Page 1

EDS84DPSO01

.Ez#

L−force Drives

Ä.Ez#ä

8400 protec

Translation

Manual

SO10 / SO20 / SO30

Drive−based safety

l

Page 2

, Please read these instructions and the documentation of the standard device before you

start working!

Observe the safety instructions given therein!

0Fig. 0Tab. 0

Page 3

Contents i

1 About this documentation 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terms and abbreviations used 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety engineering 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Introduction 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Important notes 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Hazard and risk analysis 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Standards 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Acceptance 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Description 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Periodic inspections 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Basics for safety sensors 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Safety option 10 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Operating mode 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Introduction 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Disconnecting paths 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Safety status 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Fail−safe status 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Status display 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Technical data 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Electrical installation 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Certification 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Safety option 20 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Operating mode 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 Introduction 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Disconnecting paths 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.3 Safety status 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.4 Fail−safe status 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Status display 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Technical data 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Electrical installation 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Certification 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Safety functions 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Safe parameter setting 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.1 Parameter setting 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.2 Parameter sets and axes 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDS84DPSO01 EN 2.1

l 3

Page 4

Contentsi

4.8 Error management 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.1 Error states 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.2 Logbook 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Response times 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9.1 Response times of the inputs 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9.2 Response times of the safety bus 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Safety option 30 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Operating mode 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Introduction 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Disconnecting paths 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Safety status 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 Fail−safe status 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.5 Safe inputs 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Status display 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Technical data 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Electrical installation 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Certification 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 Safety functions 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Safe torque off 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 Safe stop 1 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.3 Emergency stop 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.4 Safe operation mode selector 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.5 Safe enable switch 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Safe parameter setting 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 Parameter setting 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.2 Parameter sets and axes 57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 Error management 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.1 Error states 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.2 Logbook 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.3 Module error messages 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Response times 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.1 Response times of the inputs 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.2 Response times of the safety bus 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Appendix 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Total index 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l 4

EDS84DPSO01 EN 2.1

Page 5

1 About this documentation

Contents

The manual provides full information on the application as directed of the 8400 protec

controllers in the StateLine or HighLine versions including drive−based safety.

Validity

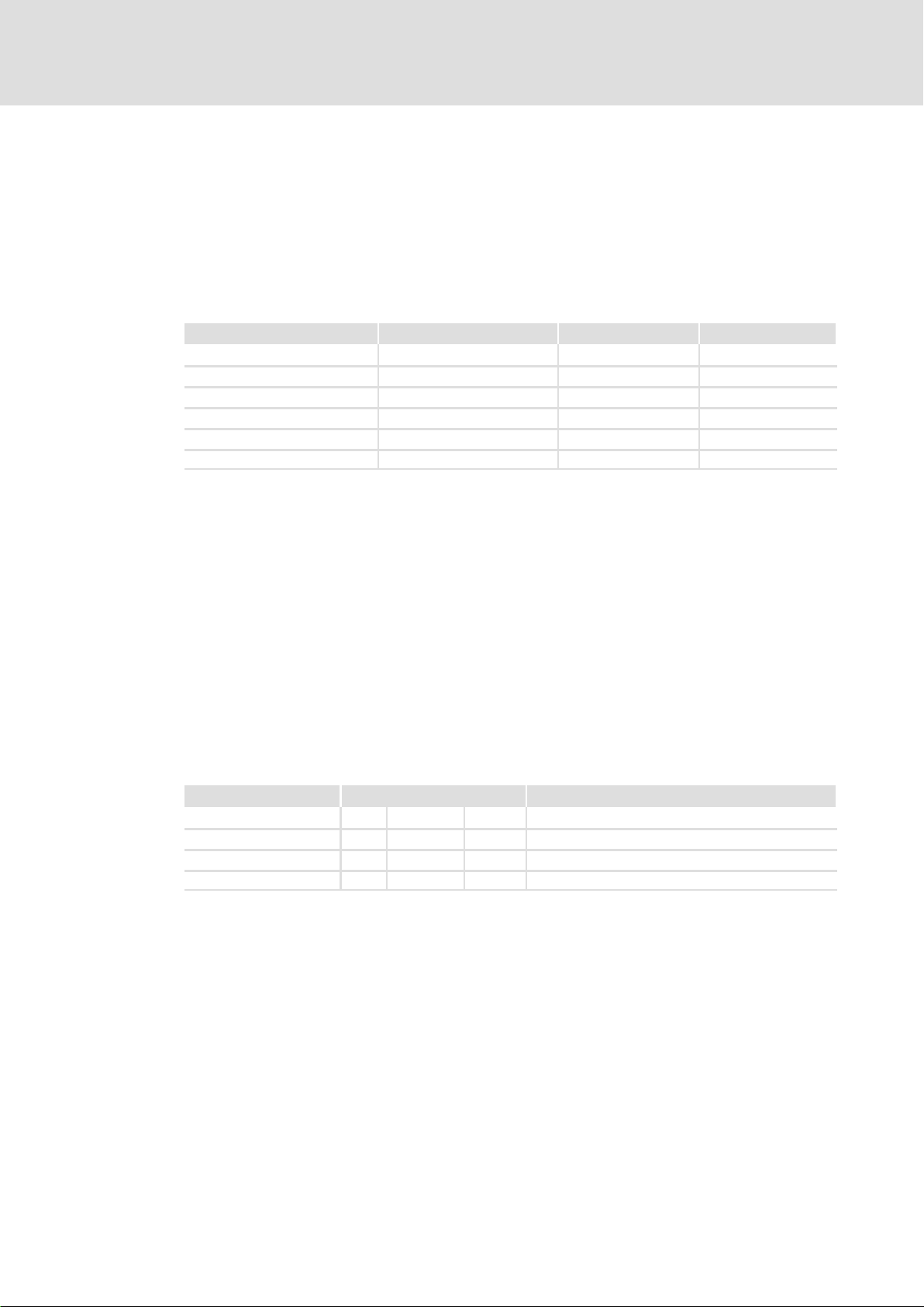

Type Type designation from hardware version from software version

8400 protec StateLine mit SO10 E84DSxxxxxxxxxxJxx PB −

8400 protec StateLine mit SO20 E84DSxxxxxxxxxxKxx PB −

8400 protec StateLine mit SO30 E84DSxxxxxxxxxxLxx PB −

8400 protec HighLine mit SO10 E84DHxxxxxxxxxxJxx PB −

8400 protec HighLine mit SO20 E84DHxxxxxxxxxxKxx PB −

8400 protec HighLine mit SO30 E84DHxxxxxxxxxxLxx PB −

About this documentation

Document history

1

Target group

This manual is intended for all persons who design, install, commission, and adjust

controllers of the 8400 protec series with drive−based safety.

I Tip!

Information and auxiliary devices around the Lenze products can be found in

the download area at

http://www.Lenze.com

1.1 Document history

Material number Version Description

13290952 1.0 03/2009 TD03 First edition

13295461 1.1 05/2009 TD03 Minor corrections to the "Certification" chapter

13297773 2.0 06/2009 TD15 Corrected and amended by further safety options

.Ez# 2.1 04/2011 TD15 General revision

EDS84DPSO01 EN 2.1

l

5

Page 6

1

About this documentation

Conventions used

1.2 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

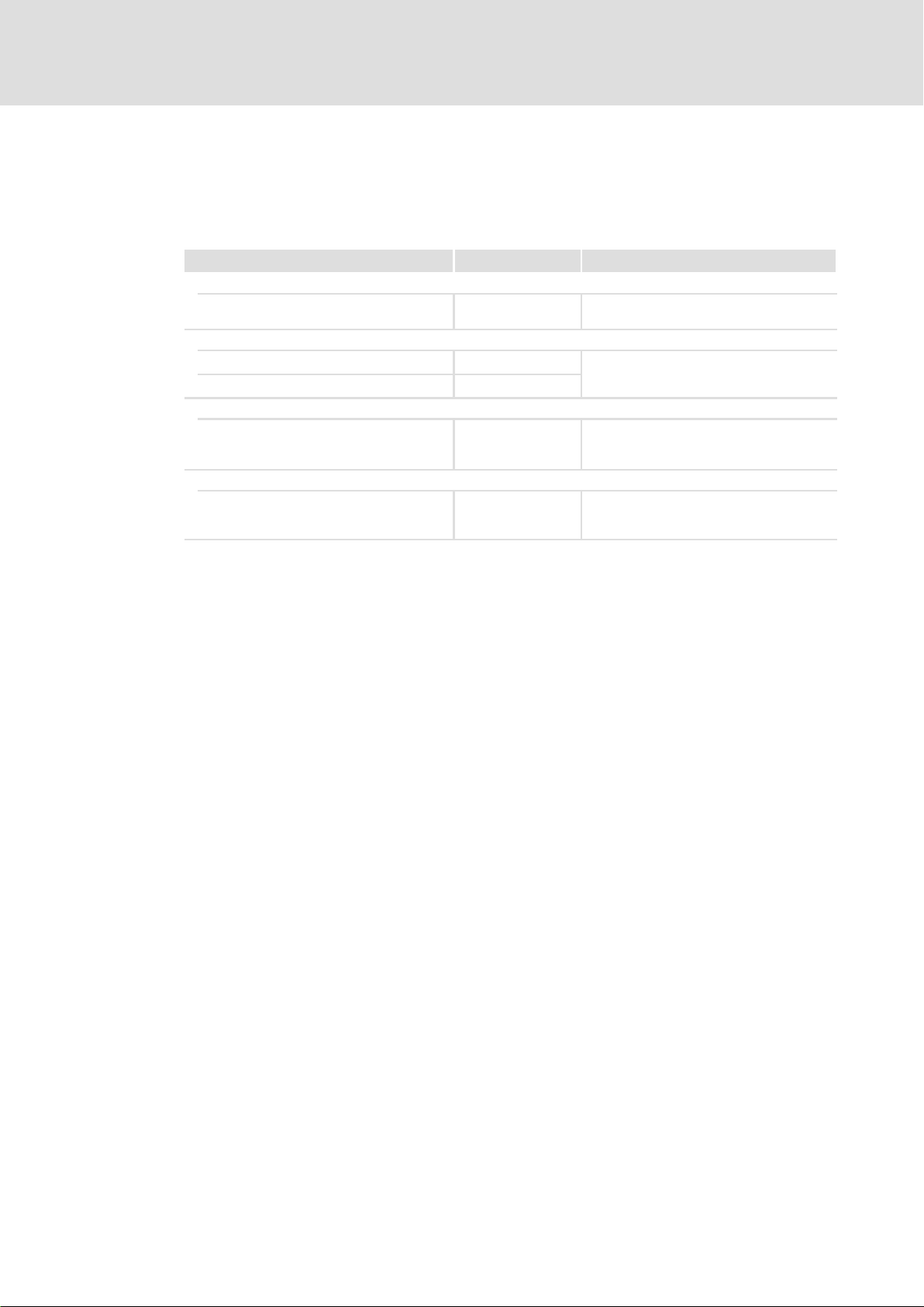

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator Point In general, the decimal point is used.

Warnings

UL warnings

UR warnings

Text

Program name » « PC software

Icons

Page reference ^ Reference to another page with additional

J

O

For instance: 1234.56

Are only given in English.

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: ^ 16 = see page 16

6

l

EDS84DPSO01 EN 2.1

Page 7

About this documentation

Terms and abbreviations used

1

1.3 Terms and abbreviations used

Abbreviation Meaning

24O 24 V voltage supply for non−safe monitoring

Cat. Category according to EN 954−1 (valid until 30 November 2009)

DO Non−safe feedback output

F−PLC Safety PLC

GSDML File containing device−specific data to establish PROFINET communication

GSE File containing device−specific data to establish PROFIBUS communication

OFF state Signal status of the safety sensors when they are activated or respond

ON state Signal status of the safety sensors during normal operation

Opto supply Optocoupler supply for controlling the drivers

OSSD Output Signal Switching Device, tested signal output

PELV Protective Extra Low Voltage

PL Performance Level according to EN ISO 13849−1

PM P/N switching signal paths

PP P/P switching signal paths

PS PROFIsafe

PWM Pulse Width Modulation

S−Bus Safety bus

SD−In Safe input (Safe Digital Input)

SD−Out Safe output (Safe Digital Output)

SELV Safety Extra Low Voltage

SIA, SIB Safe Input, channel A or B, respectively

SIL Safety Integrity Level according to IEC 61508

SO Integrated safety option

Abbreviation Safety function

AIE Error acknowledgement (Acknowledge In Error)

AIS Restart acknowledgement (Acknowledge In Stop)

ES Safe enable switch

OMS Operation Mode Selector

SS1 Safe Stop 1

SSE Safe Stop Emergency

STO Safe Torque Off

Formerly: Safe standstill

EDS84DPSO01 EN 2.1

l

7

Page 8

1

About this documentation

Notes used

1.4 Notes used

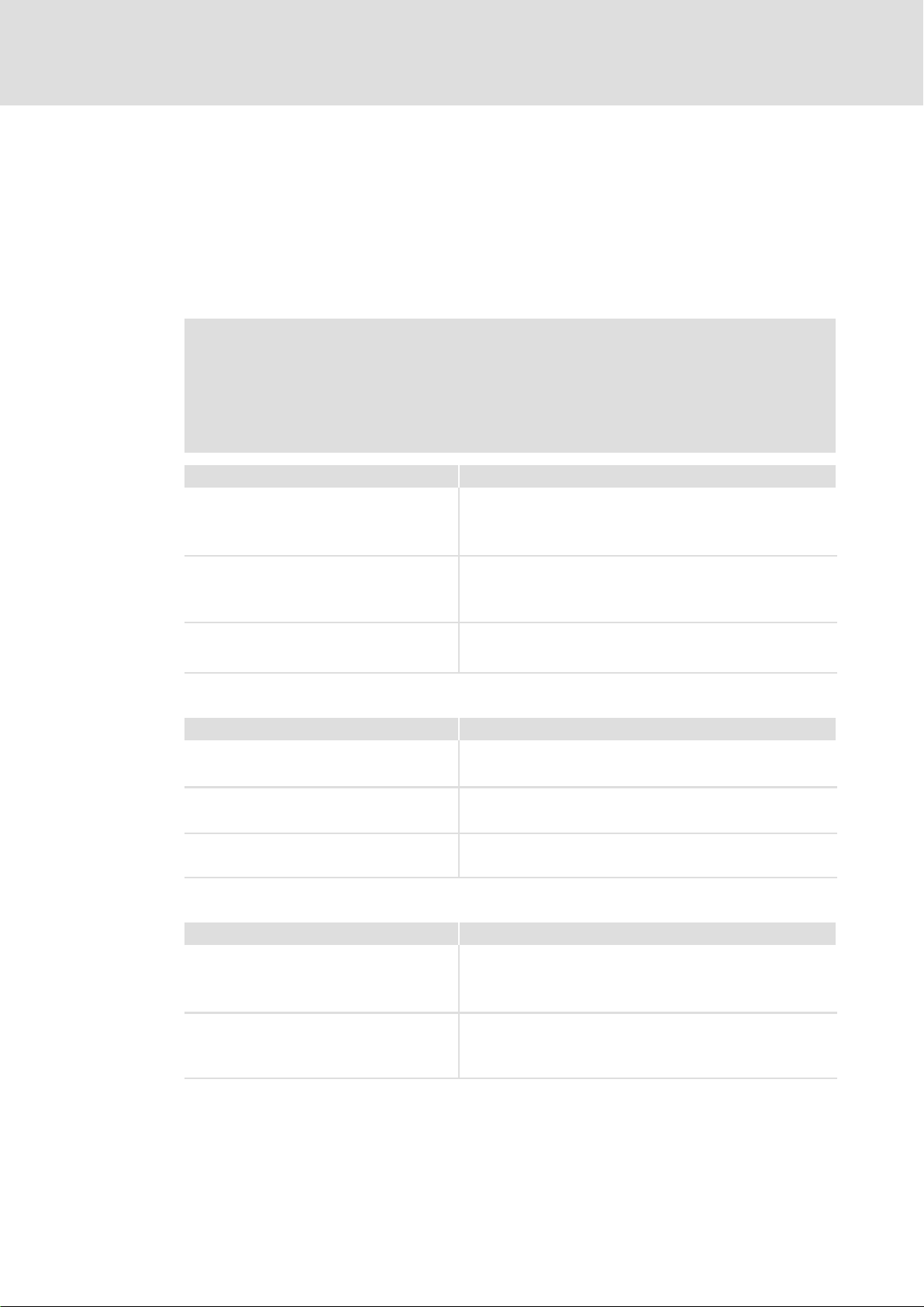

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

} Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

{ Danger!

} Danger!

( Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

) Note!

I Tip!

,

Special safety instructions and application notes for UL and UR

Pictograph and signal word Meaning

J Warnings!

O Warnings!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

Safety or application note for the operation of a UL−approved

device in UL−approved systems.

Possibly the drive system is not operated in compliance with UL

if the corresponding measures are not taken.

Safety or application note for the operation of a UR−approved

device in UL−approved systems.

Possibly the drive system is not operated in compliance with UL

if the corresponding measures are not taken.

8

l

EDS84DPSO01 EN 2.1

Page 9

2 Safety engineering

2.1 Introduction

With increasing automation, protection of persons against hazardous movements is

becoming more important. Functional safety describes the measures needed by means of

electrical or electronic equipment to reduce or remove danger caused by failures.

During normal operation, safety equipment prevents people accessing hazardous areas. In

certain operating modes, e.g. set−up mode, work needs to be carried out in hazardous

areas. In these situations the machine operator must be protected by integrated drive and

control measures.

Drive−based safety provides the conditions in the controls and drives to optimise the safety

functions. Planning and installation expenditure is reduced. In comparison to the use of

standard safety engineering, drive−based safety increases machine functionality and

availability.

Safety engineering

Introduction

2

Drive−based safety with L−force | 8400 protec

Unlike control cabinet devices, decentralised drives are frequency inverters which are not

locally mounted but directly attached to the application on site. Due to this

product−specific property, they must meet demanding requirements for robustness and

class of protection.

8400 protec controllers are optionally available with drive−based safety.

"Drive−based safety" stands for applied safety functions, which can be used for the

protection of persons working on machines.

The motion functions are continued to be executed by the controller. The drive−based

safety monitors the safe compliance with the limit values and provides the safe inputs and

outputs. When the limit values are exceeded, the drive−based safety starts the control

functions according to EN 60204−1 directly in the controller.

The safety functions are suitable for applications according to IEC 61508 to SIL 3 and

achieve a performance level (PL) e and the control category 3 or 4 depending on the safety

option according to EN ISO 13849−1.

EDS84DPSO01 EN 2.1

l

9

Page 10

2

2.2 Important notes

Safety engineering

Important notes

Application as directed

The controllers that are equipped with safety engineering must not be modified by the

user. This concerns the unauthorised exchange or removal of the safety engineering.

} Danger!

Danger to life through improper installation

Improper installation of safety engineering systems can cause an uncontrolled

starting action of the drives.

Possible consequences:

ƒ Death or severe injuries

Protective measures:

ƒ Safety engineering systems may only be installed and commissioned by

qualified and skilled personnel.

ƒ All control components (switches, relays, PLC, ...) and the control cabinet

must comply with the requirements of ISO 138491 and ISO 13849−2. This

includes i.a.:

– Switches, relays with at least IP54 enclosure.

– Control cabinet with at least IP54 enclosure.

– Please refer to ISO 138491 and ISO 13849−2 for all further requirements.

ƒ Wiring must be shielded.

ƒ All safety relevant cables outside the control cabinet must be protected, e.g.

by means of a cable duct:

– Ensure that no short circuits can occur.

– For further measures see EN ISO 13849−2.

ƒ If an external force acts upon the drive axes, additional brakes are required.

Please observe that hanging loads are subject to the force of gravity!

10

} Danger!

When the "safe torque off" (STO) function is used, an "emergency

switching−off" according to EN 60204 is not possible without additional

measures. There is no electrical isolation, no service switch or repair switch

between motor and controller!

Emergency switching−off" requires an electrical isolation, e.g. by a central

mains contactor!

l

EDS84DPSO01 EN 2.1

Page 11

During operation

After the installation is completed, the operator must check the wiring of the safety

function.

The functional test must be repeated at regular intervals. The time intervals to be selected

depend on the application, the entire system and the corresponding risk analysis. The

inspection interval should not exceed one year.

Residual hazards

In case of a short−circuit of two power transistors a residual movement of the motor of up

to 180 °/number of pole pairs may occur! (Example: 4−pole motor Þ residual movement

max. 180 °/2 = 90 °)

This residual movement must be considered in the risk analysis, e.g. safe torque off for

main spindle drives.

2.2.1 Hazard and risk analysis

Safety engineering

Important notes

Hazard and risk analysis

2

This documentation can only accentuate the need for hazard analysis. The user of the

integrated safety system must read up on standards and the legal situation:

Before the launch of a machine, the manufacturer of the machine must conduct a hazard

analysis according to Machinery Directive 2006/42/EC to determine the hazards

associated with the application of the machine. The Machinery Directive refers to three

basic principles for the highest possible level of safety:

ƒ Hazard elimination / minimisation by the construction itself.

ƒ Required protective measures must be taken against hazards which cannot be

eliminated.

ƒ Existing residual hazards must be documented and the user must be informed of

them.

Detailed information on the hazard analysis procedure is provided in the EN 1050, risk

assessment principles. The results of the hazard analysis determine the category for

safety−related control systems according to EN ISO 13849−1. Safety−oriented parts of the

machine control must be compliant.

2.2.2 Standards

Safety regulations are confirmed by laws and other governmental guidelines and

measures and the prevailing opinion among experts, e.g. by technical regulations.

The regulations and rules to be applied must be observed in accordance with the

application.

EDS84DPSO01 EN 2.1

l

11

Page 12

2

2.3 Acceptance

2.3.1 Description

Safety engineering

Acceptance

Description

The machine manufacturer must check and prove the operability of the safety functions

used.

Inspector

The machine manufacturer must authorise a person with expertise and knowledge of the

safety functions to carry out the test.

Test report

The test result of every safety function must be documented and signed by the inspector.

) Note!

If parameters of the safety functions are changed, the inspector must repeat

the test and record the results in the test report.

Scope of test

A complete test comprises the following:

ƒ Documenting the plant including the safety functions:

– Creating an overview screen of the plant

– Describing the plant

– Describing the safety equipment

– Documenting the safety functions used

ƒ Checking the function of the safety functions used:

– "Safe torque off" function, STO

– "Safe stop 1" function, SS1

– "Safe emergency stop" function, SSE

ƒ Preparing the test report:

– Documenting the functional test

– Checking the parameters

– Signing the test report

ƒ Preparing the appendix with test records:

– Protocols from the plant

– External recording

2.3.2 Periodic inspections

The correct sequence of the safety−oriented functions must be checked in periodic

inspections. The risk analysis or applicable regulations determine the time distances

between the tests. The inspection interval should not exceed one year.

12

l

EDS84DPSO01 EN 2.1

Page 13

2.4 Basics for safety sensors

Passive sensors

Passive sensors are two−channel switching elements with contacts. The connecting cables

and the sensor function must be monitored.

The contacts must switch simultaneously (equivalently). Nevertheless, safety functions

will be activated as soon as at least one channel is switched.

The switches must be wired according to the closed−circuit principle.

Examples of passive sensors:

ƒ Door contact switch

ƒ Emergency−off control units

Active sensors

Active sensors are units with 2−channel semiconductor outputs (OSSD outputs). With the

integrated safety system of this device series, test pulses < 1 ms for monitoring the

outputs and cables are permissible. The maximally permissible connection capacity of the

outputs is to be observed.

Safety engineering

Basics for safety sensors

2

P/M−switching sensors switch the positive and negative cable or the signal and ground

wire of a sensor signal.

The outputs have to switch simultaneously. Nevertheless, safety functions are triggered

as soon as at least one channel is switched.

Examples of active sensors:

ƒ Lightgrid

ƒ Laser scanner

ƒ Control systems

Use of the safety option 30 (SO30):

Sensor inputs

For unused sensor inputs, "Input deactivated" must be parameterised.

Connected deactivated sensors can create the false impression of safety technology being

provided. For this reason, a deactivation of sensors by parameter setting only is not

permissible and not possible. It is monitored that no sensor signal is pending.

EDS84DPSO01 EN 2.1

l

13

Page 14

3

M

SO

PWM

µC

PC

3x

3x

Xxx

Safety option 10

Operating mode

Introduction

3 Safety option 10

3.1 Operating mode

3.1.1 Introduction

Due to safety option 10, the following safety functions can be used:

ƒ Safe torque off (STO),

formerly: safe standstill

If requested, the safe disconnection of the drive is achieved through:

ƒ Directly connected active sensors

ƒ Passive sensors connected to a safety switching device

The safety functions are suitable for applications according to IEC 61508 to SIL 3 and

achieve a performance level (PL) e and the control category 4 according to EN ISO 13849−1.

} Danger!

If the request for the safety function is cancelled, the drive will restart

automatically.

You must provide external measures which ensure that the drive only restarts

after a confirmation (EN 60204).

3.1.2 Disconnecting paths

The transmission of the pulse width modulation is safely switched (off) by the safety unit.

After this, the power drivers do not generate a rotating field. The motor is safely switched

to torqueless operation (STO).

14

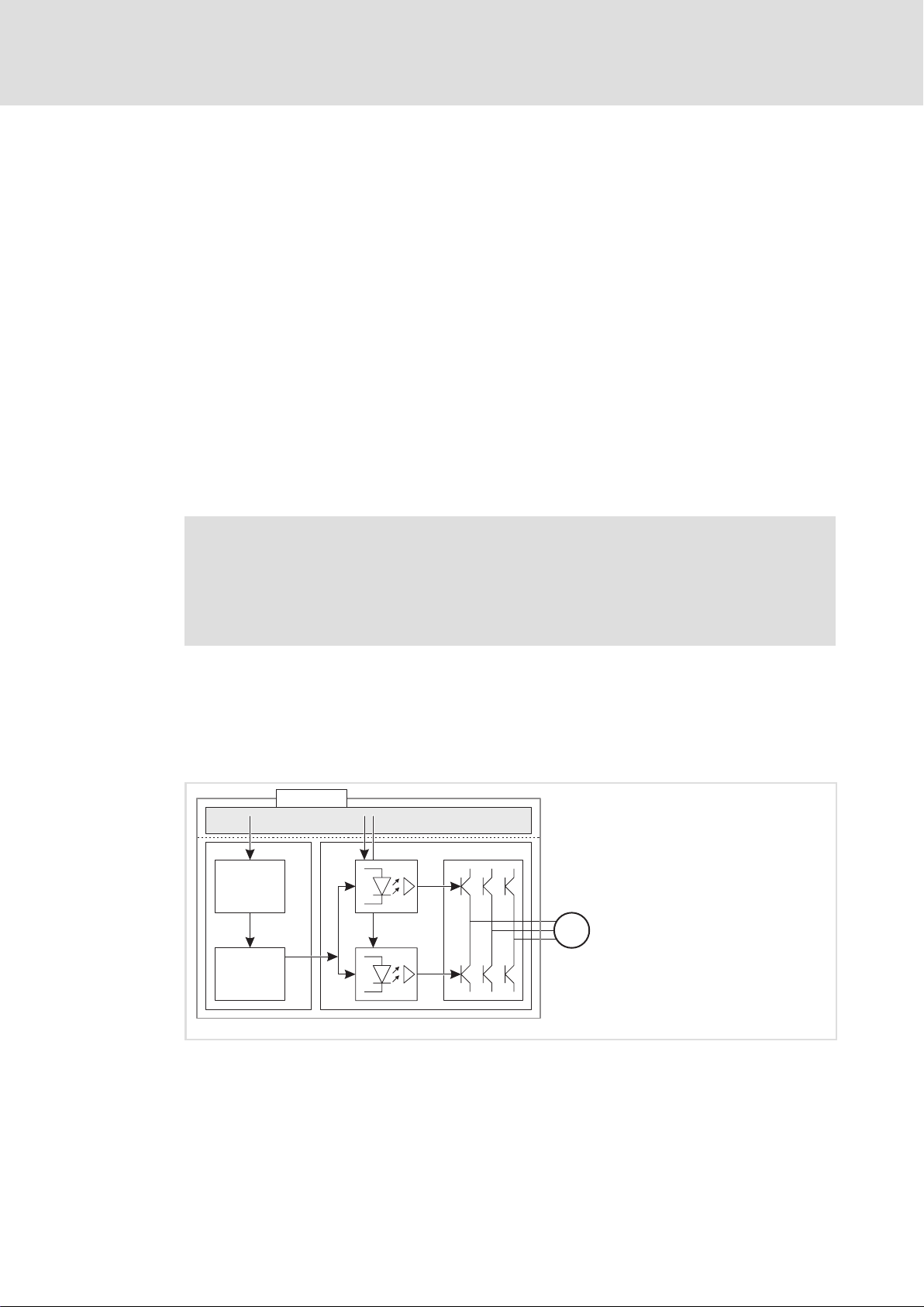

E84DPSO02

Fig. 3−1 Operating principle of safety unit

SO Safety option 10, 20, or 30

xxx Control terminals used in safety engineering systems or safety bus

C Control section

mC Microcontroller

PWM Pulse width modulation

P Power section

M Motor

l

EDS84DPSO01 EN 2.1

Page 15

3.1.3 Safety status

When the controller is disconnected from the safety unit, the "Safe torque off" (STO) status

is set (C00155 bit 10 = 1).

3.1.4 Fail−safe status

When internal errors of the safety unit are detected, the motor is safely switched to

torqueless operation (fail−safe status).

Safety option 10

Operating mode

Safety status

3

EDS84DPSO01 EN 2.1

l

15

Page 16

3

Safety option 10

Status display

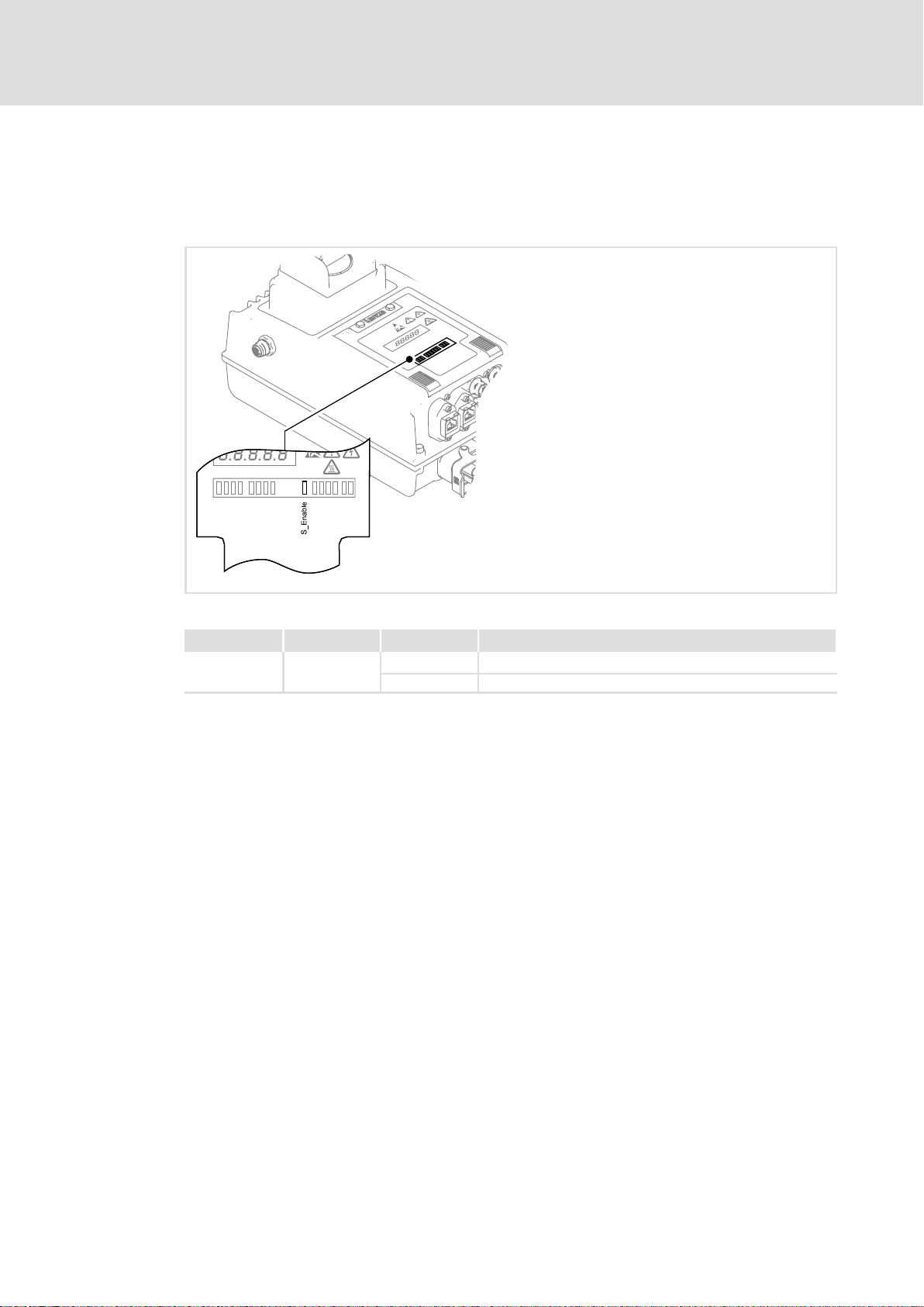

3.2 Status display

The operating status of the "STO" safety function is displayed using an LED on the front of

the controller.

Fig. 3−2 Position of the LED for the drive−based safety on the device

Pos. Colour State Description

S−Enable yellow

The status of safety option 10 is solely shown via the "S−Enable" display. All other displays have no function.

on Controller is enabled

blinking Safety function is active (non−safe display)

E84DPSO06 SO10

16

l

EDS84DPSO01 EN 2.1

Page 17

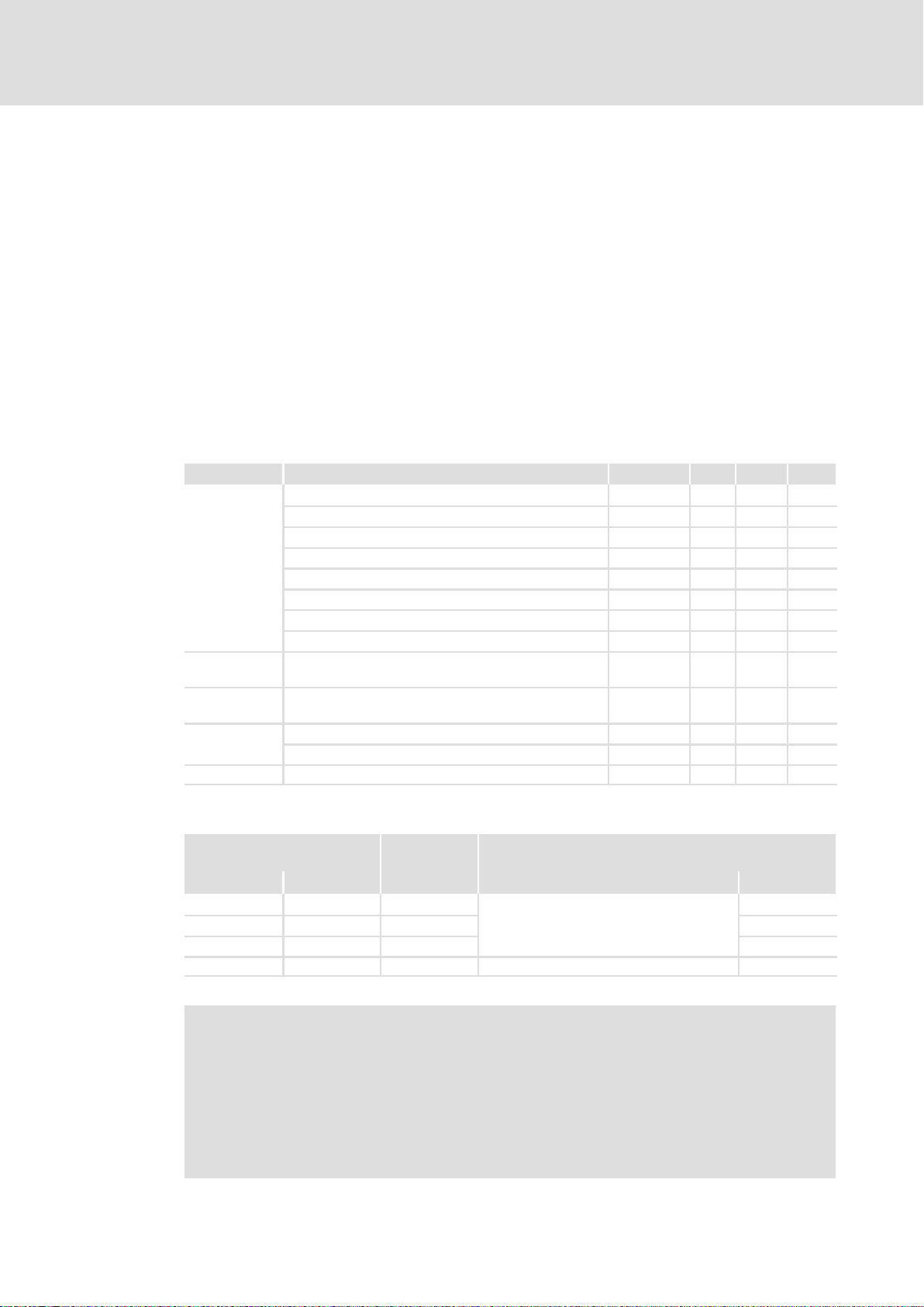

3.3 Technical data

Supply

The safe input and the output are isolated and designed for a low−voltage supply through

a safely separated power supply unit (SELV/PELV) of 24 V DC. P/N switching input signals

and test pulses £ 1 ms are permissible.

Active sensors are directly connected to the X61 circular connector.

Passive sensors are connected to the X61 circular connector via a switching device. The

switching device must comply with the required performance level of the application.

There is no monitoring for short circuits.

Detailed features of the inputs and outputs of the safety unit

Terminal Specification [Unit] min. typ. max.

SIA, SIB

GI GND potential for SIA / SIB and for the non−safe

24O Supply voltage through safely separated power supply

DO

24O, DO Output current A 0.2

Safety option 10

Technical data

Low signal

High signal

Input capacitance at switch−off

Input delay (tolerated test pulse)

Switch−off time (depending on the controller)

Running time

Input current mA 45 50

Input capacitance at switch−on, reduced

signalling output

unit (SELV/PELV)

Low signal

High signal

V −3 0 5

V 18 24 30

nF 3

ms 1

ms 2.5 4

ms 3

mF 22

V 18 24 30

V 0 0.8

V 18 24 30

3

Truth table

EDS84DPSO01 EN 2.1

Safe input / channel Signalling

SIA SIB DO1/DO Description of device status Enable

001

0 1 0 0

1 0 0 0

1 1 0 Drive active 1

output

"Safe torque off" activated

Controller

) Note!

Safe inputs have two channels (...A/...B). The channels must be triggered

separately and simultaneously (equivalent).

Active triggering of only one channel indicates faulty sensors or impermissible

wiring.

Despite this, the integrated safety system is activated as soon as at least one

channel has been triggered.

l

0

17

Page 18

3

Safety option 10

Electrical installation

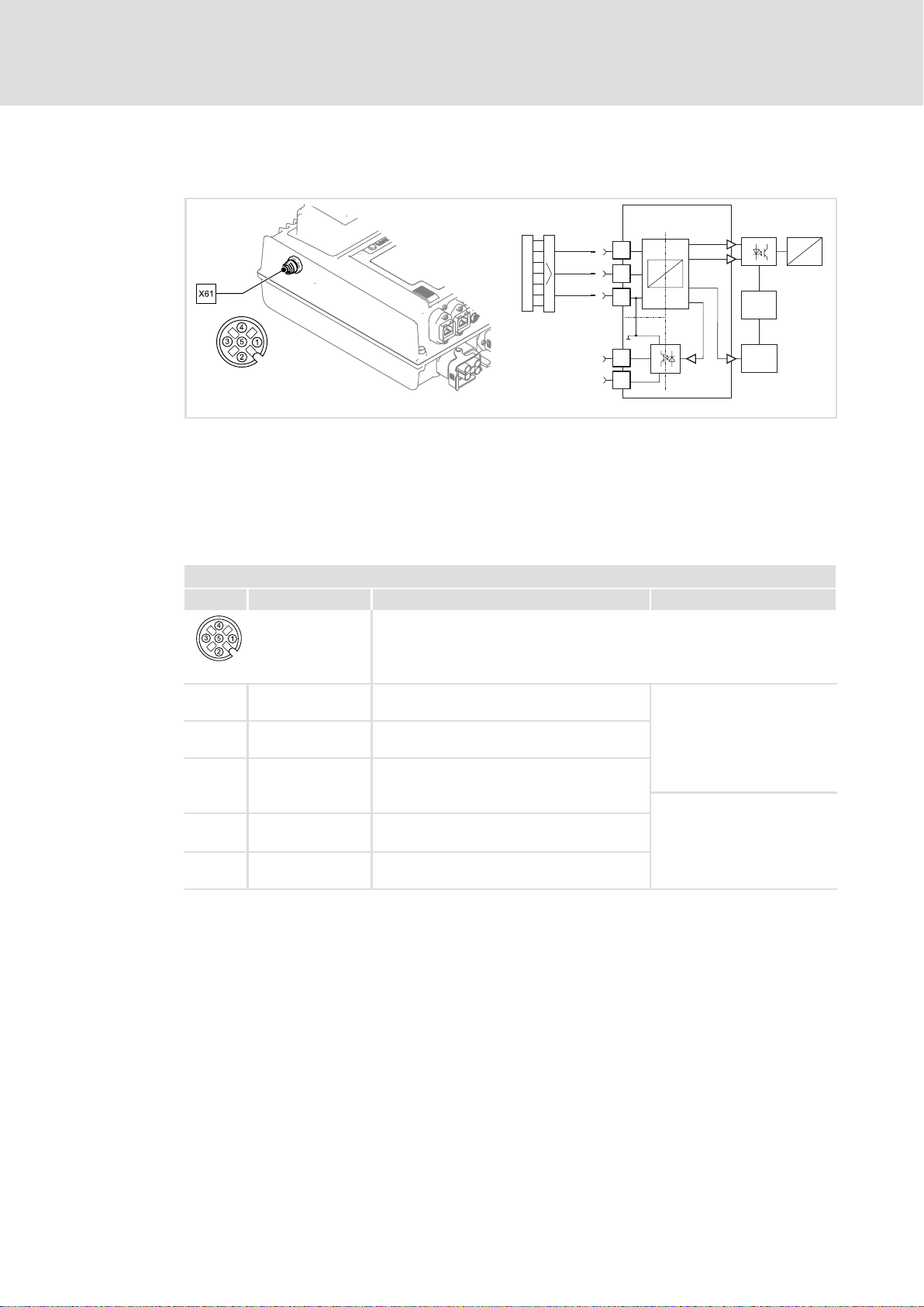

3.4 Electrical installation

SO

SIA

-

SIB

GI

DO1

24O

E84DPSO005 E84DPSO03

Fig. 3−3 Block diagram − safe torque off (STO)

SO Safety option 10

X61 M12 circular connector for safety engineering systems

SIA, SIB, GI Connections for shutdown paths

24O, DO1 Feedback connections

mC Microcontroller

PWM Pulse width modulation

X61 − connection of safety system "Safety Option 10"

Pin Connection Description Data

M12, 5−pole pins, A−coded

84DPSO05_5

1 SIA Safe input, channel A

I

typ

LOW: −3 ... 5 V

2 SIB Safe input, channel, B

HIGH: 18 ... 30 V

Supply through safely

separated power supply unit

5 GI 1. GND potential for SIA/SIB

(SELV/PELV).

2. GND potential for the non−safe signalling

output

4 24O 24−V voltage supply for the non−safe signalling

output

3 DO1 Non−safe signalling output: "SafeTorqueOff"

with 2−channel request by SIA and SIB

24 V, max. 0.2 A

short−circuit−proof

Supply through safely

separated power supply unit

(SELV/PELV).

High active

~

-

PWM

µC

= 45 mA

18

l

EDS84DPSO01 EN 2.1

Page 19

3.5 Certification

I Tip!

The "TÜV Rheinland Group" certificate is available on the Internet under:

http://www. Lenze.com

Safety option 10

Certification

3

EDS84DPSO01 EN 2.1

l

19

Page 20

4

Safety option 20

Operating mode

Introduction

4 Safety option 20

4.1 Operating mode

4.1.1 Introduction

Due to safety option 20, the following safety functions can be used:

ƒ Safe torque off (STO),

formerly: safe standstill

ƒ Safe stop 1 (SS1)

ƒ Safe stop emergency (SSE)

ƒ Safe operation mode selector (OMS)

ƒ Safe enable switch (ES)

The safe disconnection of the drive is achieved through:

ƒ a higher−level safety PLC via PROFIsafe/PROFINET

ƒ a higher−level safety PLC via PROFIsafe/PROFIBUS

The functions of the safety option must be parameterised via the »Engineer«.

The motion functions are continued to be executed by the controller. The drive−based

safety monitors the safe compliance with the limit values. When the limit values are

exceeded, the drive−based safety starts the control functions according to EN 60204−1

directly in the controller.

The safety functions are suitable for applications according to IEC 61508 to SIL 3 and

achieve a performance level (PL) e and the control category 3 according to EN ISO 13849−1.

20

l

EDS84DPSO01 EN 2.1

Page 21

4.1.2 Disconnecting paths

M

SO

PWM

µC

PC

3x

3x

Xxx

The transmission of the pulse width modulation is safely switched (off) by the safety unit.

After this, the power drivers do not generate a rotating field. The motor is safely switched

to torqueless operation (STO).

Fig. 4−1 Operating principle of safety unit

SO Safety option 10, 20, or 30

xxx Control terminals used in safety engineering systems or safety bus

C Control section

mC Microcontroller

PWM Pulse width modulation

P Power section

M Motor

Safety option 20

Operating mode

Disconnecting paths

4

E84DPSO02

4.1.3 Safety status

When the controller is disconnected from the safety unit, the "Safe torque off" (STO) status

is set (C00155 bit 10 = 1).

4.1.4 Fail−safe status

When internal errors of the safety unit are detected, the motor is safely switched to

torqueless operation (fail−safe status).

EDS84DPSO01 EN 2.1

l

21

Page 22

4

Safety option 20

Status display

4.2 Status display

Light−emitting diodes (LED) on the front of the controller display the operating status of

the safety engineering system.

Pos. Colour State Description

on

S−State green

S−Error red

S−Acknw yellow on A parameter set acceptance must be acknowledged

S−Enable yellow

blinking Drive−based safety is in service status

off

on Fault, trouble or warning

blinking

off Error−free operation

on Controller is enabled

blinking Safety function is active (non−safe display)

Communication between standard device and safety system

is running

Communication between standard device and safety system

is not possible

Drive−based safety is not accepted by the standard device

E84DPSO06 SO20

22

l

EDS84DPSO01 EN 2.1

Page 23

4.3 Technical data

Safety option 20 is exclusively controlled via the safety bus. Supply voltages, signal levels

etc. of the used safety bus system are relevant.

Since there are no inputs or outputs at the application end, connection data need not be

specified.

Safety option 20

Technical data

4

EDS84DPSO01 EN 2.1

l

23

Page 24

4

4.4 Electrical installation

Safety option 20

Electrical installation

Safety option 20 does not require external wiring because the safety functions are

exclusively controlled via the used safety bus.

24

l

EDS84DPSO01 EN 2.1

Page 25

4.5 Certification

I Tip!

The "TÜV Rheinland Group" certificate is available on the Internet under:

http://www. Lenze.com

Safety option 20

Certification

4

EDS84DPSO01 EN 2.1

l

25

Page 26

4

4.6 Safety functions

Safety option 20

Safety functions

The available safety functions comply with the safety functions of safety option 30

(¶ 45). However, the safety engineering system is exclusively controlled via the safety

bus. Therefore, the controller with safety option 20 is not provided with connections for

safety sensors.

26

l

EDS84DPSO01 EN 2.1

Page 27

4.7 Safe parameter setting

) Note!

Safety−relevant parameters can exclusively be transmitted to the drive−based

safety by safe parameter setting using the »Engineer«.

The parameter set is saved to the memory module and the drive−based safety

with a definite module ID which must comply with the effective safety address

in the drive−based safety.

The following is required for the parameterisation and configuration of the safety option:

ƒ A computer with a Windows® operating system (XP or 2000)

ƒ The Lenze »Engineer« PC software

ƒ Connection with the controller via an interface.

– diagnostic interface X70 with diagnostic USB adapter

– PROFINET

– Ethernet

Safety option 20

Safe parameter setting

Parameter setting

4

Further information and help can be found in:

ƒ the online help of the controller with safety option

ƒ the 8400 protec software manual, integrated safety system ...,

order designation: EDS84DWTSO

4.7.1 Parameter setting

Safety−relevant parameters can exclusively be transmitted to the drive−based safety by

safe parameter setting. The parameter set is saved to the memory module and the

drive−based safety with a definite module ID which must comply with the effective safety

address in the drive−based safety.

Safe parameter setting requires the service status. The service status means:

ƒ The standard stop is active and the drive is safely switched to torqueless operation

(STO).

ƒ The communication via the safety bus is active but passivated.

About the service status:

ƒ It can be activated by the Lenze »Engineer« PC software.

ƒ It can be quit by reinitialising the drive−based safety, i.e. the communication via the

safety bus is interrupted.

EDS84DPSO01 EN 2.1

) Note!

The service status also occurs if the parameter set in the memory module does

not comply with the parameter set in the drive−based safety during

initialisation.

l

27

Page 28

4

4.7.1.1 Parameter setting with the Lenze »Engineer« PC software

Safety option 20

Safe parameter setting

Parameter setting

Safe parameter setting is supported by the Lenze »Engineer« PC software as of

version 2.10.

The parameter setting is described in the software manual of drive−based safety for 8400

protec controllers. In addition, the software provides comprehensive online help.

Password

To store a safe parameter set, a password is required. The standard password is: "Lenze

SM301". The password can be changed and must have at least six characters.

Use "General reset" to delete the safe parameter set in the memory module and the

drive−based safety. The drive−based safety must be reparameterised.

The password is reset to the standard "Lenze SM301".

28

l

EDS84DPSO01 EN 2.1

Page 29

4.7.1.2 Parameter set transfer from the memory module

The safe parameter set transfer is supported by a safe parameter set saved to the memory

module, e.g. when replacing the standard device or parameterising the drive−based safety,

without the Lenze »Engineer« PC software via the memory module.

ƒ A valid parameter set with a corresponding module ID must be stored.

ƒ The drive−based safety must be in the service status.

ƒ Open the service hatch on the standard device to be able to operate the "T1" and

"T2" pushbuttons.

The transfer of the parameter set from the memory module must be acknowledged with

the pushbuttons:

ƒ the drive−based safety is in the service status

– the "S_State" LED is blinking

– the "S_Error" LED is lit

– the "S_Acknw" LED is lit

– the "S_Enable" LED is blinking

Safety option 20

Safe parameter setting

Parameter setting

4

ƒ press and hold the "T1" and "T2" pushbuttons at the same time

ƒ the "S_Acknw" LED starts blinking

ƒ if the "S_Acknw" LED goes out, release both pushbuttons immediately

ƒ after a few seconds, the "S_Acknw" LED is lit again

ƒ press and hold the "T1" and "T2" pushbuttons at the same time again

ƒ the "S_Acknw" LED starts blinking

ƒ if the "S_Acknw" LED goes out, release both pushbuttons immediately

ƒ The parameter set transfer is completed successfully.

If system−related response times (approx. 2.5 s) cannot be complied with, the parameter

transfer is cancelled. The process must be started again.

In case of success, the parameter transfer is recorded in the logbook of the standard device

and the service status is quit by a software restart.

If the parameter set is invalid, an error is indicated and the "S_Error" LED is lit.

I

AS

0

I

S82

0

t

max

Fig. 4−2 Acknowledgement procedure

AS "S_Acknw" LED

S82 "Left" and "Right" pushbuttons at the same time

t Time axis

t

max

t

max

Maximum permissible response time

t

t

max

SM301DIA_P

EDS84DPSO01 EN 2.1

l

29

Page 30

4

4.7.2 Parameter sets and axes

Safety option 20

Safe parameter setting

Parameter sets and axes

The unambiguousness of an axis with safety functions in a drive system can be achieved

by means of the safety address. In the safe parameter set a module ID is stored. This

module ID is compared to the effective safety address (C15112) in the drive−based safety.

When a drive−based safety is initialised, e.g. when loading the parameter set, the

compliance of the safety address will be checked. If no compliance exists, an initialisation

error is reported.

) Note!

ƒ Clearly define the safety address in a drive system or plant.

ƒ Document the address in circuit diagrams and labels.

ƒ Ensure identical settings when replacing the standard device or the memory

module.

In drive systems with activated safety bus the safety address is also used as the safety bus

target address. The clear assignment of the safety address must be configured in the safety

PLC.

In drive systems without activated safety bus, unambiguousness and correct assignment

of the safety address must be checked. For this purpose, use the Lenze »Engineer« PC

software or an EZAEBK200x diagnosis terminal.

30

l

EDS84DPSO01 EN 2.1

Page 31

4.8 Error management

4.8.1 Error states

Detected errors or maloperation of the drive are assigned to error states with definite

reactions. The reaction can be co−ordinated with the complete drive via the error states.

Safety option 20

Error management

Error states

4

Features

System error Trouble Warning

Event Fatal internal error Fault Monitoring function

"S_State" LED is lit is lit is lit

Status of drive−based

safety

The control category

according to EN 954−1 ...

Reaction The motor immediately

Acknowledgement after

deactivated event

Tab. 4−1 Overview of error states

Lockout (CPU stopped) Error status Normal operation

... has been abandoned ... has been abandoned ... has not been abandoned

switches to torque−free

operation via

l STO

l Connection and

disconnection of the

24−V supply at the

safety module

Error status

The motor is stopped via

l STO or

l SS1

l Error acknowledgement (AIE) via X62 (positive

signal pulse with a signal duration of 0.3 ... 10 s)

l Fault acknowledgement (AIE) via the safety bus

(Bit "PS_AIE")

l Connection and disconnection of the 24−V supply at

the safety module

) Note!

If the system fault also occurs after switching the 24−V supply, please contact

the service.

When using PROFIsafe as safety bus:

ƒ If faults occur in the PROFIsafe communication, the data is passivated by the

PROFIsafe driver.

ƒ After the PROFIsafe communication is reinitialised, the drive is automatically

enabled again if no standstill function is selected.

ƒ Events which cause an error status are sent as diagnostic telegram via the safety

bus.

4.8.2 Logbook

Error states are saved in the logbook of the standard device. The following is entered:

ƒ Type of response (e.g. trouble, warning, or information) to the event

ƒ Module which has caused the event (e.g. MCTRL or TEMPCONTROL)

ƒ Date/time (in case of memory module with real−time clock)

ƒ Value of the power−on time meter

The available logbook entries can be displayed in the »Engineer« when an online

connection has been established.

EDS84DPSO01 EN 2.1

l

31

Page 32

4

Safety option 20

Response times

4.9 Response times

In order to detect the response time to a safety function the entire system must be

considered. The following is relevant:

ƒ Response time of the connected sensors.

ƒ Input delay of the safety inputs.

ƒ Internal processing time.

ƒ When using PROFIsafe as safety bus:

– Monitoring time for the cyclic service in the PROFIBUS/PROFINET.

– Monitoring time of the PROFIsafe in the safety PLC.

– Processing time in the safety PLC.

ƒ Delay times due to further components.

S

0

1

t

t

1

t

i

2

μC

t

3

t

5

SF

t=0

t

ps

3

2

t

4

μC

Fig. 4−3 Response times to the request of a safety function

0 Standard device

1 Drive−based safety

2 Safety PLC

3 Safety bus

mC Microcontroller

S Safety sensor technology

SF Activated safety function

lcu12x_352

32

l

EDS84DPSO01 EN 2.1

Page 33

Safety option 20

Response times

Response times of the inputs

4

4.9.1 Response times of the inputs

Response time to an event in the sensors

Time interval (Fig. 4−3) [ms]

t1Response time of the sensors according to manufacturer

t

Input delay of the safe inputs

2

tiProcessing time in drive−based safety 4

Safety function starts after ... S

Tab. 4−2 Response time to an event in the sensors

C15034:

Input error:

information

0 ... 100

2

EDS84DPSO01 EN 2.1

l

33

Page 34

4

Safety option 20

Response times

Response times of the safety bus

4.9.2 Response times of the safety bus

PROFIsafe

Response time to an event in the safety sensors (PROFIsafe input data)

Time interval (Fig. 4−3) [ms]

t1Response time of the sensors according to manufacturer

t

Input delay of the safe inputs

2

t3Processing time in drive−based safety 24

PROFIsafe input data ready for transmission to ... S

tPsPROFIsafe cycle time according to manufacturer

PROFIsafe input data ready for processing in the safety PLC ... S

Tab. 4−3 Response time to an event in the sensors

Response time to a PROFIsafe control word (PROFIsafe output data)

Time interval (Fig. 4−3) [ms]

t4Processing time in the safety PLC must be calculated

tPsPROFIsafe cycle time according to manufacturer

t5Processing time in drive−based safety 14

Safety function starts after ... S

Tab. 4−4 Response time in case of PROFIsafe request

C15034:

Input error:

information

0 ... 100

2

information

information

Information on how to calculate the processing time and transmission time of the

PROFIsafe can be found in the documentation of the safety PLC used.

) Note!

If PROFIsafe communication is troubled, the fail−safe status will be reached

after the PROFIsafe monitoring time (F_WD_Time) has expired. PROFIsafe

communication is passivated.

Example

ƒ After an event has occurred at a safe input, the message is fed back to drive−based

safety via the safety PLC.

ƒ Drive−based safety activates a safety function.

ƒ Hence, the maximum response time to the event is calculated as follows:

t

max response

When calculating the maximum response time, include the times of the safety functions,

e.g. in case of SS1 the stopping time (30 s) until STO is active.

= t1 + t2 + t3 + max {tWD; tPS + t4 + tPs + t5}

34

l

EDS84DPSO01 EN 2.1

Page 35

5 Safety option 30

5.1 Operating mode

5.1.1 Introduction

Due to safety option 30, the following safety functions can be used:

ƒ Safe torque off (STO),

formerly: safe standstill

ƒ Safe stop 1 (SS1)

ƒ Safe stop emergency (SSE)

ƒ Safe operation mode selector (OMS)

ƒ Safe enable switch (ES)

The safe disconnection of the drive is achieved through:

Safety option 30

Operating mode

Introduction

5

ƒ a higher−level safety PLC via PROFIsafe/PROFINET

ƒ connected active or passive sensors

The functions of the safety option must be parameterised via the »Engineer«.

The motion functions are continued to be executed by the controller. The drive−based

safety monitors the safe compliance with the limit values. When the limit values are

exceeded, the drive−based safety starts the control functions according to EN 60204−1

directly in the controller.

The safety functions are suitable for applications according to IEC 61508 to SIL 3 and

achieve a performance level (PL) e and the control category 3 according to EN ISO 13849−1.

EDS84DPSO01 EN 2.1

l

35

Page 36

5

M

SO

PWM

µC

PC

3x

3x

Xxx

Safety option 30

Operating mode

Disconnecting paths

5.1.2 Disconnecting paths

The transmission of the pulse width modulation is safely switched (off) by the safety unit.

After this, the power drivers do not generate a rotating field. The motor is safely switched

to torqueless operation (STO).

Fig. 5−1 Operating principle of safety unit

SO Safety option 10, 20, or 30

xxx Control terminals used in safety engineering systems or safety bus

C Control section

mC Microcontroller

PWM Pulse width modulation

P Power section

M Motor

E84DPSO02

5.1.3 Safety status

When the controller is disconnected from the safety unit, the "Safe torque off" (STO) status

is set (C00155 bit 10 = 1).

5.1.4 Fail−safe status

When internal errors of the safety unit are detected, the motor is safely switched to

torqueless operation (fail−safe status).

36

l

EDS84DPSO01 EN 2.1

Page 37

Safety option 30

Operating mode

Safe inputs

5

5.1.5 Safe inputs

Contact function test

) Note!

Make sure that an internal contact function test is carried out at the safe

inputs:

Safe input in the ON state

ƒ A LOW level at one channel puts the input in the OFF state. The discrepancy

ƒ A LOW level must be detected at both channels within the discrepancy time,

ƒ To be able to acknowledge the discrepancy error, a LOW level must be

Safe input in the OFF state

ƒ A HIGH level at one channel starts the discrepancy monitoring.

ƒ A HIGH level must be detected at both channels within the discrepancy

ƒ To be able to acknowledge the discrepancy error, a HIGH level must be

monitoring starts simultaneously.

otherwise a discrepancy error will be reported.

detected before at both channels.

time, otherwise a discrepancy error will be reported.

detected before at both channels.

ON state

Value of safe input:

ON state

Switch both channels

to ON state

Discrepancy monitoring Discrepancy monitoring

Value of safe input:

OFF state

One channel in

ON state

OFF state

Value of safe input:

OFF state

Fig. 5−2 Status behaviour − contact function test

One channel in

OFF state

Value of safe input:

OFF state

Switch both channels

to OFF state

SSP94SM355

EDS84DPSO01 EN 2.1

l

37

Page 38

5

Safety option 30

Operating mode

Safe inputs

A

B

C

D

Fig. 5−3 Contact function test − error−free input signals

A

B

C

D

AIE

Fig. 5−4 Contact function test − faulty input signals

A, B Safe input, channel A and channel B

C Internal valuation of the safe input

D Discrepancy monitoring

AIE Fault acknowledgement

Discrepancy monitoring active

Discrepancy monitoring − time−out

Fault acknowledgement impermissible

Fault acknowledgement permissible

SSP94SM358_1

SSP94SM358_2

38

l

EDS84DPSO01 EN 2.1

Page 39

5.2 Status display

Light−emitting diodes (LED) on the front of the controller display the operating status of

the safety engineering system.

Safety option 30

Status display

5

Pos. Colour State Description

on

S−State green

S−Error red

S−Acknw yellow on A parameter set acceptance must be acknowledged

S−Enable yellow

blinking Drive−based safety is in service status

off

on Fault, trouble or warning

blinking

off Error−free operation

on Controller is enabled

blinking Safety function is active (non−safe display)

Communication between standard device and safety system

is running

Communication between standard device and safety system

is not possible

Drive−based safety is not accepted by the standard device

E84DPSO06 SO30

EDS84DPSO01 EN 2.1

l

39

Page 40

5

Safety option 30

Technical data

5.3 Technical data

24 V supply

The safety option 30 component does not require an external supply voltage.

Inputs and outputs

The inputs are isolated and designed for a low−voltage supply of 24 V DC.

Detailed features of the safe inputs

Terminal Specification [Unit] min. typ. max.

I1A, I1B

I2A, I2B

AIE, AIS

AIE, AIS Input delay (operating time) s 0.3 10

24I Voltage supply only for AIE and AIS V 24

CLA, CLB

PLC input, IEC−61131−2, 24 V, type 1

Low signal input voltage

Input current at low signal mA 15

High signal input voltage

Input current at high signal mA 2 15

Input capacitance

Repetition rate of the test pulses

PLC output, IEC−61131−2, 24 V DC, 50 mA

Low signal output voltage

High signal output voltage

Output current

Cable capacity

Cable resistance of a passive sensor

V −3 0 5

V 15 24 30

nF 3.5

ms 50

V 0 0.8

V 17 24 29

mA 60

nF 100

W 200

Safety option 30 does not provide any safe outputs.

40

l

EDS84DPSO01 EN 2.1

Page 41

5.4 Electrical installation

Principle circuit diagram

Safety option 30

Electrical installation

AIE

1

24_ACK

2

AIS

3

GND-SM

4

GND-SM

5

X62

5

E84Dx...-x xxS

CLA

1

CLB

2

GND-CLK

S3

S1

E84DxWT... 8400 protec controller with safety option 30

S1 Passive sensor with channel A and B (at X64 in our example)

S3 Higher−level safety control (active sensor)

S4 Lightgrid (active sensor) (at X63 in our example)

3

S4

I1A

4

GND-I1

5

I1B

6

GND-CLK

7

GND-I1

8

CLA

1

CLB

2

GND-CLK

3

I2A

4

GND-I2

5

I2B

6

GND-CLK

7

GND-I2

8

L

X63

X64

84DPSSO031

EDS84DPSO01 EN 2.1

l

41

Page 42

5

Safety option 30

Electrical installation

Terminal assignment

} Danger!

Danger to life through improper installation

Improper installation of the safety engineering systems can cause

anuncontrolled starting action of the drives.

Possible consequences:

ƒ Death or severe injuries

Protective measures:

ƒ The installation of the cables between X62, X63, and X64 and the connected

components must be shielded:

– Attach the shield at least in the connector shell.

– Also attach the shield to the connected component if possible.

X62 − connection of safety engineering system "Safety Option 30"

Pin Connection Description Data

M12, 5−pole sockets, A−coded

84DPSO05_5

1 AIE Error acknowledgement

2 24_ACK 24−V supply voltage for reset button max. 300 mA

3 AIS Restart acknowledgement

4 GND_SM

5 GND_SM

GND potential

42

l

EDS84DPSO01 EN 2.1

Page 43

Safety option 30

Electrical installation

X63 − connection of the "Safety Option 30" safety engineering system

Pin Connection Description Data

M12, sockets 8−pole, A−coded

84DSO05_8

1 CLA Clock output, channel A

2 CLB Clock output, channel B

3 GND_CLK GND potential − clock output, channel A

4 I1A Safe input 1, channel A

5 GND_I1 GND potential − input 1, channel A

6 I1B Safe input 1, channel B

7 GND_CLK GND potential − clock output, channel B

8 GND_I1 GND potential − input 1, channel B

X64 − connection of the "Safety Option 30" safety engineering system

Pin Connection Description Data

M12, sockets 8−pole, A−coded

5

84DSO05_8

1 CLA Clock output, channel A

2 CLB Clock output, channel B

3 GND_CLK GND potential − clock output, channel A

4 I2A Safe input 2, channel A

5 GND_I2 GND potential − input 2, channel A

6 I2B Safe input 2, channel B

7 GND_CLK GND potential − clock output, channel B

8 GND_I2 GND potential − input 2, channel B

EDS84DPSO01 EN 2.1

l

43

Page 44

5

5.5 Certification

Safety option 30

Certification

I Tip!

The "TÜV Rheinland Group" certificate is available on the Internet under:

http://www. Lenze.com

44

l

EDS84DPSO01 EN 2.1

Page 45

5.6 Safety functions

5.6.1 Safe torque off

Safe Torque Off/STO

This function corresponds to a "Stop 0" according to EN 60204.

When this function is used, the power supply of the motor is immediately (t1) safely

interrupted. The motor cannot create a torque and thus no dangerous movements of the

drive can occur. Additional measures, e.g. mechanical brakes are needed against

movements caused by external force.

I

0

0

n

Safety option 30

5

Safety functions

Safe torque off

t

1

0

t1

t1

2

I

STO

0

0 Input signal of the request of a safety function

I ON state

O OFF state

1 Speed characteristic n of the motor

t Time axis

tx Action instant

2 Feedback(s)

The restart behaviour can be set (C15300/1). Function sequence and error response have

no adjustable parameters.

t

t

SM301DIA_STO

} Danger!

If the request for the safety function is cancelled, the drive will restart

automatically.

You must provide external measures which ensure that the drive only restarts

after a confirmation (EN 60204).

EDS84DPSO01 EN 2.1

l

45

Page 46

5

Safety option 30

Safety functions

Safe torque off

Activation

How to activate the function:

ƒ "OFF state" at a safe input, the function of which has been assigned by parameter

setting.

ƒ Via a safety bus data telegram with corresponding content.

ƒ As response to the error stop request.

ƒ As response to the emergency stop request if the function has been parameterised

as emergency stop function (C15205).

46

l

EDS84DPSO01 EN 2.1

Page 47

Safety option 30

Safety functions

Safe stop 1

5

5.6.2 Safe stop 1

Safe Stop 1 / SS1

This function corresponds to a "Stop 1" according to EN 60204.

The function monitors the reaching of the speed n = 0 (C15310) within an adjustable

stopping time (C15305). The speed is calculated from the encoder data (safe speed

measurement). Without encoder the function evaluates the speed status n = 0 from the

standard device. For this, the monitored stopping time parameterised in the safety module

must be 0.5 s longer than the stopping time in the controller.

When the stopping time (t2) has elapsed, the power supply of the motor is immediately

safely interrupted (STO). The motor cannot create a torque and thus no dangerous

movements of the drive. If a standstill was not reached, an error message is caused

additionally.

Additional measures, e.g. mechanical brakes are needed against movements caused by

external force. The time for a brake to be applied must be considered when defining the

stopping time.

A restart is only possible after the stopping time has elapsed.

I

0

1

2

SS1

STO

0

n

0

I

0

I

0

t

S

t1 t2

t1

0 Input signal of the request of a safety function

I ON state

0 OFF state

1 Speed characteristic n of the motor

t Time axis

tx Action instant

Monitored stopping time

t

S

–– Normal operation

−−− Incorrect operation

2 Feedback(s)

t

t

t

t

SM301DIA_SS1

EDS84DPSO01 EN 2.1

l

47

Page 48

5

Safety option 30

Safety functions

Safe stop 1

Activation

How to activate the function:

ƒ "OFF state" at a safe input, the function of which has been assigned by parameter

setting.

ƒ Via a safety bus data telegram with corresponding content.

ƒ As response to the error stop request.

ƒ As response to the emergency stop request if the function has been parameterised

as emergency stop function (C15205).

48

l

EDS84DPSO01 EN 2.1

Page 49

Safety option 30

Safety functions

Emergency stop

5

5.6.3 Emergency stop

Safe Stop Emergency/SSE

The emergency stop function activates STO or SS1. The function to be executed can be

adjusted (C15205). In special operation, the emergency stop cannot be avoided.

) Note!

Connect the emergency stop buttons which must not be overruled by a special

operation to the emergency stop function. For this purpose, parameterise the

safe input as "emergency stop" (C15031).

The emergency stop function can also be requested with SSE bit via the safety

bus.

The activation of the function is reported internally to the standard device and via the

safety bus of the higher−level control.

Activation

How to activate the function:

ƒ "OFF state" at a safe input, the function of which has been assigned by parameter

setting.

ƒ Via a safety bus data telegram with corresponding content.

EDS84DPSO01 EN 2.1

l

49

Page 50

5

Safety option 30

Safety functions

Safe operation mode selector

5.6.4 Safe operation mode selector

Operation Mode Selector / OMS

The function provides a special operation of the drive. In the special operation the drive is

stopped (status 2). The drive can be traversed in the special operation via an enable switch

(status 3).

For the stop status in the special operation, the STO or SS1 functions can be parameterised.

For motion functions in the special operation, the free movement can be parameterised.

The parameterised monitoring function will be automatically activated with the transition

to the special operation.

The special operation enables an override of the simple STO and SS1 stop functions by the

enable switch.

An active emergency stop function is also executed in special operation.

The special operation can also be selected via the safety bus by the F−PLC, unless a safe

input is parameterised as operation mode selector.

The return to normal operation is only possible in the stop status. Since the drive is stopped

in status 2, the AIS acknowledgement is required for restart. The parameters for the restart

STO/SS1 are used.

) Note!

When returning to normal operation, the automatic restart is not permissible.

If "automatic restart" is parameterised, this can be prevented by special

measures, e.g. programming in the higher−level control.

) Note!

The "safe enable switch" function serves to directly cancel/complete the

stopping times assigned to the stop functions.

) Note!

If an error (e.g. a discrepancy error) occurs at a safe input to which the OMS

function has been assigned, normal operation will be selected. This

corresponds to the OFF state. The "S_Error" LED is lit and STO is not activated.

The special operation can only be selected again when the error has been

eliminated and acknowledged.

50

l

EDS84DPSO01 EN 2.1

Page 51

Safety option 30

Safety functions

Safe operation mode selector

Preconditions

A safe input must be parameterised and interconnected as operation mode selector. You

can only connect and parameterise an operation mode selector. The OMS bit of the safety

bus must be deactivated (C15113).

The special operation can also be selected via the safety bus with the OMS bit, unless a safe

input is set as operation mode selector.

The plausibility check rejects ambiguous settings until they are parameterised correctly.

) Note!

The "free traversing" setting for the special operation (C15201) motion

function must be suitable for the application!

Activation

How to activate the function:

ƒ Via a safe input which has been assigned to the function by parameterisation. In

addition, the requested operating mode depends on OMS: Function at LOW level

(C15202).

Example:

Normal operation at LOW level

The special operation is activated via a key−operated switch. The "Special operation

with LOW level" function is not permissible for a key−operated switch which uses the

special operation for short−circuiting purposes. An open circuit in the cable of the

switch would activate the special operation which is otherwise only possible with a key.

Special operation at LOW level

The special operation is active if a safety grid (safety door) is openend, i.e. the safe input

provides a LOW level and executes the parameterised stop function.

5

Only if no safe input is used, the function can only be activated via the safety bus:

ƒ A data telegram with corresponding contents must be transmitted to the standard

device.

EDS84DPSO01 EN 2.1

l

51

Page 52

5

Safety option 30

Safety functions

Safe enable switch

5.6.5 Safe enable switch

Enable Switch / ES

The drive can be traversed in special operation using an enable switch (see operation mode

selector).

Operating mode Normal Special

Event Impact Impact

− Status −

Request − OMS special operation via ...

... safe input Change W Status

... safety bus same response − only possible as an alternative to the safe input

Request − ES confirmation via ...

... safe input No function Status

... via safety bus same response − only possible as an alternative to the safe input

Stop request Status

Emergency stop Status

SM301OMS01

Stop function ...

l STO

l SS1

... is executed

Activated monitoring functions

remain active.

l Free movement

is not executed

parameterised function ...

l STO

l SS1

... is executed

parameterised function ...

l STO

l SS1

... is executed

52

l

EDS84DPSO01 EN 2.1

Page 53

Safety option 30

Safety functions

Safe enable switch

Preconditions

A safe input must be parameterised and interconnected as enable switch. You can only

connect and parameterise one enable switch. The ES bit of the safety bus must be

deactivated (C15113).

The enable switch function can also be selected via the safety bus with the ES bit, unless

a safe input is parameterised as enable switch.

The special operation must be activated.

The plausibility check rejects ambiguous settings until they are parameterised correctly.

Activation

How to activate the function:

ƒ Via a safe input which has been assigned to the function by parameterisation. In

addition, the requested operating mode depends on OMS: Function at LOW level

(C15202).

Example:

Normal operation at LOW level

The special operation is activated via a key−operated switch. The "Special operation

with LOW level" function is not permissible for a key−operated switch which uses the

special operation for short−circuiting purposes. An open circuit in the cable of the

switch would activate the special operation which is otherwise only possible with a key.

Special operation at LOW level

The special operation is active if a safety grid (safety door) is openend, i.e. the safe input

provides a LOW level and executes the parameterised stop function.

5

Only if no safe input is used, the function can only be activated via the safety bus:

ƒ A data telegram with corresponding contents must be transmitted to the standard

device.

EDS84DPSO01 EN 2.1

l

53

Page 54

5

5.7 Safe parameter setting

Safety option 30

Safe parameter setting

Parameter setting

) Note!

Safety−relevant parameters can exclusively be transmitted to the drive−based

safety by safe parameter setting using the »Engineer«.

The parameter set is saved to the memory module and the drive−based safety

with a definite module ID which must comply with the effective safety address

in the drive−based safety.

The following is required for the parameterisation and configuration of the safety option:

ƒ A computer with a Windows® operating system (XP or 2000)

ƒ The Lenze »Engineer« PC software

ƒ Connection with the controller via an interface.

– diagnostic interface X70 with diagnostic USB adapter

– PROFINET

– Ethernet

Further information and help can be found in:

ƒ the online help of the controller with safety option

ƒ the 8400 protec software manual, integrated safety system ...,

order designation: EDS84DWTSO

5.7.1 Parameter setting

Safety−relevant parameters can exclusively be transmitted to the drive−based safety by

safe parameter setting. The parameter set is saved to the memory module and the

drive−based safety with a definite module ID which must comply with the effective safety

address in the drive−based safety.

Safe parameter setting requires the service status. The service status means:

ƒ The standard stop is active and the drive is safely switched to torqueless operation

(STO).

ƒ The communication via the safety bus is active but passivated.

About the service status:

ƒ It can be activated by the Lenze »Engineer« PC software.

ƒ It can be quit by reinitialising the drive−based safety, i.e. the communication via the

safety bus is interrupted.

54

) Note!

The service status also occurs if the parameter set in the memory module does

not comply with the parameter set in the drive−based safety during

initialisation.

l

EDS84DPSO01 EN 2.1

Page 55

Safety option 30

Safe parameter setting

Parameter setting

5.7.1.1 Parameter setting with the Lenze »Engineer« PC software

Safe parameter setting is supported by the Lenze »Engineer« PC software as of

version 2.10.

The parameter setting is described in the software manual of drive−based safety for 8400

protec controllers. In addition, the software provides comprehensive online help.

Password

To store a safe parameter set, a password is required. The standard password is: "Lenze

SM301". The password can be changed and must have at least six characters.

Use "General reset" to delete the safe parameter set in the memory module and the

drive−based safety. The drive−based safety must be reparameterised.

The password is reset to the standard "Lenze SM301".

5

EDS84DPSO01 EN 2.1

l

55

Page 56

5

Safety option 30

Safe parameter setting

Parameter setting

5.7.1.2 Parameter set transfer from the memory module

The safe parameter set transfer is supported by a safe parameter set saved to the memory

module, e.g. when replacing the standard device or parameterising the drive−based safety,

without the Lenze »Engineer« PC software via the memory module.

ƒ A valid parameter set with a corresponding module ID must be stored.

ƒ The drive−based safety must be in the service status.

ƒ Open the service hatch on the standard device to be able to operate the "T1" and

"T2" pushbuttons.

The transfer of the parameter set from the memory module must be acknowledged with

the pushbuttons:

ƒ the drive−based safety is in the service status

– the "S_State" LED is blinking

– the "S_Error" LED is lit

– the "S_Acknw" LED is lit

– the "S_Enable" LED is blinking

ƒ press and hold the "T1" and "T2" pushbuttons at the same time

ƒ the "S_Acknw" LED starts blinking

ƒ if the "S_Acknw" LED goes out, release both pushbuttons immediately

ƒ after a few seconds, the "S_Acknw" LED is lit again

ƒ press and hold the "T1" and "T2" pushbuttons at the same time again

ƒ the "S_Acknw" LED starts blinking

ƒ if the "S_Acknw" LED goes out, release both pushbuttons immediately

ƒ The parameter set transfer is completed successfully.

If system−related response times (approx. 2.5 s) cannot be complied with, the parameter

transfer is cancelled. The process must be started again.

In case of success, the parameter transfer is recorded in the logbook of the standard device

and the service status is quit by a software restart.

If the parameter set is invalid, an error is indicated and the "S_Error" LED is lit.

I

AS

0

I

S82

0

t

max

Fig. 5−5 Acknowledgement procedure

AS "S_Acknw" LED

S82 "Left" and "Right" pushbuttons at the same time

t Time axis

t

max

t

max

Maximum permissible response time

t

t

max

SM301DIA_P

56

l

EDS84DPSO01 EN 2.1

Page 57

5.7.2 Parameter sets and axes

The unambiguousness of an axis with safety functions in a drive system can be achieved

by means of the safety address. In the safe parameter set a module ID is stored. This

module ID is compared to the effective safety address (C15112) in the drive−based safety.

When a drive−based safety is initialised, e.g. when loading the parameter set, the

compliance of the safety address will be checked. If no compliance exists, an initialisation

error is reported.

) Note!

ƒ Clearly define the safety address in a drive system or plant.

ƒ Document the address in circuit diagrams and labels.

ƒ Ensure identical settings when replacing the standard device or the memory

module.

In drive systems with activated safety bus the safety address is also used as the safety bus

target address. The clear assignment of the safety address must be configured in the safety

PLC.

Safety option 30

Safe parameter setting

Parameter sets and axes

5

In drive systems without activated safety bus, unambiguousness and correct assignment

of the safety address must be checked. For this purpose, use the Lenze »Engineer« PC

software or an EZAEBK200x diagnosis terminal.

EDS84DPSO01 EN 2.1

l

57

Page 58

5

Safety option 30

Error management

Error states

5.8 Error management

5.8.1 Error states

Detected errors or maloperation of the drive are assigned to error states with definite

reactions. The reaction can be co−ordinated with the complete drive via the error states.

Features

System error Trouble Warning

Event Fatal internal error Fault Monitoring function

"S_State" LED is lit is lit is lit

Status of drive−based

safety

The control category

according to EN 954−1 ...

Reaction The motor immediately

Acknowledgement after

deactivated event

Tab. 5−1 Overview of error states

Lockout (CPU stopped) Error status Normal operation