Page 1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

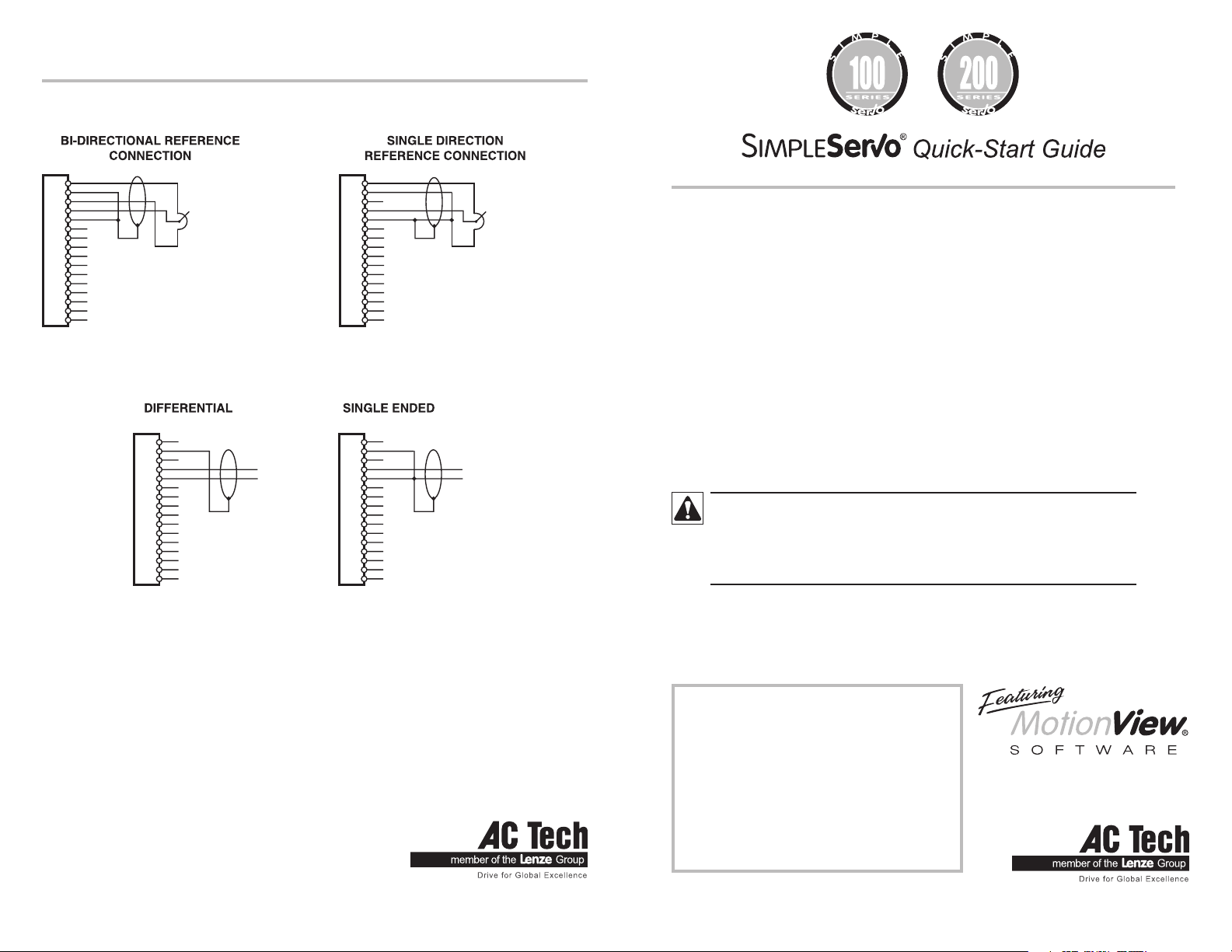

POTENTIOMETER

5-25K

POTENTIOMETER

5-25K

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

0 to ±10 0 to ±10

Detail A4 | Analog reference for torque or velocity connections

For your convenience, we have included this Quick Start Guide as a printed document.

This guide is intended to help you get up-and-running as quickly as possible.

INSTRUCTIONS:

1. Please begin by installing the MotionView software on your PC

a. Insert the SimpleServo installer CD

b. Click on your Start menu and select Run

c. Browse to your CD-ROM (usually D:) drive and select SETUP.EXE

2. After installing, double click the MotionView (MV) icon on your desktop

3. For further assistance while in MotionView click Help|Getting Started

This Quick Start Guide shows the absolute minimum you need to get started. We offer this to

make it easy to try the SimpleServo at your desk or some other convenient location.

To communicate with the SimpleServo, you must

1. Attach a straight-through RS232 serial cable (included) from the drive

to your computer.

2. Apply power to the drive.

Hazard of electrical shock! Circuit potentials are at 115 VAC or 230 VAC above

earth ground. Avoid direct contact with the printed circuit board or with circuit

elements to prevent the risk of serious injury or fatality. Disconnect incoming

power and wait 60 seconds before servicing drive. Capacitors retain charge

after power is removed.

In order to tune and control a motor, you need a motor with feedback hooked up.

NOTE: If you wish to do anything more sophisticated, you should refer to the

“SimpleServo-User-Manual” on the CD-ROM. In fact, you may choose

to print it for convenience.

PACKAGE CONTENTS

SQT01B

AC Technology Corporation

630 Douglas Street

Uxbridge, MA 01569

www.simpleservo.com

Phone: 800-217-9100

FAX: 508-278-7873

You should have one each of the following:

SimpleServo

CD-ROM

MotionView Software

Owner’s Manual

CAD drawings

Software to view drawings

Serial Cable

Page 2

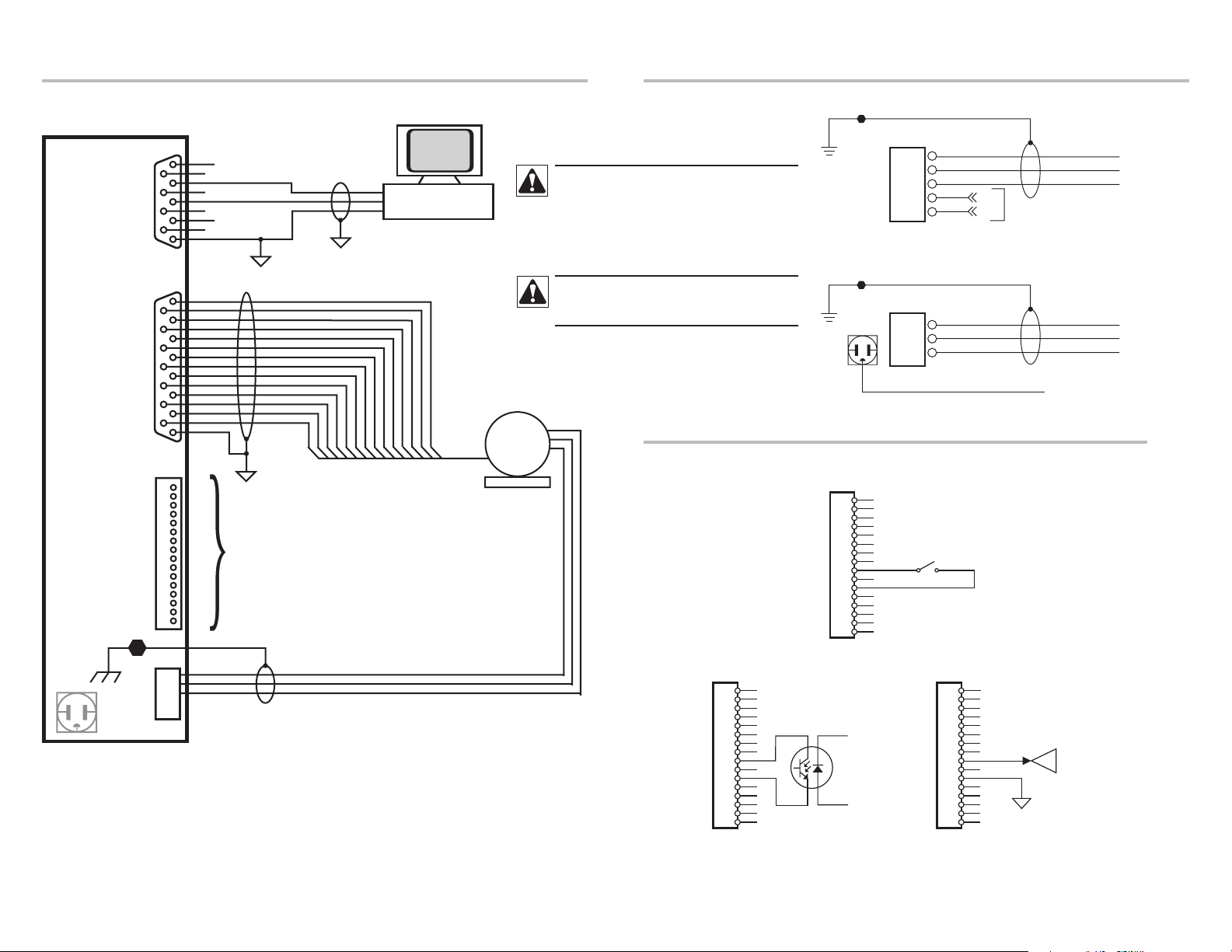

PC COMPUTER

RS-232 INTERFACE

Motor

Feedbac

k

BLDC

MOTOR

SS108

CONNECTOR DB15

CONNECTOR DB9

AHall A

B+

Hall A

+

BHall B

+

Z+

Hall C

+

ZHall B

Encoder COM

Hall C

-

A+

+5VDC (Encoder Power

)

10

2

9

DS1

15

7

14

6

13

5

12

4

11

3

1

TB2

SEE DETAIL A4

TB1

SEE DETAIL A3

TB1

8

ANALOG /DIGIT AL I/O

TX

RX

DS2

5

9

4

8

3

7

2

6

1

RS-232

TB1

80 - 170 VDC

TO MOTOR

TO MOTOR

DCDC+

1

2

3

4

5

U (R)

V (S)

W (T)

U (R)

V (S)

W (T)

TB1

100 - 120 VAC

1

2

3

SS108

SS208

SS108DC

SS208DC

DC Series

AC Series

Detail A1 | Motor and Host computer connection Detail A2 | Incoming power connection

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

ENABLE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

5V TTL/CMOS LOGIC

PLC OUTPUT

CONTROLLER

LOGIC

COMMON

Switch or Relay Enable

PLC Enable TTL Logic Enable

Hazard of electrical shock! Circuit potentials are

at 115 VAC or 230 VAC above earth ground. Avoid

direct contact with the printed circuit board or with

circuit elements to prevent the risk of serious injury

or fatality. Disconnect incoming power and wait 60

seconds before servicing drive. Capacitors retain

charge after power is removed.

DO NOT connect incoming power to the output

motor terminals (U, V, W)! Severe damage to the

drive will result.

Detail A3 | Enable Options

Loading...

Loading...