Page 1

L

Doc ID: S94CAN01A

S921

CANopen Communication Module

S94CAN01A

Page 2

Table of Contents

1 Preface and General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 How to use these Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Persons responsible for safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 General safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.1 Related documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 CANopen DS301 Communication Profile Support . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Supported NMT (Network Management) services: . . . . . . . . . . . . . . . . . . . . 7

4.2 The Heartbeat Error Control Service . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Communication Objects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5. Drive 94 Specific Objects and functionality . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1 CAN Velocity mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2 CAN Torque mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.3 E94 Drive specific objects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Page 3

Preface & General Info

1 Preface and General Information

1.1 How to use these Operating Instructions

• These Operating Instructions are intended for safety-relevant operation on and with the

E94ZACAN1 CANopen option module. They contain safety information which must be

observed.

• All personnel working on and with the module must have these Operating Instructions

available and observe the information and notes relevant for them.

• These instructions are only valid in combination with the Operating Instructions of the

corresponding controller. They must always be complete and in a perfectly readable

state.

ENGLISH

1

Page 4

2 Safety Information

2.1 Persons responsible for safety

Operator

• An operator is any natural or legal person who uses the drive system or on behalf of

whom the drive system is used.

• The operator or his safety personnel is obliged to ensure

- the compliance with all relevant regulations, instructions, and legislation.

- that only skilled personnel works on and with the drive system.

- that the personnel have the Operating Instructions available for all corresponding

works.

- that all unqualified personnel are prohibited from working on and with the drive

system.

Qualified personnel

Qualified personnel are persons who - because of their education, experience, instructions,

and knowledge about corresponding standards and regulations, rules for the prevention of

accidents, and operating conditions - are authorized by the person responsible for the safety

of the plant to perform the required actions and who are able to recognize potential hazards.

(Definition for qualified personnel to VDE 105 or IEC 364)

Safety Info

2.2 General safety information

• These safety notes do claim to be complete. In case of questions and problems please

contact your Lenze representative.

• At the time of delivery the drive system meets the state of the art and ensures basically

safe operation.

• The indications given in these Operating Instructions refer to the stated hardware and

software versions of the controller.

• The controller is hazardous if:

- unqualified personnel work on and with the controller.

- the controller is used inappropriately.

• Ensure by appropriate measures that neither personal injury nor damage to property

may occur in the event of failure of the drive system.

• The drive system must only be operated when no faults occur.

• Retrofitting, modifications, or redesigns are basically prohibited. Lenze must be

contacted in all cases.

ENGLISH

2

Page 5

3 Technical data

3.1 Related documents

• CANopen Application Layer and Communication Profile or CiA Draft Standard 301

• Drive 94 reference manual

3.2 General information

The internationally standardized CAN bus protocol, which had been developed for the

European Automobile Industry, is mainly characterized by

• Its resistance against interference and extreme temperatures

• Short transfer times

• Low connection expenses

These advantages have made CAN products interesting for other industries too.

The CANopen communication profile is based on CAN technology.

Technical Data

The CANopen protocol has been developed by the CiA(CON in Automation) in conformity

with the CAL (CON Application Layer). All mandatory parts of the CiA DS301 protocol,

version 4.01 have been implemented in the E94ZACAN1 Module.

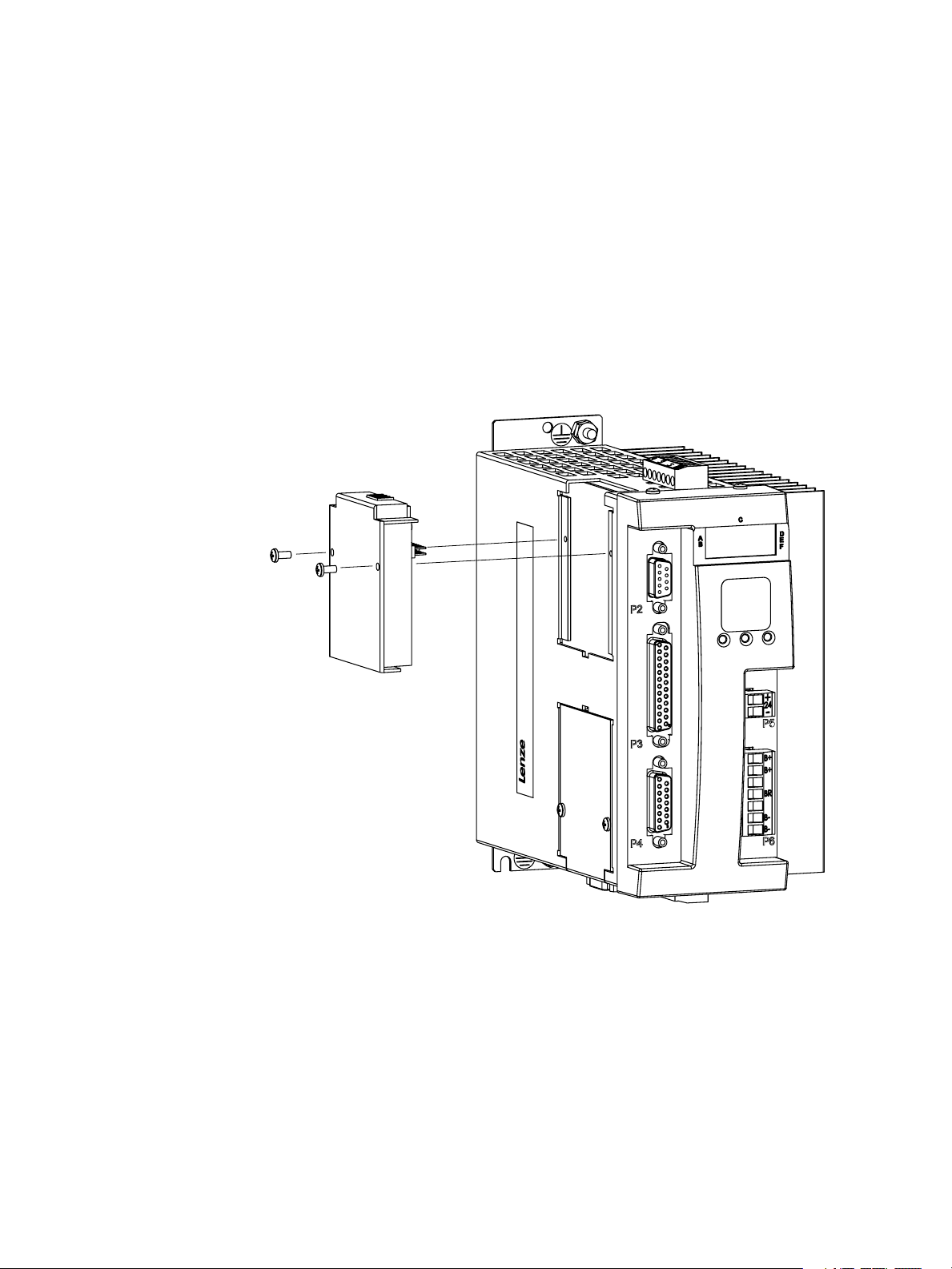

3.3 Installation

The E94ZCAN1 CANopen Communication Module is designed to operate with the E94S

SimpleServo drive. For proper installation……

• Remove power from the drive and allow unit to discharge

• Remove blank module cover from Option Bay 1

• Plug in the 20 pin connector into drive

• Plug in the CANopen module

• Use set screws to connect module to drive

ENGLISH

ENGLISH

3

3

Page 6

3.4 Configuration

Drive 94 supports CANopen communication protocol through its CANopen Communication

Module. Upon power up, the drives firmware detects the CAN Module and automatically

enables both the CANopen functionality as well as the CANopen configuration menu.

We can utilize SimpleServo LED display and push buttons to both configure the drive for the

CAN network, as well as check and set drive parameters. The “UP” (▲) and “DOWN” (▼)

buttons are used to navigate through the drives parameters.

Power up the drive and review the display.

rvn_ Drive is Enabled and in Run mode. Disable the drive by deactivating the Enable

input.

DiS_ Drive is Disabled and ready to be configured. Press the “ENTER” button

( ) to continue.

StAt Current drive status. From here you use the “UP” (▲) and “DOWN” (▼) buttons to

navigate through the drives parameters. Press the “DOWN” (▼) button to continue.

CAnd CAN delay menu. This is the delay in seconds after which a “start remote node”

message can be broadcast and its value is between 0 and 5 (seconds). Press

the “ENTER” button ( ) to view this number and use the “UP” (▲) and “DOWN”

(▼) buttons to change the delay setting. Set the delay back to “0” and press the

“ENTER” button ( ) to exit. Press the “DOWN” (▼) button to continue.

Technical Data

CAn0 CAN operational mode. This is where you define what mode you want the drive to

be in at power up. This parameter is R/W. To view the setting, press the “ENTER”

button ( ). Use the “UP” (▲) and “DOWN” (▼) buttons to change the setting.

Select setting “1” and press the “ENTER” button ( ) to store your setting and to

exit. Press the “DOWN” (▼) button to continue

___0 CAN starts in pre-operational state.

___1 CAN starts in operational mode.

___2 CAN starts in operational mode and is a “quasi master”, meaning that it

will send “start remote node” message (described in standard DS301)

after a delay specified in CAnd menu.

CAnS CAN network status value. This is a binary representation of the status of the

CAN network. This is read only parameter and you can have more than one

status active at one time. Press the “ENTER” button ( ) to view status. Press the

“ENTER” button ( ) to exit. Press the “DOWN” (▼) button to continue.

___1 Initialization Complete.

___2 CAN bit or frame error occurred.

___4 CAN “error passive” occurred.

___8 Receive queue overrun occurred.

__16 Transmit queue overrun occurred.

__32 Reserved

__64 Reserved

_128 CAN “bus off” error occurred

ENGLISH

ENGLISH

4

4

Page 7

Technical Data

CAnA CAN network address. This parameter is R/W and can be between 0 and 127. This

is the drives address on the CAN Network. Press the “ENTER” button ( ) to view

address setting. Use the “UP” (▲) and “DOWN” (▼) buttons to change the setting.

Press the “ENTER” button ( ) to store your setting and to exit. Press the “DOWN”

(▼) button to continue.

CAnb CAN network baud rate. This is R/W parameter. Use the “UP” (▲) and “DOWN”

(▼) buttons to change the setting. Select setting “500” and press the “ENTER”

button ( ) to store your setting and to exit. Press the “DOWN” (▼) button to

continue.

1000 1000Kb baud rate

_800 800Kb baud rate

_500 500Kb baud rate

_250 250Kb baud rate

_125 125Kb baud rate

__50 50Kb baud rate

__20 20Kb baud rate

__10 10Kb baud rate

Hx.xx Drive Hardware Revision (ex. H1.01). Read only press the “DOWN” (▼) button to

continue.

Fx.xx Drive Firmware Revision (Version F1.12 or greater required for CANOPEN

Network). Read only. Press the “DOWN” (▼) button to continue.

OPEr Drive Operating Mode. This is a R/W parameter. Use the “UP” (▲) and “DOWN”

(▼) buttons to change the setting. Select either CAnV (CANBUS Velocity Mode)

or CAnt (CANBUS Torque Mode). Press the “ENTER” button ( ) to store your

setting and to exit. Press the “DOWN” (▼) button to continue.

POS_ Position Mode

uEL_ Velocity Mode

torq Torque Mode

CAnu CANBUS Velocity Mode

CAnt CANBUS Torque Mode

t-uL Velocity Limited Torque Mode.

bAud E94 Drive Baud Rate. This Baud Rate is only for RS232/RS485 communications.

It doesn’t affect the CANBUS Network. This is R/W parameter. Use the “UP” (▲)

and “DOWN” (▼) buttons to change the setting. Select setting “38.4” and press the

“ENTER” button ( ) to store your setting and to exit. Press the “DOWN” (▼) button

to continue.

_38.4 8400 bits per second

_19.2 19200 bits per second

__9.6 9600 bits per second

ENGLISH

ENGLISH

5

5

Page 8

Technical Data

Adr_ E94 Drive address. This address is only for RS232/RS485 communications. It

doesn’t affect the CANBUS Network. This parameter is R/W and can be between 0

and 31. Press the “ENTER” button ( ) to view address setting. Use the “UP” (▲)

and “DOWN” (▼) buttons to change the setting. Press the “ENTER” button ( ) to

store your setting and to exit. Press the “DOWN” (▼) button to continue.

FLtS E94 Drive Fault History. This parameter is Read only. Press the “ENTER” button (

) to view. Use the “UP” (▲) and “DOWN” (▼) buttons to scroll through the fault

history. Press the “ENTER” button ( ) to exit. Press the “DOWN” (▼) button to

continue.

Ht__ E94 Drive Heatsink Temperature. This parameter is Read only and shows heatsink

temperature in °C if greater than 40°C. Otherwise the display show “LO” (low).

Press the “ENTER” button ( ) to view. Press the “ENTER” button ( ) again to

exit. Press the “DOWN” (▼) button to continue.

EnC_ E94 Drive Encoder Activity. This parameter is Read only and shows primary

encoder counts for encoder diagnostics activity. Press the “ENTER” button ( ) to

view. Press the “ENTER” button ( ) again to exit. Press the “DOWN” (▼) button

to continue.

HALL E94 Drive Hall Activity. This parameter is Read only and displays the motors Hall

sensor state. Press the “ENTER” button ( ) to view. Press the “ENTER” button (

) again to exit. Press the “DOWN” (▼) button to continue.

bUS_ E94 Drive DC Bus Voltage. This parameter is Read only and displays the DC bus

voltage value. Press the “ENTER” button ( ) to view. Press the “ENTER” button (

) again to exit. Press the “DOWN” (▼) button to continue.

CUrr E94 Drive Phase Current. This parameter is Read only and displays the current

value of the motors phase current (RMS) while the drive is enabled. If the drive is

disabled the display will show “diS”. Press the “ENTER” button ( ) to view. Press

the “ENTER” button ( ) again to exit. Press the “DOWN” (▼) button to continue.

ENGLISH

ENGLISH

6

6

Page 9

Communication Objects

4 CANopen DS301 Communication Profile Support

4.1 Supported NMT (Network Management) services:

The E94 Drive automatically goes to an Operational state upon reset without waiting for the

Start Node command from the NMT master.

• Start Node – Upon receiving this service request from the NMT master the drive will

resume operation. This only is applicable when the drive is in the Stopped state. The

drive resumes its move and its CANopen SDO and PDO services are operational again.

• Stop Node – Upon receiving this service request the drive stops its motion and holds its

position. (Note: power is still applied to the motor) The drive also disables its CANopen

SDO and PDO services.

• Reset Node – Upon receiving this service request the drive will reset. If the drive is in

motion it executes a quick stop before it resets.

• Reset Communication – Resets the CAN communication driver.

4.2 The Heartbeat Error Control Service

The E94 Drive can be set up as a heartbeat producer. In this mode the drive will periodically

send out a heartbeat requests. The heartbeat producer time is stored in index 0x1017 in the

object dictionary as a multiple of 1 millisecond.

Value of 0 for the heartbeat producer time disables the heartbeat service.

ENGLISH

7

Page 10

Communication Objects

4.3 Communication Objects

OBJECT NAME DESCRIPTION

1000h Device Type The E94 Drive is not DSP 402 compliant but follows some

of the major velocity and torque profiles recommendations.

Therefore it uses custom device profile value of

0x00022192.

1001h Error Register The following values are allowed:

0 – NO error

1 – over voltage

2 – feedback error

3 – over current

4 – over temperature

5 – external fault detection

6 – over speed

7 – position error excess

8 – bad motor data

1008h Manufacturer Device Name Drive 94 uses the ‘SS94’ device name

1009h Manufacturer Hardware Version It is 0x94xx where xx is the current version number

100Ah Manufacturer Software Version It is 0x94xx where xx is the current version number

1017h Producer Heartbeat Time See 1.2 above

1018h Identity Object Vendor ID – 0x00456765

Product Code - 0x0000005E

1400h 1st receive PDO Parameter

(Torque)

1401h 2nd receive PDO Parameter

(Velocity)

1600h 1st receive PDO Mapping (Torque) Only the following static mapping is supported:

1601h 2nd receive PDO Mapping (Velocity) Only the following static mapping is supported:

Asynchronous PDO with 255 transmission type used only

if the drive is in CAN Torque mode. The target torque

update is triggered immediately upon receiving of this

RPDO.

Sub index 01 contains the RPDO COB-ID and has R/W

access. The default value of this COB-ID is 0x200 + CAN

network node id/address.

Asynchronous PDO with 255 transmission type and used

only if the drive is in CAN Velocity mode. The target

velocity update is triggered immediately upon receiving of

this RPDO.

Sub index 01 contains the RPDO COB-ID and has R/W

access. The default value of this COB-ID is 0x300 + CAN

network node id/address.

Sub index 01 -> 6040h Control word

Sub index 02 -> 6071h Target Torque

NOTE: This object is used only in CAN Torque mode

Sub index 01 -> 6040h Control word

Sub index 02 -> 60FFh Target Velocity

NOTE: This object is used only in CAN Velocity mode

ENGLISH

8

Page 11

Communication Objects

OBJECT NAME DESCRIPTION

1800h 1st transmit PDO Parameter

(Torque)

1801h 2nd transmit PDO Parameter

(Velocity)

1A00h 1st transmit PDO Mapping (Torque) Only the following static mapping is supported:

1A01h 2nd transmit PDO Mapping

(Velocity)

Sub index 01 -> TPDO COB-ID with R/W access. The

default value of this COB-ID is 0x180 + CAN network node

id/address.

Sub index 02 -> TPDO Type. Asynchronous TPDO with

255 transmission type.

Sub index 03 -> Inhibit Time in ms with R/W access. The

TPDO cannot be transmitted before the time set in this

parameter elapses.

Value of 0 disables this functionality.

Sub index 03 -> Event Timer in ms with R/W access. The

TPDO will be sent when the time set in this parameter

elapses whether or not an occurrence of the event

associated with this TPDO is detected.

NOTE: This TPDO is used in CAN Torque Mode only.

Inhibit Time & Event Time cannot both be 0 at the same

time.

Sub index 01 -> TPDO COB-ID with R/W access. The

default value of this COB-ID is 0x180 + CAN network node

id/address.

Sub index 02 -> TPDO Type. Asynchronous TPDO with

255 transmission type.

Sub index 03 -> Inhibit Time in ms with R/W access. The

TPDO cannot be transmitted before the time set in this

parameter elapses.

Value of 0 disables this functionality.

Sub index 03 -> Event Timer in ms with R/W access. The

TPDO will be sent when the time set in this parameter

elapses whether or not an occurrence of the event

associated with this TPDO is detected.

NOTE: This TPDO is used in CAN Velocity Mode only.

Inhibit Time & Event Time cannot both be 0 at the same

time.

Sub index 01 -> 6041h Status word

Sub index 02 -> 6077h Torque Actual Value

NOTE: This object is used only in CAN Torque mode

Only the following static mapping is supported:

Sub index 01 -> 6041h Status word

Sub index 02 -> 606Ch Velocity Actual Value

NOTE: This object is used only in CAN Velocity mode

ENGLISH

9

Page 12

Drive Objects

5. Drive 94 Specific Objects and functionality

When using the CANopen protocol the E94 drive has two modes of operation.

• CAN Velocity Mode

• CAN Torque Mode.

5.1 CAN Velocity mode

The Velocity reference is provided internally through the Object 60FFh (Target Velocity)

statically mapped in RPDO2. Commands can be sent to the drive through the Object 6040h

(Control Word) also statically mapped in RPDO2.

Please see the Object 6040h (Control Word) description below for the available

commands.

The CANopen network master should use the RPDO2 service to provide Target Velocity

and Control Commands to the drive.

The E94 Drive uses TPDO2 to send to the master status information through the Object

6041h Status word and the current velocity value through the Object 606Ch Velocity

Actual Value. Please see the Object 6041h Status word description below for the

available status information.

The drive94V.eds file is provided for usage by the CANopen master when the drive is in

CAN Velocity mode.

5.2 CAN Torque mode

The Torque reference is provided internally through the Object 6071h (Target Torque)

statically mapped in RPDO1. Commands can be sent to the drive through the Object 6040h

(Control Word) also statically mapped in RPDO2.

Please see the Object 6040h (Control Word) description below for the available

commands.

The CANopen network master should use the RPDO1 service to provide Target Torque and

Control Commands to the drive.

Drive 94 uses TPDO1 to send to the master status information through the Object 6041h

Status word and the current velocity value through the Object 6077h Torque Actual

Value. Please see the Object 6041h Status word description below for the available status

information.

The drive94T.eds file is provided for usage by the CANOpen master when the drive is in

CAN Torque mode.

ENGLISH

10

Page 13

Drive Objects

5.3 E94 Drive specific objects

Please see the provided drive94T.eds and drive94V.eds files and the SimpleServo Model 94 Users

Manual for a more complete description of all SDO objects and for setup instructions.

OBJECT NAME TYPE

6040h Control Word WORD The drive can execute the following

commands:

2 – Quick Stop

3 – Enable Drive

4 – Disable Drive

5 – Fault Reset

6 - Continue

6041h Status Word WORD Two bytes status is provided with the

following meaning:

Bit 0 - RUN indication

Bit 1 - Velocity in speed window

Bit 3 - Drive at fault

Bit 5 - Zero velocity reached

Bit 8 - Under voltage

Bit 11 - Regen indication

Bit 13 - Current limit reached

6071h Target Torque Float This object provides the Torque

reference in Amperes (A) to the DSP.

NOTE: This object is used only in CAN

Torque mode

6077h Torque Actual Value Float This object represents the actual Torque

value in Amperes (A) retrieved from the

DSP.

NOTE: This object is used only in CAN

Torque mode

60FFh Target Velocity Float This object provides the Velocity

reference in RPM to the DSP.

NOTE: This object is used only in CAN

Velocity mode

606Ch Velocity Actual Value Float This object represents the actual

Velocity value in RPM retrieved from the

DSP.

NOTE: This object is used only in CAN

Velocity mode

ENGLISH

11

Page 14

OBJECT NAME TYPE

6402h TorqueConst Float

6403h VoltageConst Float

6404h Inductance Float

6405h Resistance Float

6406h MaxPhaseCurrent Float

6407h TerminalVoltage WORD

6408h RotorInertia Float

6409h MaxVelocity Float

640Ah HallCode WORD

640Bh NumberPoles WORD

640Ch Encoder WORD

640Dh CurrentLimit Float

640Eh PeakCurrentLimit Float

640Fh InvertAnalogInput BYTE

6410h CurrentAnalogInput Float

6411h VelocityAnalogInput Float

6412h AccDecFlag BYTE

6413h AccelLimit Float

6414h DecelLimit Float

6415h StepRevolution WORD

6416h StepInputType BYTE

6417h AnalogOutput BYTE

6418h CurrentScale Float

6419h VelocityScale Float

641Ah AnalogBand WORD

641Bh AnalogOffset WORD

641Ch ZeroSpeed WORD

641Dh SpeedWindow WORD

641Eh AtSpeed WORD

641Fh PosErr Float

6420h MaxErrTime WORD

6421h VelPGain WORD

6422h VelIGain WORD

6423h PosPGain WORD

6424h PosIGain Float

6425h DGain WORD

6426h VFFGain Float

6427h ILimit WORD

6428h FaultReset BYTE

6429h FeedbackLoss BYTE

642Ah In2Func BYTE

Drive Objects

ENGLISH

12

Page 15

OBJECT NAME TYPE

642Bh In2Polarity BYTE

642Ch InBounceDelay input1 WORD

642Dh InBounceDelay input2 WORD

642Eh OutFunc output1 BYTE

642Fh OutFunc output2 BYTE

6430h OutPolarity output1 BYTE

6431h OutPolarity output2 BYTE

6432h Eset UNSIGNED WORD

6433h FeedbackType UNSIGNED WORD

6434h PwmIndex UNSIGNED BYTE

6435h GearRatioTop UNSIGNED WORD

6436h GearRatioBottom UNSIGNED WORD

6437h ReferenceType UNSIGNED BYTE

6438h MotorTempSensorResistance UNSIGNED WORD

6439h MotorTempSensorEnable UNSIGNED BYTE

6440h RegenDutyCycle UNSIGNED WORD

6441h EncoderRepeatSource UNSIGNED BYTE

6442h TorqueVelocityLimit FLOAT

6443h SeGearRatioTop SIGNED WORD

6444h SeGearRatioBottom UNSIGNED WORD

6445h SeEnable UNSIGNED BYTE

6446h SeIGain FLOAT

6447h SePosErr UNSIGNED WORD

6448h SeMaxErrTime FLOAT

6449h VelocityRegWnd SIGNED WORD

6450h LowPeakCurrentLimit FLOAT

6451h CANOperationalState UNSIGNED BYTE

6452h CANStartNodeDelay UNSIGNED BYTE

Drive Objects

ENGLISH

13

Page 16

l

AC Technology Corporation

member of the Lenze Group

630 Douglas Street

Uxbridge, MA 01569

Telephone: (508) 278-9100

Facsimile: (508) 278-7873

Doc ID: S94CAN01A

Loading...

Loading...