LG ATNH126ELFB, UT18 NEB, ATNH186ELFB, ATNH246FLFB, ATNH306FLFB Service Manual

...

LG

Universal System

Air Conditioner

SERVICE MANUAL

LG

CAUTION

website http://www.lgservice.com

e-mail http://www.lgeservice.com/techsup.html

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

2 Universal System Air Conditioner

TABLE OF CONTENTS

Safety Precautions...................................................................................................3

I. Indoor Units

Introduction..............................................................................................................8

Ceiling Cassette 4-way..........................................................................................10

Ceiling & Floor.......................................................................................................31

Ceiling concealed Duct..........................................................................................45

II. Outdoor Units

Introduction............................................................................................................67

MPS Inverter Single A(AUUW-B, AUUW-O/R410A)..............................................69

III. Troubleshooting Guide

Self-diagnosis Function.........................................................................................96

Cycle Troubleshooting Guide.................................................................................97

Electronic Parts Troubleshooting...........................................................................98

General Information.............................................................................................103

IV. Electronic Control Device

Ceiling Cassette Type..........................................................................................120

Ceiling Duct Type.................................................................................................121

Ceiling & Floor.....................................................................................................123

V. Schematic Diagram

Ceiling Cassette Type..........................................................................................126

Ceiling Duct Type.................................................................................................127

Ceiling & Floor.....................................................................................................128

V. Functional Description

Ceiling Cassette Type..........................................................................................130

Ceiling Duct Type.................................................................................................132

Ceiling & Floor.....................................................................................................135

Outdoor Units ......................................................................................................138

VII. Explode View and Replacement Parts List

Indoor Units.........................................................................................................151

Outdoor Units ......................................................................................................169

Panel Assembly, Front.........................................................................................179

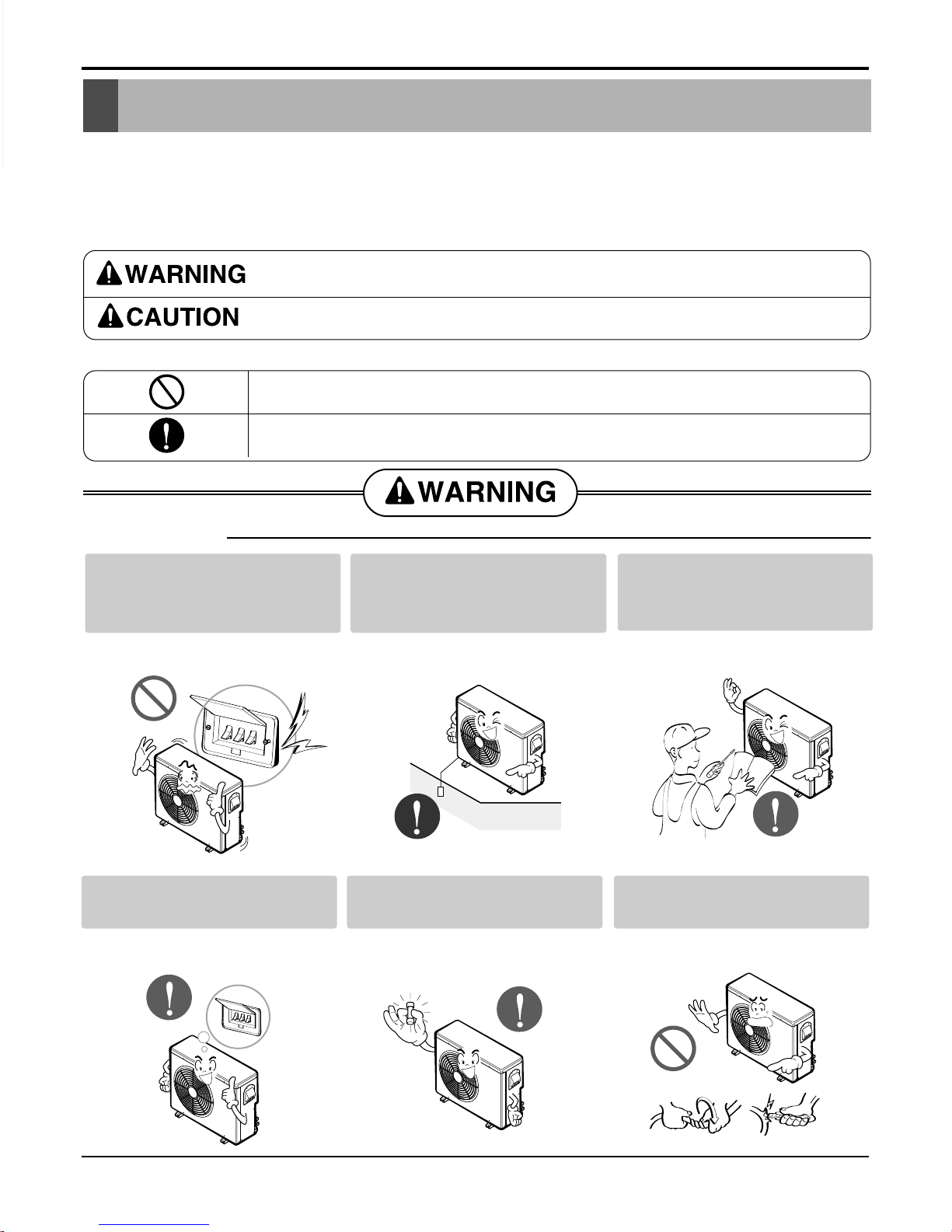

Safety Precautions

Service Manual 3

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

■ Installation

Be sure not to do.

Be sure to follow the instruction.

Do not use a defective or underrated circuit breaker. Use this

appliance on a dedicated circuit.

• There is risk of fire or electric

shock.

Always ground the product.

• There is risk of fire or electric

shock.

Install the panel and the cover

of control box securely.

• There is risk of fire or electric

shock.

Always install a dedicated circuit and breaker.

• Improper wiring or installation may

cause fire or electric shock

Use the correctly rated breaker or fuse.

• There is risk of fire or electric

shock.

Do not modify or extend the

power cable.

• There is risk of fire or electric

shock.

Safety Precautions

4 Universal System Air Conditioner

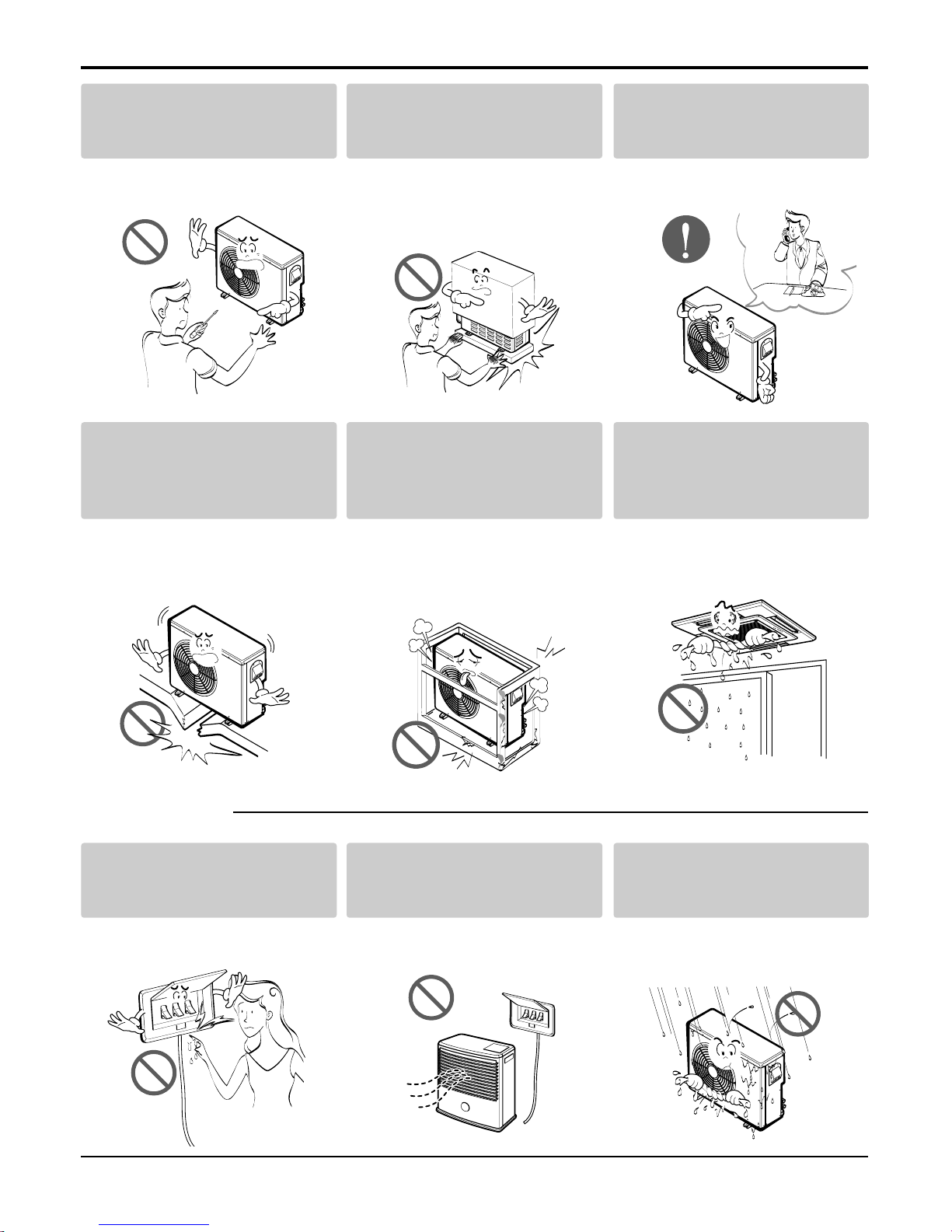

■ Operational

Do not install, remove, or reinstall the unit by yourself

(customer).

• There is risk of fire, electric shock,

explosion, or injury.

Be cautious when unpacking

and installing the product.

• Sharp edges could cause injury.

Be especially careful of the case

edges and the fins on the condenser and evaporator.

For installation, always contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric shock,

explosion, or injury.

Do not install the product on a

defective installation stand.

• It may cause injury, accident, or

damage to the product.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air conditioner could fall with it, causing

property damage, product failure,

and personal injury.

Do not let the air conditioner

run for a long time when the

humidity is very high and a

door or a window is left open.

• Moisture may condense and wet or

damage furniture.

Do not touch(operate) the

product with wet hands.

• There is risk of fire or electrical

shock.

Do not place a heater or other

appliances near the power

cable.

• There is risk of fire or electric

shock.

Do not let electric parts of the

product get wet.

• There is risk of fire, failure of the

product, or electric shock.

Safety Precautions

Service Manual 5

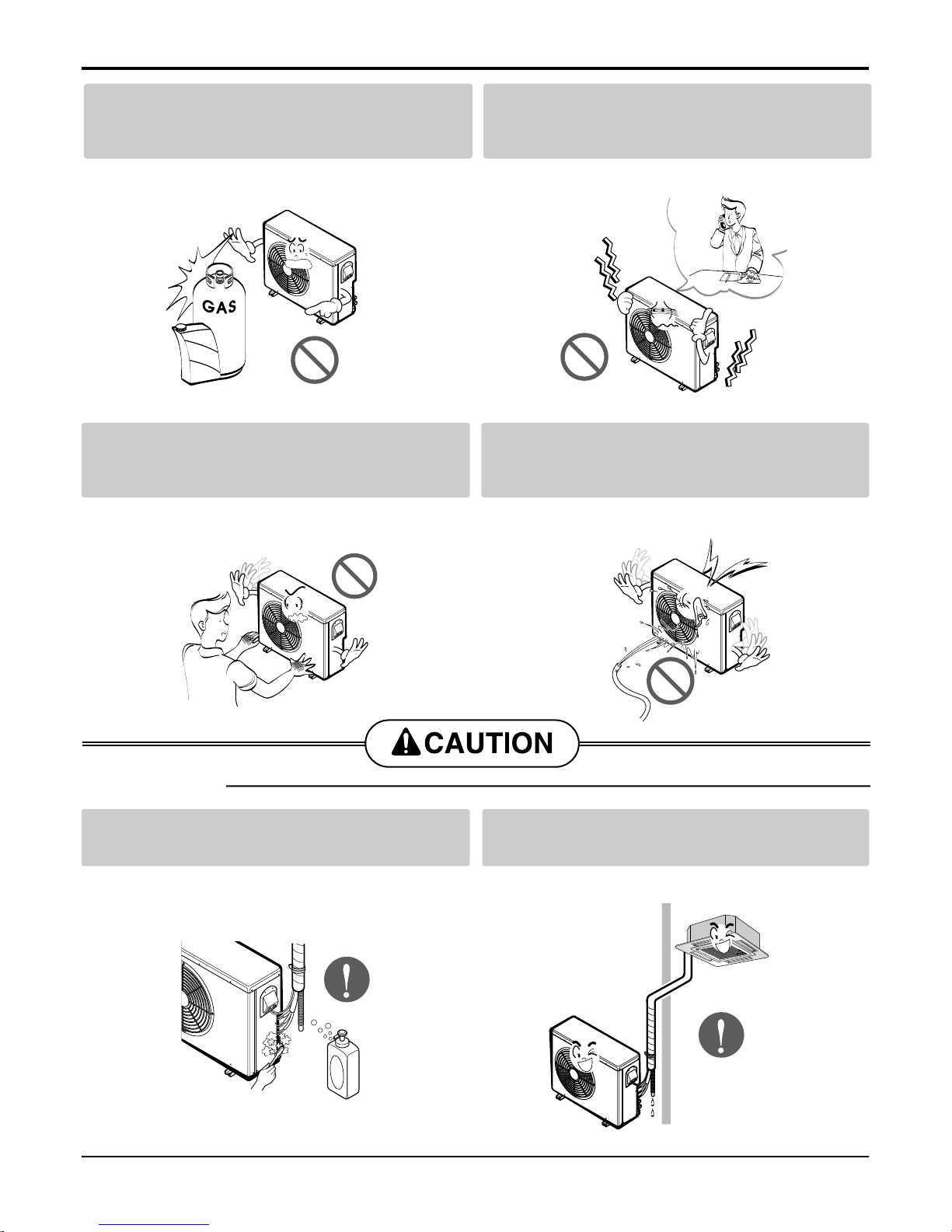

■ Installation

Do not open the inlet grill of the product during

operation. (Do not touch the electrostatic filter,

if the unit is so equipped.)

• There is risk of physical injury, electric shock, or product failure.

Be cautious that water could not enter the

product.

• There is risk of fire, electric shock, or product damage.

Always check for gas (refrigerant) leakage after

installation or repair of product.

• Low refrigerant levels may cause failure of product.

Install the drain hose to ensure that water is

drained away properly.

• A bad connection may cause water leakage.

Do not store or use flammable gas or combustibles near the product.

• There is risk of fire or failure of product.

If strange sounds, or small or smoke comes

from product. Turn the breaker off or disconnect the power supply cable.

• There is risk of electric shock or fire.

Gasolin

Safety Precautions

6 Universal System Air Conditioner

Keep level even when installing the product.

• To avoid vibration or water leakage.

Use two or more people to lift and transport

the product.

• Avoid personal injury.

Use a soft cloth to clean. Do not use harsh

detergents, solvents, etc.

• There is risk of fire, electric shock, or damage to the

plastic parts of the product.

Do not touch the metal parts of the product

when removing the air filter. They are very

sharp!

• There is risk of personal injury.

Do not step on or put anyting on the product.

(outdoor units)

• There is risk of personal injury and failure of product.

Do not insert hands or other objects through

the air inlet or outlet while the product is operated.

• There are sharp and moving parts that could cause

personal injury.

90˚

Wax

Thinner

■ Operational

I. Indoor Units

Introduction.......................................................................................................8

Ceiling Cassette 4-way...................................................................................10

Ceiling & Floor................................................................................................31

Ceiling Concealed Duct..................................................................................45

Service Manual 7

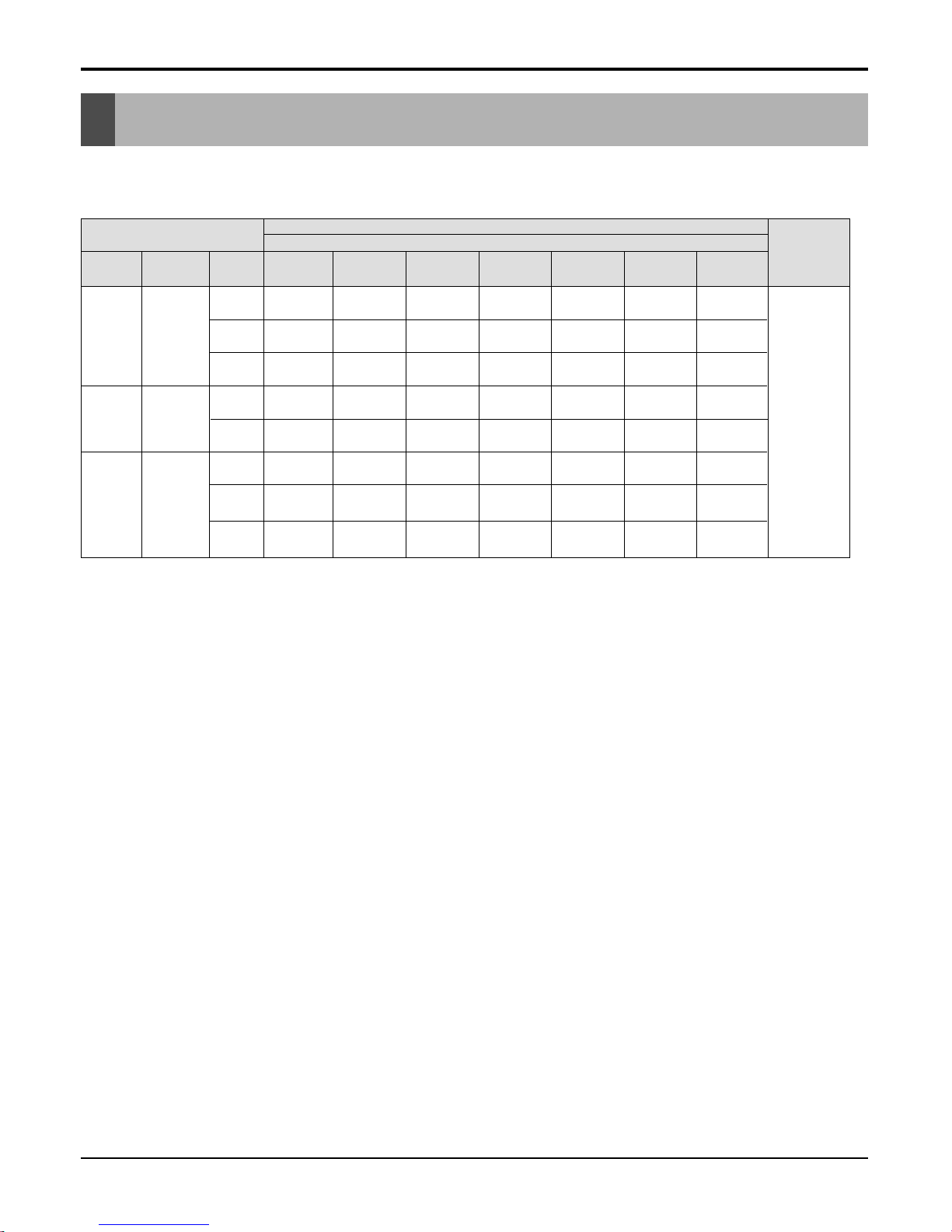

• Models List

Type Refrigerant

Chassis

name

18,000

(5.3)

24,000

(7.0)

30,000

(8.8)

36,000

(10.6)

TE

TF

TD

Ceiling

&

Floor

R410A

VB

BH

BG

12,000

(3.5)

BR

48,000

(14.1)

60,000

(17.6)

VE

1Ø, 220-240V,

50Hz

Model name

Nominal capacity [Btu/h(kW)]

Power

Supply

R410A

Ceiling

Cassette

4-Way

Ceiling

Concealed

Duct

Indoor unit

R410A

ATNH126ELFB

[UT12 NEB]

ATNH186ELFB

[UT18 NEB]

AVNH186BLAB

[UV18 NBB]

AVNH246BLAB

[UV24 NBB]

AVNH306BLAB

[UV30 NBB]

ABNH306GLAB

[UB30 NGB]

ABNH366GLAB

[UB36 NGB]

ATNH246FLFB

[UT24 NFB]

ATNH306FLFB

[UT30 NFB]

ATNH366DLFB

[UT36 NDB]

ATNH486DLFB

[UT48 NDB]

ATNH606DLFB

[UT60 NDB]

ABNH486RLAB

[UB48 NRB]

ABNH606RLAB

[UB60 NRB]

--

--

-

-

--

-- -

-- -

-

AVNH126ELAB

[UV12 NEB]

---

-

--

-

--

-

-

--

--

---

ABNH186HLAB

[UB18 NHB]

ABNH246HLAB

[UB24 NHB]

----

--

8 Universal System Air Conditioner

Introduction

Introduction

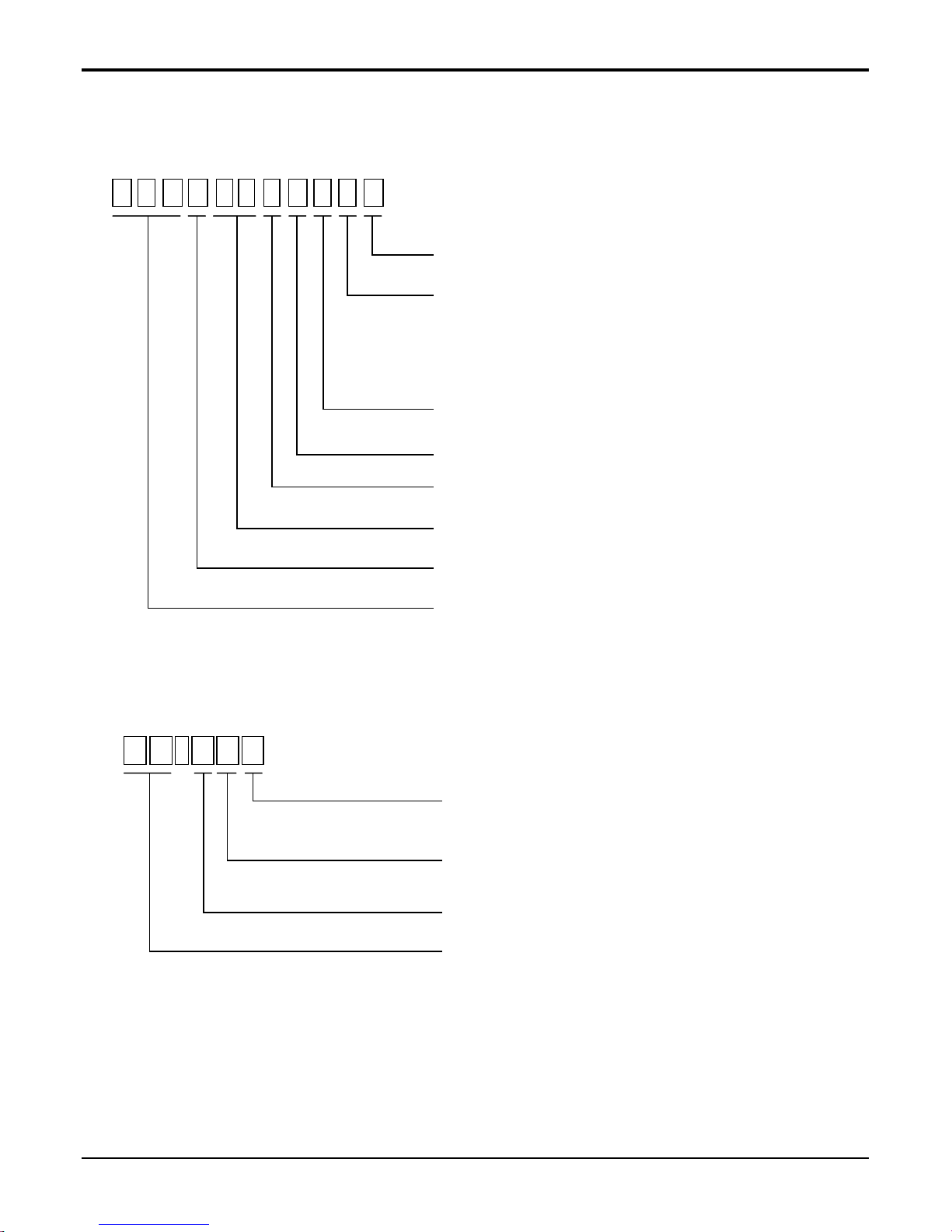

• Model Number Nomenclature

Indoor unit

Decoration panel(For Ceiling Cassette Models)

A T N H 1 8 6 E L FB

Serial Number

Functions

A : Basic B : Low Ambient

C : Plasma Filter E : Elevation Grille

F : Elevation Grille + Plasma Filter

H : Plasma Filter + Low Ambient

L : Nano Plasma M : Nano Plasma + Elevation Grille

Look

L : Basic

Chassis Name

Electrical Ratings

6:1Ø,220V~240V,50Hz 8:3Ø,380V~415V,50Hz

Nominal Cooling Capacity in Btu/h

Ex) 18 -> 18,000 Btu/h, 48 -> 48,000 Btu/h

Model Type

C : Cooling Only H : Heat Pump

Indicates that this is a indoor unit for R410A

ATN : Ceiling cassette type indoor unit

ABN : Ceiling concealed duct type indoor unit

AVN : Convertible type indoor unit

P T - H EC

Functions

A : Basic C : Plasma Air Purifier

E : Elevation Grille F : Elevation Grille + Plasma Air Purifier

Indoor Unit Chassis

D : D Chassis E : E Chassis F : F Chassis

Model Type

C : Cooling Only H : Heat Pump

Decoration Panel of Ceiling Cassette Type Indoor Unit

Service Manual 9

Introduction

10 Universal System Air Conditioner

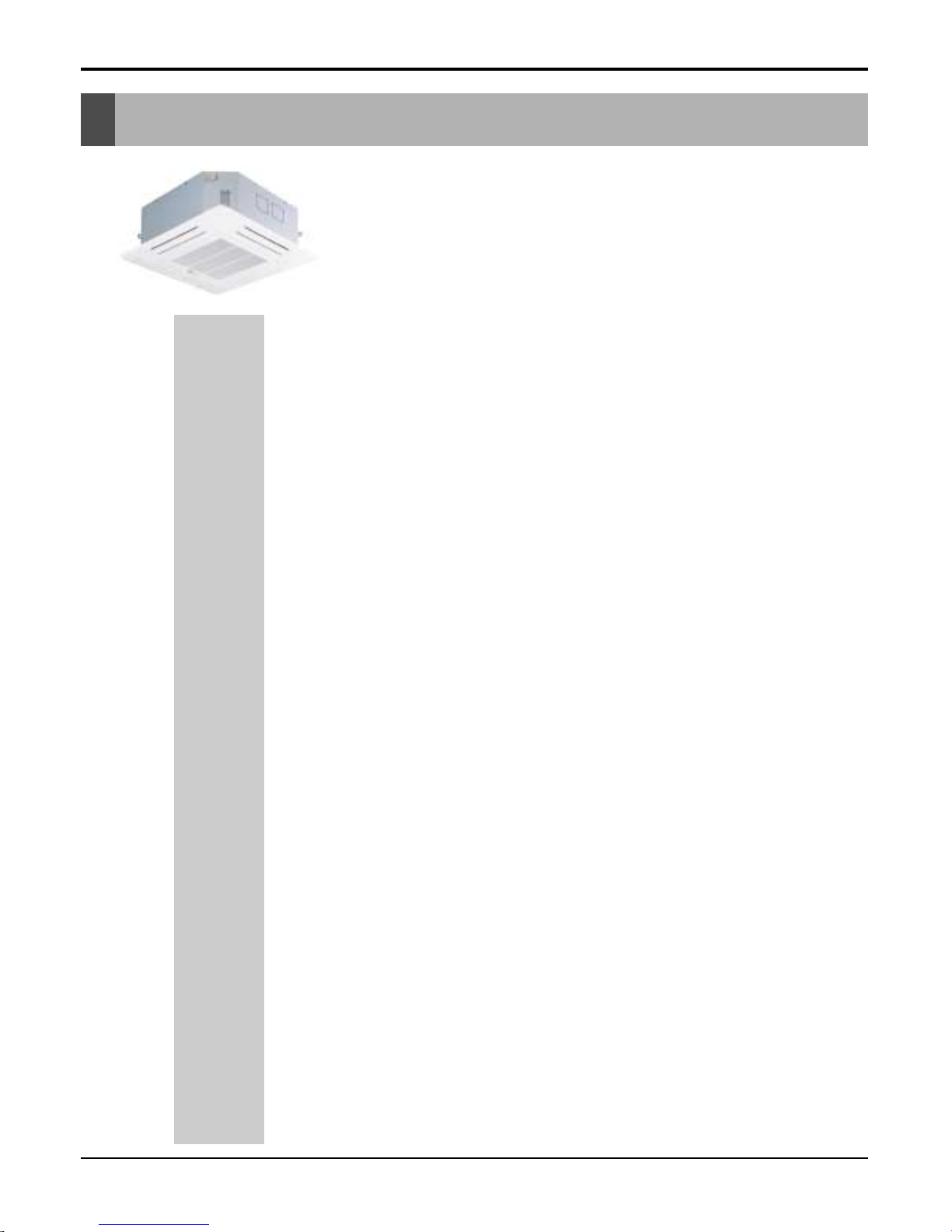

Ceiling Cassette 4-way

Contents

1. Features & Benefits ..............................................................................11

2. List of Functions....................................................................................15

3. Specifications........................................................................................16

4. Dimensional Drawings ..........................................................................18

5. Wiring Diagrams...................................................................................21

6. Piping Diagrams....................................................................................22

7. Operating Instructions...........................................................................23

8. Installation.............................................................................................25

9. Accessories ..........................................................................................30

Ceiling Cassette 4-way

(R410A·Indoor Units)

ATNH-EL/FL/DL

Ceiling Cassette 4-way

(18k Btu/h model)

■ Convenience

• Auto elevation grille(Accessory)

• Tele control(Optional)

• LCD wired remote control

• Group control

• Central control(Accessory)

• Weekly progam

■ Cleanness

• Plasma air purifying system

• Hygienic and easy to clean filter

■ Easy Installation

• Compact design & easy installation

• High ceiling corresponding operation

• High head drain pump(700mm)

■ Comfort & Reliability

• Low noise with 3-dimensional turbo fan

• 2-Thermistor control(Main body & Remote control)

• Zero stanby power consumption

• Jet cool

• Swirl swing

• Space control

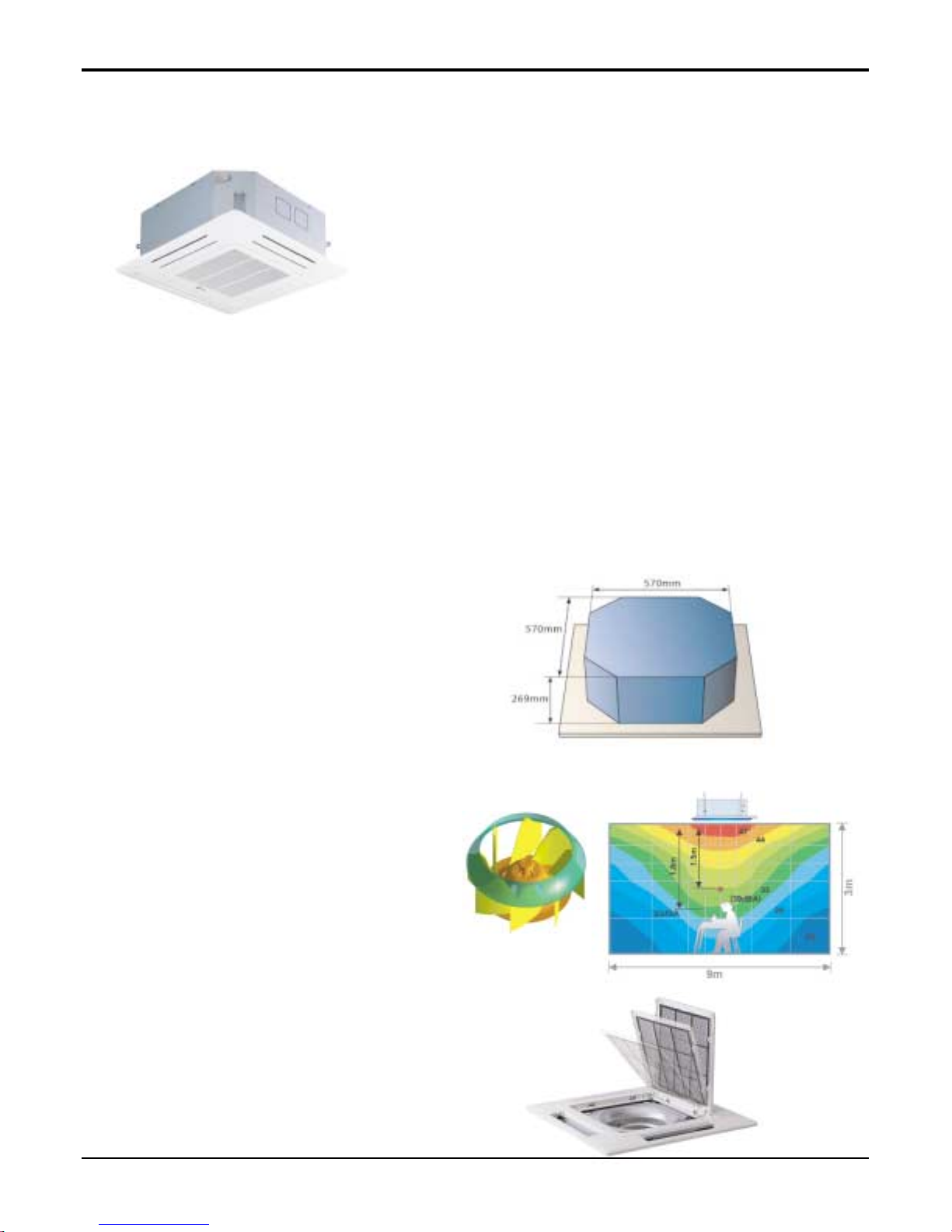

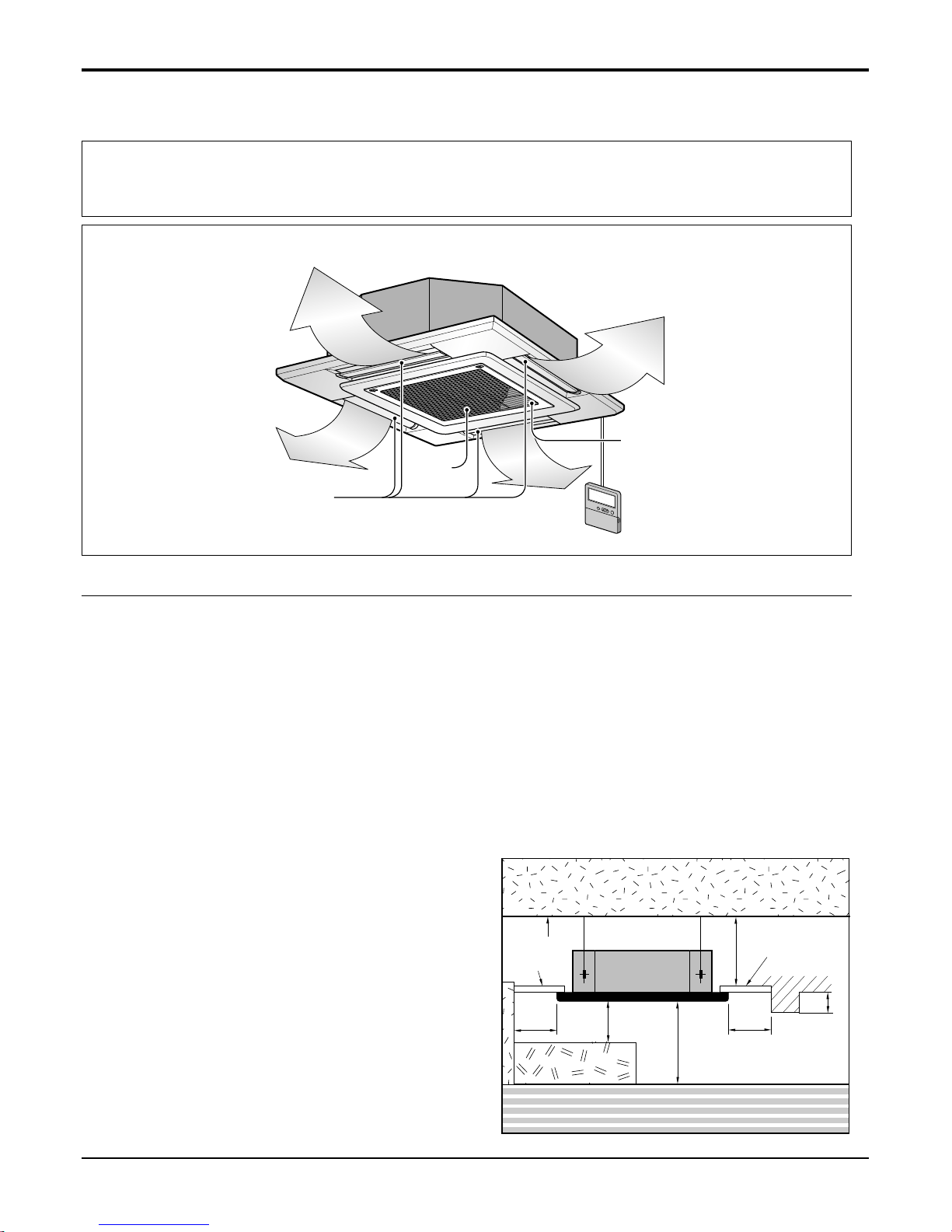

Compact Design and Easy Installation

Only about 269mm height in the ceiling is sufficient for

installation space.

A smaller size than a Textile(600X600) is very convenient for installation.

Low Noise with 3-dimensional

turbo fan

The most advanced low-noise design.

The adoption of turbo-fan and round type heat

exchanger provides the quietest operation.

Hygienic and Easy-to-Clean Filter

Washable and anti bacteria filter is adopted.

It is easy to open grille and replace clean filter.

Service Manual 11

Ceiling Cassette 4-way

1. Features & Benefits

12 Universal System Air Conditioner

Ceiling Cassette 4-way

Ceiling Board

Drain Pan

Maximum 700mm

Drain Pump

Flexible drain hose

Pipe fixture

Slope 1/50~1/100

Hard Tube(ex.PVC)

+

+

+

+

Polluted Air

Purified fresh Air

+4.8KV discharge

Ionizer Photo-Catalyst Coated Mesh

Dust particles

Odour

Dust electrode discharge

Odour molecule

Generating plasma

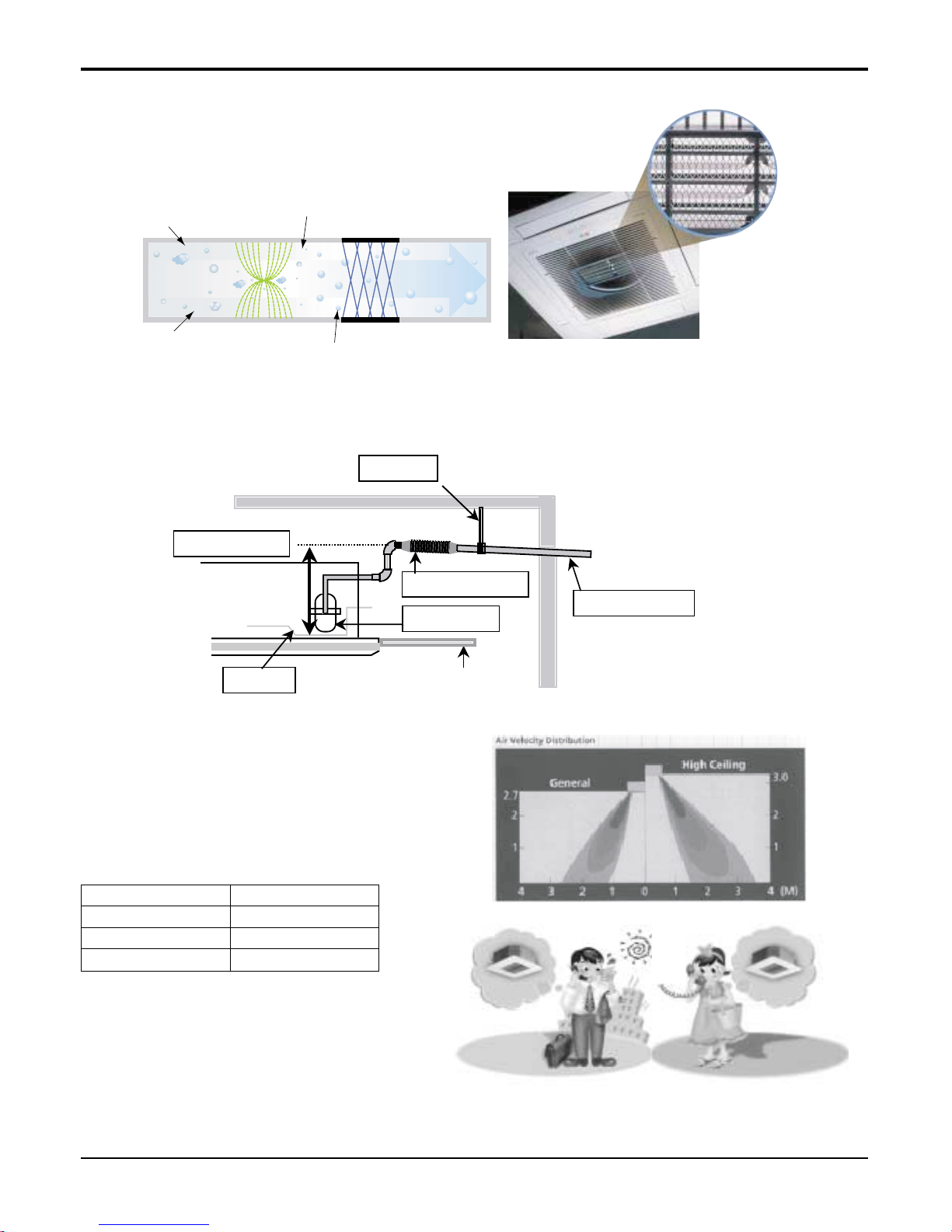

Plasma Air Purifying System

The PLASMA Air Purifying Function not only removes microscopic contaminants and dust, but also removes house

mites, pollen, and pet fur helps to prevent allergic diseases

like asthma.

High Head Drain Pump(700mm)

Built-in Drain Pump drains out water automatically.

A standard drain-head height of up to 700 mm is possible, creating the ideal solution for perfect water drainage.

High-Ceiling Corresponding Operation

According to the height of the installation, it provides variability of indoor fan motor rpm. If the height of installation is

low then you can adjust low rpm of indoor fan motor. On

the other hand if the height of the installation is high you

can adjust high rpm of indoor fan motor. Selection of

speed can be done by slide switch at the back of the LCD

wired remote.

Tele Control (Accessory)

- It provides you ease of control. Air conditioner

can be switched on/off by the telephone. It

saves time & energy.

ON

ONON OFF

OFF

OFFOFF

In Advance by Telephone

Before Coming Home...

In case of Going out

Without Turning off the

Air Conditioner...

Over than 3.3mHigh Ceiling

2.7~3.3mStandard

Ceiling HeightSwitch selection

Less than 2.7mLow Ceiling

Child Lock Function

-It prevents the children or others from tampering

with the control buttons. Unit can be controlled by

the wireless remote controller. This can be easily set

by pressing timer key & Min key simultaneously.

After child lock is set, pressing any key will display

CL on the LCD for 3 seconds and all the keys will be

ineffective.

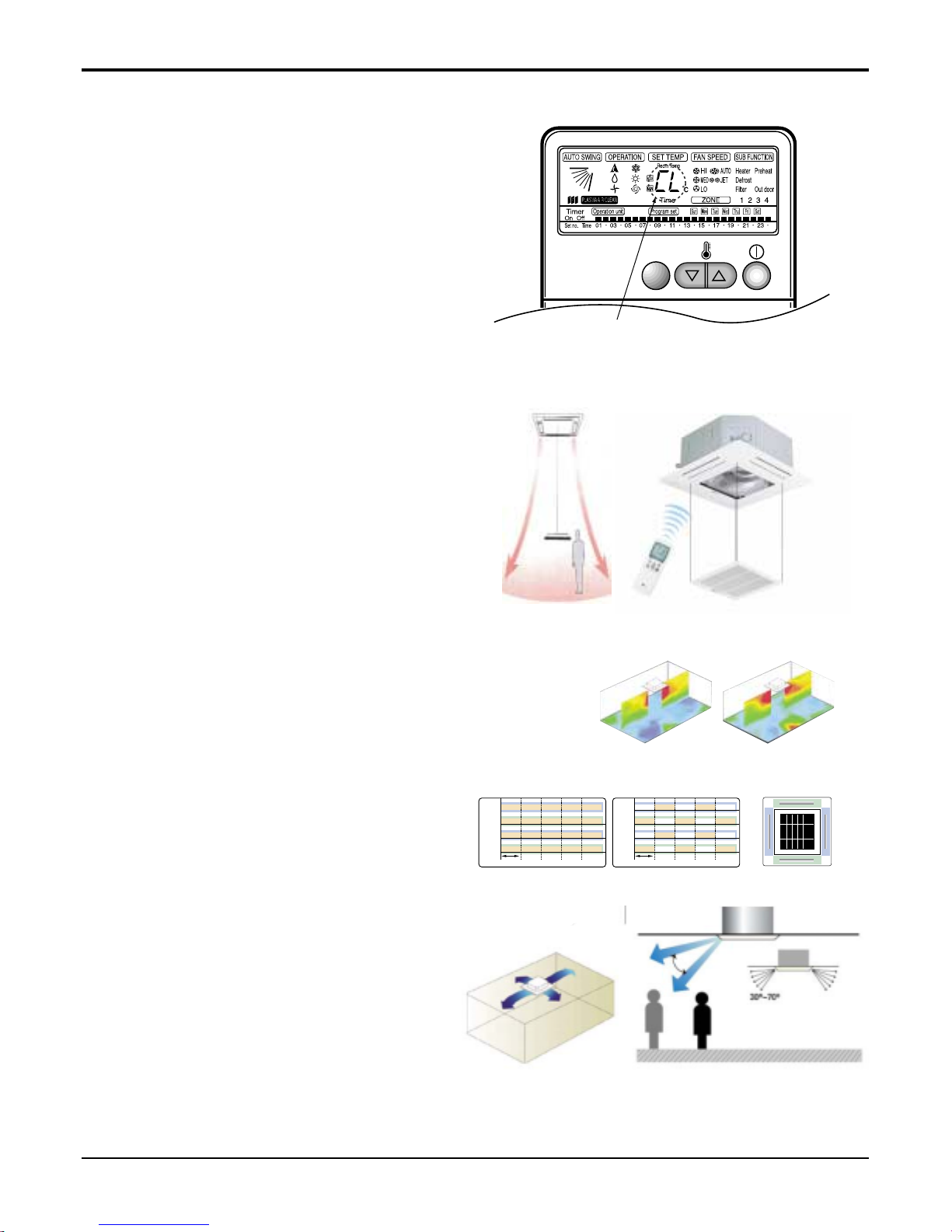

Auto Elevation Grille(Accessory)

-Auto Elevation Grille is automatically down to height

of max. 3.1 m. So it enables to install the Indoor unit

at high ceiling space. And Auto Elevation Grille

makes you cleaning the filter easily.

CHILD LOCK

-Display

71

Vane 2

Swirl Swing(New)4- Open(Conventional)

Swirl Swing(New)4- Open(Conventional)

2.4% 4.8%100% Improved

Comparison of Air Flow Types

Comparison of Floor

Temp. Distribution(20°C)

Vane 1 Close OpenOpen

Open

Open

Open

Close CloseOpen

Vane 3 Close Open Close CloseOpen

OpenOpen Close CloseOpen

Vane 2

OpenOpen

Time

Close CloseOpen

Vane 4

Vane 1

Vane 3

Vane 2

Time

Vane 4

Vane 3

Vane 4

Vane 1

Swirl Swing

- It is the function for comfort cooling/heating operation.

- The diagonal two louvers are opened the

more larger than the other louvers.

After one minute, it is opposite.

Space Control

Vanes angle can be controlled by pair, considering its

installation environment.

- For example direct drafts can be annoying, leading

to discomfort and reduced productivity vane control

helps to eliminate this problem.

- Easily controlled by wired remote control.

- Air Flow can be controlled easily regarding any

space environment.

Service Manual 13

Ceiling Cassette 4-way

14 Universal System Air Conditioner

Ceiling Cassette 4-way

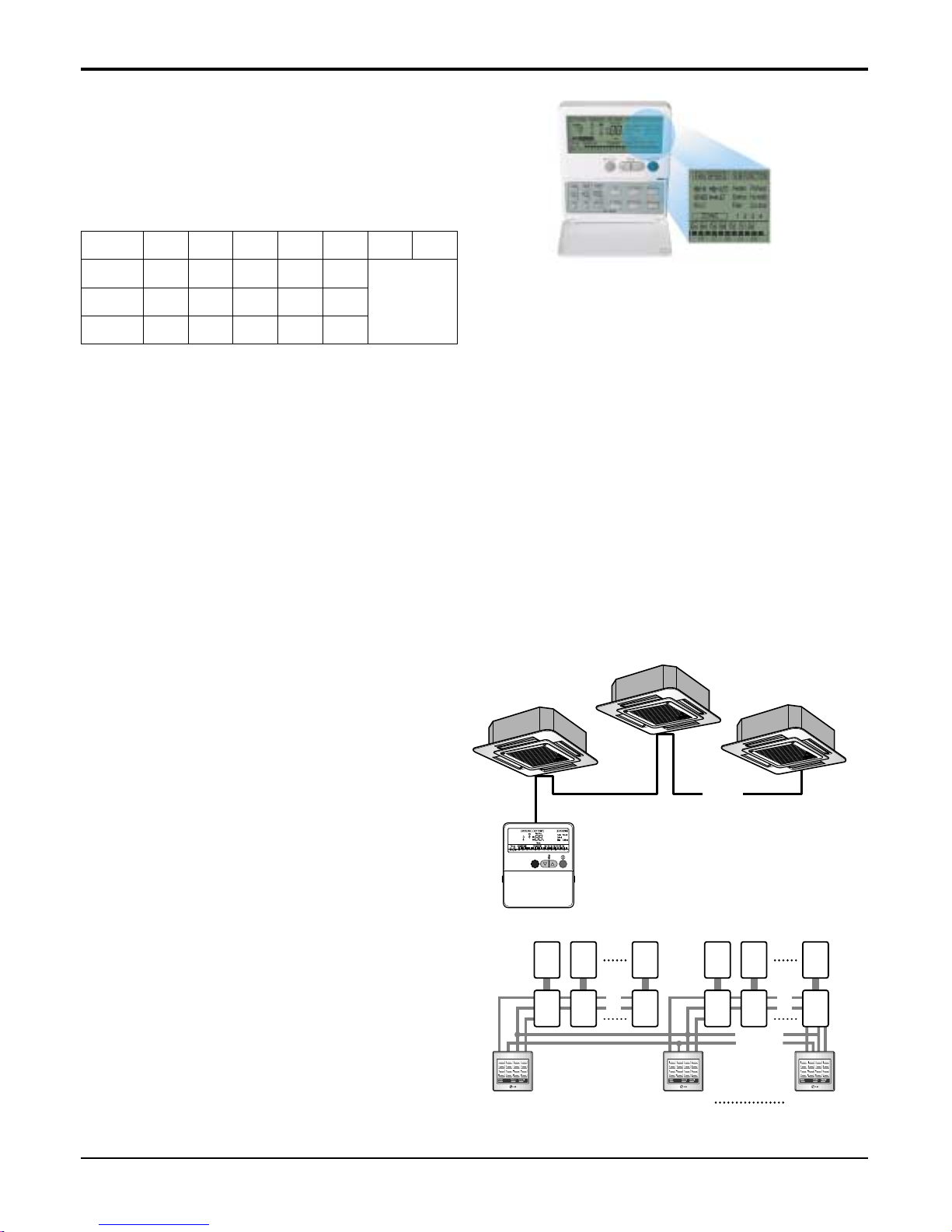

Weekly Program

- On/Off schedule of operation for a period of ONE

week.

No need to turn the unit On/OFF manually during

working days. On/Off time is scheduled in micom of

the wired remote control.

Auto Restart Operation

- Whenever there is electricity failure to the unit, and after resumption of the power, unit will start in the same

mode prior to the power failure. Memorized condition are on / off condition, operating mode (cooling/heating),

set temperature and fan speed.The unit will memorize the above conditions and start with same memorized

condition.

Two Thermistor Control

- There may be a significant difference between the temperature taken at the installed product and indoor temperature. Two thermistor control provides option to control temperature by referring any of the two temperatures. With the help of the slide switch at the back of the LCD wired remote controller, selection of the desired

thermistor for controlling the unit can be done. One thermistor is in the Indoor unit & the other one is in the

LCD wired remote.

Group Control

- It enables to control as much as 16 units with the

help of one wired remote controller. All the units will

follow same setting of temperature & other sub functions.

Central Control(Accessory)

- It enables to control 16 x 8 = 128 units with the help

of 8 controllers. All units can be put on and off from

one Central Room.For Setting Temperature, Fan

Speed and other sub functions, access the respective LCD wired remote controller of each unit.

❈ Sub PI485(with wire assembly) should be pur-

chased as optional.

Operation Time Table (Example)

Mon Tue Wed Thu Fri Sat Sun

OFF

Setting

Temp.

On

Off

25°C25°C25°C25°C25°C

09:00

12:00

08:00

17:00

09:00

12:00

08:00

12:00

09:00

12:00

10mm 10mm

1216........

........

Main

PCB

Controller

# 1

Controller

# 2

Controller

# 8

M

1

Sub

1

M

2

Sub

2

M

16

Sub

16

M

17

Sub

17

M

18

Sub

18

M

128

Sub

128

Service Manual 15

Ceiling Cassette 4-way

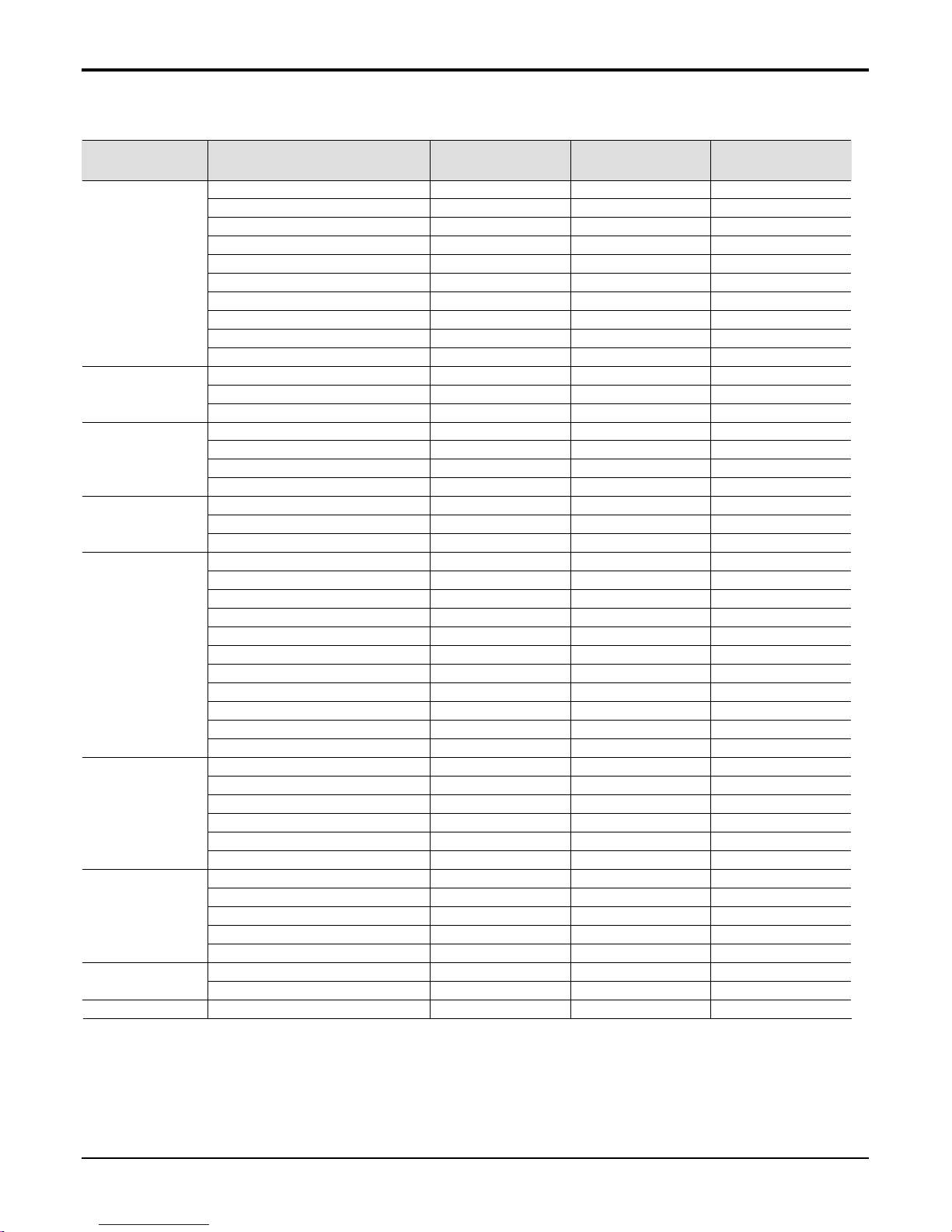

2. List of Functions

Air supply outlet

Airflow direction control (left & right)

Airflow direction control (up & down)

Auto swing (left & right)

Air flow

Auto swing (up & down)

Airflow steps(Fan / Cool / Heat)

CHAOS swing

CHAOS wind (Auto wind)

Jet cool (Power wind)

Swirl wind

Deodorizing filter

Air purifying Plasma air purifier

Prefilter(Washable / Anti-fungus)

Drain pump

Installation

E.S.P. control

Electric heater (Operation)

High ceiling operation

Hot start

Reliability Self diagnosis

Soft dry operation

Auto changeover

Auto cleaning

Auto operation(Artificial intelligence)

Auto restart operation

Child lock

Convenience Forced operation

Group control

Sleep mode

Timer (On/Off)

Timer (weekly)

Two thermistor control

Standard wired remote controller

Deluxe wired remote controller

Individual control Simple wired remote controller

Wired remote controller(for hotel use)

Wireless remote controller(simple)

Wireless LCD remote controller

General central control(Non LGAP)

Dry contact

CAC network function

Simple central control(LGAP)

PDI(Power Distribution Indicator)

PI485

Special function kit

CTIE

Zone control

Others Thermistor

444

---

Auto Auto Auto

XXX

OOO

3/4/3 3/4/3 3/4/3

XXX

--OOO

OOO

--OOO

OOO

OOO

---

--OOO

OOO

OOO

OOO

XOX

XXX

OXO

OOO

OOO

OOO

OOO

XXX

OOO

OOO

OOO

OOO

XXX

XXX

XXX

XXX

OOO

XXX

PQDSB PQDSB PQDSB

OOO

PQNUD1S00 PQNUD1S00 PQNUD1S00

PMNFP14A0 PMNFP14A0 PMNFP14A0

XXX

XXX

AQTTA AQTTA AQTTA

FunctionCategory

ATNH-EL ATNH-FL ATNH-DL

Note: Group control & CAC network function is not available which is connected with synchro.

Sleep mode is available only in case of using wireless remote controller.

• O: Applied, • X: Not applied, • - : No relation,

• Option: Model name & price are different according to options, and assembled in factory with main unit.

• Accessory: Installed at field, ordered and purchased separately by the corresponding model name, supplied with separate package.

16 Universal System Air Conditioner

Ceiling Cassette 4-way

Note :

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19°C(66.2°F) WB

- Outdoor Temperature 35°C(95°F) DB /24°C(75.2°F) WB

Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

Piping Length - Interconnecting Piping Length 7.5m

- Level Difference of Zero.

2. Cooling/heating capacity of indoor unit can be lower when it is connected to MPS variable outdoor.

3. Wiring cable size must comply with the applicable local and national code.

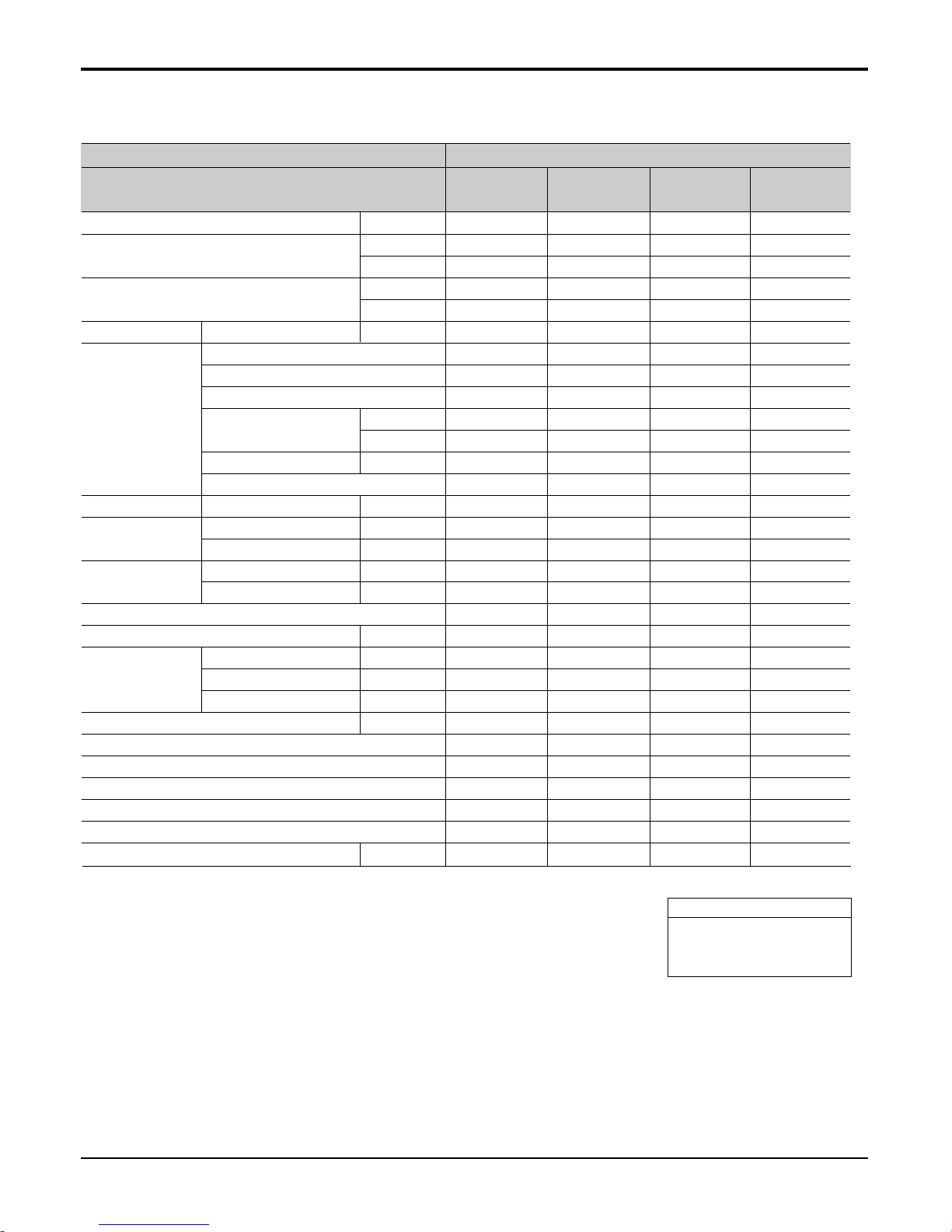

3. Specifications

Power Supply Ø/V/Hz

Cooling Capacity kW

Btu/h

Heating Capacity kW

Btu/h

Current Nominal running current A

Fan Motor Type

Fan Type

Motor Output x Number of Unit

Air Flow Rate cmm

(H/M/L) cfm

Capacitor µF/Vac

Drive

Coil Row x Column x FPI mm

Dimensions Body mm(inch)

(WxHxD) Decorative Panel mm

Weight Body kg(lbs)

Decorative Panel kg(lbs)

Air Filter

Sound Level (H/M/L) dB(A)+3

Piping Liquid mm(inch)

Connections Gas mm(inch)

Drain(OD/ID) mm

Dehumidification Rate l/h

Safety devices

Temperature Sensor

Referigerant

Referigerant Control

Connectable outdoor unit

Power and transmission interunit cable No.x mm

2

Model

ATNH126ELFB

[UT12 NEB]

ATNH186ELFB

[UT18 NEB]

ATNH246FLFB

[UT24 NFB]

ATNH306FLFB

[UT30 NEB]

Indoor unit type Ceilling Cassette - 4way

1 / 220 ~240 / 50 1 / 220 ~240 / 50 1 / 220 ~240 / 50 1 / 220 ~240 / 50

3.52 5.28 7.03 8.21

12,000 18,000 24,000 28,000

4.04 5.95 8.09 9.44

13,800 20,300 27,600 32,200

0.35 0.43 0.53 0.67

Induction Induction Induction Induction

Turbo Fan Turbo Fan Turbo Fan Turbo Fan

18.4*1 22.4*1 40.3*1 48.6*1

9.5 / 8 / 7 13 / 12 / 11 15 / 14 / 13 19 / 17 / 15

336 / 283 / 247 459 / 422 / 388 530 / 494 / 459 671 / 600 / 530

2.5/440 2.5/440 4/440 4/440

Direct Drive Direct Drive Direct Drive Direct Drive

2R x 11C x 19 2R x 11C x 19 2R x 11C x 19 2R x 12C x 21

570*269*570(22.4*10.5*22.4) 570*269*570(22.4*10.5*22.4) 744*292*744(29.3*11.5*29.3) 744*292*744(29.3*11.5*29.4)

670*30*670(26.4*1.2 *26.4) 670*30*670(26.4*1.2 *26.4) 850*30*850(33.5*1.2 *33.5) 850*30*850(33.5*1.2 *33.5)

19(41.9) 19(41.9) 24(52.9) 24(52.9)

3(6.6) 3(6.6) 3(6.6) 3(6.6)

Long life filter Long life filter Long life filter Long life filter

38 / 35 / 32 41 / 39 / 37 43 / 41 / 39 45 / 42 / 39

6.35 (1/4) 6.35 (1/4) 6.35 (1/4) 6.35 (1/4)

9.52 (3/8) 12.7 (1/2) 12.7(1/2) 15.88 (5/8)

32 / 25 32 / 25 32 / 25 32 / 25

1.2 2.4 3 3.3

Fuse, Thermal protector for fan motor Fuse, Thermal protector for fan motor Fuse, Thermal protector for fan motor Fuse, Thermal protector for fan motor

Thermistor Thermistor Thermistor Thermistor

R-410A R-410A R-410A R-410A

Capillary LEV LEV LEV

Single A Single A Single A Single A

4*0.75 4*0.75 4*0.75 4*0.75

Conversion Formula

kW = Btu/h × 0.0002931

kcal/h = Btu/h × 0.252

CFM = CMM × 35.3

Service Manual 17

Ceiling Cassette 4-way

Conversion Formula

kW = Btu/h × 0.0002931

kcal/h = Btu/h × 0.252

CFM = CMM × 35.3

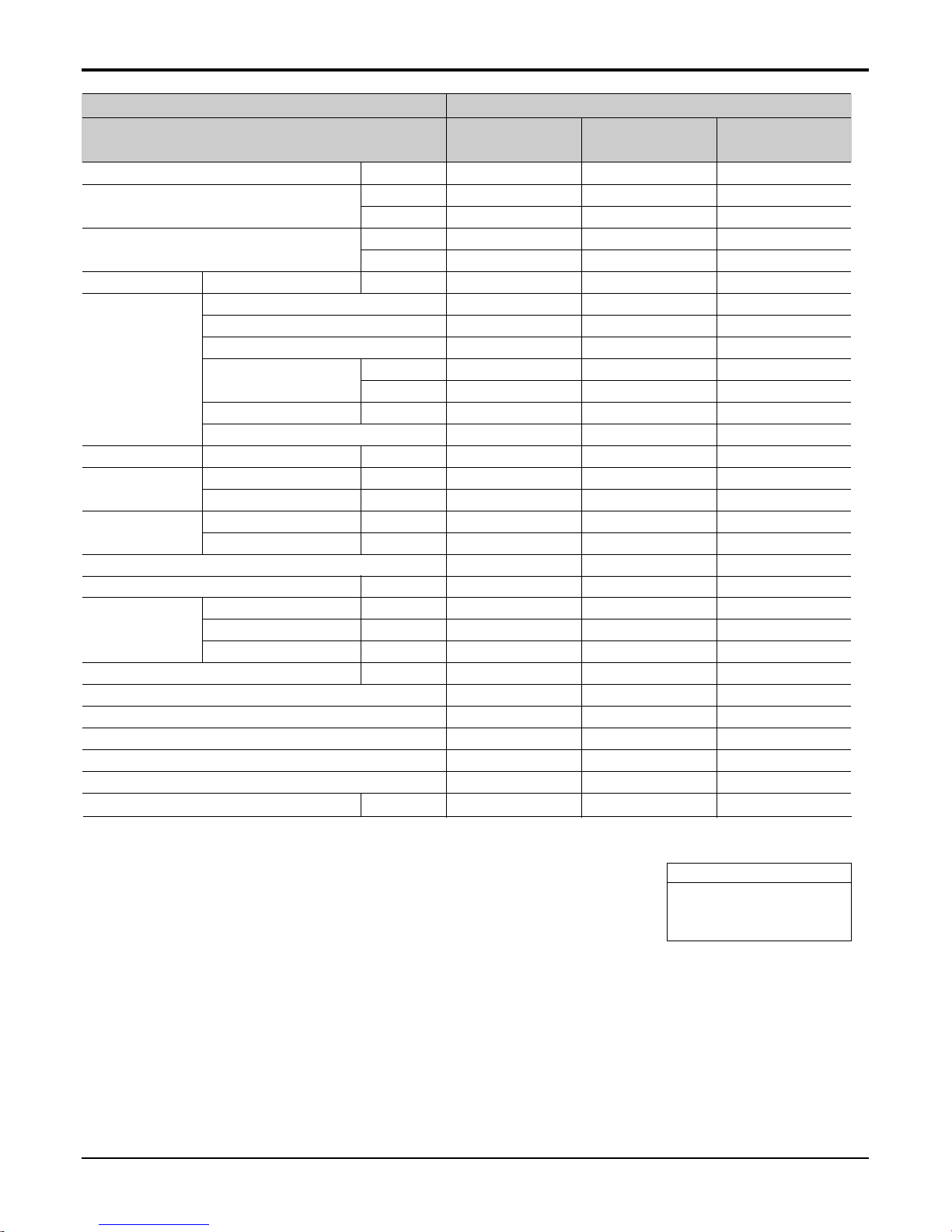

Power Supply Ø/V/Hz

Cooling Capacity kW

Btu/h

Heating Capacity kW

Btu/h

Current Nominal running current A

Fan Motor Type

Fan Type

Motor Output x Number of Unit

Air Flow Rate cmm

(H/M/L) cfm

Capacitor µF/Vac

Drive

Coil Row x Column x FPI mm

Dimensions Body mm(inch)

(WxHxD) Decorative Panel mm

Weight Body kg(lbs)

Decorative Panel kg(lbs)

Air Filter

Sound Level (H/M/L) dB(A)+3

Piping Liquid mm(inch)

Connections Gas mm(inch)

Drain(OD/ID) mm

Dehumidification Rate l/h

Safety devices

Temperature Sensor

Referigerant

Referigerant Control

Connectable outdoor unit

Power and transmission interunit cable No.x mm

2

Model

ATNH366DLFC

[UT36 NDC]

ATNH486DLFB

[UT48 NDB]

ATNH606DLFB

[UT60 NDB]

Indoor unit type Ceilling Cassette - 4way

1 / 220 ~240 / 50 1 / 220 ~240 / 50 1 / 220 ~240 / 50

10.6 14.1 16.4

36,000 48,000 56,000

12.1 15.5 18.1

41,400 52,800 61,600

0.76 1.5 1.8

Induction Induction Induction

Turbo Fan Turbo Fan Turbo Fan

52.5*1 58.5*1 107*1

25 / 23 / 21 32 / 30 / 28 34 / 32 / 30

883 / 812 / 742 1059 /988 / 918 1200 / 1130 / 1059

2.5/440 6/400 6/400

Direct Drive Direct Drive Direct Drive

2R x 12C x 21 2R x 12C x 21 2R x 12C x 21

840*288*840(33.1*11.3*33.1) 840*288*840(33.1*11.3*33.1) 840*288*840(33.1*11.3*33.1)

950*30*950(37.4*1.2 *37.4) 950*30*950(37.4*1.2 *37.4) 950*30*950(37.4*1.2 *37.4)

32(70.4) 32(70.4) 32(70.4)

5(11) 5(11) 5(11)

Long life filter Long life filter Long life filter

40 / 38 / 36 43 / 41 / 39 50 / 47 / 43

6.35 (1/4) 9.52 (3/8) 9.52 (3/8)

15.88(5/8) 19.05(3/4) 19.05(3/4)

32 / 25 32 / 25 32 / 25

4.0 5.5 6.5

Fuse, Thermal protector for fan motor Fuse, Thermal protector for fan motor Fuse, Thermal protector for fan motor

Thermistor Thermistor Thermistor

R-410A R-410A R-410A

LEV LEV LEV

Single A Single A Single A

4*0.75 4*0.75 4*0.75

Note :

1. Capacities are based on the following conditions:

Cooling: - Indoor Temperature 27°C(80.6°F) DB /19°C(66.2°F) WB

- Outdoor Temperature 35°C(95°F) DB /24°C(75.2°F) WB

Heating: - Indoor Temperature 20°C(68°F) DB / 15°C(59°F) WB

- Outdoor Temperature 7°C(44.6°F) DB / 6°C(42.8°F) WB

Piping Length - Interconnecting Piping Length 7.5m

- Level Difference of Zero.

2. Cooling/heating capacity of indoor unit can be lower when it is connected to MPS variable outdoor.

3. Wiring cable size must comply with the applicable local and national code.

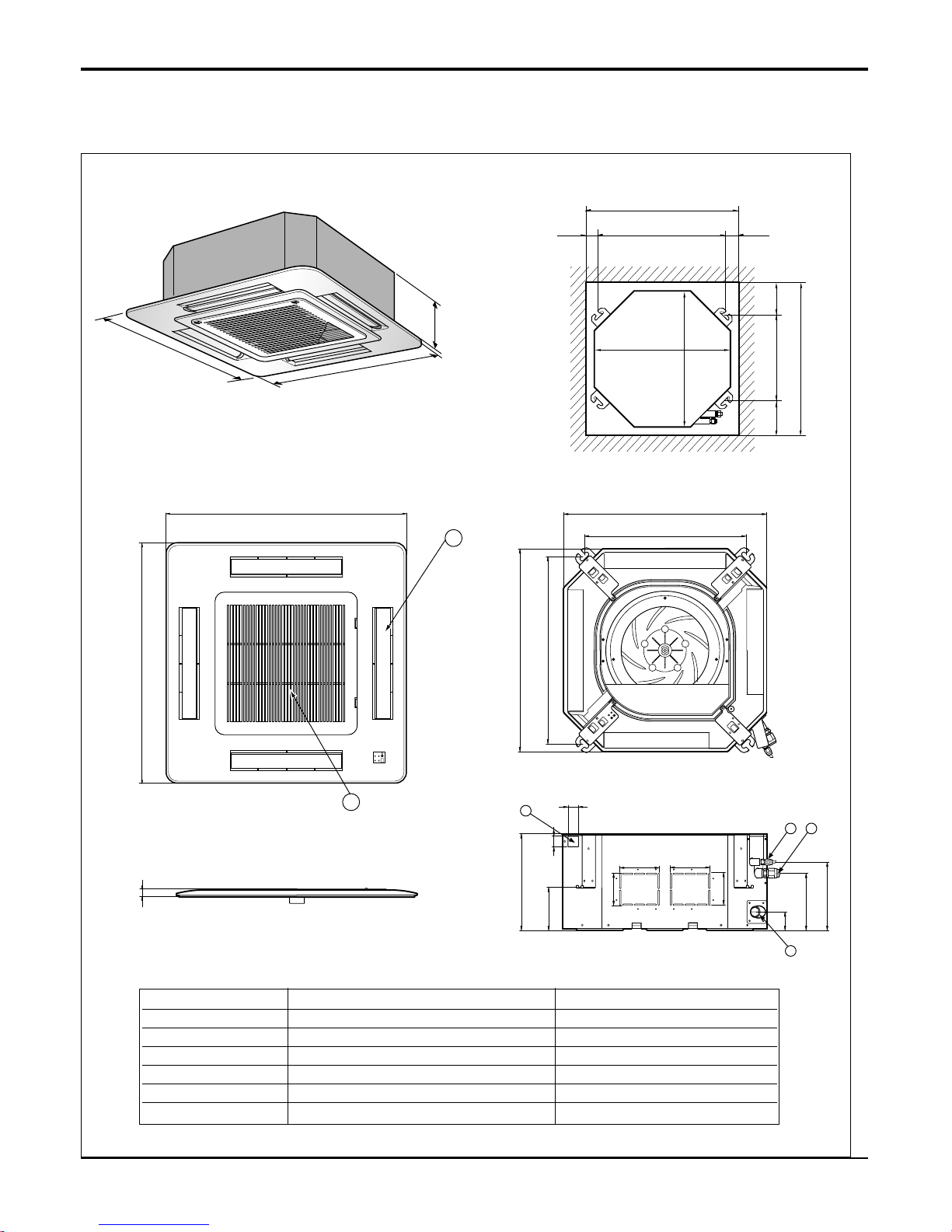

18 Universal System Air Conditioner

Ceiling Cassette 4-way

269

570

269

190.5

160

52

90

90

120.4

30

521

570

450

40

110 110

670

670

4

132

Unit:mm

570 Unit size

570 Unit size

450 (Hanging bolt)

7575

600 (Ceiling opening)

600 (Ceiling opening)

521(Hanging bolt)

39.5

39.5

670

670

5

6

30

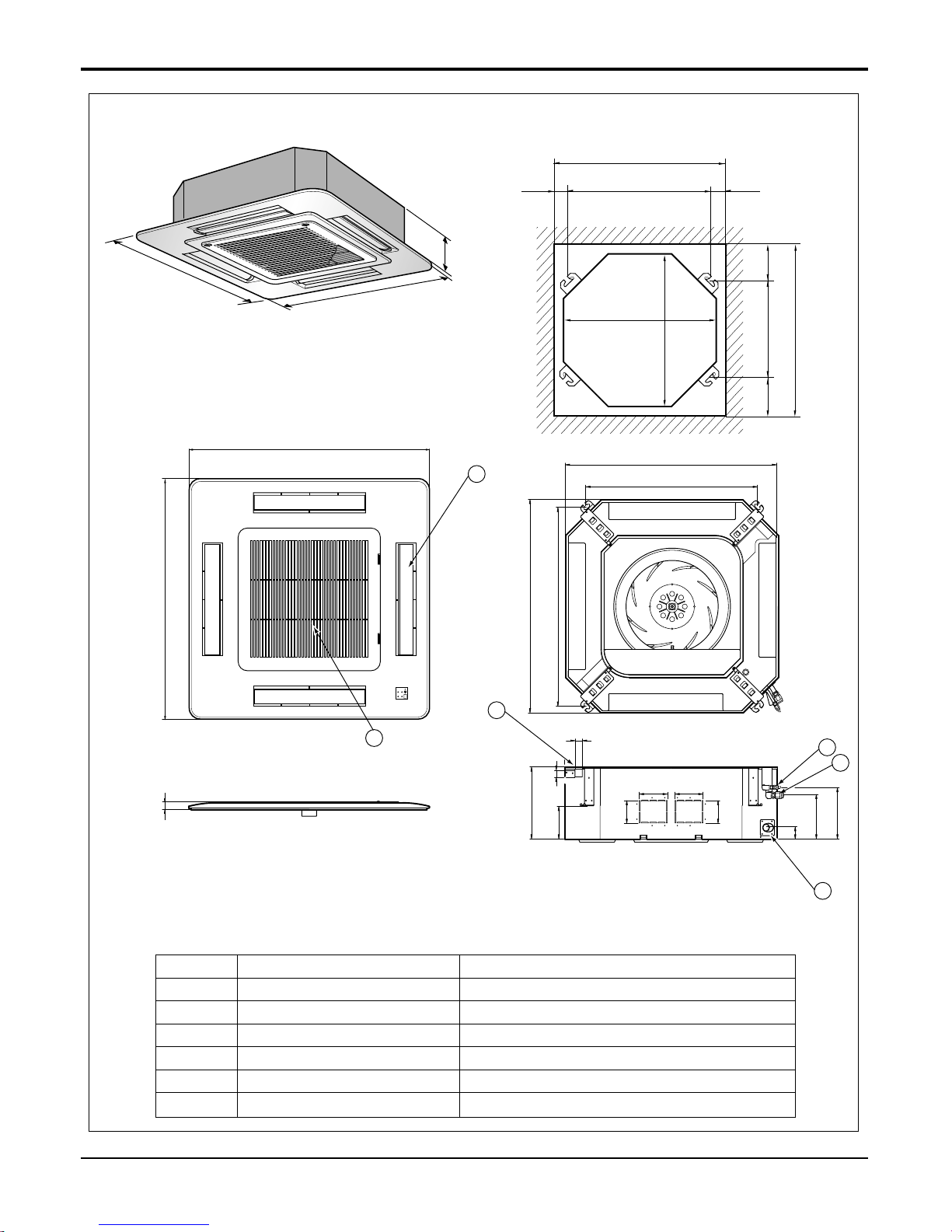

ATNH-EL(Decoration Panel : PT-HEA, PT-HEC)

(unit : mm)

Number Name Descripition

1 Liquid pipe connection ø6.35 flare

2 Gas pipe connection 12k: ø9.52, 18k:

ø12.7 flare

3 Drain pipe connection

4 Power supply connection

5 Air discharge grille

6 Air suction grille

4. Dimensional Drawings

Service Manual 19

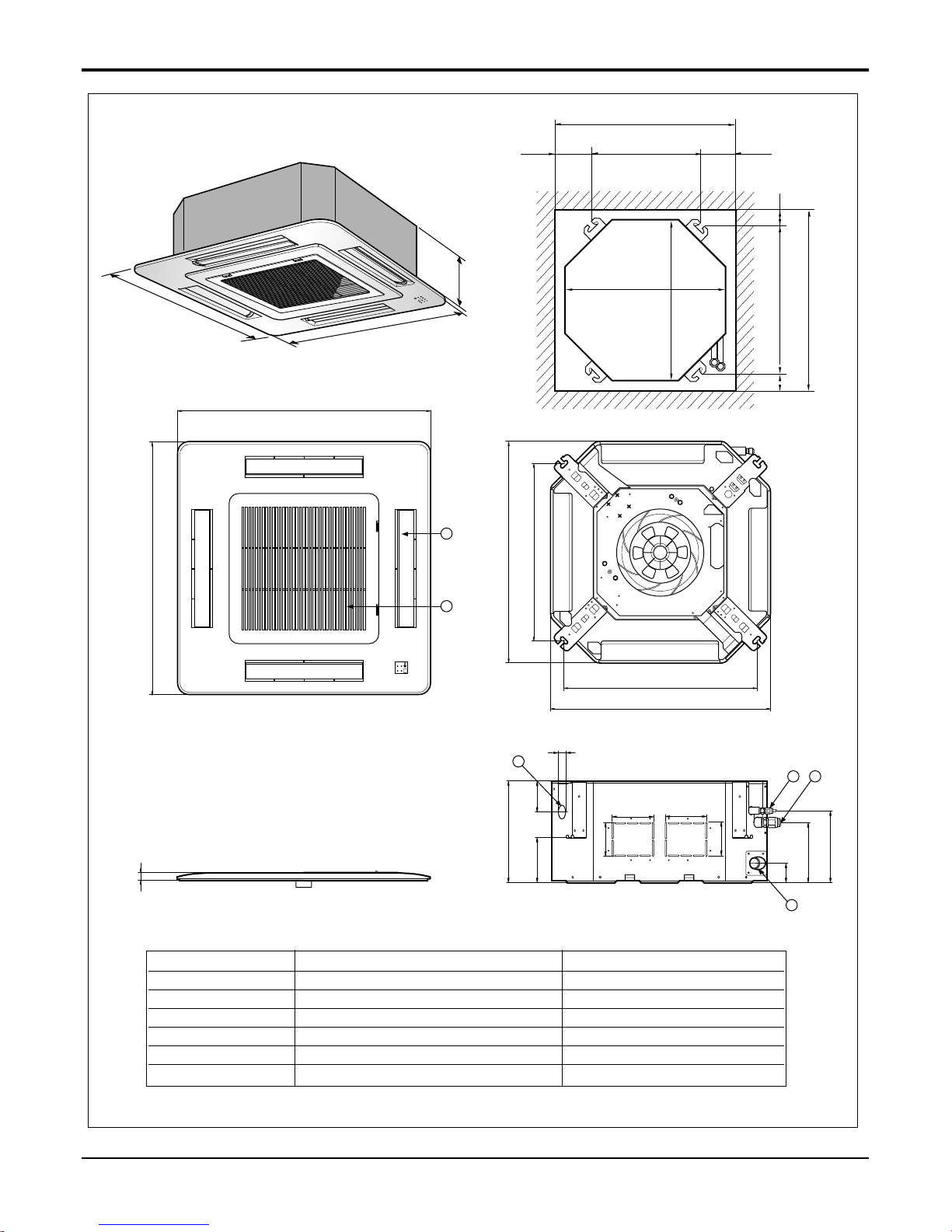

Ceiling Cassette 4-way

292

850

850

850

850

744

658

572

744

292

212

150

54

90

90

192 117

70

110 110

4

132

5

6

Unit:mm

744 Unit size

744 Unit size

658 (Hanging bolt)

6666

790 (Ceiling opening)

790 (Ceiling opening)

572(Hanging bolt)

109

109

30

ATNH-FL(Decoration Panel : PT-HFA, PT-HFC)

(unit : mm)

Number Name Descripition

1 Liquid pipe connection ø6.35 flare

2 Gas pipe connection 24K:

ø12.7, 30K: ø15.88 flare

3 Drain pipe connection

4 Power supply connection

5 Air discharge grille

6 Air suction grille

20 Universal System Air Conditioner

Ceiling Cassette 4-way

ATNH-DL(Decoration Panel : PT-HDA, PT-HDC)

288

950

950

290

210.5

180

52

140

40

110

30

90

90

110

840

785

840

678

840 Unit size

840 Unit size

672 (Hanging bolt)

101.5101.5

875 (Ceiling opening)

875 (Ceiling opening)

785(Hanging bolt)

45

45

Unit:mm

4

1

2

3

950

950

5

6

30

Number Name Descripition

1 Liquid pipe connection 36k:ø6.35, 48/60k: ø9.52 flare

2 Gas pipe connection 36k:ø15.88, 48/60k: ø19.05flare

3 Drain pipe connection

4 Power supply connection

5 Air discharge grille

6 Air suction grille

(unit : mm)

Service Manual 21

Ceiling Cassette 4-way

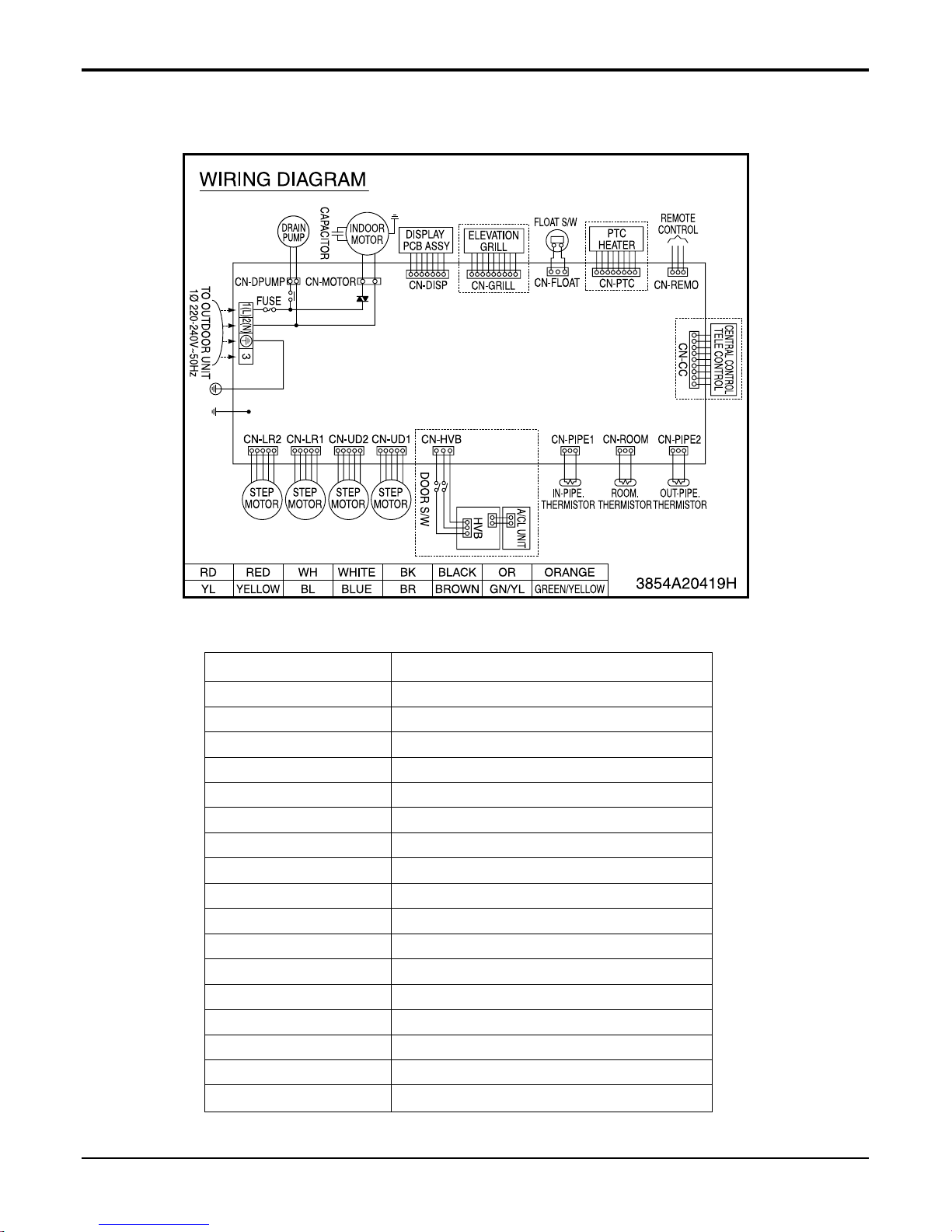

CONNECTOR NUMBER LOCATION

CN-POWER AC POWER SUPPLY

CN-MOTOR BLDC FAN MOTOR OUTPUT

CN-D/PUMP DRAIN PUMP OUTPUT

CN-DISP DISPLAY

CN-FLOAT FLOAT SWITCH INPUT

CN-PTC PTC HEATER INUT

CN-REMO REMOTE CONTROL

CN-GRILL GRILL CONTROL

CN-CC CENTRAL CONTROL

CN-PIPE2 DISCHARGE PIPE SENSOR

CN-ROOM ROOM SENSOR

CN-PIPE1 PIPE SENSOR

CN-HVB AIR CLEANER

CN-UD1 STEP MOTOR

CN-UD2 STEP MOTOR

CN-LR1 STEP MOTOR

CN-LR2 STEP MOTOR

5. Wiring Diagrams

22 Universal System Air Conditioner

Ceiling Cassette 4-way

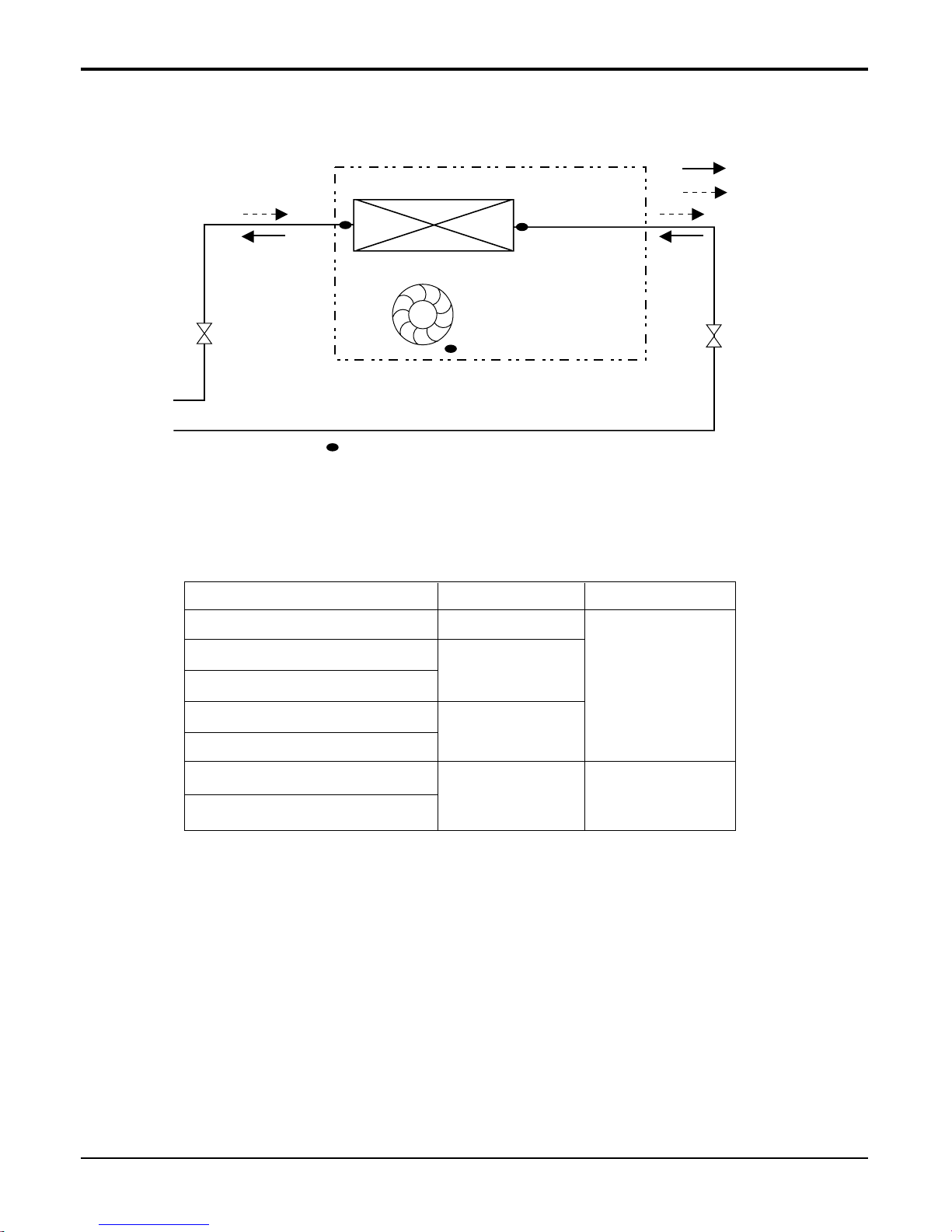

Refrigerant pipe connection port diameter

Model

ATNH126ELFB [UT12 NEB]

ATNH186ELFB [UT18 NEB]

ATNH246FLFB [UT24 NFB]

ATNH306FLFB [UT30 NFB]

ATNH366DLFB [UT36 NDB]

ATNH486DLFB [UT48 NDB]

ATNH606DLFB [UT60 NDB]

Gas

9.52(3/8)

12.7(1/2)

15.88(5/8)

19.05(3/4)

Liquid

6.35(1/4)

9.52(3/8)

[unit: mm(inch)]

Heat Exchanger

Turbo Fan

lndoor unit

:Heating

:Cooling

: Thermistor

6. Piping Diagrams

Service Manual 23

Ceiling Cassette 4-way

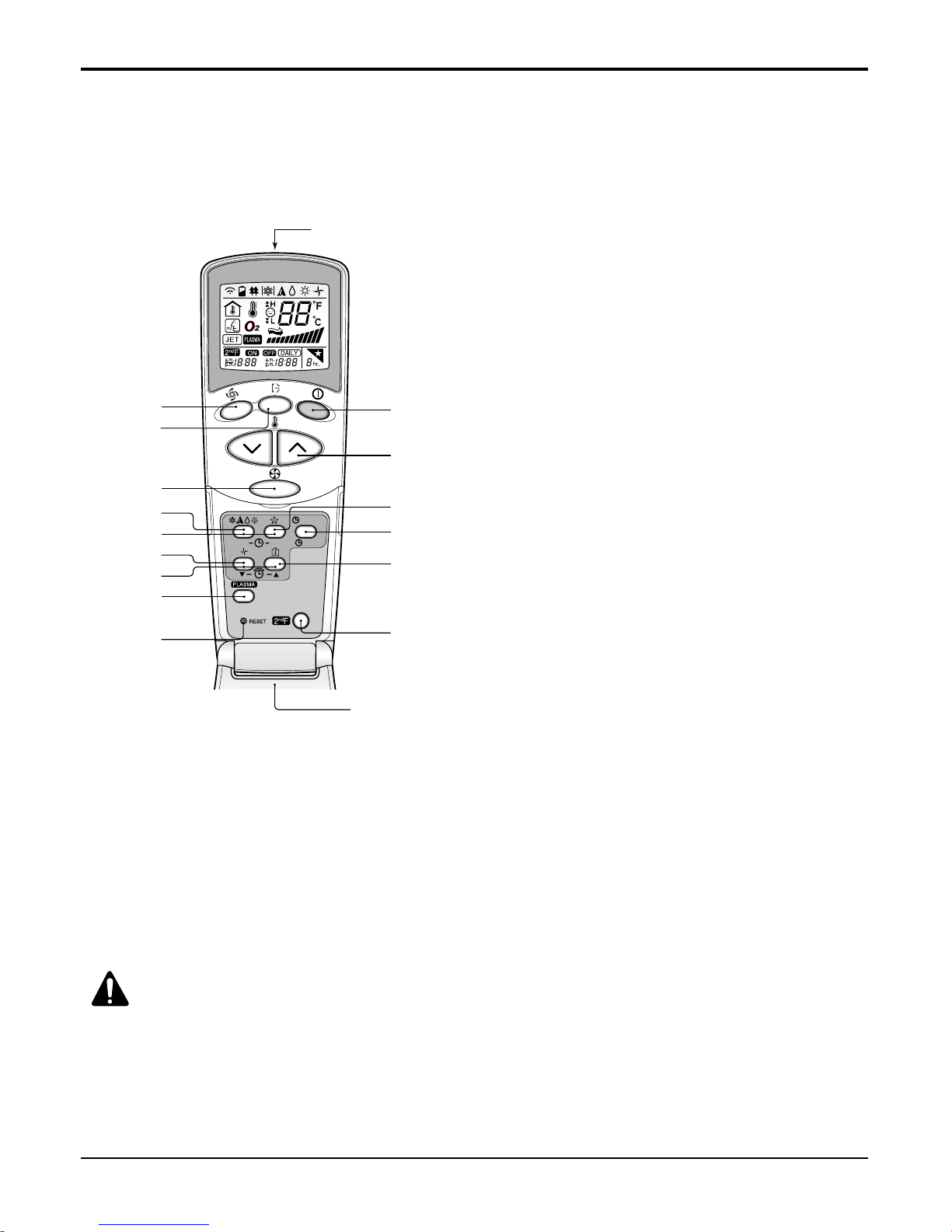

7. Operating Instructions

1. Operation display

Displays the operation conditions.

2. On/Off Button

Operation starts when this button is pressed, and

stops when the button is pressed again.

3. Set Temperature Button

Used to set the temperature when the desired temperature is obtained.

4. FAN Operation Button

Used to circulate room air without cooling or heating.

5. Fan Speed (Jet Cool Button: 4 way)

Used to set the desired fan speed or select Jet cool

mode.

6. Operation Mode Selection Button

Used to select the operation mode.

• Auto Operation Mode

• Cooling Operation Mode

• Soft Dry Operation Mode

• Heating Operation Mode(except cooling model)

7. Auto Swing Button

Used to swing up and down.

8.

Room Temperature Checking Button

Used to check the room temperature.

9. Plasma Air Clean Button (optional)

10. Timer Cancel Button

Used to cancel the timer.

11. Timer Set Button

Used to set the timer when the desired time is

obtained.

12.

Week Button

Used to set a day of the week.

13. Program Button

Used to set the weekly timer.

14. Holiday Button

Used to set a holiday of the week.

15. Time Set Button

Used to set the time of the day and change the time

in the weekly timer Function.

16. Set and Clear Button

Used to set and clear the weekly timer.

17. Swirl Button (4 way)

Used to select swirl mode.

Jet Cool Button (1 way)

18. Reset Button

Used to set the current time and clear the setting

time.

❈

Display temperature can be different from actual room temperature if the remote controller is installed

at the place where sun-rays are falling directly or the place nearby heat source.

Timer Cancel

Program Week

Hour Min

Holiday

Set/Clr

RESET

Plasma

ZONE

1234

Operation unit

Humidify

JET

AUTO

AUTO SWING OPERATION

FAN SPEED

Program set

SUB FUNCTION

SET TEMP

Room Temp

HI

MED

LO

Heater

Defrost

Filter

Preheat

Out door

Time

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

3

10

12

14

15

11

13

18

16

2

1

Heat Pump Model

Cooling Model

5

4

6

8

9

7

17

■ Name and Function of Remote Controller

24 Universal System Air Conditioner

Ceiling Cassette 4-way

This air-conditioner is equipped with wired remote controller basically. But if you want to be available with wireless remote

controller, you pay for it.

1. START/STOP BUTTON

Operation starts when this button is pressed and

stops when the button is pressed again.

2. OPERATION MODE SELECTION BUTTON

Used to select the operation mode.

3. ROOM TEMPERATURE

SETTING BUTTONS

Used to select the room temperature.

4. INDOOR FAN SPEED SELECTOR

Used to select fan speed in four steps

low, medium, high and CHAOS.

5. JET COOL

Used to start or stop the speed cooling/heating.

(Speed cooling/heating operates super high fan

speed.)

6. CHAOS SWING BUTTON

Used to stop or start louver movement and set the

desired up/down airflow direction.

7. ON/OFF TIMER BUTTONS

Used to set the time of starting and stopping operation.

8. TIME SETTING BUTTONS

Used to adjust the time.

9. TIMER SET/CANCEL BUTTON

Used to set the timer when the desired time is

obtained and to cancel the Timer operation.

10. SLEEP MODE AUTO BUTTON

Used to set Sleep Mode Auto operation.

11. AIR CIRCULATION BUTTON

Used to circulate the room air without cooling or

heating.

12. ROOM TEMPERATURE CHECKING BUTTON

Used to check the room temperature.

13. PLASMA(OPTIONAL)

Used to start or stop the plasma-purification function.

14. RESET BUTTON

Initialize remote controller.

15. 2nd F Button

Used prior to using modes printed in blue at the

bottom of buttons.

CAUTION:

of handling the Remote Controller

• Aim at the signal receiver on the wired remote controller so as to operate.

• The remote control signal can be received at a distance of up to about 7m.

• Be sure that there are no obstructions between the remote controller and the signal receptor.

• Do not drop or throw the remote controller.

• Do not place the remote controller in a location exposed to direct sunlight, or near the heating unit, or any other

heat source.

• Block a strong light over the signal receptor with a curtain or etc. so as to prevent the abnormal operation. (ex:electronic quick start, ELBA, inverter type fluorescent lamp)

❈ The wireless remote controller do not operate the swirl mode.

AUTO CLEAN

ON

OFF

CANCEL

SET

Flip-up door

(opened)

Signal transmitter

5

1

3

10

9

12

15

6

4

2

7

11

8

13

14

■ Wireless Remote Controller (optional)

Service Manual 25

Ceiling Cassette 4-way

8. Installation

• Please read this instruction sheet completely before installing the product.

• When the power cord is damaged, replacement work shall be performed by authorized personnel only.

• Installation work must be performed in accordance with the national wiring standards by authorized personnel only.

Anti-bacteria filter

Air

Intake

Air Outlet

Required Parts Required Tools

• Connecting cable

• Pipes: Gas side

Liquid side

• Hanging Bolt

(W 3/8 or M10 length 650mm)

• Insulated drain hose

• Additional Drain hose

(Inner Diameter...........................32mm)

• Level

• Screw driver

• Electric drill

• Hole core drill (ø70mm)

• Flaring Tools set

• Torque Wrenches

• Hexagonal Wrench (4mm, 5mm)

• Gas-leak detector

• Owner’s Manual

• Thermometer

8.1 Selection of the best location

• There should not be any heat source or steam near the

unit.

• There should not be any obstacles to the air circulation.

• There should be provision of easy condensate drain.

• Taking into accounting the noise prevention criteria,

spot the installation location.

• Do not install the unit near the door way.

• Keep proper distances, of the unit, from ceiling, fence,

floor, walls and other obstacles as shown in figure.

• The indoor unit must have the maintenance space.

Unit:cm

Ceiling

Ceiling Board

Ceiling Board

30 or more

Above 250

400 or less

100

or more

50 or

more

50 or

more

30 or less

Floor

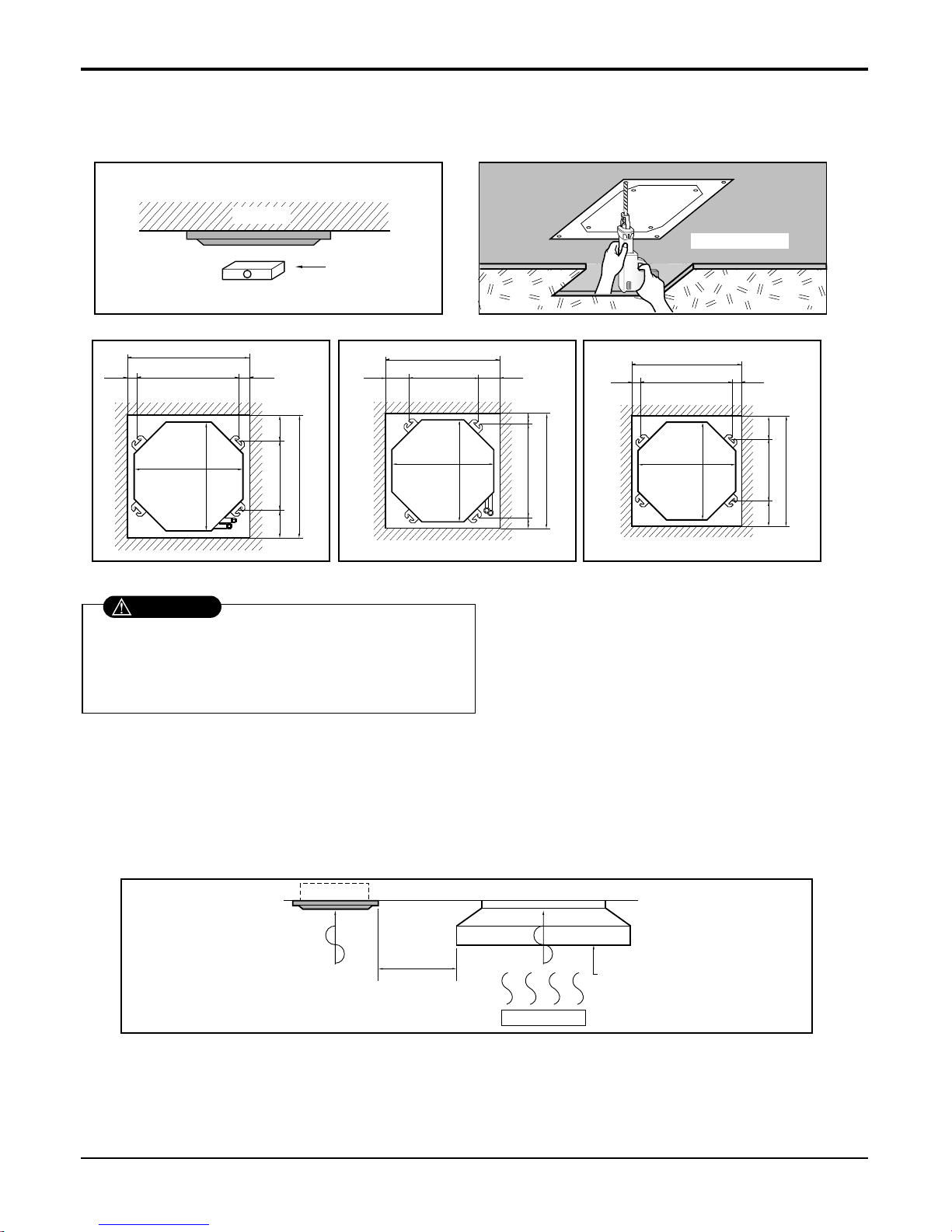

8.2 Ceiling opening dimensions and hanging bolt location

NOTE:

• Avoid the following installation location.

1. Such places as restaurants and kitchen where considerable amount of oil steam and flour is generated.

These may cause heat exchange efficiency reduction, or water drops, drain pump mal-function.

In these cases, take the following actions;

• Make sure that ventilation fan is enough to cover all noxious gases from this place.

• Ensure enough distance from the cooking room to install the air conditioner in such a place where it may not suck oily steam.

Ceiling board

Level gauge

Ceiling

Unit:mm

570 Unit size

570 Unit size

672 (Hanging bolt)

7575

600 (Ceiling opening)

600 (Ceiling opening)

521(Hanging bolt)

39.5

39.5

TE Model TF Model TD Model

Unit:mm

744 Unit size

744 Unit size

658 (Hanging bolt)

6666

790 (Ceiling opening)

790 (Ceiling opening)

572(Hanging bolt)

109

109

Unit:mm

840 Unit size

840 Unit size

672 (Hanging bolt)

101.5101.5

875 (Ceiling opening)

875 (Ceiling opening)

785(Hanging bolt)

45

45

• The dimensions of the paper pattern for installation are the same as those of the ceiling opening dimensions.

• Select and mark the position for fixing bolts and

piping hole.

• Decide the position for fixing bolts slightly tilted to

the drain direction after considering the direction

of drain hose.

• Drill the hole for anchor bolt on the wall.

• This air-conditioner uses a drain pump.

• Install the unit horizontally using a level gauge.

• During the installation, care should be taken not to

damage electric wires.

CAUTION

2. Avoid installng air conditioner in such places where cooking oil or iron powder is generated.

3. Avoid places where inflammable gas is generated.

4. Avoid place where noxious gas is generated.

5. Avoid places near high frequency generators.

Use the ventilation fan

for smoke-collecting

hood with sufficient

capacity.

Cooking table

Air conditioner

Take enough

distance

26 Universal System Air Conditioner

Ceiling Cassette 4-way

Service Manual 27

Ceiling Cassette 4-way

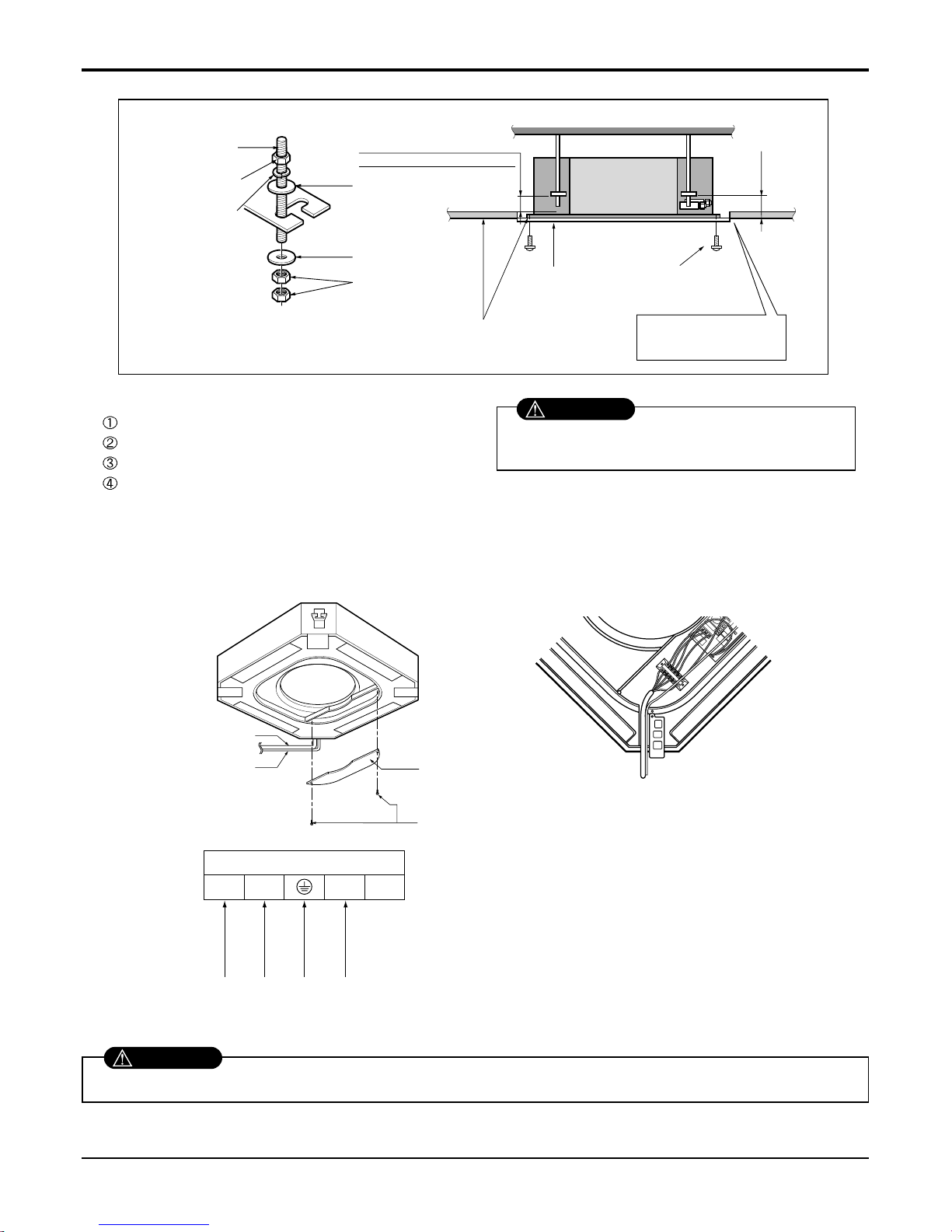

Set screw of

paper pattern (4 pieces)

Paper pattern

for installation

Ceiling board

150mm

Adjust the same height

Ceiling board

Ceiling

Flat washer for M10

(accessory)

Keep the length of the bolt

from the bracket to 40mm

Open the ceiling board

along the outer edge of the

paper pattern.

Flat washer for M10

(accessory)

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Nut

(W3/8 or M10)

Spring washer

(M10)

Air Conditioner body

• The following parts are local purchasing.

Hanging Bolt - W 3/8 or M10

Nut - W 3/8 or M10

Spring Washer - M10

Plate Washer - M10

• Tighten the nut and bolt to prevent unit from

falling off.

CAUTION

[Air inlet side view]

Control box cover

Indoor

power cord

Remote

controller

cord

Control box cover

fitting screw(2 units)

Terminal Block in Indoor

1(L) 2(N) 3 4

Connected to outdoor unit

8.3 Wiring Connection

• Open the control box cover and connect the remote control cord and Indoor power wires.

Make sure that the screws of the terminal are free from looseness.

WARNING

28 Universal System Air Conditioner

Ceiling Cassette 4-way

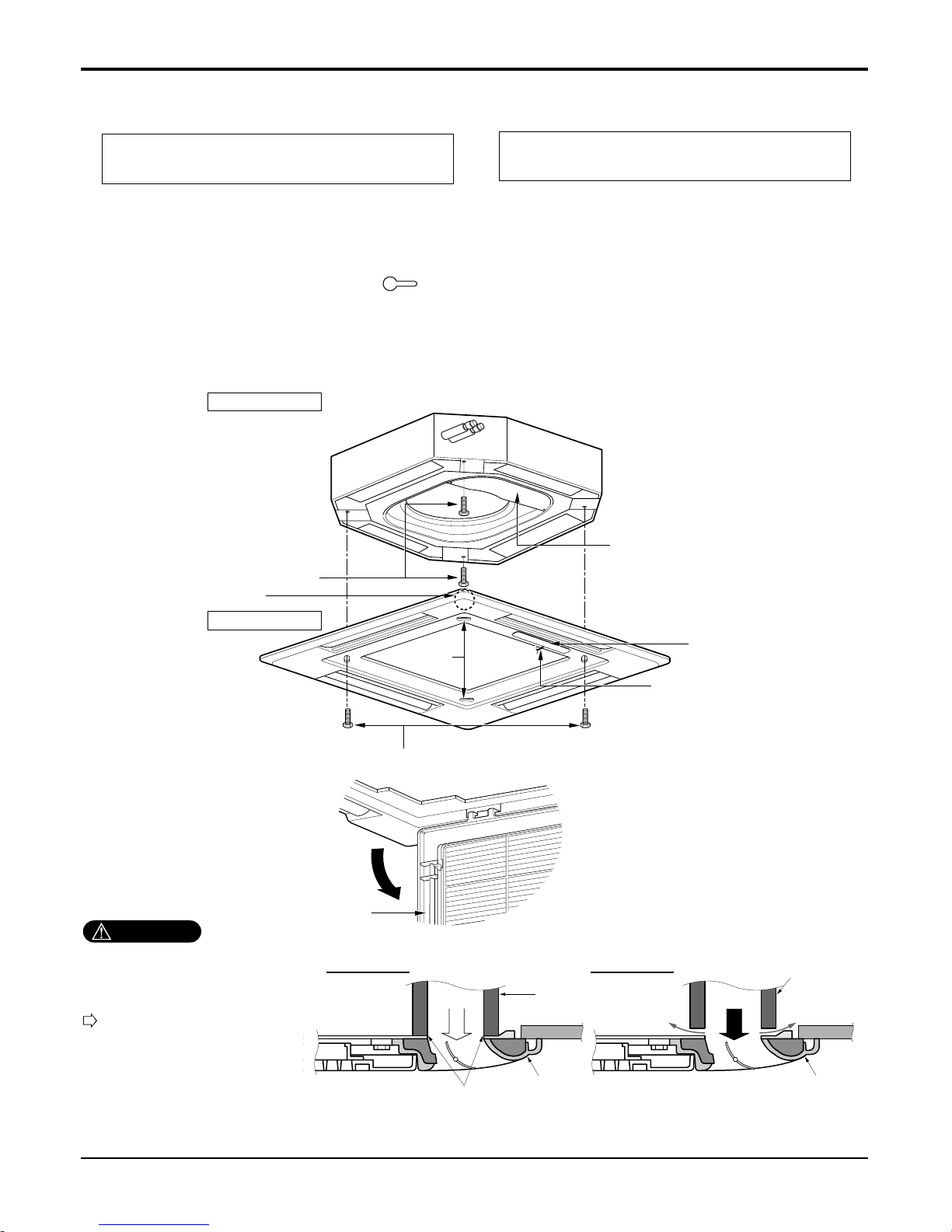

8.4 Installation of Decoration Panel

1. Temporarily fix two decoration panel fixing screws (hexagon M5 screw) on the unit body. (Tighten by

amount 10mm in length.)

The fixing screws (hexagon M5 screw) are included the indoor unit box.

2. Remove the air inlet grille from the decoration panel. (Remove the hook for the air inlet grille cord.)

3. Hook the decoration panel key hole ( ) on the screws fixed in step above, and slide the panel so

that the screws reach the key hole edge.

4. Retighten completely two temporarily fixed screws and other two screws. (Total 4 screws)

5. Connect the louver motor connector and display connector.

6. After tightening these screws, install the air inlet grille (including the air filter).

Decoration panel fixing screws

(hexagon M5 screws)

Temporally fitting at 2 places

(Tightening about 10mm)

Control box cover

Piping side

Inlet GrilleInlet GrilleInlet Grille

Inlet GrilleInlet Grille

Louver motor

Decoration panel fixing screws

(Hexagon M5 screw)

Air conditioner unit

Decoration panel

Key holes

Display

Lead wire for

louver motor and

display

The decoration panel has its installation

direction.

Before installing the decoration panel,

always remove the paper template.

CAUTION

Install certainly the decoration

panel.

Cool air leakage causes sweating.

Water drops fall.

Air conditioner

unit

Ceiling

board

Decoration panel

Decoration

panel

Fit the insulator (this part) and

be careful for cool air leakage

Good example

Air

Cool air leakage

(no good)

Bad example

Ceiling

board

Air conditioner unit

Service Manual 29

Ceiling Cassette 4-way

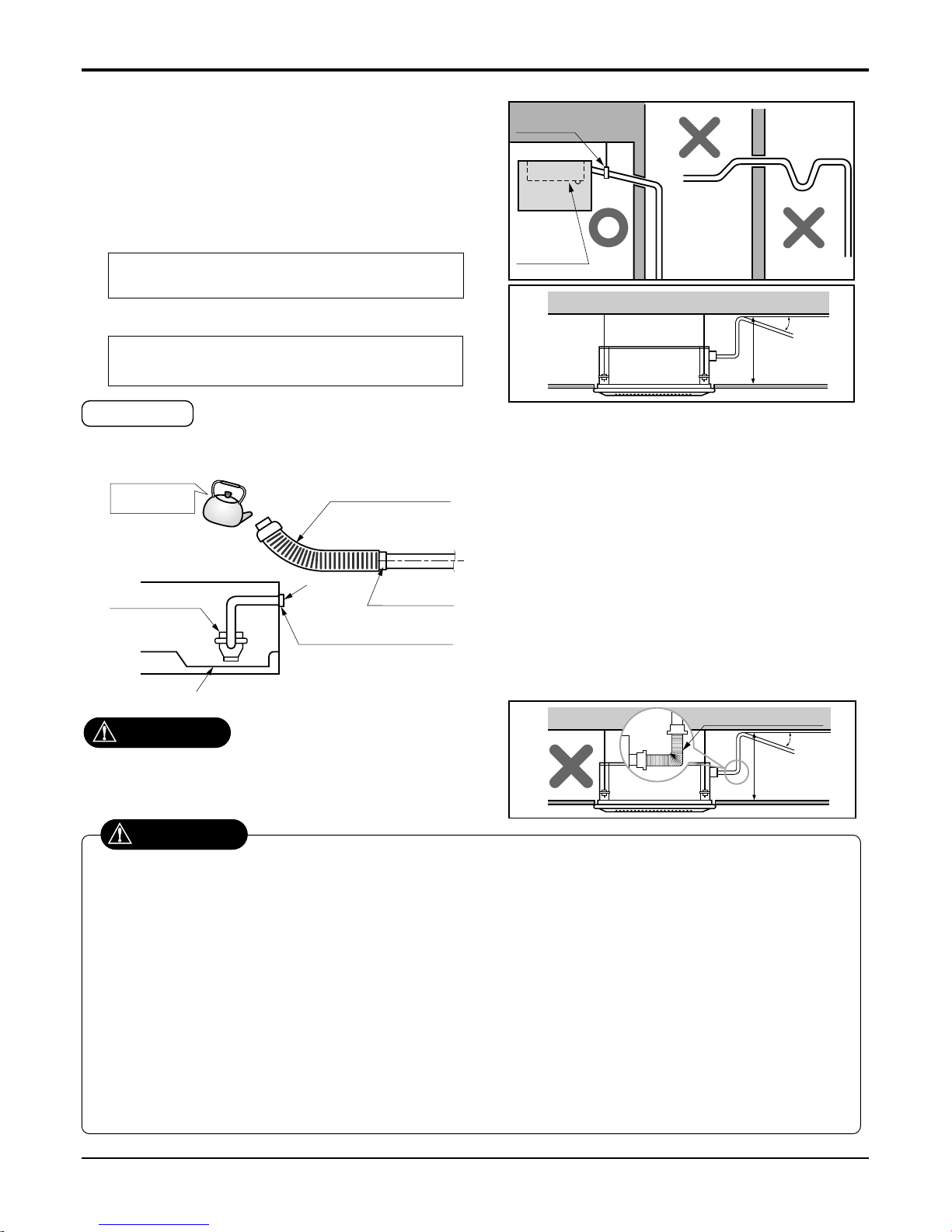

8.5 Indoor Unit Drain Piping

• Drain piping must have down-slope (1/50 to 1/100): be sure

not to provide up-and-down slope to prevent reversal flow.

• During drain piping connection, be careful not to exert extra

force on the drain port on the indoor unit.

• The outside diameter of the drain connection on the indoor

unit is 32mm.

•

Be sure to install heat insulation on the drain piping.

Piping material: Polyvinyl chloride pipe VP-25

and pipe fittings

The air conditioner uses a drain pump to drain water.

Use the following procedure to test the drain pump operation:

• Connect the main drain pipe to the exterior

and leave it provisionally until the test

comes to an end.

• Feed water to the flexible drain hose and

check the piping for leakage.

• Be sure to check the drain pump for normal

operating and noise when electrical wiring

is complete.

• When the test is complete, connect the

flexible drain hose to the drain port on the

indoor unit.

Heat insulation material: Polyethylene foam with

thickness more than 8 mm.

Drain test

Maintenance

drain port

Upward

routing

not allowed

Pipe clamp

Indoor unit

1/50~1/100

MAX 700mm

Feed water

Drain Pump

Drain pan

Flexible drain hose

(accessory)

Main

drain pipe

Glue the joint

Drain

port

Drain hose connection

Use the clip (accessory)

CAUTION

The supplied flexible drain hose should not be curved,

neither screwed. The curved or screwed hose may

cause a leakage of water.

1/50~1/100

MAX 700mm

Flexible drain hoseFlexible drain hose

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power specialized for the air conditioner. As for the method of wiring, be guided by the

circuit diagram pasted on the inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screw which fasten the wiring in the casing of electrical fittings are liable to come loose from vibrations to which the

unit is subjected during the course of transportation. Check them and make sure that they are all tightly fastened. (If they

are loose, it could give rise to burn-out of the wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of the rated voltage marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip a leakage breaker where it is wet or moist.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point there of, fuse breaking, disturbance to the normal function of a

overload protection device.

• Proper starting power is not given to the compressor.

CAUTION

30 Universal System Air Conditioner

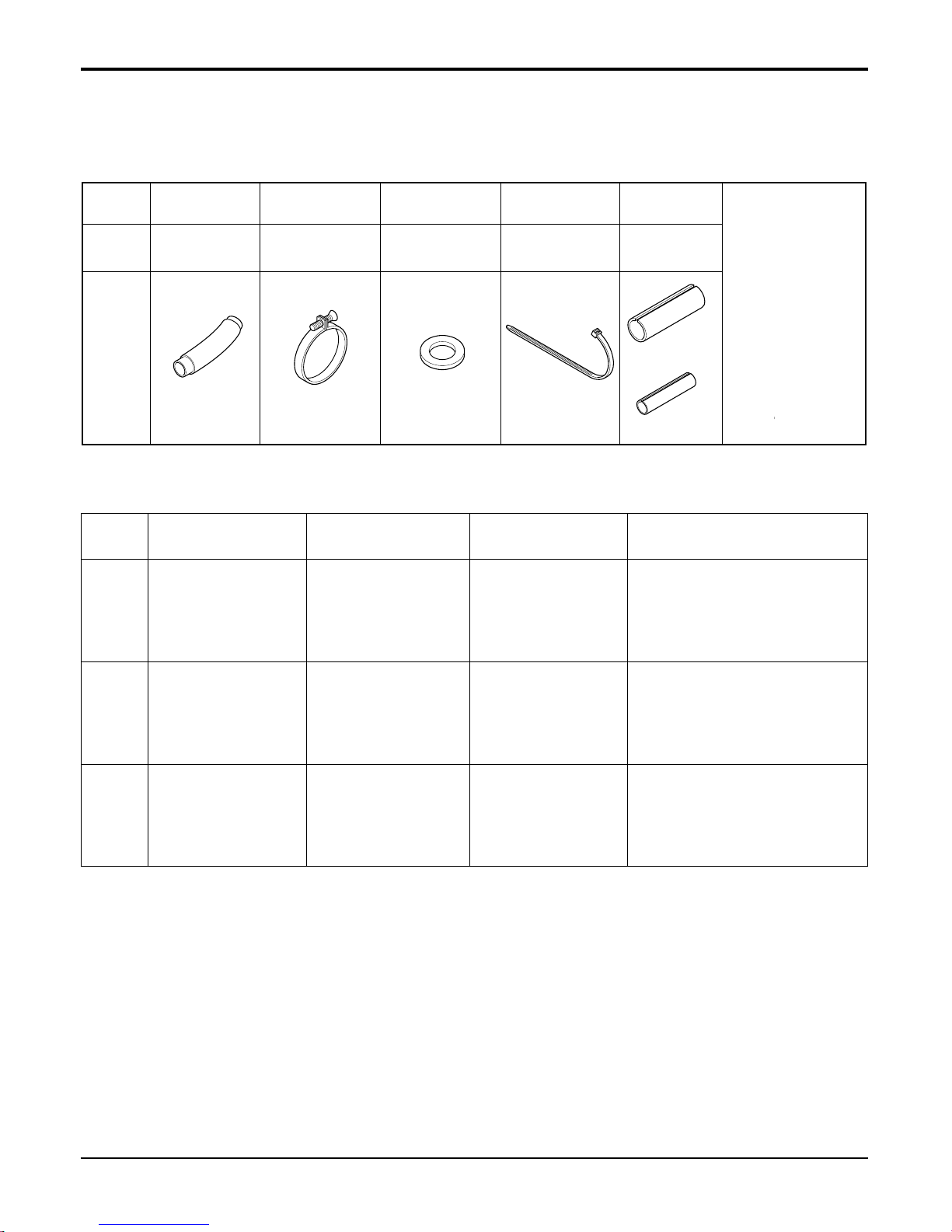

Ceiling Cassette 4-way

Name

Quantity

Shape

for gas pipe

for liquid pipe

Clamp metal

1 EA

Insulation for

fitting

1 SET

Drain hose

1 EA

Clamp

8 EA

Washer for

hanging backet

8 EA

(Other)

Optional Accessories(For Unit)

Standard Accessories

• Paper pattern for

installation

• Owner's manual

• Installation manual

No. Item Type Model No.

Component Parts

• Wireless remote control : 1EA

• Holder : 1EA

• Battery : 2EA

• Screw : 2EA

• Central control

• Installation manual

• PCB: 1EA

• Installation manual

• Wire assembly

1

2

3

Wireless remote

control

With air purifying

function

AHWRHD

Central control Simple PQCSA101S0

PI485 Gateway For central control PHNFP14A0

9. Accessories

Loading...

Loading...