Page 1

Use and Care

Manual

Combined fridge-freezer,

freestanding/semi built-in

CS 1311 / CS 1360

090616 7085514 - 02

Page 2

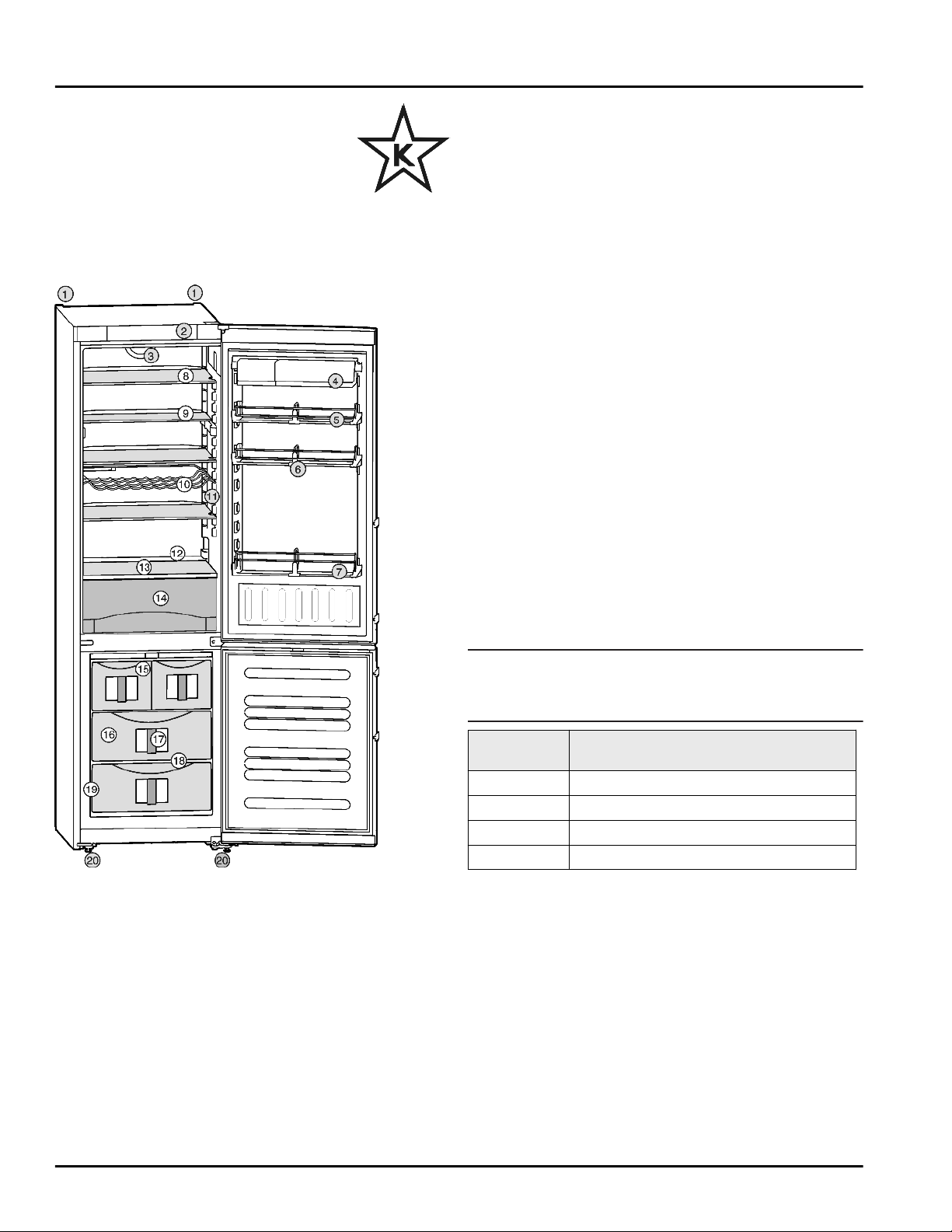

The appliance at a glance

Contents

1 The appliance at a glance............................. 2

1.1 Additional benefits............................................ 2

1.2 Overview of the appliance and its equipment... 3

1.3 Range of appliance use.................................... 3

1.4 Conformity........................................................ 3

1.5 Installation dimensions .................................... 4

1.6 Energy saving................................................... 4

1.7 Example of food arrangement.......................... 4

2 General safety information........................... 4

3 Controls and displays................................... 5

3.1 Operating and control elements....................... 5

3.2 Temperature display......................................... 6

4 Start-up........................................................... 6

4.1 Transporting the appliance............................... 6

4.2 Setting up the appliance................................... 6

4.3 Changing the door hinges................................ 7

4.4 Side-by-side installation................................... 11

4.5 Water connection............................................. 14

4.6 Installation into a fitted kitchen......................... 15

4.7 Anti-tip device................................................... 15

4.8 Installing the water filter.................................... 15

4.9 Disposal of packaging...................................... 17

4.10 Connecting the appliance................................. 17

4.11 Switching on the appliance............................... 18

5 Operation........................................................ 18

5.1 Temperature display unit.................................. 18

5.2 Brightness of the temperature display.............. 18

5.3 Child-proof lock................................................ 19

5.4 Door alarm....................................................... 19

5.5 Temperature alarm........................................... 19

5.6 Sabbath Mode.................................................. 19

5.7 Fridge compartment......................................... 20

5.8 Freezer compartment....................................... 22

6 Maintenance................................................... 24

6.1 Replacing the water filter.................................. 24

6.2 Defrosting with NoFrost.................................... 25

6.3 Cleaning the appliance..................................... 25

6.4 Cleaning the IceMaker..................................... 26

6.5 Customer service............................................. 26

6.6 Appliance Information...................................... 26

7 Troubleshooting............................................. 27

8 Putting appliance out of service.................. 30

8.1 Vacation Tips.................................................... 30

8.2 Switching off the appliance............................... 30

8.3 Decommissioning ............................................ 30

9 Disposing of the appliance........................... 30

10 Liebherr Warranty Plan................................. 31

Congratulations on the purchase of your new appliance.

With this purchase, you have chosen all the advantages of

the latest refrigeration technology, guaranteeing you a

high-quality appliance with a long life span and high operating safety.

The equipment of your appliance gives you the highest

level of day-to-day ease of operation.

Together we are making an active contribution to the

conservation of our environment by purchasing this appliance which is manufactured in an environmentally friendly

process with the use of recyclable materials.

We hope you enjoy your new appliance.

The manufacturer is constantly working to improve all

models. Therefore please understand that we reserve the

right to make design, equipment and technical modifications.

To get to know all the benefits of your new appliance,

please read the information contained in these instructions carefully.

The instructions apply to several models, so there may be

differences. Sections which only apply to certain appliances are indicated with an asterisk (*).

Instructions for action are marked with a , the

results of action are marked with a .

1 The appliance at a glance

1.1 Additional benefits

- CFC free

- Energy-optimized refrigerant circuit

- Energy-efficient insulation

- Low energy consumption

- User-friendly electronic controls

- Active function indicators

- Temperature can be controlled in the appliance independent of ambient conditions according to its climate

rating - Temperature can be displayed as °C or °F

- The appliance defrosts automatically - no need to

spend time defrosting

- Large refrigeration capacity

- Safety glass storage shelves

- Adjustable door shelves for tall bottles

- Large freezing capacity

- Shelves can be removed to make space for large items.

- Freezer over-temperature alarm

- Quick-freeze feature for fresh food (SuperFrost)

- Frozen food temperature indicator

- Power failure/“frost-control” display

- All freezer drawers suitable for quick-freeze

- Bright LED interior light

- Door ajar alarm

- Handle grips on all extra-large drawers for easy transport

- Integrated transport grips on appliance housing

- Transport castors at back

- Easy to clean

- Door hinges can be reversed

2 * Depending on model and options

Page 3

The appliance at a glance

- This unit is certified as Sabbath

compliant by the Star-K organization

thus allowing the appliance to be used

during religious holidays. For more information please visit Star-K on the web at

www.star-k.org.

1.2 Overview of the appliance and its

equipment

1.3 Range of appliance use

Normal use

The appliance is only suitable for cooling food for

residential or other similar environments. This

includes the following types of uses

- in staff kitchens, bed and breakfasts,

- by guests in country homes, hotels, motels

and other types of accommodations,

- for catering and similar wholesale services.

All other types of uses are not permitted.

Foreseeable misuse

The following uses are specifically prohibited:

- Storage and cooling of medication, blood

plasma, laboratory preparations or similar

substances and products in accordance with

the CMDCAS and FDA 510(k)

- Use in areas at risk of explosion

Incorrect appliance use can cause damage to

the stored products or cause them to spoil.

Climate ratings

The appliance is set to operate within specific

ambient temperature limits according to its

climate rating The climate rating for your appliance is printed on the rating plate

Fig. 1

(1) Rear transport

handles

(2) Operating and control

elements

(3) Fan (13)Coldest zone

(4) Container shelf (14)Vegetable drawer

(5) Door rack, moveable (15)IceMaker*

(6) Bottle partition,

adjustable

(7) Gallon-capacity rack (17)InfoSystem

(8) Shelf, moveable (18)VarioSpace

(9) Shelf, can be split (19)Rating plate

(10)Bottle shelf (20)Adustable feet, front

(11)Interior light

(12)Drain hole

(16)Freezer compartment

transport handles, rear

transport castors

Note

uTo guarantee trouble-free operation, comply

with the indicated ambient temperatures.

Climate

rating

SN 50 °F (10 °C) to 90 °F (32 °C)

N 61 °F (16 °C) to 90 °F (32 °C)

ST 61 °F (16 °C) to 101 °F (38 °C)

T 61 °F (16 °C) to 110 °F (43 °C)

for ambient temperatures from

1.4 Conformity

The refrigerant circuit has been tested for leaks. The

appliance complies with the relevant safety regulations

and the directives UL250 and CAN/CSA C22.2 No.63-93.

* Depending on model and options 3

Page 4

General safety information

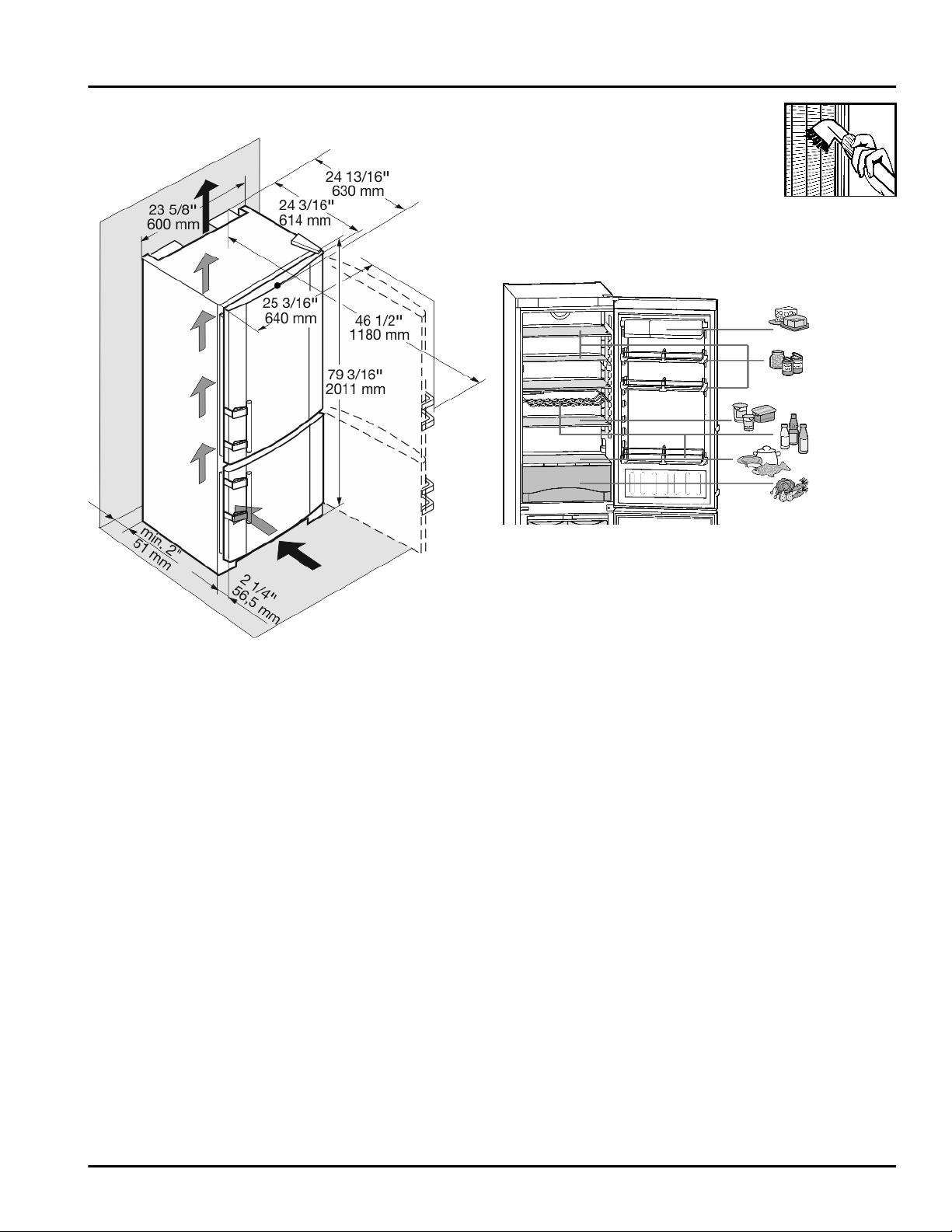

1.5 Installation dimensions

Dust deposits increase energy

consumption:

- Once a year the dust should be

removed from the refrigerating

machine and the heat exchanger

metal grid at the back of the appliance

1.7 Example of food arrangement

Fig. 3

Fig. 2

1.6 Energy saving

- Always ensure good ventilation. Do not obstruct ventilation openings or grilles.

- Do not install the appliance in direct sunlight or next to

an oven, heater, or similar heat source.

- Energy consumption depends on installation conditions

such as the ambient temperature (see 1.3) . If the

ambient temperature differs from the standard temperature of 25 °C, energy consumption can change.

- Avoid opening the appliance door for any longer then

necessary

- The lower the temperature is set the higher the energy

consumption.

- Store food logically (see The appliance at a glance).

- All food stored in the appliance should be well wrapped

and covered. This prevents frost buildup.

- Only take food out for as long as necessary so that it

does not get too warm.

- Insertion of warm foods: first let the food cool down to

room temperature.

- Defrost frozen food in the fridge

2 General safety information

Read and follow these instructions. They contain

safety advice which is important for safe and

problem-free installation and operation. Always

read and follow the safety advice.

Dangers for the user:

- This appliance can be operated by children 8

years and older as well as by persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if

they are supervised or have been instructed in

the safe use of the appliance and understand

the associated risks. Children must not play

with the appliance. Cleaning and user maintenance must not be performed by children

unless they are supervised.

- When disconnecting the appliance from the

outlet, always take hold of the plug. Do not pull

on the cable.

- Disconnect the power plug or switch off the

power if a fault occurs.

- Do not damage the mains power line. Do not

operate the appliance from a defective mains

power line.

- Repairs, work on the appliance and replace-

ment of the power cord should only be carried

out by the customer service department.

4 * Depending on model and options

Page 5

Controls and displays

- The appliance should only be assembled,

connected and disposed of in accordance with

the instructions.

- Please keep the instructions and pass them on

to any future owner.

- All repairs to or work on the IceMaker must

only be carried out by the customer service

department or other specialist engineers

trained to do this.*

- The manufacturer is not liable for damage

arising from incorrect connection to the water

supply.*

Risk of fire:

- Do not operate the appliance near explosive

gases.

- Do not store explosive materials or spray cans

with flammable propellants, such as e.g.

butane, propane, pentane, etc. in the appliance. You can recognize such spray cans by

the printed contents or a flame symbol. Any

leaking gasses can be ignited by electrical

components.

- Keep burning candles, lamps and other

objects with open flames away from the appliance so that they do not set it on fire.

- Alcoholic beverages or other containers

holding alcohol must always be tightly sealed

for storage purposes. Any leaking alcohol can

be ignited by electrical components

Tipover hazard:

- Do not stand or climb on the base, drawers,

doors, etc. This applies in particular to children.

Risk of food poisoning:

- Do not consume food that has passed its best

before date.

Danger of frostbite, feelings of numbness

and pain:

- Avoid continued skin contact with the cold

surfaces or chilled/frozen food or adopt protective measures, e. g. use gloves. Do not

consume ice cream (especially sherbets) and

ice cubes immediately when they are too cold.

Risk of injury and damage:

- Hot steam may lead to injuries. Do not use any

electrical heating or steam cleaning equipment, naked flames or defrosting sprays for

defrosting

- Do not remove ice with sharp objects

Risk of crushing:

- Do not hold onto the hinge when opening and

closing the door. Fingers may get caught.

California Proposition 65

- This product contains chemicals known to the

state of California to cause cancer or reproductive harm.

Symbols on the device:

The symbol can be on the compressor. It refers to

the oil in the compressor and refers to the following

danger: Can be lethal if swallowed or inhaled. This

notice only applies for recycling. There is no danger

during normal operation.

Follow the specific instructions in the other

sections:

DANGER indicates a hazardous situation,

which if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation,

which if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation,

which if not avoided, will result in

minor or moderate injury.

NOTICE indicates a hazardous situation,

which if not avoided, could result in

damage to property.

Note indicates useful advice and tips.

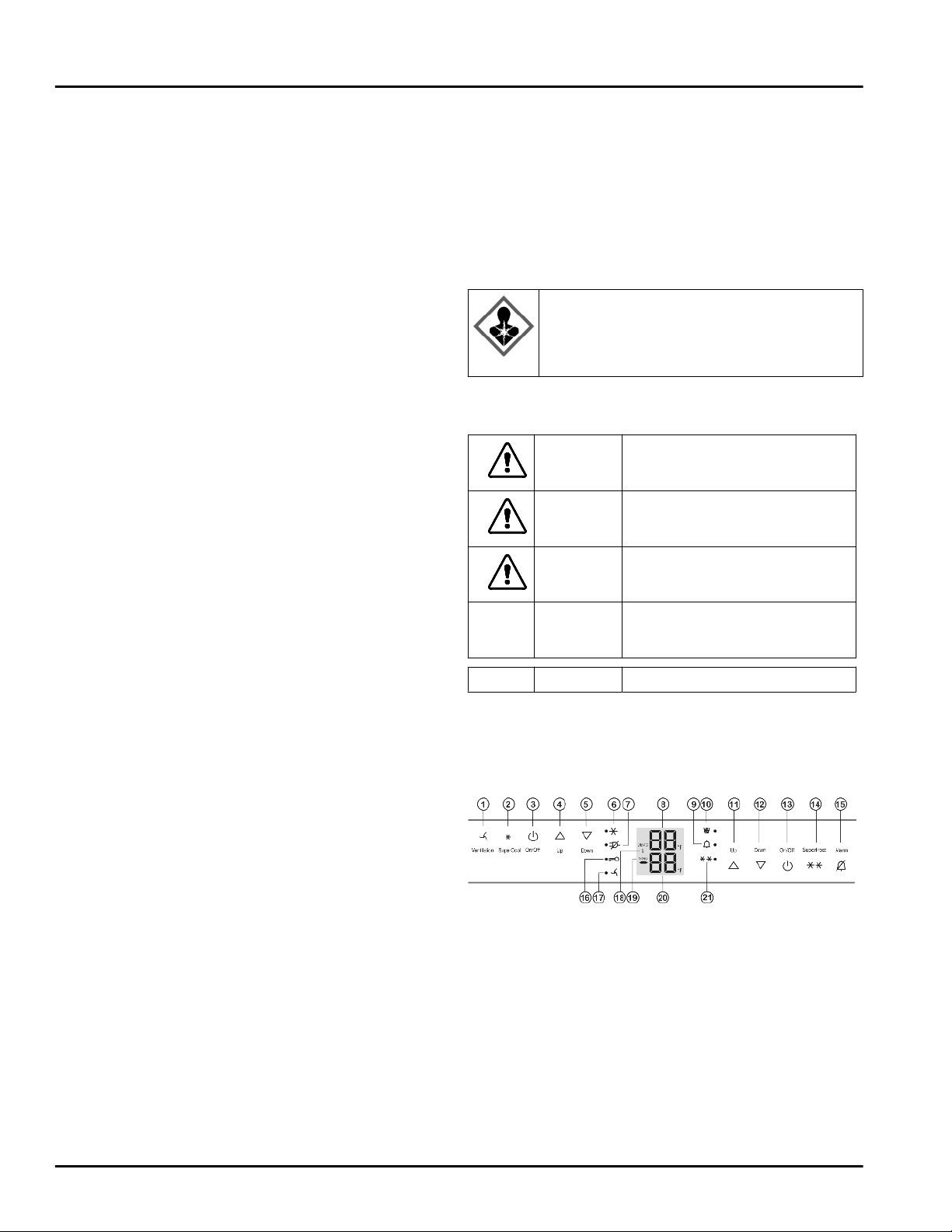

3 Controls and displays

3.1 Operating and control elements

Fig. 4

(1) Ventilation button (12)Freezer compartment

Down button

(2) SuperCool button (13)Freezer compartment

On/Off button

(3) Fridge compartment

On/Off button

(4) Fridge compartment

Up button

(5) Fridge compartment

Down button

(6) SuperCool symbol (17)Ventilation symbol

(7) Power failure symbol (18)Sabbath mode symbol

(14)SuperFrost button

(15)Alarm button

(16)Child lock symbol

* Depending on model and options 5

Page 6

Start-up

(8) Fridge compartment

temperature display

(9) Alarm symbol (20)Freezer compartment

(10)IceMaker symbol* (21)SuperFrost symbol

(11)Freezer compartment

Up button

The touch point is located between the symbol and the

symbol label.

(19)Menu symbol

temperature display

3.2 Temperature display

The following is displayed in normal operation:

- the highest freezer temperature

- the average fridge temperature

The freezer compartment temperature display is flashing:

- the temperature setting has been changed

- after switch-on the temperature is not yet cold enough

- the temperature has risen several degrees

Dashes are shown on the display:

- the freezer temperature is above 32 °F (0 °C).

The following displays indicate malfunction. Possible

causes and corrective actions: (see Troubleshooting).

- F0 through F9

- FE*

- The power failure symbol LED

flashes.

WARNING

Risk of fire due to short circuit.

If the power cable or plug of the appliance or another

appliance and the back of the appliance touch each other

the power cable or plug will be damaged by the vibrations

of the appliance which could lead to a short circuit.

u Install the appliance so that it does not touch any plugs

or power cables.

u Do not connect the appliance or other appliances to the

sockets on the back of the appliance.

WARNING

Danger of fire and damage!

u Do not place devices that give off heat, e.g. micro-

waves, toasters, etc. on the appliance.

CAUTION

Risk of personal injury!

u Have two people move this appliance into place.

WARNING

Danger of fire and damage due to blocked ventilation

openings!

u Never block the ventilation openings. Always ensure

good ventilation!

4 Start-up

4.1 Transporting the appliance

CAUTION

Risk of injury or damage if incorrectly transported.

u Transport the appliance in its packaging.

u Transport the appliance upright.

u Do not move the appliance on your own.

4.2 Setting up the appliance

WARNING

Risk of fire due to moisture!

If live parts or the power cord get wet, this can cause a

short circuit.

u The appliance is designed for use in enclosed spaces.

Do not operate the appliance in open space or in damp

areas or where there is spray.

NOTICE

Risk of damage caused by condensation

Installing the appliance next to any other refrigerator or

freezer can cause condensation or damage to the Liebherr appliance.

u Do not install this appliance next to any other refriger-

ator or freezer except another Liebherr model. Liebherr

models are designed to allow side-by-side installation.

They are equipped with a heating system to eliminate

condensation when refrigerators or freezers are

installed side-by-side.

NOTICE

Risk of damage for the finished floor surface!

u Protect the finished floor surface before you uncrate the

unit.

Verify that:

q The floor under the appliance is flat and level.

q The floor can support the appliance's weight plus

approximately 1200 pounds (544 kg) of food weight.

q The appliance is not placed in direct sunlight or near

the stove, range top, radiators and similar heat sources.

u Examine the unit and packaging for shipping damage.

Contact the carrier immediately if you suspect there is

any damage.

6 * Depending on model and options

Page 7

Start-up

u Note the type (model, number), index, appliance/serial

number, date of purchase and where purchased

(see 6.6) .

u Remove anything attached to the rear or side walls of

appliance that would prevent proper installation or

impede proper ventilation.

u Remove the protective film from the outside of the

appliance.

NOTICE

The stainless steel doors are treated with a high-grade

surface coating and must not be cleaned with the

supplied cleaning agent.

This would damage the surface coating.

u Wipe the coated door surfaces using a soft, clean

cloth only.

u Apply a stainless steel cleaner only to the stainless

steel side walls evenly, wiping with the grain. Subse-

quent cleaning becomes easier as a result.

u Wipe painted side walls with a clean, soft cloth only.

u Align the appliance so that it

stands firmly and on a level

by applying the accompanying spanner to the adjustable-height feet (A) and

using a spirit level.

u Then support the door:

Extend the adjustable foot at

the turn hinge (B) until it

rests on the floor and then

make a further 90° turn.

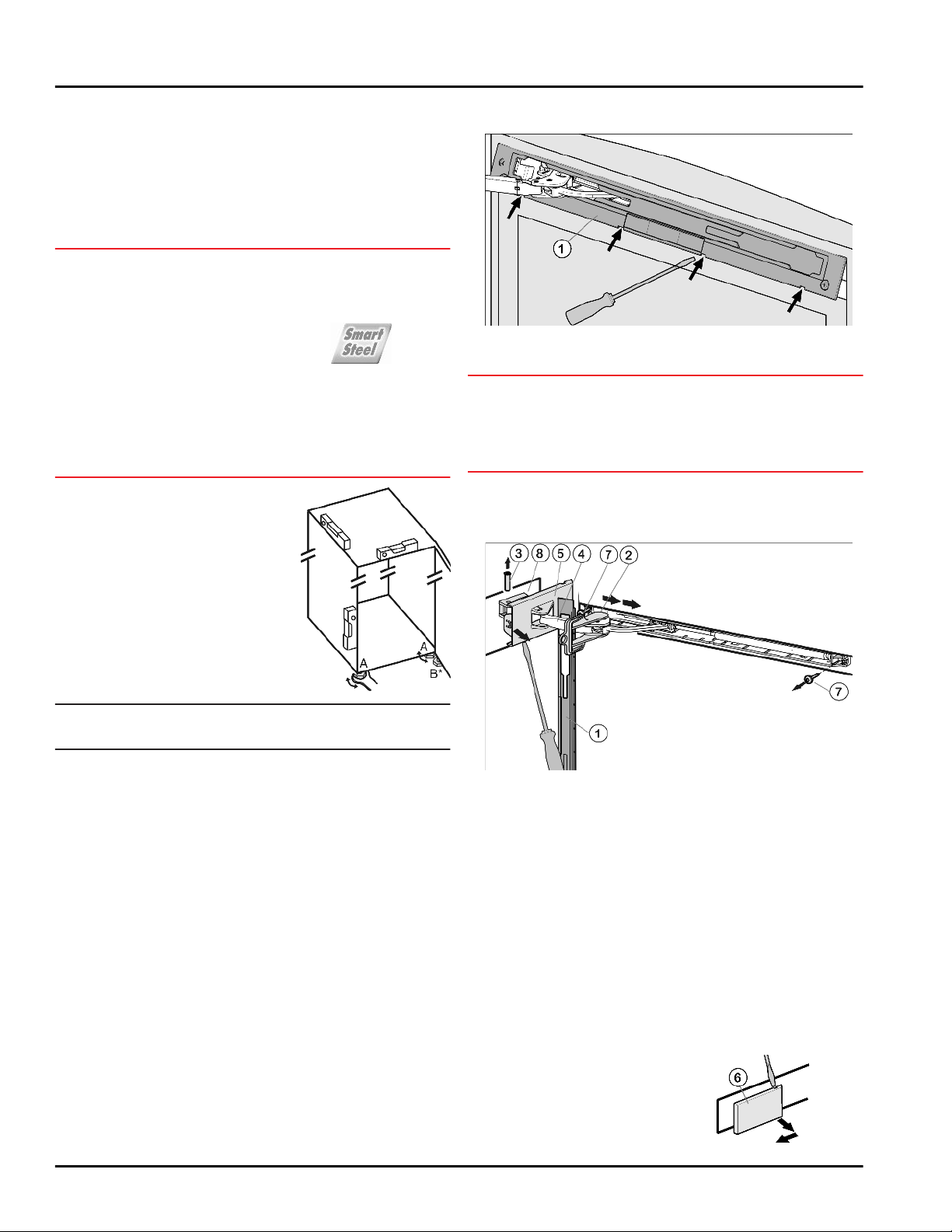

4.3.1 Remove upper soft stop damper

Fig. 5

u Open upper door.

NOTICE

Risk of damage!

If the door seal is damaged the door may not close properly and the level of cooling is insufficient.

u Do not damage the door seal with the screwdriver!

u Release panel

remove.

The panel hangs above the damper bracket.

w

Fig. 5 (1)

using a slotted screwdriver and

Note

u Clean the appliance (see 6.3) .

If the appliance is set up in humid areas, condensation

may build on the outside of the appliance.

u Always ensure proper ventilation.

Note

If the gap between the rear of the appliance and the

wall is less than 2 in. (51 mm), the power consumption

level may increase.

4.3 Changing the door hinges

You can reverse the door hinges, if necessary:

Make sure you have the following tools on hand:

q Torx® 25

q Torx® 15

q Screwdriver

q Cordless screwdriver, if necessary

q Another person to help with the installation, if

necessary

q SW2 Allen key (supplied)

Fig. 6

u Push panel forward over the damper bracket

the direction of the appliance.

u Engage locking device

hole.

The locking device prevents the hinge from snapping

w

shut.

u Unscrew cover

the first notch using a screwdriver.

The bolt will become visible.

w

u Push bolt

u Press damper bracket

door.

u Completely loosen cover

side and remove.

u Remove panel

u Loosen cover that is on the

hinge side

screwdriver and remove by

pulling outwards.

Fig. 6 (3)

Fig. 6 (1)

Fig. 7 (6)

Fig. 6 (2)

Fig. 6 (5)

that is on the hinge side until

out from below.

Fig. 6 (4)

Fig. 6 (5)

.

using a

into place inside oblong

in the direction of the

that is on the hinge

Fig. 6 (4)

in

Fig. 7

* Depending on model and options 7

Page 8

Start-up

u Unscrew soft stop unit (2 x Torx® 15)

u Slightly pull out soft stop unit, push it towards the

handle side and open it out.

u Set soft stop unit to the side.

u Unscrew bearing part

Fig. 6 (8)

move it to the opposite

side. Make preliminary

holes (optional) or use a

cordless screwdriver.

, turn it 180° and

Fig. 6 (7)

.

Fig. 8

4.3.2 Removing the upper door

Note

u To prevent food items from falling out, take all food out

of the door racks before removing the door.

4.3.3 Remove lower soft stop damper

Fig. 10

u Open the lower door.

NOTICE

Risk of damage!

If the door seal is damaged the door may not close properly and the level of cooling is insufficient.

u Do not damage the door seal with the screwdriver!

u Release panel

and remove.

The panel hangs above the damper bracket

w

Fig. 10 (20)

using a slotted screwdriver

Fig. 9

u Close upper door.

u Pull cover

u Lift off cover

Risk of injury if the door tips out!

u Keep a steady grip on the door.

u Set the door down carefully.

u Unscrew upper bearing bracket

Fig. 9 (13)

u Lift the upper door up and off and set it to the side.

Fig. 9 (10)

Fig. 9 (11)

CAUTION

and pull it upwards to remove.

forward and upwards to remove.

.

Fig. 9 (12)

(2 x Torx® 25)

Fig. 11

u Push panel forward over the damper bracket

Fig. 11 (24)

u Engage locking device

oblong hole.

The locking device prevents the hinge from snapping

w

shut

u Lift off cover

driver and remove by pulling outwards.

u Tip the appliance rearwards with the help of a second

person if needed.

u Push bolt

u Press damper bracket

door.

u Remove panel

u Unscrew entire soft stop unit (2 x Torx® 15)

u Slightly pull out soft stop unit, push it towards the

handle side and open it out

u Set soft stop unit to the side

in the direction of the appliance.

Fig. 11 (21)

Fig. 11 (23)

Fig. 11 (20)

Fig. 11 (22)

from the outside using a screw-

out from below.

Fig. 11 (24)

.

into place inside

in the direction of the

Fig. 11 (25)

4.3.4 Removing the lower door

u Close the lower door.

.

8 * Depending on model and options

Page 9

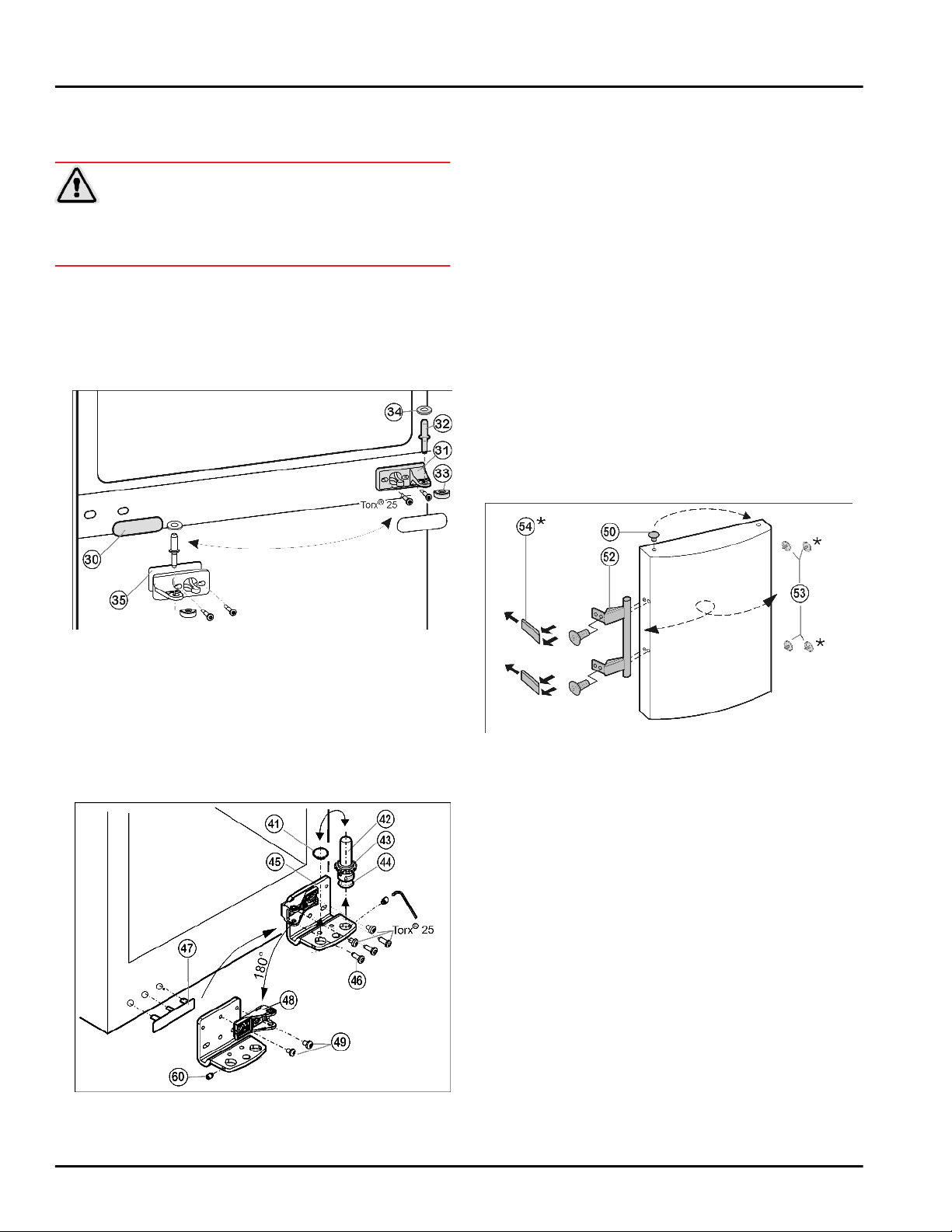

Start-up

u Pull center bearing pin

Fig. 12 (32)

and disc

Fig. 12 (34)

out of the bearing bracket and the lower door.

u Remove plastic cap

Fig. 12 (33)

.

CAUTION

Risk of injury if the door tips out!

u Keep a steady grip on the door.

u Set the door down carefully.

u Open the lower door.

u Unscrew center bearing bracket

Fig. 12 (31)

(2 x Torx®

25).

u Lift lower door upwards to remove and set it to the side

4.3.5 To swap over central bearing parts

u Unscrew the bearing pin

Fig. 13 (43)

and positioning foot

Fig. 13 (42)

Fig. 13 (44)

, with disc

, in an

upwards direction.

u Lift off plug

u Unscrew

u Completely unscrew the grub screw

Fig. 13 (41)

Fig. 13 (46)

.

bearing bracket

Fig. 13 (45)

Fig. 13 (60)

.

and

screw it into the opposite side of the bearing bracket

until it is externally flush with the bearing bracket.

u Unscrew bearing part

tighten

Fig. 13 (49)

u Insert plug

Fig. 13 (41)

u Carefully lift off the cover on the handle side

Fig. 13 (48)

, turn it 180° and

it to the inside.

back into the other hole.

Fig. 13 (47)

and move it to the opposite side.

u Using a cordless screwdriver if necessary, again secure

the bearing bracket

Fig. 13 (45)

on the new hinge side

tightly (to 4 Nm).

u Screw complete bearing pin

Fig. 13 (42)

, with disc and

positioning foot, back into place again.

u Tighten grub screw

Fig. 13 (60)

.

4.3.7 Swapping the handles

For both the upper and lower door:

Fig. 12

u Carefully remove cover trim

u Turn the center bearing bracket

Fig. 12 (35)

180° and secure tightly (to 4 Nm) on the

Fig. 12 (30)

Fig. 12 (31)

.

and washer

new hinge side.

u Turn the cover trim

Fig. 12 (30)

180° and snap it back

into place on the new handle side.

4.3.6 To swap over lower bearing parts

u Unscrew grub screw

the socket wrench supplied.

Fig. 13 (60)

by approx. 1 turn using

Fig. 13

Fig. 14

u Pull plugs

Fig. 14 (50)

out of the door bearing bushes

and move them to the other side.

u Detach the door handle

pressure plates*

Fig. 14 (52)

Fig. 14 (54)

, plug

Fig. 14 (53)

and

and move them to the

opposite side.

u When fitting the pressure plates on the opposite side,

make sure they engage correctly.*

4.3.8 Fitting the lower door

u Position the lower door from above onto the lower

bearing pins

u Close the door.

u Place the plastic cap

bearing bracket

u Insert the center bearing pin

hinge side through the center bearing bracket

Fig. 12 (31)

u Place disc

Fig. 12 (32)

Fig. 13 (42)

Fig. 12 (31)

.

Fig. 12 (33)

.

into the lower door.

Fig. 12 (34)

onto the center bearing pin

.

back onto the center

Fig. 12 (32)

on the new

* Depending on model and options 9

Page 10

Start-up

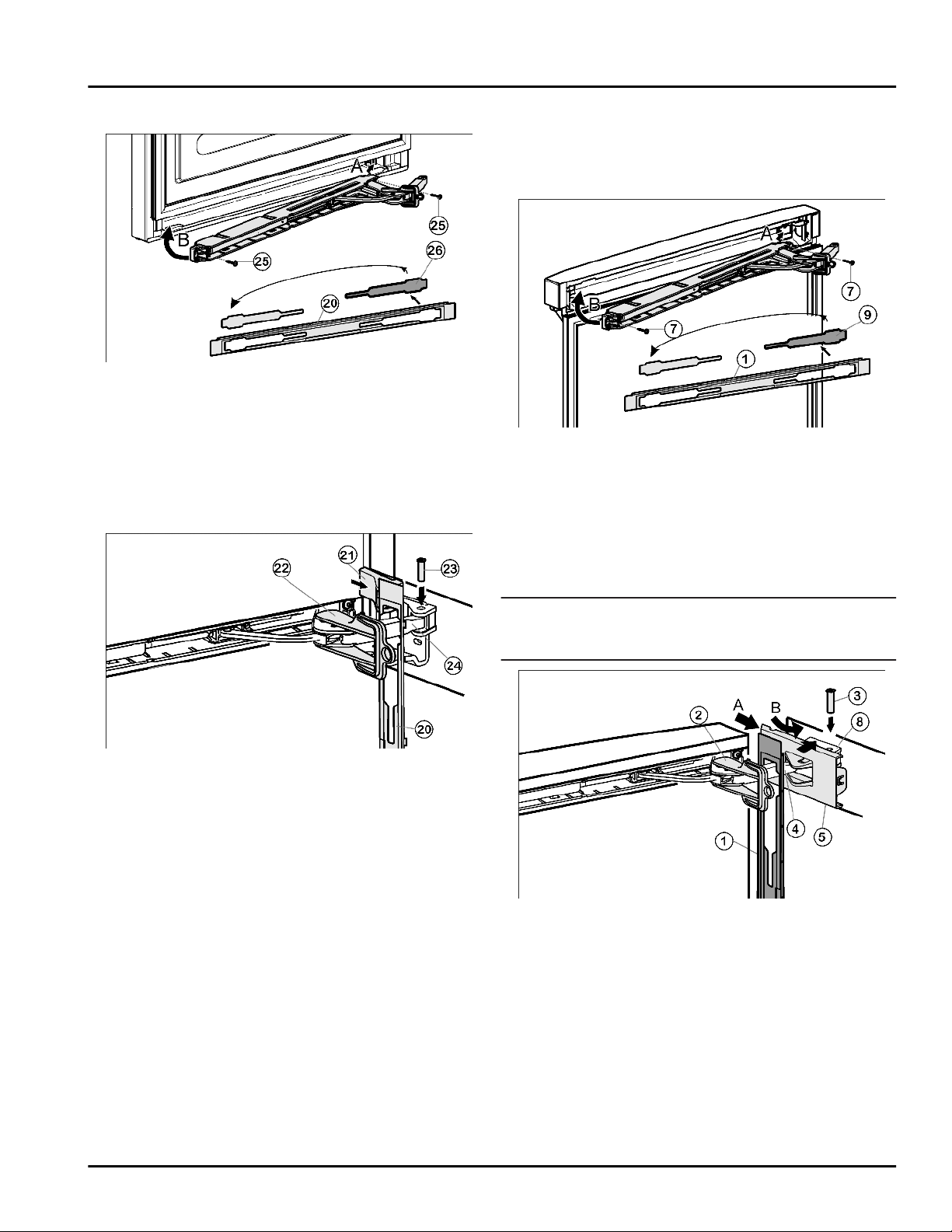

4.3.9 Fitting the lower soft stop damper

Fig. 15

u Loosen cover

insert on the other side.

u With the hinge of the soft stop unit facing the door

hinge side, engage the soft stop unit (A) and swivel

inwards (B)

The holes on the left and right must lie exactly above

w

each other

u Tighten soft stop unit (2 x Torx® 15)

Fig. 15 (26)

from the panel

Fig. 15 (25)

Fig. 15 (20)

.

and

u Snap both cover

Fig. 9 (11)

and cover

Fig. 9 (10)

into

place on the opposite side.

u Leave upper door open.

4.3.11 Fitting the upper soft stop damper

Fig. 17

u Loosen cover

insert on the other side.

u With the hinge of the upper soft stop unit facing the

door hinge side, engage the soft stop unit (A) and

swivel inwards (B)

The holes on the left and right must lie exactly above

w

each other

u Tighten soft stop unit (2 x Torx® 15)

Fig. 17 (9)

from the panel

Fig. 17 (7)

Fig. 17 (1)

.

and

Fig. 16

u Hook panel

Fig. 16 (20)

into the damper bracket such

that the detent hooks are pointing forwards and the

front side is facing the appliance.

u Pull damper bracket

and insert bolt

Fig. 16 (24)

Fig. 16 (23)

towards bearing bracket

from above such that the

square is resting in the recess.

u Position cover

Check that the cover is positioned correctly such that

w

Fig. 16 (21)

and snap in.

the door can close properly and the bolt is secured

u Remove locking device

u Snap panel

Fig. 16 (20)

Fig. 16 (22)

by twisting it.

into place on the door.

u Close the lower door.

4.3.10 Fitting the upper door

u Place the upper door onto the center bearing pin

Fig. 12 (32)

u Insert the upper bearing bracket

hinge side into the door.

u Tighten the upper bearing bracket (to 4 Nm)(2 x Torx®

25)

Fig. 9 (13)

a cordless screwdriver.

.

Fig. 9 (12)

on the new

. Make preliminary holes (optional) or use

Note

u Follow the correct sequence First hang the panel over

the damper bracket, then the cover

Fig. 18

u Hook panel

Fig. 18 (1)

into the damper bracket

Fig. 18 (4)

such that the detent hooks are pointing inwards and the

front side is facing the appliance.

u Push on cover

over the bearing part

u Place cover

Fig. 18 (5)

Fig. 18 (8)

Fig. 18 (5)

from the outside (A) and pivot

(B).

on top and allow to snap into

place until the first notch.

The openings for the bolts lie above each other after

w

positioning the damper bracket

u Pull damper bracket

and insert bolt

Fig. 18 (4)

Fig. 18 (3)

towards bearing bracket

from above such that the

square is resting in the recess.

10 * Depending on model and options

Page 11

Start-up

u Now snap cover

bearing part

Check that the cover is positioned correctly such that

w

the door can close properly and the bolt is secured

u Remove locking device

u Snap panel

u Turn cover

on top from the outside and snap into place.

Fig. 18 (5)

Fig. 18 (8)

Fig. 18 (1)

Fig. 7 (6)

completely into place on the

.

Fig. 18 (2)

into place on the door.

180° from the handle side, place it

by twisting it.

4.3.12 Aligning the doors

u Align the doors flush with the appliance housing, using

the two oblong holes in the lower bearing bracket

Fig. 13 (45)

as a guide, if needed. To do so, unscrew the center

screw on the lower bearing bracket

Risk of bodily injury due to the door falling off.

If the bearing parts are not installed with the proper

torque, the door may fall off. In addition, the door may not

close, thus impairing the cooling performance of the appliance.

u Securely tighten the bearing brackets by applying a

torque of 3 lb-ft (4 Nm).

u Check all screws and retighten if necessary.

and in the center bearing bracket

WARNING

Fig. 13 (45)

Fig. 12 (31)

.

4.4 Side-by-side installation

As seen from the front, install the appliance with an

IceMaker on the right and the appliance without an

IceMaker on the left.

Fig. 20

Fig. 21

Make sure you have the following tools on hand:

q Spirit level

q Cordless screwdriver

q Torx® 25 screwdriver

q Open-end wrench, SW 10 (supplied)

q 1/4 in. socket

q Allen wrench, SW 2 (supplied)

Tips on moving the combination:

q Before assembly, set the appliances up as close as

possible to the final location.

q When moving the appliances, always grasp the front

outside corners. Never press your knee against the

side walls or door.

q The easiest way to move the combination is diagonally,

by moving the left and right corner in turn.

If the combination is positioned exactly in front of the

recess, slide it in straight.

q If you need to pull the

combination back out of

the recess, grasp it in the

bottom third and pull

forward.

NOTICE

Moving the SBS combination may result in damage!

The assembled SBS combination is heavy. If not moved

properly, the appliance may become dented.

u Read and follow the moving tips (see above).

Fig. 19

The fixing accessories are supplied with model CS 1311.

If you have model CS 1360 you can purchase the fixing

accessories by contacting customer services.

* Depending on model and options 11

u Remove all protective films from the housing exterior.

Front of the appliance:

Page 12

Start-up

Fig. 22

u If necessary screw in the adjustment feet

the front of both appliances completely so that there is

no floor contact.

u Place the caps

Fig. 22 (1)

on the four front adjustment

feet.

u Move both units together so that there is a gap of up to

approx. 3/8 " (10 mm) between them so that they are

flush as seen from the front.

Fig. 22 (A)

at

u If your appliance has been fitted with the pre-fitted

screw

Fig. 24 (7)

: Undo the screw.

The appliances are automatically aligned in depth with the

connecting sheet. If one appliance projects further

forward than the other start with this one. Otherwise start

with the left hand appliance.

u Fix the connecting sheet

ance with two screws

Fig. 24 (5)

Fig. 24 (6)

loosely to one appli-

.

u Move the connecting sheet to the side so that the

centre bar of the sheet is touching the side wall of the

appliance. Tighten the screws.

u Screw the connecting sheet to the second appliance

too. If necessary push the appliances together or apart

a little.

Back of the appliance:

Fig. 23

u Release and remove the covers

Fig. 23 (2)

.

The appliances are automatically aligned in height with

the connecting plate. If one appliance is somewhat higher

than the other start with this one.

u Fit a connecting plate

appliance with two screws

Fig. 23 (3)

Fig. 23 (4)

and fix loosely to one

.

u Move the connecting plate to the side so that the centre

bar of the plate is touching the side wall of the appliance. Tighten the screws.

u Screw the connecting plate to the second appliance

too. If necessary push the appliances together or apart

a little.

Fig. 25

u Place the connecting clamps

Fig. 25 (8)

at the top of the

centre side walls.

u Insert theconnecting angle

Fig. 25 (9)

underneath into

the corresponding space.

u If the connecting angle is somewhat loose, fit a screw

Fig. 25 (10)

.

Note

u To prevent vibration noise, the brackets and screws

must not come into contact with the clamps or the

screws on the pipework on the back.

Front of the appliance:

Fig. 26

NOTICE

Risk of damage to the castors.

u Do not use a power tool to adjust the rear adjustment

feet as it will damage the leveling mechanism or disengage the rod – instead use a hand ratchet.

Fig. 24

12 * Depending on model and options

Page 13

The front adjustment feet can be adjusted with the

supplied open-end wrench

Fig. 26 (11)

and the rear adjust-

ment feet* with a 1/4'' bit attachment.

u Tighten the centre adjustment feet

Fig. 22 (C)

so that

there is no floor contact.

u Align the combination with the outer adjustment feet

Fig. 22 (B)

Before inserting the trim

.

Fig. 27

Fig. 27 (12)

squeeze the two fillets

together along the entire length. The trim can now be

inserted more easily into the gap. When pressing in the

trim, use a soft cloth to prevent dents on the surface of the

trim. Press the trim carefully and evenly into the gap to

achieve the best possible fit.

u On the front press the long trim

Fig. 27 (12)

into the

vertical gap. Ensure that the trim rests on the

connecting panel

Fig. 27 (5)

.

u Remove protective film from the trim.*

Fig. 28

u On the top, press the short trim

Fig. 28 (13)

into the gap.

The trim must form a flush finish with the connecting

plate

Fig. 28 (3)

u Snap the cover

on the front edge.

Fig. 28 (14)

onto the open space

between the two control panel trims. Make sure that the

outer surfaces of the cover form a flush finish with the

control panel trims. The cover can be extended for this

purpose.

Start-up

Fig. 29

u Position the lower cover

connecting panel

u Connect the combination unit to the power supply

(see 4.10) .

Appliances with IceMaker:

u Connect the appliance to the water supply (see 4.5) .

All appliances

u Fit the anti-tip device (see 4.7) .

NOTICE

Moving the SBS combination may result in damage!

The assembled SBS combination is heavy. If not moved

properly, the appliance may become dented.

u Read and follow the moving tips (see above).

u Carefully push the combination into the designated

position.

u Align the combination again if necessary using the

adjustment feet.

u Lower thecentre adjustment feet

they touch the floor.

u Then shore up the door: Lower theadjutment feet

Fig. 22 (A)

onto the bearing bracket until they contact the

floor then turn 90° again.

The door height can be

adjusted at the lower outside

bearing brackets:

u Unscrew the threaded pin

Fig. 30 (17)

a little (no more

than one turn).

Fig. 29 (15)

Fig. 29 (5)

from above onto the

and snap it down into place.

Fig. 22 (C)

again until

Fig. 30

Fig. 31

u To lift the door unscrew the bearing pin

Fig. 31 (18)

clockwise using the supplied open-end wrench

Fig. 31 (11)

. The appliance is delivered from the factory

with the bearing pin screwed in completely.

* Depending on model and options 13

Page 14

Start-up

u Screw the threaded pin

Fig. 30 (17)

in again to fix the

bearing pin.

4.5 Water connection*

WARNING

Electrical Shock Hazard!

u Do not make the water connection while the appliance

is connected to an electrical outlet.

u Disconnect the water supply before connecting the

water lines for the IceMaker.

u The connection to the water supply may only be made

by a trained and licensed plumber.

WARNING

Poisoning Hazard!

u The water quality must comply with the drinking water

regulations for the geographical area where the appliance is located.

u Connect to potable water supply only.

u The IceMaker is designed exclusively to make ice

cubes in quantities needed by a household and must

only be operated with water appropriate for this

purpose.

Water pressure:

psi MPa (bars)

21.76 to 87.02 0.15 to 0.6 (1.5 to 6)

If a water filter is used, the instructions on water pressure

in the Installing the water filter section apply.

- Water must be supplied to the appliance through a cold

water pipe that complies with hygiene standards and

can withstand the operating pressure.

- All devices and equipment used to supply water must

comply with the regulations in force in the respective

country.

- The solenoid valve is located at the bottom of the back

of the appliance. It has a metric R3/4 connecting

thread.

u Remove the cap

Fig. 32 (2)

.

u Insert the coupler

u Insert the water filter

down towards the coupler

Fig. 32 (1)

Fig. 32 (3)

Fig. 32 (5)

Fig. 32 (3)

from the solenoid valve

in theunion nut

Fig. 32 (4)

with the recess pointing

.

.

NOTICE

Risk of damage to the water filter!

If you insert the filter incorrectly you could damage it.

u Insert the filter with the recess pointing towards the

coupler.

u Lock the union nut

Fig. 32 (2)

and tighten.

Fig. 32 (4)

onto the solenoid valve

NOTICE

Risk of damage to the thread!

u Do not overtighten the union nut.

u To turn the water connection 90°, tighten the elbow

connector

u Connect the water supply

the aid of the clamp ring

the coupler

Fig. 32 (6)

Fig. 32 (3)

if necessary.

Fig. 32 (7)

Fig. 32 (8)

and nut

or elbow connector

(e.g. copper) with

Fig. 32 (9)

Fig. 32 (6)

to

.

Before fitting into the cabinet:

u Check the whole water system for leaks.

Before using for the first time:

u Have the water line bled (remove air) by a competent

professional.

NOTICE

Malfunction of the water intake!

If the water intake is shut off during operation but the

IceMaker remains in operation, the water intake pipe may

ice up.

u Switch off the IceMaker if the water supply is inter-

rupted (e.g. holiday).

Fig. 32

14 * Depending on model and options

Page 15

Start-up

4.6 Installation into a fitted kitchen

4.7 Anti-tip device

The screws for fastening the anti-tip device are not

supplied with the appliance. Appropriate screws must be

used for the material (wood, concrete, etc.) in which the

safety device is mounted.

WARNING

Risk of injury if the appliance tips over!

u Install the anti-tip device to prevent the appliance from

tipping over when the fully loaded door is open.

NOTICE

Risk of damage due to leaking water!

If the tilt safety device has been fitted in another position

than the one given, the water hoses may be damage

when pushing the appliance into the niche.

u Only fit the tilt safety device in the position shown in the

diagram.

Fig. 33

(1) Top cupboard (3) Kitchen cabinet

(2) Appliance (4) Wall

The appliance can be built into kitchen cabinets. To bring

the appliance

kitchen units, a top cupboard

above the appliance.

When converting kitchen cabinets (max. depth 22-13/16 "

(580 mm)) the device can be set up directly beside the

kitchen cabinet

(34 mm) at the side and in the center of the appliance

(50 mm) from the front of the kitchen cabinet. This allows

it to open and close properly.

Ventilation requirements:

- There must be a ventilation shaft at least 2 " (51 mm)

deep at the back of the top cupboard over the entire

width of the top cupboard.

- The cross section of the ventilation gap below the

ceiling must be at least 46-1/2 in2 (300 cm2).

- The bigger the ventilation gap, the more energy-saving

the operation of the appliance.

If the appliance is installed with the hinges next to a wall

Fig. 33 (4)

must be at least 1-9/16 '' (40 mm). This is how far the

handle protrudes when the door is open.

Fig. 33 (2)

Fig. 33 (3)

, the gap between the appliance and the wall

up to the height of the fitted

Fig. 33 (1)

. The appliance door projects

can be added

Fig. 34

u Mark the installation position for the anti-tip device on

the wall or back of the unit.

u Install the anti-tip device

screws

Fig. 34 (2)

.

Fig. 34 (1)

using appropriate

4.8 Installing the water filter*

The water filter ensures optimum water

quality and is available as an accessory. It

should be installed near the appliance in

the cabinet, for example in the adapter

cabinet above the appliance. To connect

the filter to the appliance, it may be

necessary to make an opening (C) in the

floor of the adapter cabinet through which

the hoses will be routed. Depending on

your installation setup, you can route the

two water filter hoses either through the

rear panel or through the base of the

cabinet. The maximum length of the water

hose is118-1/8 '' (3 m).

* Depending on model and options 15

Page 16

Start-up

Alternatively, the appliance can also be

operated without the water filter.

Fig. 35

(A) 13/16 in (20mm) (C) 1-3/16in. x 3/8in.

( 30mm x 10mm )

(B) 3-15/16 in (100mm) (D) min. 4 in (100mm)

The filter cover must be installed during assembly, so

leave sufficient space around the filter module. Maintain

the dimensions shown in

Fig. 35

so that the filter can be

replaced and the cover can be removed.

Flow rate 0.5 gpm (1.89 lpm)

Water connection Drinking water

Water pressure 40 psi - 90 psi ( 2.8 bar - 6.2 bar/ 0.28 MPa

- 0.62 MPa )

Water temperature 33 °F - 100 °F ( 0.6 °C - 37 °C )

Capacity 300 gal. (1.14 l)

NOTICE

Leakage water may damage the system!

u Do not install this system on hot water lines. The

maximum operating temperature of the water in this

system is 100 °F (37.7 °C).

u This system MUST be installed and used in compliance

with federal and local installation regulations.

u Do not install under water hammer conditions. A water

hammer arrestor must be used to prevent water

hammering. If you are unsure how to check these

conditions, consult a professional installer.

u Do not install with a water pressure greater than 90 psi

(6.2 bar). If your water pressure exceeds 80 psi, install

a pressure limiting valve. If you are unsure how to

check the water pressure, consult a professional

installer.

u Protect against frost; if temperatures below 33 °F

(0.6 °C) are expected, remove the filter.

u When used as indicated, the disposable filter

cartridges must be replaced every 6 months or whenever you notice a considerable decrease in the flow

rate.

q Disconnect the appliance from the mains.

q Close off the main water supply if the appliance has

already been connected to the tap.

q Position appliance in front of the recess.

WARNING

Consuming contaminants can be harmful to your health!

u If there is a chance the water may contain harmful

bacteria or if the water quality is unknown, do not use

this system without appropriate disinfection measures

upstream or downstream of the system.

Fig. 36

u Slice open the water hose

Fig. 36 (7)

located behind the

appliance both in front of and behind the connector

Fig. 36 (8)

(90° to direction of hose).

When doing so, make sure the hose does not become

kinked and the cross-section of the hose remains round.

u Connect the supplied exten-

sion hoses

appliance hoses

Slide the appliance hoses

Fig. 37 (1)

Fig. 37 (7)

to the

:

Fig. 37

into the connectors as far as

they will go (approx. 25/32 ''

(20 mm)).

u Pull the tray

Fig. 38 (4)

out

until it catches.

u Secure the module with 4

screws

Fig. 38 (5)

through

the recesses in the front

and directly through the

module in the back.

Fig. 38

16 * Depending on model and options

Page 17

Start-up

u Shorten hoses if necessary (90° to direc-

tion of hose). The hoses should be long

enough to allow the appliance to be

pulled out of the recess even when it is

connected to the water filter.

Make sure the hoses do not become kinked and the

cross-section of the hose remains round.

u On the thin hose measure the inser-

tion depth (E) of 21/32 '' (17 mm) and

make a mark.

u On the thick hose measure the inser-

tion depth (E) of 25/32 '' (20 mm) and

make a mark.

u Insert the hoses

the water filter module as far as

they will go (i.e. to the mark

you made) past the point of

resistance.

Note

u If you need to disassemble the unit: Push back the dark

grey ring on the connector and hold it in this position.

While still holding the ring back, briefly push the hose

into the connector, then pull it out.

u Insert the power cable into the socket (see 4.10) .

u Connect appliance to the water supply (see 4.5) .

u Make sure the filter is leak-tight and no water is coming

out.

u Place the tray cover

Fig. 41 (3)

into position.

Fig. 39 (1)

into

Fig. 39

Fig. 40

Note

New water filters may contain particulate matter.

u Do not consume or use ice cubes produced within 72

hours after replacing the filter.

The water filter is now ready for use.

w

NOTICE

Risk of damage due to leaking water!

u When pushing the appliance into the recess ensure

that the water connection does not bend or become

damaged.

4.9 Disposal of packaging

WARNING

Danger of suffocation from packaging materials and films!

u Do not allow children to play with packaging materials.

The packaging is made from recyclable materials:

- Corrugated card/cardboard

- Parts made of foamed polystyrene

- Films and bags from polyethylene

- Packing bands from polypropylene

- Wood frame nailed together with a polyethylene

window*

u Take the packaging material to an official collection

point.

4.10 Connecting the appliance

WARNING

Electrical shock hazard!

u Start-up should only take place once the appliance has

been installed according to these instructions.

u Electrically ground appliance.

u Do not ground to a gas pipe.

u Check with a qualified electrician if you are not sure the

appliance is properly grounded.

u Do not have a fuse in the neutral or grounding circuit.

u Do not use an extension cord, power bar or a multiple

socket adapter.

u Do not use a power cord that is frayed or damaged.

Fig. 41

u Remove the film from the water filter

u Insert the water filter

100° to the right until it locks into position.

u Place the cover on the filter

u Slide the tray in.

u Write the date of the next filter replacement on the

supplied adhesive label

module.

* Depending on model and options 17

Fig. 41 (6)

Fig. 41 (2)

Fig. 41 (9)

Fig. 41 (6)

and turn it approximately

.

and affix it to the

.

Electrical shock hazard!

This appliance is equipped with a three-prong (grounding)

polarized plug for your protection against possible shock

hazards. Electrical Grounding Required.

u Do not remove the round grounding prong from the

u Use only an grounded adapter.

WARNING

plug.

Page 18

Operation

- Wait 1 hour after installation before you plug in the

appliance. This allows the refrigerant and system lubrication to reach equilibrium.

- Make sure incoming voltage is the same as the appliance rating. A 110-120 Volt, 60 Hz, 15 Amp electrical

supply (20 Amp for side-by-side installations) circuit

that is controlled by a circuit breaker or fuse is required.

- We recommend using a dedicated circuit for this appliance to prevent electrical overload.

- Follow all Federal, State and local electrical, fire and

building codes and ordinances when installing the

receptacle and / or the appliance.

- In some communities, a wall switch is required to turn

power to the appliance ON and OFF.

- To reduce the risk of fire, electric shock, or personal

injury, installation work and electrical wiring must be

done by a qualified electrician in accordance with all

applicable codes and standards, including fire-rated

construction.

- The Power Plug must be easily accessible so that the

appliance can be disconnected from the mains quickly

in an emergency. It must not be behind the back of the

appliance.

4.11 Switching on the appliance

Note

u To switch on the entire appliance, only the freezer

compartment needs to be switched on.

5 Operation

5.1 Temperature display unit

The temperature display can be changed from °F to °C.

5.1.1 To change the unit

u Activate setting mode: Press SuperFrost button

Fig. 4 (14)

w

S is displayed in the temperature display.

The Menu symbol

w

u Using Freezer compartment Up button

Fig. 4 (11)

Fig. 4 (12)

u To confirm: Briefly press SuperFrost button

Fig. 4 (14)

u Using Freezer compartment Up button

Fig. 4 (11)

Fig. 4 (12)

u To confirm: Briefly press SuperFrost button

Fig. 4 (14)

u To exit setting mode: Press Freezer compartment

On/Off button

-or-

u Wait 5 minutes.

The temperature is again displayed in the temperature

w

display.

for about 5 seconds.

Fig. 4 (19)

/ Freezer compartment Down button

select °.

.

/ Freezer compartment Down button

select °F or °C.

.

Fig. 4 (13)

lights up.

.

Switch on the appliance 2 hours before loading

with frozen food for the first time.

Do not load frozen foods until the temperature

display reads 0 °F (-18 °C).

4.11.1 Switching on the freezer compart-

ment

u Press On/Off button, freezer compartment

The fridge compartment temperature display shows the

w

current temperature in the interior.

The freezer compartment temperature display and the

w

Alarm symbol will flash until the temperature is cold

enough. If the temperature is greater than 32 °F (0 °C),

flashing dashes will appear; if the temperature is lower

than this, the current temperature will flash on the

display.

Whenever “DEMO” appears on the display, the appli-

w

ance is running in demonstration mode. Contact the

customer service department.

Fig. 4 (13)

.

4.11.2 Switching on the fridge compartment

u Press Fridge compartment On/Off button

The interior light comes on when the door is opened.

w

The temperature display flashes. The fridge compart-

w

ment is switched on.

Fig. 4 (3)

.

5.2 Brightness of the temperature display

You can adapt the brightness of the temperature display

to the light conditions in the room in which it is installed.

If the door is open or the control panel is used the temperature indicator lights up at maximum brightness. About 1

minute after the door is closed or no button has been

pressed on the control panel, the temperature display

goes back to the set brightness.

This function works when the door is closed, and is not

relevant for appliances with a covered screen.

5.2.1 Setting the brightness

The brightness can be set between h0 (minimum luminosity) and h5 (maximum luminosity).

u To activate setting mode: Press SuperFrost button

Fig. 4 (14)

w

S is shown on the display.

The Menu symbol

w

u Press Freezer compartment Up button

Freezer compartment Down button

h.

u To confirm: Briefly press SuperFrost button

u To set the display brighter: Press Freezer

compartment Up button

u To set the display darker: Press Freezer

compartment Down button

for about 5 seconds.

Fig. 4 (19)

lights up.

Fig. 4 (11)

Fig. 4 (12)

Fig. 4 (12)

.

.

Fig. 4 (11)

to select

Fig. 4 (14)

or

.

18 * Depending on model and options

Page 19

Operation

u To confirm: Press SuperFrost button

Fig. 4 (14)

The brightness is set to the new value.

w

u To deactivate setting mode: Press Freezer compart-

ment On/Off button

-or-

u Wait 5 minutes.

The temperature is again displayed in the temperature

w

display.

.

Fig. 4 (13)

.

5.3 Child-proof lock

You can use the child-proof lock to lock the

buttons. This means that children cannot accidentally switch off the appliance when playing.

5.3.1 Switching on the child-proof lock

u Activate setting mode: press and hold the SuperFrost

button

Fig. 4 (14)

w

S is shown on the display.

The Menu symbol

w

u Using the Freezer compartment Up button

Freezer compartment Down button

u Press the SuperFrost button

confirm.

When c1 is shown on the display:

u To switch on the child-proof lock, press the

SuperFrost button

w

The Child lock symbol

flashes on the display.

When c0 is shown on the display:

u To switch off the child-proof lock, press the SuperFrost

button

Fig. 4 (14)

w

The Child safety symbol

flashes on the display.

u Deactivate setting mode: press the Freezer compart-

ment On/Off button

-or-

u Wait 5 min.

The temperature is again displayed on the temperature

w

display.

for approximately 5 s.

Fig. 4 (19)

Fig. 4 (14)

briefly.

Fig. 4 (13)

lights up.

Fig. 4 (14)

briefly.

Fig. 4 (16)

Fig. 4 (16)

.

Fig. 4 (12)

LED lights up. c

Fig. 4 (11)

, select c.

briefly to

LED goes out. c

or

5.5 Temperature alarm

If the freezer temperature is not cold enough,

the audible warning sounds.

At the same time, the temperature display and

the Alarm symbol

The cause of a temperature being too high may be:

- Hot fresh food was placed in the appliance.

- When sorting and removing food from the appliance,

too much warm ambient air got in.

- The power was cut off for a while.

- The appliance is faulty.

The audible warning automatically ceases, the Alarm

symbol

stops flashing when the temperature is cold enough

again.

If the alarm status remains: (see Troubleshooting).

Note

If the temperature is not cold enough, food may spoil.

u Check the quality of the food. Do not consume spoiled

Fig. 4 (9)

food.

Fig. 4 (9)

goes out, and the temperature display

LED will flash.

5.5.1 Switching off the temperature alarm

The acoustic warning can be switched off. When the

temperature is cold enough again, the alarm function is

active again.

u Press Alarm button

The acoustic warning ceases.

w

Fig. 4 (15)

.

5.6 Sabbath Mode

This function meets the religious requirements on the

Sabbath and Jewish festivals. When the appliance is in

Sabbath mode some control electronic functions are

switched off. After setting Sabbath mode you no longer

need to worry about indicator lights, figures, symbols,

displays, alarm messages and fans. The thawing cycle

only operates at the specified time without taking refrigerator use into account. After a power cut the appliance

automatically switches on again in Sabbath mode.

5.4 Door alarm

If the door is open for longer than 180 seconds,

the acoustic warning sounds.

The acoustic warning stops automatically when

the door is closed

5.4.1 Switching off the door alarm

The acoustic warning can be switched off when the door

is open. The acoustic warning remains switched off as

long as the door is open. When the door is closed, the

alarm function is active again.

u Press Alarm button

The door alarm stops.

w

* Depending on model and options 19

Fig. 4 (15)

.

Danger of food poisoning!

No record will be kept of a power failure during Sabbath

Mode. Thus, during Sabbath mode, if a power failure

occurs that you are not aware of, when the power comes

back on, the unit will continue to be in Sabbath Mode but

when Sabbath Mode is ended there will be no indication

that a power failure occurred.

If a power failure occurs during Sabbath mode:

u Check the quality of the food. Do not consume spoiled

- All functions are blocked until Sabbath mode is

WARNING

food!

switched off.

Page 20

Operation

- If the unit is currently running in a mode such as Superfrost, Supercool or the Ventilation is enabled these

functions will continue and finish their timed cycles

independent of now being in Sabbath mode.

- The Ice Maker is disabled.*

- No audible signals are emitted, and the temperature

display does not indicate any warnings or settings

(such as a temperature alarm or door alarm).

- Light does not operate.

5.6.1 Setting Sabbath mode

u To activate setting mode: Press and hold the Super-

Frost button

w

S flashes on the display.

The Menu symbol

w

u To access the Sabbath mode function: Briefly press

theSuperFrost button

When S1 is shown on the display:

u To turn on Sabbath mode, briefly press the

SuperFrost button

When S0 is shown on the display:

u To turn off Sabbath mode, briefly press the

SuperFrost button

u To deactivate setting mode: Press the Freezer compart-

ment On/Off button

-or-

u Wait 5 min.

The Sabbath Mode symbol

w

temperature display as long as Sabbath Mode is active.

Sabbath mode switches off automatically after 120

w

hours if it is not manually switched off beforehand.

Fig. 4 (14)

Fig. 4 (19)

Fig. 4 (14)

Fig. 4 (14)

Fig. 4 (13)

for approx. 5 s.

lights up.

Fig. 4 (14)

.

.

.

.

Fig. 4 (18)

appears on the

5.7 Fridge compartment

The natural circulation of air in the refrigerator compartment results in zones with differing temperatures. It is

coldest directly above the vegetable drawers and at the

rear wall. It is warmest at the top front of the compartment

and in the door.

5.7.1 Refrigerating food

Note

u Do not load the door with more than 40 lbs (18 kg) of

food.

Note

Insufficient ventilation results in an increase in energy

consumption and reduction of the refrigerating performance.

u Never block the air slits in the fan.

u Use recyclable plastic, metal, aluminum and glass

containers and cling film to wrap foods.

u Always use closed containers for liquids and for food

that may give off or be tainted by odor or flavor transfer

or cover them.

u Foods which give off a large amount of ethylene gas

and those that are sensitive to this gas, such as fruit,

vegetables and salad, should always be separated or

wrapped so as not to reduce the storage life; for

example, do not store tomatoes together with kiwi fruits

or cabbage.

u Do not store food too close together to enable sufficient

air circulation.

u To ensure bottles do not tip over: move the bottle

holder.

5.7.2 Setting the temperature

The temperature depends on the following factors:

- the number of times the door is opened

- the room temperature of the installation location

- the type, temperature and amount of food.

The temperature can be set from 35 °F (2 °C) to 45 °F

(7 °C), 41 °F (5 °C) is recommended.

u To set a higher temperature: press the Fridge compart-

ment Up button

u To set a lower temperature: press the Fridge compart-

ment Down button

When pressed once the previously set fridge compart-

w

ment temperature display value will flash.

u To change the temperature in 1 °F (1 °C) increments:

briefly press the button.

u To change the temperature continuously: hold the

button down.

The value is displayed flashing during the setting oper-

w

ation.

The actual temperature is displayed about 5 seconds

w

after the last press of a button. The temperature slowly

adjusts to the new value.

Fig. 4 (4)

Fig. 4 (5)

.

.

5.7.3 SuperCool

With SuperCool you switch to the highest cooling

performance to reach lower cooling temperatures. Use SuperCool to rapidly cool large quantities of food.

If SuperCool is on, the fan* may come on. The appliance

works at maximum refrigerating power. The sound of the

refrigeration unit may be temporarily louder as a result.

SuperCool will use more energy than normal operation.

Cooling with SuperCool

u Briefly press the SuperCool button

The SuperCool symbol

w

display.

The cooling temperature drops to the coldest value.

w

SuperCool is switched on.

SuperCool automatically switches itself off after about

w

6-12 hours. The appliance returns to work in the

energy-saving normal mode.

To prematurely switch off SuperCool

u Briefly press the SuperCool button

The SuperCool symbol

w

display.

Fig. 4 (6)

Fig. 4 (6)

Fig. 4 (2)

LED lights up on the

Fig. 4 (2)

LED goes out on the

.

.

20 * Depending on model and options

Page 21

SuperCool is switched off.

w

5.7.4 Fan

The fan allows you to rapidly cool large amounts

of fresh food or to achieve a relatively even

distribution of temperature across all the storage

levels.

Re-circulated air cooling is advisable:

- at high room temperatures (from approx. 95 °F

(35 °C) )

- in the case of high humidity

Re-circulated air cooling has a somewhat higher energy

consumption. To save energy, the fan automatically

switches off when the door is open.

Switching on the fan

u Briefly press Ventilation button

The Ventilation symbol

w

The fan is on. On some appliances it only switches on

w

when the compressor is running.

Fig. 4 (17)

Fig. 4 (1)

.

LED lights up.

Operation

u To remove the shelf completely, set it at an angle and

pull it out towards you.

u Insert the shelf with the raised edge to the back

pointing upwards.

This prevents food from contacting and freezing to the

w

back wall.

The bottle holder offers additional storage for bottles

(maximum height 11-13/16 '' (300 mm)). It fits onto the

same supports as the other racks.

u Insert the bottle holder into any position, but not right at

the bottom.

To dismantle shelves

u The shelves can be

dismantled for cleaning.

5.7.6 Using the split shelf

Switching the fan off (default)

u Briefly press Ventilation button

The Ventilation symbol

w

The fan is switched off.

w

Fig. 4 (17)

Fig. 4 (1)

.

LED goes out.

5.7.5 Shelves

Shifting or removing shelves

CAUTION

Danger of lacerations!

The storage shelf can shatter if dropped or mishandled.

You could cut yourself on the pieces of broken glass.

u Only remove storage shelves when there is nothing on

them.

Extension stops secure the shelves against being accidentally pulled out.

CAUTION

Danger of lacerations!

The storage shelf can shatter if dropped or mishandled.

You could cut yourself on the pieces of broken glass.

u Only remove storage shelves when there is nothing on

them.

Fig. 43

u Attach support bars supplied, ensuring right (R) and left

(L) parts are correctly positioned.

u The glass shelf with stop face (2) has to be at the back.

5.7.7 Door racks

Note

u Do not load the door with more than 40 lbs (18 kg) of

food.

Repositioning the door racks

Fig. 42

u Lift up the shelf and pull it slightly forward.

u Adjust the shelf height by shifting the spacers in the

runners.

u Insert the short shelf at the height of the gallon capacity

rack so that door closes properly. It is supported on

support bars.

* Depending on model and options 21

Page 22

Operation

u Push rack up, pull forward, and reinsert in the reverse

order.

The container trays can be

removed and placed on the

table as a unit.

Instead of one wide container and one small container, a

special set containing three small containers is available

from Customer Service.

It is possible to use one or both boxes. If unusually tall

bottles are to be stored, only suspend one box above the

bottle rack.

u To swap containers: pull

up to remove and reinsert

in the desired position.

To dismantle door racks

5.7.9 Vegetable drawers

Fig. 45

To remove the vegetable drawers:

u Pull the vegetable drawer completely out and tilt it

slightly forward.

u Push the protruding telescopic rails back in.

Fig. 46

To insert the vegetable drawers:

u Place the vegetable drawer on the telescopic rails and

slide it back while applying light pressure.

5.8 Freezer compartment

You can store frozen food, make ice cubes and freeze

fresh food in the freezer compartment.

Fig. 44

u The door racks can be dismantled for cleaning.

5.7.8 Removing the bottle holder

u Always take hold of the bottle

holder by the plastic part.

5.8.1 Freezing food

Each drawer can hold up to 55.12 lbs (25 kg) of frozen

food; each plate can hold up to 77.16 lbs (35 kg).

So that the food is rapidly frozen through to the core, do

not exceed the following quantities per pack:

- fruit, vegetables up to 2.2 lb (1 kg)

- meat up to 5.51 lbs (2.5 kg)

u Pack the food in portions in freezer bags, reusable

plastic, metal or aluminum containers.

5.8.2 Defrosting food

- in the fridge compartment

- in the microwave

- in the oven/fan oven

- at room temperature

WARNING

Danger of food poisoning!

u Do not re-freeze defrosted food.

u Only take out the amount of food that is required. Use

defrosted food as quickly as possible.

5.8.3 Setting the temperature in the freezer compartment

The appliance is set as standard for normal operation.

22 * Depending on model and options

Page 23

Operation

The temperature can be set between 7 °F (-14 °C) and

-16 °F (-26 °C), 0 °F (-18 °C) is recommended.

u To set a higher temperature: press the Freezer

compartment Up button

u To set a lower temperature: press the Freezer compart-

ment Down button

When the button is pressed for the first time, the

w

previous value is indicated on the freezer compartment

temperature display.

u To change the temperature in 1 °F (1 °C) increments:

briefly press the button.

-or-

u To change the temperature continuously: hold the

button down.

The value is displayed flashing during the setting oper-

w

ation.

The actual temperature is displayed about 5 seconds

w

after the last press of a button. The temperature slowly

adjusts to the new setting.

Fig. 4 (11)

Fig. 4 (12)

.

.

5.8.4 SuperFrost

Depending on how much fresh food is to be frozen you

must switch SuperFrost on in advance - for a small

amount of food to be frozen, about 6 hours, for the

maximum amount about 24 hours before putting the food

in.

You do not need to switch SuperFrost on in the following

cases:

- when placing frozen food in the freezer

- when freezing up to about 2 kg of fresh food a day

Freezing with SuperFrost

u Briefly press the SuperFrost button

The SuperFrost symbol

w

The freezing temperature drops and the appliance

w

operates at its maximum refrigeration power rating.

When a small amount of food is to be frozen.

u Wait approx. 6 hrs.

u Place packaged food in the upper drawers.

When the maximum amount of food is to be frozen.

u Wait approx. 24 hrs.

u Remove upper drawers and place the food directly onto

the upper shelves.

SuperFrost is automatically switched off. At the earliest

w

after 30 hours, at the latest after 65 hours, depending

on the quantity placed inside the appliance.

The LED for the SuperFrost symbol

w

when the freezing process is complete.

u Place food inside the drawers and push them closed

again.

The appliance returns to work in the energy-saving

w

normal mode.

Fig. 4 (21)

Fig. 4 (14)

LED lights up.

Fig. 4 (21)

once.

goes out

5.8.5 Drawers

Note

Insufficient ventilation results in an increase in energy

consumption and reduction of the refrigerating performance.

For appliances with NoFrost:

u Leave the bottom drawer in the appliance.

u Never block the air slits in the fan on the rear wall.

u To store frozen food directly on the shelves: pull the

drawer forward and lift it out.

5.8.6 Shelves

u To remove shelf: lift it at the front and

pull out forward.

u To reinsert shelf: simply slide it in as

far as it will go.

5.8.7 VarioSpace

In addition to the drawers, you

can also take out the shelves.

This gives you space for large

frozen items. Poultry, meat, large

joints of game and tall bakery

items can be frozen and then

presented whole.

u Each drawer can hold up to

55.12 lbs (25 kg) of frozen

food; each plate can hold up to

77.16 lbs (35 kg).

5.8.8 Pull-out rails

5.8.9 Info system

Fig. 47

(1) Ready meals, ice

cream

(2) Pork, fish (5) Game, mushrooms

(3) Fruit, vegetables (6) Poultry, beef/veal

The numbers indicate the storage time in months for

different types of frozen foods. The storage times given

are guidelines.

(4) Sausages, bread

* Depending on model and options 23

Page 24

Maintenance

5.8.10 IceMaker*

The IceMaker is in the top drawer. The drawer is labeled

“IceMaker”.

Make sure that the following conditions are fulfilled:

- The appliance is level.

- The appliance is connected to the electricity supply.

- The freezer compartment is switched on.

- The minimum freezer temperature is 14 °F (-10 °C).

- The IceMaker is connected to the water supply.

- All air was bled from the waterline before starting the

icemaker. The icemaker will only work if there is no air

in the waterline.

Switching on the IceMaker*

Fig. 48

u Pull out the drawer.

u Press On/Off button

lights up.

u Push in the drawer.

The IceMaker symbol

w

Note

u The IceMaker only produces ice cubes when the

drawer is completely closed.

Producing ice cubes*

The production capacity depends on the freezer temperature. The lower the temperature, the more ice cubes can

be produced in a certain period.

The production capacity is 90- 100 ice cubes in 24 hours

at a freezing temperature of 0 °F (-18 °C).

To have the maximum capacity of approx. 130 ice cubes

in 24 hours, activate the SuperFrost Function. Be aware

that this increases the energy consumption because the

compressor will run constantly.

The ice cubes fall out of the IceMaker into the drawer.

When the ice cubes reach a certain height in the drawer,

no more ice cubes can be produced. The IceMaker will

not fill the drawer to the top.

If large quantities of ice cubes are required, the complete

IceMaker drawer can be swapped with the neighboring

drawer. When you close the drawer, the IceMaker automatically restarts production.