Page 1

LexmarkTM W820, X820e, X830e, X832e

• Table of Contents

• Start Diagnostics

• Safety and Notices

Printers

4025-XXX

•Trademarks

• Index

• Manuals Menu

Lexmark and Lexmark with diamond design are

trademarks of Lexmark International, Inc., registered

in the United States and/ or other countries.

Page 2

Edition: March 24, 2006

©

The following paragraph does not apply to any country where such provisions are inconsistent with local law:

LEXMARK INTERNATIONAL, INC. PROVIDES THIS PUBLICATION “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO , THE IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or

implied warr anties in certain transacti ons; therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made to the

information herein; these changes will be incorporated in later editions. Improvements or changes in the products or the

programs described may be made at any time.

Comments may be addressed to Lexmark Internation al, Inc., Department D22A/032-2, 740 WestNew Circle Road,

Lexington, Kentuc ky 40550, U.S.A or e-m ail at ServiceInfoAndTraining@Lexmark.com. Lexm ark may use or distribute an y

of the inf ormati on you supply in any way it believ es appropriate without incur ring any obligation to you.

Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc., registered in the United States

and/or other cou ntri es.

Pos tScri pt is a registered trademark of Adobe Systems Incorporated.

Other trademarks are the property of their respective owners.

Copyright Lexmark International, Inc. 2001, 2005.

All rights reserved.

UNITED STATES GOVERNMENT RESTRICTED RIGHTS

This software and documentation are provided with RESTRICTED RIGHTS. Use, duplication or disclosure by the

Government is subject to restrictions as set forth in subparagraph (c)(1) (i i) of the Rights in Technical Data and Computer

Software cl ause at DFARS 252.227-7013 and in applicable FAR provisions: Lexmark International, Inc., Lexington, KY

U.S .A. P/N 12G9449

Page 3

4025-XXX

Table of Contents

Notices and Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Laser Advisory and Caution Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Class 1 Laser Statement Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .x

Laser Not ices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Safe ty In fo rma tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Maintena nce Approa ch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Tools Required For Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Serial Number Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Symbols Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Safety Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Power Supply and Electrical Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Mechanical Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Laser Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Fuser Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Safety Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Caution Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Service Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Printer Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Schematic Diagram of Printer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Printer Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Power Supply Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Electrical Safety Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Printer Con trol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Control Functions of the Machine Control Unit (MCU) . . . . . . . . . . . . . . . . . . 1-24

Mechanical Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-28

Mechanical Drive Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Printer Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-32

Paper Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Paper Path Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-35

Paper Path Mechanical Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-36

Paper Path Component Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-45

iii

Page 4

4025-XXX

Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-46

Printhead Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-47

Printhead Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-48

Image Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-49

Printhead Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-50

Printhead Safeguards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-51

Xerographics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-52

Xerographics Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-53

Xerographic Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-54

Xerographic Process During a Print Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . .1-56

Mechanical Drive for Xerographics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-61

Xerographic Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-61

Image Quality Control - The Toner Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . .1-62

Fuser Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-64

Mechanical Drive for the Fuser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-65

Fuser Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-67

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-69

Image Regi st rat i on an d R eproduction Tolerances . . . . . . . . . . . . . . . . . . . . . . .1-71

Paper Handling Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-72

Face Down Tray (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-72

Finisher - option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-72

Mailbox - option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-72

Duplex - option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-72

Envelope Feeder - option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-72

MP Feeder (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-72

Glossary of Terms, Acronyms, and Abbreviations . . . . . . . . . . . . . . . . . . . . . . 1-7 3

Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Operator Panel Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Status Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Service Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Attendance Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Accessing Additional Debug Information for Service Errors . . . . . . . . . . . . . . . 2-3

Service Er ror Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

iv

Symptom Service Check T a ble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Attendance Message T able . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Page 5

4025-XXX

Service Checks Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

How to Use the Service Checks Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

How to Follow a Service Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

General Notes on Using Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Error Code Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Attendance Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Symptom Service Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

Print Quality Serv ice Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-59

Electrical Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

Diagnostic Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Analyzing the Test Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Using Test Print to Locate a Feed or Paper Transpor t Problem . . . . . . . . . . . . 3-1

Using Test Print to Analyze a Print Quality Problem . . . . . . . . . . . . . . . . . . . . . 3-1

Using the Operat or Panel Diagnost ics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Entering Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Exiting Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Print Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Print Quality Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Hardware Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

LCD Hardware Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Button Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

DRAM M emory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

DRAM Er ror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

ROM Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Parallel Wrap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Serial Wrap Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Duplex Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Duplex Qui ck Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Duplex Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Input T ray Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Input Tray Feed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Input Tray Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Output Bin Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Output Bin Feed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Feed All Bins Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Output Bin Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

v

Page 6

4025-XXX

Finisher Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Staple Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Finisher Sens or Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Base Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Storage Device Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Quick Disk Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Disk Test/Clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Flash Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Printer Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Configuration ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Setting the Page Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Viewing the Per man ent Page Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Setting Configuration ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

EP Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Restoring EP Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Error Lo g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Viewing the Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Clearing the Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Configurati on Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Viewing and Resetting the Maintenance Page Count . . . . . . . . . . . . . . . . . . . 3-31

Setting Printer Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Repair Info rmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removal and Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Fuser Full C over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Top Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Front Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Front Inner Cove r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Rear Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Right Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Operator Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Rear Cover 1TM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

Tray 1 Lift Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Tray 1 Feed Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Tray 1 Feed Rolls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Feeder, Nudger, and Retard Rolls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Tray 1 Take A way Rol l Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Tray 1 Feeder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Support Assembly Spr ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Tray 1 Retard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Tray 1 & Tray 2 Front Chute Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

vi

Page 7

4025-XXX

Tray 1 & 2 Level Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Tray 1 & Tray 2 Paper Size Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Tray 1 & 2 No Paper Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Actuator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Tray 2 Lift Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Tray 2 Feed Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Tray 2 Feeder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Tray 2 Take A way Rol l Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Tray 2 Retard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

MP Feeder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

MP Feeder Tray Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

MP Feeder Support Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

L/H Low Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Left Lower Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Left Lower Cover Pinch Roll Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Left Lower Cover Interlock Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-49

Tray 2 Take Away Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-50

Registration Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

Left Upper Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

Registration Chute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Registration Roll Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

Registration Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

Printhead Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

EP Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

BTR Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

Toner Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-63

CRU Interlock Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

Fuser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-65

Fuser Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

Fuser Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

Offset/Exi t Asse mbly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-69

Exit Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-71

Exit Gate Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-72

Offset Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-73

Inverter Clutches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

Full Stack Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

Face Up Exit Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-77

Flywheel Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

Main Drive A ssembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-79

Low Voltage Power Supply (LVPS) Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 4-82

Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-84

AC Driver PWB 120/230 VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-86

High Voltage Power Supply (HVPS) Assembly . . . . . . . . . . . . . . . . . . . . . . . . 4-88

vii

Page 8

4025-XXX

I/O PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-89

Left C over Interlock Switch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-90

Engine Board (MCU PWB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-92

Controller Board (ESS PWB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-94

ESS Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-96

220VAC Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-97

ESS Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-98

Connector Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

P/J Locati on Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

P/J Locati on Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Printer Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Prevent ati ve Ma in ten an ce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Parts Catalog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

How to Use This Parts Catalog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Assembly 1: Top Cover Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Assembly 2: Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Assembly 3: Rear, Left, and Right Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Assembly 4: Tray Unit - Paper Stack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Assembly 5: Tray Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Assembly 6: Paper Pick Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Assembly 7: Retard and Take Away - Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

Assembly 8: Retard and Take Away - Tray 2 . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Assembly 9: Feed Drive Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Assembly 10: Multi Purpose Feeder and MPF/Duplex Supp ort . . . . . . . . . . 7-20

Assembly 11: Tray 1 Frame and Left Cover . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

Assembly 12: Tray 2 Frame and Left Cover . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Assembly 13: Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

Assembly 14: Left Upper Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

Assembly 15: Printhead Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

Assembly 16: Xerography and Development . . . . . . . . . . . . . . . . . . . . . . . . . 7-32

Assembly 17: Fuser Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Assembly 18: Exit Lower Chute. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-36

Assembly 19: Exit Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-38

Assembly 20: Main Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-40

Assembly 21: Fuser Drive Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Assembly 22: Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-44

Assembly 23: HVPS and I/O PWB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-46

Assembly 24: ESS Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Assembly 25: Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

Assembly 26: Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-52

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

viii

Page 9

4025-XXX

Notices and Safety Information

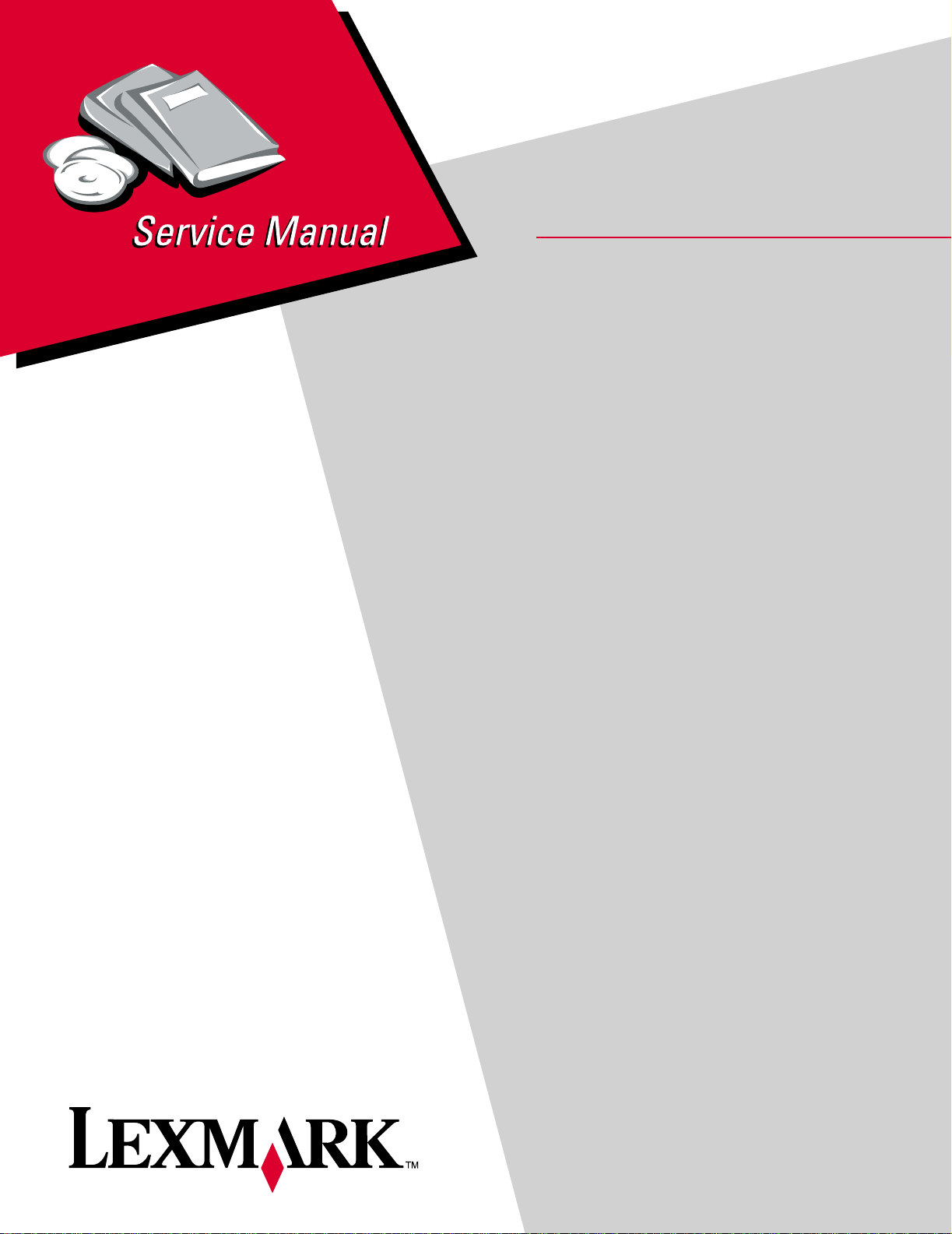

Laser Advisory and Caution Labels

Notices and Safety Information ix

Page 10

4025-XXX

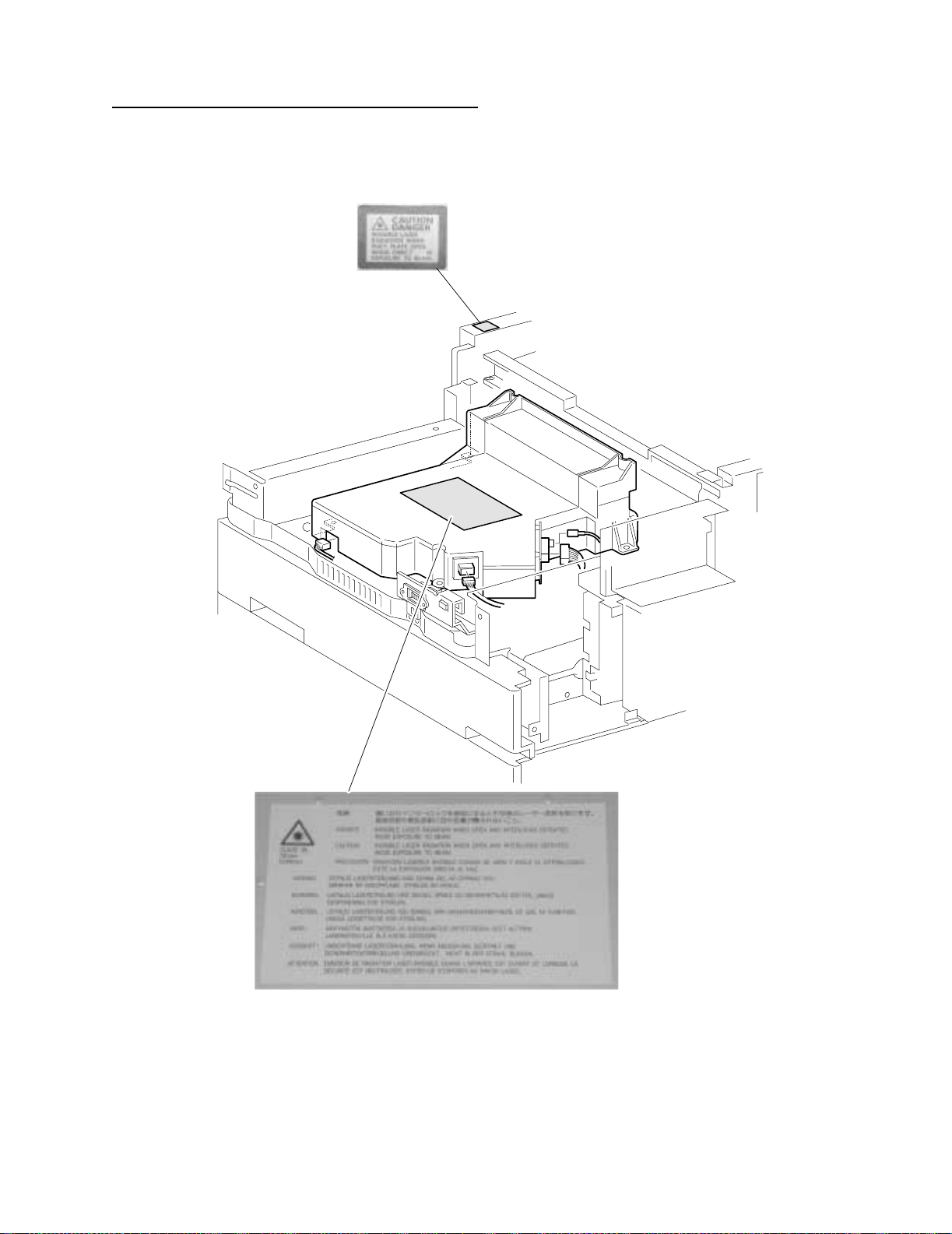

Class 1 Laser Statement Label

x Notices and Safety Information

Page 11

Laser Not ice s

Laser

4025-XXX

The printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR

Subchapter J for Class I (1) laser products, and elsewhere is certified as a Class I laser

product conforming to the requirements of IEC 60825.

Class I laser products are not considered to be hazardous. The printer contains internally

a Class IIIb (3b) laser that is nominally a 5 milliwatt gallium arsenide laser operating in the

wavelength region of 770-795 nanometers. The laser syst em and printer are designed so

there is never any human access to laser radiation above a Class I level during normal

operation, user maintenance, or prescribed service condition.

Der Drucker erfüllt gemäß amtlicher Bestätigung der USA die Anforderungen der

Bestimmung DHHS (Department of Health and Human Se r v ices) 21 CFR Teil J für

Laserprodukte der Klasse I (1). In anderen Ländern gilt der Drucker als Laserprodukt der

Klasse I, der die Anforderungen der IEC (International Electrotechnical Commission)

60825 gemäß amtlicher Bestätigung erfüllt.

Laserprodukte der Klasse I gelten als unschädlich. Im Inneren des Druckers befindet sich

ein Laser der Klasse IIIb (3b), bei dem es sich um einen Galliumarsenlaser mit 5 Milliwatt

handelt, der Wellen der Länge 770-795 Nanometer ausstrahlt. Das Lasersystem und der

Drucker sind so konzipiert, daß im Normalbetrieb, bei der Wartung durch den Benutzer

oder bei ordnungsgemäßer Wartung durch den Kundendienst Laserbestrahlung, die die

Klasse I übersteigen würde, Menschen keinesfalls erreicht.

Avis relatif à l’utilisation de laser

Pour les Etats-Unis : cette imprimante est cert ifiée conforme aux provisions DHHS 21

CFR alinéa J concernant les produits laser de Classe I (1). Pour les autres pays : cette

imprimante répond aux normes IEC 60825 relatives aux produits laser de Classe I.

Les produits laser de Classe I sont considérés comme des produits non dangereux.

Cette imprimante est équipée d’un laser de Classe IIIb (3b) (arséniure de gallium d’une

puissance nominale de 5 milliwatts) émettant sur des longueurs d’onde comprises entre

770 et 795 nanomètres. L’imprimante et son système laser sont conçus pour impossible,

dans des conditions normales d’utilisation, d’entretien par l’utilisateur ou de révision,

l’exposition à des rayonnements laser supérieurs à des rayonnements de Classe I .

Avvertenze sui prodotti laser

Questa stampante è certificata negli Stati Uniti per essere conforme ai requisiti del DHHS

21 CFR Sottocapitolo J per i prodotti laser di classe 1 ed è certificata negli altri Paesi

come prodotto laser di classe 1 conforme ai requisiti della norma CEI 60825.

I prodotti laser di classe non sono considerati pericolosi. La stampante contiene al suo

interno un laser di classe IIIb (3b) all’arseniuro di gallio della potenza di 5mW che opera

sulla lun gh ez z a d’onda compresa tra 770 e 795 nanometri. Il sistema laser e la

Notices and Safety Information xi

Page 12

stampante sono stati progettati in modo tale che le persone a contatto con la stampante,

durante il normale funzionamento, le operazioni di servizio o quelle di assistenza tecnica,

non ricevano radiazioni laser superior i al livello della classe 1.

Avisos sobre el láser

Se certifica que, en los EE.UU., esta impresora cumple los requisitos para los productos

láser de Clase I (1) establecidos en el subcapítulo J de la norma CFR 21 del DHHS

(Departamento de Sa nidad y Ser vi cios ) y, en los demás países, reúne todas las

condiciones expuestas en la norma IEC 60825 para productos láser de Clase I (1).

Los productos láser de Clase I no se consideran peligrosos. La impresora contiene en su

interior un láser de Clase IIIb (3b) de arseniuro de galio de funcionamiento nominal a 5

milivatios en una longitud de onda de 770 a 795 nanómetros. El sistema láser y la

impresora están diseñados de forma que ningun a persona pueda verse afectada por

ningún tipo de radiación láser superior al nivel de la Clase I durante su uso normal, el

mantenimiento realizado por el usuario o cualquier otra situación de servicio técnico.

Declaração sobre La ser

4025-XXX

A impressora está certificada nos E.U.A. em conformidade com os requisitos da

regulamentação DHHS 21 CFR Subcapítulo J para a Classe I (1) de produtos laser. Em

outros locais, está certificada como um produto laser da Classe I, em conformidade com

os requisitos da norma IEC 60825.

Os produtos laser da Classe I não são considerados perigosos. Internamente, a

impressora contém um produto laser da Classe IIIb (3b), designado laser de arseneto de

potássio, de 5 milliwatts ,operando numa faixa de comprimento de onda entre 770 e 795

nanómetros. O sistema e a impressora laser foram concebidos de forma a nunca existir

qualquer possiblidade de acesso humano a radiação laser superior a um nível de Classe

I durante a operação normal, a manutenção feita pelo utilizador ou condições de

assistência prescritas.

Laserinformatie

De printer voldoet aan de eisen die gesteld worden aan een laserprodukt van klasse I.

Voor de Verenigde Staten zijn deze eisen vastgelegd in DHHS 21 CFR Subchapter J,

voor andere landen in IEC 60825.

Laserprodukten van klasse I worden niet als ongevaarlijk aangemerkt. De printer is

voorzien van een laser van klasse IIIb (3b), dat wil zeggen een gallium arsenide-laser van

5 milliwatt met een golflengte van 770-795 nanometer. Het lasergedeelte en de printer

zijn zo ontworpen dat bij normaal gebruik , bij onderhoud of reparatie conform de

voorschriften, nooit blootstelling mogelijk is aan laserstraling boven een niveau zoals

voorgeschrev en is voor klasse 1.

xii Notices and Safety Information

Page 13

Lasermeddelelse

Printeren er godkendt som et Klasse I-laserprodukt, i overenstemmelse med kravene i

IEC 60825.

Klasse I-laserprodukter betragtes ikke som farlige. Printeren indeholder internt en Klasse

IIIB (3b)- las e r, der nom ine lt er en 5 milli watt ga lliumars en id la s e r, som ar be jder på

bølgelængdeområdet 770-795 nanom eter. Lasersystemet og printeren er udformet

således, at mennesker aldrig udsættes for en laserstråling over Klasse I-niveau ved

normal drift, brugervedligeholdelse eller obligatoriske servicebetingelser.

Huomautu s las er laittees ta

Tämä kirjoitin on Yhdysvalloissa luokan I (1) l aserlaitteiden DHHS 21 CFR Subchapter J määrityksen mukainen ja muualla luokan I laserlaitteiden IEC 60825 -määrityksen

mukainen.

Luokan I laserlaitteiden ei katsota olevan vaar allisia käyttäjälle . Kir joittimessa on sisäinen

luokan IIIb (3b) 5 milliwatin gallium ar se nidil as er, joka toimii aaltoaluee lla 770 - 79 5

nanometriä. Laserjärjestelmä ja kirjoitin on suunniteltu siten, että käyttäjä ei altistu luokan

I määrityksiä voimakkaammalle säteilylle kirjoittimen normaalin toiminnan, käyttäjän

tekemien huoltotoimien tai muiden huoltotoimien yhteydessä.

4025-XXX

Laser-notis

Laser-melding

VARO! Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle

lasersäteilylle. Älä katso säteeseen.

VARNING! Osynlig laserstrålning när denna del är öppnad och spärren är urkopplad.

Betra k ta e j s trålen.

Denna skrivare är i USA certifierad att motsvara krav en i DHHS 21 CFR, underparagraf J

för laserprodukter av Klass I (1). I andra länder uppfyller skrivaren kraven för

laserprodukter av Klass I enligt kraven i IEC 60825.

Laserprodukter i Klass I anses ej hälsovådliga. Skrivaren har en inbyggd laser av Klass

IIIb (3b) som består av en laserenhet av gallium-arsenid på 5 milliwatt som arbetar i

våglängdsområdet 770-795 nanometer. Lasersystemet och skrivaren är utformade så att

det aldrig finns risk för att någon person utsätts för laserstrålning över Klass I-nivå vid

normal användning, underhåll som utförs av användaren eller annan föreskriven

serviceåtgärd.

Skriveren er godkjent i USA etter kravene i DHHS 21 CFR, underkapittel J, for klasse I (1)

laserprodukter, og er i andre land godkjent som et Klasse I-laserprodukt i samsvar med

kravene i IEC 60825.

Notices and Safety Information xiii

Page 14

Klasse I-laserprodukte r er ik ke å betrakte som farlige. Skriveren inneholder internt en

klasse IIIb (3b)-laser, som består av en gallium-arsenlaserenhet som avgir stråling i

bølgelengdeområdet 770-795 nanometer. Lasersystemet og skriveren er utformet slik at

personer aldri utsettes for laserstråling ut ov er klasse I-nivå under vanlig bruk, vedlikehold

som utføres av brukeren, eller foreskrevne serviceoperasjoner.

Avís sobre el Làser

Segons ha estat certificat als Estats Units, aquesta impressora compleix els requisits de

DHHS 21 CFR, apartat J, pels productes làser de classe I (1), i segons ha estat certificat

en altres llocs, és un producte làser de classe I que compleix els requisits d’IEC 60825.

Els productes làser de classe I no es consideren perillosos. Aquesta impressora conté un

làser de classe IIIb (3b) d’arseniür de gal.li, nominalment de 5 mil.liwats, i funciona a la

regió de longitud d’ona de 770-795 nanòmetres. El sistema làser i la impressora han

sigut concebuts de manera que mai hi hagi exposició a la radiació làser per sobre d’un

nivell de classe I durant una operació normal, durant les tasques de manteniment

d’usuari ni durant els serveis que satisfacin les condicions prescrites.

4025-XXX

Safety Information

• This product is designed, tested and approved to meet strict global safety standards

with the use of specific Lexmark components. The safety features of some parts may

not always be obvious. Lexmark is not responsible for the use of other replacement

parts.

• The maintenance information for this product has been prepared for use by a

professional service person and is not intended to be used by others.

• There may be an increased risk of electric shock and personal injury during

disassembly and servicing of this product. Professional service personnel should

understand this and take necessary precautions.

Consignes de Sécurité

• Ce produit a été conçu, testé et approuvé pour respecter les normes strictes de

sécurité globale lors de l'utilisation de composants Lexmark spécifiques. Les

caractéristiques de sécurité de certains éléments ne sont pas toujours évidentes.

Lexmark ne peut être tenu responsable de l'utilisation d'autres pièces de rech ange.

• Les consignes d'entretien et de réparation de ce produit s'adressen t uniqueme nt à

un personnel de maintenance qualifié.

• Le démontage et l'entretien de ce produit pouvant présenter certains risques

électriques, le personnel d'entretien qualifié devra prendre toutes les précautions

nécessaires.

Norme di sicurezza

• Il prodotto è stato progettato, testato e approvato in conformità a severi standard di

sicurezza e per l’utilizzo con componenti Lexmark specifici. Le caratteristiche di

xiv Notices and Safety Information

Page 15

sicurezza di alcune parti non sempre sono di immediata co mpre nsione. Lexmark

non è responsabile per l’utilizzo di parti di ricambio di altri produttori.

• Le informazioni riguardanti la manutenzione di questo prodotto sono indirizzate

soltanto al personale di assistenza autorizzato.

• Durante lo smontaggio e la manutenzione di questo prodotto, il rischio di subire

scosse elettriche e danni alla persona è più elevato. Il personale di assistenza

autorizzato, deve, quindi, adottare le precauzioni necessarie.

Sicherheitshinweise

• Dieses Produkt und die zugehörigen Komponenten wurden entworfen und getestet,

um beim Einsatz die weltweit gültigen Sicherheitsanforderunge n zu erfüllen. Die

sicherheitsrelevanten Funktionen der Bauteile und Optionen sind nicht immer

offensichtlich. Sofern Teile eingesetzt werden, die nicht von Lexmark sind, wird von

Lexmark keinerlei Verantwortung oder Haftung für dieses Produkt übernommen.

• Die War tungs inform ationen für dieses Produkt sind ausschließlich für die

Verwendung durch einen Wartungsfachmann bestimmt.

• Während des Auseinandernehmens und der Wartung des Geräts besteht ein

zusätzliches Risiko eines elektrischen Schlags und körperlicher V erletzung. Das

zuständige Fachpersonal sollte entsprechende Vorsichtsmaßnahmen treffen.

•

4025-XXX

Pautas de Seguridad

• Este producto se ha diseñado, verificado y aprobado para cumplir los más estrictos

estándares de seguridad global usando los componentes específicos de Lexmark.

Puede que las características de seguridad de algunas piezas no sean siempre

evidentes. Lexmar k no se hace responsa ble del uso de otras piezas de recambio.

• La informac ión sobre el mantenimiento de este producto está dirigida

exclusivamente al personal cualificado de mantenimiento.

• Existe mayor riesgo de descarga eléctr ica y de daños personal es durante el

desmontaje y la reparación de la máquina. El personal cualificado debe ser

consciente de este peligro y tomar las precauciones necesarias.

Informações de Segurança

• Este produto foi concebido, testado e aprovado para satisfazer os padrões globais

de segurança na utilização de componentes específicos da Lexmark. As funções de

segurança de alguns dos componentes podem não ser sempre óbvias. A Lexmark

não é responsável pela u t iliz a ção de outros componentes de substituição.

• As informações de segurança relativas a este produto destinam-se a profissionais

destes serviços e não devem ser utilizadas por outras pessoas.

• Risco de choques eléctricos e ferimentos graves durante a desmontagem e

manutenção deste produto. Os profissionais destes serviços devem estar avisados

deste facto e tomar os cuidados necessários.

Notices and Safety Information xv

Page 16

Informació de Seguretat

• Aquest producte està dissenyat, comprovat i aprovat per tal d'acomplir les estrictes

normes de seguretat globals amb la utililització de compo nent s específi cs de

Lexmark. Les característiques de seguretat d'algunes peces pot ser que no sempre

siguin òbvies. Lexmark no es responsabilitza de l'us d'altres peces de recanvi.

• La informac ió pel manteniment d’aquest producte està orientada exclusivament a

professionals i no està destinada a ningú que no ho sigui.

• El risc de xoc elèctric i de danys personals pot augmentar durant el procés de

desmuntatge i de servei d’aquest producte. El personal professional ha d’estar-ne

assabentat i prendre les mesures convenients.

4025-XXX

xvi Notices and Safety Information

Page 17

Preface

4025-XXX

This manual describes the Lexmark

procedures for service personnel only. It is divided into the following chapters:

TM

W820 (4025-XXX) and contains maintenance

1. General Inf o rmation contains a general description of the printer and the

maintenance approach used to repair it. Special tools and test equipment are listed

in this chapter, as well as general environmental and safety instructions.

2. Diagnostic Information contains an error indicator table, symptom tables, and

service checks used to isolate failing field replaceable units (FRUs).

3. Diagnostic Aids contains tests and checks used to locate or repeat symptoms of

printer problems.

4. Repa ir Informatio n provides instructions for removing and installing FRUs.

5. Connector Locations uses illustrations to identify the connector locations and test

points on the printer.

6. Prevent ive Maintenanc e contains the lubrication specifications and

recommendations to prevent problems.

7. Parts Catalog contains illustrations and part numbers for individual FRUs.

Preface xvii

Page 18

4025-XXX

xviii Preface

Page 19

1. General Information

This service manual is written for the following products:

W820 printer (base) 4025-001

W820 printer (network) 4025-N01

Printer for X820e bundle* 4025-N01

Printer for X830e bundle* 4025-N02

Printer for X832e bundle* 4025-N03

* For scanner repair of the X820e, X830e or X832e, refer to the 4036-501 service manual.

Options

The following options are available for this printer :

4025-XXX

• Envelope Feeder

• Duplex

• Mailbox

• High Capacity Feeder

• Finisher

Service information for the Envelope Feeder, Duplex, Mailbox, and High Capacity Feeder

is contained in the Lexmark W820 Options Service Manual. Ser v ice information for the

Finisher is in the Lexmark W820 Finisher Service Manual.

Maintenance Approach

The diagnostic information in this manual leads you to the correct field replaceable unit

(FRU) or part for the printer. Use the error code table, symptom ser vice check table,

attendance message table, service checks, print quality service checks and symptom

service checks to determine the corrective action necessary to repair a malfunctioning

printer. After you complete the repair, perform tests as needed to verify the repair.

Tools Required For Service

The removal and replacement procedures described in this manual require the following

tools and equipment:

• Magnetic tip Phillips screwdrivers, large and small

• Flat-blade screwdrivers

• Analog volt ohmmeter (a digital volt ohmmeter may also be used)

General Information 1-1

Page 20

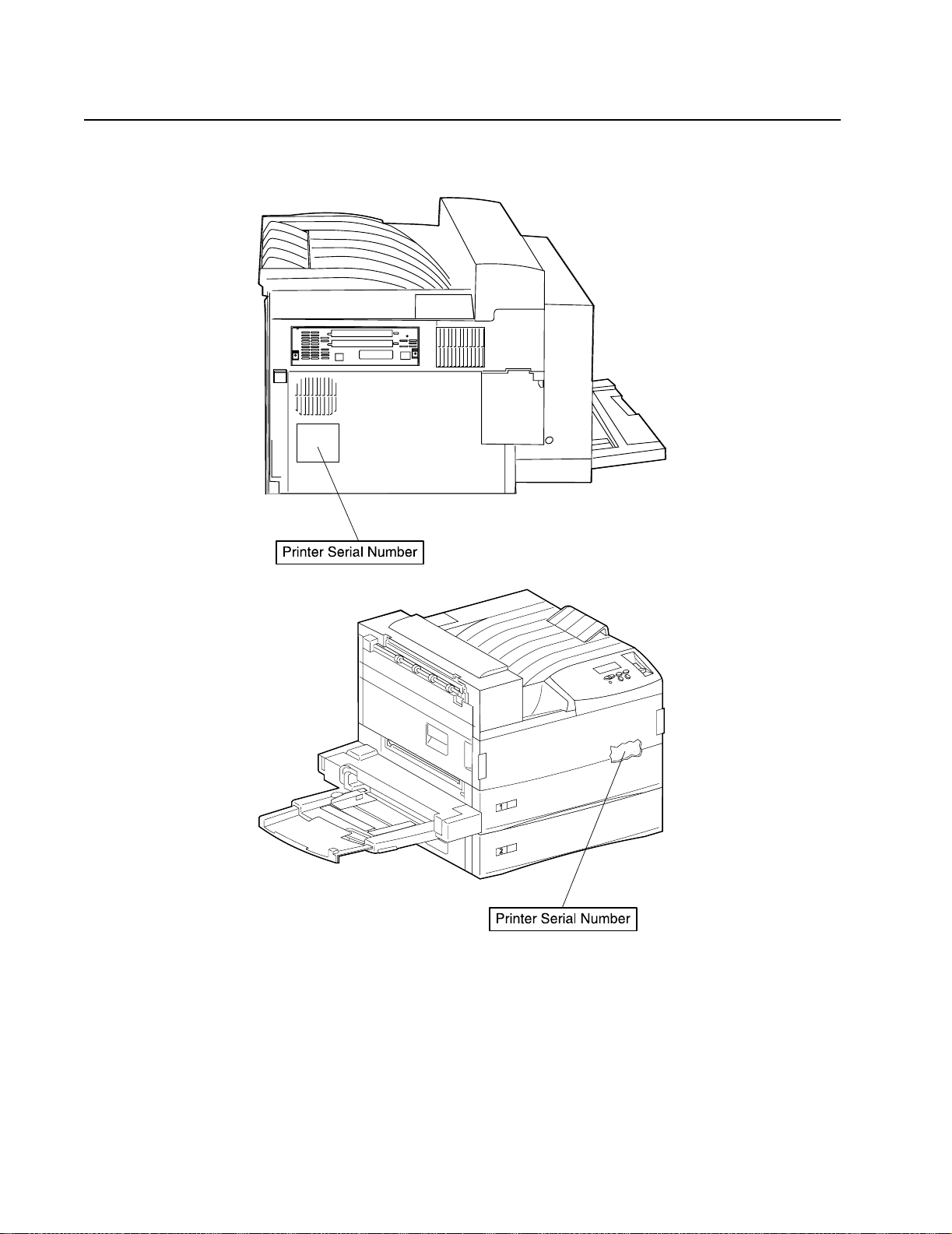

Serial Number Locations

Printer serial number labels are on the rear of the printer and inside the front cover.

4025-XXX

1-2 Service Manual

Page 21

Symbols Used in this Manual

Various symbols are used throughout this manual to either provide additional information

on a specific topic or to warn of possible danger that might be present during a procedure

or action. Be aware of all symbols when they are used, and always read NOTE,

CAUTION, and WARNING messages.

Note: A NOTE may indicate an operating or maintenance procedure, practice, or

condition that is necessary to efficiently accomplish a task. A NOTE may also provide

additional information related to a specific subject or add a comment on the results

achieved through a previous action.

WARNI NG: A WARNING indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to, or destruction of,

equipment.

CAUTION: A CAUTION indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in injury.

Safety Details

4025-XXX

Follow all safety instructions to prevent accidents while servicing this printer. Always be

aware of the potential dangers that are present when you are working with electrical or

mechanical equipment.

Power Supply and Electrical Com ponents

Before starting any service procedure, switch off the printer power and unplug the power

cord from the wall outlet. If you must service the printer with power applied, be aware of

the potential for electrical shock.

CAUTION: Do not touch any electrical component unless you are instructed to do so by

a service procedure.

General Information 1-3

Page 22

4025-XXX

Mechanical Components

Manually rotate drive assemblies to inspect sprockets and gears.

CAUTIO N: Do not t ry to manually rotate or manually stop the drive assemblies while any

printer motor is running.

Laser Com p on ents

CAUTIO N: This printer generates a laser beam as part of the printing process. The laser

beam is a concentrated narrow beam of light that produces extreme heat at its focal point.

The laser beam in this printer is invisible. Although you cannot see the beam, it can still

cause severe damage. Direct eye exposure to the laser beam may cause eye injury or

blindness.

To avoid permanent eye damage, follow these directions:

• Before starting any service procedure, switch off the printer power and unplug the

power cord from the AC wall outlet.

• Do not disassemble the Printhead Assembly or any laser component that displays a

Laser Warning sticker.

• Use caution when you are working around the Printhead Assembly or when you are

performing laser related troubleshooting or repair procedures.

• Never place a mirror or a reflective tool or object in the laser beam path.

• Do not disassemble the printer in such a way that the laser beam can exit the print

engine during a print cycle.

Fuser Components

CAUTION: This printer uses heat to fuse the toner image to a sheet paper. The Fuser

Assembly is very hot. Switch off printer power and wait at least 45 minutes for the fuser to

cool before you attempt to service the Fuser Assembly or adjacent components.

Safety Components

Make sure covers and panel are in place and that all interlock s witches are all functioning

correctly after you have completed a printer service call. If you bypass, or cheat, an

interlock switch during a service call, use extreme caution when working on or around the

printer.

1-4 Service Manual

Page 23

Cautio n Labels

Throughout the printer, warning labels are displayed on potentially dangerous

components. When you service the printer, check to make sure that all caution labels are

in place.

Most importantly, read and obey all posted caution labels.

Service Flowchart

Included is a Service Flowchar t that outlines the approach to troubleshooting and repair

of the printer. The Service Flowchart is an overview of the path a service technician can

take, using this service manual, to service the printer.

Identify the problem. After you identify the problem, inspect and clean the printer (a

thorough cleaning frequently solves many printer problems). Continue down the

Flowchart in this manner, alway s retur ni ng to the next step in the Service Flowchart after

you complete the tasks outlined in the previous step.

If you choose not to use the Service Flowchart, we recommend that you start at the

appropriate Service Check and proceed from there.

4025-XXX

Identity the Problem

1. Verify that the reported problem does exist.

2. Check for any error codes and write them down.

3. Print three test prints.

4. Make note of any print quality problems in the test prints.

5. Make note of any unusual noise or smell coming from the printer.

Inspect and Cle an the Prin ter

Switch OFF printer power.

1.

2. Disconnect the AC power cord from the wall outlet.

3. Remove the EP Cartridge and shield it from strong light.

4. Inspect the printer interior and remove any foreign matter such as paper clips,

staples, pieces of paper, paper dust, or toner.

5. Clean the printer interior with a lint-free cloth, dampened slightly with cold water . Do

not use solvents or chemical cleaners to clean the printer interior. Do not use any

type of oil or lubricant on printer parts.

6. Clean all rubber rollers with a lint-free cloth that is dampened slightly with cold water.

Use a clean, dry , lint-free cloth to dry the rollers. Do not use solvents or chemical

cleaners to clean rubber rollers.

7. While you are cleaning, inspect the interior of the printer for damaged wires, loose

connections, toner leakage, and damaged or obviously worn parts.

8. If the EP Cartridge appears damag ed, replace it with a new one.

General Information 1-5

Page 24

Find the Cause of the Problem

1. Use the “Servi ce Flowchar t” on page 1-5 to find out how to use the Service

2. Use the “Servi ce Che cks” on pag e 2 -1 1 to check printer components.

3. Use the “Connector Locati ons” on page 5-1 to locate P/Js and test points.

4. Take voltage readings at various test points.

Correct the Problem

1. Use the “Par ts Ca talo g” on page 7-1 to locate the FRU number.

2. Use the “Removal and Replacement Procedures” on page 4-2 to replace a FRU.

Final Checkout

Test the printer to be sure you corrected the initial problem and there are no additional

problems.

Printer Overview

4025-XXX

Checks.

• Th e prin t er is a 45 page per minute (35 page per minute for X830e) black and white,

600 dots per inch laser printer that uses a data-modulated laser beam, standard dryink xerographic imaging processes, and heat and pressure fusing to place a

computer generated image onto the surface of a sheet of plain paper.

• The printer uses a semicon ducto r laser in the Pri nth ead to gene rate a 5 milli watt

infrared laser beam. Image data sent from the host computer modulates the beam,

creating a latent image on the surface of the electrically charged xerographic drum.

• The printer runs on 110VA C @ 60 Hz or 220VAC @ 50Hz using approximately 900

watts during an average print cycle. Two power supplies within the printer conv ert AC

line voltage to the various AC and DC voltages that are needed for printer operation.

• Safety circuits withi n the printer remove power to the printer whenever the Left Front

Cover is open or the EP Car tr idge is removed.

• The Machine Control Unit PWB (MCU PWB) controls all printer functions, houses

printer diagnostics, stores operating parameters, and signals printer errors.

• The ESS (Controller) PWB interfaces a host computer with the MCU PWB (Engine

Card).

• The printer has one Customer Replaceable Unit, or CRU, that the customer must

replace at specific intervals. That CRU is the EP Cartridge. The printer displays an

error code when it is time to replace the EP Cartridge.

1-6 Service Manual

Page 25

4025-XXX

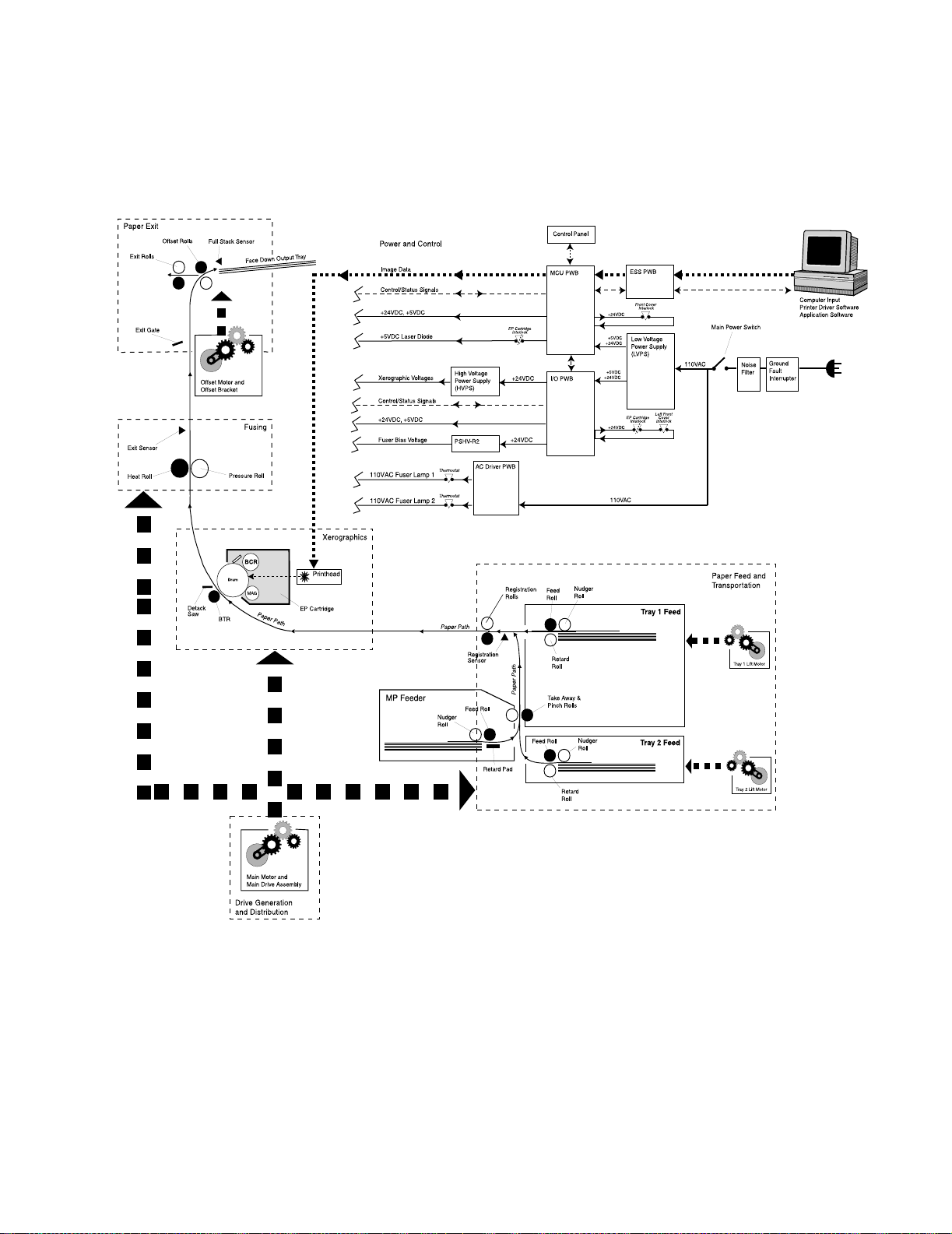

Schematic Diagram of Printer Operation

The following illustration is a simplified schematic of the printer components, subsystems,

and paper paths. Refer to individual sections of the Principles of Operation for greater

detail on specific areas.

General Information 1-7

Page 26

4025-XXX

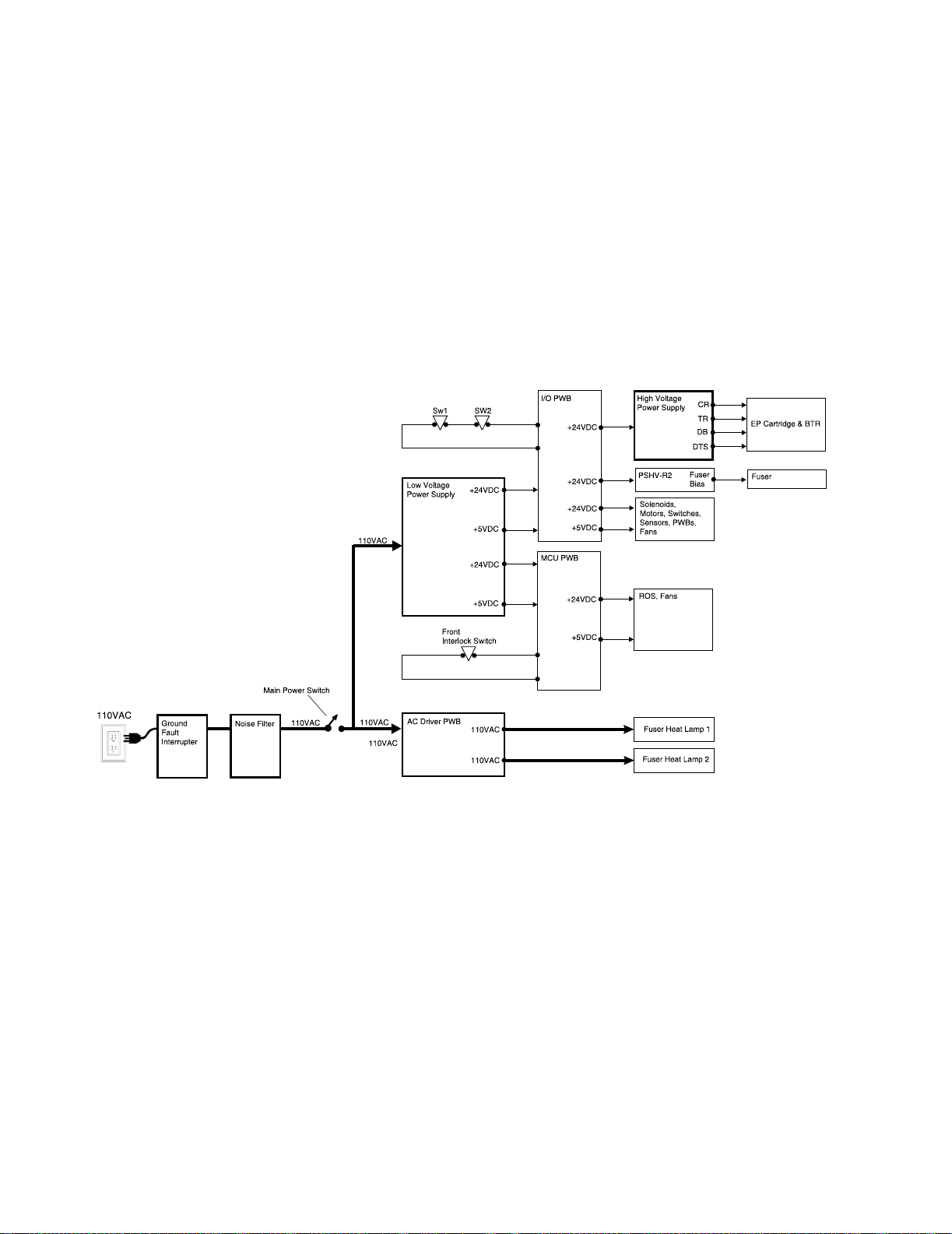

Power and Control

The printer power cord plugs into an AC wall outlet. The other end of the power cord

plugs into the Noise Filter PWB, where the Filter removes fluctuations from the AC line

voltage. A Ground Fault Interrupter in the AC line protects the printer from electrical

shorts. With the Main Power Switch on, AC line voltage flows from the Noise Filter, and

into the Low Voltage Power Supply (LVPS) and into the AC Driver PWB. The LVPS

converts and distributes +5VDC and +24VDC voltages to the MCU PWB and I/O PWB.

The MCU PWB distributes +5VDC and +24VDC to the Printhead and various printer

components. The I/O PWB distributes +5VDC and +24VDC to various printer

components and distributes +24VDC to the High Volta ge Power Supply (HVPS) and to

the PSHV-R2 power supply. The HVPS converts the +24VDC supplied to it by the MCU

PWB into the high voltages that are used by the xerographic components of the printer.

The PSHV-R2 provides the Fuser Bias voltage. The AC Drive PWB distributes 110VAC

filtered line voltage to the two Fuser Heat Lamps.

The host computer, loaded with the correct printer driv er sof tw are, connects to the printer

through the ESS (Controller) PWB. The ESS PWB is connected to the MCU PWB. The

ESS PWB sends image data and process information to the MCU PWB. The MCU PWB

is the brain of the printer - housing printer parameters and timing tables, monitoring

printer operations, and controlling all printer functions. The MCU PWB monitors sensors

along the paper path, signaling the I/O PWB to switch components on and off, and

generates error codes whenever sensor statuses indicate a problem.

Drive Generation and Distribution

The printer base engine contains five motors. The MCU PWB controls all motor functions.

The Main Mot or supplies mechanical drive to the Main Drive Assembly. The Main Drive

Assembly and a series of individual gear clusters transfer drive throughout the printer.

The Drum Motor also supplies mechanical drive to the Main Drive Assembly. Electric

clutches control drive to specific components. Lift Motor 1 and 2 supply drive to Trays 1

and 2. The Offset Motor supplies drive to the Offset Rollers.

Xerographics

Xerographics consists of the Printhead which houses the laser, the EP Cartridge, and

the Bias Transfer Roll (BTR). Image data sent from the host computer to the MCU PWB

rapidly switches the laser on and off, shining onto the Drum and creating an invisible

electrical image on the surface of the electrically charged Drum. Dry ink, or toner,

transfers to the Drum surface, creating a visible toner image. The Drum, the Bias Charge

Roll (BCR), and the toner are all housed in the replaceable EP Car tri dge. When the

sheet of paper travels between the Drum and the electrically charged Bias Transfer R oll

(BTR), the toner image on the Drum transfers to the sheet of paper. The Detack Saw

helps remove the paper from the Drum.

1-8 Service Manual

Page 27

Printer Power

4025-XXX

Fusing

After image transfer, the toner image is not permanently fixed to the sheet of paper - it is

still dry power and can be easily rubbed off. The Fuser has two rotating rolls; the Hot Roll

and the Pressure Roll. A Lamp inside each of the Rolls heats the Fuser Rolls to

temperatures in access of 300

image melts and is pressed into the surface of the paper. Fuser Drive Rolls help move

the paper from the Fuser Rolls to the Exit Rolls. The Fuser Exit Sensor monitors the

sheet of paper leaving the Fuser.

°F. Paper passes between the two rolls where the toner

Paper E xit

Rolls in the O ffset and Exit Unit drive the sheet of paper out of the printer and into the

Face Down Output Tray or face up into the optional Duplex Module. The Full Stack

Sensor monitors the level of paper in the Fac e Down Output Tray.

The power supplies in the printer provide the voltages that t he printer requires to operate.

The various printer functions require +5VDC, +24VDC, and several high voltage DC and

AC values that are used by xerographics.

The printer AC power cord plugs into a grounded AC wall outlet. The cord carries AC line

voltage to a Ground Fault Interrupter, then on to the Noise Filter PWB. The Noise Filter

smooths the AC voltage and sends it to the Main Power Switch. Switching on the Main

Power Switch applies AC voltage to the AC Driver PWB and to the Low Voltage Power

Supply (LVPS) PWB.

The AC Driver PWB is the interface between printer control (MCU) and the Fuser. Fuser

sensors connected to the AC Driver PWB send Fuser status information to the Driver

PWB, which the PWB routes to the MCU PWB. The MCU processes the information and

sends commands back to the AC Driver PWB to tell the AC Driver whether or not to

switch on the Fuser Heat Lamps.

The Low Voltage Power Supply PWB, or LVP S, converts the 110VAC to regulated

+24VDC and +5VDC voltages. The LVPS sends these voltages to the I/O PWB and to the

MCU PWB. The MCU uses the voltages for internal processing and for printer component

operation. The I/O PWB uses the voltages for printer component operation and also

sends +24VDC to the High Voltage Power Supply PWB.

The High V oltage Power Supply PWB, or HVPS, conver ts the +24VDC received from

the I/O PWB to the high voltages that are required by the xerographic system of the

printer. The HVPS produces the Charge (CR), Transfer (TR), Dev eloper Bias (DB), and

Detack (DTS) voltages, and sends them on to the EP Cartridge Detack Saw and to the

Bias Transfer Roll (BTR).

General Information 1-9

Page 28

4025-XXX

The PSHV-R2 converts the +24VDC received from the I/O PWB into the bias voltage

required by the Fuser.

Safety Interlocks for the printer are made up of two separate switches that are wired in

series with the I/O PWB and one switch that is attached to the MCU PWB. When the

Front Cover is open, the Front Cover Interlock Switch cuts +24VDC output from the

MCU PWB.

When the EP Cartridge is in place, Interlock Switch SW1 is closed. When the Left Hand

Cover is closed, Interloc k Swit ch SW2 is closed. With both switches closed, the circuit is

complete and the I/O PWB sends +24VDC to the HVPS and other printer components. If

either SW1 is open (the EP Cartridge removed) or SW2 is open (the Left Hand Cover is

open) the I/O PWB cuts all +24VDC output from the I/O PWB.

1-10 Service Manual

Page 29

4025-XXX

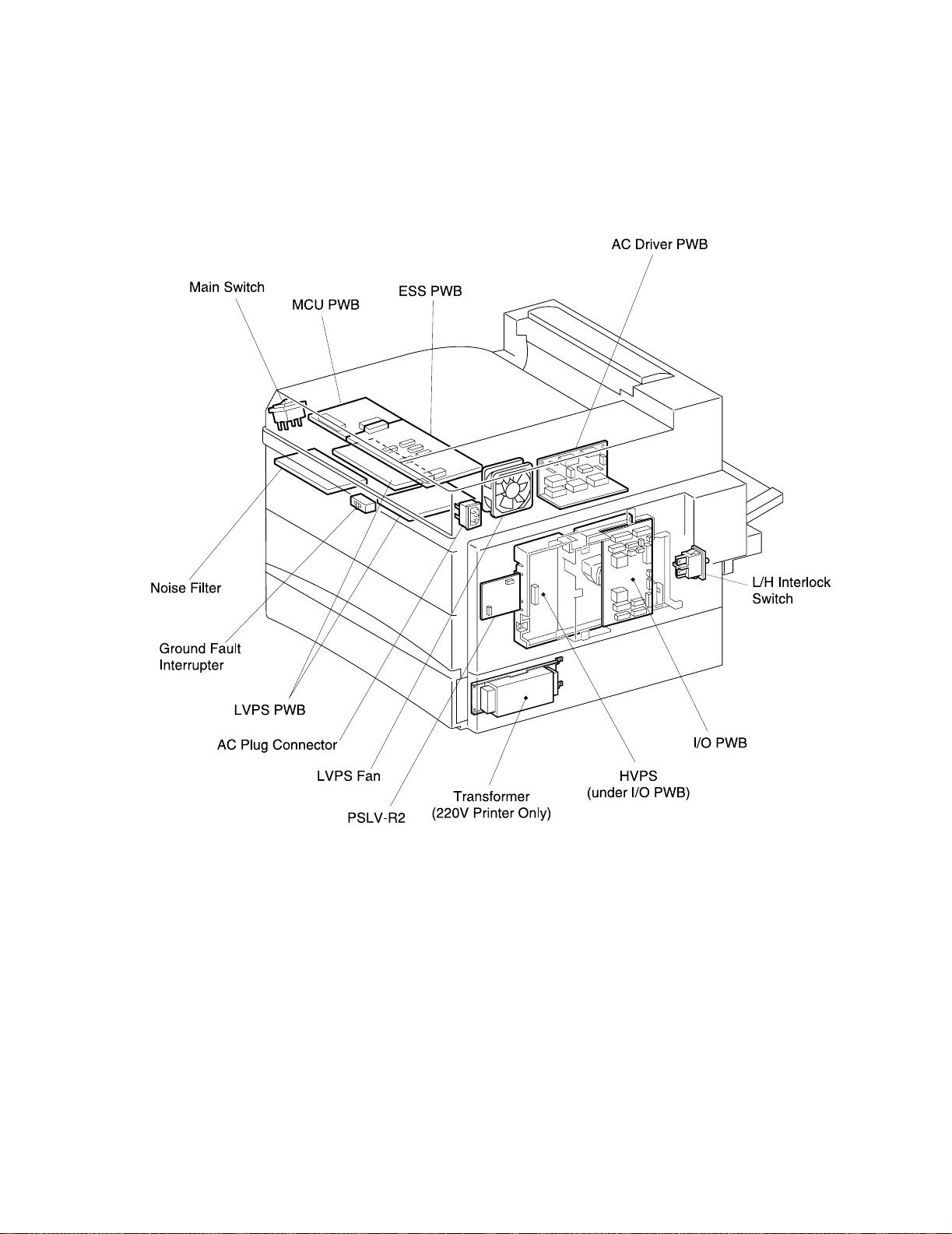

Power Supply Components

The printer Power Supply is made up of five major components and a number of

subcomponents.

1. Noise Filter PWB

Smooths and removes any fluctuation or hum from the AC line voltage.

Main Power Switch: Used to switch AC voltage on and off (switches the printer on

and off).

Ground Fault Interrupter (GFI): Used as a safety measure. If there is a short-

circuit, the GFI immediately cuts AC line voltage to the Noise Filter.

2. AC Dr ive r PWB

Receives smoothed AC voltage from the Noise Filter. The AC Driver PWB receives

Fuser temperature information from Fuser sensors and passes that information on to

the I/O PWB for processing. The MCU PWB signals the AC Driver to switch on or to

switch off AC voltage to the Fuser Heat Lamps.

General Information 1-11

Page 30

4025-XXX

3. Low Voltage Power Supply (LVPS)

Takes filtered AC voltage and converts it into regulated +24VDC and +5VDC.

The LVPS contains overcurrent protection circuits. If an excessive current begins

to flow through any of the components supplied by the LVPS, the LVPS immediately

shuts down all low voltage output. To reset the LVPS after an overcurrent shutdown;

switch off the printer, wait a few minutes, then switch on the printer.

The LVPS contains open circuit protection circuits. If the LVPS detects that a

circuit is open for longer than one minute, the LVPS slowly decreases the LVPS

output until the output is zero. To reset the LVPS after an open circuit shutdown;

switch off the printer, wait a few minutes, then switch on the printer.

The LVPS co ntains a low +24VDC output protection circuit. If the LVP S detects the

+24VDC output dropping below +15VDC, the LVPS slowly decreases the +24VDC

LVPS output until the output is zero.

LVPS Fan: A +24VDC fan that cools the LVPS PWB.

4. Machine Control Unit (MCU PWB)

Takes the +24VDC and +5VDC generated by the LVPS and distributes them to the

various components through out the printer, including the Printhead.

Front Cover Interl ock Swi t ch: Used as a safety measure. If the Interlock Switch is

closed (the Front Cover is closed) the MCU PWB sends +5VDC and +24VDC to

printer components. If the Interlock Switch is open (the Front Cover is open) the

MCU PWB cuts all +24VDC output.

5. I/O PW B

Takes the +24VDC and +5VDC generated by the LVPS and distributes them to the

various components through out the printer, including the HVPS.

Interlock Switches SW1 and SW2: Used as a safety measure. The main interlock

circuit for the printer is actually two separated switches wired in series with the I/O

PWB. When the EP Cartridge is in place, Interlock Switch SW1 is closed. When the

Left Front Cover is closed, Interlock Switch SW2 is closed. With both switches

closed, the circuit is complete and the I/O PWB sends +24VDC to the HVPS and

other printer components. If either SW1 is open (the EP Cartridge removed) or SW2

is open (the Left Front Cover is open) the I/O PWB cuts all +24VDC output.

CAUTION: Even though the interlock switches cut the +24VDC output from the MCU

PWB and I/O PWB, +24VDC output from the LVP S is still present throughout the printer

as well as 110VAC line voltage along the AC paths in the printer.

6. High Voltage Power Supply (HVPS)

Takes the +24VDC received from the I/O PWB and converts it into the high voltages

that are required by the printer xerographic components.

1-12 Service Manual

The HVPS contains overcurrent protection circuits. If an excessive current begins to

flow through any of the xerographic components, the HVPS immediately shuts down

all high voltage output. To reset the HVPS after an overcurrent shutdown; switch off

the printer, wait a few minutes, then switch on the printer.

Page 31

4025-XXX

7. PSHV-R2

Takes the +24VDC received from the I/O PWB and converts it into the Fuser Bias

voltage.

Electrical Safety Circuits

The printer contains three safety circuits that are controlled by three interlock switches

and one Ground Fault Interrupte r (GFI). Cutting power prevents a service technician or a

printer user from being injured by high voltage, by moving parts, or by exposure to the

laser beam.

SW1 (CRU Interlock Switch) is wired in series with SW2. SW1 is closed when the EP

Cartridge is in place inside the printer. When the EP Cartridg e is removed from the

printer, SW1 is open. An open SW1 cuts all +24VDC output from the I/O PWB.

SW2 (Left Cover Interlock Switch) is wired in series with SW1. SW2 is closed when the

printer Left Cover is closed. When the Left Cover is open, SW2 is open. An open SW2

cuts all +24VDC output from the I/O PWB.

If either SW1 or SW2 is open, the I/O PWB cuts all +24VDC output.

Front Cover Interl ock Swi t ch is connected to the MCU PWB. When the printer Front

Cover is open, the Interlock Switch cuts all +24VDC output from the MCU PWB.

Ground Fault Interrupter (GFI) senses minute amounts of current flowing to ground and

immediately cuts all AC line voltage into the Noise Filter. Faster than conventional circuit

breakers, the main purpose of the GFI is to prevent electrical shocks to the technician or

printer user.

CAUTION: It is dangerous to bypass, or cheat, either the CRU Interlock Switch or the

Left Cover I nterlock Switch while the EP Cartridge is out of the printer. With the interlocks

bypassed, the Laser Diode is active and generates intense laser light. Without the EP

Cartridge in place to block the laser beam, you risk serious eye injury.

General Information 1-13

Page 32

4025-XXX

I/O PWB

MCU PWB

HOT

N

+24VDC

+24VDC

Ground Fault Interrupter

SW1 (CRU Interlock)

SW2 (Left Cover Interlock)

Front Cover Interlock

Main Power Switch

EP Cartridge

Left Cover

Front Cover

Ground Fault

Interrupter

(GFI)

1-14 Service Manual

Left Front Cover

Interlock Switch

Page 33

Printer Control

4025-XXX

Printer control is a broad term that is used to describe the printer resources that monitor

and control the actions and operations of the print engine - from warm-up, through the

print cycle , t o machine error detection. T he ce nte r of printer control for the base engine is

the M

achine Control Unit PWB, or MCU PWB. The MCU PWB provides the logic and

information processing that is necessary for the printer to function. Almost every electrical

component within the printer is connected either directly or indirectly to the MCU PWB or

to the I/O PWB. The MCU polls the status of sensors in the printer and compares that

information to timing tables that are stored in onboard memory. Acting on the results of

the comparison, the MCU sends commands to various printer components or to the I/O

PWB; switching on motors, switching off voltages, signaling statuses. Non-Vol atile RAM

on the MCU PWB stores adjustable operation parameters, such as fuser temperature and

laser intensity, that are used as reference values during printer operation.

General Information 1-15

Page 34

4025-XXX

1-16 Service Manual

Page 35

4025-XXX

Printer Control Componen ts

The printer control is made up of the MCU PWB, the I/O PWB, and numerous connected

components.

Machine Control Unit PWB (MCU PWB)

The printer receives status and command information from the I/O PWB and from the

ESS PWB and controls most printer operations. The MCU PWB performs nine major

functions:

1. Communicates with the Printer Controller (ESS).

2. Maintains the system clock.

3. Controls the printing process.

4. Controls the Printhead, the Fuser, and the drive assemblies.

5. Distributes +5VDC and +24VDC to various printer components.

6. Monitors printer status.

7. Maintains a running print count.

8. Maintains NVRAM settings.

9. Controls printer options.

The ESS PWB is connected to the MCU PWB. Video data travels from the ESS PWB,

through the MCU PWB to the Laser Diode PWB.

General Information 1-17

Page 36

4025-XXX

Components attached to or associated with the MCU PWB:

1. I/O PW B

Interface between the MCU PWB and most of the printer components.

2. Low Voltage Power Supply

Converts AC line voltage to +5VDC and +24VDC.

3. ESS PWB

Connected to the MCU PWB. The interface between the print engine and the host

computer. The ESS processes the raw video data sent by the host computer.

4. Control Panel

Connected to the MCU PWB, the Control Panel displays status information sent from

the MCU PWB and ESS PWB.

5. AC Dr ive r PWB

Switches 110VAC to the two Fuser Heat Lamps. Fuser temperature sensors are

connected to the AC Drive PWB. The AC Drive PWB sends the temperature

information to the I/O PWB, which sends the information along to the MCU PWB.

6. High Voltage Power Supply

Converts +24VDC received from the I/O PWB to several high voltages that are

required by printer xerographics.

7. PSHV-R2

Converts +24VDC received from the I/O PWB to the Fuser bias voltage.

8. Toner Sensor

Magnetic sensor that monitors the CRU toner level.

9. CRU

Drum usage information that is stored in the CRU.

10. Printhead

The SOS (Start of Scan) Sensor, the Printhead Motor, and the Laser Diode.

11. Main Moto r

Provides most of the mechanical drive for the printer.

12. Drum Motor

Provides drive for the CRU.

13. Fuser Fan

Cools the Fuser area.

14. Feed Clutch

Transmits Main Motor drive to the Tray 1 Feed Rolls.

15. Registration Gate Clutch

Transmits Main Motor drive to the Registration Rolls.

1-18 Service Manual

Page 37

4025-XXX

16. Fuser Exit Sensor

Monitors paper travel out of the Fuser.

17. Face Up Exit Sensor

Monitors paper travel out of the Offset Unit.

18. Full Stack Sensor

Monitors the paper level in the Output Tray.

19. Exit Gate Solenoid

Tog g les the E x it Gate.

20. Inverter CW Clutch

Transmits Main Motor drive, forward, to the Offset Rolls.

21. Inverter CCW Clutch

Transmits Main Motor drive, reverse, to the Offset Rolls.

22. Offset Motor

Provides mechanical drive for the Offset Unit.

23. Duplex Module PWB

Provides +5VDC, +24VDC, and command and status lines to the Duplex PWB

option.

24. Mailbox

Provides +5VDC, +24VDC, and command and status lines to the Mailbox option.

25. Finisher

Provides +5VDC, +24VDC, and command and status lines to the Finisher option.

26. Envelope Feeder

Provides +5VDC, +24VDC, and command and status lines to the Envelope Feeder

option.

27. Cabinet Drive PWB

Provides +5VDC, +24VDC, and command and status lines to the High Capacity

Feeder option.

28. Size Sensor 1

Monitors the size of the paper that is loaded in Feeder 1. The Actuator Assembly

located at the rear of the Paper Tray has a series of cams that face the Size Sensor

PWB. Pushing the Paper Guide against the paper stack slides the Actuator

Assembly along a track. When the T ray is inserted into the Feeder, the cams on the

Actuator press the switches on the Size Sensor PWB in a pattern that is unique to

the position of the Paper Guide. The MCU PWB interprets this pattern as a specific

paper size.

General Information 1-19

Page 38

4025-XXX

29. Registration Sensor

Monitors paper travel out of the paper tray.

30. No Paper Sensor 1

Monitors the paper level in Feeder 1. When the Lift Motor raises the Bottom Plate,

the Plate raises the paper stack, the stack pushes the No Paper Actuator up and

away from the No Paper Sensor. The Sensor sends a paper present signal to the

MCU PWB. When the last sheet of paper is fed out of the Paper Tray, the No Paper

Actuator drops through a cutout in the Bottom Plate. The Actuator then blocks the

Sensor, and the Sensor sends a no paper signal to the I/O PWB - MCU PWB.

1-20 Service Manual

Page 39

4025-XXX

General Information 1-21

Page 40

4025-XXX

31. Level 1 Sensor

Monitor s wh ether or no t Tray 1 is installed. Installing the Tray pushes th e Link

Stopper out, which in turn lowers the Feed Roll and moves the Level 1 Sensor

Actuator tab away from the Sensor window.

32. MP Feeder Size Sensor

33. MP Feeder No Paper Sensor

34. MP Feeder Feed Clutch

1-22 Service Manual

Monitors the size of paper that is loaded in the MP Feeder.

Monitors the paper level in the MP Feeder.

Transmits Main Motor drive to the MP Feeder Feed Rolls.

Page 41

4025-XXX

35. Lift Motor 1

Raises the paper tray in Feeder 1. The MCU PWB switches on the Lift Motor. The

Motor rotates a square, metal shaft that is located inside the Paper Tray. The Shaft

raises the Tongue, which in turn raises the Bottom Plate, and the paper stack, up to

the Feed Rolls.

36. Take Away Roll Sensor

Monitors the paper travel at the Take Away Roll.

37. Interlock Switches 1 and 2

Monitors the CRU position Switch 1 and Left Cover Interlock Switch 2 on Feeder 1.

38. Feed Clutch 2

Transmits Main Motor drive to the Tray 2 Feed Rolls.

General Information 1-23

Page 42

4025-XXX

39. No Paper Sensor 2

Monitors the paper level in Feeder 2. Functions identical to No Paper Sensor 1.

40. Level 2 Sensor

Monitors whether or not Tray 2 is installed.

41. Size Sensor 2

Monitors the size of the paper that is loaded in Feeder 2.

42. Take Away Roll Sensor 2

Monitors the paper travel at the Take Away Roll 2.

43. Lift Motor 2

Raises the paper tray in Feeder 2.

44. Left C over Inte rlock 2

Monitors the Left Cover Interlock Switch on Feeder 2.

Control Functions of the Machine Control Unit (MCU)

1. Input from sensors

Sensors tell the MCU what is going on within the printer and what is happening to

the sheet of paper during a print cycle.

Example:

Printer sensors send their current status to the I/O PWB, which transfers the data on

to the MCU PWB. The sensor status signals tell the MCU whether they are actuated

or not a ctua te d (on or off, high o r low). If meas u r e d with a voltmeter, some senso r