LG K3P-07AS, K3P-07BS, K3P-07CS, MASTER-K200S Datasheet

LG Programmable Logic Controller

MASTER-K200S

CPU Module

K3P-07AS

K3P-07BS

K3P-07CS

●●●●

Beijing Branch

●●●●

Bangkok Branch

LG Industrial Systems LG Industrial Systems (Thailand)

Elevator Co., Ltd. Co., Ltd

T : +86-10-6462-3256 T : +66-2-381-8443

F : +86-10-6462-3255 F : +66-2-381-8445

●●●●

Bogota Branch

●●●●

Chicago Branch

LG Industrial Systems de LG Industrial Systems Co., Ltd.

Colombia S.A. Chicago Office

T : +57-1-310-6077 T : +1-708-692-4500

F : +57-1-310-5831 F : +1-708-692-4501

●●●●

Dalian Branch

●●●●

Hanoi Branch

Dalian LG Industrial Systems LG Industrial Systems Co., Ltd.

Co., Ltd. Hanoi Office

T : +86-411-281-2579 T : +64-4-821-0388

F : +86-411-281-2578 F : +64-4-821-0399

●●●●

Hong Kong Branch

●●●●

Shanghai Branch

LG Industrial Systems (HK) Ltd. Shanghai LG Industrial Systems Co., Ltd.

T : +852-2598-6615 T : +86-21-6248-2710

F : +852-2598-7105 F : +86-216248-3236

●●●●

Singapore Branch

●●●●

Taipei Branch

LG Industrial Systems Co., Ltd. LG Industrial Systems (Taiwan) Co. Ltd.

T : +65-323-7361 T : +886-2-516-5010

F : +65-323-7362 F : +886-2-516-5035

●●●●

Tokyo Branch

LG Industrial Systems Co., Ltd. Tokyo Office

T : +81-3-3589-6362

F : +81-3-3588-1810

LG Industrial Systems Co., Ltd.

●●●●

Head Office

LG Mullae Building 9

th

F, 10, Mullae-dong 6-ga, Yongdungpo-gu, Seoul, KOREA

Tel : +82-2-2006-3751~6 Fax : +82-2-2006-3951

Home page : http:www.lgis.lg.co.kr/fa

702006186

Before handling the product

Read this data sheet carefull y prior to any operation, m ounting, installation or

start-up of the product.

Materials for MASTER-K

Name Code

MASTER-K KGL-WIN (Programming software) 702005036

MASTER-K (Instructions & Programming) 702006539

MASTER-K CPU User’s Manual 702006391

❏❏❏❏

Safety Precautions

Be sure to read carefully the safety precautions given in data sheet and user’s manual before

operating the module and follow them.

The precautions explained here only apply to the MASTER-K 200S CPU module. For safety

precautions on the PLC system, see the MASTER-K CPU User’s manual.

A precaution is given with a hazard alert triangular symbol to call your attention, and

precautions are represented as follows according to the degree of hazard..

!

!

However, a precaution followed with ‘Caution’ can also result in serious conditions.

Both of two symbols indicate that an important content is mentioned, therefore, be sure

to observe it. Keep this manual handy for your quick reference in necessary.

❏❏❏❏

Design Precautions

❏❏❏❏

Installation Precautions

❏❏❏❏

Wiring Precautions

Make sure that FG the terminal is grounded with class 3 grounding which is

dedicated to the PLC. Otherwise, it can cause disorder or malfunction of PLC.

Before the PLC wiring, be sure to check the rated voltage and terminal

arrangement for the module and observe them correctly. If a different power, not of

the rated voltage, is applied or wrong wiring is provided, it can cause a fire or

disorder of the module.

Drive the terminal screws firmly to the defined torque. If loosely driven, it can cause

short circuit, a fire or malfunction.

Be careful that any foreign matter like wire scraps should not enter into the module.

It can cause a fire, disorder or malfunction.

❏❏❏❏

Test RUN and maintenance precautions

❏❏❏❏

Waste Disposal Precaution

This data sheet provides brief information about characteristics, configuration, and usage of

MASTER-K200S CPU modules (K3P-07AS, K3P-07BS, K3P-07CS).

No Item Specifications Standard

1

Operating

temperature

0 ~ 55℃

2

Storage

temperature

-25 ~ 70℃

3

Operating

Humidity

5 ~ 95%RH, non-condensing

4

Storage

humidity

5 ~ 95%RH, non-condensing

Occasional vibration

Frequency Acceleration Amplitude

Sweep

count

10≤f∠57 Hz

- 0.075 mm

57 ≤f≤150 Hz 9.8㎨ {1G}

-

Continuos vibration

Frequency Acceleration Amplitude

10≤f∠57 Hz

- 0.035 mm

5 Vibration

57≤f≤150 Hz 4.9㎨{0.5G}

-

10 times

in each

direction

for

X, Y, Z

IEC 1131-2

6 Shocks

*Maximum shock acceleration: 147㎨ {15G}

*Duration time :11 ms

*Pulse wave: half sine wave pulse

( 3 times in each of X, Y and Z directions )

IEC 1131-2

Square wave

impulse noise

±

1,500 V

Electrostatic

discharge

Voltage :4kV(contact discharge)

IEC 1131-2

IEC 801-2

Radiated

electromagnetic field

27 ~ 500 MHz, 10 V/m

IEC 1131-2

IEC 801-3

Severity

Level

All power

modules

Digital

I/Os

( Ue

≥

24 V)

Digital I/Os

(Ue < 24 V)

Analog I/Os

communication

I/Os

7

Noise

immunity

Fast transient burst

noise

Voltage 2 kV 1 kV 0.25 kV

IEC 1131-2

IEC 801-4

8 Atmosphere Free from corrosive gases and excessive dust

9

Altitude for

use

Up to 2,000m

10

Pollution

degree

2 or lower

11

Cooling

method

Self-cooling

Specifications

Items

K3P-07AS, K3P-07BS, K3P-07CS

Remark

Operation method

Cyclic operation of stored program

Time driven operation, Interrupt operation

I/O control method

Scan synchronized batch processing

method (Refresh method)

Programming Language

Ladder Diagram (LD)

Instruction List (IL)

Basic

instructions

30

Numbers

of

instructions

Application

instructions

218

Execution Time

0.5㎲/step

Program memory capacity 7k steps

Max. I/O points 256 points

P(I/O Relay) P000 ~ P15F (256 points)

M(Auxiliary Relay) M0000 ~ M191F (3,072 points)

K(Keep Relay) K000 ~ K31F (512 points)

L(Link Relay) L000 ~ L63F (1,024 points)

F(Special Relay) F000 ~ F63F (1,024 points)

T(Timer) T000 ~ T255 (256 points)

C(Counter) C000 ~ C255 (256 points)

S(Step Controller) S00.00 ~ S99.99 (100 x 100 steps)

Memory

Device

D(Data Register) D0000 ~ D4999 (5000 words)

Timer (5 type)

On Delay, Off Delay, Integrating, Monos-

table ,Retriggerable

Counter (6 type) Up, Down, Up-Down, Ring

Operation mode RUN,STOP,PAUSE,DEBUG

Self-diagnostic functions

Memory error detection, I/O error detection,

Operation delay monitoring etc.

Internal current consumption 0.17A

Weight (㎏)

0.11

1) Cyclic operation

A PLC program is sequentially executed from the first step to the last step, which is called scan. This

sequential processing is called cyclic operation. Cyclic operation of the PLC continues as long as

conditions do not change for interrupt processing during program execution.

Stages Processing

Operation Start

·Stage for the start of a scan processing. It is executed only

Initialization one time when the power is applied or reset is executed. It

executes the following process.

▶I/O module reset ▶Self diagnosis

▶Data clear ▶I/O module address allocation

·Read input module conditions and store it into the input image

Input image area refresh area before operation processing of a program.

Program operation

·

Program is sequentially executed from the first step to the last

The start of program step.

The end of program

·

The contents stored in the output image area is output to output

Output image area refresh modules when operation processing of a program is finished

·Stage for return processing after the CPU module has finished

END processing 1 scan. The following processing are executed..

▶Self-diagnosis

▶Change of the present values of timer and counter, etc.

▶

Check the status of mode setting switch

2) Time driven interrupt operation method

In time driven interrupt operation method, operations are processed not repeatedly but at every preset

interval. In the K200S CPU module, interval can be set to between 0.01 ~ 600 second. This operation is

used to process operation with a constant cycle

3) Event driven interrupt operation method

If a situation occurs which is requested to be urgently processed during execution of a PLC program,

this operation me thod processes immed iately the operation wh ich corresponds to inter rupt program. The

signal which informs those urgent conditions to the CPU module is called interrupt signal. The K200S

CPU module has two kind of interrupt operation methods, which are internal and external interrupt signal

methods.

If not provided with proper prevention, it can cause death, fatal

injury or considerable loss of property

If not properly observed, it can cause a hazard situation to resul

t

in severe or slight injury or a loss of property.

Don not run I/O signal lines near to high voltage line or power line.

Separate them as 100mm or more as possible. Otherwise, noise can cause module

malfunction.

Operate the PLC in the environment conditions given in the general specifications..

If operated in other environment not specified in the general specifications, it can

cause an electric shock, a fire, malfunction or damage or degradation of the module.

Make sure the module fixing projections is inserted into the module fixing hole and

fixed.

Improper installation of the module can cause malfunction, disorder or falling.

Do not separate the module from the printed circuit board, or do not remodel the

module. They can cause disorder, malfunction, damage of the module or a fire. When

mounting or dismounting the module, perform them after the power has been turned off.

Do not change battery while power is off. It can cause loss of data.

Do not contact the terminals while the power is applied. It can cause malfunction.

When cleaning or driving a terminal screw, perform them after the power has been

turned off.

When disposing the module, do it as an industrial waste.

Caution

Caution

Caution

Warning

Caution

DATA SHEET

1. I

ntroduction

2. G

eneral Spec

ificati

ons

Warning

Caution

3. Perf

ormance Spec

ificati

ons

4. O

peration Processing Method

PLC Others

< Best >

PLC Others PLC Others

< Good > < Bad >

Caution

LG Industrial Systems

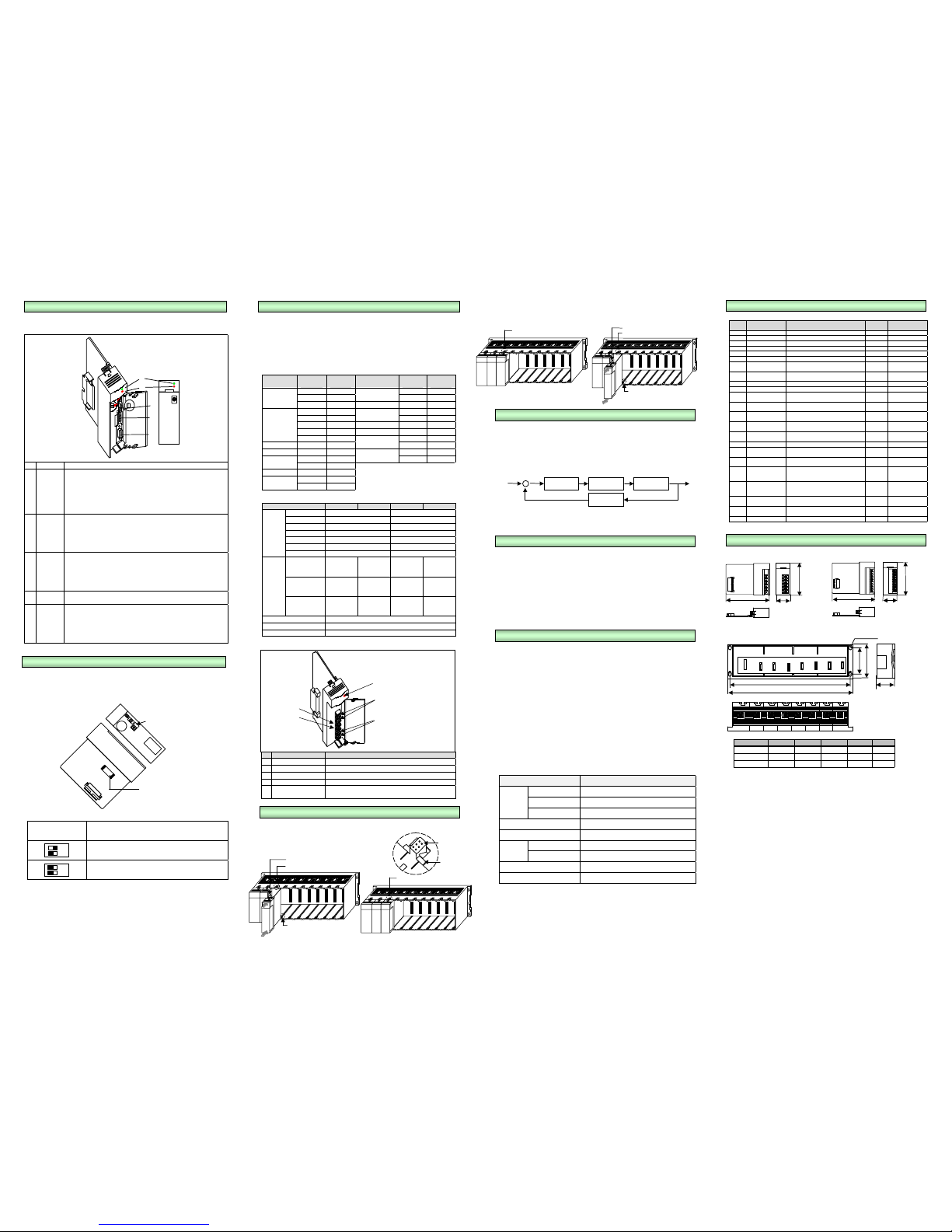

The following describes the names and functions of parts of the CPU module.

No. Name Function

1 RUN LED

Indicates the operation status of the CPU module.

•

On : when the CPU module operates with the mode setting switch in the

local or remote RUN state.

•

Off : when the followings occur

The voltage is not normally supplied to the CPU module.

The mode setting switch is in the STOP or PAU/REM state.

An error which makes operation stop is detected.

2 STOP LED

•

On : when the mode setting switch is in the local or remote STOP state.

•

Off : when the followings occur

The mode setting switch is in the local RUN or local PAUSE state.

The operation state is in the RUM/PAUSE/DEBUG state.

•

Flickering : when an error is detected by self-diagnosis during

operation.

3

Mode

setting

switch

Sets the operation mode of the CPU module. .

•

RUN : Program operation is executed.

•

STOP : Program operation is temporarily stopped.

•

PAU/REM :

PAUSE : Program operation is temporarily stopped.

REMOTE: Used for the remote operation

4

RS-232C

connector

9-pin connector for KGL-WIN and Cnet (RS-232C)

5

RS-422

and HSC

terminal

(B/C type

only)

Pin No RS-422/485 High Speed Counter

1 RDA A phase input

2 RDB B phase input

3 SDA A/B phase common

4 SDB Preset input (+24V)

5 S.G Preset common (0V)

This chapter describes how to store and operate user program with the flash memory .

Flash memory is used to store a user program and installed in PLC.

1) Structure

Read / Write is available to flash memory in accordance with selection of DIP switch.

Selection of DIP switch

for flash memory

Operation

PLC is operated by the program in flash memory when power

on or PLC reset.

PLC recognize that no program is in flash memory.

( Caution : Lower switch should be at the off position. )

User program can be written to flash memory at the PLC stop mode and then the selection of

switch is ignored.

This chapter describes type and specifi cations of the power supply modules

1) Selection of power supply module

Selection of the power supply module is determined by the total current consumption

of digital input modules, special modules and communications modules, etc. whose

powers are supplied by the power supply module.

If total load overrun the rated output capacity, the system will not normally operate.

When configuring a system, select a power supply module with due consideration of

current consumption of each module.

Current Consumption of K200S Series Modules (Unit:㎃)

Module

Model

Name

Current

Consumption

Module

Model

Name

Current

Consumption

K3P-07AS 170 K3Y-303S 140

K3P-07BS 210

Transistor Output

K3Y-304S 145

CPU

K3P-07CS 170 A/D Module K3F-AD2A 50

K3X-110S 40 K3F-DV2A 50

K3X-210S 70

D/A Module

K3F-DI2A 50

K3X-240S 70 High Speed Counter K3F-HSCA 220

K3X-310S 75 Positioning module K 3F-POPA 345

DC 12/24V

Input

K3X-340S 75 K3F-CU2A 140

AC110V Input K3X-120S 35

Computer link module

(Cnet)

K3F-CU4A 180

AC220V Input K3X-130S 35 K3F-FUEA 215

K3Y-101S 210

Fnet I/F module

K3F-RBEA 215

Relay Output

K3Y-201S 400

Triac Output K3Y-102S 190

K3Y-203S 180

Transistor

Output

K3Y-204S 170

2) Specification

Item K3S-302S K3S-304S K3S-012S K3S-014S

Voltage

AC100 ~ 240V (85∼264V)

DC12 ~ 24V

Frequency

50/60Hz(47∼63 Hz)

-

Current 0.7/0.35A 0.7 / 1.8A

Inrush Current 30A or less 40A or less

Efficiency 65% or more (Normal load) 60% or more (normal load)

Fuse Type 250VAC / 2A 250VAC/ 3A

Input

Dropout Tolerance 20ms or less 1ms or l ess

Voltage

DC5V

DC24V

DC5V

DC+15V

DC-15V

DC5V

DC5V

DC+15V

DC-15V

Current

DC5V:2A

DC24V:0.3A

DC5V:2A

DC+15V:0.5A

DC-15V:0.2A

DC5V : 2A

DC5V:2A

DC+15V:0.5A

DC-15V:0.2A

Output

Over-current

Protection

DC5V:2.2A

DC24V:0.33A

DC5V:2.2A

DC+15V:0.55A

DC-15V:0.22A

DC5V : 2.2A

DC5V:2.2A

DC+15V:0.55A

DC-15V:0.22A

LED Indication On : The output voltage is normal

Allowable Cable Specification

0.75∼2mm²

Weight (kg) 0.32

3) Names of Parts

No. Name Description

1 Power LED

*

The LED indicator for DC5V power

2 Power Input Terminal

*

The terminal to connect 100~240VAC power

3 LG Terminal

*

Line ground

4 FG Terminal

*

Frame ground

5

DC24V Terminal

DC24VGTerminal

*

Supply DC24V power to the other modules (K3S-302S)

*

No Connection(K3S-304S, K3S-012S, K3S-014S)

The following explains that how to mount/dismount various module to the base.

1) Mounting a module

- Insert the module to mounting slot along sliding guide.

- Check that the module is firmly mounted onto the base.

2) Dismounting a module

- First, push the locked hook (①) and pull the module with direction of arrow (②).

K3P-07BS and K3P-07CS module include PID (Proportional Integral Differential) function,

and no external PID module is required.

1) Characteristics of K200S PID function

a) PID function is included in the CPU module, and no PID module is required.

b) User can select forward or reverse operation.

c) P, PI, PID or On/Off operation modes are available.

d) Manual output (user-defined output) is available.

e) Sampling time can be varied for flexibility of control system.

2) Programming of PID control function

- Refer the MASTER-K Programming manual for details

1) Introduction

The K3P-07BS module has RS-422/485 master function and can operate as master

station of 1:N network.

2) Functions

a) User can define a data access block and set time-out value at each blocks. The

maximum size of block is 64 words.

b) Maximum station number is 32 stations.

c) According to the parameter setting, the operation mode and error code of slave

stations is stored at the relevant flag.

d) The communication status can be monitored with the monitoring function of KGL-

WIN software.

1) Introduction

The K3P-07CS module includes a built-in high speed counter, and it can count a

fast pulse input that are generated by encoder or pulse generator.

The built-in HSC has following functions;

-

3 counter functions as followings

-

1-phase up / down counter : Up / down is selected by user program

-

1-phase up / down counter : Up / down is selected by external B phase input

-

2-phase up / down counter : Up / down is automatically selected by the

phase difference between phase A and B.

-

Multiplication (1, 2, or 4) with 2-phase counter

-

2-phase pulse input multiplied by one : Counts the pulse at the leading edge

of phase A.

-

2-phase pul se i nput multipli ed by two : Counts the pulse at the leading /

falling edge of phase A.

-

2-phase pul se i nput multipli ed by four : Counts the pulse at the leading /

falling edge of phase A and B

2) Performance specifications

Items Specifications

Types Phase A, Phase B, Preset

Rated level 24VDC (13mA)

Input

signal

Signal type Voltage input

Counting range 0 ~ 16,777,215 (Binary 24 bits)

Max. counting speed 50k pps

1-phase Sequence program or B-phase input

Up /

Down

selection

2-phase Auto-select by phase difference of phase A and B

Multiplication 1, 2, or 4

Preset input Sequence program or external preset input

1) Error code

Error

code

Message Description Error Cause

Operation

status

Corrective Action

h0001 System error Internal H/W fault STOP Contact A/S center

h0002 OS ROM error Internal H/W O/S ROM fault STOP Contact A/S center

h0003 OS RAM error Fault of RAM for internal system STOP Contact A/S center

h0004 Data RAM error Fault of RAM for internal data STO P Contact A/S center

h0005 Program RAM error Fault of RAM for internal program STOP Contact A/S center

h0006 G/ A error Internal Gate Array(G/A) fault STOP Contact A/S center

h0007

Expansion base power

fault

It is down or fault to power for the expansion base STOP

Check the power of

expansion base center

h0008 CP U WDT error

It is over to the monitoring time for operation delay

of CPU

STOP Contact A/S center

h0009 Special RAM error Internal special RAM fault RUN/STOP Contact A/S center

h000A Fuse error It is opened to fuse to be used for the I/O module STOP Contact A/S center

h000B Instruct ion code error

It is to be used instruction code which is impossible

to decode

STOP Contact A/S center

h000C Flash memory error It is fault to flash memory to be used STOP

Confirm flash memory

or replace

h000D I/O error

Module dismounting or additional mounting during

run, bad contact, I/O fault, expansion cable fault

STOP

Confirm I/O module or

expansion cable

h0011 Maximum I/O slot error

It is over maximum I/O points to the I/O module

mounted(Fnet, Cnet)

STOP Replace I/O modul e

h0012

Special function module

error

Special function module interface part fault STOP Contact A/S center

h0020 Parameter error Specified parameter fault S TOP Resetting parameters

h0021 Specif ied I/O error

It is different to I/O parameters specified and I/O

module mounted

STOP

Correct the parameters

or replace the I/ O module

h0022 Maximum I/O slot error

It is over maximum I/O points to the I/O module

mounted

STOP Replace the I/O mod ule

h0030 Operation error

Use of the improp er operand when i t is used B CD

conversion instruction (except for 0~9 )

In case of over in the domain of #D

RUN/STOP Correct the program

h0031 W DT error The scan time is over monitoring time STOP

Increment the scan time

in parameters or add

WDT instruction

h0040 Code check error

It is used to the instruction which is impossible to

decode

STOP Correct the program

h0049 Syntax error

Improper program input condition or error of LOAD

Instruct ion overused

STOP Correct the program

h0050 Battery error Dismounted battery or abnormal voltage RUN Replace the battery

◆

Power Supply Module

◆

CPU & I/O Module

◆

Base

Slot Type A B C D E

4 slots 230.5 244 92 110 62

6 slots 300.5 314 92 110 62

8 slots 370.5 384 92 110 62

6. Usi

ng The User Program in Flash Memory

7. P

ower Supply Modules

8. M

ounting and Dismounting of Module

9. PID

control function

(K3P-07BS / K3P-07CS)

13. Di

mension (mm)

Dip switch for operation

Flash me mory

①

②

⑤

③

④

PID operation D/A conversion Actuator

A/D conversion

SV DV PV

10. RS-422/485

master function

(K3P-07BS)

①

②

③

④

⑤

11. Built-in high

speed counter

(K3P-07CS)

12. T

roubleshooting

Sliding Guide

Locking Hook

Locking part for hook

Locking part

for hook

Locking Hook

4 – ψψψψ 4.5

4.54.5

4.5

100

100100

100

45

4545

45

110

110110

110

100

100100

100

35

3535

35

110

110110

110

Locking part for hook

Sliding Guide

Locking part for hook

Locking Hook

5. Parts N

ames and Descriptions

Loading...

Loading...