Use and Care

Manual

Combined fridge-freezer,

freestanding/semi built-in

Mode

d'emploi

Combiné réfrigérateur-

congélateur, pose libre

Instrucciones

de uso

Combinado frigorífico-congelador,

independiente

CS 1311 / CS 1360

260514 7085514 - 00

The appliance at a glance

Contents

1 The appliance at a glance............................. 2

1.1 Additional benefits............................................ 2

1.2 Overview of the appliance and its equipment... 3

1.3 Range of appliance use.................................... 3

1.4 Conformity........................................................ 3

1.5 Installation dimensions .................................... 4

1.6 Energy saving.................................................. 4

1.7 Example of food arrangement.......................... 4

2 General safety information........................... 4

3 Controls and displays................................... 5

3.1 Operating and control elements....................... 5

3.2 Temperature display........................................ 5

4 Start-up........................................................... 6

4.1 Transporting the appliance............................... 6

4.2 Setting up the appliance................................... 6

4.3 Changing the door hinges................................ 7

4.4 Side-by-side installation................................... 11

4.5 Water connection............................................. 13

4.6 Installation into a fitted kitchen......................... 14

4.7 Anti-tip device.................................................. 15

4.8 Installing the water filter.................................... 15

4.9 Disposal of packaging...................................... 17

4.10 Connecting the appliance................................. 17

4.11 Switching on the appliance............................... 17

5 Operation........................................................ 17

5.1 Temperature display unit.................................. 17

5.2 Brightness of the temperature display.............. 18

5.3 Child-proof lock................................................ 18

5.4 Door alarm....................................................... 18

5.5 Temperature alarm........................................... 18

5.6 Sabbath Mode.................................................. 19

5.7 Fridge compartment......................................... 19

5.8 Freezer compartment....................................... 22

6 Maintenance................................................... 24

6.1 Replacing the water filter.................................. 24

6.2 Defrosting with NoFrost.................................... 24

6.3 Cleaning the appliance..................................... 24

6.4 Cleaning the IceMaker..................................... 25

6.5 Customer service............................................. 25

6.6 Appliance Information...................................... 26

7 Troubleshooting............................................ 26

8 Putting appliance out of service.................. 29

8.1 Vacation Tips................................................... 29

8.2 Switching off the appliance............................... 29

8.3 Decommissioning ............................................ 29

9 Disposing of the appliance........................... 29

10 Liebherr Warranty Plan................................. 30

Congratulations on the purchase of your new appliance.

With this purchase, you have chosen all the advantages

of the latest refrigeration technology, guaranteeing you a

high-quality appliance with a long life span and high operating safety.

The equipment of your appliance gives you the highest

level of day-to-day ease of operation.

Together we are making an active contribution to the

conservation of our environment by purchasing this appliance which is manufactured in an environmentally friendly

process with the use of recyclable materials.

We hope you enjoy your new appliance.

The manufacturer is constantly working to improve all

models. Therefore please understand that we reserve the

right to make design, equipment and technical modifications.

To get to know all the benefits of your new appliance,

please read the information contained in these instructions carefully.

The instructions apply to several models, so there may be

differences. Sections which only apply to certain appliances are indicated with an asterisk (*).

Instructions for action are marked with a , the

results of action are marked with a .

1 The appliance at a glance

1.1 Additional benefits

CFC free

Energy-optimized refrigerant circuit

Energy-efficient insulation

Low energy consumption

User-friendly electronic controls

Active function indicators

Temperature can be controlled in the appliance inde-

pendent of ambient conditions according to its climate

rating - Temperature can be displayed as °C or °F

The appliance defrosts automatically - no need to

spend time defrosting

Large refrigeration capacity

Safety glass storage shelves

Adjustable door shelves for tall bottles

Large freezing capacity

Shelves can be removed to make space for large

items.

Freezer over-temperature alarm

Quick-freeze feature for fresh food (SuperFrost)

Frozen food temperature indicator

Power failure/“frost-control” display

All freezer drawers suitable for quick-freeze

Bright LED interior light

Door ajar alarm

Handle grips on all extra-large drawers for easy trans-

port

Integrated transport grips on appliance housing

Transport castors at back

Easy to clean

Door hinges can be reversed

-

2 * Depending on model and options

This unit is certified as Sabbath

compliant by the Star-K organization

thus allowing the appliance to be used

during religious holidays. For more information please visit Star-K on the web at

www.star-k.org.

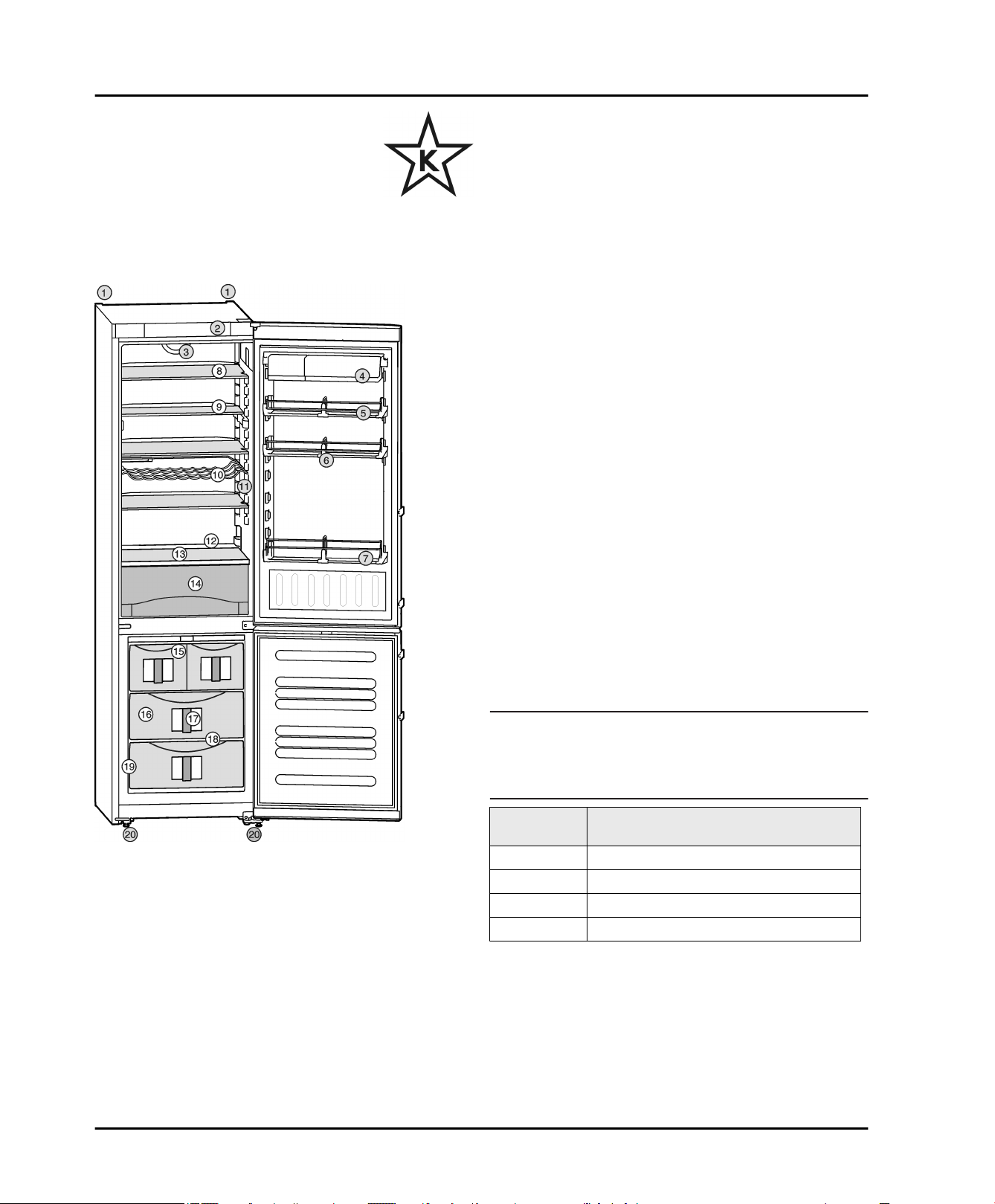

1.2 Overview of the appliance and its

equipment

The appliance at a glance

1.3 Range of appliance use

Normal use

The appliance is only suitable for refrigerating

food in a domestic environment or an environment that is similar to a domestic one. This

includes, for example, use

-

in staff kitchens, bed and breakfast establishments,

-

by guests in country homes, hotels, motels

and other types of accommodations,

-

for catering and similar wholesale services.

Use the appliance only for normal household

purposes. All other types of uses are not

permitted.

Foreseeable misuse

The following uses are specifically prohibited:

-

Storage and cooling of medication, blood

plasma, laboratory preparations or similar

substances and products in accordance with

the CMDCAS and FDA 510(k)

-

Use in areas at risk of explosion

Incorrect appliance use can cause damage to

the stored products or cause them to spoil.

Climate ratings

The appliance is set to operate within specific

ambient temperature limits according to its

climate rating. The climate rating for your appliance is printed on the rating plate.

Note

Compliance with the specified ambient

u

temperatures is required, otherwise the refrigeration performance is reduced.

Climate

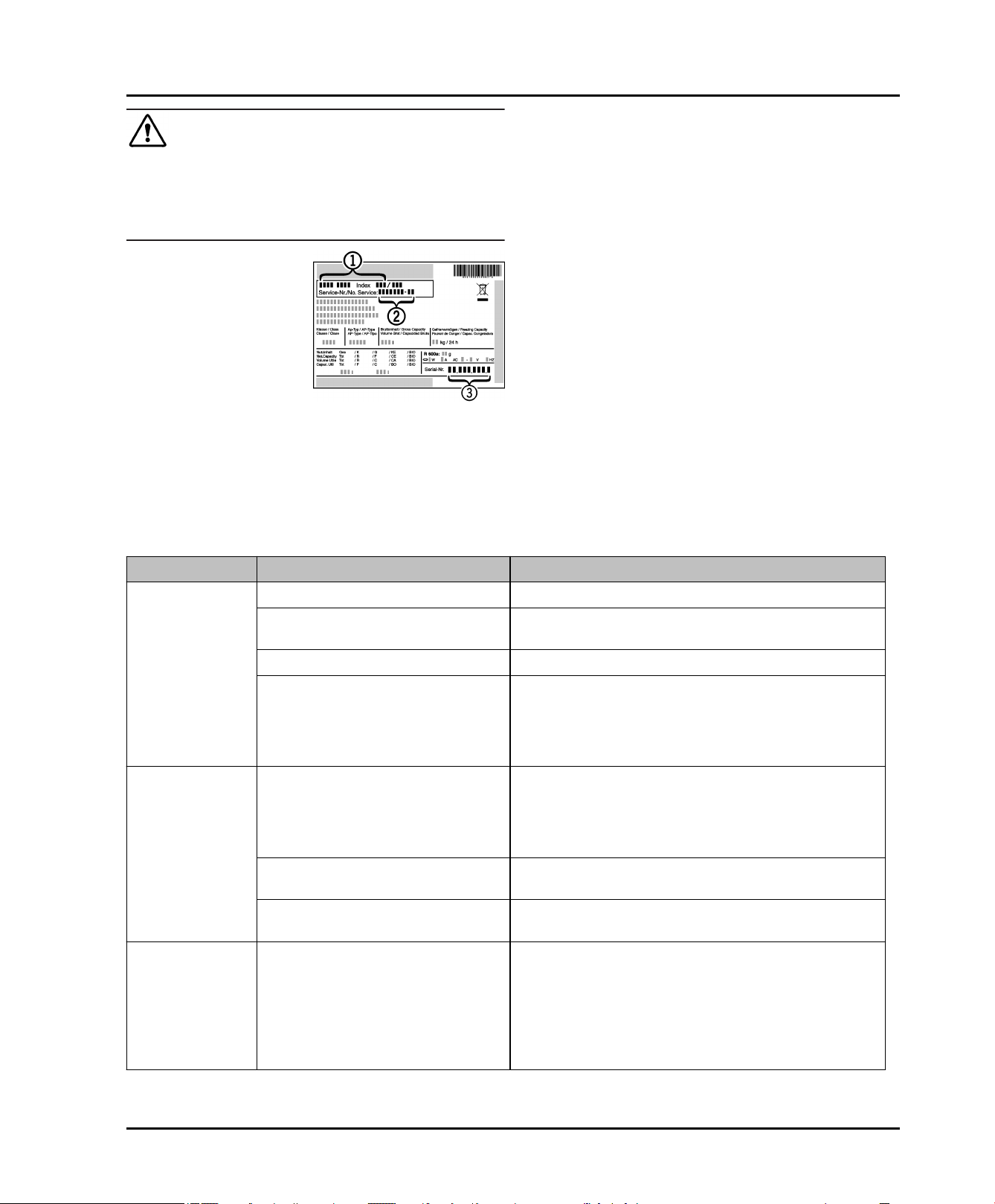

Fig. 1

(1) Rear transport

handles

(2) Operating and control

elements

(3) Fan (13)Coldest zone

(4) Container shelf (14)Vegetable drawer

(5) Door rack, moveable (15)IceMaker*

(6) Bottle partition,

adjustable

(7) Gallon-capacity rack (17)InfoSystem

(8) Shelf, moveable (18)VarioSpace

(9) Shelf, can be split (19)Rating plate

(10)Bottle shelf (20)Adustable feet, front

* Depending on model and options 3

(11)Interior light

(12)Drain hole

(16)Freezer compartment

transport handles, rear

transport castors

rating

SN 50 °F (10 °C) to 90 °F (32 °C)

N 61 °F (16 °C) to 90 °F (32 °C)

ST 61 °F (16 °C) to 101 °F (38 °C)

T 61 °F (16 °C) to 110 °F (43 °C)

1.4 Conformity

The refrigerant circuit has been tested for leaks. The

appliance complies with the relevant safety regulations

and the directives UL250 and CAN/CSA C22.2 No.63-93.

Instructions for testing institutes:

Tests must be carried out in accordance with the applicable standards and guidelines.

for ambient temperatures from

General safety information

The preparation and testing of the appliance must be

carried out taking account of the manufacturer's

loading plans and the instructions in the operating

manual .

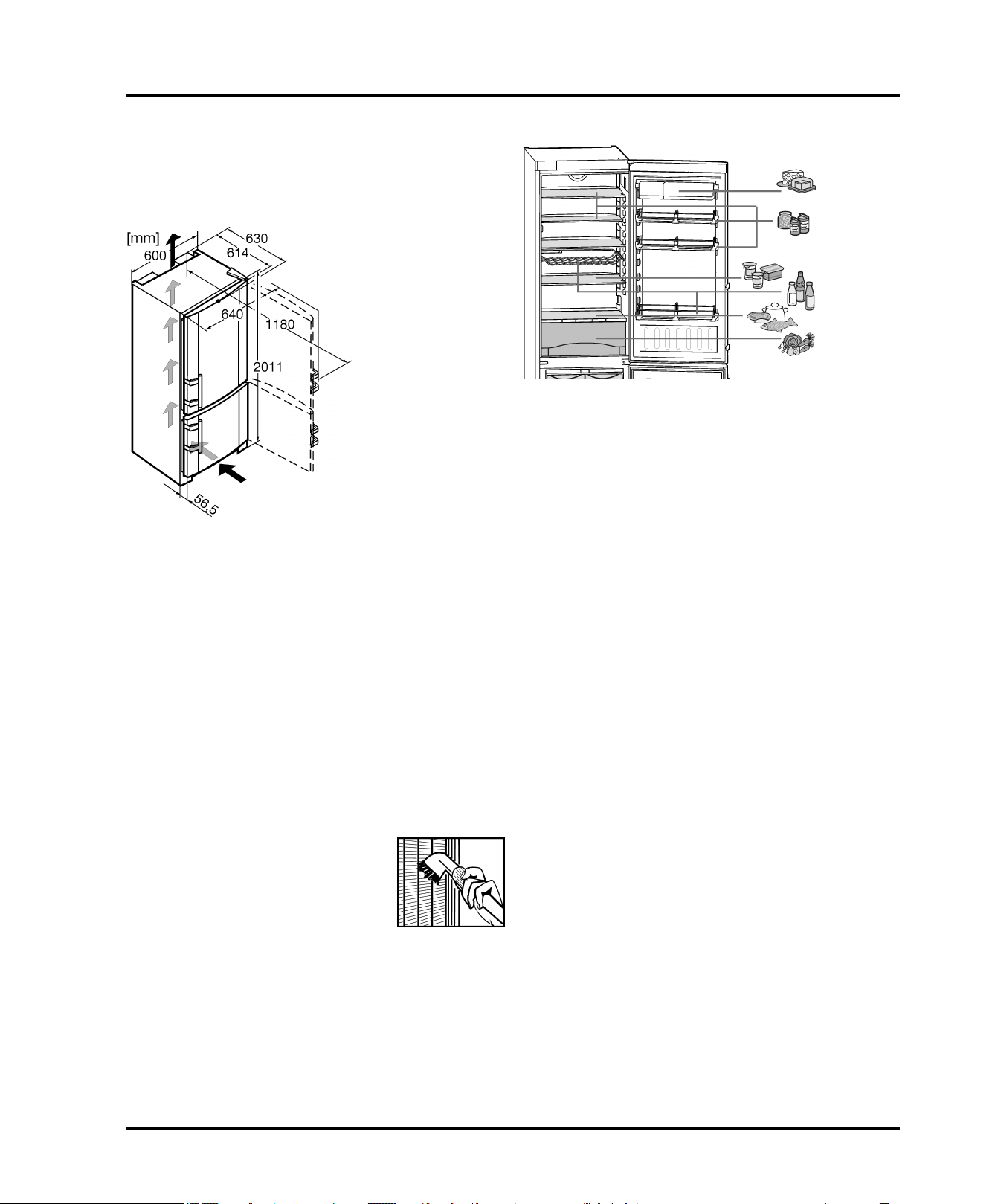

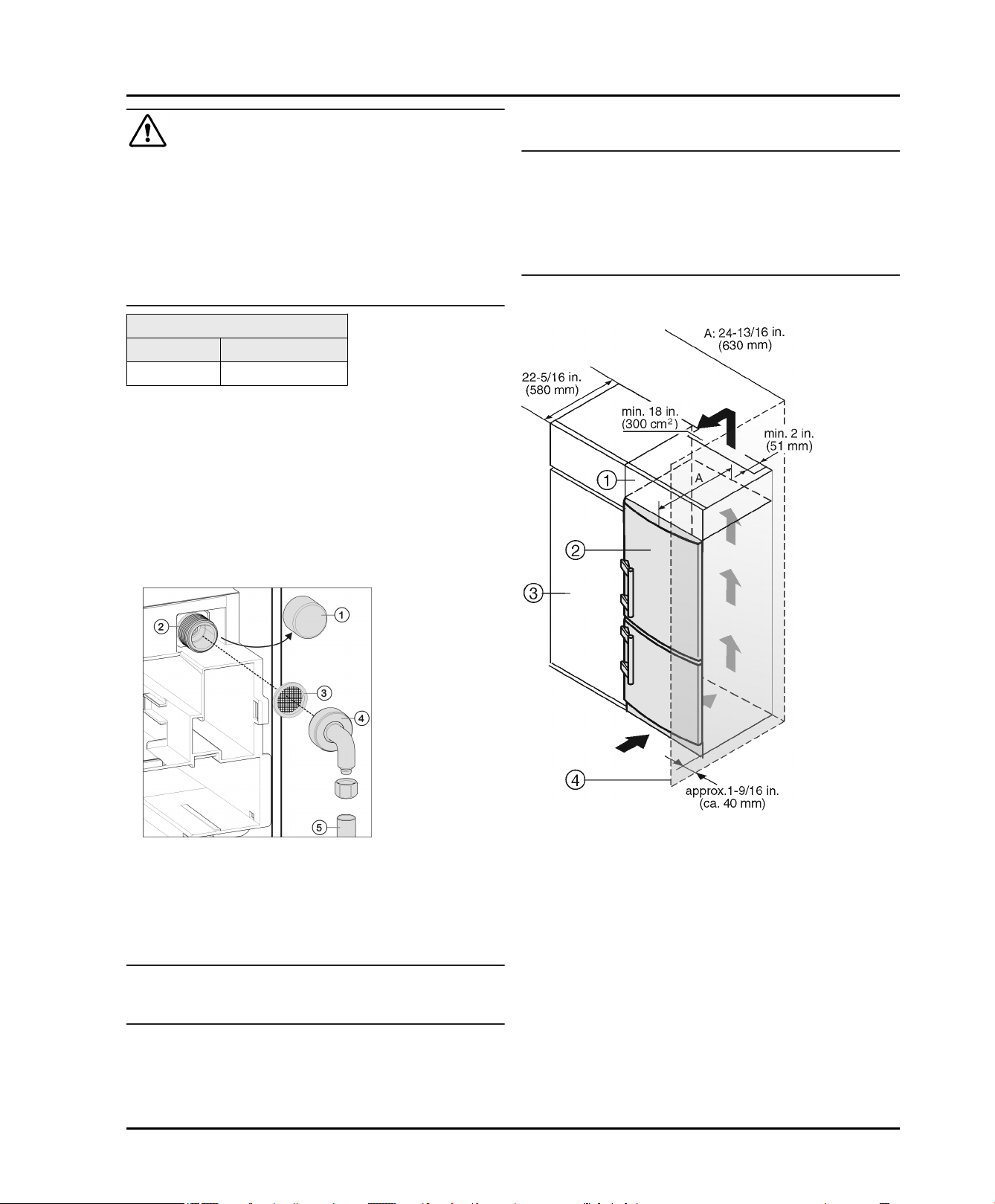

1.5 Installation dimensions

Fig. 2

1.6 Energy saving

Always ensure good ventilation. Do not obstruct venti-

lation openings or grilles.

Do not install the appliance in direct sunlight or next to

an oven, heater, or similar heat source.

Energy consumption depends on installation conditions

such as the ambient temperature (see 1.3) .

Avoid opening the appliance door for any longer then

neccesary.

The lower the temperature is set the higher the energy

consumption.

All food stored in the appliance should be well wrapped

and covered. This prevents frost buildup.

Only take food out for as long as necessary so that it

does not get too warm.

Storing hot food: let it cool to room temperature first.

Defrost frozen food in the fridge.

-

Dust deposits increase energy

consumption:

Once a year the dust should be

removed from the refrigerating

machine and the heat exchanger

metal grid at the back of the appliance.

1.7 Example of food arrangement

Fig. 3

2 General safety information

Read and follow these instructions. They contain

safety advice which is important for safe and

problem-free installation and operation. Always

read and follow the safety advice.

Dangers for the user:

-

This appliance can be operated by children 8

years and older as well as by persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge if

they are supervised or have been instructed in

the safe use of the appliance and understand

the associated risks. Children must not play

with the appliance. Cleaning and user maintenance must not be performed by children

unless they are supervised.

-

When disconnecting the appliance from the

outlet, always take hold of the plug. Do not pull

on the cable.

-

Disconnect the power plug or switch off the

power if a fault occurs.

-

Do not damage the mains power line. Do not

operate the appliance from a defective mains

power line.

-

Repairs, work on the appliance and replacement of the power cord should only be carried

out by the customer service department.

-

The appliance should only be assembled,

connected and disposed of in accordance with

the instructions.

-

Please keep the instructions and pass them on

to any future owner.

-

All repairs to or work on the IceMaker must

only be carried out by the customer service

4 * Depending on model and options

Controls and displays

department or other specialist engineers

trained to do this.*

-

The manufacturer is not liable for damage

arising from incorrect connection to the water

supply.*

Risk of fire:

-

Do not operate the appliance near explosive

gases.

-

Do not store explosive materials or spray cans

with flammable propellants, such as e.g.

butane, propane, pentane, etc. in the appliance. You can recognize such spray cans by

the printed contents or a flame symbol. Any

leaking gasses can be ignited by electrical

components.

-

Keep burning candles, lamps and other

objects with open flames away from the appliance so that they do not set it on fire.

-

Alcoholic beverages or other containers

holding alcohol must always be tightly sealed

for storage purposes. Any leaking alcohol can

be ignited by electrical components

Tipover hazard:

-

Do not stand or climb on the base, drawers,

doors, etc. This applies in particular to children.

Risk of food poisoning:

-

Do not consume food that has passed its best

before date.

Danger of frostbite, feelings of numbness

and pain:

-

Avoid continued skin contact with the cold

surfaces or chilled/frozen food or adopt protective measures, e. g. use gloves. Do not

consume ice cream (especially sherbets) and

ice cubes immediately when they are too cold.

Risk of injury and damage:

-

Hot steam may lead to injuries. Do not use any

electrical heating or steam cleaning equipment, naked flames or defrosting sprays for

defrosting

-

Do not remove ice with sharp objects

Risk of crushing

-

Do not reach into the soft stop mechanism.

Fingers may be trapped when the door is

closed.

Follow the specific instructions in the other

sections:

DANGER indicates a hazardous situation,

which if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation,

which if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation,

which if not avoided, will result in

minor or moderate injury.

NOTICE indicates a hazardous situation,

which if not avoided, could result in

damage to property.

Note indicates useful advice and tips.

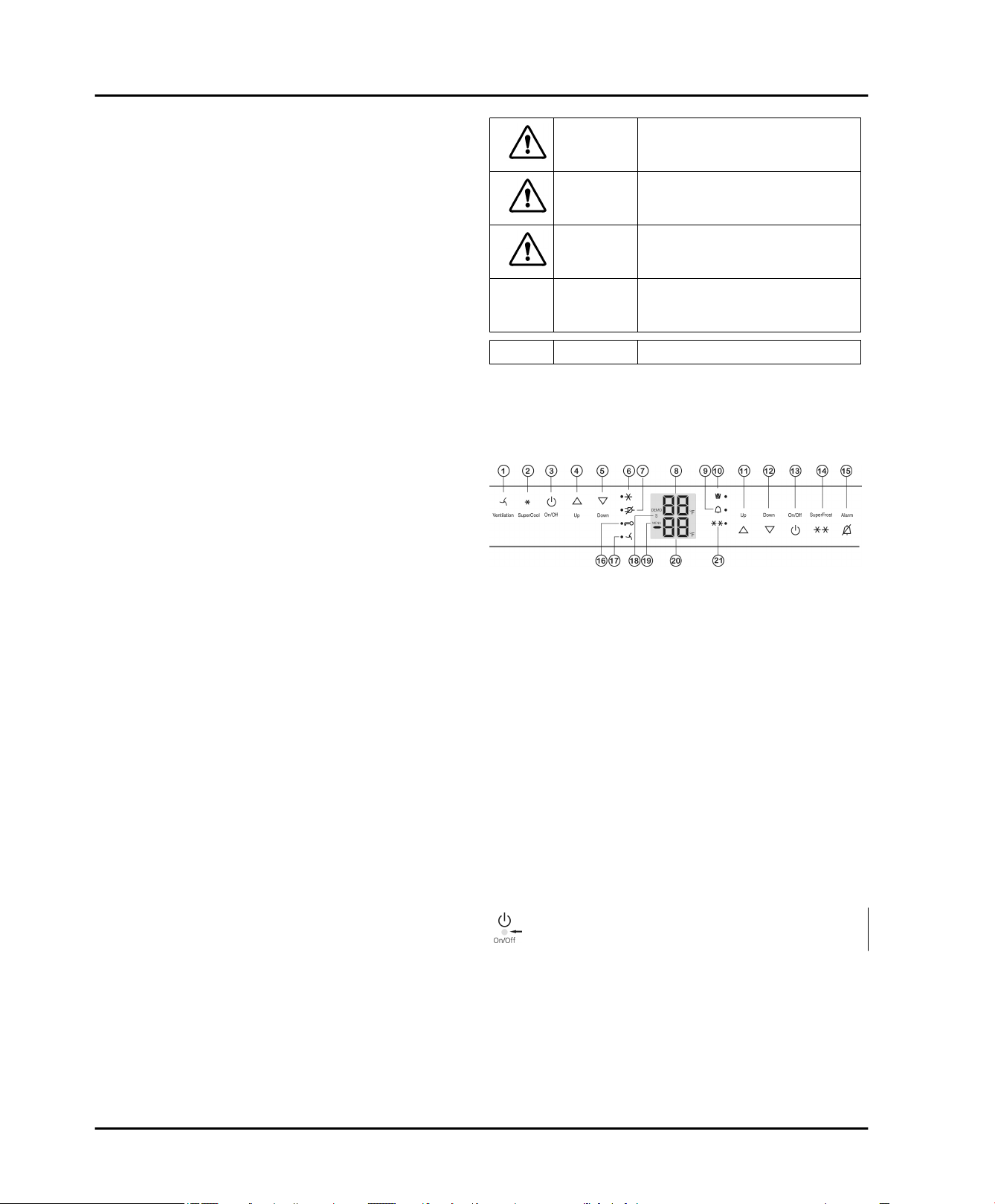

3 Controls and displays

3.1 Operating and control elements

Fig. 4

(1) Ventilation button (12)Freezer compartment

Down button

(2) SuperCool button (13)Freezer compartment

On/Off button

(3) Fridge compartment

On/Off button

(4) Fridge compartment

Up button

(5) Fridge compartment

Down button

(6) SuperCool symbol (17)Ventilation symbol

(7) Power failure symbol (18)Sabbath mode symbol

(8) Fridge compartment

temperature display

(9) Alarm symbol (20)Freezer compartment

(10)IceMaker symbol* (21)SuperFrost symbol

(11)Freezer compartment

Up button

The touch point is located between the symbol and the

symbol label.

3.2 Temperature display

The following is displayed in normal operation:

the highest freezer temperature

the average fridge temperature

-

The freezer compartment temperature display is flashing:

the temperature setting has been changed

-

(14)SuperFrost button

(15)Alarm button

(16)Child lock symbol

(19)Menu symbol

temperature display

* Depending on model and options 5

Start-up

after switch-on the temperature is not yet cold enough

the temperature has risen several degrees

-

Dashes are shown on the display:

the freezer temperature is above 32 °F (0 °C).

-

The following displays indicate malfunction. Possible

causes and corrective actions: (see Troubleshooting).

-

F0 through F9

-

FE*

The power failure symbol LED

flashes.

4 Start-up

4.1 Transporting the appliance

WARNING

Danger of fire and damage due to blocked ventilation

openings!

Never block the ventilation openings. Always ensure

u

good ventilation!

NOTICE

Risk of damage caused by condensation

Installing the appliance next to any other refrigerator or

freezer can cause condensation or damage to the Liebherr appliance.

Do not install this appliance next to any other refriger-

u

ator or freezer except another Liebherr model. Liebherr

models are designed to allow side-by-side installation.

They are equipped with a heating system to eliminate

condensation when refrigerators or freezers are

installed side-by-side.

CAUTION

Risk of injury or damage if incorrectly transported.

Transport the appliance in its packaging.

u

Transport the appliance upright.

u

Do not move the appliance on your own.

u

4.2 Setting up the appliance

WARNING

Risk of fire due to moisture!

If live parts or the power cord get wet, this can cause a

short circuit.

The appliance is designed for use in enclosed spaces.

u

Do not operate the appliance in open space or in damp

areas or where there is spray.

WARNING

Risk of fire due to short circuit.

If the power cable or plug of the appliance or another

appliance and the back of the appliance touch each other

the power cable or plug will be damaged by the vibrations

of the appliance which could lead to a short circuit.

Install the appliance so that it does not touch any plugs

u

or power cables.

Do not connect the appliance or other appliances to the

u

sockets on the back of the appliance.

NOTICE

Risk of damage for the finished floor surface!

Protect the finished floor surface before you uncrate the

u

unit.

Verify that:

The floor under the appliance is flat and level.

q

The floor can support the appliance's weight plus

q

approximately 1200 pounds (544 kg) of food weight.

The appliance is not placed in direct sunlight or near

q

the stove, range top, radiators and similar heat

sources.

Examine the unit and packaging for shipping damage.

u

Contact the carrier immediately if you suspect there is

any damage.

Note the type (model, number), index, appliance/serial

u

number, date of purchase and where purchased

(see 6.6) .

Remove anything attached to the rear or side walls of

u

appliance that would prevent proper installation or

impede proper ventilation.

Remove the protective film from the outside of the

u

appliance.

NOTICE

The stainless steel doors are treated with a high-grade

surface coating and must not be cleaned with the

supplied cleaning agent.

This would damage the surface coating.

Wipe the coated door surfaces using a soft, clean

WARNING

Danger of fire and damage!

Do not place devices that give off heat, e.g. micro-

u

waves, toasters, etc. on the appliance.

CAUTION

Risk of personal injury!

Have two people move this appliance into place.

u

6 * Depending on model and options

u

cloth only.

Apply a stainless steel cleaner only to the stainless

u

steel side walls evenly, wiping with the grain. Subsequent cleaning becomes easier as a result.

Wipe painted side walls with a clean, soft cloth only.

u

Align the appliance so that it

u

stands firmly and on a level

by applying the accompanying spanner to the adjustable-height feet (A) and

using a spirit level.

Then support the door:

u

Extend the adjustable foot

at the turn hinge (B) until it

rests on the floor and then

make a further 90° turn.

Start-up

Note

Clean the appliance (see 6.3) .

u

If the appliance is set up in humid areas, condensation

may build on the outside of the appliance.

Always ensure proper ventilation.

u

4.3 Changing the door hinges

You can reverse the door hinges, if necessary:

Make sure you have the following tools on hand:

Torx® 25

q

Torx® 15

q

Screwdriver

q

Cordless screwdriver, if necessary

q

Another person to help with the installation, if neces-

q

sary

SW2 Allen key (supplied)

q

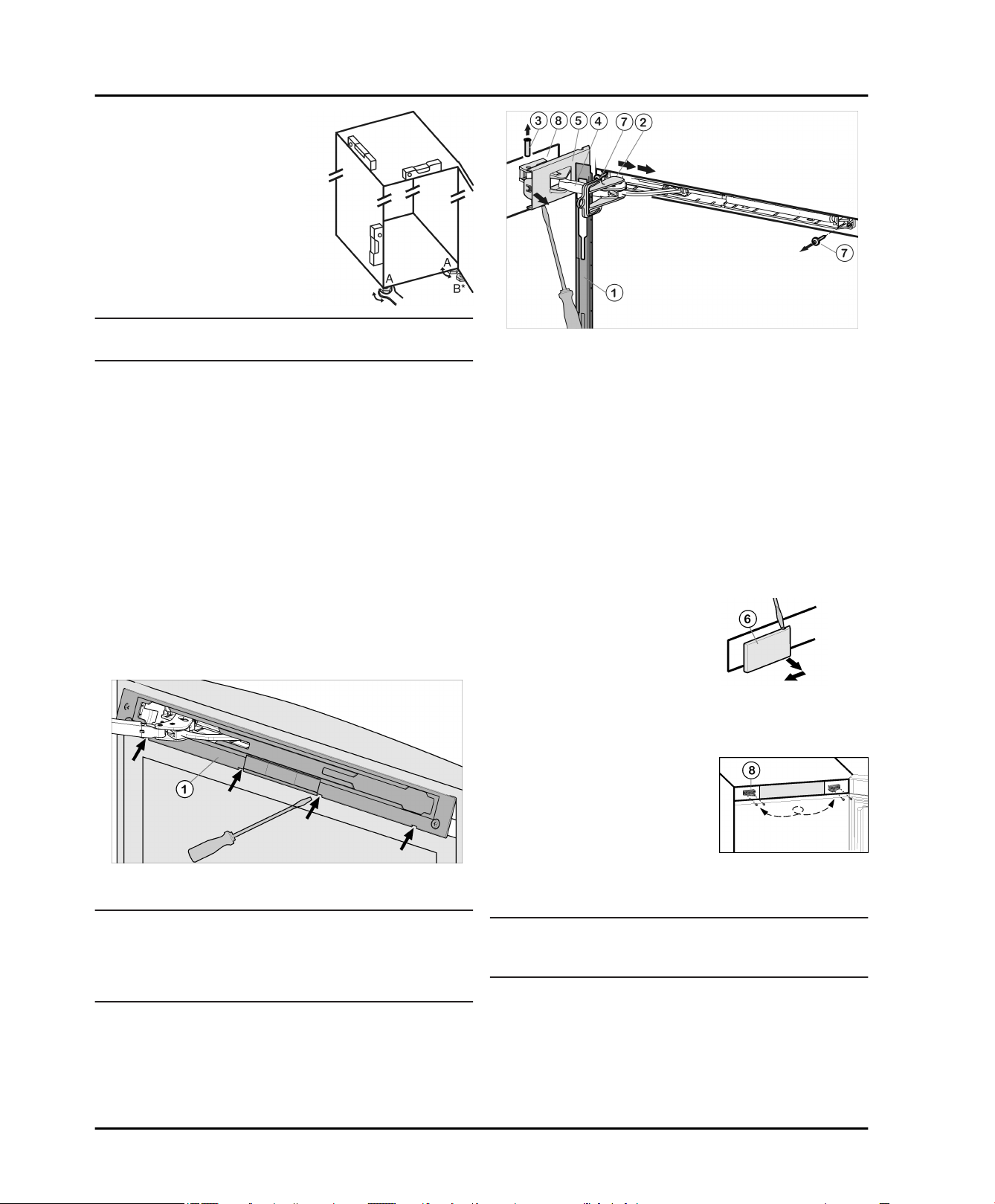

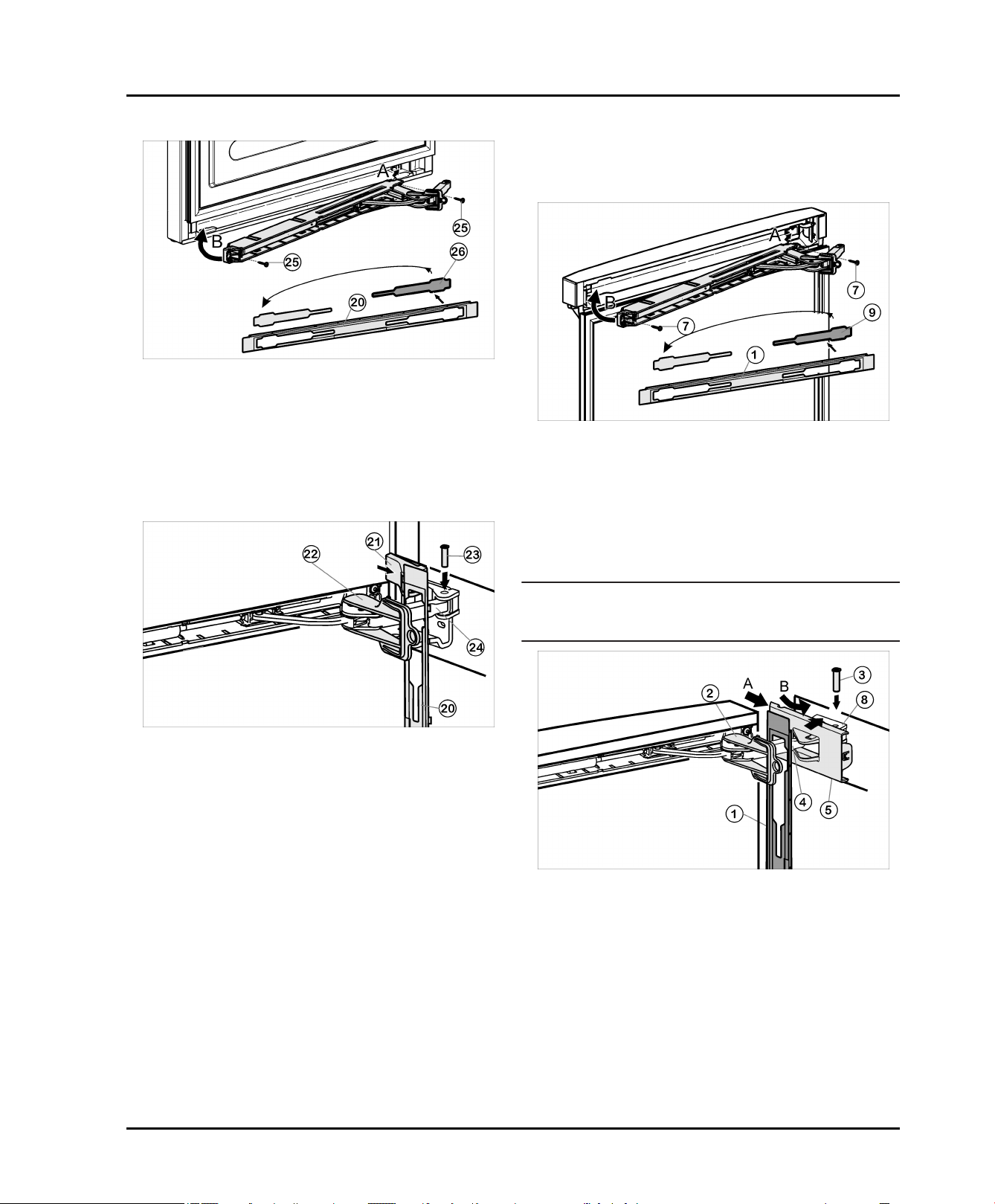

4.3.1 Remove upper soft stop damper

Fig. 5

Open upper door.

u

NOTICE

Risk of damage!

If the door seal is damaged the door may not close properly and the level of cooling is insufficient.

Do not damage the door seal with the screwdriver!

u

Fig. 6

Push panel forward over the damper bracket

u

the direction of the appliance.

Engage locking device

u

oblong hole.

The locking device prevents the hinge from snapping

w

shut.

Unscrew cover

u

the first notch using a screwdriver.

The bolt will become visible.

w

Push bolt

u

Press damper bracket

u

door.

Completely loosen cover

u

side and remove.

Remove panel

u

Loosen cover that is on the

u

hinge side

screwdriver and remove by

pulling outwards.

Unscrew soft stop unit (2 x Torx® 15)

u

Slightly pull out soft stop unit, push it towards the

u

handle side and open it out.

Set soft stop unit to the side.

u

Unscrew bearing part

u

Fig. 6 (8)

move it to the opposite

side. Make preliminary

holes (optional) or use a

cordless screwdriver.

, turn it 180° and

Fig. 6 (5)

Fig. 6 (3)

Fig. 6 (1)

Fig. 7 (6)

Fig. 6 (2)

that is on the hinge side until

out from below.

Fig. 6 (4)

Fig. 6 (5)

.

using a

into place inside

in the direction of the

that is on the hinge

Fig. 6 (7)

Fig. 6 (4)

.

4.3.2 Removing the upper door

Note

To prevent food items from falling out, take all food out

u

of the door racks before removing the door.

in

Fig. 7

Fig. 8

Release panel

u

remove.

The panel hangs above the damper bracket.

w

* Depending on model and options 7

Fig. 5 (1)

using a slotted screwdriver and

Start-up

Fig. 9

Close upper door.

u

Pull cover

u

Lift off cover

u

Fig. 9 (10)

Fig. 9 (11)

CAUTION

Risk of injury if the door tips out!

Keep a steady grip on the door.

u

Set the door down carefully.

u

Unscrew upper bearing bracket

u

25)

Fig. 9 (13)

Lift the upper door up and off and set it to the side.

u

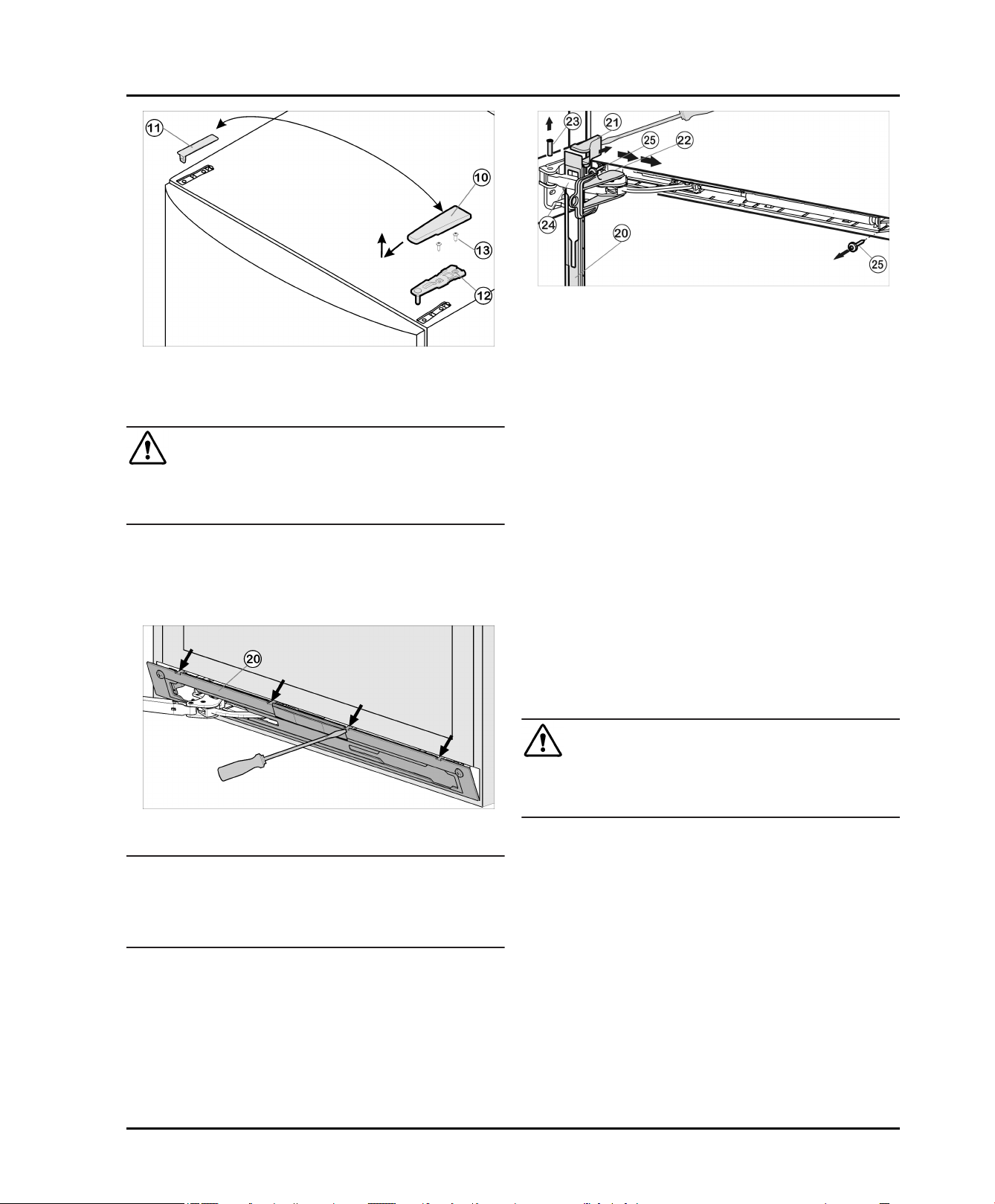

4.3.3 Remove lower soft stop damper

forward and upwards to remove.

.

Fig. 9 (12)

and pull it upwards to remove.

(2 x Torx®

Fig. 11

Push panel forward over the damper bracket

u

Fig. 11 (24)

Engage locking device

u

in the direction of the appliance.

Fig. 11 (22)

into place inside

oblong hole.

The locking device prevents the hinge from snapping

w

shut

Lift off cover

u

Fig. 11 (21)

from the outside using a screwdriver and remove by pulling outwards.

Tip the appliance rearwards with the help of a second

u

person if needed.

Push bolt

u

Press damper bracket

u

Fig. 11 (23)

out from below.

Fig. 11 (24)

in the direction of the

door.

Remove panel

u

Unscrew entire soft stop unit (2 x Torx® 15)

u

Slightly pull out soft stop unit, push it towards the

u

Fig. 11 (20)

.

Fig. 11 (25)

handle side and open it out

Set soft stop unit to the side

u

4.3.4 Removing the lower door

.

Fig. 10

Open the lower door.

u

NOTICE

Risk of damage!

If the door seal is damaged the door may not close properly and the level of cooling is insufficient.

Do not damage the door seal with the screwdriver!

u

Release panel

u

Fig. 10 (20)

using a slotted screwdriver

and remove.

The panel hangs above the damper bracket

w

Close the lower door.

u

Pull center bearing pin

u

Fig. 12 (32)

and disc

Fig. 12 (34)

out of the bearing bracket and the lower door.

Remove plastic cap

u

Fig. 12 (33)

.

CAUTION

Risk of injury if the door tips out!

Keep a steady grip on the door.

u

Set the door down carefully.

u

Open the lower door.

u

Unscrew center bearing bracket

u

Fig. 12 (31)

(2 x Torx®

25).

Lift lower door upwards to remove and set it to the side

u

8 * Depending on model and options

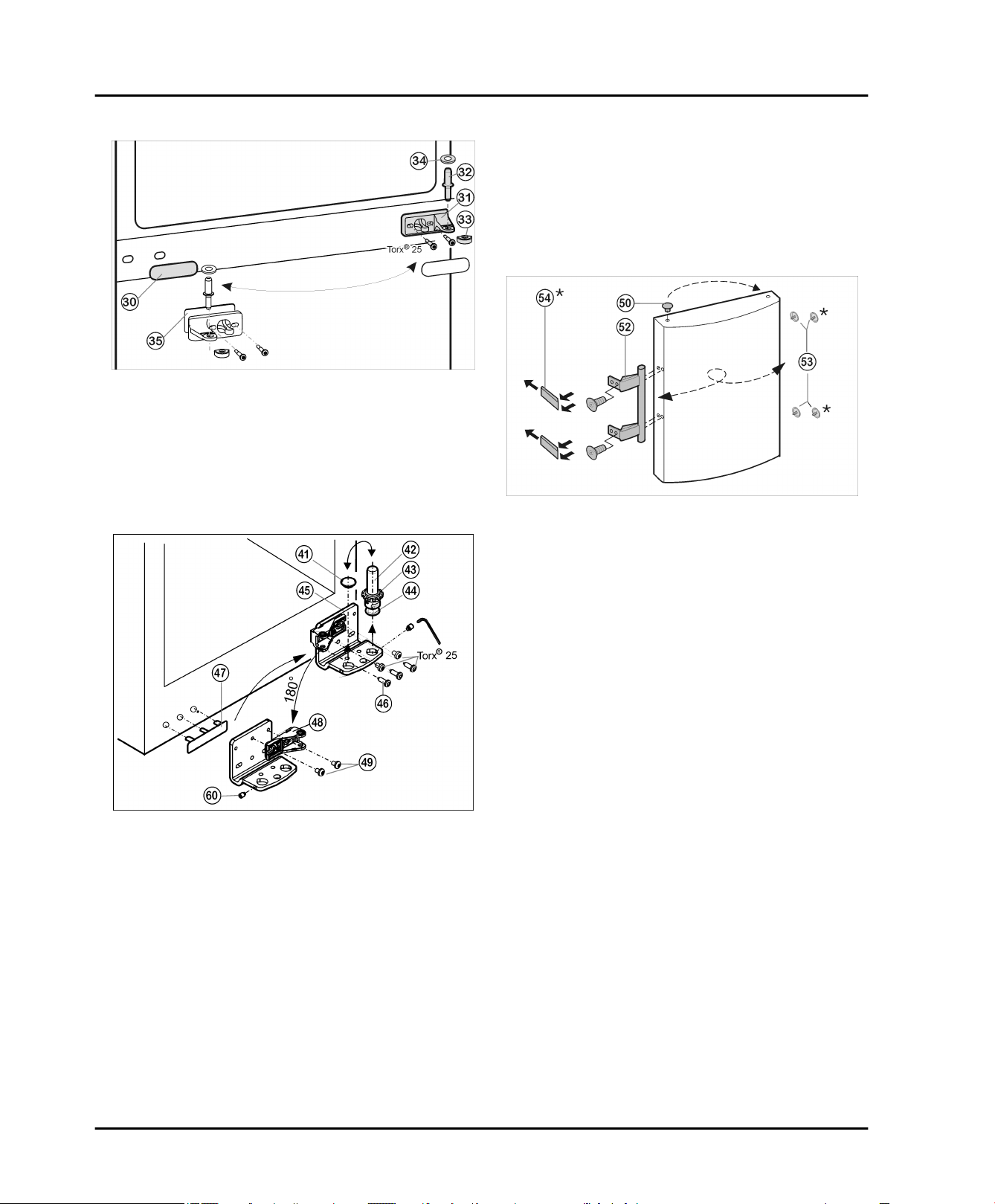

4.3.5 To swap over central bearing parts

Fig. 12

Carefully remove cover trim

u

Turn the center bearing bracket

u

Fig. 12 (35)

180° and secure tightly (to 4 Nm) on the

new hinge side.

Turn the cover trim

u

Fig. 12 (30)

into place on the new handle side.

Fig. 12 (30)

180° and snap it back

.

Fig. 12 (31)

and washer

Start-up

Using a cordless screwdriver if necessary, again

u

secure the bearing bracket

Fig. 13 (45)

side tightly (to 4 Nm).

Screw complete bearing pin

u

Fig. 13 (42)

positioning foot, back into place again.

Tighten grub screw

u

Fig. 13 (60)

.

4.3.7 Swapping the handles

For both the upper and lower door:

on the new hinge

, with disc and

4.3.6 To swap over lower bearing parts

Unscrew grub screw

u

the socket wrench supplied.

Unscrew the bearing pin

u

Fig. 13 (43)

and positioning foot

upwards direction.

Lift off plug

u

Unscrew

u

Completely unscrew the grub screw

u

Fig. 13 (41)

Fig. 13 (46)

screw it into the opposite side of the bearing bracket

until it is externally flush with the bearing bracket.

Unscrew bearing part

u

tighten

Fig. 13 (49)

Insert plug

u

Carefully lift off the cover on the handle side

u

Fig. 13 (41)

and move it to the opposite side.

Fig. 13 (60)

by approx. 1 turn using

Fig. 13 (42)

Fig. 13 (44)

.

bearing bracket

Fig. 13 (48)

Fig. 13 (45)

, turn it 180° and

it to the inside.

back into the other hole.

, with disc

, in an

.

Fig. 13 (60)

Fig. 13 (47)

Fig. 13

and

Fig. 14

Pull plugs

u

Fig. 14 (50)

out of the door bearing bushes

and move them to the other side.

Detach the door handle

u

pressure plates*

Fig. 14 (52)

Fig. 14 (54)

, plug

Fig. 14 (53)

and move them to the

opposite side.

When fitting the pressure plates on the opposite side,

u

make sure they engage correctly.*

4.3.8 Fitting the lower door

Position the lower door from above onto the lower

u

bearing pins

Close the door.

u

Place the plastic cap

u

bearing bracket

Insert the center bearing pin

u

Fig. 13 (42)

Fig. 12 (31)

hinge side through the center bearing bracket

Fig. 12 (31)

Place disc

u

Fig. 12 (32)

into the lower door.

Fig. 12 (34)

.

.

Fig. 12 (33)

back onto the center

.

Fig. 12 (32)

on the new

onto the center bearing pin

and

* Depending on model and options 9

Start-up

4.3.9 Fitting the lower soft stop damper

Fig. 15

Loosen cover

u

Fig. 15 (26)

insert on the other side.

With the hinge of the soft stop unit facing the door

u

hinge side, engage the soft stop unit (A) and swivel

inwards (B)

The holes on the left and right must lie exactly above

w

each other

Tighten soft stop unit (2 x Torx® 15)

u

from the panel

Fig. 15 (25)

Fig. 15 (20)

.

and

Snap both cover

u

Fig. 9 (11)

and cover

Fig. 9 (10)

place on the opposite side.

Leave upper door open.

u

4.3.11 Fitting the upper soft stop damper

Fig. 17

Loosen cover

u

insert on the other side.

With the hinge of the upper soft stop unit facing the

u

door hinge side, engage the soft stop unit (A) and

swivel inwards (B)

The holes on the left and right must lie exactly above

w

each other

Tighten soft stop unit (2 x Torx® 15)

u

Fig. 17 (9)

from the panel

Fig. 17 (7)

Fig. 17 (1)

.

into

and

Fig. 16

Hook panel

u

Fig. 16 (20)

into the damper bracket such

that the detent hooks are pointing forwards and the

front side is facing the appliance.

Pull damper bracket

u

bracket and insert bolt

Fig. 16 (24)

Fig. 16 (23)

from above such that

towards bearing

the square is resting in the recess.

Position cover

u

Check that the cover is positioned correctly such that

w

Fig. 16 (21)

and snap in.

the door can close properly and the bolt is secured

Remove locking device

u

Snap panel

u

Close the lower door.

u

Fig. 16 (20)

Fig. 16 (22)

by twisting it.

into place on the door.

4.3.10 Fitting the upper door

Place the upper door onto the center bearing pin

u

Fig. 12 (32)

Insert the upper bearing bracket

u

hinge side into the door.

Tighten the upper bearing bracket (to 4 Nm)(2 x Torx®

u

25)

Fig. 9 (13)

a cordless screwdriver.

.

Fig. 9 (12)

on the new

. Make preliminary holes (optional) or use

Note

Follow the correct sequence First hang the panel over

u

the damper bracket, then the cover

Fig. 18

Hook panel

u

Fig. 18 (1)

into the damper bracket

Fig. 18 (4)

such that the detent hooks are pointing inwards and the

front side is facing the appliance.

Push on cover

u

over the bearing part

Place cover

u

Fig. 18 (5)

Fig. 18 (8)

Fig. 18 (5)

from the outside (A) and pivot

(B).

on top and allow to snap into

place until the first notch.

The openings for the bolts lie above each other after

w

positioning the damper bracket

Pull damper bracket

u

and insert bolt

Fig. 18 (4)

Fig. 18 (3)

towards bearing bracket

from above such that the

square is resting in the recess.

10 * Depending on model and options

Start-up

Now snap cover

u

bearing part

Check that the cover is positioned correctly such that

w

the door can close properly and the bolt is secured

Remove locking device

u

Snap panel

u

Turn cover

u

on top from the outside and snap into place.

Fig. 18 (5)

Fig. 18 (8)

Fig. 18 (1)

Fig. 7 (6)

completely into place on the

.

Fig. 18 (2)

into place on the door.

180° from the handle side, place it

by twisting it.

4.3.12 Aligning the doors

Align the doors flush with the appliance housing, using

u

the two oblong holes in the lower bearing bracket

Fig. 13 (45)

as a guide, if needed. To do so, unscrew the center

screw on the lower bearing bracket

Risk of bodily injury due to the door falling off.

If the bearing parts are not installed with the proper

torque, the door may fall off. In addition, the door may not

close, thus impairing the cooling performance of the appliance.

Securely tighten the bearing brackets by applying a

u

torque of 3 lb-ft (4 Nm).

Check all screws and retighten if necessary.

u

and in the center bearing bracket

WARNING

Fig. 12 (31)

Fig. 13 (45)

.

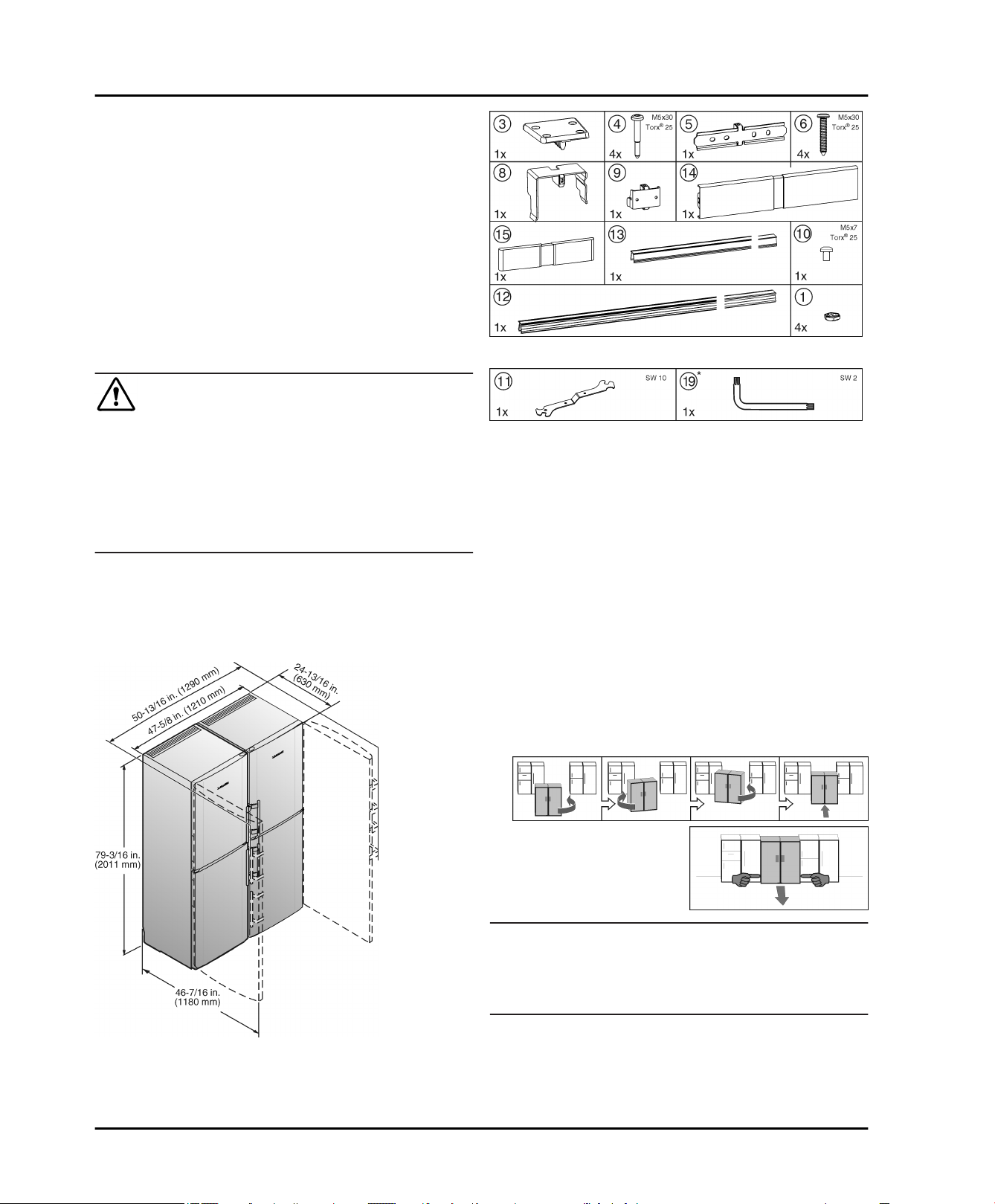

4.4 Side-by-side installation

As seen from the front, install the appliance with an

IceMaker on the right and the appliance without an

IceMaker on the left.

Fig. 20

Fig. 21

Make sure you have the following tools on hand:

Spirit level

q

Cordless screwdriver

q

Torx® 25 screwdriver

q

Open-end wrench, SW 10 (supplied)

q

1/4 in. socket

q

Allen wrench, SW 2 (supplied)

q

Tips on moving the combination:

Before assembly, set the appliances up as close as

q

possible to the final location.

When moving the appliances, always grasp the front

q

outside corners. Never press your knee against the

side walls or door.

The easiest way to move the combination is diagonally,

q

by moving the left and right corner in turn.

If the combination is positioned exactly in front of the

recess, slide it in straight.

If you need to pull the

q

combination back out of

the recess, grasp it in the

bottom third and pull

forward.

NOTICE

Moving the SBS combination may result in damage!

The assembled SBS combination is heavy. If not moved

properly, the appliance may become dented.

Read and follow the moving tips (see above).

u

Remove all protective films from the housing exterior.

Fig. 19

The fixing accessories are supplied with model CS 1311.

If you have model CS 1360 you can purchase the fixing

accessories by contacting customer services.

* Depending on model and options 11

u

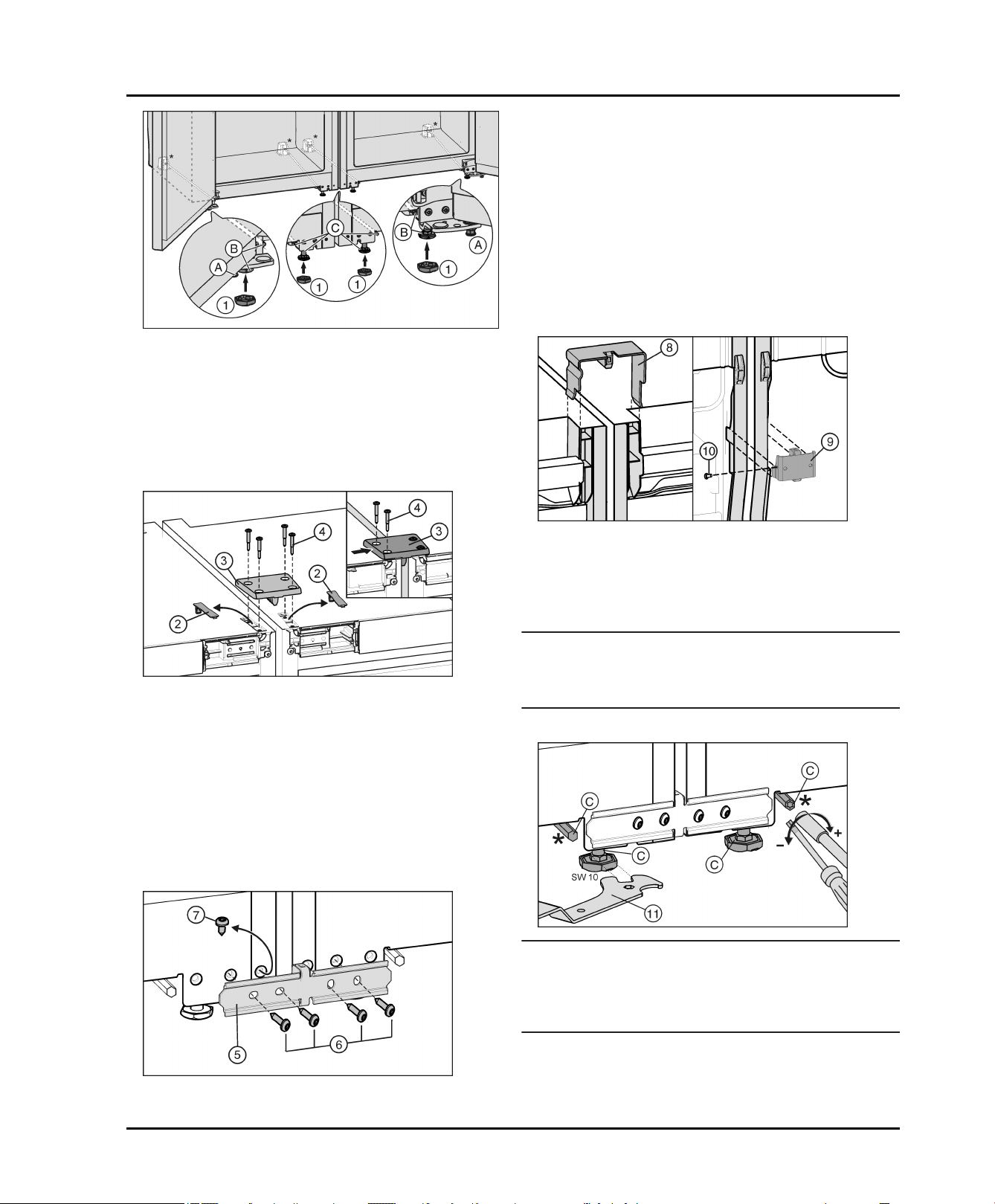

Front of the appliance:

Start-up

Fig. 22

If necessary screw in the adjustment feet

u

the front of both appliances completely so that there is

no floor contact.

Place the caps

u

Fig. 22 (1)

on the four front adjustment

feet.

Move both units together so that there is a gap of up to

u

approx. 3/8 " (10 mm) between them so that they are

flush as seen from the front.

Fig. 22 (A)

The appliances are automatically aligned in depth with the

connecting sheet. If one appliance projects further

forward than the other start with this one. Otherwise start

with the left hand appliance.

Fix the connecting sheet

u

ance with two screws

Move the connecting sheet to the side so that the

u

Fig. 24 (5)

Fig. 24 (6)

loosely to one appli-

.

centre bar of the sheet is touching the side wall of the

appliance. Tighten the screws.

Screw the connecting sheet to the second appliance

u

too. If necessary push the appliances together or apart

a little.

Back of the appliance:

at

Fig. 23

Release and remove the covers

u

Fig. 23 (2)

.

The appliances are automatically aligned in height with

the connecting plate. If one appliance is somewhat higher

than the other start with this one.

Fit a connecting plate

u

appliance with two screws

Move the connecting plate to the side so that the centre

u

Fig. 23 (3)

Fig. 23 (4)

and fix loosely to one

.

bar of the plate is touching the side wall of the appliance. Tighten the screws.

Screw the connecting plate to the second appliance

u

too. If necessary push the appliances together or apart

a little.

Fig. 25

Place the connecting clamps

u

Fig. 25 (8)

at the top of the

centre side walls.

Insert theconnecting angle

u

Fig. 25 (9)

underneath into

the corresponding space.

If the connecting angle is somewhat loose, fit a screw

u

Fig. 25 (10)

.

Note

To prevent vibration noise, the brackets and screws

u

must not come into contact with the clamps or the

screws on the pipework on the back.

Front of the appliance:

Fig. 26

NOTICE

Risk of damage to the castors.

Do not use a power tool to adjust the rear adjustment

u

feet as it will damage the leveling mechanism or disengage the rod – instead use a hand ratchet.

The front adjustment feet can be adjusted with the

Fig. 24

If your appliance has been fitted with the pre-fitted

u

screw

Fig. 24 (7)

12 * Depending on model and options

: Undo the screw.

supplied open-end wrench

ment feet* with a 1/4'' bit attachment.

Fig. 26 (11)

and the rear adjust-

Start-up

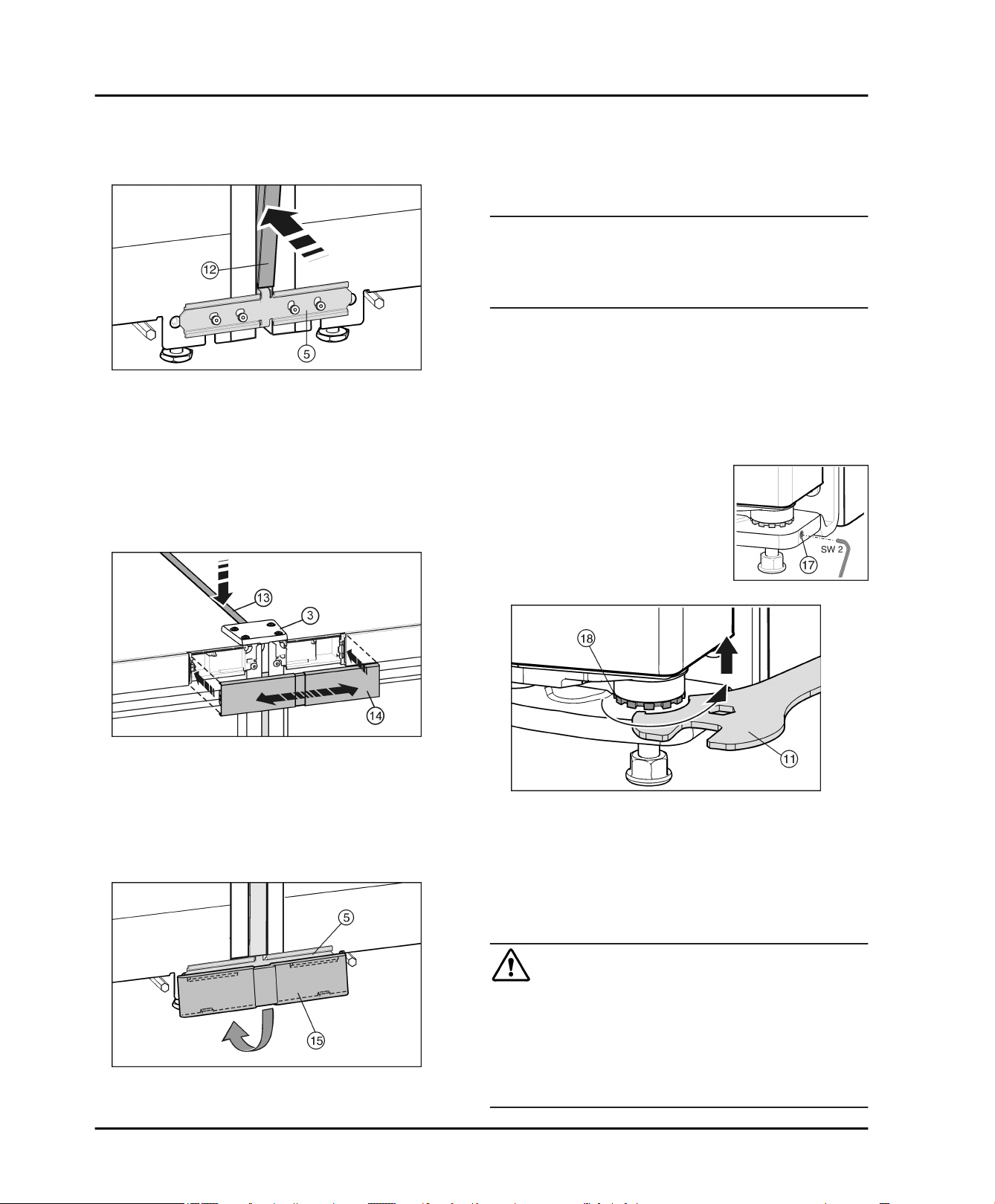

Tighten the centre adjustment feet

u

Fig. 22 (C)

so that

there is no floor contact.

Align the combination with the outer adjustment feet

u

Fig. 22 (B)

Before inserting the trim

.

Fig. 27

Fig. 27 (12)

squeeze the two fillets

together along the entire length. The trim can now be

inserted more easily into the gap. When pressing in the

trim, use a soft cloth to prevent dents on the surface of the

trim. Press the trim carefully and evenly into the gap to

achieve the best possible fit.

On the front press the long trim

u

Fig. 27 (12)

into the

vertical gap. Ensure that the trim rests on the

connecting panel

Remove protective film from the trim.*

u

Fig. 27 (5)

.

Connect the combination unit to the power supply

u

(see 4.10) .

Appliances with IceMaker:

Connect the appliance to the water supply (see 4.5) .

u

All appliances

Fit the anti-tip device (see 4.7) .

u

NOTICE

Moving the SBS combination may result in damage!

The assembled SBS combination is heavy. If not moved

properly, the appliance may become dented.

Read and follow the moving tips (see above).

u

Carefully push the combination into the designated

u

position.

Align the combination again if necessary using the

u

adjustment feet.

Lower thecentre adjustment feet

u

Fig. 22 (C)

again until

they touch the floor.

Then shore up the door: Lower theadjutment feet

u

Fig. 22 (A)

onto the bearing bracket until they contact

the floor then turn 90° again.

The door height can be

adjusted at the lower outside

bearing brackets:

Unscrew the threaded pin

u

Fig. 30 (17)

a little (no more

than one turn).

Fig. 28

On the top, press the short trim

u

Fig. 28 (13)

into the gap.

The trim must form a flush finish with the connecting

plate

Fig. 28 (3)

Snap the cover

u

on the front edge.

Fig. 28 (14)

onto the open space

between the two control panel trims. Make sure that the

outer surfaces of the cover form a flush finish with the

control panel trims. The cover can be extended for this

purpose.

Fig. 29

Position the lower cover

u

connecting panel

Fig. 29 (15)

Fig. 29 (5)

and snap it down into place.

from above onto the

To lift the door unscrew the bearing pin

u

Fig. 31 (18)

clockwise using the supplied open-end wrench

Fig. 31 (11)

. The appliance is delivered from the factory

with the bearing pin screwed in completely.

Screw the threaded pin

u

Fig. 30 (17)

in again to fix the

bearing pin.

4.5 Water connection*

WARNING

Electrical Shock Hazard!

Do not make the water connection while the appliance

u

is connected to an electrical outlet.

Disconnect the water supply before connecting the

u

water lines for the IceMaker.

The connection to the water supply may only be made

u

by a trained and licensed plumber.

Fig. 30

Fig. 31

* Depending on model and options 13

Start-up

WARNING

Poisoning Hazard!

The water quality must comply with the drinking water

u

regulations for the geographical area where the appliance is located.

Connect to potable water supply only.

u

The IceMaker is designed exclusively to make ice

u

cubes in quantities needed by a household and must

only be operated with water appropriate for this

purpose.

Water pressure:

psi MPa (bars)

21.76 to 87.02 0.15 to 0.6 (1.5 to 6)

If a water filter is used, the instructions on water pressure

in the Installing the water filter section apply.

- Water must be supplied to the appliance through a cold

water pipe that complies with hygiene standards and

can withstand the operating pressure.

- All devices and equipment used to supply water must

comply with the regulations in force in the respective

country.

- The solenoid valve is located at the bottom of the back

of the appliance. It has a metric R3/4 connecting

thread.

Have the water line bled (remove air) by a competent

u

professional.

NOTICE

Malfunction of the water intake!

If the water intake is shut off during operation but the

IceMaker remains in operation, the water intake pipe may

ice up.

Switch off the IceMaker if the water supply is inter-

u

rupted (e.g. holiday).

4.6 Installation into a fitted kitchen

Fig. 33

(1) Top cupboard (3) Kitchen cabinet

(2) Appliance (4) Wall

The appliance can be built into the range of kitchen units.

To bring the appliance

fitted kitchen units, a suitable top cupboard

Fig. 33 (2)

up to the height of the

Fig. 33 (1)

can

be added above the appliance.

When installing with kitchen cabinets (max.

depth. 22-27/32 '' (580 mm)) the appliance can be

installed right next to the kitchen cabinet

Fig. 33 (3)

. The

appliance door projects 1-11/32 '' (34 mm) at the side and

in the center of the appliance 1-31/32 '' (50 mm) from the

front of the kitchen cabinet. This allows it to open and

Remove the cap

u

Fig. 32 (2)

Ensure that the gasket

u

.

elbow connection

Connect the elbow adapter

u

valve

Fig. 32 (2)

Fig. 32 (1)

Fig. 32 (4)

and tighten with an open-ended

wrench, for example.

NOTICE

Risk of thread damage!

Do not overtighten.

u

Fig. 32

from the solenoid valve

Fig. 32 (3)

is inserted in the

supplied.

Fig. 32 (4)

to the solenoid

close properly.

Connect the domestic water supply

u

copper pipe) to the elbow connector

Fig. 32 (5)

Fig. 32 (4)

Before fitting into the cabinet:

Check the whole water system for leaks.

u

Before using for the first time:

14 * Depending on model and options

(e.g.

.

Ventilation requirements:

There must be a ventilation shaft at least 1-31/32 ''

-

(50 mm) deep at the back of the top cupboard over the

entire width of the top cupboard.

The cross section of the ventilation gap below the

ceiling must be at least 46.5 in 2 (300 cm 2).

The bigger the ventilation gap, the more energy-saving

the operation of the appliance.

If the appliance is installed with the hinges next to a wall

Fig. 33 (4)

must be at least 1-9/16 '' (40 mm). This is how far the

handle protrudes when the door is open.

, the gap between the appliance and the wall

4.7 Anti-tip device

The screws for fastening the anti-tip device are not

supplied with the appliance. Appropriate screws must be

used for the material (wood, concrete, etc.) in which the

safety device is mounted.

WARNING

Risk of injury if the appliance tips over!

Install the anti-tip device to prevent the appliance from

u

tipping over when the fully loaded door is open.

NOTICE

Risk of damage due to leaking water!

If the tilt safety device has been fitted in another position

than the one given, the water hoses may be damage

when pushing the appliance into the niche.

Only fit the tilt safety device in the position shown in the

u

diagram.

Start-up

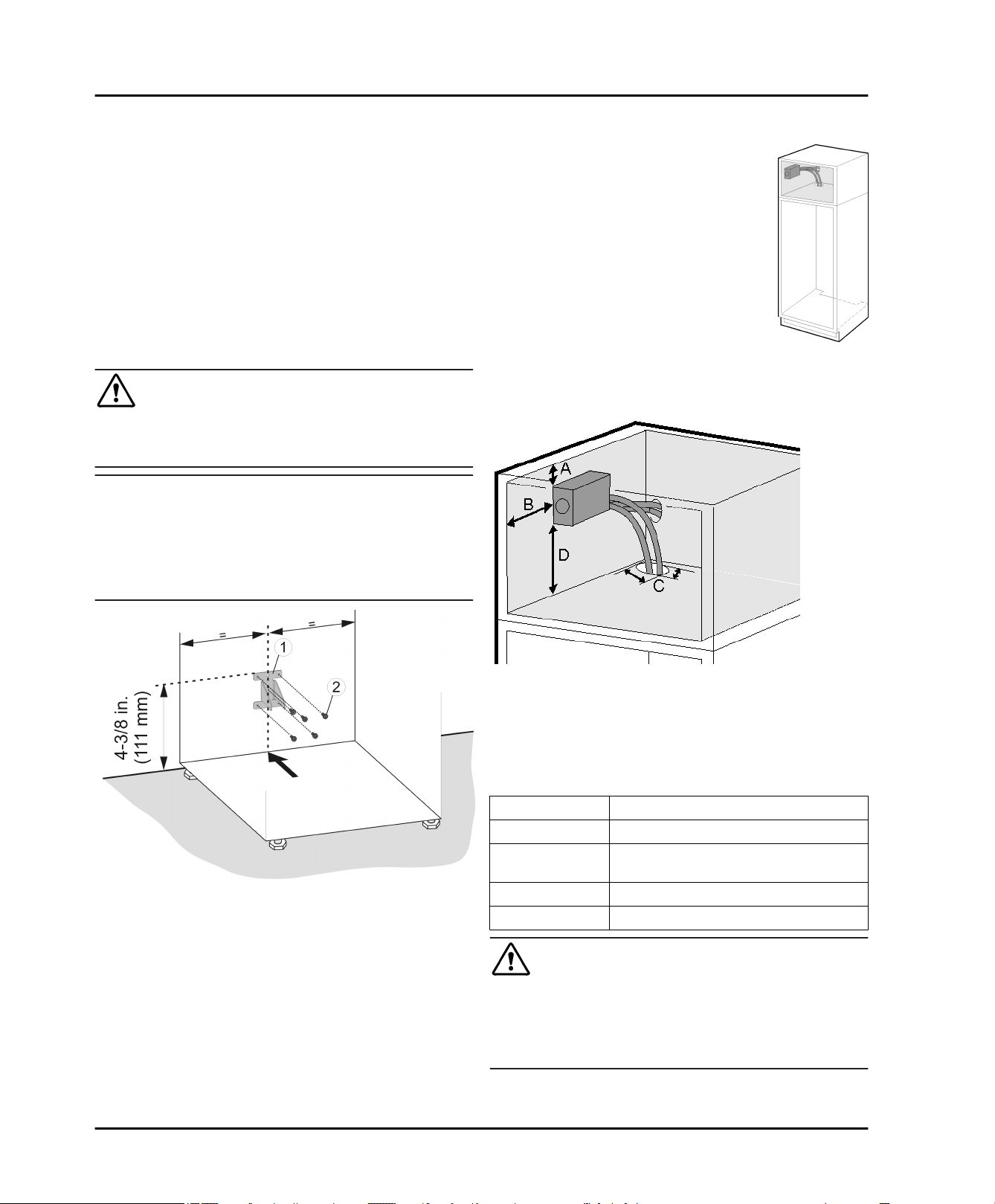

4.8 Installing the water filter*

The water filter ensures optimum water

quality and is available as an accessory. It

should be installed near the appliance in

the cabinet, for example in the adapter

cabinet above the appliance. To connect

the filter to the appliance, it may be necessary to make an opening (C) in the floor of

the adapter cabinet through which the

hoses will be routed. Depending on your

installation setup, you can route the two

water filter hoses either through the rear

panel or through the base of the cabinet.

The maximum length of the water hose

is118-1/8 '' (3 m).

Alternatively, the appliance can also be

operated without the water filter.

Mark the installation position for the anti-tip device on

u

the wall or back of the unit.

Install the anti-tip device

u

screws

Fig. 34 (2)

.

Fig. 34 (1)

using appropriate

Fig. 34

Fig. 35

(A) 13/16 in (20mm) (C) 1-3/16in. x 3/8in.

( 30mm x 10mm )

(B) 3-15/16 in (100mm) (D) min. 4 in (100mm)

The filter cover must be installed during assembly, so

leave sufficient space around the filter module. Maintain

the dimensions shown in

replaced and the cover can be removed.

Flow rate 0.5 gpm (1.89 lpm)

Water connection Drinking water

Water pressure 40 psi - 90 psi ( 2.8 bar - 6.2 bar/ 0.28 MPa

Water temperature 33 °F - 100 °F ( 0.6 °C - 37 °C )

Capacity 300 gal. (1.14 l)

WARNING

Consuming contaminants can be harmful to your health!

If there is a chance the water may contain harmful

u

bacteria or if the water quality is unknown, do not use

this system without appropriate disinfection measures

upstream or downstream of the system.

Fig. 35

- 0.62 MPa )

so that the filter can be

* Depending on model and options 15

Start-up

NOTICE

Leakage water may damage the system!

Do not install this system on hot water lines. The

u

maximum operating temperature of the water in this

system is 100 °F (37.7 °C).

This system MUST be installed and used in compli-

u

ance with federal and local installation regulations.

Do not install under water hammer conditions. A water

u

hammer arrestor must be used to prevent water

hammering. If you are unsure how to check these

conditions, consult a professional installer.

Do not install with a water pressure greater than 90 psi

u

(6.2 bar). If your water pressure exceeds 80 psi, install

a pressure limiting valve. If you are unsure how to

check the water pressure, consult a professional

installer.

Protect against frost; if temperatures below 33 °F

u

(0.6 °C) are expected, remove the filter.

When used as indicated, the disposable filter

u

cartridges must be replaced every 6 months or whenever you notice a considerable decrease in the flow

rate.

Disconnect the appliance from the mains.

q

Close off the main water supply if the appliance has

q

already been connected to the tap.

Position appliance in front of the recess.

q

Make sure the hoses do not become kinked and the

cross-section of the hose remains round.

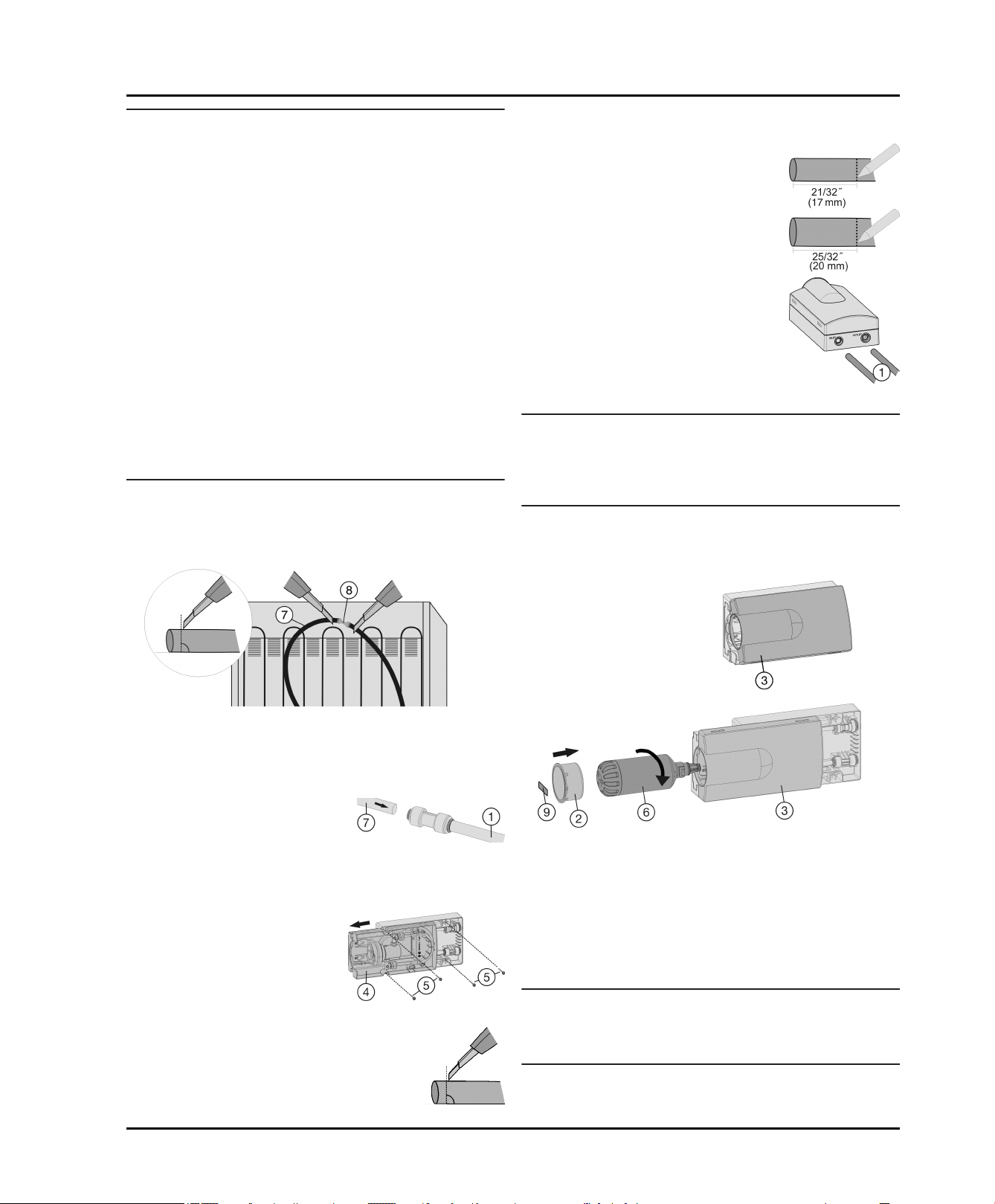

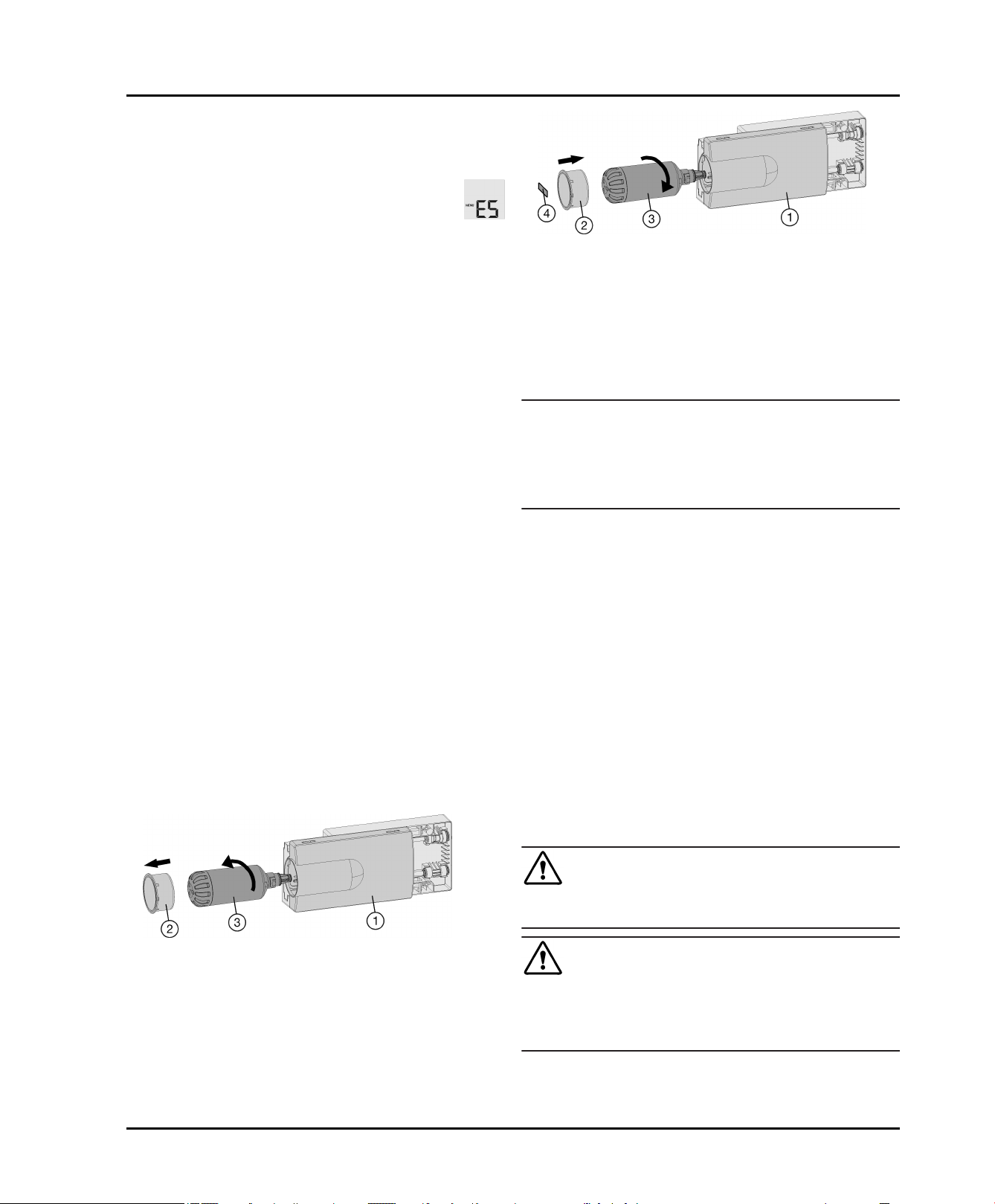

On the thin hose measure the inser-

u

tion depth (E) of 21/32 '' (17 mm) and

make a mark.

On the thick hose measure the inser-

u

tion depth (E) of 25/32 '' (20 mm) and

make a mark.

Insert the hoses

u

Fig. 39 (1)

into

the water filter module as far

as they will go (i.e. to the mark

you made) past the point of

resistance.

Fig. 39

Note

If you need to disassemble the unit: Push back the dark

u

grey ring on the connector and hold it in this position.

While still holding the ring back, briefly push the hose

into the connector, then pull it out.

Insert the power cable into the socket (see 4.10) .

u

Connect appliance to the water supply (see 4.5) .

u

Make sure the filter is leak-tight and no water is coming

u

out.

Place the tray cover

u

Fig. 41 (3)

into position.

Fig. 36

Slice open the water hose

u

Fig. 36 (7)

located behind the

appliance both in front of and behind the connector

Fig. 36 (8)

(90° to direction of hose).

When doing so, make sure the hose does not become

kinked and the cross-section of the hose remains round.

Connect the supplied exten-

u

sion hoses

Fig. 37 (1)

appliance hoses

Slide the appliance hoses

to the

Fig. 37 (7)

:

Fig. 37

into the connectors as far as

they will go (approx. 25/32 ''

(20 mm)).

Pull the tray

u

Fig. 38 (4)

out

until it catches.

Secure the module with 4

u

screws

Fig. 38 (5)

through

the recesses in the front

and directly through the

module in the back.

Shorten hoses if necessary (90° to direc-

u

Fig. 38

tion of hose). The hoses should be long

enough to allow the appliance to be

pulled out of the recess even when it is

connected to the water filter.

Fig. 41

Remove the film from the water filter

u

Insert the water filter

u

Fig. 41 (6)

Fig. 41 (6)

and turn it approximately

.

100° to the right until it locks into position.

Place the cover on the filter

u

Slide the tray in.

u

Write the date of the next filter replacement on the

u

supplied adhesive label

Fig. 41 (2)

Fig. 41 (9)

.

and affix it to the

module.

Note

New water filters may contain particulate matter.

Do not consume or use ice cubes produced within 72

u

hours after replacing the filter.

The water filter is now ready for use.

w

Fig. 40

16 * Depending on model and options

NOTICE

Risk of damage due to leaking water!

When pushing the appliance into the recess ensure

u

that the water connection does not bend or become

damaged.

4.9 Disposal of packaging

WARNING

Danger of suffocation from packaging materials and films!

Do not allow children to play with packaging materials.

u

The packaging is made from recyclable materials:

Corrugated card/cardboard

Parts made of foamed polystyrene

Films and bags from polyethylene

Packing bands from polypropylene

Wood frame nailed together with a polyethylene

window*

Take the packaging material to an official collection

u

point.

4.10 Connecting the appliance

WARNING

Electrical shock hazard!

Start-up should only take place once the appliance has

u

been installed according to these instructions.

Electrically ground appliance.

u

Do not ground to a gas pipe.

u

Check with a qualified electrician if you are not sure the

u

appliance is properly grounded.

Do not have a fuse in the neutral or grounding circuit.

u

Do not use an extension cord, power bar or a multiple

u

socket adapter.

Do not use a power cord that is frayed or damaged.

u

Operation

Follow all Federal, State and local electrical, fire and

building codes and ordinances when installing the

receptacle and / or the appliance.

In some communities, a wall switch is required to turn

power to the appliance ON and OFF.

To reduce the risk of fire, electric shock, or personal

injury, installation work and electrical wiring must be

done by a qualified electrician in accordance with all

applicable codes and standards, including fire-rated

construction.

The Power Plug must be easily accessible so that the

appliance can be disconnected from the mains quickly

in an emergency. It must not be behind the back of the

appliance.

4.11 Switching on the appliance

Note

To switch on the entire appliance, only the freezer

u

compartment needs to be switched on.

Switch on the appliance 2 hours before loading

with frozen food for the first time.

Do not load frozen foods until the temperature

display reads 0 °F (-18 °C).

4.11.1 Switching on the freezer compart-

ment

Press On/Off button, freezer compartment

u

The fridge compartment temperature display shows the

w

current temperature in the interior.

The freezer compartment temperature display and the

w

Alarm symbol will flash until the temperature is cold

enough. If the temperature is greater than 32 °F (0 °C),

flashing dashes will appear; if the temperature is lower

than this, the current temperature will flash on the

display.

Whenever “DEMO” appears on the display, the appli-

w

ance is running in demonstration mode. Contact the

customer service department.

Fig. 4 (13)

.

WARNING

Electrical shock hazard!

This appliance is equipped with a three-prong (grounding)

polarized plug for your protection against possible shock

hazards. Electrical Grounding Required.

Do not remove the round grounding prong from the

u

plug.

Use only an grounded adapter.

u

Wait 1 hour after installation before you plug in the

appliance. This allows the refrigerant and system lubrication to reach equilibrium.

Make sure incoming voltage is the same as the appli-

ance rating. A 110-120 Volt, 60 Hz, 15 Amp electrical

supply (20 Amp for side-by-side installations) circuit

that is controlled by a circuit breaker or fuse is required.

We recommend using a dedicated circuit for this appli-

ance to prevent electrical overload.

* Depending on model and options 17

4.11.2 Switching on the fridge compartment

Press Fridge compartment On/Off button

u

The interior light comes on when the door is opened.

w

The temperature display flashes. The fridge compart-

w

ment is switched on.

Fig. 4 (3)

.

5 Operation

5.1 Temperature display unit

The temperature display can be changed from °F to °C.

5.1.1 To change the unit

Activate setting mode: Press SuperFrost button

u

Fig. 4 (14)

w

S is displayed in the temperature display.

for about 5 seconds.

Operation

The Menu symbol

w

Using Freezer compartment Up button

u

Fig. 4 (11)

Fig. 4 (12)

To confirm: Briefly press SuperFrost button

u

Fig. 4 (14)

Using Freezer compartment Up button

u

Fig. 4 (11)

Fig. 4 (12)

To confirm: Briefly press SuperFrost button

u

Fig. 4 (14)

To exit setting mode: Press Freezer compartment

u

On/Off button

-or-

Wait 5 minutes.

u

The temperature is again displayed in the temperature

w

display.

/ Freezer compartment Down button

select °.

.

/ Freezer compartment Down button

select °F or °C.

.

Fig. 4 (19)

Fig. 4 (13)

lights up.

.

5.2 Brightness of the temperature display

You can adapt the brightness of the temperature display

to the light conditions in the room in which it is installed.

If the door is open or the control panel is used the temperature indicator lights up at maximum brightness. About 1

minute after the door is closed or no button has been

pressed on the control panel, the temperature display

goes back to the set brightness.

5.2.1 Setting the brightness

The brightness can be set between h0 (minimum luminosity) and h5 (maximum luminosity).

To activate setting mode: Press SuperFrost button

u

Fig. 4 (14)

w

S is shown on the display.

The Menu symbol

w

Press Freezer compartment Up button

u

Freezer compartment Down button

h.

To confirm: Briefly press SuperFrost button

u

To set the display brighter: Press Freezer

u

compartment Up button

To set the display darker: Press Freezer

u

compartment Down button

To confirm: Press SuperFrost button

u

Fig. 4 (14)

The brightness is set to the new value.

w

To deactivate setting mode: Press Freezer compart-

u

ment On/Off button

-or-

Wait 5 minutes.

u

The temperature is again displayed in the temperature

w

display.

for about 5 seconds.

Fig. 4 (19)

.

Fig. 4 (13)

lights up.

Fig. 4 (11)

Fig. 4 (12)

.

Fig. 4 (12)

.

.

Fig. 4 (11)

to select

Fig. 4 (14)

or

.

5.3 Child-proof lock

You can use the child-proof lock to lock the

buttons. This means that children cannot accidentally switch off the appliance when playing.

5.3.1 Switching on the child-proof lock

Activate setting mode: press and hold the SuperFrost

u

Fig. 4 (14)

button

w

S is shown on the display.

The Menu symbol

w

Using the Freezer compartment Up button

u

Freezer compartment Down button

Press the SuperFrost button

u

confirm.

When c1 is shown on the display:

To switch on the child-proof lock, press the

u

SuperFrost button

w

The Child lock symbol

flashes on the display.

When c0 is shown on the display:

To switch off the child-proof lock, press the SuperFrost

u

button

Fig. 4 (14)

w

The Child safety symbol

flashes on the display.

Deactivate setting mode: press the Freezer compart-

u

ment On/Off button

-or-

Wait 5 min.

u

The temperature is again displayed on the temperature

w

display.

for approximately 5 s.

Fig. 4 (19)

Fig. 4 (14)

briefly.

Fig. 4 (13)

lights up.

Fig. 4 (14)

briefly.

Fig. 4 (16)

Fig. 4 (16)

.

Fig. 4 (12)

LED lights up. c

Fig. 4 (11)

, select c.

briefly to

LED goes out. c

or

5.4 Door alarm

If the door is open for longer than 180 seconds,

the acoustic warning sounds.

The acoustic warning stops automatically when

the door is closed.

5.4.1 Switching off the door alarm

The acoustic warning can be switched off when the door

is open. The acoustic warning remains switched off as

long as the door is open. When the door is closed, the

alarm function is active again.

Press Alarm button

u

The door alarm stops.

w

Fig. 4 (15)

.

5.5 Temperature alarm

If the freezer temperature is not cold enough,

the audible warning sounds.

At the same time, the temperature display and

the Alarm symbol

Fig. 4 (9)

LED will flash.

The cause of a temperature being too high may be:

Hot fresh food was placed in the appliance.

-

18 * Depending on model and options

Operation

When sorting and removing food from the appliance,

too much warm ambient air got in.

The power was cut off for a while.

The appliance is faulty.

-

The audible warning automatically ceases, the Alarm

symbol

stops flashing when the temperature is cold enough

again.

If the alarm status remains: (see Troubleshooting).

Note

If the temperature is not cold enough, food may spoil.

u

Fig. 4 (9)

Check the quality of the food. Do not consume spoiled

food.

goes out, and the temperature display

5.5.1 Switching off the temperature alarm

The acoustic warning can be switched off. When the

temperature is cold enough again, the alarm function is

active again.

Press Alarm button

u

The acoustic warning ceases.

w

Fig. 4 (15)

.

5.6 Sabbath Mode

After entering Sabbath Mode, you do not have to worry

about lights, digits, icons, tones, alarms or fans. The

defrost cycle operates solely on clock time without any

feedback from usage of the refrigerator. After a power

failure, the appliance will return to Sabbath Mode without

requiring additional input.

w

S flashes on the display.

The Menu symbol

w

To access the Sabbath mode function: Briefly press

u

theSuperFrost button

When S1 is shown on the display:

To turn on Sabbath mode, briefly press the

u

SuperFrost button

When S0 is shown on the display:

To turn off Sabbath mode, briefly press the

u

SuperFrost button

To deactivate setting mode: Press the Freezer

u

compartment On/Off button

-or-

Wait 5 min.

u

The Sabbath Mode symbol

w

temperature display as long as Sabbath Mode is active.

Sabbath mode switches off automatically after 120

w

hours if it is not manually switched off beforehand.

Fig. 4 (19)

Fig. 4 (14)

Fig. 4 (14)

lights up.

Fig. 4 (14)

.

.

Fig. 4 (13)

Fig. 4 (18)

.

.

appears on the

5.7 Fridge compartment

The natural circulation of air in the refrigerator compartment results in zones with differing temperatures. It is

coldest directly above the vegetable drawers and at the

rear wall. It is warmest at the top front of the compartment

and in the door.

5.7.1 Refrigerating food

Note

Do not load the door with more than 40 lbs (18 kg) of

u

food.

WARNING

Danger of food poisoning!

No record will be kept of a power failure during Sabbath

Mode. Thus, during Sabbath mode, if a power failure

occurs that you are not aware of, when the power comes

back on, the unit will continue to be in Sabbath Mode but

when Sabbath Mode is ended there will be no indication

that a power failure occurred.

If a power failure occurs during Sabbath mode:

Check the quality of the food. Do not consume spoiled

u

food!

No control operations are possible other than switching

off Sabbath Mode.

If the unit is currently running in a mode such as Super-

frost, Supercool or the Ventilation is enabled these

functions will continue and finish their timed cycles

independent of now being in Sabbath mode.

The Ice Maker is disabled.*

No audible signals are emitted, and the temperature

display does not indicate any warnings or settings

(such as a temperature alarm or door alarm).

Light does not operate.

-

5.6.1 Setting Sabbath mode

To activate setting mode: Press and hold the Super-

u

Frost button

Fig. 4 (14)

for approx. 5 s.

Note

Insufficient ventilation results in an increase in energy

consumption and reduction of the refrigerating performance.

Never block the air slits in the fan.

u

Use recyclable plastic, metal, aluminum and glass

u

containers and cling film to wrap foods.

Always use closed containers for liquids and for food

u

that may give off or be tainted by odor or flavor transfer

or cover them.

Foods which give off a large amount of ethylene gas

u

and those that are sensitive to this gas, such as fruit,

vegetables and salad, should always be separated or

wrapped so as not to reduce the storage life; for

example, do not store tomatoes together with kiwi fruits

or cabbage.

Do not store food too close together to enable sufficient

u

air circulation.

To ensure bottles do not tip over: move the bottle

u

holder.

5.7.2 Setting the temperature

The temperature depends on the following factors:

the number of times the door is opened

the room temperature of the installation location

-

* Depending on model and options 19

Operation

the type, temperature and amount of food.

The temperature can be set from 35 °F (2 °C) to 45 °F

(7 °C), 41 °F (5 °C) is recommended.

To set a higher temperature: press the Fridge compart-

u

ment Up button

To set a lower temperature: press the Fridge compart-

u

ment Down button

When pressed once the previously set fridge compart-

w

ment temperature display value will flash.

To change the temperature in 1 °F (1 °C) increments:

u

briefly press the button.

To change the temperature continuously: hold the

u

button down.

The value is displayed flashing during the setting oper-

w

ation.

The actual temperature is displayed about 5 seconds

w

after the last press of a button. The temperature slowly

adjusts to the new value.

5.7.3 SuperCool

With SuperCool you switch to the highest cooling

performance to reach lower cooling temperatures. Use SuperCool to rapidly cool large quantities of food.

If SuperCool is on, the fan* may come on. The appliance

works at maximum refrigerating power. The sound of the

refrigeration unit may be temporarily louder as a result.

SuperCool will use more energy than normal operation.

Fig. 4 (4)

Fig. 4 (5)

.

.

Switching on the fan

Briefly press Ventilation button

u

The Ventilation symbol

w

The fan is on. On some appliances it only switches on

w

when the compressor is running.

Switching the fan off (default)

Briefly press Ventilation button

u

The Ventilation symbol

w

The fan is switched off.

w

Fig. 4 (17)

Fig. 4 (17)

Fig. 4 (1)

Fig. 4 (1)

.

LED lights up.

.

LED goes out.

5.7.5 Shelves

Shifting or removing shelves

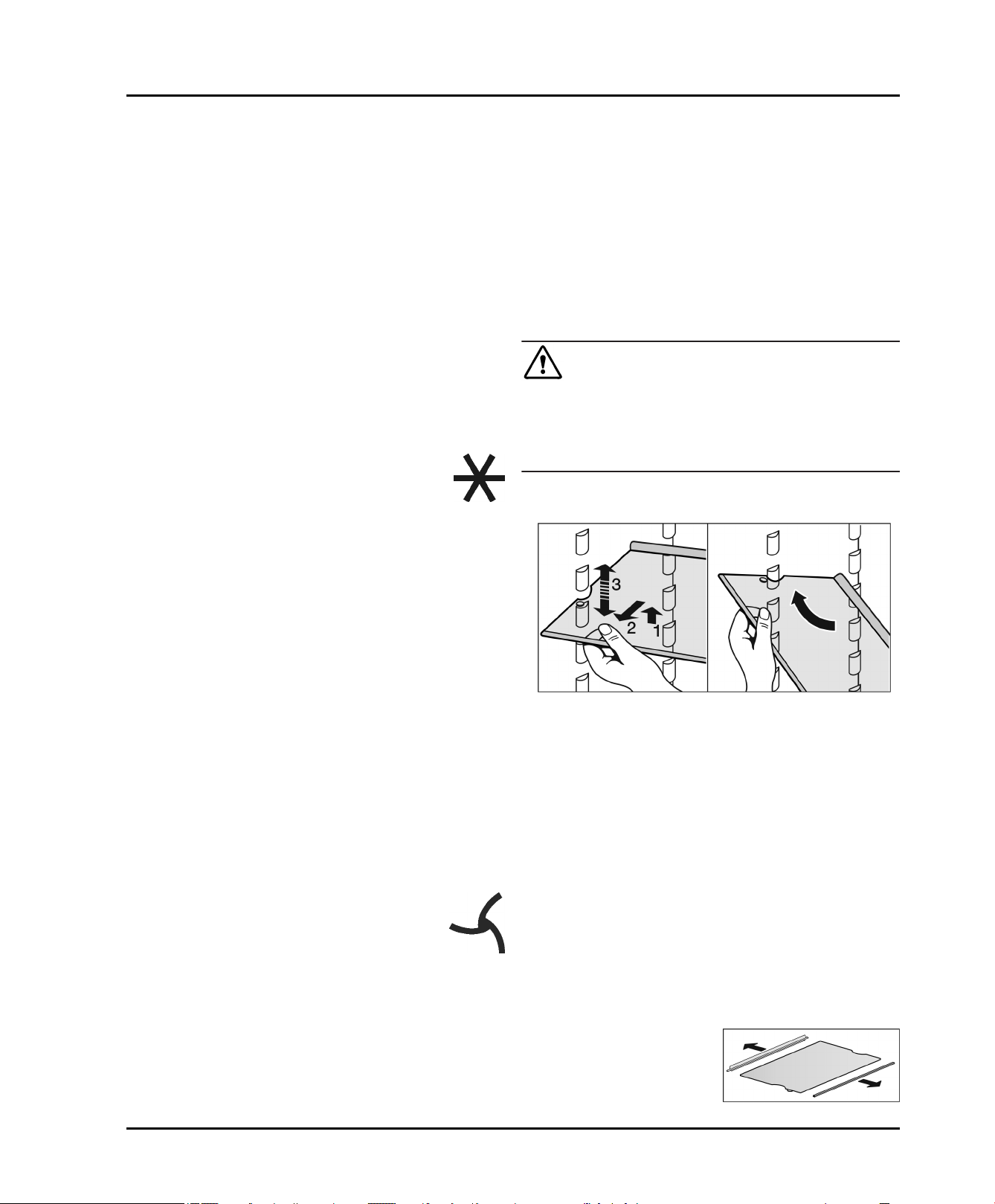

CAUTION

Danger of lacerations!

The storage shelf can shatter if dropped or mishandled.

You could cut yourself on the pieces of broken glass.

Only remove storage shelves when there is nothing on

u

them.

Extension stops secure the shelves against being accidentally pulled out.

Cooling with SuperCool

Briefly press the SuperCool button

u

The SuperCool symbol

w

display.

The cooling temperature drops to the coldest value.

w

SuperCool is switched on.

SuperCool automatically switches itself off after about

w

6-12 hours. The appliance returns to work in the

energy-saving normal mode.

To prematurely switch off SuperCool

Briefly press the SuperCool button

u

The SuperCool symbol

w

display.

SuperCool is switched off.

w

Fig. 4 (6)

Fig. 4 (6)

Fig. 4 (2)

LED lights up on the

Fig. 4 (2)

LED goes out on the

.

.

5.7.4 Fan

The fan allows you to rapidly cool large amounts

of fresh food or to achieve a relatively even

distribution of temperature across all the storage

levels.

Re-circulated air cooling is advisable:

at high room temperatures (from approx. 95 °F

(35 °C) )

in the case of high humidity

-

Re-circulated air cooling has a somewhat higher energy

consumption. To save energy, the fan automatically

switches off when the door is open.

Fig. 42

Lift up the shelf and pull it slightly forward.

u

Adjust the shelf height by shifting the spacers in the

u

runners.

Insert the short shelf at the height of the gallon capacity

u

rack so that door closes properly. It is supported on

support bars.

To remove the shelf completely, set it at an angle and

u

pull it out towards you.

Insert the shelf with the raised edge to the back

u

pointing upwards.

This prevents food from contacting and freezing to the

w

back wall.

The bottle holder offers additional storage for bottles

(maximum height 11-13/16 '' (300 mm)). It fits onto the

same supports as the other racks.

Insert the bottle holder into any position, but not right at

u

the bottom.

To dismantle shelves

The shelves can be

u

dismantled for cleaning.

20 * Depending on model and options

Operation

5.7.6 Using the split shelf

CAUTION

Danger of lacerations!

The storage shelf can shatter if dropped or mishandled.

You could cut yourself on the pieces of broken glass.

Only remove storage shelves when there is nothing on

u

them.

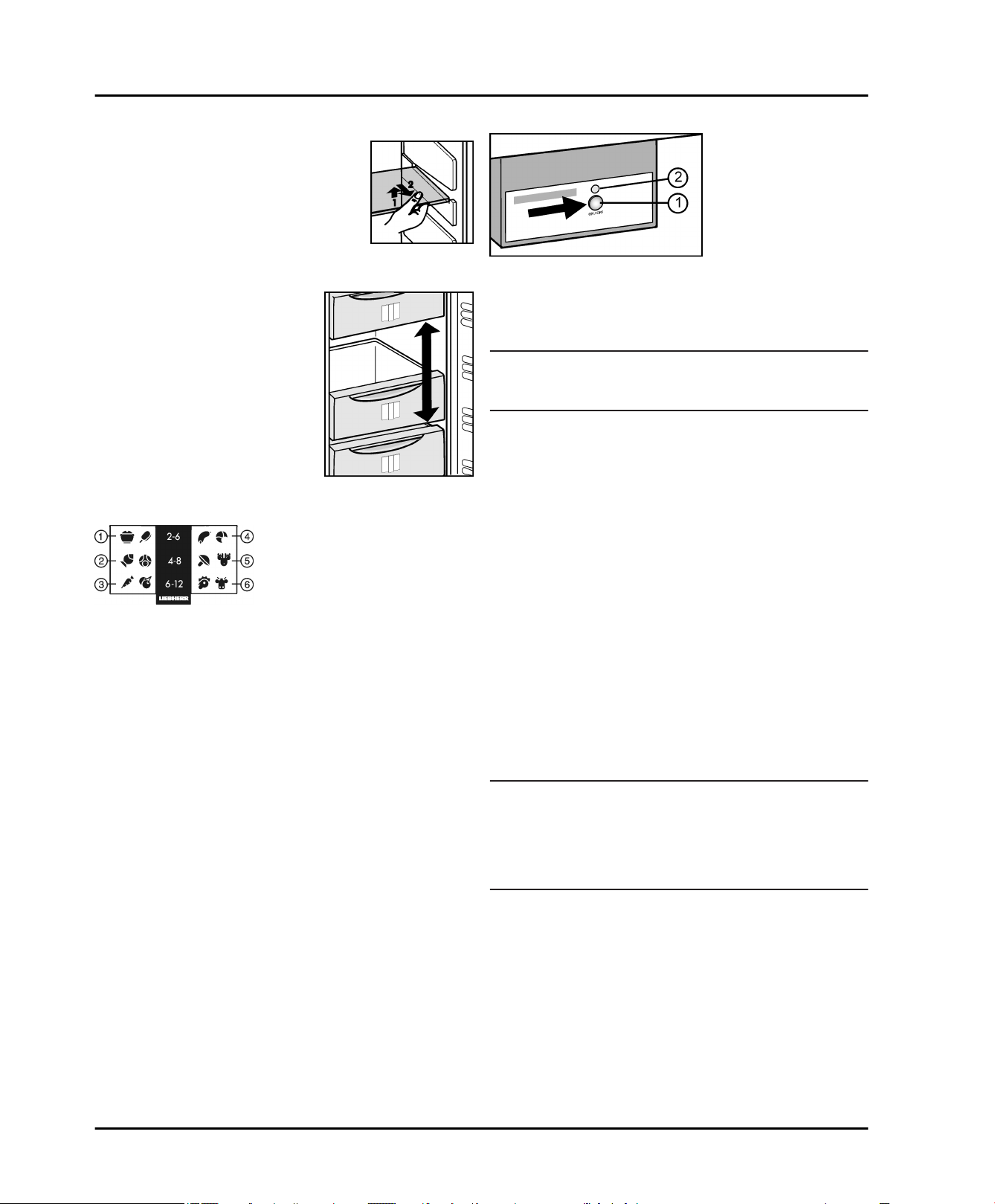

Fig. 43

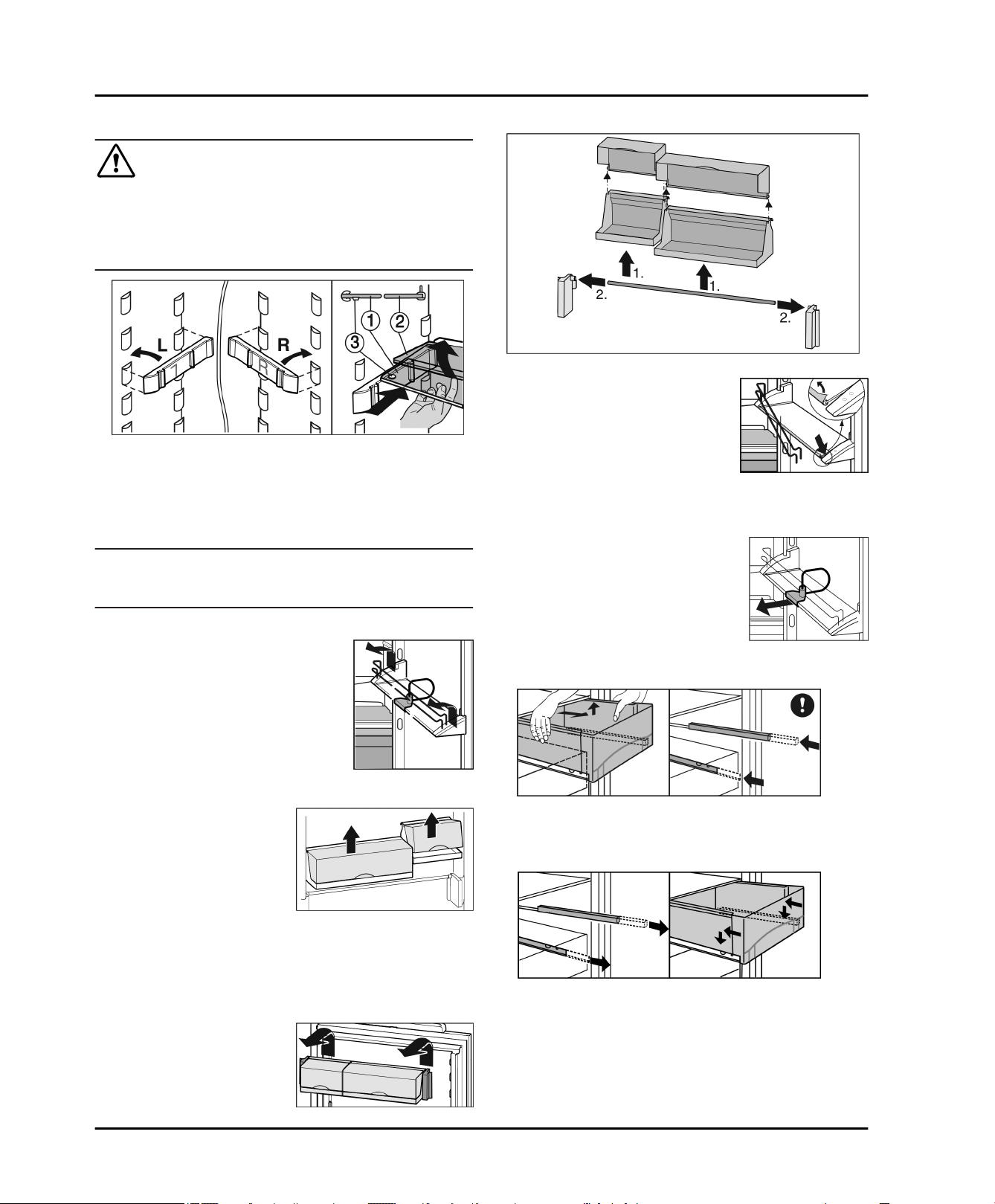

Attach support bars supplied, ensuring right (R) and left

u

(L) parts are correctly positioned.

The glass shelf with stop face (2) has to be at the back.

u

5.7.7 Door racks

Note

Do not load the door with more than 40 lbs (18 kg) of

u

food.

To dismantle door racks

Fig. 44

The door racks can be dismantled for cleaning.

u

5.7.8 Removing the bottle holder

Always take hold of the bottle

u

holder by the plastic part.

Repositioning the door racks

Push rack up, pull forward, and reinsert in the reverse

u

order.

The container trays can be

removed and placed on the

table as a unit.

Instead of one wide container and one small container, a

special set containing three small containers is available

from Customer Service.

It is possible to use one or both boxes. If unusually tall

bottles are to be stored, only suspend one box above the

bottle rack.

To swap containers: pull

u

up to remove and reinsert

in the desired position.

5.7.9 Vegetable drawers

To remove the vegetable drawers:

Pull the vegetable drawer completely out and tilt it

u

slightly forward.

Push the protruding telescopic rails back in.

u

To insert the vegetable drawers:

Place the vegetable drawer on the telescopic rails and

u

slide it back while applying light pressure.

Fig. 45

Fig. 46

* Depending on model and options 21

Operation

5.8 Freezer compartment

You can store frozen food, make ice cubes and freeze

fresh food in the freezer compartment.

5.8.1 Freezing food

The actual temperature is displayed about 5 seconds

w

after the last press of a button. The temperature slowly

adjusts to the new setting.

5.8.4 SuperFrost

Each drawer can hold up to 55.12 lbs (25 kg) of frozen

food; each plate can hold up to 77.16 lbs (35 kg).

CAUTION

There is a risk of injury from pieces of broken glass.

Bottles and cans containing drinks can split or crack when

frozen. This applies in particular to carbonated drinks.

Do not freeze bottles and cans containing drinks.

u

So that the food is rapidly frozen through to the core, do

not exceed the following quantities per pack:

- fruit, vegetables up to 2.2 lb (1 kg)

- meat up to 5.51 lbs (2.5 kg)

Pack the food in portions in freezer bags, reusable

u

plastic, metal or aluminum containers.

5.8.2 Defrosting food

- in the fridge compartment

- in the microwave

- in the oven/fan oven

- at room temperature

WARNING

Danger of food poisoning!

Do not re-freeze defrosted food.

u

Only take out the amount of food that is required. Use

u

defrosted food as quickly as possible.

5.8.3 Setting the temperature in the freezer

compartment

The appliance is set as standard for normal operation.

The temperature can be set between 7 °F (-14 °C) and

-16 °F (-26 °C), 0 °F (-18 °C) is recommended.

To set a higher temperature: press the Freezer

u

compartment Up button

To set a lower temperature: press the Freezer compart-

u

ment Down button

When the button is pressed for the first time, the

w

previous value is indicated on the freezer compartment

temperature display.

To change the temperature in 1 °F (1 °C) increments:

u

briefly press the button.

-or-

To change the temperature continuously: hold the

u

button down.

The value is displayed flashing during the setting oper-

w

ation.

Fig. 4 (11)

Fig. 4 (12)

.

.

Depending on how much fresh food is to be frozen you

must switch SuperFrost on in advance - for a small

amount of food to be frozen, about 6 hours, for the

maximum amount about 24 hours before putting the food

in.

You do not need to switch SuperFrost on in the following

cases:

when placing frozen food in the freezer

when freezing up to about 2 kg of fresh food a day

-

Freezing with SuperFrost

Briefly press the SuperFrost button

u

The SuperFrost symbol

w

The freezing temperature drops and the appliance

w

operates at its maximum refrigeration power rating.

When a small amount of food is to be frozen.

Wait approx. 6 hrs.

u

Place packaged food in the upper drawers.

u

When the maximum amount of food is to be frozen.

Wait approx. 24 hrs.

u

Remove upper drawers and place the food directly

u

onto the upper shelves.

SuperFrost is automatically switched off. At the earliest

w

after 30 hours, at the latest after 65 hours, depending

on the quantity placed inside the appliance.

The LED for the SuperFrost symbol

w

when the freezing process is complete.

Place food inside the drawers and push them closed

u

again.

The appliance returns to work in the energy-saving

w

normal mode.

Fig. 4 (21)

Fig. 4 (14)

LED lights up.

Fig. 4 (21)

once.

goes out

5.8.5 Drawers

Note

Insufficient ventilation results in an increase in energy

consumption and reduction of the refrigerating performance.

For appliances with NoFrost:

Leave the bottom drawer in the appliance.

u

Never block the air slits in the fan on the rear wall.

u

To store frozen food directly on the shelves: pull the

u

drawer forward and lift it out.

22 * Depending on model and options

Operation

5.8.6 Shelves

To remove shelf: lift it at the front and

u

pull out forward.

To reinsert shelf: simply slide it in as

u

far as it will go.

5.8.7 VarioSpace

In addition to the drawers, you

can also take out the shelves.

This gives you space for large

frozen items. Poultry, meat, large

joints of game and tall bakery

items can be frozen and then

presented whole.

Each drawer can hold up to

u

55.12 lbs (25 kg) of frozen

food; each plate can hold up to

77.16 lbs (35 kg).

5.8.8 Info system

Fig. 47

(1) Ready meals, ice

cream

(2) Pork, fish (5) Game, mushrooms

(3) Fruit, vegetables (6) Poultry, beef/veal

The numbers indicate the storage time in months for

different types of frozen foods. The storage times given

are guidelines.

(4) Sausages, bread

5.8.9 IceMaker*

The IceMaker is in the top drawer. The drawer is labeled

“IceMaker”.

Make sure that the following conditions are fulfilled:

The appliance is level.

The appliance is connected to the electricity supply.

The freezer compartment is switched on.

The minimum freezer temperature is 14 °F (-10 °C).

The IceMaker is connected to the water supply.

All air was bled from the waterline before starting the