Page 1

LS430 UCF30

Safety Recall – Fuel Pump Replacement

Investigations by Toyota Motor Corporation have determined a requirement exists for the initiation of a

safety recall campaign, to be conducted in accordance with the FCAI Code of Practice for safety related

recalls, affecting a range of Lexus LS430 vehicles.

DESCRIPTION OF PROBLEM

In the subject vehicles, the fuel pump impeller may have been moulded in such a way that it can be

deformed by alcohol contained in the fuel, causing the impeller to contact the fuel pump body. This

condition could increase the rotation resistance of the impeller and, in the worst case, may result in

failure of the fuel pump.

INVOLVED VEHICLES

Lexus LS430 vehicles produced from 29th July 2003 to 9th March 2004 are being recalled, refer VIN

range listed below.

A total of 179 vehicles are involved.

VEHICLE IDENTIFICATION

Model Name Model Code VDS VIS Production Period

LS430 UCF30 BN36F# 00123382 – 00155462

NOTE:

(1) Not all vehicles within the above range were sold in Australia.

(2) # = Check digit – alpha or numeric.

29 July 2003 to

9 March 2004

TIMING / OWNER NOTIFICATION

Lexus has contacted owners of the involved vehicles by telephone and letter advising them of the need

for this campaign. The mail out occurred on 11th February 2005.

1

© Toyota Motor Corporation Australia Limited Date: Feb 2006

A.B.N. 64 009 686 097 Section: Fuel

Reproduction in whole or part prohibited without written approval. No: 01

Page 2

DEALER ACTION

Dealers are required to:

1. Confirm vehicle is within involved VIN range.

2. Replace the fuel pump as per the Technical Instructions included in this Bulletin.

3. Apply the Campaign Identification Label and Submit a warranty claim.

CORRECTION PARTS REQUIRED TO COMPLETE THIS CAMPAIGN

Replacement parts are packaged together in kit form and are available through normal parts channels.

Parts information is as follows.

Part Number Part Name Quantity per Vehicle

04004 – 18150 Pump Kit, Fuel 1

TECHNICAL INSTRUCTIONS

Refer to the Technical Instructions included in this Bulletin for details of the fuel pump replacement

procedures.

CAMPAIGN IDENTIFICATION LABEL

Fill in the Campaign Identification Label and affix it to the right hand side ‘A’ pillar post between the

upper and lower door hinges. The diagram below shows the type of label and completion method.

This label is designed so the completion information can be impressed into the label rather than being

marked with ink, therefore the following applies:

1. Prior to affixing label, using a ballpoint pen, impress the date and campaign code number (4520M)

and dealer code onto the label.

2. Ensure the right hand ‘A’ pillar post between the upper and lower door hinges is free of grease and

oil in the area where the label is to be affixed.

3. Peel label from backing and affix to the ‘A’ pillar.

2

© Toyota Motor Corporation Australia Limited Date: Feb 2006

A.B.N. 64 009 686 097 Section: Fuel

Reproduction in whole or part prohibited without written approval. No: 01

Page 3

TECHNICAL INSTRUCTIONS

FUEL PUMP REPLACEMENT ON LS430

Page

1. OPERATION FLOW CHART

2. AFFECTED VEHICLES

3. PREPARATION

4. WORK PROCEDURE

−−−−−−−−−−−−−−−−−−−−−−−−−−−

−−−−−−−−−−−−−−−−−−−−−

−−−−−−−−−−−−−−−−−−−−−−

−−−−−−−−−−−−−−−−−

2

2

2

3

1

Page 4

1. OPERATION FLOW CHART

Check whether or not the vehicle has the

affected vehicle frame number.

Yes

Replace the fuel pump

Finish

2. AFFECTED VEHICLES

Frame No. list:

No

No further action required.

WMI VDS Frame No.

JTH BN36F# 00123382 to 00155462

A

B

3. PREPARATION

Necessary Parts:

Part No. Part Name Q’ty/Vehicle

04004−18150

(23239−21010)

(23221−50110)

(77169−33020)

(23217−74021)

(23229−16010)

B74205

Fuel Pump Kit

1. VEHICLE IDENTIFICATION NUMBER

The vehicle identification number is stamped on the outer surface of the front right side frame. This number is also stamped

on the manufacturer’s plate and certification regulation plate,

as shown in the illustration.

A: Vehicle Identification Number Plate

B: Certification Label

1

(Fuel Pump Filter Seal)

(Fuel Pump Assy)

(Fuel Suction Tube Set Gasket)

(Fuel Pump Filter)

(Clip for Fuel Pump Filter)

(1)

(1)

(1)

(1)

(1)

Tools:

Name Part No.

Standard tools −

2

Page 5

4. WORK PROCEDURE

COMPONENTS

Rear Seat Cushion Assy (Fixed Type)

Rear Floor Service Hole Cover No. 2

Fuel Pump & Sender Gauge Connector

6.0 (61, 52 in.·lbf)

Rear Seat Cushion Assy (Power Adjust Type)

Fuel Tank Main Tube Sub−assy

x8

Fuel Tank Vent Tube Set Plate

N·m (kgf·cm, ft·lbf)

# Non−reusable part

Tube Joint Clip

Fuel Pump and

Sender Gauge Assy

# Gasket

Fuel Sub−suction Hose

: Specified torque

A93909

3

Page 6

# Fuel Pump Filter Seal

Fuel Suction Plate

with Sender Gauge

Fuel Suction Plate

Fuel Filter Assy

Fuel Pump

Connector

Spacer

Fuel Pump Assembly

Fuel Pump Cushion Rubber

Fuel Suction Support No. 2

# Non−reusable part

G37988

4

Page 7

REPLACEMENT

Hook

Removal

CAUTION:

Do not smoke or work near an open flame when working on

the fuel pump.

1.

RECORD RADIO STATION PRESETS AND CUSTOMER

STATION SETTINGS

2.

DISCONNECT BATTERY NEGATIVE TERMINAL

DRAIN FUEL

3.

NOTICE:

These procedures should be performed with the fuel tank

less than 1/4 full.

SEPARATED TYPE REAR SEAT:

4.

REMOVE SEPARATE TYPE REAR SEAT CUSHION

ASSY LH

(a) Pull up the 2 front portions of the seat cushion, then re-

move it.

(b) w/ Seat heater or climate control seat system:

Disconnect the connector.

Hook

B75246

B75248

FIXED TYPE REAR SEAT:

5.

REMOVE BENCH TYPE REAR SEAT CUSHION ASSY

(a) w/ Seat heater:

Disconnect the connector.

(b)

Pull up the front portion of the seat and remove.

NOTICE:

The cushion frame deforms easily. To avoid deforming the

seat cushion, place your hands near the hook and on both

sides of the hook, and then pull up on the seat cushion. Do

the same for all the hooks.

6. REMOVE REAR FLOOR SERVICE HOLE COVER NO.

(a) Remove the 3 cap nuts and service hole cover.

2

A89509

5

Page 8

Fuel

Pump

Connector

Pull

A89497

. WORK FOR PREVENTING FUEL FROM SPILLING

7

OUT

(a) Disconnect the fuel pump connector.

(b) Start the engine. After the engine has stopped on its own,

turn the ignition switch OFF.

HINT:

There is a possibility that DTC P0171 and/or P0174 system

too lean is output.

(c) Disconnect the negative (−) terminal cable from the bat-

tery.

(d) Check that the engine does not start.

(e) Remove the fuel tank cap, and let the air out of the fuel

tank

8.

REMOVE FUEL TANK MAIN TUBE SUB−ASSY

NOTICE:

Check for dirt contamination in the pipe and around

-

the connector. Clean if necessary. Foreign matter

may damage the O−ring or cause leaks in the seal between the pipe and connector.

Do not use any tools in these procedures.

-

Do not forcefully bend or twist the nylon tube.

-

Check for dirt contamination on the pipe seal surface.

-

Clean if necessary.

Put the pipe and connector ends in vinyl bags to pre-

-

vent damage and dirt contamination.

If the pipe and connector are stuck together, pinch the

-

tube between your fingers and turn it carefully to free

it. Then disconnect the tube.

(a) Remove the tube joint clip.

(b) Pull out the fuel main tube.

(c) Plug the port of the fuel suction plate with a clean rubber

cap.

Remove

Plug

A54096

9. REMOVE FUEL TANK VENT TUBE SET PLATE

(a) Remove the 8 bolts and set plate.

G37984

6

Page 9

Fuel Sub−suction Hose

Pry

Pry

A54098

A89518

.

10

REMOVE FUEL PUMP AND SENDER GAUGE

ASSEMBLY

(a) Lift up the fuel pump and sender gauge. Disconnect the

fuel sub−suction hose from the fuel return jet tube and remove the fuel pump, sender gauge and gasket.

CAUTION:

Do not damage the fuel pump filter.

-

Be careful not to bend the arm of the sender gauge.

-

11. REMOVE FUEL SUCTION SUPPORT NO.2

(a) Using 2 screwdrivers, disconnect the 3 snap claws from

the claw holes and remove the fuel suction support.

NOTICE:

Be careful not to damage the suction support and fuel filter.

12. REMOVE FUEL PUMP CUSHION RUBBER

13.

DISCONNECT FUEL SUCTION PLAT E W/SENDER

GAUGE

(a) Using 2 screwdrivers, disconnect the 4 snap claws from

the claw holes and disconnect the fuel filter.

NOTICE:

Be careful not to damage the filter assy and suction plate.

Fuel Pump

Filter Seal

Snap Claw

Spacer

G37991

G37990

14. REMOVE FUEL PUMP

(a) Disconnect the lower fuel pump connector from the

pump.

(b) Pull out the fuel pump.

(c) Remove the spacer and fuel pump filter seal.

fuel

G37994

7

Page 10

New

Fuel Pump

Filter Seal

Spacer

Snap Claw

Install

Installation

1. INSTALL NEW FUEL PUMP

(a) Install a new fuel pump filter seal and spacer to the fuel

pump.

(b) Apply a light coat of fuel to the seal.

G37994

(c) Push in the fuel pump.

(d) Connect the lower fuel pump connector.

(e) Push the fuel filter, and attach the 4 snap claws to the claw

holes.

2. INSTALL FUEL PUMP CUSHION RUBBER

Push

New Gasket

Fuel Sub−suction Hose

Push

G37985

3. INSTALL FUEL SUCTION SUPPORT NO.2

(a) Push the fuel suction support, and attach the 3 snap

claws to the claw holes.

A89503

4. INSTALL F UEL PUMP AND SENDER GAUGE

ASSEMBLY

(a) Install a new gasket to the fuel suction plate.

(b) Connect the fuel sub−suction hose to the fuel return jet

tube.

(c) Attach the fuel pump and sender gauge to the fuel tank.

G38159

8

Page 11

Attach

Install

G37984

A54101

5. INSTALL FUEL TANK VENT TUBE SET PLATE

(a) Install the set plate with the 8 bolts.

Torque: 6.0 N!m (61 kgf!cm, 52 in.!lbf)

6. INSTALL FUEL TANK MAIN TUBE SUB−ASSY

(a) Attach the fuel tube connector to the port of the fuel suc-

tion plate.

Install the tube joint clip.

(b)

(c)

Connect the fuel pump connector.

7. INSTALL REAR FLOOR SERVICE HOLE COVER NO.2

Install the service hole cover with the 3 cap nuts.

Hook

Hook

A89509

B75248

B75246

8. FIXED TYPE REAR SEAT:

INSTALL BENCH TYPE REAR SEAT CUSHION ASSY

(a) w/ Seat heater:

Connect the connector.

(b) Install the frame into the 3 hooks.

HINT:

Confirm that the seat cushion is firmly installed.

9. SEPARATE TYPE REAR SEAT:

INSTALL SEPARATE TYPE REAR SEAT CUSHION

ASSY LH

(a)

w/ Seat heater:

Connect the connector.

(b) Place the 2 hooks in the body firmly.

(c) Insert the frame into the 2 hooks.

9

Page 12

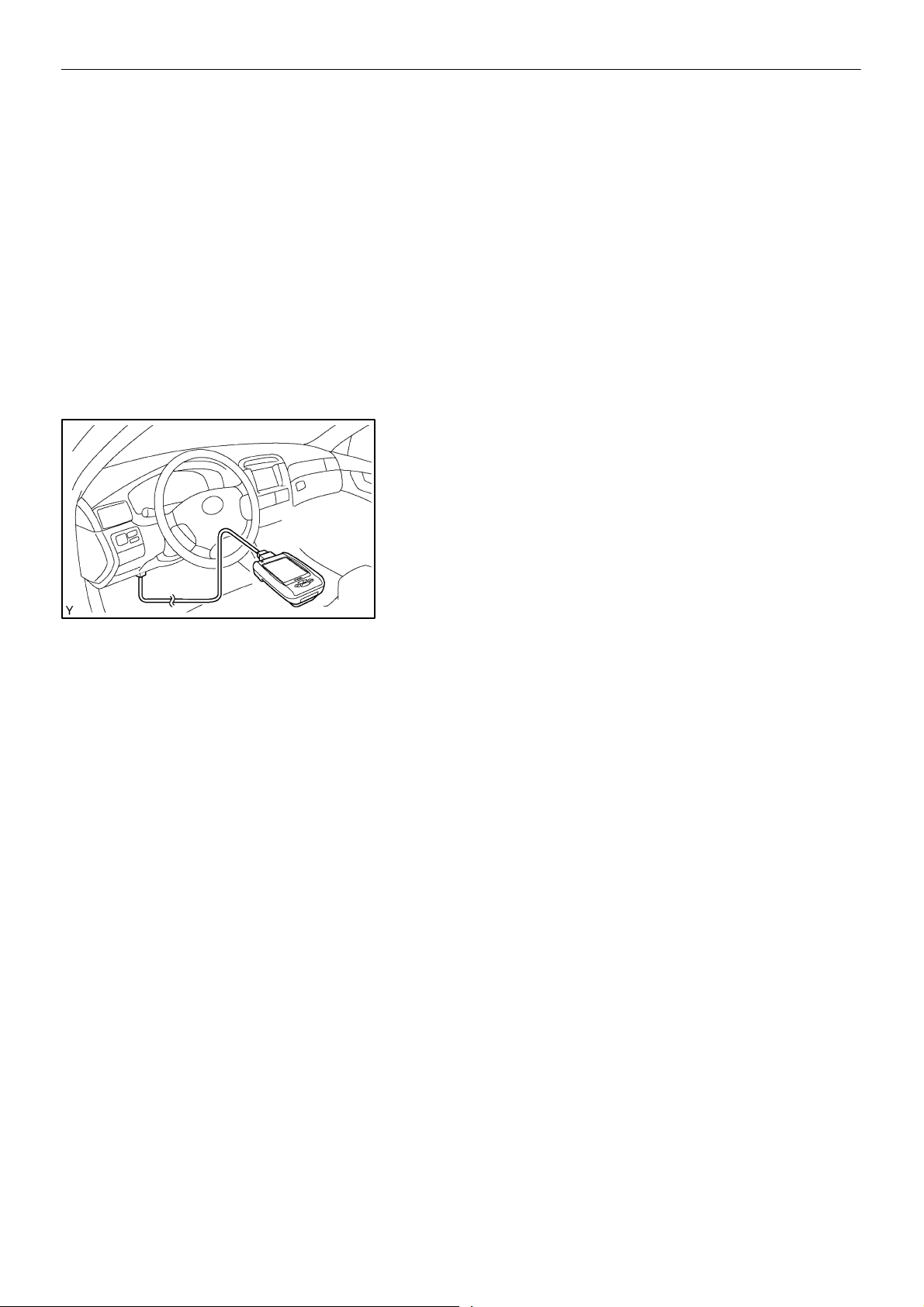

DLC3

Intelligent

Tester II

A87985

CONNECT BATTERY NEGATIVE TERMINAL

10.

NOTICE:

When disconnecting the negative (−) battery terminal, initialize the following system after the terminal is reconnected.

(a) Initialize the position control ECU & switch assy (power

seat ECU) as follows.

(1) Using the seat switches, fully slide the seat forward,

fully recline the seatback forward, and fully raise the

seat cushion and headrest.

(2) Using the seat switches, fully slide the seat rear-

ward, fully recline the seatback rearward and fully

lower the seat cushion and headrest.

CHECK FUEL PUMP OPERATION AND FUEL LEAKS

11.

(a) Connect the Intelligent Tester II to the Data Link Connec-

tor 3 (DLC3).

(b) Turn the ignition switch ON and push the intelligent tester

II main switch ON.

NOTICE:

Do not start the engine.

(c) Select the active test mode on the Intelligent Tester II.

(d) Please refer to the Intelligent Tester II operator’s manual

for further details.

(e) Check that there is pressure in the fuel inlet hose from the

fuel filter.

HINT:

If there is fuel pressure, you will hear the sound of fuel flowing.

If there is no pressure, check the fusible link, fuses, EFI MAIN

relay, fuel pump, ECM and wiring connections.

(f) Check that there are no fuel leaks after doing mainte-

nance anywhere on the fuel system.

(1) Check that there are no leaks from any part of the

fuel system.

(g) Turn the ignition switch to OFF.

(h) Disconnect the Intelligent Tester II from the DLC3.

12. RESET RADIO STATION PRESETS AND CUSTOMER

SETTINGS

13. ADD FUEL IF REMOVED AS PER STEP 3

(Replacement)

10

Loading...

Loading...