Page 1

Tmd

Modbus Communications Reference Guide

Series Drives

Page 2

About These Instructions

This documentation applies to the use of an

should be used in conjunction with the

drive. These documents should be read in their entirety as they contain important technical data and describe the

installation and operation of the drive.

Modbus® and Modicon® are registered trademarks of Schneider Electric; http://www.schneider-electric.com.

For more information about the Modbus Protocol please refer to the Modicon Modbus Protocol Reference Guide;

http://www.Modbus.org

Tmd

Tmd

Series Variable Frequency Drive in a Modbus Network and

Series Operating Instructions (Document TD03) that shipped with the

© 2003 AC Technology Corporation

No part of this documentation may be copied or made available to third parties without the explicit written approval

of AC Technology Corporation. All information given in this documentation has been carefully selected and tested

for compliance with the hardware and software described. Nevertheless, discrepancies cannot be ruled out. AC

Tech does not accept any responsibility nor liability for damages that may occur. Any necessary corrections will be

implemented in subsequent editions.

Page 3

Contents

1 Safety Information .............................................................................................................1

1.1 Warnings, Cautions and Notes ..............................................................................1

1.1.1 General ....................................................................................................1

1.1.2 Application ...............................................................................................1

1.1.3 Installation ...............................................................................................1

1.1.4 Electrical Connection ................................................................................2

1.1.5 Operation .................................................................................................2

1.2 Reference and Links .............................................................................................2

2 Introduction .......................................................................................................................3

2.1 RS485 Details .......................................................................................................3

2.2 Electrical Installation .............................................................................................3

2.2.1 Cable Type ...............................................................................................3

2.2.2 Connections and Shielding .......................................................................3

2.2.3 Network Termination ................................................................................4

2.3 Modbus Details .....................................................................................................4

2.4 Universal Registers ...............................................................................................6

3 Data Representation - Internal and External .......................................................................7

3.1 Register Format ....................................................................................................7

3.2 Data Types ...........................................................................................................7

3.3

4

Tmd

4.1 Control Parameter .................................................................................................8

4.2 Serial Address ......................................................................................................8

4.3 Serial Communications Parameter ........................................................................8

4.4 Watchdog Timer ...................................................................................................9

4.5 Unlocking & Locking Controls ...............................................................................10

4.6 Unlocking & Locking Programming Parameters only .............................................10

4.7 Monitoring Only Operation ....................................................................................10

4.8 Normal Control Operation Sequence .....................................................................11

4.9 Start/Stop, Speed Control and Parameter Change Operation .................................11

Tmd

Drive Registers .............................................................................................7

Drive Setup & Operation ............................................................................................8

i RG-TDMOD

Page 4

Contents

5

Tmd

Drive Control Registers ..............................................................................................12

5.1 Abbreviations ........................................................................................................13

5.2 Drive Control - Register #1....................................................................................13

5.3 Drive Size - Register #21 ......................................................................................14

5.4 Drive Hardware Configuration - Register #22 ........................................................15

5.5 Drive Status - Registers #24-29 ............................................................................15

5.5.1 Reading Register #24 ...............................................................................15

5.5.2 Operational Status - Register #26 .............................................................16

5.5.3 Actual Rotational Direction - Registers #24 & 27 ......................................16

5.5.4 Control Mode - Registers #24 & 27 ..........................................................17

5.5.5 Speed Command Source - Registers #24 & 28 .........................................17

5.5.6 Speed Reference Status - Registers #24 & 28 ..........................................17

5.5.7 Present Fault - Registers #24 & 29 ...........................................................18

5.5.8 Commanded Rotational Direction - Registers #24 & 29 ............................18

5.6 Motor Volts - Register #30 ....................................................................................18

5.7 Serial Speed - Register #40 ..................................................................................19

5.8 Unlock Commands - Register #48 .........................................................................19

5.9 Unlock Parameters - Register #49 ........................................................................19

5.10 Register Version ....................................................................................................19

6

Tmd

Programming Parameters ..........................................................................................20

6.1 Format ..................................................................................................................20

6.2 Parameter List ......................................................................................................21

7 Quick Start Instructions .....................................................................................................27

7.1 Initial Settings .......................................................................................................27

7.2 Drive Control .........................................................................................................28

7.3 Basic Drive Commands .........................................................................................28

7.4 Basic Drive Status .................................................................................................29

RG-TDMOD ii

Page 5

1 Safety Information

1.1 Warnings, Cautions and Notes

1.1.1 General

Some parts of Lenze controllers (frequency inverters, servo inverters, DC controllers) can be live, moving

and rotating. Some surfaces can be hot.

Non-authorized removal of the required cover, inappropriate use, and incorrect installation or operation

creates the risk of severe injury to personnel or damage to equipment.

All operations concerning transport, installation, and commissioning as well as maintenance must be

carried out by qualified, skilled personnel (IEC 364 and CENELEC HD 384 or DIN VDE 0100 and IEC report

664 or DIN VDE0110 and national regulations for the prevention of accidents must be observed).

According to this basic safety information, qualified skilled personnel are persons who are familiar with

the installation, assembly, commissioning, and operation of the product and who have the qualifications

necessary for their occupation.

1.1.2 Application

Safety Information

Drive controllers are components designed for installation in electrical systems or machinery. They are

not to be used as appliances. They are intended exclusively for professional and commercial purposes

according to EN 61000-3-2. The documentation includes information on compliance with EN 61000-3-2.

When installing the drive controllers in machines, commissioning (i.e. the starting of operation as directed)

is prohibited until it is proven that the machine complies with the regulations of the EC Directive 98/37/EC

(Machinery Directive); EN 60204 must be observed.

Commissioning (i.e. starting drive as directed) is only allowed when there is compliance to the EMC Directive

(89/336/EEC).

The drive controllers meet the requirements of the Low Voltage Directive 73/23/EEC. The harmonised

standards of the series EN 50178/DIN VDE 0160 apply to the controllers.

The availability of controllers is restricted according to EN 61800-3. These products can cause

radio interference in residential areas. In the case of radio interference, special measures may be

necessary for drive controllers.

1.1.3 Installation

Ensure proper handling and avoid excessive mechanical stress. Do not bend any components and do not

change any insulation distances during transport or handling. Do not touch any electronic components

and contacts. Controllers contain electrostatically sensitive components, which can easily be damaged by

inappropriate handling. Do not damage or destroy any electrical components since this might endanger

your health! When installing the drive ensure optimal airflow by observing all clearance distances in the

drive's user manual. Do not expose the drive to excessive: vibration, temperature, humidity, sunlight, dust,

pollutants, corrosive chemicals or other hazardous environments.

1 RG-TDMOD

Page 6

1.1.4 Electrical Connection

When working on live drive controllers, applicable national regulations for the prevention of accidents (e.g.

VBG 4) must be observed.

The electrical installation must be carried out in accordance with the appropriate regulations (e.g.

cable cross-sections, fuses, PE connection). Additional information can be obtained from the regulatory

documentation.

The regulatory documentation contains information about installation in compliance with EMC (shielding,

grounding, filters and cables). These notes must also be observed for CE-marked controllers.

The manufacturer of the system or machine is responsible for compliance with the required limit values

demanded by EMC legislation.

1.1.5 Operation

Systems including controllers must be equipped with additional monitoring and protection devices according

to the corresponding standards (e.g. technical equipment, regulations for prevention of accidents, etc.).

You are allowed to adapt the controller to your application as described in the documentation.

Safety Information

DANGER!

• After the controller has been disconnected from the supply voltage, do not touch the live components and power

connection until the capacitors have discharged. Please observe the corresponding notes on the controller.

• Do not continuously cycle input power to the controller more than once every three minutes.

• Close all protective covers and doors during operation.

WARNING!

Network control permits automatic starting and stopping of the inverter drive. The system design must incorporate adequate

protection to prevent personnel from accessing moving equipment while power is applied to the drive system.

Table 1: Pictographs used in these instructions

Pictograph Signal word Meaning Consequences if ignored

DANGER!

WARNING!

STOP!

NOTE

Warning of Hazardous Electrical

Voltage.

Impending or possible danger

for persons

Possible damage to equipment Damage to drive system or its surroundings

Useful tip: If observed, it will

make using the drive easier

Reference to an imminent danger that may

result in death or serious personal injury if the

corresponding measures are not taken.

Death or injury

1.2 Reference and Links

Tmd

Series Variable Frequency Drives visit: http://www.lenze-actech.com

Modbus-IDA visit: http://www.modbus.org

RG-TDMOD 2

Page 7

2 Introduction

This document defines the specifics required for Modbus serial communication with a Lenze-AC Tech

standard

with normal drive capabilities and operations is assumed. If this is not the case, refer to the

Operating Instructions (TD03) for more information.

2.1 RS485 Details

Tmd

Series drive for control, status monitoring, and programming parameters. A familiarity

Introduction

Tmd

Series

Only standard

Tmd

models with an “L” as the eighth digit in the model number (ex. ETMD371L4TXA) are

equipped with Modbus RS-485 capabilities. When using this feature the drive can communicate with a PC,

PLC, or other external device that utilizes Modbus RS-485 serial communication for control or monitoring.

Refer to the

Tmd

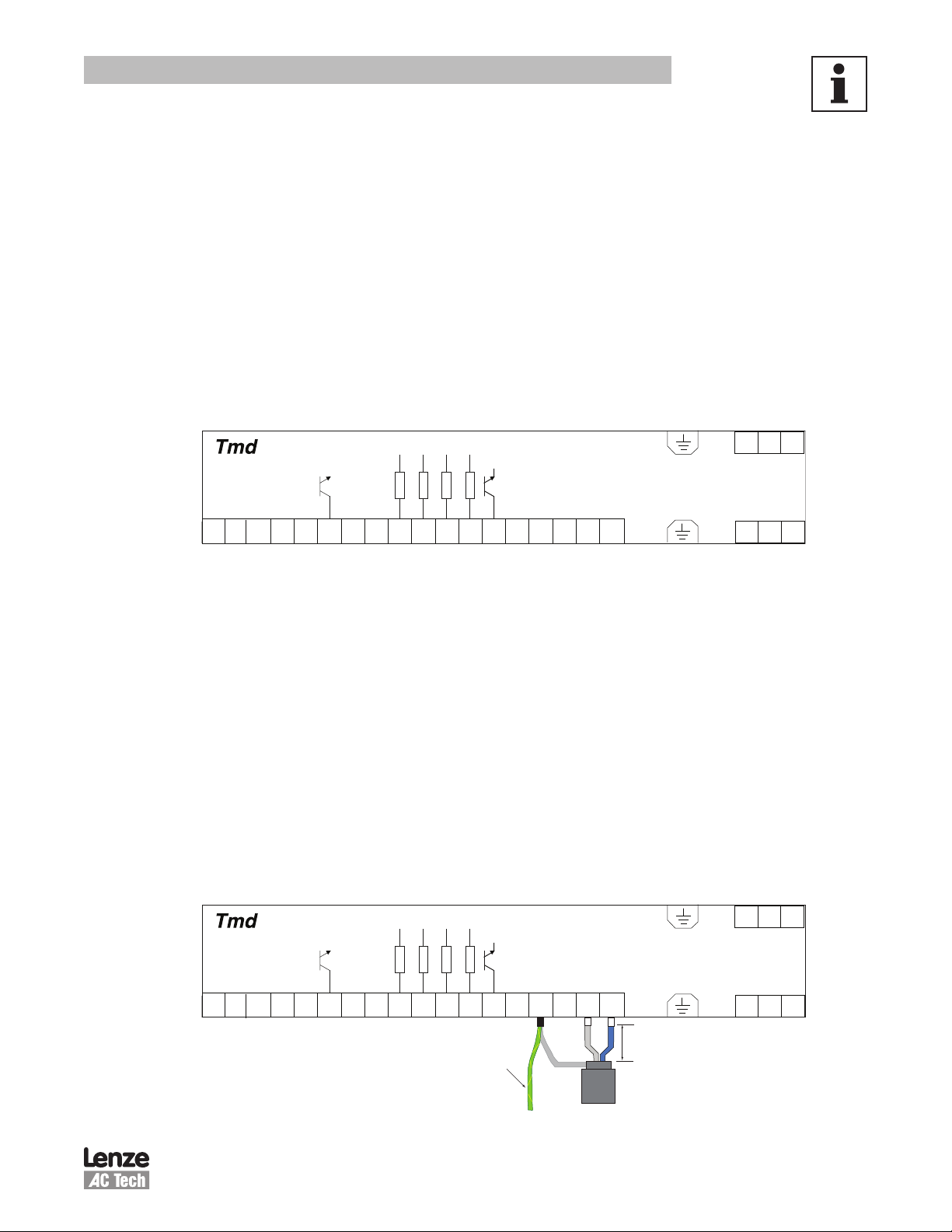

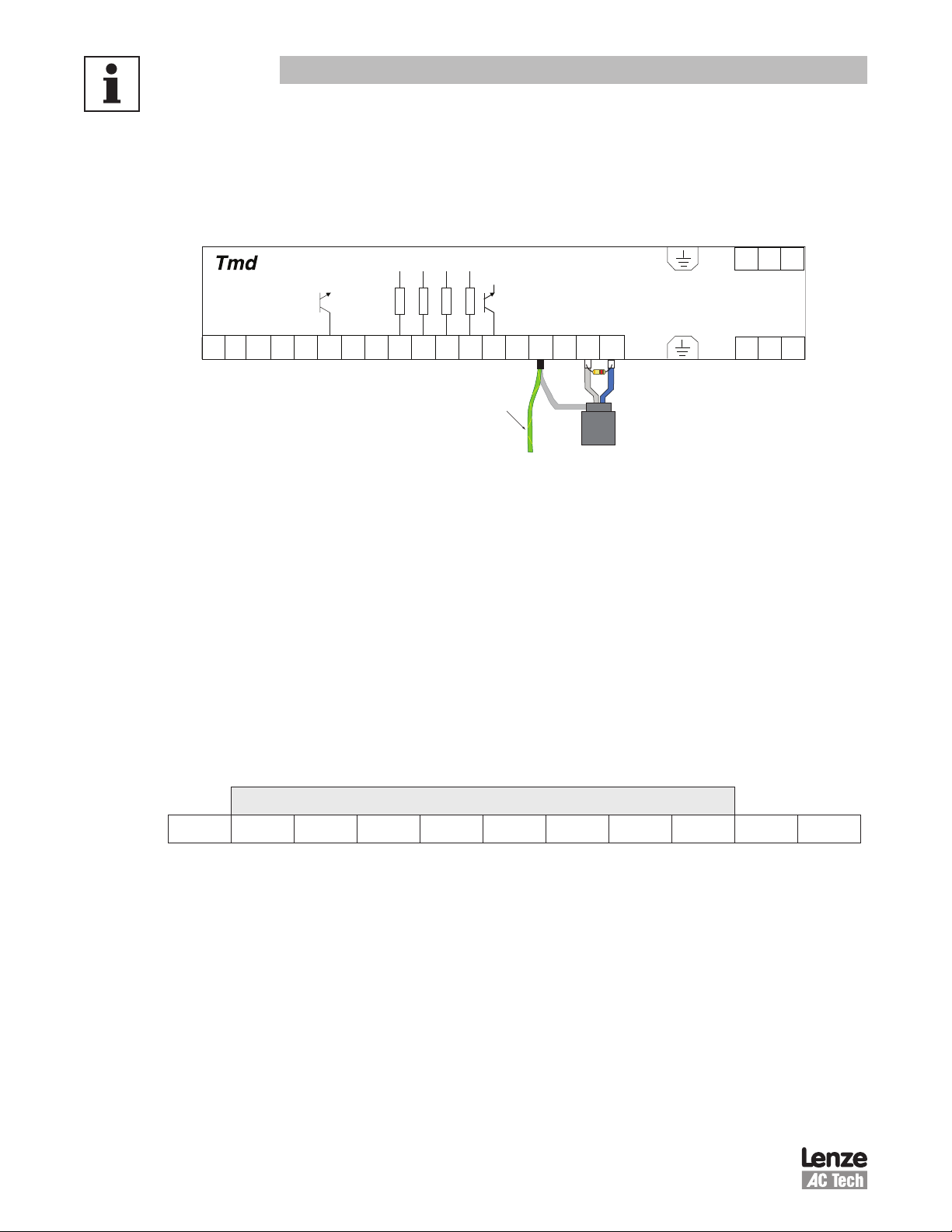

Operating Instructions (TD03) for connection details. Figure 1 illustrates the

strip. Terminals 7 (COM), 71 (TXB) and 72 (TXA) are used for RS485 communication.

COM

AIN

28 7

COM

8U

9

+10 V

+12 V

A+ A1

2.2 Electrical Installation

2.2.1 Cable Type

For RS485 Modbus networks, use a quality shielded twisted pair cable. The use of low quality cable will

result in excess signal attenuation and data loss.

2.2.2 Connections and Shielding

To ensure good system noise immunity all networks cables should be correctly grounded:

COM

+15 V

+15 V

2020

E1 E2 E3 71

Figure 1:

E4 A2

Tmd

Control Strip

AIN

COM

772

8I

Tmd

control

L1 L2

L3

TXB

TXA

62

U V W

• Minimum grounding recommendation: ground the network cable shield once in every cubical.

• Ideal grounding recommendation: ground the network cable on or as near to each drive as possible.

• For wiring of cable to the

Tmd

control terminal, the unscreened cable cores should be kept as short as

possible; recommended maximum of 20mm. Ground the shield at the drive end only.

• In addition, grounding terminal 7 on the

COM

AIN

28 7

COM

8U

9

+10 V

+12 V

A+ A1

+15 V

+15 V

2020

E1 E2 E3 71

Tmd

is recommended when using serial communications.

L1 L2

COM

TXB

TXA

U V W

20mm

max

E4 A2

Connect to

drive earth

(PE)

AIN

COM

772

8I

62

L3

Figure 2: Connector Wiring Diagram

3 RG-TDMOD

Page 8

Introduction

2.2.3 Network Termination

For an RS-485 network it is essential to install the specified termination resistors (120W), i.e. one at both

ends of a network segment. Failure to do so will result in signals being reflected back along the cable which

will cause data corruption. An external 120W 1/4W resistor can be connected as shown in Figure 3.

AIN

COM

9

8U

28 7

RS-485 half-duplex interface allows up to 32 devices to communicate on the network using a twisted

pair of wires. The wires must be terminated at both ends of the network with resistors equal to their

characteristic impedance, typically 120W. In noisy environments, twisted and shielded wire should be

used. Ground the shield at the drive end only. This will further reduce unwanted noise and improve overall

communication reliability. In addition, grounding terminal 7 on the

communications.

+10 V

COM

+12 V

A+ A1

COM

+15 V

+15 V

2020

E1 E2 E3 71

E4 A2

Connect to

drive earth

(PE)

AIN

772

8I

COM

62

TXB

Figure 3: Network Termination Resistor

Tmd

L1 L2

L3

TXA

U V W

120Ω

1/4W

is recommended when using serial

2.3 Modbus Details

A.

Tmd

Drives running the Modbus communication protocol use the RTU (Remote Terminal Unit)

transmission mode and are slaves only. Therefore, the device communicating with the drives must be

a Modbus Master. The baud rate is 9600. By default the Tmd uses no parity and two stop bits. There

are provisions for Odd parity, 1 stop bit and Even parity 1 stop bit as well. The bit sequence is:

Start bit 1 2 3 4 5 6 7 8 Stop bit Stop bit

B. At this time the

C. IMPORTANT NOTE: Modbus 3X and 4X Registers are numbered starting at 1. However, when transmitted

to a slave over the serial link, the actual address transmitted is one less. This is because the addresses

are numbered starting from 0. The

Tmd

register numbers always correspond exactly with the address transmitted. As a result, MODBUS

REGISTER NUMBERS ARE ALWAYS ONE GREATER THAN

WORDS “REGISTER #xx” APPEAR, IT SHOULD BE ASSUMED THAT THEY MEAN “

and the Modbus Register number will be one larger. In some instances we may show both for clarity.

For example: “Register #24 (Modbus Register #25) . . .”

DATA

Tmd

drive does not support the broadcast function of the protocol.

Tmd

register numbers are also numbered starting from 0. Therefore,

Tmd

REGISTER NUMBERS. WHENEVER THE

Tmd

REGISTER xx”

RG-TDMOD 4

Page 9

Data & Register Format

D. The function codes supported by the

03 Read Holding Register (4X references). In general we can read only one register at a time. However,

there are a few limited exceptions.

Exception One:

Register #24 (Modbus Register #25) Drive Status, can also be read as a group of 6 words.

Exception Two:

The

Tmd

uses a method of reading a group of related registers that may not be consecutive within

the drive memory map. When this is done for the registers below, the response from the drive will

be for the number of words requested but will not be with consecutive registers.

Register #114 (Modbus Register #115), Software version, should be read as a group of 4 words.

04 Read Input Register (3X references). As with function 03, we read one register at a time except

where noted.

06 Preset Single Register (4X references). Write single register.

16 Preset Multiple Registers (4X references). Although the function is for multiple registers, we will

accept only a single register to be written.

Note: Since we do not differentiate between 4X and 3X references, function codes 03 and 04 are

treated identically.

Tmd

drives are:

E. Exception codes:

01 - Command rejected, Illegal function

02 - No such register

03 - Data out of range

04 - Wrong data format

06 - Slave device busy

F. The

G. Modbus® and Modicon® are registered trademarks of Schneider Electric. For more information about

Tmd

drive will most nearly conform to the Modicon® Micro 84 in capabilities. This may be of

importance when configuring networks for DDE Servers.

the Modbus Protocol please refer to the Modicon Modbus Protocol Reference Guide. Web resources:

http://www.Modbus-IDA.org and http://www.schneider-electric.com.

5 RG-TDMOD

Page 10

Drive Setup & Operation

2.4 Universal Registers

Lenze-AC Tech manufactures several drive families. Currently the QC, MC, MCH, SC, TC,

smd, Tmd

and

SMV Series drives support Modbus based communications. Since each drive family has different parameters

and size ranges, the parameter (register) definitions are in many cases quite different. In order to facilitate

communication in a network with a mix of drive types, certain Lenze-AC Tech Register locations have been

made universal among Lenze-AC Tech drives. While their locations are consistent, their contents may vary

as defined in Table 2.

Table 2: Contents of Universal Registers

AC Tech Reg # Function

1 Drive Control (WRITE ONLY). Not all drives will have all control functions but when the function is

available it will be at a defined bit location within Register #1. Drive Family and register Configuration

Number dependent.

19 Drive Family (READ ONLY) This register is consistent among all Lenze-AC Tech drives:

- 64 -- QC family - 67 -- - 70 -- TC family

- 65 -- MC family - 68 -- MCH family - 71 --

- 66 -- SC family - 69 --

21 Drive Size (READ ONLY). Code to identify Power (HP/KW) and Line Voltage of the drive. Family

dependent. For the

22 Hardware Configuration word register (READ ONLY). Individual bit flags.

24 Drive Status (READ ONLY). Various operational variables.

48 Unlock Control (WRITE ONLY).

49 Unlock Writing of registers (WRITE ONLY).

50 Parameter Configuration Number (READ ONLY).

Tmd

series, the drive size values are shown in Table 9.

smd

family - 72 -- SMV family

Tmd

family

RG-TDMOD 6

Page 11

Drive Setup & Operation

3 Data Representation - Internal and External

3.1 Register Format

All registers are 16 bits. The data within these registers can take on the following forms:

• Individual bit commands (16 per register).

Example: Register #1 (Modbus Register #2).

• Individual bit flags (16 per register).

Example: Register #22.

• A chain of two 8 bit unsigned integers.

• A 16 bit unsigned integer.

This unsigned integer could in turn represent many different types of data with various scaling

rules and units, which are defined by the DATA TYPE of the register.

3.2 Data Types

3.3

Data passed in registers across the Modbus communications link are always in INTERNAL units. The drive

itself may show the information in alternate DISPLAYED units. For Example: drive speeds are always stored

internally as tenths of a Hz but the drive may display that speed in whole Hz by dropping the tenth using

programmed conversion factors. Table 3 lists examples of the internal units used on the

Table 3:

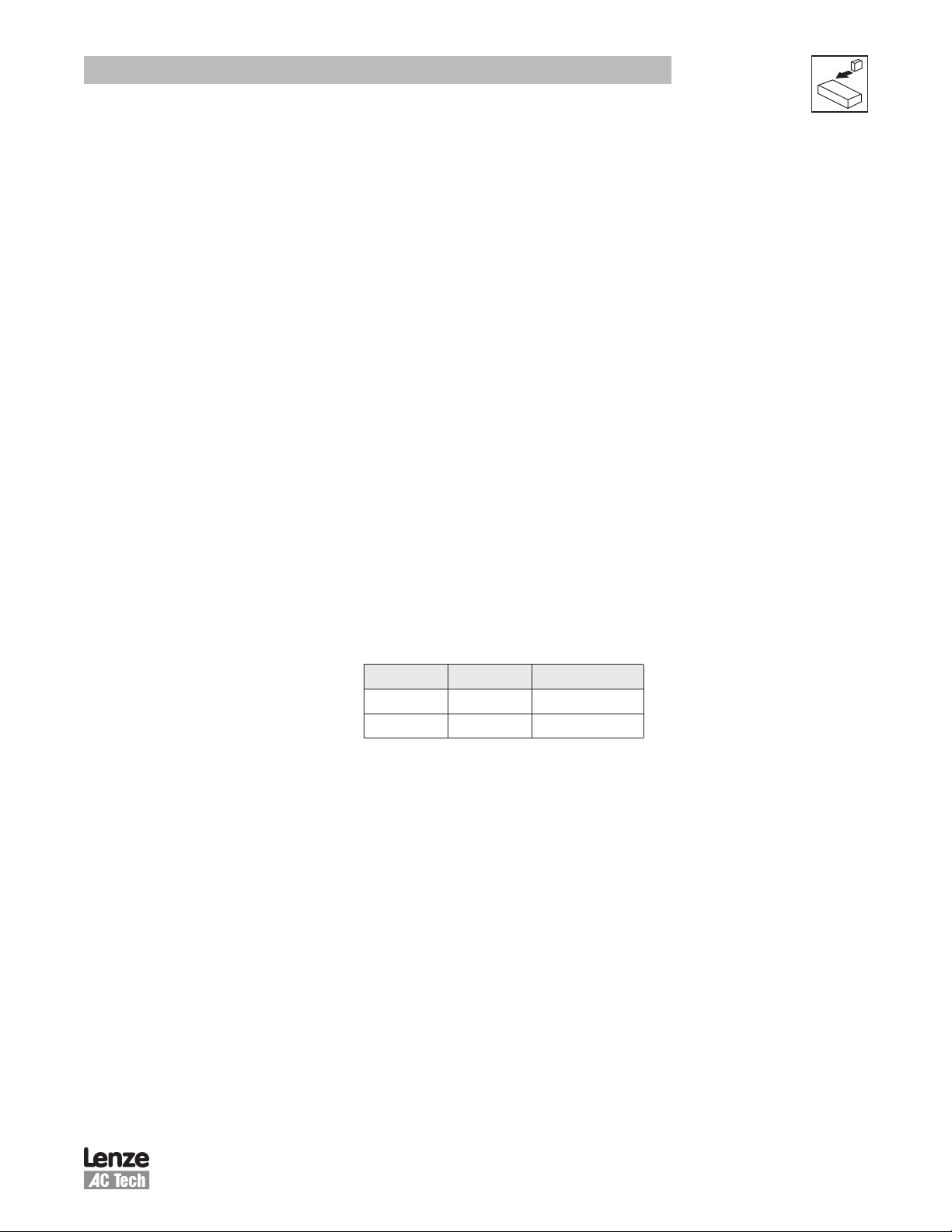

Type Unit Example

SPEED .1Hz 60Hz = 600

TIME .1Sec 30.0 Sec = 300

Tmd

Drive Registers

Registers #0 through #50: (Modbus Registers #1 to #51) Reserved for configuration and control

Registers #51 through #255 (Modbus Registers #52 to #256) Reserved for the drives’ programming

mode parameters. Programming Mode Parameters are the parameters

that can be accessed from the local keypad on the drive.

The entries in Table 6 are based on

revision of software were to change register definitions, drive operation could be seriously affected. This will

be identified for a given drive by examining Register #50 (Parameter Configuration Number). The number

displayed at power up on drive display can also identify it. If it is not 503, writing to any register on the

drive MUST NOT BE ATTEMPTED unless your Controller has been setup to support the new configuration.

Tmd

Tmd

Series Internal Units

Drive Software # 1.20 (Parameter Configuration = 503). If a later

Tmd

series.

7 RG-TDMOD

Page 12

Drive Setup & Operation

4

Tmd

Drive Setup & Operation

4.1 Control Parameter

In order to communicate using Modbus protocol, the

be set to one of the selections listed in Table 4.

Setting Source Description

Program

(Monitoring)

8 Modbus Terminal Analog Input Drive is controlled via terminal programming and is monitored via Modbus

9 Modbus Terminal c40 Drive is controlled via terminal programming and is monitored via Modbus

10 Modbus Modbus Analog Input Drive is controlled via serial interface and is monitored via Modbus

11 Modbus Modbus c40 Drive is controlled via serial interface and is monitored via Modbus

Control

(Start/Stop,

Direction)

4.2 Serial Address

Tmd

Control Source Setpoint (parameter #C01) must

Table 4: Control Source Setpoint C01 (Register 51)

Speed

(Source)

interface or keypad. The default speed source is the analog input.

interface or keypad. The default speed source is c40.

interface or keypad. The default speed source is the analog input.

interface or keypad. The default speed source is c40

The

Tmd

drive has a serial address parameter that must be programmed prior to attempting to operate the

serial interface. Set Parameter C09 (Network Address) to a valid address (1-247).

Tip

Most Modbus devices ship with a default address of 1. As such, it is recommended to not

use address 1 in order to avoid duplicate address conflicts when replacing devices.

4.3 Serial Communications Parameter

Lenze-AC Tech drives have a Serial Communications Parameter that governs the operation of the serial

link. On

value of 8-11. Table 5a lists the selections for Parameter c25, Baud Rate. Table 5b lists the selections for

the controller's reaction to serial timeout (n22).

Tmd

drives this is c25 Baud Rate. Parameter C01 Control Source Setpoint must first be set to a

Tables 5a & 5b: Serial Communications

Table 5a: Baud Rate c25 Table 5b: Serial Timeout Action n22

Setting Description Setting Description

0 9600, 8, N, 2 0 Not active

1 9600, 8, N, 1 1 Controller Inhibit

2 9600, 8, E, 1 2 Quick Stop

3 9600, 8, O, 1 3 Trip Fault FC3

The Serial Communications Parameter c25 must be appropriately programmed prior to attempting to

communicate with the drive. The timeout period is programmed in Parameter n23, Serial Fault Time.

RG-TDMOD 8

Page 13

4.4 Watchdog Timer

The

Tmd

drive is equipped with a Serial Link “Watchdog Timer”. If the Modbus Master wishes to control

the drive (start, stop, forward, reverse, etc.) it must first “Unlock Controls” (section 4.4). If the Watchdog

Timer is enabled and controls have been unlocked, the Master MUST PERIODICALLY COMMUNICATE with

the drive or the timer will timeout. Communications should typically be done at less than 1/2 the interval

specified in n23, Serial Fault Time.

The Watchdog Timer does not operate unless Controls have been UNLOCKED via Register #48, or parameters

writing has been unlocked via Register #49. In case of unlocking parameters only, watchdog timer will

disable write permission but will not stop the drive.

The Watchdog Timer is setup using parameters n22 (Serial Timeout Action) and n23 (Serial Fault Time).

Drive Setup & Operation

Selection of n22 determines the

n22 = 0: Not Active The Watchdog Timer is disabled

n22 = 1: Controller Inhibit If the drive doesn't receive valid communication for period longer

n22 = 2: Quick Stop If drive doesn't receive valid communication for period longer than

n22 = 3: Trip Fault FC3 If drive doesn't receive valid communication for period longer than

The setting of Parameter n23, Serial Fault Time, sets the serial timeout length in miiliseconds. The valid

range is 50 - 65535 ms and the default setting is 50ms.

NOTE - Trip Prevention

To prevent erroneous timeout trips, make sure the time set in parameter n23 is appropriate

for the particular network. The defualt value of 50ms may be too restrictive.

Tmd

drive's reaction to serial timeout:

than time specified in parameter n23, it will COAST to a STOP and

status display (c61) will show inhibit state 'Inh'.

time specified in parameter n23, it will RAMP to a STOP and status

display (c61) will show inhibit state 'Stp'.

time specified in parameter n23, it will TRIP with an 'FC3' fault.

WARNING

Disabling the Watchdog Timer may cause injury to personnel and/or damage to equipment.

The Watchdog Timer should only be disabled during configuration or diagnosis to prevent

nuisance timeout trips.

9 RG-TDMOD

Page 14

Drive Control & Communication

4.5 Unlocking & Locking Controls

Registers #48 and #1 are used in Unlocking and Locking Controls.

• A write to Register #48 (Unlock Controls) with a value of 0 will unlock controls. This enables the writing

of Register #1 – the Drive Control Register and register #40 (serial speed reference).

Note: C01 must be set to 10 or 11 in order to unlock serial control.

• If Register #48 (Unlock Controls) is written with a value that is the Drive’s Programming Password

(C94), then in addition to Register #1(Drive Control), writing to all other writeable registers is enabled

(e.g.: parameter C37 -- Preset Speed #1). The factory default password for

• Once Register #48 (Unlock Controls) has been written, Controls are unlocked until Register#1 bit 1

(Lock Bit) has been written, Parameter C01 is changed to a value different than 10 or 11, the drive is

powered down or a watchdog timeout has occurred.

• Writing to Register #1 (Drive Control) with bit 1 set will Lock both Controls and Parameters (prevents

writing to any register).

• When LOCK is asserted, the drive drops out of SERIAL control. After receiving the WRITE message

when serial control is locked, the drive will return exception code 01.

Tmd

series drives is 0.

• Even though drive might be locked, and thus parameters and control cannot be written, parameters

and status can always be read. Refer to section 4.7,

Monitoring Only Operation

4.6 Unlocking & Locking Programming Parameters only

Registers #49 and #1 are used in Unlocking and Locking Programming Parameters.

• Writing to any writeable register other than #1 can be enabled by writing the Drive’s Programming

Password (C94) to Register #49 (Unlock Parameters). This would be done when Drive Control (start,

stop, etc.) is not required.

• The Factory Default password is 0.

• Once Register #49 (Unlock Parameters) has been written, the writing of parameter registers is unlocked

until Register #1bit 1 (Lock Bit) has been set or a watchdog timeout has occurred.

4.7 Monitoring Only Operation

1. Power up drive.

2. Set parameter C01 (Control Source Setpoint) to selection 8 or 9.

3. Simply read

4. No unlocking or watchdog issues apply for monitoring.

Tmd

Register #24 (Modbus Register #25) or any other readable register.

.

RG-TDMOD 10

Page 15

Drive Control & Communication

4.8 Normal Control Operation Sequence

1. Power up drive.

2. Set parameter C01 (Control Source Setpoint) to selection 10 or 11.

3. Close terminal 28.

4. Unlock control by writing a zero to Register #48.

5. Set the network speed reference by setting bit 8 of Register #1. The drive must be in "NETWORK

SPEED REFERENCE" (Register #1, Drive Control) in order to control speed via Register #40.

6. Control drive operation via various commands to Register #1 (Start, Stop, Reverse direction, etc.) and

change the speed command by writing to Register #40.

7. If serial timeout is activated (n22 = 1, 2 or 3), keep it from timing out by assuring that repeated reads

of drive status (Register #24, 6 registers) are performed at reasonable intervals smaller than the time

set in parameter n23.

8. Lock Control when drive operations are complete by writing a 2 to Register #1. (assert bit 1 of Register

#1).

4.9 Start/Stop, Speed Control and Parameter Change Operation

The typical sequence for a Start/Stop, Speed Control or Parameter Change operation is listed herein.

1. Power up drive.

2. Set parameter C01 (Control Source Setpoint) to selection 10 or 11.

3. Close terminal 28.

4. Unlock Controls and Parameters by writing the current programming password (default 0) to Register

#48.

5. Control Drive Operation via various commands to Register #1 (Start, Stop, Reverse direction, etc.).

6. Set the network speed reference by setting bit 8 of Register #1. The drive must be in "NETWORK

SPEED REFERENCE" (Register #1, Drive Control) in order to control speed via Register #40.

7. Control Drive Speed by writing the Speed Commands to Register #40 (Serial Speed Command).

8. Change the programming parameters (e.g., change the acceleration rate by writing new acceleration

rate to register #62)

9. If serial timeout is activated (n22 = 1, 2 or 3), keep it from timing out by assuring that repeated reads

of drive status (Register #24, 6 registers) are performed at reasonable intervals smaller than the time

set in parameter n23.

10. Lock Controls and Parameters when drive operations are complete by writing a 2 to Register #1 (assert

bit 1 of Register 1).

11 RG-TDMOD

Page 16

Drive Control & Communication

5

Tmd

Drive Control Registers

Table 6 describes the

Tmd

Drive Control Registers in ascending order of

representation is given in parenthesis next to the

REGISTER NAME

# (HEX

Tmd

representation)

1 (01) Drive Control

19 (13) Drive Family

21 (15) Drive Size

22 (16) Drive H/W

Drive Status

24 (18)

24 (18) Command Speed

25 (19) Actual Speed

26 (1A)

27 (1B)

28 (1C)

29 (1D)

30 (1E) Motor Voltage

40 (28) Serial Speed Command

48 (30) Unlock Commands

49 (31) Unlock Parameters

50 (32) Register Version

(6 register read)

(reg. #24 to 29)

Load (DH) /

Status (DL)

Act. Direction (DH)/

Control Mode (DL)

Speed Source (DH)/

Speed Reference (DL)

Fault (DH)/

Commanded Direction (DL)

Table 6:

R/W/RS

W SA 06 00 01 DH DL CRCH CRCL

RS SA 06 00 01 DH DL CRCH CRCL

R SA 03 00 13 00 01 CRCH CRCL

RS SA 03 02 00 42 CRCH CRCL

R SA 03 00 15 00 01 CRCH CRCL

RS SA 03 02 00 00 CRCH CRCL

R SA 03 00 16 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

R SA 03 00 18 00 06 CRCH CRCL

RS SA 03 0C D1H D1L D2H D2L

R SA 03 00 18 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

R SA 03 00 19 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

R SA 03 00 1A 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

R SA 03 00 1B 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

R SA 03 00 1C 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

R SA 03 00 1D 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

R SA 03 00 1E 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

R SA 03 00 28 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

W SA 06 00 28 DH DL CRCH CRCL

RS SA 06 00 28 DH DL CRCH CRCL

W SA 06 00 30 DH DL CRCH CRCL

RS SA 06 00 30 DH DL CRCH CRCL

W SA 06 00 31 DH DL CRCH CRCL

RS SA 06 00 31 DH DL CRCH CRCL

R SA 03 00 32 00 01 CRCH CRCL

RS SA 03 02 DH DL CRCH CRCL

Tmd

Tmd

Register #. The HEX

Tmd

Register # in the left-most column.

Drive Control Registers

MESSAGE MIN MAX UNITS

Refer to Section 5.2 [1]

Refer to Section 5.2 [2]

Refer to Section 5.2 [3]

Refer to Section 5.3

D3H D3L D4H D4L

D5H D5L D6H D6L

CRCH CRCL

Refer to Section 5.4

0 2400 0.1 Hz [4a]

0 2400 0.1 Hz [4b]

Refer to Section 5.4.2 [4c]

Refer to Section 5.4.3

Refer to Section 5.4.4

Refer to Section 5.4.5/6 [4d]

0 800 1V 5.5

C10

C11

Min

Freq.

Max

Freq.

0 9999 None 5.7

0 9999 None 5.8

0 65535 None 5.9

[NOTE]

or

Section

0.1 Hz 5.6

RG-TDMOD 12

Page 17

5.1 Abbreviations

Drive Control & Communication

Table 7 lists the abbreviations used in Table 6

Abbreviation Description

R Read

W Write

RS Response

SA Slave Address (typically 01 through F7 hex)

CRCH Cyclic Redundancy Check High byte

CRCL Cyclic Redundancy Check Low byte

DH Data High byte

DL Data Low byte

Tmd

#

5.2 Drive Control - Register #1

Table 8 illustrates the Data High Byte and Data Low Byte format of Register #1, Drive Control.

Tmd

Drive Control Registers:

Table 7: Abbreviations

Tmd

Register # (Modbus Register numbers are 1 larger)

Table 8: Drive Control - Register #1

0 UPDATE BUFFERS

1 LOCK SECURITY

2 STOP DRIVE (COAST TO STOP)

3 START DRIVE

4 UNUSED

5 UNUSED

Data Low Byte

6 SET REVERSE

7 SET FORWARD

8 NETWORK SPEED REFERENCE

9 LOCAL SPEED REFERENCE

10

11

12

13

Data High Byte

14

15

The appropriate bit is set to 1. For example, to stop the drive bit two is set (send 0004H). To start the drive

send 0008H. Setting update buffers bit, enables to start the drive using downloaded data. Locking security

disables the serial drive control, the communications watchdog timer and prevents any further writing to

control or parameter registers.

13 RG-TDMOD

Page 18

Drive Control & Communication

NOTE 1 - Drive Control

• During each write to Register #1 only one bit should be set in the drive control word.

• If more than 1 bit is set, the drive responds to stop bit only.

• If stop bit is not set, but more than 1 bit is set, drive responds with exception 04.

NOTE 2 - Drive Family

• The QC and DL Series drives return 64 (40H)

• The MC Series drives return 65 (41H)

• The SC Series drives return 66 (42H)

• The MCH Series drives return 68 (44H)

• The

smd

Series drives return 69 (45H)

• The TC Series drives return 70 (46H)

• The

Tmd

Series drives return 71 (47H)

• The SMV Series drives return 72 (48H)

5.3 Drive Size - Register #21

Table 9 lists the

Tmd

Series drives. Register 21 will contain the value in the "Size" column.

Size kW Voltage Size kW Voltage

00 0.55

01 0.37 29 0.37

02 0.75 30 0.75

03 1.1 31 1.1

04 1.5 32 1.5

05 2.2 33 2.2

16 0.75

17 1.1 35 5.5

18 1.5 36 7.5

19 2.2 44 3.0

20 4.0

21 5.5

22 7.5

Table 9: Drive Size - Register #21

28 0.55

1/N/PE or 3/PE

230V

3/PE

400/480V

34 4.0

3/PE

230V

RG-TDMOD 14

Page 19

Drive Control & Communication

5.4 Drive Hardware Configuration - Register #22

Table 10 lists the

Tmd

Drive Hardware Configuration, Register #22. Bits 4 - 15 are not used at this time.

Table 10: Register 22 - Drive Hardware Configuration

BIT # STATE MEANING

0 1 Non-isolated drive (hot)

1 1 Reserved

2 1 Reserved

3 1 OEM defaults present

5.5 Drive Status - Registers #24-29

5.5.1 Reading Register #24

When reading register #24, the group of words requested can be either 1 or 6. This is an exception to the

rule of being able to read only one register at a time. If 6 words are requested at register #24, the following

will be returned:

0 Isolated

0 Reserved

0 Reserved

0 No OEM defaults

Table 11: 6 Register read at #24

Parameter Data Byte

Command Speed D1H D1L

Actual Speed D2H D2L

Load D3H

Operation Status D3L

Rotational Direction D4H

Control Mode D4L

Speed Command Source D5H

Speed Reference Status D5L

Present Fault D6H

Command Rotation D6L

NOTE 4a - Command Speed (Register #24 Bytes D1H and D1L or Register #24)

• In tenths of a Hz

• Most significant byte is first, followed by Least significant

• Example: 02 01 in hex converts to 51.3Hz in decimal (assumed 1 decimal place).

15 RG-TDMOD

Page 20

Drive Control & Communication

NOTE 4b - Actual Speed (Register #24 Bytes D2H and D2L or Register #25)

• In tenths of a Hz

• Most significant byte is first, followed by Least significant

NOTE 4c - Load (Register #24 Byte D3H or Register #26 DH)

• In percent of full load

• Example: 64 (one byte in hex) ==> 100 in decimal ==> 100% (drive load).

5.5.2 Operational Status - Register #26

Table 12 lists the Operational Status (Register #24 byte D3L or Register #26 DL)

Bit Parameter

0 FAULT LOCKOUT

1 FAULT

2 START PENDING

3 MOTOR CALIBRATION NOT DONE

4 STOP

5 LOWER TRANSISTORS SWITCHING ON

6 MOTOR CALIBRATION ENABLED

7 RUN AT 0Hz

8 RUN

9 ACCEL

10 DECEL

11 DECEL OVERRIDE

12 DC BRAKE

13 FLYING START

14 SLOW CURRENT LIMIT

15 FAST CURRENT LIMIT

16 OFF

17 INHIBIT

Table 12: Operational Status

5.5.3 Actual Rotational Direction - Registers #24 & 27

Table 13 lists the Actual Rotational Direction (Register #24 byte D4H or Register #27 DH).

Table 13: Actual Rotational Direction

Setting Direction

0 FORWARD

1 REVERSE

RG-TDMOD 16

Page 21

Drive Control & Communication

5.5.4 Control Mode - Registers #24 & 27

Table 14 lists the Control Mode (Register #24 byte D4L or Register #27 DL).

Control Mode Speed Source Control Source Program Source

0 Analog Terminal Keypad

1 c40 Terminal Keypad

2 Analog Terminal LECOM

3 LECOM LECOM LECOM

4 Analog Terminal Remote Keypad

5 c40 Terminal Remote Keypad

6 Analog Remote Keypad Remote Keypad

7 c40 Remote Keypad Remote Keypad

8 Analog Terminal Modbus

9 c40 Terminal Modbus

10 Analog Modbus Modbus

11 c40 Modbus Modbus

Table 14: Control Mode

5.5.5 Speed Command Source - Registers #24 & 28

Table 14 lists the Speed Command Source (Register #24 byte D5H or Register #28 DH).

Table 14: Speed Command Source

Setting Source

0 ANALOG FREQ.

1 PRESET c40

2 PRESET 1

3 PRESET 2

4 PRESET 3

5 MOP SPEED

6 SERIAL SPEED

5.5.6 Speed Reference Status - Registers #24 & 28

Table 15 lists the Speed Reference Status (Register #24 byte D5L or Register #28 DL).

Table 15: Speed Reference Status

Setting Status

0 SERIAL SPEED REFERENCE

1 LOCAL SPEED REFERENCE

17 RG-TDMOD

Page 22

Drive Control & Communication

5.5.7 Present Fault - Registers #24 & 29

Table 16 lists the Present Fault (Register #24 byte D6H of Register #29 DH)

Setting Fault Display Setting Fault Display

0 NO FAULT 18 INTERNAL FAULT 1 (EPM) F1

1, 2 OUTPUT (TRANSISTOR) FAULT OC1 19 INTERNAL FAULT 2 F2

3 EARTH FAULT OC2 20 INTERNAL FAULT 3 F3

4 RESERVED 21, 22 INTERNAL FAULT 5 F5

5 OVER TEMPERATURE FAULT OH 23 INTERNAL FAULT 6 F6

6 FLYING RESTART FAULT rF 24 INTERNAL FAULT 7 F7

7 OVER VOLTAGE FAULT OU 25 INTERNAL FAULT 8 F8

8 UNDER VOLTAGE FAULT LU 26 INTERNAL FAULT 9 F9

9 MOTOR OVERLOAD FAULT OC6 27 IDENTIFICATION FAULT bF

10 OEM DATA FAULT GF 28 A/D CONVERTER FAULT Ad

11 CONFIGURATION FAULT CFG 29 REMOTE KEYPAD FAULT JF

12 DYNAMIC BRAKE OVERHEATED FAULT dF 30 LOSS OF 4-20mA SIGNAL Sd5

13 SINGLE PHASE FAULT SF 31 COMMUNICATION FAULT FC5

14 EXTERNAL FAULT EEr 32 INTERNAL FAULT 4 F4

15 CONTROL FAULT CF 33 LOSS OF MOTOR PHASE LP1

16 AUTOMATIC START INHIBITED LC 34 INTERNAL FAULT 10 Fo

17 INCOMPATIBILITY FAULT cF

Table 16: Present Fault

5.5.8 Commanded Rotational Direction - Registers #24 & 29

Table 17 lists the Commanded Rotational Direction (Register #24 byte D6L or Register #29 DL)

Table 17: Commanded Rotational Direction

Setting Direction

0 FORWARD

1 REVERSE

5.6 Motor Volts - Register #30

Output Voltage to the motor is expressed in volts (V). It is not expressed as a percentage of the nominal

drive voltage.

RG-TDMOD 18

Page 23

Drive Control & Communication

5.7 Serial Speed - Register #40

This register enables the user to set the serial speed to desired value.

• In tenths of a Hz

• Most significant byte is first, followed by Least significant

• CONTROL OF THE DRIVE SPEED VIA THE SERIAL LINK IS NORMALLY DONE USING THIS PARAMETER.

This register can be written only after enabling parameter writes.

• To use this register, SPEED REFERENCE must first be set to SERIAL SPEED REFERENCE by setting bit

8 in control register #1.

5.8 Unlock Commands - Register #48

Register #48 (Unlock Commands) unlocks commands by using 0000 for the password. If the correct

Programming mode password (C94) is entered then the appropriate programming parameters can also

be accessed (refer to the full parameter protocol specification if access to programming parameters is

required).

5.9 Unlock Parameters - Register #49

Register #49 (Unlock Parameters) unlocks programming parameters for writing when the proper

Programming Password (C94) is entered. Whenever a parameter writing session (where #49 was activated)

is to be ended, register #1 bit 1 (Lock Security) must be asserted. This disables the watchdog and prevents

further write access to Parameter Registers.

5.10 Register Version

Register Version is the number to identify if current version of software has any register changes relative

to previous versions: a register has been added or deleted, a register’s min/max limits have changed, a

register’s function has been changed, or a register’s default value has been changed. Generally it is the

programming parameters that are changed. Typically the Control Registers (

are quite stable.

Tmd

Register #1 through #50)

19 RG-TDMOD

Page 24

Drive Control & Communication

6

Tmd

Programming Parameters

6.1 Format

Abbreviations:

SA (1byte) Drive Address (1-247)

RA (1byte) Register Address

CRCH Cyclic Redundancy Check High byte

CRCL Cyclic Redundancy Check Low byte

READING:

Message structure for reading 1 word: (most of parameters)

NOTE - Attention

Parameter list presented in Section 6.2 is valid only for

parameter version 503. For revisions, refer to appropriate

Request: SA 03 00 RA 00 01 CRCH CRCL

Response: SA 03 02 DH DL CRCH CRCL

Tmd

Tmd

Manual.

software version 1.20,

Message structure for reading 4 word: (Register #114, Parameter C99: Software Version)

Request: SA 03 00 RA 00 04 CRCH CRCL

Response: SA 03 08 D1H D1L D2H D2L D3H D3L D4H D4L CRCH CRCL

WRITING:

Message structure for writing 1 word: (all parameters)

Request: SA 06 00 RA DH DL CRCH CRCL

Response: SA 06 00 RA DH DL CRCH CRCL

LEGEND for Parameter List

1st Column: Parameter No.

4th Column: Range of Adjustment The Modbus values are whole numbers. One decimal place is

1

= Drive's programming code number

assumed. A superscript 2 denotes parameter where two decimal

places are assumed.

RG-TDMOD 20

Page 25

Drive Control & Communication

6.2 Parameter List

1

Tmd

Register #

(hexadecimal

representation)

Parameter Name Range of Adjustment

Modbus value (decimal value)

Factory

Default

Parameter No.

C01 51 (33H) Setpoint and Control Source Speed Control Program

C02 52 (34H) Load Lenze setting 0 No action/loading complete

CE1

CE2

CE3

CE4

C09 59 (3BH) Network Address 1 - 247 1

C10 60 (3CH) Minimum Output Freq. 0 - 2400 (0.0 - 240 Hz) 0.0 Hz

C11 61 (3DH) Maximum Output Freq. 75 - 2400 (7.5 - 240 Hz) 50.0 Hz

C12 62 (3EH) Acceleration Time 0 - 9990 (0.0 - 999 sec) 5.0 sec

C13 63 (3FH) Deceleration Time 0 - 9990 (0.0 - 999 sec) 5.0 sec

PV503

53 (35H)

54 (36H)

55 (37H)

56 (38H)

57 (39H) Not Used

58 (3AH) RESERVED

Configuration

Digital Inputs

E1, E2, E3, E4

0 Analog Terminal Keypad

1 c40 Terminal Keypad

2 Analog Terminal LECOM

3 LECOM LECOM LECOM

4 Analog Terminal Remote Keypad

5 c40 Terminal Remote Keypad

6 Analog Remote Keypad Remote Keypad

7 c40 Remote Keypad Remote Keypad

8 Analog Terminal Modbus

9 c40 Terminal Modbus

10 Analog Modbus Modbus

11 c40 Modbus Modbus

1 Load 50Hz Lenze settings

2 Load 60Hz Lenze settings

3 Load OEM settings (if present)

1 Activate fixed setpoint 1 (JOG1)

2 Activate fixed setpoint 2 (JOG2)

3 DC Braking (DCB)

4 Direction of Rotation

5 Quick Stop

6 CW Rotation

7 CCW Rotation

8 UP

9 DOWN

10 TRIP set

11 TRIP reset

12 Accel/decel 2

0

0

CE1 = 1

CE2 = 2

CE3 = 3

CE4 = 4

1 = The drive's programming code number; (2) = Two decimal places assumed

21 RG-TDMOD

Page 26

1

Tmd

Register #

(hexadecimal

representation)

Drive Control & Communication

Parameter Name Range of Adjustment

Modbus value (decimal value)

Factory

Default

Parameter No.

C14 64 (40H) Operating Mode 0 Linear with Auto Boost

PV503

2

1 Square Law with Auto Boost

2 Linear with Constant V

3 Square Law with Constant V

min

Boost

min

Boost

4 Vector Speed Control

5 Vector Torque Control

6 Enhanced Linear Characteristic with Auto Boost

7 Enhanced Linear Characteristic with V

min

Boost

C15 65 (41H) V/f Reference Point 250 - 9990 (25.0 - 999 Hz) 50.0 Hz

C16 66 (42H) V

Boost 0 - 400 (0.0 - 40.0%) 4.0%

min

C17 67 (43H) Frequency Threshold 0 - 2400 (0.0 - 240 Hz) 0.0 Hz

C18 68 (44H) Chopper Frequency 0 4kHz

2

1 6kHz

2 8kHz

3 10kHz

69 (45H) RESERVED

C21 70 (46H) Slip Compensation 0 - 400 (0.0 - 40.0%) 0.0%

C22 71 (47H) Current Limit 30 - 200% 200%

C24 72 (48H) Accel Boost 0 - 200 (0.0 - 20.0%) 0.0%

C34 73 (49H) Configuration

Analog Input

0 0...10V

1 0...5V

0

2 -10...+10V

3 0...20mA

4 4...20mA

5 4...20mA Monitored

74 (4AH) RESERVED

C36 75 (4BH) Voltage (DCB)

0 - 500 (0.0 - 50.0%) 4.0%

DC Injection Brake

C37 76 (4CH) Fixed Setpoint 1 (JOG1) 0 - 2400 (0.0 - 240 Hz) 20.0 Hz

C38 77 (4DH) Fixed Setpoint 2 (JOG2) 0 - 2400 (0.0 - 240 Hz) 30.0 Hz

C39 78 (4EH) Fixed Setpoint 3 (JOG3) 0 - 2400 (0.0 - 240 Hz) 40.0 Hz

79 (4FH) Not Used

80 (50H) Not Used

C46 81 (51H) Frequency Setpoint 0 - 2400 (0.0 - 240 Hz)

C47 82 (52H) Torque Setpoint 0 - 400% 100%

83 (53H) RESERVED

C50 84 (54H) Output Frequency 0 - 2400 (0.0 - 240 Hz) Read Only

85 (55H) RESERVED

1 = The drive's programming code number; (2) = Two decimal places assumed.

RG-TDMOD 22

Page 27

1

Tmd

Register #

(hexadecimal

representation)

Drive Control & Communication

Parameter Name Range of Adjustment

Modbus value (decimal value)

Factory

Default

Parameter No.

PV503

C52 86 (56H) Motor Voltage 0 - 255% Read Only

C53 87 (57H) DC Bus Voltage 0 - 255% Read Only

C54 88 (58H) Motor Current 0 - 255% Read Only

C56 89 (59H) Drive Load 0 - 255% Read Only

C57 90 (5AH) Motor Torque 0 - 400% Read Only

91 (5BH) RESERVED

C61 92 (5CH) Heatsink Temperature 0 - 255 °C Read Only

C65 93 (5DH) Vector Speed Loop Gain 0 - 1000 (0.0 - 100) 30.0

C66 94 (5EH) Vector Speed Stability 0 - 1000 (0.0 - 100) 30.0

95 (5FH) Not Used

96 (60H) RESERVED

97 (61H) RESERVED

98 (62H) RESERVED

99 (63H) RESERVED

C77 100 (64H) Imax Gain 0 - 1600 (0.00 - 16.0)

(2)

0.25

C78 101 (65H) Integral Action Time 12 - 9990 ms 65 ms

C84 102 (66H) Motor Stator Resistance 0 - 6400 (0.00 - 64.0 W)

C86 103 (67H) Motor Rated Power 0 - 9990 (0.00 - 99.9 kW)

(2)

(2)

0.00 W

C87 104 (68H) Motor Rated Speed 300 - 65000 RPM 1390 RPM

C88 105 (69H) Motor Rated Current 0 - 4800 (0.0 - 480 A) 0.0 A

C89 106 (6AH) Motor Rated Frequency 10 - 999 Hz 50 Hz

C90 107 (6BH) Motor Rated Voltage 0 - 600 V 0 V

C91 108 (6CH) Motor Cosine Phi 40 - 100 (0.40 - 1.00)

(2)

0.80

C92 109 (6DH) Motor Stator Inductance 0 - 20000 (0.0 - 2000 mH) 0.0 mH

C93 110 (6EH) Drive Identification

C94 111 (6FH) User Password 0 - 999 0

112 (70H) RESERVED

113 (71H) RESERVED

C99 114 (72H) Software Version Read 4 words (fromat 'TMD 1.20') Read Only

c01 115 (73H) Acceleration Time 2 0 - 9990 (0.0 - 999 sec) 5.0 sec

c03 116 (74H) Deceleration Time 2 0 - 9990 (0.0 - 999 sec) 5.0 sec

c06 117 (75H) Holding Time - Auto

0 - 9990 (0.0 - 999 sec) 0.0 sec

DC Injection Brake

c08 118 (76H) Analog Output Scaling 0 - 9990 (0.0 - 999) 100.0

119 (77H) RESERVED

1 = The drive's programming code number; (2) = Two decimal places assumed.

23 RG-TDMOD

Page 28

1

Tmd

Register #

(hexadecimal

representation)

Drive Control & Communication

Parameter Name Range of Adjustment

Modbus value (decimal value)

Factory

Default

Parameter No.

c11 120 (78H) Configuration

c17

c18

c20 123 (7BH) I2T Switch-Off 30 - 100% 100%

c25 124 (7CH) LECOM Baud Rate 0 (9600, 8, N, 2 if C01 = 8...11)

c40 127 (7FH) Freq. Setpoint Command 0 - 2400 (0.0 - 240 Hz) 0.0 Hz

c42 128 (80H) Start Condition 0 Start after LOW-HIGH change at 28

c43 129 (81H) Flying Restart Selection 0 Search range: C11 ... 0Hz

c48 131 (83H) Motor Auto-Calibration 0 Calibration not done

c60 133 (85H) Mode Select for c61 0 Monitor Only

c61 134 (86H) Present Fault Status / Error Message (refer to Note 5) Read Only

c62 135 (87H) Last Fault Error Message (refer to Note 5) Read Only

c63 136 (88H) Last but one Fault Error Message (refer to Note 5) Read Only

c64 137 (89H) Last but two Fault Error Message (refer to Note 5) Read Only

PV503

Analog Output (62)

121 (79H)

122 (7AH)

125 (7DH) Not Used

126 (7EH) RESERVED

130 (82H) Not Used

132 (84H) Not Used

Configuration Digital Outputs

(A1, A2)

0 None

1 Output frequency 0 - 10V

2 Output frequency 2 - 10V

3 Load 0 - 10V

4 Load 2- 10V

5 Dynamic Braking

0 Ready

1 Fault

2 Motor is running

3 Motor is running - CW rotation

4 Motor is running - CCW rotation

5 Output frquency = 0Hz

6 Frequency setpoint reached

7 Threshold (C17) exceeded

8 Current limit reached

1 (9600, 8, N, 1 if C01 = 8...11)

2 (9600, 8, E, 1 if C01 = 8...11)

3 (9600, 8, O, 1 if C01 = 8...11)

1 Auto Start if 28 = HIGH

2 Flying restart (auto start disabled)

3 Auto Start if 28 = HIGH, with flying restart

1 Search range: last frequency ... 0Hz

1 Calibration enabled

2 Calibration complete

1 Monitor and Edit

0

c17 = 0

c18 = 1

0

1

0

Read Only

0

1 = The drive's programming code number; (2) = Two decimal places assumed.

RG-TDMOD 24

Page 29

1

Tmd

Register #

(hexadecimal

representation)

Drive Control & Communication

Parameter Name Range of Adjustment

Modbus value (decimal value)

Factory

Default

Parameter No.

c70 138 (8AH) Configuration

c71 139 (8BH) Auto TRIP Reset Delay 0 - 600 (0.0 - 60.0 sec) 0.0 sec

c73 140 (8CH) Input Voltage Selection 0 Low

c78 141 (8DH) Operating Time Counter (In hours) Read Only

c79 142 (8EH) Mains Connect Time Counter (In hours) Read Only

c82 144 (90H) S-Ramp Integral Time 0 - 500 (0.0 - 50.0 sec) 0.0 sec

L25 155 (9BH) Skip Frequency 1 0 - 2400 (0.0 - 240 Hz) 0.0 Hz

L26 156 (9CH) Skip Frequency 2 0 - 2400 (0.0 - 240 Hz) 0.0 Hz

L28 157 (9DH) Skip Frequency Bandwidth 0 - 100 (0.0 - 10.0 Hz) 0.0 Hz

n20 160 (A0H) LECOM Power-Up State 0 Quick Stop

n22 161 (A1H) Serial Timeout Action 0 Not Active

n23 162 (A2H) Serial Fault Time 50 - 65535 milliseconds 50 ms

PV503

TRIP Reset

143 (8FH) RESERVED

145 (91H) RESERVED

146 (92H) RESERVED

147 (93H) RESERVED

148 (94H) RESERVED

149 (95H) RESERVED

150 (96H) RESERVED

151 (97H) RESERVED

152 (98H) RESERVED

153 (99H) Not Used

154 (9AH) Not Used

158 (9EH) RESERVED

159 (9FH) RESERVED

0 TRIP reset by LOW-HIGH signal at 28

or mains switching

or LOW-HIGH signal at digital input "TRIP reset"

1 Auto TRIP reset

1 High

1 Inhibit

1 Controller Inhibit

2 Quick Stop

3 Trip Fault "FC3"

0

1 = The drive's programming code number; (2) = Two decimal places assumed

25 RG-TDMOD

Page 30

Drive Control & Communication

NOTE 5 -

Tmd

Fault History

Parameters c61 (Present Fault), c62 (Last Fault), c63 (Last but one Fault) and c64 (Last

but two Fault) provide the Fault History for the

Tmd

drive. Table 18 lists the fault codes.

Table 18: Fault Codes

Code Fault Description Display

0 NO FAULT

1, 2 OUTPUT (TRANSISTOR) FAULT OC1

3 EARTH FAULT OC2

4 RESERVED

5 OVER TEMPERATURE FAULT OH

6 FLYING RESTART FAULT rF

7 OVER VOLTAGE FAULT OU

8 UNDER VOLTAGE FAULT LU

9 MOTOR OVERLOAD FAULT OC6

10 OEM DATA FAULT GF

11 CONFIGURATION FAULT CFG

12 DYNAMIC BRAKE OVERHEATED FAULT dF

13 SINGLE PHASE FAULT SF

14 EXTERNAL FAULT EEr

15 CONTROL FAULT CF

16 AUTOMATIC START INHIBITED LC

17 INCOMPATIBILITY FAULT cF

18 INTERNAL FAULT 1 (EPM) F1

19 INTERNAL FAULT 2 F2

20 INTERNAL FAULT 3 F3

21, 22 INTERNAL FAULT 5 F5

23 INTERNAL FAULT 6 F6

24 INTERNAL FAULT 7 F7

25 INTERNAL FAULT 8 F8

26 INTERNAL FAULT 9 F9

27 IDENTIFICATION FAULT bF

28 A/D CONVERTER FAULT Ad

29 REMOTE KEYPAD FAULT JF

30 LOSS OF 4-20mA SIGNAL Sd5

31 SERIAL COMMUNICATION FAULT FC5

32 INTERNAL FAULT 4 F4

33 LOSS OF MOTOR PHASE LP1

34 INTERNAL FAULT 10 Fo

RG-TDMOD 26

Page 31

Drive Control & Communication

7 Quick Start Instructions

Follow these Quick Start instructions to use ModBus Communications for basic network control of an

Tmd

drive. These instructions are for basic start, stop, direction and speed control of the

download the

7.1 Initial Settings

Tmd

product manual visit the AC Tech Technical Library at http://www.lenze-actech.com.

Tmd

drive. To

These instructions are for basic start, stop, direction and speed control of the

Tmd

drive using modbus

communications.

1. For this application set Parameter C01 of the drive to 11.

2. Set C09 to the desired network address that the Modbus master will poll. Valid Modbus addresses are

1-247.

Tip - Avoid using address 1. Most Modbus devices ship with a default address of 1. As duplicate

addressing on a Modbus network is not allowed, this can lead to conflicts when replacing and

commissioning nodes. To avoid this, it is recommended not to set the slave address to 1.

3. The Modbus master needs to be set to use 9600 baud. No other baud rates are supported by the TMD

drive.

4. The TMD series drive has the provision for a watchdog timer to monitor network communications to

the drive. The drive’s timeout behavior is set using Parameter n22 and the timeout period is set using

Parameter n23 as shown in Table 19.

Table 19: Watchdog Timer

Code Possible Settings Important

No. Name Lenze Selection

n22 Serial Timeout Action 0 0 Not Active

1 Controller Inhibit

2 Quick Stop

3 Trip Fault "FC3"

n23 Serial Fault Time 50 50 - 65535 ms Sets the serial timeout length

Selects controller reaction to

serial timeout

Set n22 and n23 as appropriate for the application

5. The drive needs to have its network data formatting set the same as the Modbus master.

a. If the Modbus master is set to use 8 data bits, no parity and two stop bits, set c25 to 0.

b. If the Modbus master is set to use 8 data bits, no parity and one stop bit, set c25 to 1.

c. If the Modbus master is set to use 8 data bits, even parity and one stop bit, set c25 to 2.

d. If the Modbus master is set to use 8 data bits, odd parity and one stop bit, set c25 to 3.

27 RG-TDMOD

Page 32

7.2 Drive Control

1. Please be advised that while the drive is under network control the local STOP circuit is always enabled.

Input 28 needs to be asserted in order for the drive to start. If you will not be using start/stop simply

jumper TB28 input to TB20.

2. Use either Modbus function code 16 with a length of 1 or Modbus function code 06 to perform any

writes to the drive.

3. Unlocking the Drive.

The first write necessary to the drive to perform any function (start,change speed, change a parameter,

etc) needs to be an unlock.

If you want to both control the drive and alter any programming parameters then write the drive’s

programming password to Modbus register 40049. The default password for the TMD drive is 0.

You should only need to send the unlock command once after power up. As long as the communications

do not timeout you should not need to write another unlock to the drive before writing any other

function.

Drive Control & Communication

4. Setting the Drive to Network Speed reference:

In order for the drive to respond to speed commands written to the keypad speed register the drive

must be put into manual mode. To do this write a value of 100H to Modbus register 40002 (the drive’s

control register).

7.3 Basic Drive Commands

The following are the basic drive commands. ONLY ONE OF THESE CAN BE DONE AT A TIME:

1. To STOP the drive using COAST TO STOP, write a value of 0004hex to Modbus register 40002 (AC Tech

register 1).

2. To Start the drive write a value of 0008hex to Modbus register 40002.

3. To Set Reverse direction write a value of 0040hex to Modbus register 40002.

4. To Set Forward direction (the drive powers up with forward direction already selected) write a value of

0080hex to Modbus register 40002.

5. If you want the network to control speed of the drive, write the speed to the Serial Speed Command

Register, Modbus register 40041 (AC Tech register 40). Speed is written in 0.1Hz (so 412 would be

41.2 Hz). In this mode the drive’s initial speed reference on power up will be the last speed written to

the drive.

RG-TDMOD 28

Page 33

Drive Control & Communication

7.4 Basic Drive Status

AC Tech register 24 is a 6 word entity containing the drive’s status information. To read the entire status

block use Modbus function code 3 with a length of 6 to read starting at Modbus register number 40025.

The low byte of the third word in this block of data contains the operational status. If this is the only data

you want you can use Modbus function code 3 with a length of 1 to read register 40027.

The value of that low byte of data corresponds to the following operational states:

Table 20: Operational Status

Bit Parameter

0 FAULT LOCKOUT

1 FAULT

2 START PENDING

3 MOTOR CALIBRATION NOT DONE

4 STOP

5 LOWER TRANSISTORS SWITCHING ON

6 MOTOR CALIBRATION ENABLED

7 RUN AT 0Hz

8 RUN

9 ACCEL

10 DECEL

11 DECEL OVERRIDE

12 DC BRAKE

13 FLYING START

14 SLOW CURRENT LIMIT

15 FAST CURRENT LIMIT

16 OFF

17 INHIBIT

29 RG-TDMOD

Page 34

AC Technology Corporation

630 Douglas Street • Uxbridge MA 01569 • USA

Sales: 800-217-9100 •Service: 508-278-9100

www.lenze-actech.com

RG-TDMOD-e3

Loading...

Loading...