Page 1

COPY

105

4

EP01E

- en

EN

Operating Instructions

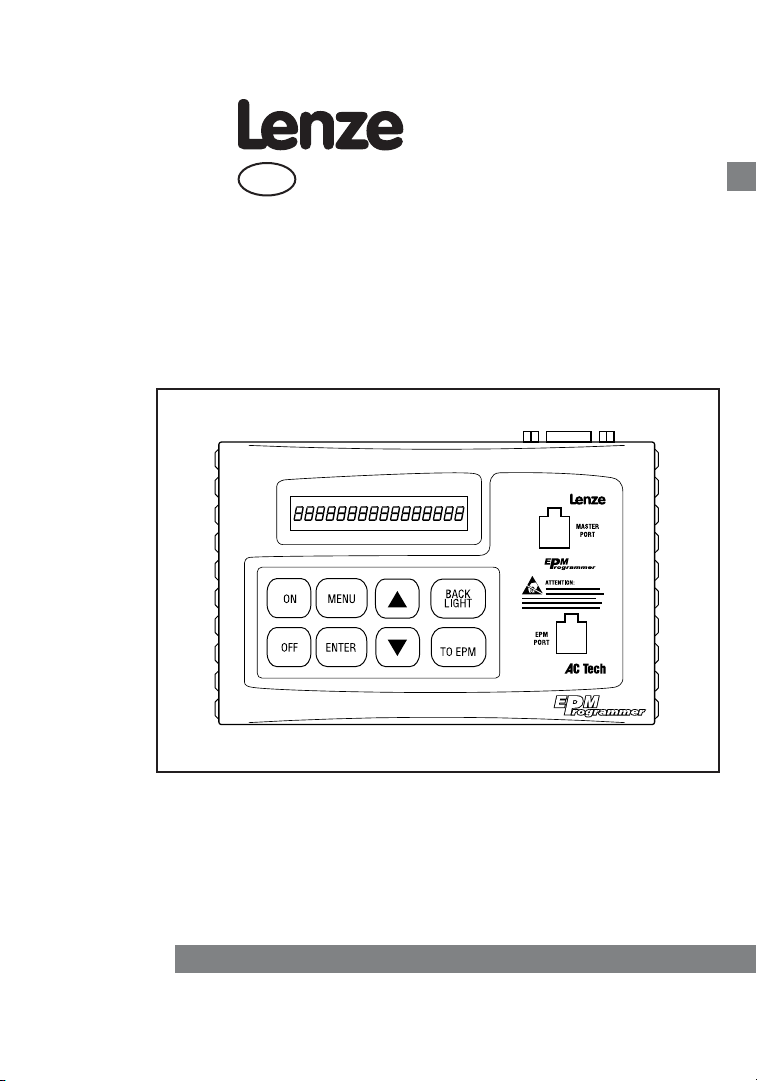

EPM Programmer EEPM1RA

epm001

Page 2

© 2004 Lenze gmbH & C0 KG

No part of this documentation may be copied or made available to third parties without the explicit written approval

of Lenze GmbH & Co KG.

All information given in this documentation has been carefully selected and tested for compliance with the hardware

and software described. Nevertheless, discrepancies cannot be ruled out. We do not accept any responsibility nor

liability for damages that may occur. Any necessary corrections will be implemented in subsequent editions.

Page 3

Contents

1 Prefaceandgeneralinformation....................................................2

1.1 AbouttheseOperatingInstructions.......................................................................2

1.2 Terminologyused..................................................................................................2

EPMTechnologyandOperation............................................................................3

1.3

PictographsusedintheseOperatingInstructions................................................3

1.4

Scopeofdelivery...................................................................................................3

1.5

2 Technicaldata..................................................................................4

2.1 Generaldataandapplicationconditions..............................................................4

2.2 ElectricalData........................................................................................................4

2.3 Dimensions............................................................................................................5

3 Commissioning................................................................................6

3.1 BatteryOperation...................................................................................................6

3.2 ChangingBatteries................................................................................................6

Operationwithexternalpowersupply...................................................................7

3.3

4 Operation..........................................................................................8

4.1 Overviewofoperatingelements............................................................................8

4.2 KeyFunctions........................................................................................................8

Switchon/offEPMProgrammer.............................................................................9

4.3

SelectLanguage..................................................................................................10

4.4

Switchon/offdisplaybackgroundillumination....................................................10

4.5

MenuOverview....................................................................................................11

4.6

CopyfromoneEPMtoanotherEPM...................................................................12

4.7

CopyalestoredintheProgrammertoanEPM................................................13

4.8

EdittheEPM........................................................................................................14

4.9

EditalestoredintheProgrammer....................................................................15

4.10

Createanewle..................................................................................................16

4.11

DeletealestoredintheProgrammer................................................................17

4.12

ChangeEPMProgrammerInternalConguration...............................................17

4.13

Contrastsetting....................................................................................................18

4.14

Displaystatusmessages.....................................................................................18

4.15

Enter/changepassword.......................................................................................19

4.16

5 Troubleshooting.............................................................................20

5.1 Errormessages....................................................................................................20

ENGLISH

1

Page 4

Preface and general information

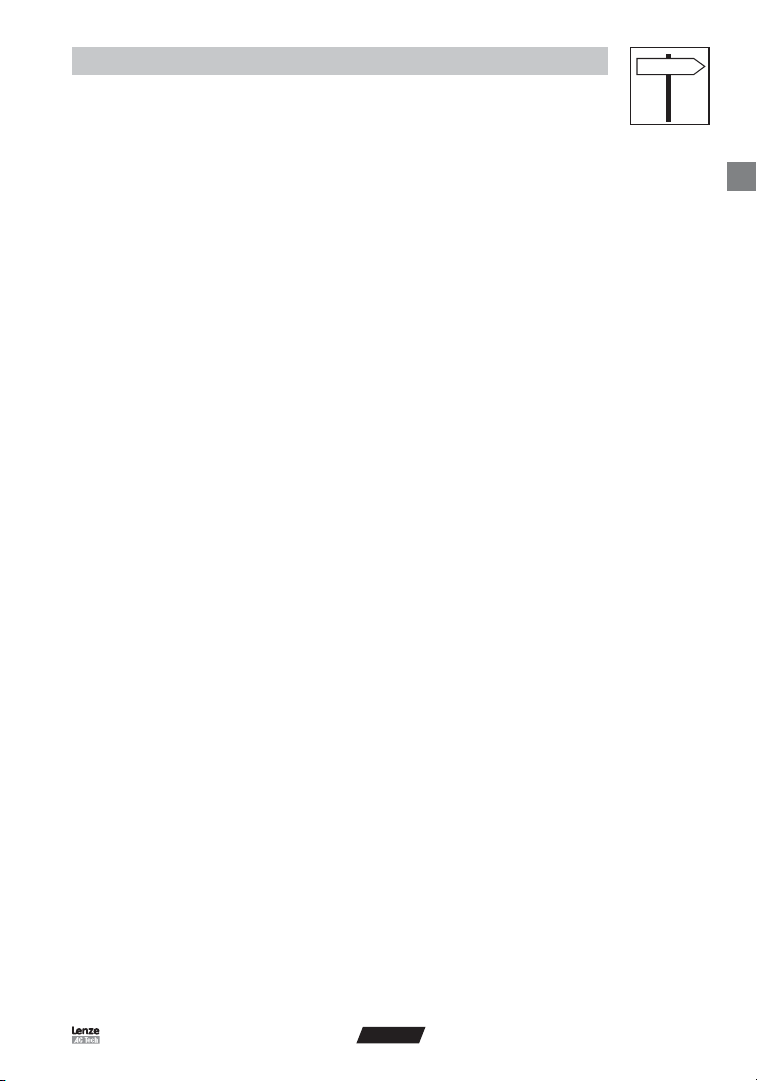

Type: EEPM1RA

For detailed nformation refer

to instruction manual EP01x

EEMP1RA 1A 10

Made in USA

EPM Programmer

L

LISTED

ND

CONT EQ

5D81

xxxxx xx xx

6VDC 150mA min

Power Suppy

(FRIWO 7207/06 15 0791 MPP15)

A B C

1 Preface and general information

The EEPM1RA EPM programmer enables you to easily duplicate and archive the memory and configuration of inverter

drives and servo controllers that utilize the EPM feature.

The EEPM1RA EPM programmer enables you to:

• copy the contents of one EPM to another EPM,

• read out contents of EPMs and save them to a PC or the EPM programmer as files,

• edit files stored in the EPM programmer,

• store edited files under another file name and create new files,

• copy files stored in the EPM programmer into EPMs.

1.1 About these Operating Instructions

This documentation applies to the EPM Programmer as of version:

epm010

A

Type EEPM1RA

B

Hardware version 1A

C

Software version 10

• These Operating Instructions are designed to ensure safe and trouble-free working with the EEPM1RA EPM

programmer.

• Before you start working with the EEPM1RA EPM programmer, please read the Operating Instructions carefully and

follow the notes.

• These Operating Instructions must always be kept as a complete legible document.

1.2 Terminology used

Term Meaning in this document

Drive controller Lenze - AC Tech submicro frequency inverter

Servo controller Lenze - AC Tech SimpleServo, PositionServo

2

ENGLISH

Page 5

Preface and general information

1.3 EPM Technology and Operation

The EPM uses EEPROM technology housed in a removable plastic

casing for protection and ruggedness. A removable memory

structure, as provided by an EPM include:

• Programming a drive without power.

• Easily duplicate proven programs using the EPM Programmer.

• Reduce down-time and troubleshooting.

The EPM feature is included with several Lenze and AC Tech inverter

drive controllers and in the new SimpleServo products. Operation and

some functionality differ between the Drive and Servo product lines.

Drive Controllers

Servo Controllers

OEM Defaults

The EPM, when used in Inverter Drive Controllers, actually contains two sets of drive parameters. The USER memory is

the memory the drive typically uses for operation and is actually the drives operating memory that can be accessed and

changed from the front of the drive, a remote keypad or serial communications. The OEM Default values can only be written

by the EPM Programmer and cannot be altered through normal drive operation or programming. This provides a benefit

in that an OEM using the EPM Programmer to quickly copy the drive configuration, actually ships the drive with their own

“Factory Defaults”.

Lenze Servo Controllers are programmed using MotionView94 Software via serial link with a PC. Field reprogramming from the

front of the controller is not possible. As such, resetting to OEM defaults is impossible and this second memory set is not used.

1.4 Pictographs used in these Operating Instructions

Pictograph used Signal words

Stop! Warns of possible malfunctions of the EPM Programmer due to

EPM Color: Blue

EPM files can be stored in EPM Programmer

EPM Color: Blue (Model 94)

EPM files cannot be stored in EPM Programmer

electrostatic discharge (ESD)

epm011

1.5 Scope of delivery

Scope of delivery Important

• 1 EEPM1RA EPM programmer with 4 batteries (already

installed)

•

1 Operating Instructions

Tip! Designates a general and useful note. If observed, it will make using the

EPM Programmer easier.

After receipt of the delivery, check immediately whether

the items delivered match the accompanying papers.

Lenze does not accept any liability for deficiencies claimed

subsequently.

Claim

•

visible transport damage immediately to the forwarder.

• visible deficiencies / incompleteness immediately to

your Lenze representative.

ENGLISH

3

Page 6

Technical data

2 Technical data

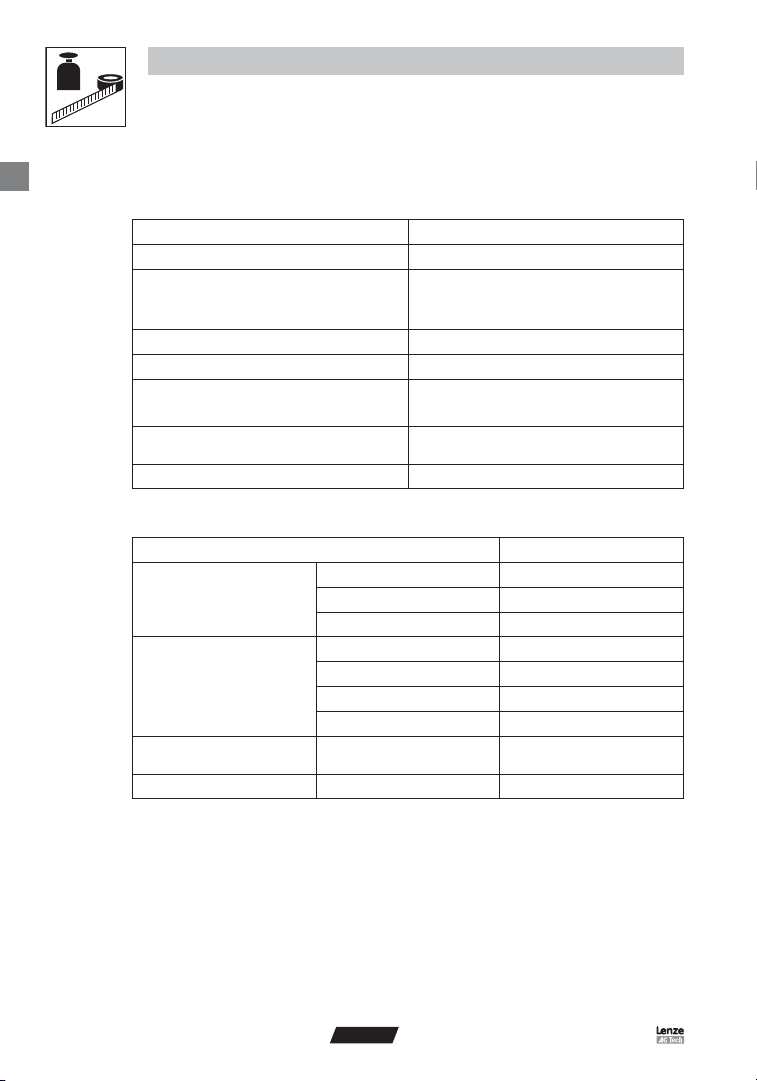

2.1 General data and application conditions

Field Values

Type of Protection IP20

Permissible temperature ratings Operation

Humidity <85 %, without condensation

Weight 1.3 kg with batteries

Applied Standards Noise emission to EN 50081-2: 1993

Approvals UL 508C

Conformity CE

2.2 Electrical Data

Field Values

DC Voltage Supply + 6 VDC, min. 150 mA

Internal Batteries 4 mono-cells (type D), 1.5 VDC each

External power supply unit + 6 VDC, 300 mA

Display Type LCD

Display format Text

Lines x characters 1 x 16

Contrast setting Via menu

Memory Data Memory up to 120 parameter files for inverter

Serial Interface DB9 Connector RS232

Transport -20 … +60 °C

Storage -20 … +60 °C

Noise immunity to EN 61000-6-2 : 1999

Power Conversion Equipment

EMC Directive (89/336/CEE)

0 … +50 °C

Underwriters Laboratories

drive controllers

4

ENGLISH

Page 7

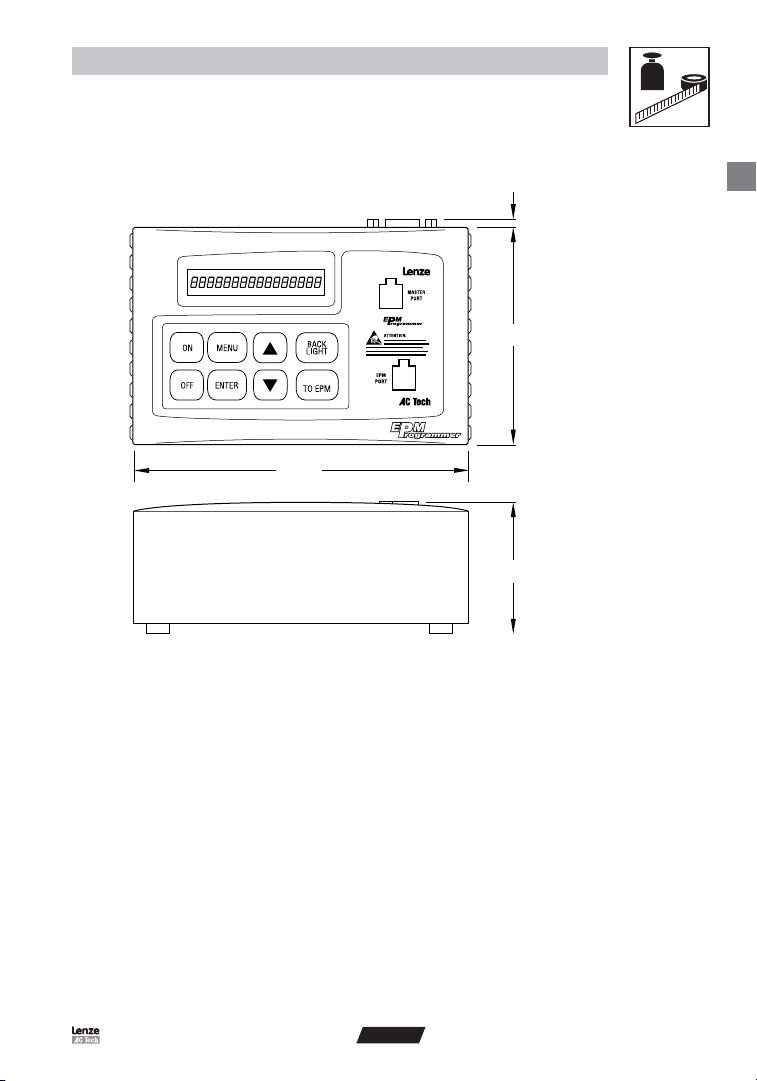

2.3 Dimensions

COPY

105

76

155

4

Technical data

Dimensions in mm

ENGLISH

epm001

5

Page 8

Commissioning

3 Commissioning

3.1 Battery Operation

The EPM programmer is immediately ready for operation. It is delivered with 4 batteries

(1.5 V mono-cells).

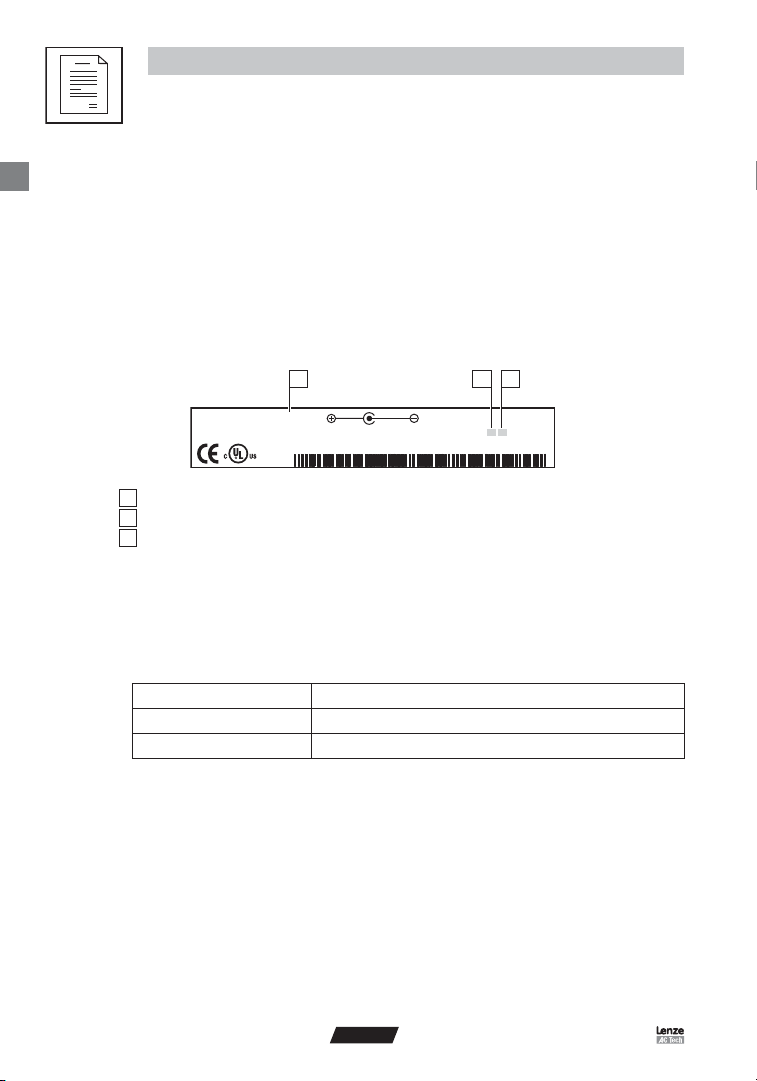

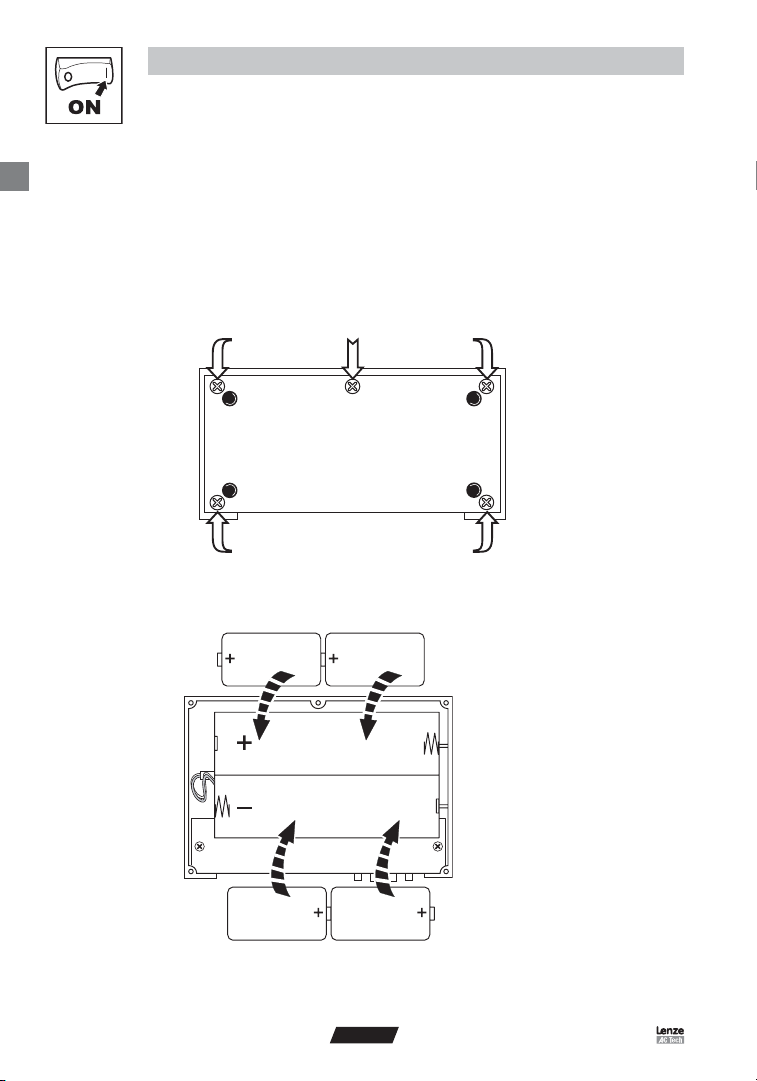

3.2 Changing Batteries

For battery operation you need four mono-cell (D size) with 1.5V each. In order to access the battery compartment, you

must open the housing of the EPM programmer.

Open the battery compartment of the EPM programmer

1. Remove the 5 screws on the bottom of the EPM programmer

2. Remove the EPM Programmer base plate carefully.

epm004

Insert the batteries into the battery compartment

1. Insert the batteries into the battery compartment as shown in figure above.

- Pay attention to the correct polarity of the batteries!

2. Replace the base plate carefully and secure the housing with the 5 screws.

6

epm007

ENGLISH

Page 9

Commissioning

A

Type EEPM1RA

For detaled nformation refer

to nstruction manual EP01x

EEMP1RA 1A 10

Made in USA

EPM Programmer

L

LSTED

IND

CONT EQ

5D81

xxxxx xx xx

6VDC 150mA min

Power Supply

FRIWO 720706 15 0791 MPP15)

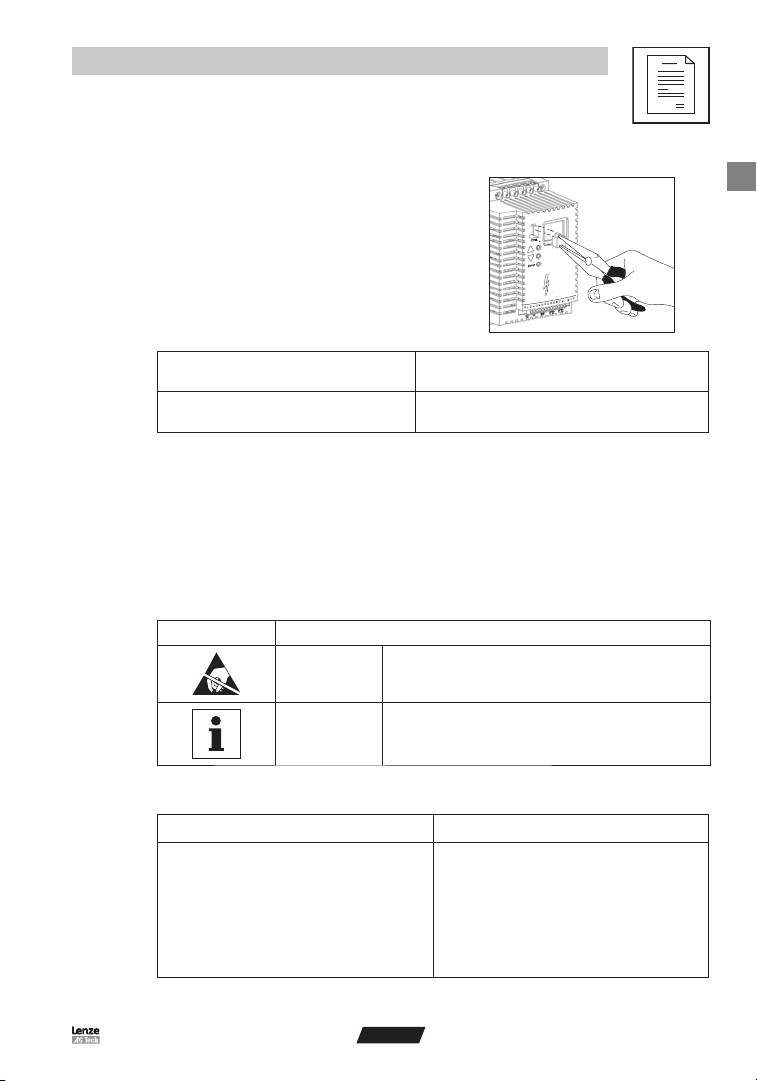

3.3 Operation with external power supply

Stop!

• Avoid electrostatic discharges (ESD) at the connector for the voltage supply. EPM programmer malfunction

may occur.

• Take appropriate measures to avoid electrostatic conditions.

• Occasionally occurring malfunctions can normally be remedied by switching the EPM Programmer off and then

on again.

It is also possible to operate the EPM programmer with an external power supply.

Power supply output data:

• Output voltage: 6 VDC, stabilized

• Output current: 300 mA

Power supply connector plug details

For connections to the EPM programmer the power supply

unit requires an extra-low voltage plug with the following

+6 VDC

–

Connect the power supply unit

dimensions: 2.1 × 5.5 × 9.5 mm.

epm005

Plug the extra-low voltage plug of the power supply into the A connector at the back of the EPM Programmer

ENGLISH

epm006

7

Page 10

4 Operation

COPY

ON

OFF

MENU

ENTER

BACK

LIGHT

COPY

TO EPM

Operation

4.1 Overview of operating elements

epm001

4.2 Key Functions

Key Level Function

Switch on EPM programmer

Switch off EPM programmer

Menu level: Select menu, quit submenu

Parameter level: Return to the main menu without saving changes

Menu level: Select submenu, execute menu command

Parameter level: Select parameter to enter a value, accept a value entered

Menu level: Select submenu/file

Parameter level: Enter a higher value

Menu level: Select submenu/file

Parameter level: Enter a lower value

Display

MASTER PORT

Plug-in-station for EPM from which the data is to be read.

EPM Port

Plug-in-station for EPM memory chip on which the data is to

be written.

Operator Keypad

Switch on/off background illumination for the display

Copy data to EPM PORT

8

ENGLISH

Page 11

4.3 Switch on/off EPM Programmer

ON

ENTER

OFF

Switch-onwithunprotectedaccess(withoutpassword)

Press The display shows... Explanation

1.

2.

3.

4.

Switch-onwithprotectedaccess(withpassword)

Steps 1…4 as above ( Section 4.16, Enter/change password)

Press The display shows... Explanation

5.

6.

EPM PROGRAMMER

INTERN CFG 400

MASTER CFG 400

MSTFILE#DEFAULTS

MASTER MISSING!

PASSWORD?? 000

PASSWORD?? xxxx

0

Operation

Shows the parameter version that the EPM

programmer is configured with (e.g. 400).

Shows the parameter version of the EPM (e.g. 400)

plugged into the MASTER PORT.

Shows the name of the parameter file (e.g.

DEFAULTS) stored in the EPM plugged into the

MASTER PORT.

This message is displayed, if no EPM is plugged

into the MASTER PORT.

The cursor is blinking in the display on the right.

Enter the password

If you do not enter a password, you have restricted

access to the main menus after confirmation (only

the menus CONTRAST, DISPLAY, and MASTER –>

EPM are available).

If you enter a wrong password, WRONG

PASSWORD will be displayed. If you press the

MENU key, you abort the process and get the

restricted access to the main menus.

using the buttons.

Tip!

• After the initialization, the main menu shown last is automatically called up.

• If you lose or forget your password, please contact your Lenze representative.

Switch-off

Press The display shows... Explanation

1.

Tip!

• The EPM programmer automatically turns off after 5 minutes, if no operation takes place during this time.

SHUTDOWN.. 5SEC

The shutdown process takes 5 seconds.

If you press any key within these 5 seconds, the

shutdown process is aborted

ENGLISH

9

Page 12

Operation

ON

BACK

LIGHT

BACK

LIGHT

4.4 Select Language

You can choose between English, German, French, Italian and Spanish languages.

• The language change over can be carried out on the menu level and parameter level.

• The language set remains stored even after switching off the EPM Programmer.

Press The display shows... Explanation

1.

Tip!

• Languages are a part of the product “Configuration File”. If, when changing the internal configuration (section

4.13), the new configuration file does not contain the selected language, English will be displayed.

4.5 Switch on/off display background illumination

Press The display shows... Explanation

1.

Press and hold the ON button. The languages will

scroll in 5 second intervals in the sequence: English,

German, French, Italian, Spanish. Release ON

button when desired language is displayed.

The background illumination is switched on.

10

2.

Tip!

• If you operate the EPM programmer with a power supply unit, the background illumination will always be

switched on.

The background illumination is switched off.

ENGLISH

Page 13

Operation

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

4.6 Menu Overview

After power is switched on and the initialization screens have been displayed, the primary functions of the EPM Programmer

are accessed by pressing the MENU button.

MASTER –> EPM

FILE –> EPM

EDIT EPM

EDIT FILE

CREATE NEW FILE

DELETE FILE

LOAD CFG EPM

DISPLAY CONTRAST

MISCELLANEOUS

Tip!

• When copying to an EPM using MASTER->EPM or FILE->EPM, all data on the target EPM will be overwritten.

SECTION 4.7

SECTION 4.8

SECTION 4.9 (servo config. only)

SECTION 4.10

SECTION 4.11

SECTION 4.12

SECTION 4.13

SECTION 4.14

SECTION 4.15

ENGLISH

11

Page 14

Operation

MENU

ENTER

COPY

TO EPM

ENTER

MENU

4.7 Copy from one EPM to another EPM

With this function it is possible to copy a parameter file directly from one EPM (a “Master”) to another EPM.

• Plug the EPM containing the parameter file you want to copy into the MASTER PORT.

• Plug the EPM, to which you want to copy the parameter file, into the EPM PORT.

Press The display shows... Explanation

1.

MASTER –> EPM

Press the key until the menu appears in the display.

2.

3.

#DEFAULTS(400)>>

TRANSFERRING 0%

DAT=400 EPM=312

4.

CONFIRM= [ENTER]

TRANSFERRING 100%

The name of the parameter file (e.g. DEFAULTS)

of the EPM in the MASTER PORT is displayed.

The parameter version of the file is shown in

parenthesis.

The parameter file is copied or..

...if the parameter version of the file does not

correspond with the parameter version of the EPM

in the EPM PORT,...

...a security check takes place concerning the

existing data on the EPM:

Press the ENTER key to overwrite the existing data.

Press the MENU key, if you want to abort the

process.

The parameter file will be copied.

#DEFAULTS(400)>>

5.

Tip!

• The file name on the MASTER EPM, is only displayed if the user parameters exactly match the OEM Default

parameters ( see Section 1.3, EPM Technology and Operation).

• If the user and OEM memory areas do NOT match, the name of the parameter file of the EPM in the MASTER

PORT will be displayed as #********(400)>>. This indicates that the user parameters have been changed

from the OEM defaults or the Factory Defaults.

• Copy from MASTER -> EPM will copy only the user parameter file from the MASTER and save this to both the

user and OEM memory locations of the EPM in the EPM PORT. The parameter file name of the new EPM will be

displayed as #????????(400)>>.

• Servo controllers do not store OEM defaults, so the parameter file name in the master will always be displayed

as ********(16384)>.

MASTER –> EPM

Returns to the main menu.

12

ENGLISH

Page 15

Operation

MENU

ENTER

ENTER

COPY

TO EPM

ENTER

MENU

4.8 Copy a file stored in the Programmer to an EPM

With this function it is possible to copy a parameter file saved in the EPM programmer to an EPM.

• Plug the EPM, to which you want to copy the parameter file, into the EPM PORT.

Press The display shows... Explanation

1.

FILE –> EPM

Press the key until the menu appears in the display.

The stored name of a parameter file (e.g. DEFAULTS)

stored in the EPM programmer, is displayed.

The cursor is blinking in the display on the right.

Select the parameter file you want to copy (e.g.

ABC_ _ _ _ _).

The parameter file is copied or..

...if the parameter version of the file does not

correspond with the parameter version of the EPM

in the EPM PORT,...

...a security check takes place concerning the

existing data on the EPM:

Press the ENTER key to overwrite the existing data.

Press the MENU key, if you want to abort the

process.

The parameter file will be copied.

#DEFAULTS(400)>>

#DEFAULTS(400

)

#ABC_ _ _ _ _(400

TRANSFERRING 0%

>>

)

>>

2.

3.

4.

5.

DAT=400 EPM=312

CONFIRM= [ENTER]

6.

TRANSFERRING 100%

#ABC_ _ _ _ _(400)>>

7.

FILE –> EPM

Returns to the main menu.

ENGLISH

13

Page 16

Operation

MENU

ENTER

ENTER

ENTER

ENTER

MENU

4.9 Edit the EPM

This menu item is only displayed when the EPM Programmer is configured for a Servo product.

With this function it is possible to edit PPP BAUDRATE, NETWORK ADDRESS, CAN NODE ID, and CAN BAUDRATE

for Model 94 Servo drives.

Press The display shows... Explanation

1.

EDIT EPM

Press the key until the menu appears in the display.

2.

EPM INFO

********(16384)>

CAN NODE ID

NETWORK ADDRESS

NET ADDR 3

NET ADDR

NETWORK ADDRESS

1

5

3.

4.

EDIT EPM

Tip!

• The EPM can only be edited if the configuration of the EPM Programmer and the parameter version of the EPM

are identical. See section 4.13 for changing the configuration of the EPM Programmer.

This request is briefly shown in the display.

The EPM parameter version is displayed.

Displays the parameters that can be edited

Select the parameter file you want to Edit

(NETWORK ADDRESS is shown as an example)

The cursor is blinking in the display on the right

Change the parameter

Stores the new value onto the EPM

Returns to the main menu.

14

ENGLISH

Page 17

Operation

MENU

ENTER

ENTER

MENU

4.10 Edit a file stored in the Programmer

With this function it is possible to edit an Inverter Drive controller parameter file stored in the EPM programmer.

Press The display shows... Explanation

1.

EDIT FILE

Press the key until the menu appears in the display.

2.

3.

SELECT FILE

>#DEFAULTS (400

>#ABC_ _ _ _ _(400

<

)

)

<

4.

:DATA FILE NAME

A

:MOP SAVED FREQ

B

or

:KEYPAD SPEED

B

:DIRECTION

C

X:PARAMETER

X

EDIT FILE

Tip!

• The parameter file DEFAULTS is write protected.

- If you want DEFAULTS to be the basis for editing, create a copy of this file (see section 4.11).

• A file can only be edited if the configuration of the EPM Programmer and the parameter version of the file

(shown in parenthesis) are identical. If these two are not the same, this will result in the error message

FILE VER INCOMP! See section 4.13 for changing the configuration of the EPM Programmer.

This request is briefly shown in the display.

The cursor is blinking in the display on the right.

The file name of a parameter file (e.g. DEFAULTS)

is displayed.

Select the parameter file you want to edit

(e.g. ABC_ _ _ _ _).

The cursor is blinking in the display on the left.

The first entry which can be edited is displayed (e.g.

DATA FILE NAME).

Press ENTER to edit the file name:

• Use buttons to change letters

• Use ENTER to move to next letter

• Pressing ENTER at the last character stores

the name, press MENU to abort

This parameter sets the initial run speed when the

speed source is either MOP or KEYPAD.

Press ENTER to access and

Selects default direction for the motor when

controlled by a remote keypad.

Sequence through the parameters available for the

configuration loaded into the programmer.

Press ENTER to edit the parameter:

• Use buttons to change selection or value

• Press ENTER to store the new value or press

MENU to abort

to adjust.

Returns to the main menu.

ENGLISH

15

Page 18

Operation

MENU

ENTER

ENTER

ENTER

ENTER

ENTER

4.11 Create a new file

With this function you create a new parameter file in the EPM programmer. Data for your new file can be copied from the

following sources:

• Parameter files available on the EPM programmer.

• Parameter file from an EPM mounted in the MASTER PORT.

Press The display shows... Explanation

1.

CREATE NEW FILE

Press the key until the menu appears in the display.

2.

3.

4.

5.

6.

7.

8.

9.

10.

ENTER FILE NAME

NAME:=_ _ _ _ _ _ _

NAME:A_ _ _ _ _ _ _

NAME: A=_ _ _ _ _ _

NAME: ABC=_ _ _ _

NAME: ABC_ _ _ _

=

COPY DATA FROM..

1) FIL

E

SELECT FILE

>#DEFAULTS(400

>#ABC_ _ _ _ _(400

<

)

<

)

TRANSFERRING 100%

This request is briefly shown in the display

The cursor is positioned under the first character

of the file name.

A file name can consist of 8 characters maximum.

Use the buttons to select a value. To scroll

quickly to a value, keep the key pressed. The scroll

rate increases as you hold the button.

The cursor is positioned under the next character

of the file name.

Repeat step 3. until the desired name is entered.

Press ENTER until the cursor is positioned on the

eighth character position. If you re-press ENTER,

the file name is stored.

Press MENU at any time to abort the file creation

and return to the main menu.

The cursor is blinking in the display on the right.

Select a source (e.g FILE) whose parameters you

want to copy into your new file:

1) FILE

2) MASTER

(this message is not displayed when selecting

MASTER and steps 8 and 9 are skipped)

The cursor is blinking in the display on the right.

Select a parameter file you want to copy

(e.g. ABC_ _ _ _ _). Press the MENU key, if you

want to abort this proceedure.

The new file has been created.

16

FILE CREATED!

CREATE NEW FILE

ENGLISH

The EPM programmer automatically returns to the

main menu.

Page 19

4.12 Delete a file stored in the Programmer

MENU

ENTER

ENTER

ENTER

MENU

ENTER

ENTER

With this function you delete the parameter files stored in the EPM Programmer

Press The display shows... Explanation

1.

DELETE FILE

Press the key until the menu appears in the display.

Operation

2.

3.

4.

5.

SELECT FILE

>#DEFAULTS(400

>#ABC_ _ _ _ _(400

CONFIRM=[ENTER]

DELETING FILE…

<

)

)

<

This request is briefly shown in the display

The cursor is blinking in the display on the right.

Select the parameter file you want to delete (e.g.

ABC_ _ _ _ _).

Press the MENU key, if you want to abort the

process.

The parameter file is deleted.

FILE DELETED!

DELETE FILE

The EPM programmer automatically returns to the

main menu.

4.13 Change EPM Programmer Internal Configuration

With this function, you can change the type of files that the EPM Programmer can EDIT by downloading the proper

configuration for the file you will be working with from a “Configuration EPM” loaded in the MASTER PORT.

Press The display shows... Explanation

1.

2.

LOAD CFG EPM

VERIFYING MASTER

CONFIRM=[ENTER]

3.

4.

TRANSFERRING 0%...100%

WAIT-LOADING CFG

CFG LOADED!

LOAD CFG EPM

Press the key until the menu appears in the display.

The programmer verifies that the EPM in the

MASTER PORT is a valid Configuration EPM.

Press the ENTER button to confirm this action

The new configuration is loaded into the EPM

Programmer’s memory and verified.

Messages are displayed briefly then the EPM

programmer automatically returns to the main

menu.

Tip!

• Changing the EPM Programmer’s internal configuration is only required if you are going to EDIT an inverter drive

file stored in the EPM Programmer or EDIT a servo drive EPM. The Programmer must be configured for the

parameter version of the file.

• Configuration EPM’s can be purchased from Lenze, AC Tech or your local distributor.

• Configuration files can be downloaded into the EPM Programmer from your PC via RS232 connection using

TECHLINK software.

ENGLISH

17

Page 20

Operation

ON

ENTER

ENTER

ENTER

MENU

MENU

ENTER

MENU

4.14 Contrast setting

With this function, you can adjust the viewing angle for the EPM Programmer display.

Press The display shows... Explanation

1.

DISPLAY CONTRAST

Press the key until the menu appears in the display.

2.

3.

4.

5.

6.

CONTRAST MEDIUM

CONTRAST MEDIU

CONTRAST XXXXX

CONTRAST LOW

DISPLAY CONTRAST

M

The currently set value is indicated (e.g. MEDIUM). .

The cursor is blinking in the display on the right.

Select the setting wanted:

CONTRAST LOW

CONTRAST MEDIUM

CONTRAST HIGH

The setting selected (e.g. LOW) is accepted. The

cursor stops blinking.

Returns to the main menu..

4.15 Display status messages

With this function, you can set the Programmer’s password and view other important information.

Press The display shows... Explanation

1.

2.

3.

4.

5.

6.

7.

8.

MISCELLANEOUS

/W VERSION X.XX

S

INTERN CFG 400

ILES: 1

F

ATTERY: 5.8VDC

B

ASSWORD: 0000

P

MISCELLANEOUS

Press the key until the menu appears in the display.

Takes you to the submenu. The software version

(e.g. 1.00) of the EPM programmer is displayed.

With the you can select the status messages.

Shows the parameter version that the EPM

programmer is configured for (e.g.400).

Indicates the number of parameter files saved in the

EPM programmer.

Displays the current voltage level of the 4 internal

batteries. To guarantee safe operation, the battery

voltage must not fall below 3.6 VDC.

Displays the set password for the access protection

(Lenze setting: 0000), entering and changing the

password is described in the next section.

Returns to the main menu.

18

ENGLISH

Page 21

Operation

MENU

ENTER

ENTER

ENTER

MENU

4.16 Enter/change password

When a password has been set, only the main menus can be accessed until the correct password has been entered.

• MASTER –> EPM

• DISPLAY CONTRAST

• MISCELLANEOUS (without the submenu PASSWORD).

Press The display shows... Explanation

1.

MISCELLANEOUS

Press the key until the menu appears in the display.

2.

3.

4.

5.

6.

7.

/W VERSION X.XX

S

ASSWORD: 0000

P

PASSWORD: 000

PASSWORD: XXX

ASSWORD: XXXX

P

MISCELLANEOUS

0

X

Takes you to the submenu. The cursor is blinking in

the display on the left.

Displays the set password for the access protection

(Factory setting: 0000).

When the password is set to 0000, the access

protection is deactivated.

The cursor is blinking in the display on the right.

Enter a password. Any value between 0000 and

9999.

Use the

buttons to select a value. To scroll

quickly to a value, keep the key pressed. The scroll

rate increases as you hold the button.

The cursor is blinking in the display on the left.

The new password has been stored.

Returns to the main menu.

ENGLISH

19

Page 22

Troubleshooting and fault elimination

5 Troubleshooting

5.1 Error messages

Display Cause Remedy

CHANGE BATTERY!

FILE VER INCOMP!

READ ONLY FILE!

EPM DAMAGED!

EPM MISSING!

EPM TOO SMALL!

INTERNAL ERROR!

INVALID INT CFG

WRONG PASSWORD

The battery voltage is <3.6V (the

message is displayed after switching

on the EPM programmer.

The parameter file or servo EPM

you are attempting to edit has a

different parameter version than

the configuration file of the EPM

programmer.

You have tried to edit or delete the file

DEFAULTS.

The EPM in the EPM PORT is

defective.

The EPM is not placed correctly in the

EPM PORT.

There is no EPM in the EPM PORT to

which you are attempting to transfer

data or edit..

EPM in EPM PORT does not have

sufficient memory for the file you are

attempting to copy.

Internal device error. Please contact your Lenze

The configuration file of the EPM

programmer is invalid.

Attempting to reconfigure the

EPM programmer without a valid

configuration EPM.

The access protection is activated and

you have entered the wrong password

after switch-on.

Change the batteries

( See Section 3.2)

You can only edit a file if the

parameter version corresponds to

the configuration file of the EPM

programmer.

See Section 4.13 on changing the

programmers internal configuration.

The file DEFAULTS cannot be edited

or deleted.

Exchange the defective EPM.

Plug the EPM correctly in the PORT.

Press the menu key now to return to

the main menu.

Plug an EPM in the EPM PORT.

Replace the EPM in the EPM PORT

with an EPM that has a higher memory

capacity.

representative.

Please contact your Lenze

representative.

Insert a valid configuration EPM into

the MASTER PORT. See section 4.13.

Only if you enter the correct password

will you have full access to the main

menus.

If you press the MENU key, the

process is aborted and you have only

restricted access to the main menus.

(see Section 4.16 )

If you have forgotten your

password, please contact your Lenze

representative.

20

ENGLISH

Page 23

Troubleshooting and fault elimination

Display Cause Remedy

MASTER DAMAGED!

MASTER MISSING

INVALID MASTER!

NAME EXISTS!

MEMORY FULL

TRANSFER FAILED

INVALID OPTION!

INVALID EPM!

NO FILES

CFG EPM MISSING!

The EPM in the MASTER PORT is

defective.

The EPM is not placed correctly in the

MASTER PORT.

Seen on power-up if there is no EPM

in the MASTER PORT.

Programmer is trying to read data

from the MASTER PORT but cannot

detect an EPM in this PORT.

The EPM you are attempting to read in

the MASTER PORT is defective or has

no valid data.

The EPM in the MASTER PORT is a

Configuration EPM.

The file name you want to allocate to a

parameter file already exists.

The internal memory of the EPM

programmer is full.

Error in the data transmission to the

EPM PORT, because the memory chip

is defective, or is not placed correctly

in the PORT.

Attempted MASTER -> EPM transfer

when- the memory size of the

MASTER EPM is different from that

of the target.

Error in the data transmission to the

EPM PORT, because of an internal

error in the EPM programmer.

Attempted to CREATE a new file from

a servo drive EPM in the MASTER

PORT.

Attempted to EDIT a non-servo EPM

or a corrupted servo EPM.

Attempting to EDIT, DELETE or

CREATE a file, but there are no stored

files in the EPM Programmer.

Attempt to LOAD CFG EPM without

a valid configuration EPM in the

MASTER PORT.

Press the menu key to return to the

main menu.

Plug an EPM in the MASTER PORT.

The message does not indicate an

error but only serves as a note.

The message is only displayed for a

short time.

Information only.

Insert a valid EPM into the MASTER

PORT.

Press the menu key now to return to

the main menu.

Exchange the EPM in the MASTER

PORT.

A Configuration EPM cannot be

copied.

Select another file name.

It is not possible to save any more

parameter files.

If necessary, delete parameter files

you do not need anymore.

Exchange the defective EPM or plug

the EPM correctly in the PORT.

Replace the EPM in the EPM PORT

with an EPM of the same color as

the Master.

Please contact your Lenze

representative.

Only inverter drive EPM’s can be

saved as files in the EPM Programmer.

Replace the EPM in the EPM PORT

with a valid servo EPM.

Insert a configuration EPM into the

MASTER PORT.

ENGLISH

21

Page 24

Notes

22

ENGLISH

Page 25

Page 26

AC Technology Corporation

630 Douglas Street • Uxbridge, MA 01569 • USA

Sales (800) 217-9100 • Service (508) 278-9100

www.actech.com

EP01E-en

Loading...

Loading...