Page 1

(13360151)

SC SERIES DIN RAIL MOUNTING KIT

Part Number(s) 844-001, 844-002, 844-003

Manual Number: IMSDIN03

GENERAL

The SC Series DIN rail mounting kit allows SC Series drives to be mounted to a standard 35mm DIN

rail, which simplifies panel layouts and installation. The kit uses mounting brackets that fasten to the

DIN rail. The brackets allow for mounting at different heights on the DIN rail so that different size drives

may be aligned with the top, bottom, or center of the drives at the same level to suit various wire-routing

styles.

Drive

Size

A 2.88” 844-001 3.75”

B 3.76” 844-002 4.63”

C 5.02” 844-003 5.89”

Drive

Width

DIN Rail

Mounting Kit P/N

Bracket

Width

There are three different versions of the DIN Rail Mounting Kit (P/N 844-001, 844-002, 844-003). The

following table illustrates which kit should be used depending on the size of the drive:

PARTS LIST

Each kit includes the following parts:

• DIN Rail Mounting Brackets (Quantity 6)

• Mounting Screws (Quantity 24)

• Clamping Screws (Quantity 6, except kit version 844-003 has 12 Clamping Screws)

NOTE:

The DIN Rail Mounting Brackets in kit version 844-002 can also be used to mount A size

drives with 2.88” width.

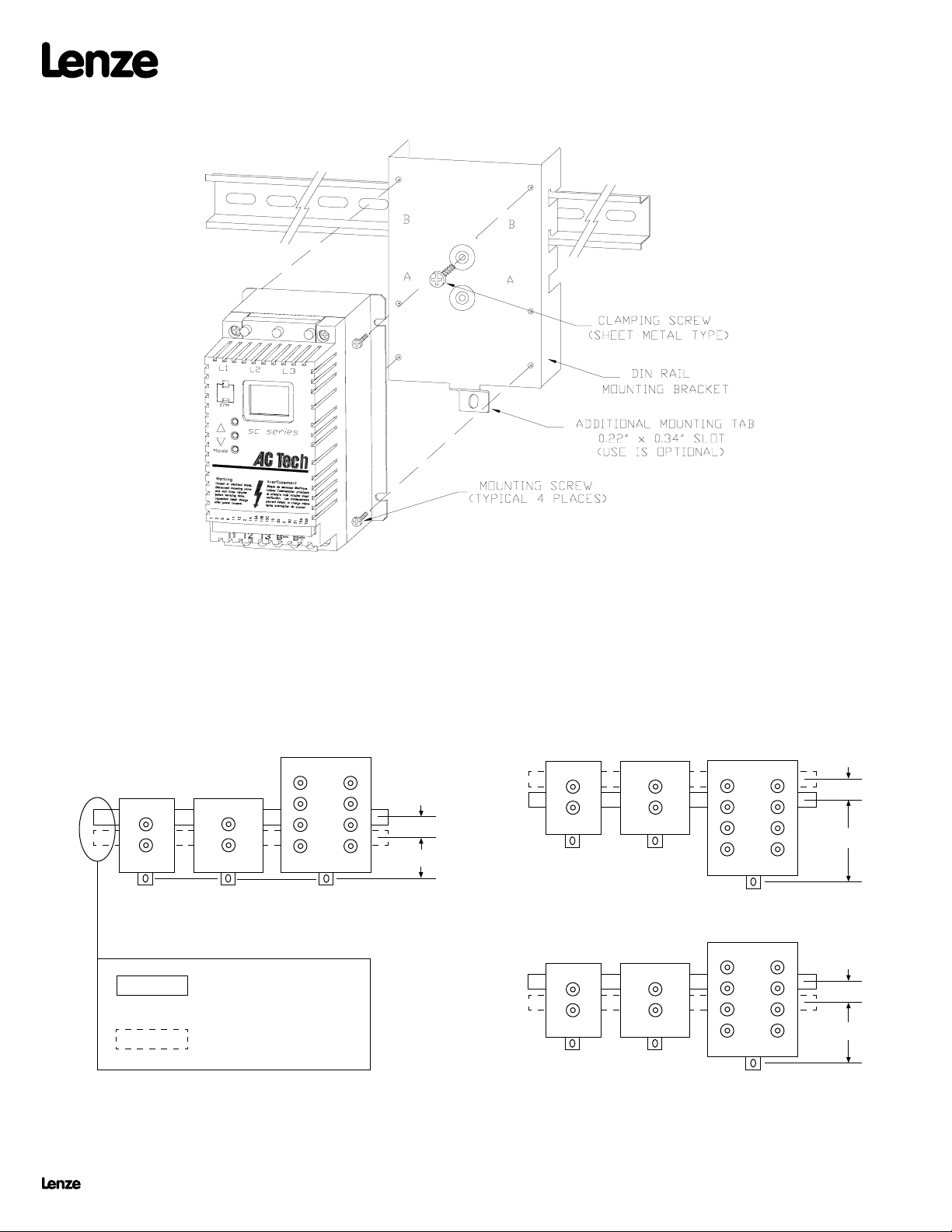

INSTALLATION

Refer to the drawings on the back of this page during installation.

1. Position the DIN Rail Mounting Bracket onto the DIN rail such that the top edge of the DIN rail fits

into the desired slot on the back of the DIN Rail Mounting Bracket. NOTE: The DIN Rail Mounting

Bracket has several mounting positions which allow different size drives to be mounted with the top,

bottom, or center of the drives at the same level.

2. Screw the Clamping Screw into the hole that matches the selected mounting position. The Clamping

Screw should engage the bottom edge of the DIN rail to hold the DIN Rail Mounting Bracket securely

in place. NOTE: Kit version 844-003 uses two (2) Clamping Screws.

3. Mount the SC Series drive onto the DIN Rail Mounting Bracket using the four (4) Mounting Screws

included with the kit.

4. The tab at the bottom of the DIN Rail Mounting Bracket can be used as an additional mounting point

to fasten the DIN Rail Mounting Bracket directly to the back panel. A screw for this is NOT provided

in the kit.

Sales (800) 217-9100 • Service (508) 278-9100 • Fax (508) 278-7873 • www.lenzeamericas.com

Lenze Americas • 630 Douglas Street • Uxbridge, MA 01569 • USA

IMSDIN03

13360151

Page 2

Figure 1: Exploded View

MOUNTING POSITIONS

Figure 2 illustrates the different mounting positions that are possible with the DIN Rail Mounting Kit.

Drives can be mounted next to each other with the top, bottom, or center of the drives aligned. The

diagrams indicate recommended and alternate mounting positions to use on each DIN Rail Mounting

Bracket to achieve the desired alignment.

TOP ALIGNEDBOTTOM ALIGNED

1.00"

1.00"

3.13"

4.63"

5.89"3.75"

CENTER ALIGNED

RECOMMENDED DIN

RAIL POSITION

ALTERNATE DIN RAIL

POSITION

Figure 2: Mounting Positions

Sales (800) 217-9100 • Service (508) 278-9100 • Fax (508) 278-7873 • www.lenzeamericas.com

Lenze Americas • 630 Douglas Street • Uxbridge, MA 01569 • USA

5.13"

1.00"

4.13"

IMSDIN03

13360151

Loading...

Loading...