.9* 4.4* 4.4* 3.9* 3.9* 3.4* 3.4* 2.9* 2.9* 18.7

2.7* 2.7* 4.6* 4.6* 8.5* 8.5* 9.6* 9.6* 7.9* 7.9* 6.6* 6.6* 5.7* 5.7* 4.9* 4.9* 4.3* 4.3* 3.8* 3.8* 3.2* 3.2* 17.8

5.0* 5.0* 8.1* 8.1* 9.5* 9.5* 7.8* 7.8* 6.5* 6.5* 5.6* 5.6* 4.8* 4.8* 4.2* 4.2* 3.6* 3.6* 16.4

8.3* 8.3* 9.1* 9.1* 7.5* 7.5* 6.3* 6.3* 5.3* 5.3* 4.5* 4.5* 4.2* 4.2* 14.1

12 ER 934 C ER 944 C ER 954 C High Rise

Page 13

Industrial Attachment

with Industrial-Type Straight Mono Boom 10.60 m

m

-10

-15

-20

-25

-30

ft

80

24

75

22

70

20

65

60

18

55

16

50

14

45

40

12

35

10

30

8

25

20

6

15

4

10

2

5

0

0

-5

-2

-4

-6

-8

16

18

2022

1

3

2

4

6

8

10

12

14

R0102

Attachment Envelope

Kinematic variants 2A

1 with industrial stick 9.00 m

2 with industrial stick 9.00 m and grapple model GM 65

3 with industrial stick 10.00 m

4 with industrial stick 10.00 m and grapple model GM 65

Operating Weight

and Ground Pressure

Operating weight includes basic machine with hydraulic cab elevation

+ intermediate piece 0.5 m, counterweight 7.5 t, industrial-type

straight mono boom 10.60 m, industrial stick 9.00 m and grapple

model GM 65 with 5 semi-closed tines 0.60 m

Undercarriage HR

Pad width mm 750

Weight kg 56,200

Ground pressure kg/cm

2

4

0

3

(1,415 kg).

2

0.70

ER 934 C

-10

-15

-20

-25

-30

70 65 60

m

ft

80

24

75

22

70

20

65

60

18

55

16

50

14

45

40

12

35

10

30

8

25

20

6

15

4

10

2

5

0

0

-5

-2

-4

-6

-8

55 50

R0103

Attachment Envelope

Kinematic variants 3B

1 with industrial stick 9.00 m

2 with industrial stick 9.00 m and grapple model GM 65

3 with industrial stick 10.00 m

4 with industrial stick 10.00 m and grapple model GM 65

Operating Weight

and Ground Pressure

Operating weight includes basic machine with hydraulic cab elevation

+ intermediate piece 0.5 m, counterweight 7.5 t, industrial-type

straight mono boom 10.60 m, industrial stick 10.00 m and grapple

model GM 65 with 5 semi-closed tines 0.60 m

Undercarriage HR

Pad width mm 750

Weight kg 56,400

Ground pressure kg/cm

1

3

2

4

2

4

6

8

10

12

14

16

18

2022

0

3

(1,415 kg).

2

0.70

0mft

5

15 10

25 20

30

35

40

54

70 65 60

55 50

0mft

5

15 10

25 20

30

35

40

54

ER 934 C ER 944 C ER 954 C High Rise 13

Page 14

Lift Capacities

with Industrial-Type Straight Mono Boom 10.60 m

Industrial Stick 9.00 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m

Under m carriage m

ER 934 C

24.0

HR

22.5

21.0

19.5

18.0

16.5

15.0

13.5

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

0

– 1.5

– 3.0

– 4.5

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

6.1* 6.1* 6.1* 6.1* 6.0

6.2* 6.2* 5.1* 5.1* 4.6* 4.6* 9.4

6.0* 6.0* 5.1* 5.1* 3.9* 3.9* 11.7

6.4* 6.4* 5.9* 5.9* 5.0* 5.0* 3.5* 3.5* 13.5

6.0* 6.0* 5.4* 5.4* 4.8* 4.8* 3.3* 3.3* 14.8

6.0* 6.0* 5.4* 5.4* 4.8* 4.8* 4.3* 4.3* 3.1* 3.1* 16.0

6.0* 6.0* 5.4* 5.4* 4.8* 4.8* 4.3* 4.3* 3.6* 3.6* 3.0* 3.0* 16.9

6.9* 6.9* 6.0* 6.0* 5.4* 5.4* 4.8* 4.8* 4.3* 4.3* 3.8* 3.8* 2.9* 2.9* 17.6

7.0* 7.0* 6.1* 6.1* 5.4* 5.4* 4.8* 4.8* 4.3* 4.3* 3.8* 3.8* 3.3* 3.3* 2.9* 2.9* 18.2

7.4* 7.4* 7.2* 7.2* 6.2* 6.2* 5.5* 5.5* 4.8* 4.8* 4.3* 4.3* 3.8* 3.8* 3.3* 3.3* 2.9* 2.9* 18.6

7.5* 7.5* 8.8* 8.8* 7.4* 7.4* 6.3* 6.3* 5.5* 5.5* 4.8* 4.8* 4.3* 4.3* 3.7* 3.7* 3.2* 3.2* 2.8* 2.8* 18.9

10.8* 10.8* 11.4* 11.4* 9.1* 9.1* 7.5* 7.5* 6.4* 6.4* 5.5* 5.5* 4.8* 4.8* 4.2* 4.2* 3.7* 3.7* 3.1* 3.1* 2.6* 2.6* 19.1

11.1* 11.1* 11.8* 11.8* 9.3* 9.3* 7.6* 7.6* 6.4* 6.4* 5.5* 5.5* 4.8* 4.8* 4.1* 4.1* 3.6* 3.6* 3.0* 3.0* 2.3* 2.3* 19.2

3.1* 3.1* 11.7* 11.7* 9.2* 9.2* 7.5* 7.5* 6.3* 6.3* 5.4* 5.4* 4.6* 4.6* 4.0* 4.0* 3.4* 3.4* 2.8* 2.8* 2.1* 2.1* 19.1

0.8* 0.8* 2.6* 2.6* 6.7* 6.7* 8.9* 8.9* 7.3* 7.3* 6.1* 6.1* 5.2* 5.2* 4.4* 4.4* 3.8* 3.8* 3.2* 3.2* 2.5* 2.5* 1.8* 1.8* 19.0

1.5* 1.5* 2.9* 2.9* 5.7* 5.7* 8.2* 8.2* 6.8* 6.8* 5.7* 5.7* 4.9* 4.9* 4.1* 4.1* 3.5* 3.5* 2.8* 2.8* 2.1* 2.1* 1.6* 1.6* 18.6

3.5* 3.5* 5.7* 5.7* 7.3* 7.3* 6.1* 6.1* 5.2* 5.2* 4.4* 4.4* 3.7* 3.7* 3.0* 3.0* 2.3* 2.3* 1.8* 1.8* 17.5

6.2* 6.2* 6.0* 6.0* 5.2* 5.2* 4.4* 4.4* 3.7* 3.7* 3.1* 3.1* 2.4* 2.4* 2.0* 2.0* 15.9

3.5* 3.5* 2.9* 2.9* 2.8* 2.8* 12.3

Industrial Stick 10.00 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m

Under m carriage m

24.0

HR

22.5

HR

21.0

HR

19.5

HR

18.0

HR

16.5

HR

15.0

HR

13.5

HR

12.0

HR

10.5

HR

9.0

HR

7.5

HR

6.0

HR

4.5

HR

3.0

HR

1.5

HR

0

HR

– 1.5

HR

– 3.0

HR

– 4.5

HR

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 750 mm track flat pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic

capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the

load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

5.4* 5.4* 4.4* 4.4* 8.7

5.3* 5.3* 4.4* 4.4* 3.6* 3.6* 11.3

5.2* 5.2* 4.4* 4.4* 3.2* 3.2* 13.3

5.5* 5.5* 5.0* 5.0* 4.2* 4.2* 2.9* 2.9* 14.8

5.7* 5.7* 5.2* 5.2* 4.7* 4.7* 3.9* 3.9* 2.7* 2.7* 16.1

5.7* 5.7* 5.1* 5.1* 4.6* 4.6* 4.2* 4.2* 3.4* 3.4* 2.6* 2.6* 17.1

5.7* 5.7* 5.1* 5.1* 4.6* 4.6* 4.2* 4.2* 3.7* 3.7* 2.5* 2.5* 18.0

5.8* 5.8* 5.2* 5.2* 4.6* 4.6* 4.2* 4.2* 3.7* 3.7* 3.3* 3.3* 2.5* 2.5* 18.7

5.9* 5.9* 5.2* 5.2* 4.7* 4.7* 4.2* 4.2* 3.7* 3.7* 3.3* 3.3* 2.4* 2.4* 19.2

6.5* 6.5* 6.0* 6.0* 5.3* 5.3* 4.7* 4.7* 4.2* 4.2* 3.7* 3.7* 3.3* 3.3* 2.7* 2.7* 2.4* 2.4* 19.6

6.5* 6.5* 7.1* 7.1* 6.1* 6.1* 5.3* 5.3* 4.7* 4.7* 4.2* 4.2* 3.7* 3.7* 3.2* 3.2* 2.7* 2.7* 2.4* 2.4* 19.9

7.0* 7.0* 8.4* 8.4* 7.3* 7.3* 6.2* 6.2* 5.4* 5.4* 4.7* 4.7* 4.1* 4.1* 3.6* 3.6* 3.1* 3.1* 2.6* 2.6* 2.3* 2.3* 20.1

15.4* 15.4* 11.4* 11.4* 9.0* 9.0* 7.4* 7.4* 6.3* 6.3* 5.4* 5.4* 4.7* 4.7* 4.1* 4.1* 3.6* 3.6* 3.0* 3.0* 2.5* 2.5* 2.1* 2.1* 20.2

0.8* 0.8* 6.0* 6.0* 11.6* 11.6* 9.1* 9.1* 7.4* 7.4* 6.2* 6.2* 5.3* 5.3* 4.6* 4.6* 4.0* 4.0* 3.4* 3.4* 2.9* 2.9* 2.3* 2.3* 1.9* 1.9* 20.1

0.9* 0.9* 3.2* 3.2* 9.4* 9.4* 8.9* 8.9* 7.3* 7.3* 6.1* 6.1* 5.2* 5.2* 4.5* 4.5* 3.8* 3.8* 3.2* 3.2* 2.7* 2.7* 2.0* 2.0* 1.6* 1.6* 20.0

1.5* 1.5* 3.0* 3.0* 6.5* 6.5* 8.5* 8.5* 7.0* 7.0* 5.8* 5.8* 4.9* 4.9* 4.2* 4.2* 3.6* 3.6* 3.0* 3.0* 2.4* 2.4* 1.5* 1.5* 1.4* 1.4* 19.7

2.1* 2.1* 3.4* 3.4* 5.9* 5.9* 7.7* 7.7* 6.4* 6.4* 5.4* 5.4* 4.6* 4.6* 3.9* 3.9* 3.2* 3.2* 2.6* 2.6* 1.9* 1.9* 1.5* 1.5* 18.8

3.9* 3.9* 6.0* 6.0* 6.7* 6.7* 5.7* 5.7* 4.8* 4.8* 4.0* 4.0* 3.4* 3.4* 2.7* 2.7* 2.1* 2.1* 1.6* 1.6* 17.5

5.4* 5.4* 4.7* 4.7* 4.0* 4.0* 3.3* 3.3* 2.7* 2.7* 2.1* 2.1* 2.0* 2.0* 15.3

14 ER 934 C ER 944 C ER 954 C High Rise

Page 15

Lift Capacities

with Industrial-Type Straight Mono Boom 10.60 m

Industrial Stick 9.00 m (Variant 3B)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m

Under m carriage m

24.0

22.5

21.0

19.5

18.0

16.5

15.0

13.5

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

0

– 1.5

– 3.0

– 4.5

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

6.4* 6.4* 5.8* 5.8* 6.6

6.3* 6.3* 5.3* 5.3* 4.5* 4.5* 9.8

5.5* 5.5* 5.0* 5.0* 3.9* 3.9* 3.9* 3.9* 12.0

5.2* 5.2* 4.8* 4.8* 4.5* 4.5* 3.8* 3.8* 3.5* 3.5* 13.7

4.7* 4.7* 4.4* 4.4* 4.1* 4.1* 3.4* 3.4* 3.3* 3.3* 15.1

4.6* 4.6* 4.3* 4.3* 4.1* 4.1* 3.9* 3.9* 3.1* 3.1* 16.2

4.7* 4.7* 4.3* 4.3* 4.1* 4.1* 3.8* 3.8* 3.6* 3.6* 3.0* 3.0* 17.1

5.2* 5.2* 4.8* 4.8* 4.4* 4.4* 4.1* 4.1* 3.8* 3.8* 3.6* 3.6* 2.9* 2.9* 17.8

5.4* 5.4* 4.9* 4.9* 4.5* 4.5* 4.2* 4.2* 3.9* 3.9* 3.6* 3.6* 3.4* 3.4* 2.9* 2.9* 18.3

6.5* 6.5* 5.7* 5.7* 5.1* 5.1* 4.7* 4.7* 4.3* 4.3* 3.9* 3.9* 3.7* 3.7* 3.4* 3.4* 2.9* 2.9* 18.8

7.6* 7.6* 7.1* 7.1* 6.1* 6.1* 5.4* 5.4* 4.8* 4.8* 4.4* 4.4* 4.0* 4.0* 3.7* 3.7* 3.4* 3.4* 2.9* 2.9* 19.1

12.6* 12.6* 9.6* 9.6* 7.7* 7.7* 6.5* 6.5* 5.7* 5.7* 5.0* 5.0* 4.5* 4.5* 4.1* 4.1* 3.7* 3.7* 3.4* 3.4* 2.9* 2.9* 19.2

7.2* 7.2* 10.6* 10.6* 8.4* 8.4* 6.9* 6.9* 5.9* 5.9* 5.2* 5.2* 4.6* 4.6* 4.2* 4.2* 3.8* 3.8* 3.4* 3.4* 3.0* 3.0* 19.3

2.7* 2.7* 9.9* 9.9* 8.9* 8.9* 7.3* 7.3* 6.1* 6.1* 5.3* 5.3* 4.7* 4.7* 4.2* 4.2* 3.8* 3.8* 3.4* 3.4* 3.0* 3.0* 19.2

0.8* 0.8* 2.4* 2.4* 6.0* 6.0* 9.2* 9.2* 7.5* 7.5* 6.3* 6.3* 5.4* 5.4* 4.8* 4.8* 4.2* 4.2* 3.8* 3.8* 3.3* 3.3* 2.9* 2.9* 19.1

2.8* 2.8* 5.4* 5.4* 9.3* 9.3* 7.6* 7.6* 6.4* 6.4* 5.5* 5.5* 4.8* 4.8* 4.2* 4.2* 3.7* 3.7* 3.2* 3.2* 2.9* 2.9* 18.6

3.4* 3.4* 5.6* 5.6* 9.1* 9.1* 7.5* 7.5* 6.3* 6.3* 5.4* 5.4* 4.7* 4.7* 4.1* 4.1* 3.5* 3.5* 3.2* 3.2* 17.5

6.0* 6.0* 8.7* 8.7* 7.2* 7.2* 6.1* 6.1* 5.2* 5.2* 4.5* 4.5* 3.9* 3.9* 3.6* 3.6* 15.8

ER 934 C

Industrial Stick 10.00 m (Variant 3B)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m

Under m carriage m

24.0

HR

22.5

HR

21.0

HR

19.5

HR

18.0

HR

16.5

HR

15.0

HR

13.5

HR

12.0

HR

10.5

HR

9.0

HR

7.5

HR

6.0

HR

4.5

HR

3.0

HR

1.5

HR

0

HR

– 1.5

HR

– 3.0

HR

– 4.5

HR

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 750 mm track flat pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic

capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the

load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

6.3* 6.3* 5.1

5.6* 5.6* 4.5* 4.5* 4.3* 4.3* 9.2

5.3* 5.3* 4.6* 4.6* 3.6* 3.6* 11.7

4.6* 4.6* 4.3* 4.3* 3.3* 3.3* 3.2* 3.2* 13.6

4.4* 4.4* 4.1* 4.1* 3.9* 3.9* 3.1* 3.1* 2.9* 2.9* 15.1

4.3* 4.3* 4.0* 4.0* 3.8* 3.8* 3.6* 3.6* 2.7* 2.7* 16.3

4.3* 4.3* 4.0* 4.0* 3.8* 3.8* 3.6* 3.6* 3.4* 3.4* 2.6* 2.6* 17.3

4.3* 4.3* 4.0* 4.0* 3.8* 3.8* 3.5* 3.5* 3.4* 3.4* 2.8* 2.8* 2.5* 2.5* 18.2

4.4* 4.4* 4.1* 4.1* 3.8* 3.8* 3.6* 3.6* 3.4* 3.4* 3.2* 3.2* 2.5* 2.5* 18.9

4.5* 4.5* 4.2* 4.2* 3.9* 3.9* 3.6* 3.6* 3.4* 3.4* 3.2* 3.2* 2.4* 2.4* 19.4

5.3* 5.3* 4.8* 4.8* 4.3* 4.3* 4.0* 4.0* 3.7* 3.7* 3.4* 3.4* 3.2* 3.2* 2.9* 2.9* 2.4* 2.4* 19.8

6.5* 6.5* 5.6* 5.6* 5.0* 5.0* 4.5* 4.5* 4.1* 4.1* 3.8* 3.8* 3.5* 3.5* 3.2* 3.2* 3.0* 3.0* 2.4* 2.4* 20.1

4.9* 4.9* 7.3* 7.3* 7.1* 7.1* 6.1* 6.1* 5.3* 5.3* 4.7* 4.7* 4.2* 4.2* 3.9* 3.9* 3.5* 3.5* 3.3* 3.3* 3.0* 3.0* 2.4* 2.4* 20.2

13.3* 13.3* 9.8* 9.8* 7.8* 7.8* 6.5* 6.5* 5.6* 5.6* 4.9* 4.9* 4.4* 4.4* 4.0* 4.0* 3.6* 3.6* 3.3* 3.3* 3.0* 3.0* 2.5* 2.5* 20.3

0.6* 0.6* 4.7* 4.7* 10.7* 10.7* 8.4* 8.4* 6.9* 6.9* 5.8* 5.8* 5.1* 5.1* 4.5* 4.5* 4.0* 4.0* 3.6* 3.6* 3.3* 3.3* 2.9* 2.9* 2.5* 2.5* 20.2

0.9* 0.9* 2.9* 2.9* 8.1* 8.1* 8.8* 8.8* 7.2* 7.2* 6.0* 6.0* 5.2* 5.2* 4.6* 4.6* 4.1* 4.1* 3.6* 3.6* 3.3* 3.3* 2.9* 2.9* 2.6* 2.6* 20.1

1.4* 1.4* 2.9* 2.9* 6.0* 6.0* 9.0* 9.0* 7.3* 7.3* 6.2* 6.2* 5.3* 5.3* 4.6* 4.6* 4.1* 4.1* 3.6* 3.6* 3.2* 3.2* 2.7* 2.7* 2.6* 2.6* 19.7

2.1* 2.1* 3.3* 3.3* 5.6* 5.6* 9.0* 9.0* 7.4* 7.4* 6.2* 6.2* 5.3* 5.3* 4.6* 4.6* 4.0* 4.0* 3.5* 3.5* 3.0* 3.0* 2.7* 2.7* 18.8

3.8* 3.8* 5.8* 5.8* 8.8* 8.8* 7.2* 7.2* 6.1* 6.1* 5.2* 5.2* 4.5* 4.5* 3.9* 3.9* 3.4* 3.4* 3.0* 3.0* 17.4

8.3* 8.3* 6.9* 6.9* 5.8* 5.8* 5.0* 5.0* 4.3* 4.3* 3.6* 3.6* 3.6* 3.6* 15.1

ER 934 C ER 944 C ER 954 C High Rise 15

Page 16

Industrial Attachment

with Industrial-Type Angled Mono Boom 9.60 m

m

ft

20

65

60

18

55

ER 934 C

16

50

14

45

40

12

35

10

30

8

25

20

6

15

4

10

2

5

0

0

-5

-2

-10

-4

-15

-6

-20

-25

-30

-35

-40

-8

-10

-12

20

70 65 60

18

16

55 50

1

3

2

4

6

8

10

12

14

15 10

25 20

30

35

40

54

R0104

Attachment Envelope

Kinematic variant 3C

1 with industrial stick 9.00 m

2 with industrial stick 10.00 m

3 with industrial stick 9.00 m and grapple model GM 70C

4 with industrial stick 10.00 m and grapple model GM 70C

Operating Weight

and Ground Pressure

Operating weight includes basic machine with hydraulic cab elevation

+ intermediate piece 0.5 m, counterweight 7.5 t, industrial-type

angledmono boom 9.60 m, industrial stick 9.00 m and grapple

modelGM 70C with 5 semi-closed tines 0.80 m

Undercarriage HR

Pad width mm 750

Weight kg 56,400

Ground pressure kg/cm

Operating weight includes basic machine with hydraulic cab elevation

+ intermediate piece 0.5 m, counterweight 7.5 t, industrial-type

angledmono boom 9.60 m, industrial stick 10.00 m and grapple

model GM 70C with 5 semi-closed tines 0.80 m

0

2

4

0mft

5

Undercarriage HR

Pad width mm 750

Weight kg 56,600

Ground pressure kg/cm

3

(1,705 kg).

3

(1,705 kg).

2

0.70

2

0.70

16 ER 934 C ER 944 C ER 954 C High Rise

Page 17

Lift Capacities

with Industrial-Type Angled Mono Boom 9.60 m

Industrial Stick 9.00 m (Variant 3C)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m

Under m carriage m

18.0

HR

16.5

15.0

13.5

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

0

– 1.5

– 3.0

– 4.5

– 6.0

– 7.5

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

3.2* 3.2* 13.0

3.5* 3.5* 3.1* 3.1* 14.3

3.4* 3.4* 3.3* 3.3* 3.0* 3.0* 15.3

3.4* 3.4* 3.4* 3.4* 2.9* 2.9* 16.1

3.5* 3.5* 3.4* 3.4* 3.2* 3.2* 2.9* 2.9* 16.7

3.8* 3.8* 3.6* 3.6* 3.5* 3.5* 3.4* 3.4* 2.9* 2.9* 17.2

4.2* 4.2* 4.0* 4.0* 3.8* 3.8* 3.6* 3.6* 3.5* 3.5* 2.9* 2.9* 17.5

5.1* 5.1* 4.6* 4.6* 4.3* 4.3* 4.0* 4.0* 3.8* 3.8* 3.6* 3.6* 3.0* 3.0* 17.7

17.3* 17.3* 11.0* 11.0* 8.3* 8.3* 6.7* 6.7* 5.8* 5.8* 5.1* 5.1* 4.6* 4.6* 4.2* 4.2* 3.9* 3.9* 3.7* 3.7* 3.1* 3.1* 17.8

3.5* 3.5* 11.4* 11.4* 9.8* 9.8* 7.7* 7.7* 6.4* 6.4* 5.5* 5.5* 4.9* 4.9* 4.4* 4.4* 4.1* 4.1* 3.8* 3.8* 3.2* 3.2* 17.7

3.0* 3.0* 6.3* 6.3* 10.9* 10.9* 8.4* 8.4* 6.9* 6.9* 5.9* 5.9* 5.2* 5.2* 4.6* 4.6* 4.2* 4.2* 3.9* 3.9* 3.4* 3.4* 17.5

3.4* 3.4* 5.6* 5.6* 10.4* 10.4* 9.0* 9.0* 7.4* 7.4* 6.2* 6.2* 5.4* 5.4* 4.8* 4.8* 4.3* 4.3* 3.9* 3.9* 3.6* 3.6* 17.2

3.9* 3.9* 5.6* 5.6* 9.1* 9.1* 9.4* 9.4* 7.7* 7.7* 6.5* 6.5* 5.6* 5.6* 4.9* 4.9* 4.4* 4.4* 3.9* 3.9* 3.9* 3.9* 16.7

4.4* 4.4* 5.9* 5.9* 8.8* 8.8* 9.6* 9.6* 7.8* 7.8* 6.6* 6.6* 5.7* 5.7* 5.0* 5.0* 4.4* 4.4* 3.9* 3.9* 16.1

4.9* 4.9* 6.4* 6.4* 9.0* 9.0* 9.5* 9.5* 7.8* 7.8* 6.6* 6.6* 5.6* 5.6* 4.9* 4.9* 4.2* 4.2* 4.0* 4.0* 15.3

9.5* 9.5* 9.1* 9.1* 7.5* 7.5* 6.3* 6.3* 5.4* 5.4* 4.5* 4.5* 4.2* 4.2* 14.1

ER 934 C

Industrial Stick 10.00 m (Variant 3C)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m

Under m carriage m

18.0

HR

16.5

HR

15.0

HR

13.5

HR

12.0

HR

10.5

HR

9.0

HR

7.5

HR

6.0

HR

4.5

HR

3.0

HR

1.5

HR

0

HR

– 1.5

HR

– 3.0

HR

– 4.5

HR

– 6.0

HR

– 7.5

HR

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 750 mm track flat pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic

capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the

load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

2.9* 2.9* 12.9

3.2* 3.2* 2.7* 2.7* 14.3

3.1* 3.1* 2.6* 2.6* 15.5

3.0* 3.0* 2.5* 2.5* 16.4

3.0* 3.0* 3.0* 3.0* 2.4* 2.4* 17.2

3.1* 3.1* 3.1* 3.1* 3.0* 3.0* 2.4* 2.4* 17.7

3.2* 3.2* 3.2* 3.2* 3.1* 3.1* 2.7* 2.7* 2.4* 2.4* 18.2

3.6* 3.6* 3.4* 3.4* 3.3* 3.3* 3.2* 3.2* 3.1* 3.1* 2.4* 2.4* 18.5

4.1* 4.1* 3.9* 3.9* 3.6* 3.6* 3.4* 3.4* 3.3* 3.3* 3.2* 3.2* 2.5* 2.5* 18.7

5.1* 5.1* 4.6* 4.6* 4.2* 4.2* 3.9* 3.9* 3.6* 3.6* 3.4* 3.4* 3.2* 3.2* 2.6* 2.6* 18.7

7.6* 7.6* 11.8* 11.8* 8.6* 8.6* 6.9* 6.9* 5.8* 5.8* 5.0* 5.0* 4.5* 4.5* 4.1* 4.1* 3.8* 3.8* 3.5* 3.5* 3.3* 3.3* 2.7* 2.7* 18.7

3.6* 3.6* 8.9* 8.9* 10.0* 10.0* 7.8* 7.8* 6.4* 6.4* 5.5* 5.5* 4.8* 4.8* 4.3* 4.3* 3.9* 3.9* 3.6* 3.6* 3.4* 3.4* 2.8* 2.8* 18.5

3.4* 3.4* 6.2* 6.2* 11.0* 11.0* 8.5* 8.5* 6.9* 6.9* 5.9* 5.9* 5.1* 5.1* 4.5* 4.5* 4.1* 4.1* 3.7* 3.7* 3.3* 3.3* 3.0* 3.0* 18.2

3.7* 3.7* 5.7* 5.7* 9.9* 9.9* 9.0* 9.0* 7.3* 7.3* 6.2* 6.2* 5.3* 5.3* 4.7* 4.7* 4.2* 4.2* 3.8* 3.8* 3.2* 3.2* 17.7

4.1* 4.1* 5.8* 5.8* 9.0* 9.0* 9.3* 9.3* 7.6* 7.6* 6.4* 6.4* 5.5* 5.5* 4.8* 4.8* 4.2* 4.2* 3.8* 3.8* 3.5* 3.5* 17.1

4.5* 4.5* 6.0* 6.0* 8.8* 8.8* 9.4* 9.4* 7.6* 7.6* 6.4* 6.4* 5.5* 5.5* 4.8* 4.8* 4.2* 4.2* 3.6* 3.6* 16.4

4.9* 4.9* 6.4* 6.4* 9.0* 9.0* 9.2* 9.2* 7.5* 7.5* 6.3* 6.3* 5.4* 5.4* 4.6* 4.6* 4.0* 4.0* 3.7* 3.7* 15.5

9.6* 9.6* 8.7* 8.7* 7.2* 7.2* 6.0* 6.0* 5.1* 5.1* 4.3* 4.3* 13.4

ER 934 C ER 944 C ER 954 C High Rise 17

Page 18

The Right Attachment

for Every Application

Industrial-type straight mono boom 8.50 m

ER 944 C

Sorting

grapple

Stick 6.00 m

Industrial-type straight mono boom 9.50 m

Uppercarriage Elevation

Undercarriage

Wood

grapple

Multi-tine

grapple

Industrial stick 5.80 m

Industrial stick 7.30 m

Industrial stick 8.80 m*

Industrial stick 9.50 m*

Industrial-type straight mono boom 10.50 m*

Cylindrical cable reel

Industrial-type straight mono boom 11.50 m*

Spiral cable reel

Rigid cab elevation

Industrial-type angled mono boom 7.50 m

Hydraulic Cab Elevation

Clamshell

bucket

* presented configurations

18 ER 934 C ER 944 C ER 954 C High Rise

Industrial stick 12.00 m*

Industrial-type angled mono boom 9.50 m

Industrial-type angled mono boom 11.50 m*

Hydraulic Cab Elevation

+ Rigid cab elevation

Hydraulic Cab Elevation

+ Intermediate Piece

Page 19

Dimensions

R0105

WW

LL

UU

ZZ

VV

XX

mm

A 3,070

A1 6,150

C with Rigid Cab Elevation 2 m 7,700

C with Hydraulic Cab Elevation Parallelogram

+ Intermediate Piece 0,5 m 6,170

D 4,250

E 4,350

F 4,100

H with Rigid Cab Elevation 2 m 5,300

H with Hydraulic Cab Elevation Parallelogram

+ Intermediate Piece 0,5 m 6,170

K 3,600

L 6,000

P 1,280

Q 555

S 5,000

U 7,000

Z 7,750

N 750

B 5,830

G 5,860

E = Tail radius

EE

DD

HH

KK

NN

A1A1

AA

QQ

SS

BB

GG

Industrial-Type Straight Mono Boom 10.50 m

and Industrial Stick m 8.80 9.50

V mm 8,000 7,150

W mm 5,700 5,700

X mm 15,250 15,250

Industrial-Type Straight Mono Boom 11.50 m

and Industrial Stick m 9.50 12.00

V mm 8,150 *

W mm 5,700 5,700

X mm 16,250 16,250

Industrial-Type Angled Mono Boom 11.50 m

and Industrial Stick m 9.50 12.00

V mm 7,400 *

W mm 5,950 5,950

X mm 16,100 16,100

* = without stick

CC

ER 944 C

PP

FF

WW

LL

UU

ZZ

VV

XX

EE

DD

HH

KK

NN

A1A1

AA

CC

QQ

SS

BB

GG

PP

R0106

ER 934 C ER 944 C ER 954 C High Rise 19

Page 20

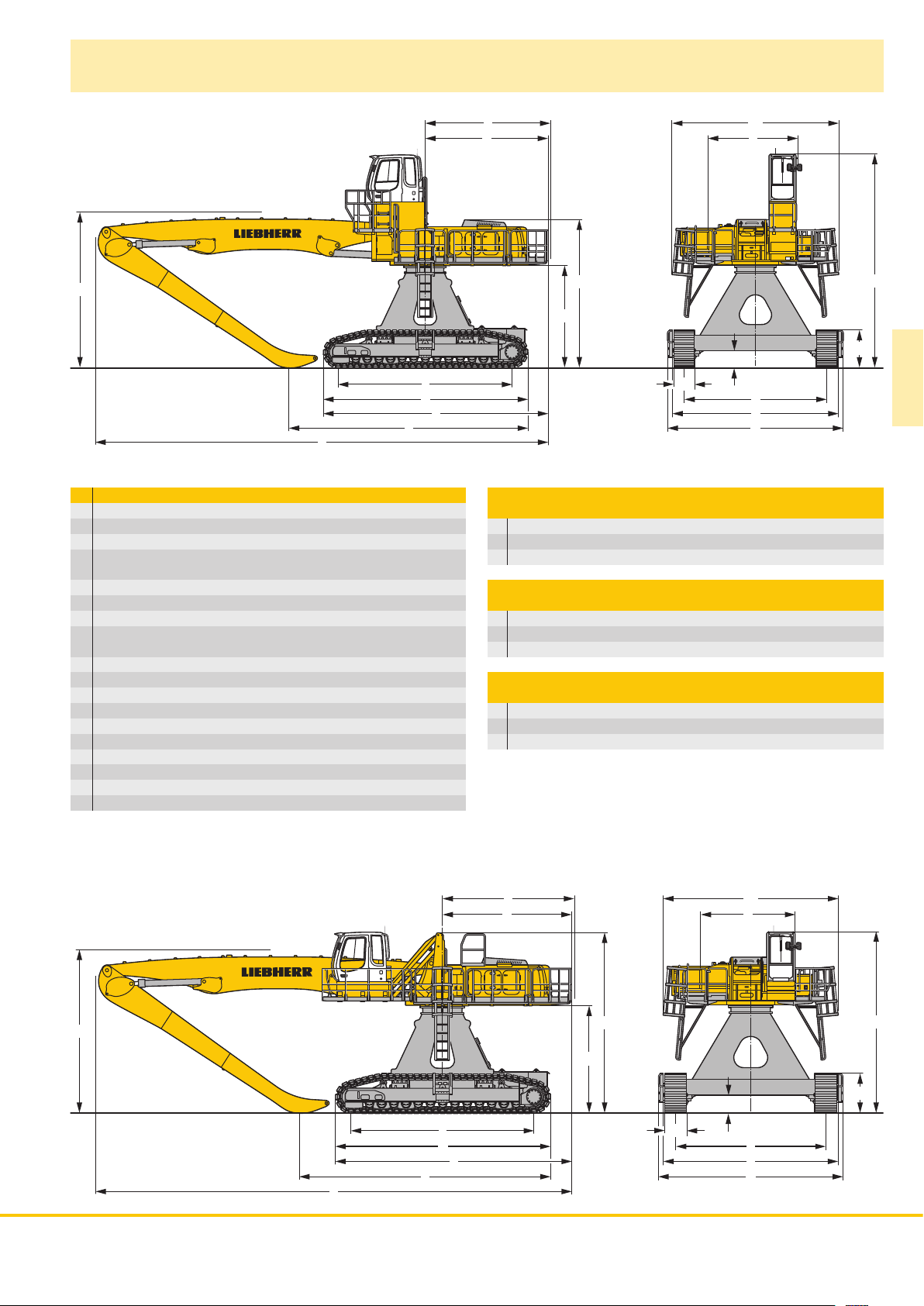

Industrial Attachment

with Industrial-Type Straight Mono Boom 10.50 m

m

ft

80

24

75

22

70

20

65

60

18

55

16

50

14

45

ER 944 C

40

12

35

10

30

8

25

20

6

15

4

10

2

5

0

0

-5

-2

-10

-15

-20

-25

-4

-6

-8

20

16

18

1

3

2

4

6

8

10

12

14

R0112

Attachment Envelope

Kinematic variants 2A

1 with industrial stick 8.80 m

2 with industrial stick 8.80 m and grapple model GM 70C

3 with industrial stick 9.50 m

4 with industrial stick 9.50 m and grapple model GM 70C

Operating Weight

and Ground Pressure

Operating weight includes basic machine with hydraulic cab elevation

+ intermediate piece 0.5 m, counterweight 11.0 t, industrial-type

straight mono boom 10.50 m, industrial stick 8.80 m and grapple

model GM 70C with 5 semi-closed tines 1.10 m

Undercarriage HR

Pad width mm 750

Weight kg 73,400

Ground pressure kg/cm

2

4

0

3

(1,860 kg).

2

0.82

80

75

70

65

60

55

50

45

40

35

30

25

20

15

10

-10

-15

-20

-25

-30

ft

5

0

-5

70 65 60

m

24

22

20

18

16

14

12

10

8

6

4

2

0

-2

-4

-6

-8

70 65 6 0

0mft

5

15 10

25 20

30

35

40

54

55 50

R0111

Attachment Envelope

Kinematic variants 3B

1 with industrial stick 8.80 m

2 with industrial stick 8.80 m and grapple model GM 70C

3 with industrial stick 9.50 m

4 with industrial stick 9.50 m and grapple model GM 70C

Operating Weight

and Ground Pressure

Operating weight includes basic machine with hydraulic cab elevation

+ intermediate piece 0.5 m, counterweight 11.0 t, industrial-type

straight mono boom 10.50 m, industrial stick 9.50 m and grapple

model GM 70C with 5 semi-closed tines 1.10 m

Undercarriage HR

Pad width mm 750

Weight kg 73,600

Ground pressure kg/cm

1

3

2

4

0

2

4

6

8

10

12

14

16

18

2022

0mft

5

15 10

25 20

30

35

40

54

55 50

3

(1,860 kg).

2

0.82

20 ER 934 C ER 944 C ER 954 C High Rise

Page 21

Lift Capacities

with Industrial-Type Straight Mono Boom 10.50 m

Industrial Stick 8.80 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m

Under m carriage m

HR

25.5

HR

24.0

22.5

21.0

19.5

18.0

16.5

15.0

13.5

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

0

– 1.5

– 3.0

– 4.5

– 6.0

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

9.7* 9.7* 5.9

9.7* 9.7* 8.0* 8.0* 7.5* 7.5* 9.3

9.5* 9.5* 8.1* 8.1* 6.5* 6.5* 11.6

10.1* 10.1* 9.2* 9.2* 7.9* 7.9* 5.9* 5.9* 13.3

10.4* 10.4* 9.5* 9.5* 8.5* 8.5* 7.5* 7.5* 5.6* 5.6* 14.6

10.5* 10.5* 9.4* 9.4* 8.5* 8.5* 7.7* 7.7* 6.7* 6.7* 5.3* 5.3* 15.7

10.6* 10.6* 9.4* 9.4* 8.5* 8.5* 7.7* 7.7* 6.9* 6.9* 5.4* 5.4* 5.2* 5.2* 16.6

10.8* 10.8* 9.5* 9.5* 8.5* 8.5* 7.7* 7.7* 6.9* 6.9* 6.2* 6.2* 5.1* 5.1* 17.3

11.3* 11.3* 11.0* 11.0* 9.7* 9.7* 8.6* 8.6* 7.7* 7.7* 6.9* 6.9* 6.1* 6.1* 5.0* 5.0* 17.9

12.6* 12.6* 11.4* 11.4* 9.9* 9.9* 8.7* 8.7* 7.7* 7.7* 6.9* 6.9* 6.1* 6.1* 5.2* 5.2* 5.0* 5.0* 18.3

10.6* 10.6* 13.9* 13.9* 13.9* 13.9* 11.7* 11.7* 10.1* 10.1* 8.8* 8.8* 7.8* 7.8* 6.9* 6.9* 6.0* 6.0* 5.1* 5.1* 4.7* 4.7* 18.6

37.3* 37.3* 24.4* 24.4* 18.1* 18.1* 14.4* 14.4* 12.0* 12.0* 10.2* 10.2* 8.8* 8.8* 7.7* 7.7* 6.8* 6.8* 5.9* 5.9* 5.0* 5.0* 4.4* 4.4* 18.7

9.9* 9.9* 18.7* 18.7* 14.7* 14.7* 12.1* 12.1* 10.2* 10.2* 8.8* 8.8* 7.6* 7.6* 6.6* 6.6* 5.7* 5.7* 4.7* 4.7* 4.1* 4.1* 18.8

0.9* 0.9* 4.9* 4.9* 15.8* 15.8* 14.6* 14.6* 12.0* 12.0* 10.1* 10.1* 8.6* 8.6* 7.4* 7.4* 6.4* 6.4* 5.4* 5.4* 4.3* 4.3* 3.7* 3.7* 18.7

2.0* 2.0* 4.7* 4.7* 10.7* 10.7* 14.0* 14.0* 11.5* 11.5* 9.7* 9.7* 8.2* 8.2* 7.1* 7.1* 6.0* 6.0* 5.0* 5.0* 3.8* 3.8* 3.3* 3.3* 18.5

5.4* 5.4* 9.8* 9.8* 12.8* 12.8* 10.7* 10.7* 9.0* 9.0* 7.7* 7.7* 6.5* 6.5* 5.4* 5.4* 4.4* 4.4* 3.0* 3.0* 18.0

6.4* 6.4* 10.1* 10.1* 11.2* 11.2* 9.5* 9.5* 8.1* 8.1* 6.9* 6.9* 5.7* 5.7* 4.7* 4.7* 3.5* 3.5* 3.2* 3.2* 16.8

9.1* 9.1* 7.9* 7.9* 6.8* 6.8* 5.7* 5.7* 4.7* 4.7* 3.8* 3.8* 14.7

ER 944 C

Industrial Stick 9.50 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m

Under m carriage m

HR

25.5

HR

24.0

HR

22.5

HR

21.0

HR

19.5

HR

18.0

HR

16.5

HR

15.0

HR

13.5

HR

12.0

HR

10.5

HR

9.0

HR

7.5

HR

6.0

HR

4.5

HR

3.0

HR

1.5

HR

0

HR

– 1.5

HR

– 3.0

HR

– 4.5

HR

– 6.0

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 750 mm track flat pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic

capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the

load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

8.3* 8.3* 7.8* 7.8* 7.8

8.4* 8.4* 6.6* 6.6* 6.4* 6.4* 10.6

9.2* 9.2* 8.2* 8.2* 6.7* 6.7* 5.7* 5.7* 12.6

8.9* 8.9* 7.9* 7.9* 6.4* 6.4* 5.3* 5.3* 14.2

9.1* 9.1* 8.3* 8.3* 7.5* 7.5* 5.9* 5.9* 5.0* 5.0* 15.5

9.1* 9.1* 8.2* 8.2* 7.5* 7.5* 6.8* 6.8* 4.8* 4.8* 4.8* 4.8* 16.5

9.1* 9.1* 8.2* 8.2* 7.5* 7.5* 6.8* 6.8* 6.1* 6.1* 4.6* 4.6* 17.4

10.1* 10.1* 9.2* 9.2* 8.3* 8.3* 7.5* 7.5* 6.8* 6.8* 6.1* 6.1* 4.7* 4.7* 4.5* 4.5* 18.0

10.6* 10.6* 9.4* 9.4* 8.4* 8.4* 7.5* 7.5* 6.8* 6.8* 6.1* 6.1* 5.3* 5.3* 4.5* 4.5* 18.6

10.6* 10.6* 11.0* 11.0* 9.6* 9.6* 8.5* 8.5* 7.6* 7.6* 6.8* 6.8* 6.0* 6.0* 5.3* 5.3* 4.5* 4.5* 19.0

10.5* 10.5* 12.6* 12.6* 11.4* 11.4* 9.8* 9.8* 8.6* 8.6* 7.6* 7.6* 6.8* 6.8* 6.0* 6.0* 5.2* 5.2* 4.4* 4.4* 19.2

7.8* 7.8* 13.8* 13.8* 16.8* 16.8* 14.1* 14.1* 11.7* 11.7* 10.0* 10.0* 8.7* 8.7* 7.6* 7.6* 6.7* 6.7* 5.9* 5.9* 5.1* 5.1* 4.1* 4.1* 19.4

24.9* 24.9* 18.3* 18.3* 14.5* 14.5* 11.9* 11.9* 10.1* 10.1* 8.7* 8.7* 7.6* 7.6* 6.6* 6.6* 5.7* 5.7* 4.9* 4.9* 3.8* 3.8* 19.4

1.4* 1.4* 6.6* 6.6* 18.5* 18.5* 14.5* 14.5* 11.9* 11.9* 10.0* 10.0* 8.6* 8.6* 7.4* 7.4* 6.4* 6.4* 5.5* 5.5* 4.6* 4.6* 3.5* 3.5* 19.4

2.1* 2.1* 5.2* 5.2* 12.6* 12.6* 14.1* 14.1* 11.6* 11.6* 9.7* 9.7* 8.3* 8.3* 7.1* 7.1* 6.1* 6.1* 5.1* 5.1* 4.1* 4.1* 3.1* 3.1* 19.2

3.1* 3.1* 5.5* 5.5* 10.4* 10.4* 13.2* 13.2* 10.9* 10.9* 9.2* 9.2* 7.8* 7.8* 6.7* 6.7* 5.6* 5.6* 4.6* 4.6* 3.5* 3.5* 2.7* 2.7* 18.8

6.3* 6.3* 10.1* 10.1* 11.8* 11.8* 9.9* 9.9* 8.4* 8.4* 7.1* 7.1* 6.0* 6.0* 5.0* 5.0* 3.9* 3.9* 2.9* 2.9* 17.7

10.6* 10.6* 10.0* 10.0* 8.5* 8.5* 7.3* 7.3* 6.1* 6.1* 5.1* 5.1* 4.1* 4.1* 3.3* 3.3* 16.0

6.7* 6.7* 5.8* 5.8* 4.8* 4.8* 4.4* 4.4* 12.6

ER 934 C ER 944 C ER 954 C High Rise 21

Page 22

Lift Capacities

with Industrial-Type Straight Mono Boom 10.50 m

Industrial Stick 8.80 m (Variant 3B)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m

Under m carriage m

HR

25.5

HR

24.0

ER 944 C

22.5

21.0

19.5

18.0

16.5

15.0

13.5

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

0

– 1.5

– 3.0

– 4.5

– 6.0

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

10.2* 10.2* 9.2* 9.2* 6.7

10.0* 10.0* 8.5* 8.5* 7.3* 7.3* 9.8

8.7* 8.7* 8.1* 8.1* 6.4* 6.4* 12.0

8.3* 8.3* 7.8* 7.8* 7.3* 7.3* 6.1* 6.1* 5.9* 5.9* 13.6

7.6* 7.6* 7.1* 7.1* 6.8* 6.8* 5.5* 5.5* 14.9

7.5* 7.5* 7.1* 7.1* 6.7* 6.7* 6.4* 6.4* 5.3* 5.3* 16.0

8.2* 8.2* 7.6* 7.6* 7.1* 7.1* 6.7* 6.7* 6.4* 6.4* 6.0* 6.0* 5.1* 5.1* 16.8

8.5* 8.5* 7.8* 7.8* 7.2* 7.2* 6.8* 6.8* 6.4* 6.4* 6.1* 6.1* 5.0* 5.0* 17.5

8.9* 8.9* 8.1* 8.1* 7.5* 7.5* 6.9* 6.9* 6.5* 6.5* 6.1* 6.1* 5.2* 5.2* 5.0* 5.0* 18.1

10.8* 10.8* 9.5* 9.5* 8.5* 8.5* 7.7* 7.7* 7.1* 7.1* 6.6* 6.6* 6.1* 6.1* 5.7* 5.7* 5.0* 5.0* 18.5

11.0* 11.0* 14.2* 14.2* 11.8* 11.8* 10.2* 10.2* 9.0* 9.0* 8.0* 8.0* 7.3* 7.3* 6.7* 6.7* 6.2* 6.2* 5.8* 5.8* 5.1* 5.1* 18.7

21.8* 21.8* 16.2* 16.2* 13.0* 13.0* 10.9* 10.9* 9.4* 9.4* 8.4* 8.4* 7.5* 7.5* 6.9* 6.9* 6.3* 6.3* 5.8* 5.8* 5.1* 5.1* 18.9

7.1* 7.1* 17.9* 17.9* 14.0* 14.0* 11.6* 11.6* 9.9* 9.9* 8.7* 8.7* 7.7* 7.7* 7.0* 7.0* 6.4* 6.4* 5.8* 5.8* 5.3* 5.3* 18.9

0.8* 0.8* 4.3* 4.3* 13.0* 13.0* 14.8* 14.8* 12.1* 12.1* 10.3* 10.3* 8.9* 8.9* 7.9* 7.9* 7.1* 7.1* 6.4* 6.4* 5.7* 5.7* 5.3* 5.3* 18.8

2.0* 2.0* 4.5* 4.5* 9.7* 9.7* 15.3* 15.3* 12.5* 12.5* 10.5* 10.5* 9.1* 9.1* 8.0* 8.0* 7.1* 7.1* 6.3* 6.3* 5.5* 5.5* 5.2* 5.2* 18.6

5.3* 5.3* 9.2* 9.2* 15.3* 15.3* 12.6* 12.6* 10.6* 10.6* 9.1* 9.1* 8.0* 8.0* 7.0* 7.0* 6.2* 6.2* 5.2* 5.2* 18.0

9.7* 9.7* 15.0* 15.0* 12.4* 12.4* 10.4* 10.4* 9.0* 9.0* 7.8* 7.8* 6.8* 6.8* 5.8* 5.8* 5.7* 5.7* 16.7

14.2* 14.2* 11.8* 11.8* 10.0* 10.0* 8.6* 8.6* 7.4* 7.4* 6.8* 6.8* 14.4

Industrial Stick 9.50 m (Variant 3B)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m

Under m carriage m

HR

25.5

HR

24.0

HR

22.5

HR

21.0

HR

19.5

HR

18.0

HR

16.5

HR

15.0

HR

13.5

HR

12.0

HR

10.5

HR

9.0

HR

7.5

HR

6.0

HR

4.5

HR

3.0

HR

1.5

HR

0

HR

– 1.5

HR

– 3.0

HR

– 4.5

HR

– 6.0

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 750 mm track flat pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic

capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the

load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

8.8* 8.8* 7.6* 7.6* 8.4

8.7* 8.7* 7.2* 7.2* 6.3* 6.3* 11.1

8.2* 8.2* 7.6* 7.6* 7.1* 7.1* 5.6* 5.6* 13.0

7.3* 7.3* 6.9* 6.9* 6.6* 6.6* 5.2* 5.2* 14.5

7.1* 7.1* 6.7* 6.7* 6.4* 6.4* 6.2* 6.2* 4.9* 4.9* 15.8

7.1* 7.1* 6.7* 6.7* 6.4* 6.4* 6.1* 6.1* 5.3* 5.3* 4.7* 4.7* 16.8

7.2* 7.2* 6.7* 6.7* 6.4* 6.4* 6.1* 6.1* 5.8* 5.8* 4.6* 4.6* 17.6

7.4* 7.4* 6.9* 6.9* 6.5* 6.5* 6.1* 6.1* 5.8* 5.8* 5.2* 5.2* 4.5* 4.5* 18.3

8.4* 8.4* 7.7* 7.7* 7.1* 7.1* 6.6* 6.6* 6.2* 6.2* 5.8* 5.8* 5.5* 5.5* 4.5* 4.5* 18.8

10.0* 10.0* 8.9* 8.9* 8.1* 8.1* 7.4* 7.4* 6.8* 6.8* 6.3* 6.3* 5.9* 5.9* 5.5* 5.5* 4.5* 4.5* 19.2

10.7* 10.7* 11.1* 11.1* 9.6* 9.6* 8.5* 8.5* 7.7* 7.7* 7.0* 7.0* 6.5* 6.5* 6.0* 6.0* 5.6* 5.6* 4.5* 4.5* 19.4

10.5* 10.5* 16.4* 16.4* 15.1* 15.1* 12.2* 12.2* 10.4* 10.4* 9.0* 9.0* 8.0* 8.0* 7.3* 7.3* 6.6* 6.6* 6.1* 6.1* 5.6* 5.6* 4.8* 4.8* 4.6* 4.6* 19.6

16.0* 16.0* 17.0* 17.0* 13.4* 13.4* 11.1* 11.1* 9.5* 9.5* 8.4* 8.4* 7.5* 7.5* 6.8* 6.8* 6.2* 6.2* 5.6* 5.6* 5.0* 5.0* 4.7* 4.7* 19.6

1.2* 1.2* 5.5* 5.5* 18.4* 18.4* 14.3* 14.3* 11.7* 11.7* 10.0* 10.0* 8.7* 8.7* 7.7* 7.7* 6.9* 6.9* 6.2* 6.2* 5.6* 5.6* 4.9* 4.9* 19.5

2.0* 2.0* 4.8* 4.8* 11.1* 11.1* 14.9* 14.9* 12.2* 12.2* 10.3* 10.3* 8.9* 8.9* 7.8* 7.8* 7.0* 7.0* 6.2* 6.2* 5.5* 5.5* 4.9* 4.9* 19.3

3.1* 3.1* 5.3* 5.3* 9.7* 9.7* 15.1* 15.1* 12.4* 12.4* 10.4* 10.4* 9.0* 9.0* 7.8* 7.8* 6.9* 6.9* 6.1* 6.1* 5.4* 5.4* 4.8* 4.8* 18.8

6.2* 6.2* 9.7* 9.7* 15.0* 15.0* 12.3* 12.3* 10.4* 10.4* 8.9* 8.9* 7.8* 7.8* 6.8* 6.8* 5.9* 5.9* 5.2* 5.2* 17.7

10.3* 10.3* 14.4* 14.4* 11.9* 11.9* 10.1* 10.1* 8.6* 8.6* 7.5* 7.5* 6.5* 6.5* 5.9* 5.9* 15.9

9.0* 9.0* 11.0

22 ER 934 C ER 944 C ER 954 C High Rise

Page 23

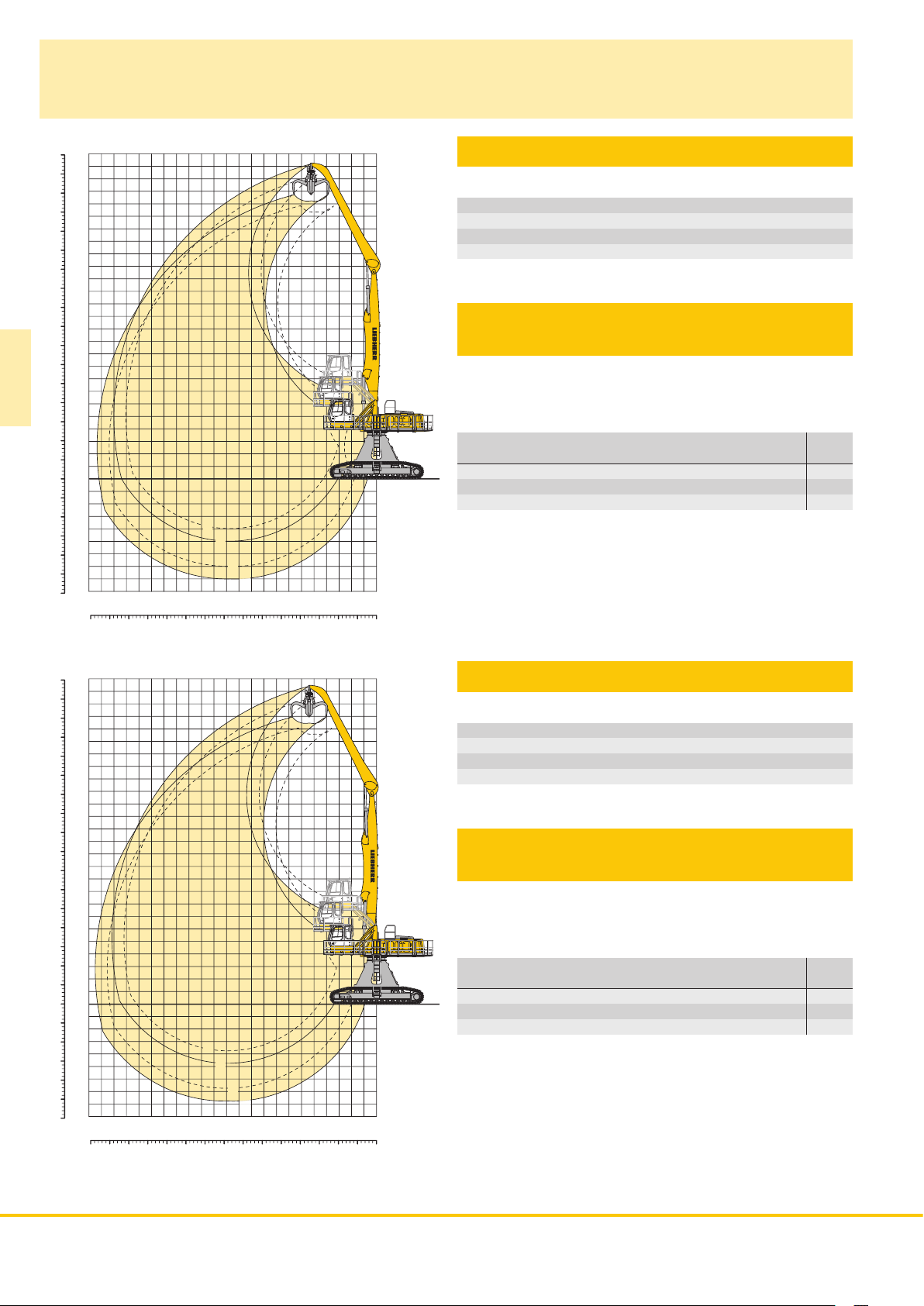

Industrial Attachment

with Industrial-Type Straight Mono Boom 11.50 m

m

-10

-20

-30

ft

80

70

60

50

40

30

20

10

0

-10

26

24

22

20

18

16

14

12

10

8

6

4

2

0

-2

-4

-6

-8

80 70 60

1

3

2

4

1012

18

202224

1416

30

40

50

R0113

24106208

Attachment Envelope

Kinematic variants 2A

1 with industrial stick 9.50 m

2 with industrial stick 9.50 m and grapple model GM 70C

3 with industrial stick 12.00 m

4 with industrial stick 12.00 m and grapple model GM 70C

Operating Weight

and Ground Pressure

Operating weight includes basic machine with hydraulic cab elevation

+ intermediate piece 0.5 m, counterweight 11.0 t, industrial-type

straight mono boom 11.50 m, industrial stick 9.50 m and grapple

model GM 70C with 5 semi-closed tines 0.80 m

Undercarriage HR

Pad width mm 750

Weight kg 73,800

Ground pressure kg/cm

0

0mft

3

(1,705 kg).

2

0.82

ER 944 C

-10

-20

-30

90

80

70

60

50

40

30

20

10

m

ft

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0

0

-2

-10

-4

-6

-8

18

202224

1

3

2

4

1012

1416

R0114

24106208

Attachment Envelope

Kinematic variants 3B

1 with industrial stick 9.50 m

2 with industrial stick 9.50 m and grapple model GM 70C

3 with industrial stick 12.00 m

4 with industrial stick 12.00 m and grapple model GM 70C

Operating Weight

and Ground Pressure

Operating weight includes basic machine with hydraulic cab elevation

+ intermediate piece 0.5 m, counterweight 11.0 t, industrial-type

straight mono boom 11.50 m, industrial stick 12.00 m and grapple

model GM 70C with 5 semi-closed tines 0.80 m

Undercarriage HR

Pad width mm 750

Weight kg 74,500

Ground pressure kg/cm

0

3

(1,705 kg).

2

0.83

80 70 60

30

40

50

0mft

ER 934 C ER 944 C ER 954 C High Rise 23

Page 24

Lift Capacities

with Industrial-Type Straight Mono Boom 11.50 m

Industrial Stick 9.50 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m

Under m carriage m

HR

25.5

ER 944 C

24.0

22.5

21.0

19.5

18.0

16.5

15.0

13.5

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

0

– 1.5

– 3.0

– 4.5

– 6.0

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

9.5* 9.5* 8.7* 8.7* 6.7

9.3* 9.3* 8.0* 8.0* 6.8* 6.8* 10.0

9.0* 9.0* 8.0* 8.0* 6.4* 6.4* 6.0* 6.0* 12.3

9.4* 9.4* 8.8* 8.8* 7.8* 7.8* 6.3* 6.3* 5.4* 5.4* 14.1

9.1* 9.1* 8.1* 8.1* 7.3* 7.3* 6.0* 6.0* 5.1* 5.1* 15.5

9.0* 9.0* 8.1* 8.1* 7.2* 7.2* 6.5* 6.5* 5.2* 5.2* 4.9* 4.9* 16.7

9.0* 9.0* 8.1* 8.1* 7.2* 7.2* 6.5* 6.5* 5.9* 5.9* 4.7* 4.7* 17.6

9.1* 9.1* 8.1* 8.1* 7.2* 7.2* 6.5* 6.5* 5.8* 5.8* 5.2* 5.2* 4.6* 4.6* 18.4

10.4* 10.4* 9.2* 9.2* 8.1* 8.1* 7.3* 7.3* 6.5* 6.5* 5.8* 5.8* 5.2* 5.2* 4.5* 4.5* 19.1

10.8* 10.8* 9.3* 9.3* 8.2* 8.2* 7.3* 7.3* 6.5* 6.5* 5.8* 5.8* 5.1* 5.1* 4.4* 4.4* 4.3* 4.3* 19.6

11.6* 11.6* 11.0* 11.0* 9.5* 9.5* 8.3* 8.3* 7.3* 7.3* 6.5* 6.5* 5.8* 5.8* 5.1* 5.1* 4.3* 4.3* 4.1* 4.1* 20.0

10.0* 10.0* 13.3* 13.3* 13.6* 13.6* 11.3* 11.3* 9.6* 9.6* 8.3* 8.3* 7.3* 7.3* 6.5* 6.5* 5.7* 5.7* 5.0* 5.0* 4.2* 4.2* 3.8* 3.8* 20.2

23.9* 23.9* 17.6* 17.6* 13.9* 13.9* 11.5* 11.5* 9.7* 9.7* 8.4* 8.4* 7.3* 7.3* 6.4* 6.4* 5.6* 5.6* 4.9* 4.9* 4.1* 4.1* 3.5* 3.5* 20.4

4.9* 4.9* 17.8* 17.8* 14.0* 14.0* 11.5* 11.5* 9.6* 9.6* 8.3* 8.3* 7.2* 7.2* 6.2* 6.2* 5.4* 5.4* 4.7* 4.7* 3.8* 3.8* 3.2* 3.2* 20.4

2.9* 2.9* 9.4* 9.4* 13.7* 13.7* 11.2* 11.2* 9.4* 9.4* 8.1* 8.1* 7.0* 7.0* 6.0* 6.0* 5.2* 5.2* 4.4* 4.4* 3.5* 3.5* 2.9* 2.9* 20.3

1.1* 1.1* 3.1* 3.1* 7.1* 7.1* 13.0* 13.0* 10.7* 10.7* 9.1* 9.1* 7.7* 7.7* 6.6* 6.6* 5.7* 5.7* 4.9* 4.9* 4.0* 4.0* 3.1* 3.1* 2.5* 2.5* 20.1

3.8* 3.8* 6.9* 6.9* 11.8* 11.8* 9.9* 9.9* 8.4* 8.4* 7.2* 7.2* 6.2* 6.2* 5.3* 5.3* 4.4* 4.4* 3.5* 3.5* 2.4* 2.4* 2.1* 2.1* 19.8

4.8* 4.8* 7.4* 7.4* 10.3* 10.3* 8.8* 8.8* 7.6* 7.6* 6.5* 6.5* 5.5* 5.5* 4.7* 4.7* 3.8* 3.8* 2.9* 2.9* 2.3* 2.3* 18.7

8.4* 8.4* 7.4* 7.4* 6.4* 6.4* 5.5* 5.5* 4.7* 4.7* 3.8* 3.8* 3.0* 3.0* 2.6* 2.6* 17.0

5.0* 5.0* 4.3* 4.3* 3.6* 3.6* 3.5* 3.5* 13.6

Industrial Stick 12.00 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m

Under m carriage m

HR

25.5

HR

24.0

HR

22.5

HR

21.0

HR

19.5

HR

18.0

HR

16.5

HR

15.0

HR

13.5

HR

12.0

HR

10.5

HR

9.0

HR

7.5

HR

6.0

HR

4.5

HR

3.0

HR

1.5

HR

0

HR

– 1.5

HR

– 3.0

HR

– 4.5

HR

– 6.0

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 750 mm track flat pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic

capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of the

load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

6.2* 6.2* 5.8* 5.8* 9.4

6.3* 6.3* 5.0* 5.0* 4.8* 4.8* 12.2

6.9* 6.9* 6.1* 6.1* 5.1* 5.1* 4.2* 4.2* 14.3

6.6* 6.6* 5.9* 5.9* 4.9* 4.9* 3.8* 3.8* 16.0

6.9* 6.9* 6.4* 6.4* 5.7* 5.7* 4.6* 4.6* 3.6* 3.6* 17.4

7.1* 7.1* 6.6* 6.6* 6.0* 6.0* 5.4* 5.4* 4.1* 4.1* 3.4* 3.4* 18.6

6.5* 6.5* 5.9* 5.9* 5.4* 5.4* 4.9* 4.9* 3.4* 3.4* 3.3* 3.3* 19.6

7.2* 7.2* 6.5* 6.5* 5.9* 5.9* 5.4* 5.4* 4.9* 4.9* 4.3* 4.3* 3.2* 3.2* 20.4

7.3* 7.3* 6.6* 6.6* 5.9* 5.9* 5.4* 5.4* 4.9* 4.9* 4.4* 4.4* 3.2* 3.2* 3.1* 3.1* 21.1

7.4* 7.4* 6.6* 6.6* 6.0* 6.0* 5.4* 5.4* 4.8* 4.8* 4.3* 4.3* 3.8* 3.8* 3.1* 3.1* 21.6

7.5* 7.5* 6.7* 6.7* 6.0* 6.0* 5.4* 5.4* 4.8* 4.8* 4.3* 4.3* 3.8* 3.8* 3.1* 3.1* 22.1

8.1* 8.1* 7.6* 7.6* 6.7* 6.7* 6.0* 6.0* 5.4* 5.4* 4.8* 4.8* 4.3* 4.3* 3.7* 3.7* 3.1* 3.1* 22.4

8.1* 8.1* 8.8* 8.8* 7.7* 7.7* 6.8* 6.8* 6.0* 6.0* 5.4* 5.4* 4.8* 4.8* 4.2* 4.2* 3.6* 3.6* 3.0* 3.0* 2.9* 2.9* 22.7

8.6* 8.6* 10.1* 10.1* 9.0* 9.0* 7.8* 7.8* 6.8* 6.8* 6.0* 6.0* 5.3* 5.3* 4.7* 4.7* 4.1* 4.1* 3.5* 3.5* 2.8* 2.8* 2.6* 2.6* 22.8

9.0* 9.0* 12.1* 12.1* 13.2* 13.2* 10.8* 10.8* 9.2* 9.2* 7.9* 7.9* 6.8* 6.8* 6.0* 6.0* 5.3* 5.3* 4.6* 4.6* 4.0* 4.0* 3.4* 3.4* 2.6* 2.6* 2.4* 2.4* 22.8

2.5* 2.5* 20.5* 20.5* 17.1* 17.1* 13.4* 13.4* 10.9* 10.9* 9.2* 9.2* 7.8* 7.8* 6.8* 6.8* 5.9* 5.9* 5.2* 5.2* 4.5* 4.5* 3.8* 3.8* 3.2* 3.2* 2.4* 2.4* 2.2* 2.2* 22.7

1.6* 1.6* 5.5* 5.5* 17.0* 17.0* 13.3* 13.3* 10.8* 10.8* 9.1* 9.1* 7.7* 7.7* 6.6* 6.6* 5.7* 5.7* 5.0* 5.0* 4.3* 4.3* 3.6* 3.6* 2.9* 2.9* 2.0* 2.0* 1.9* 1.9* 22.6

2.1* 2.1* 4.5* 4.5* 9.7* 9.7* 12.8* 12.8* 10.5* 10.5* 8.8* 8.8* 7.4* 7.4* 6.4* 6.4* 5.5* 5.5* 4.7* 4.7* 4.0* 4.0* 3.3* 3.3* 2.5* 2.5* 1.6* 1.6* 22.3

2.7* 2.7* 4.6* 4.6* 8.1* 8.1* 11.9* 11.9* 9.8* 9.8* 8.3* 8.3* 7.0* 7.0* 6.0* 6.0* 5.1* 5.1* 4.3* 4.3* 3.6* 3.6* 2.9* 2.9* 2.0* 2.0* 1.4* 1.4* 21.8

3.5* 3.5* 5.1* 5.1* 7.9* 7.9* 10.7* 10.7* 8.9* 8.9* 7.5* 7.5* 6.4* 6.4* 5.4* 5.4* 4.6* 4.6* 3.8* 3.8* 3.1* 3.1* 2.3* 2.3* 1.5* 1.5* 20.7

5.7* 5.7* 8.2* 8.2* 9.1* 9.1* 7.7* 7.7* 6.6* 6.6* 5.6* 5.6* 4.7* 4.7* 3.9* 3.9* 3.2* 3.2* 2.4* 2.4* 1.7* 1.7* 19.2

7.2* 7.2* 6.2* 6.2* 5.4* 5.4* 4.5* 4.5* 3.8* 3.8* 3.1* 3.1* 2.3* 2.3* 2.1* 2.1* 16.9

24 ER 934 C ER 944 C ER 954 C High Rise

Page 25

Lift Capacities

with Industrial-Type Straight Mono Boom 11.50 m

Industrial Stick 9.50 m (Variant 3B)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m 19.5 m 21.0 m 22.5 m

Under m carriage m

HR

25.5

24.0

22.5

21.0

19.5

18.0

16.5

15.0

13.5

12.0

10.5

9.0

7.5

6.0

4.5

3.0

1.5

0

– 1.5

– 3.0

– 4.5

– 6.0

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

HR

8.3* 8.3* 7.4

8.4* 8.4* 6.7* 6.7* 6.7* 6.7* 10.5

8.3* 8.3* 7.6* 7.6* 6.9* 6.9* 5.9* 5.9* 12.7

7.3* 7.3* 6.7* 6.7* 6.3* 6.3* 5.4* 5.4* 14.4

7.1* 7.1* 6.6* 6.6* 6.2* 6.2* 5.8* 5.8* 5.1* 5.1* 15.8

7.0* 7.0* 6.5* 6.5* 6.1* 6.1* 5.7* 5.7* 5.5* 5.5* 4.8* 4.8* 17.0

7.1* 7.1* 6.5* 6.5* 6.1* 6.1* 5.7* 5.7* 5.4* 5.4* 4.7* 4.7* 17.9

7.2* 7.2* 6.6* 6.6* 6.1* 6.1* 5.7* 5.7* 5.4* 5.4* 5.1* 5.1* 4.6* 4.6* 18.7

8.2* 8.2* 7.4* 7.4* 6.8* 6.8* 6.2* 6.2* 5.8* 5.8* 5.4* 5.4* 5.1* 5.1* 4.5* 4.5* 19.3

8.6* 8.6* 7.7* 7.7* 7.0* 7.0* 6.4* 6.4* 5.9* 5.9* 5.5* 5.5* 5.1* 5.1* 4.8* 4.8* 4.5* 4.5* 19.8

10.5* 10.5* 9.1* 9.1* 8.0* 8.0* 7.2* 7.2* 6.6* 6.6* 6.0* 6.0* 5.6* 5.6* 5.2* 5.2* 4.8* 4.8* 4.5* 4.5* 20.1

10.6* 10.6* 14.1* 14.1* 11.5* 11.5* 9.7* 9.7* 8.4* 8.4* 7.5* 7.5* 6.7* 6.7* 6.1* 6.1* 5.6* 5.6* 5.2* 5.2* 4.8* 4.8* 4.6* 4.6* 20.4

21.5* 21.5* 15.7* 15.7* 12.4* 12.4* 10.3* 10.3* 8.9* 8.9* 7.8* 7.8* 6.9* 6.9* 6.3* 6.3* 5.7* 5.7* 5.2* 5.2* 4.8* 4.8* 4.5* 4.5* 20.5

3.6* 3.6* 17.1* 17.1* 13.3* 13.3* 10.9* 10.9* 9.3* 9.3* 8.0* 8.0* 7.1* 7.1* 6.4* 6.4* 5.8* 5.8* 5.3* 5.3* 4.8* 4.8* 4.4* 4.4* 20.5

2.6* 2.6* 8.0* 8.0* 13.9* 13.9* 11.3* 11.3* 9.6* 9.6* 8.3* 8.3* 7.3* 7.3* 6.5* 6.5* 5.8* 5.8* 5.3* 5.3* 4.7* 4.7* 4.3* 4.3* 20.5

1.1* 1.1* 3.0* 3.0* 6.5* 6.5* 14.2* 14.2* 11.6* 11.6* 9.8* 9.8* 8.4* 8.4* 7.4* 7.4* 6.5* 6.5* 5.8* 5.8* 5.2* 5.2* 4.6* 4.6* 4.2* 4.2* 20.2

3.8* 3.8* 6.6* 6.6* 12.1* 12.1* 11.7* 11.7* 9.8* 9.8* 8.4* 8.4* 7.4* 7.4* 6.5* 6.5* 5.8* 5.8* 5.1* 5.1* 4.4* 4.4* 4.2* 4.2* 19.8