Page 1

Inverter

8400

Inverter Drives 8400 BaseLine C

_ _ _ _ _ _ _ _ _ _ _ _ _ _

E84AVBCxxxxx...

Reference manual EN

Ä.>ZVä

13295753

L

Page 2

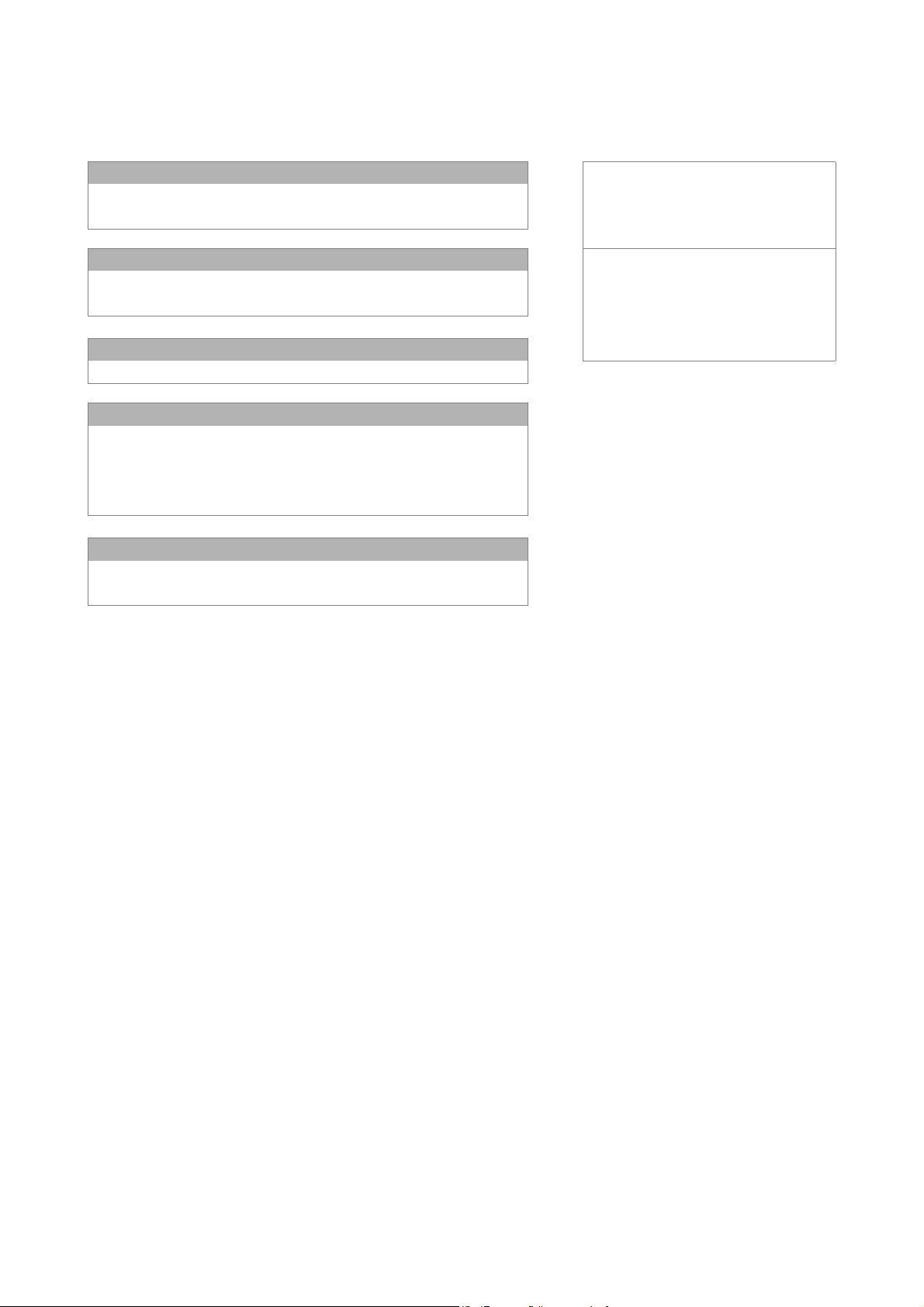

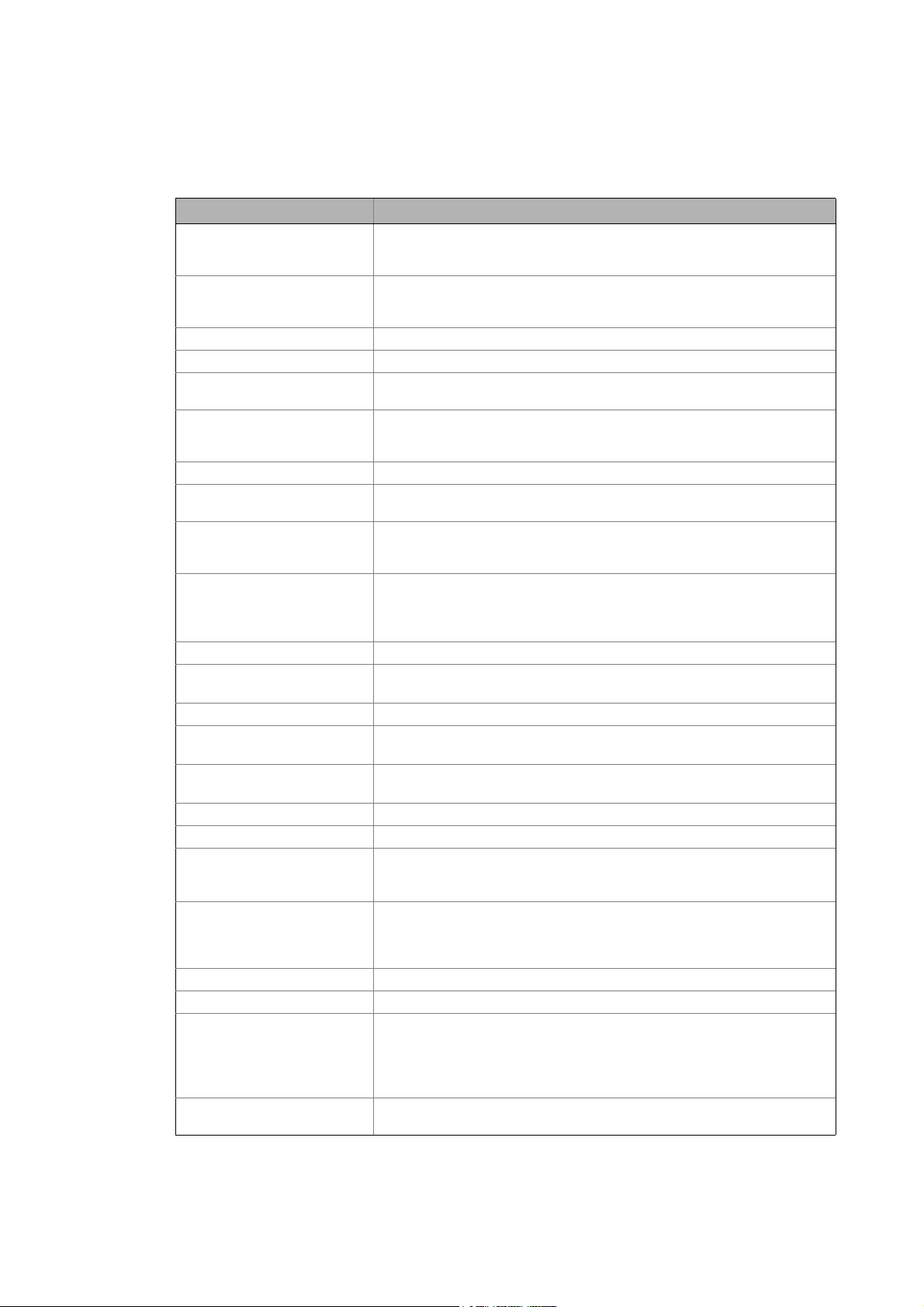

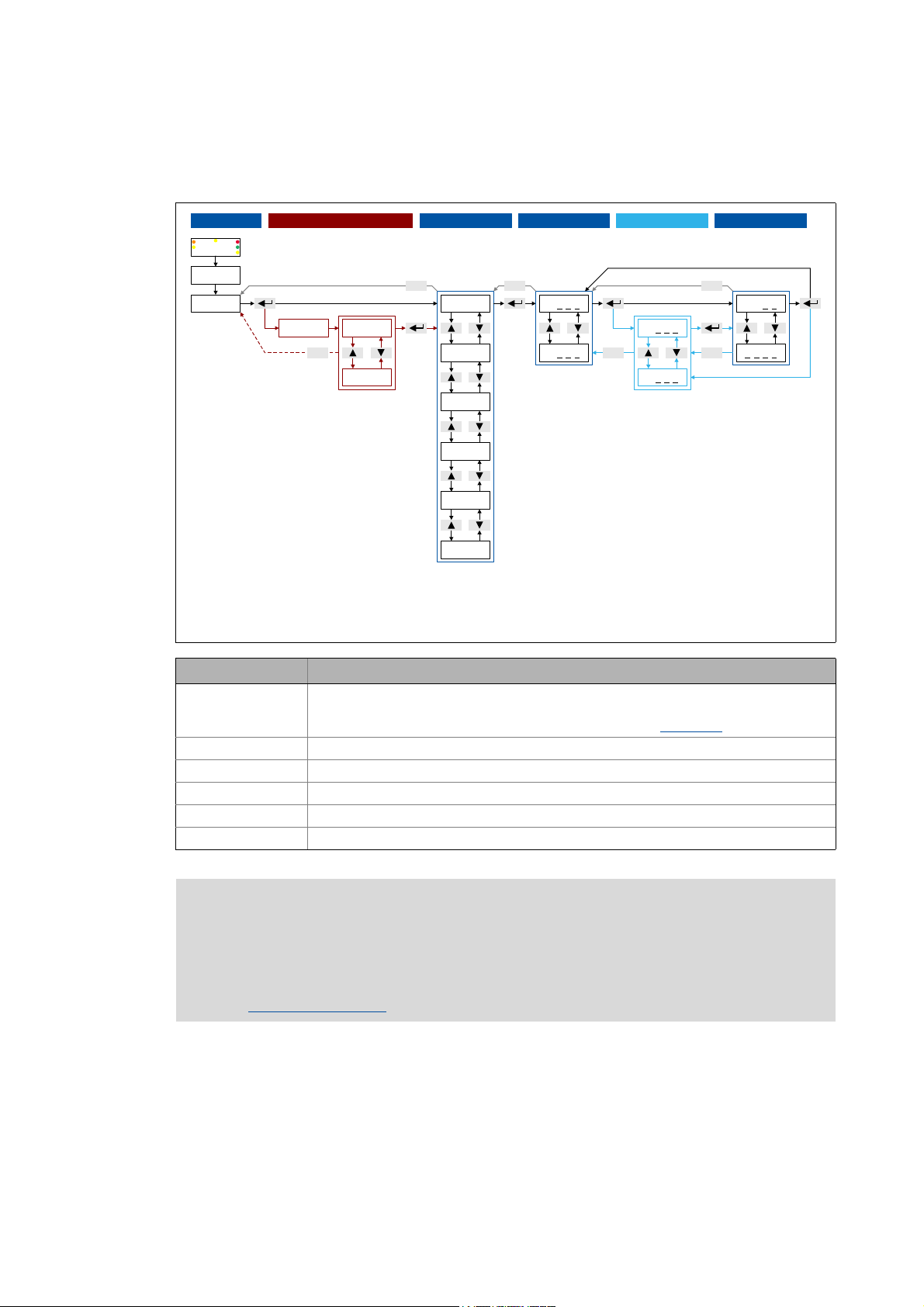

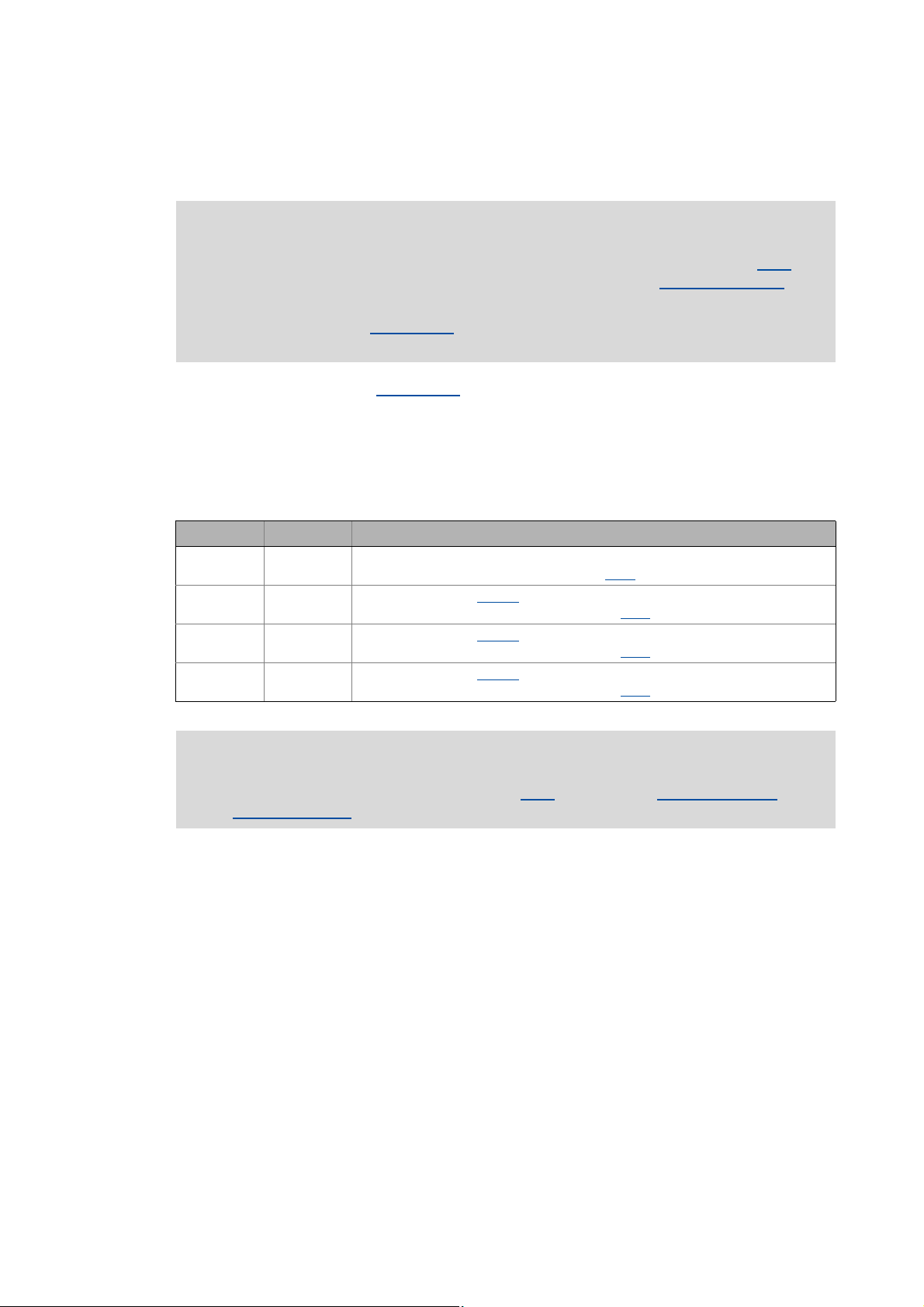

Overview of technical documentation for Inverter Drives 8400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Project planning, selection & ordering Legend:

Hardware manual 8400 BaseLine C/D Printed documentation

Catalogue Online documentation

(PDF/Engineer online help)

Mounting & wiring Abbreviations used:

MA 8400 BaseLine C BA Operating Instructions

MA for the accessories KHB Communication manual

MA Mounting instructions

Parameterisation SW Software/reference manual

SW 8400 BaseLine C This documentation

Drive commissioning

SW 8400 BaseLine C This documentation

Chapter "Commissioning"

Chapter "Diagnostics & error management"

Remote maintenance manual

Networking

KHB for the communication medium used

MA for the accessories

2 Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 3

Contents

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

1.3 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

1.4 Definition of the notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

2 Introduction: Parameterising the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

2.1 General notes on parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

2.2 Handling the memory module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

2.3 Internal Keypad _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

2.3.1 Display elements and control panel _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

2.3.2 LED status display _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

2.3.3 Display messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

2.3.4 Menu structure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

2.3.5 User menu _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

2.3.6 Quick saving of all parameters at the push of a button _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

2.3.7 Password protection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

3 Commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

3.1 Safety instructions with regard to commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

3.2 Preparing the 8400 BaseLine for commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

3.3 Commissioning with integrated keypad _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.3.1 Load Lenze setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.3.2 Parameterise drive/application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

3.3.3 Save parameter settings safe against mains failure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

3.3.4 Enable controller and select speed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

3.4 Commissioning with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

3.4.1 Preconditions for commissioning with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

3.4.2 Creating an »Engineer« project & going online _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

3.4.3 Parameterise drive/application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

3.4.4 Save parameter settings safe against mains failure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

3.4.5 Enable controller and select speed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

3.5 PC manual control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

3.5.1 Activating PC manual control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

3.5.2 Speed control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

4 Device control (DCTRL) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

4.1 Device commands _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

4.1.1 Load Lenze setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

4.1.2 Loading parameter settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

4.1.3 Save parameter settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

4.1.4 Import EPM data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

4.1.5 Enable/Inhibit controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

4.1.6 Activate/Deactivate quick stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

4.1.7 Reset error _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

4.1.8 Delete logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

4.1.9 Identify motor parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

4.1.10 CAN reset node _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

4.2 Device states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

4.2.1 Init _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

4.2.2 MotorIdent _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 56

4.2.3 SafeTorqueOff _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 56

4.2.4 ReadyToSwitchON _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

4.2.5 SwitchedON _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

4.2.6 OperationEnabled _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 59

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 3

Page 4

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.7 Trouble _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 60

4.2.8 Fault _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

4.3 "Inhibit at power-on" auto-start option _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 62

5 Motor control (MCTRL) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 64

5.1 Motor selection/Motor data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 65

5.1.1 Selecting a motor from the motor catalogue in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

5.1.2 Automatic motor data identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

5.2 Selecting the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 73

5.2.1 Selection help _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 75

5.3 Defining current and speed limits _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 76

5.4 V/f characteristic control (VFCplus) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 78

5.4.1 Parameterisation dialog/signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 78

5.4.2 Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 80

5.4.2.1 Defining the V/f characteristic shape _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 80

5.4.2.2 Defining current limits (Imax controller) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 81

5.4.3 Optimise control behaviour _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 82

5.4.3.1 Adapting the V/f base frequency _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 83

5.4.3.2 Adapting the Vmin boost _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 84

5.4.3.3 Optimising the Imax controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 85

5.4.3.4 Torque limitation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 85

5.4.4 Remedies for undesired drive behaviour _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 86

5.5 Sensorless vector control (SLVC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 87

5.5.1 Parameterisation dialog _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 88

5.5.2 Speed control with torque limitation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 89

5.5.3 Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 90

5.5.4 Optimise control behaviour _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 90

5.5.5 Remedies for undesired drive behaviour _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 91

5.6 Parameterisable additional functions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 92

5.6.1 Selection of switching frequency _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 92

5.6.2 Flying restart function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 94

5.6.3 DC-injection braking _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

5.6.4 Slip compensation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 99

5.6.5 Oscillation damping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 100

5.7 Braking operation/braking energy management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 101

5.7.1 Setting the voltage source for braking operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 102

5.7.2 Avoiding thermal overload of the brake resistor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 102

5.8 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

5.8.1 Device overload monitoring (Ixt) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

5.8.2 Motor load monitoring (I2xt) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 104

5.8.3 Brake resistor monitoring (I2xt) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 106

5.8.4 Mains phase failure monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 107

5.5.4.1 Optimising the starting performance after a controller enable _ _ _ _ _ _ _ 90

5.6.3.1 Manual DC-injection braking (DCB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 97

5.6.3.2 Automatic DC-injection braking (Auto-DCB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 97

6I/O terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 108

6.1 Digital terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 109

6.2 Analog terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 111

6.2.1 Parameterising analog input _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 112

6.3 User-defined terminal assignment _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 114

6.3.1 Source-destination principle _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 115

6.3.2 Changing the terminal assignment with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 116

6.3.3 Changing the terminal assignment via configuration parameters _ _ _ _ _ _ _ _ _ _ _ _ 117

6.4 Electrical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 119

4 Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 5

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Drive application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 121

7.1 Parameterisation dialog _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 122

7.1.1 Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 124

7.1.1.1 Selection of the main speed setpoint _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

7.1.1.2 Motor potentiometer function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

7.1.1.3 Process controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

7.2 Interface description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 127

7.3 Setting parameters (short overview) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 132

7.4 Pre-assignment of the drive application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 133

7.4.1 Input connections _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 133

7.4.2 Output connections _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 134

7.4.3 Internal signal flow for control via terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 135

7.4.4 Internal signal flow for control via CAN _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 136

7.4.5 Process data assignment for control via CAN _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 137

7.5 Terminal assignment of the control modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 139

7.5.1 Terminals 0 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 140

7.5.2 Terminals 2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 140

7.5.3 Terminals 11 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 141

7.5.4 Terminals 16 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 141

7.5.5 Keypad _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 142

7.5.6 PC _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 143

7.5.7 CAN _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 144

8 Diagnostics & error management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 145

8.1 Basics on error handling in the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 145

8.2 Drive diagnostics with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 146

8.3 Drive diagnostics via bus system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 148

8.4 Logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 149

8.4.1 Functional description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 149

8.4.2 Reading out logbook entries _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 150

8.4.3 Exporting logbook entries to a file _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 150

8.5 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 151

8.5.1 Monitoring configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 152

8.5.2 Setting the error response _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 153

8.6 Maloperation of the drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 154

8.7 Error messages of the operating system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 156

8.7.1 Structure of the error number (bit coding) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 156

8.7.1.1 Error type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 156

8.7.1.2 Error subject area _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

8.7.1.3 Error ID _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

8.7.1.4 Example for bit coding of the error number _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 158

8.7.2 Reset of error message _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 158

8.7.3 Short overview (A-Z) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 159

8.7.4 Cause & possible remedies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 161

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 5

Page 6

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9 System bus "CAN on board" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 169

9.1 General information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 170

9.1.1 General data and application conditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 171

9.1.2 Supported protocols _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 171

9.1.3 Communication time _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 172

9.1.4 Activating the bus terminating resistor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 173

9.1.5 Setting baud rate & node address _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 173

9.2 LED status displays for the system bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 174

9.3 Going online via system bus (CAN on board) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 175

9.4 Structure of the CAN data telegram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 176

9.4.1 Identifier _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 176

9.4.2 User data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 178

9.5 Communication phases/network management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 179

9.5.1 Status transitions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 180

9.5.2 Network management telegram (NMT) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 181

9.5.3 Parameterising the controller as CAN master _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 182

9.6 Process data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 183

9.6.1 Available process data objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 184

9.6.1.1 RPDO1 | Port block "LP_CanIn1" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 185

9.6.1.2 RPDO2 | Port block "LP_CanIn2" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 186

9.6.1.3 TPDO1 | Port block "LP_CanOut1" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 187

9.6.1.4 TPDO2 | Port block "LP_CanOut2" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 188

9.6.2 Identifiers of the process data objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 189

9.6.3 Transmission type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 190

9.6.4 PDO synchronisation via sync telegram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 192

9.6.5 Monitoring of the RPDOs for data reception _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 193

9.7 Parameter data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 194

9.7.1 Identifiers of the parameter data objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 195

9.7.2 User data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 195

9.7.2.1 Command _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 196

9.7.2.2 Addressing by means of index and subindex _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 197

9.7.2.3 Data 1 ... Data 4 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 198

9.7.2.4 Error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 199

9.7.3 Parameter data telegram examples _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 201

9.7.3.1 Read parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 201

9.7.3.2 Write parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 202

9.7.3.3 Read block parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 203

9.8 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 206

9.8.1 Integrated error detection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 206

9.8.2 Heartbeat protocol _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 207

9.8.2.1 Telegram structure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 207

9.8.2.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 208

9.8.2.3 Commissioning example _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 209

9.8.3 Emergency telegram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 210

9.9 Implemented CANopen objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 211

6 Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 7

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

10 Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 228

10.1 Structure of the parameter descriptions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 229

10.1.1 Data type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 230

10.1.2 Parameters with read-only access _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 230

10.1.3 Parameters with write access _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 231

10.1.3.1 Parameters with setting range _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 231

10.1.3.2 Parameters with selection list _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 231

10.1.3.3 Parameters with bit-coded setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 232

10.1.3.4 Parameters with subcodes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 233

10.1.4 Parameter attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 234

10.2 Parameter list _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 235

10.2.1 Selection lists for configuration parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 298

10.2.1.1 Selection list - analog signals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 298

10.2.1.2 Selection list - digital signals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 299

10.3 Table of attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 300

11 Function library _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 304

11.1 L_MPot_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 305

11.1.1 Activate & control motor potentiometer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 307

11.1.2 Deactivate motor potentiometer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 308

11.2 L_NSet_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 309

11.2.1 Main setpoint path _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 310

11.2.2 JOG setpoints _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 310

11.2.3 Setpoint inversion _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 311

11.2.4 Ramp function generator for the main setpoint _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 311

11.2.5 S-shaped ramp _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 311

11.3 L_PCTRL_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 312

11.3.1 Control characteristic _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 315

11.3.2 Ramp function generator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 316

11.3.3 Operating range of the PID process controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 316

11.3.4 Evaluation of the output signal _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 316

11.4 L_RLQ_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 317

11.5 LS_AnalogInput _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 319

11.6 LS_DigitalInput _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 320

11.7 LS_DigitalOutput _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 321

11.8 LS_DisFree _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 322

11.9 LS_DisFree_a _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 323

11.10 LS_DisFree_b _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 324

11.11 LS_DriveInterface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 325

11.12 LS_Keypad _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 328

11.13 LS_ParFix _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 329

11.14 LS_ParFree_a _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 330

11.15 LS_ParFree_b _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 331

11.16 LS_SetError_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 332

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 333

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 340

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 7

Page 8

1 About this documentation

1.1 Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

Danger!

The controller is a source of danger which may lead to death or severe injury of persons.

To protect yourself and others against these dangers, observe the safety instructions before switching on the controller.

Please read the safety instructions in the mounting instructions and the hardware manual of the 8400 BaseLine C controller. Both documents are supplied with the controller.

This documentation contains information on the parameterisation of the 8400 BaseLine C controller using the integrated keypad and the L-force »Engineer«.

The information in this documentation is valid for the 8400 BaseLine C controller with the following

nameplate data:

Product series Type designation From software version

8400 BaseLine C E84AVBCxxxxxxxx 01.00

Depending on the software version of the controller and the version of the installed »Engineer«

software, the screenshots in this documentation may differ from the representation in the »Engineer«.

Tip!

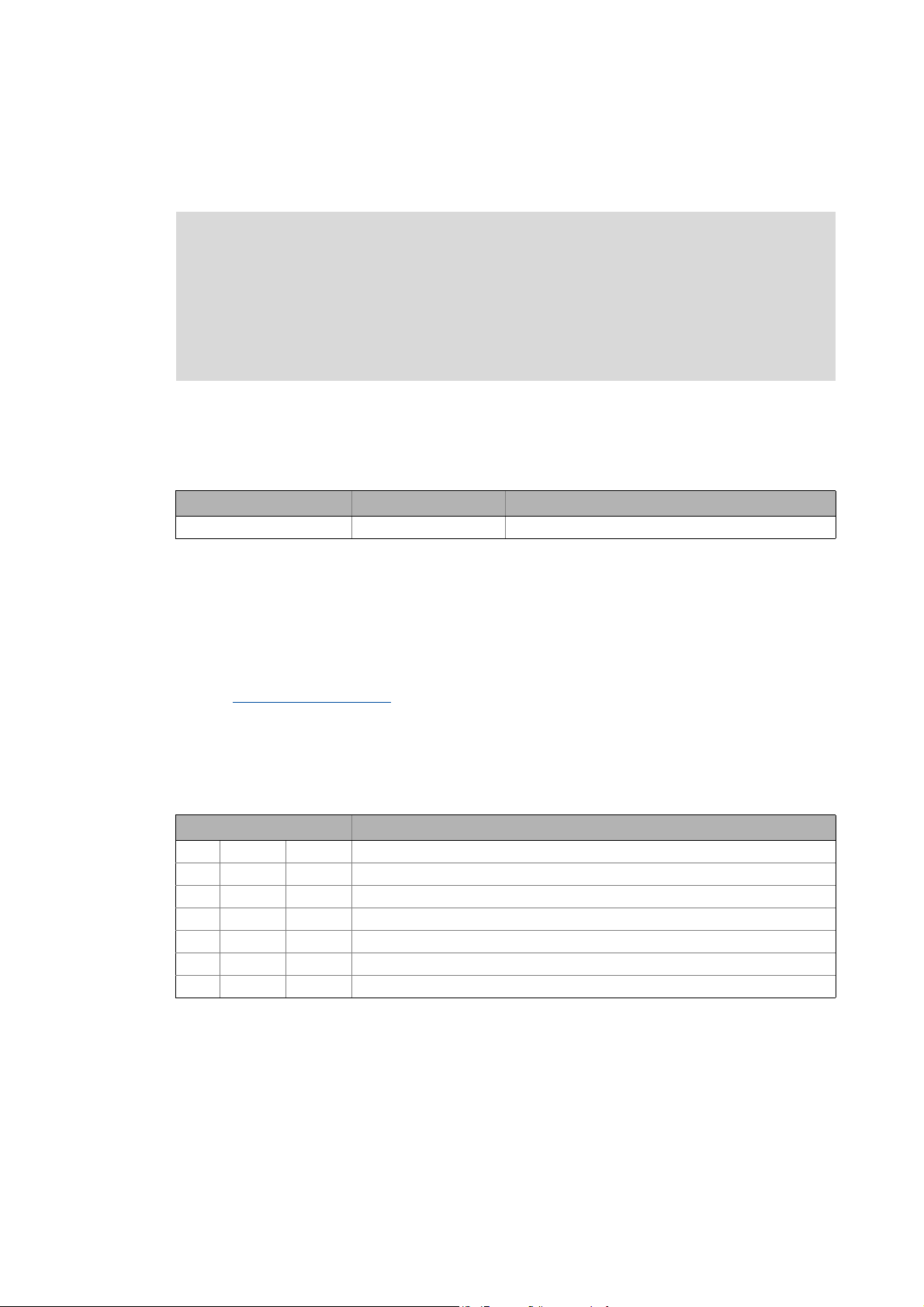

1.1 Document history

Version Description

Information and tools around the Lenze products can be found in the Download area on

http://www.Lenze.com

1.6 01/2014 TD05 Error corrections & supplements and converted to new layout

1.5 04/2013 TD05 Error corrections & supplements, parameter reference V03.04.00

1.4 04/2011 TD05 Error corrections & supplements, parameter reference V03.03.00

1.3 09/2010 TD05 Restructuring of some chapters, error corrections & supplements

1.2 11/2009 TD06 Error corrections

1.1 05/2009 TD06 Error corrections

1.0 04/2009 TD06 First edition

8

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 9

1 About this documentation

1.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

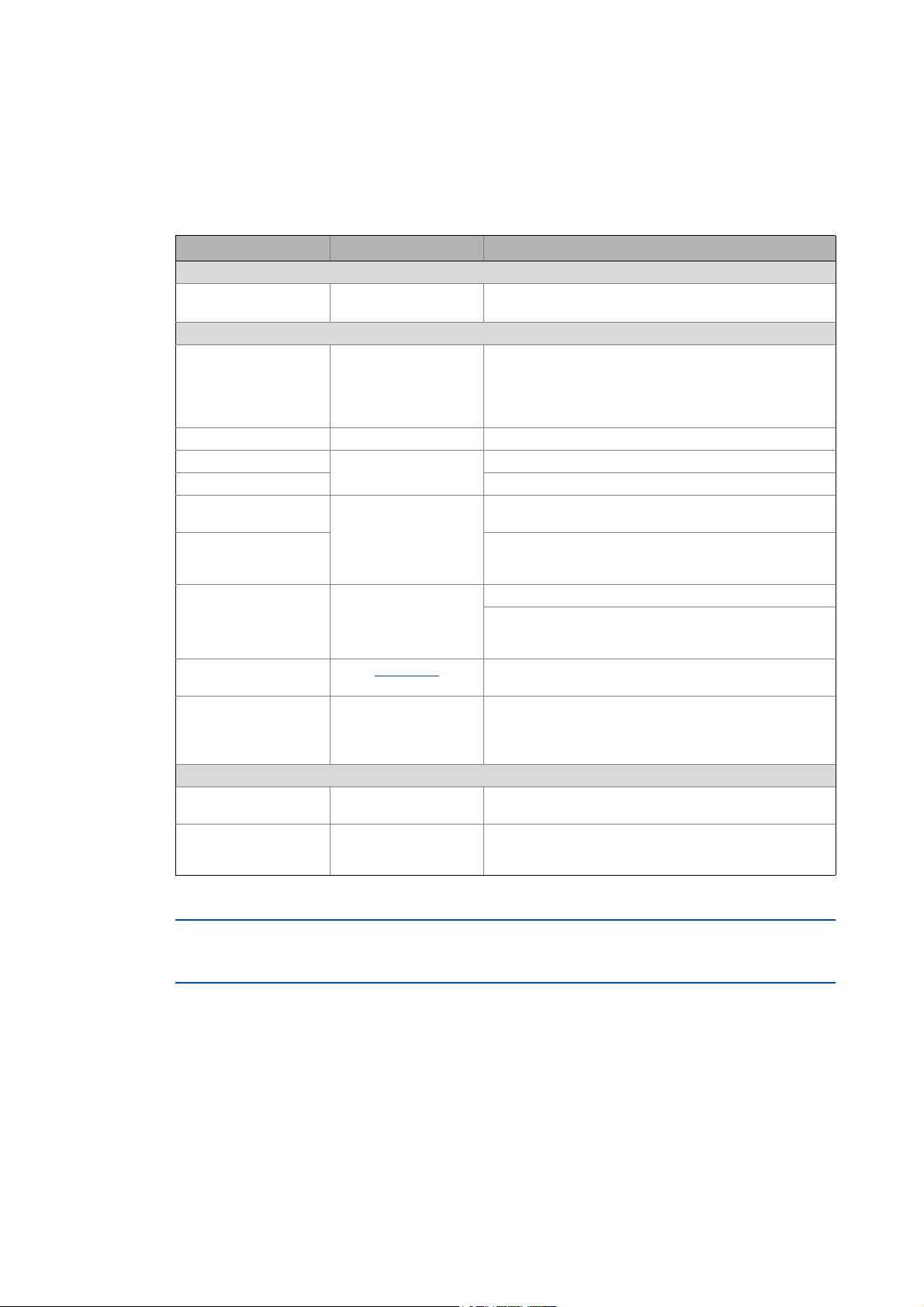

1.2 Conventions used

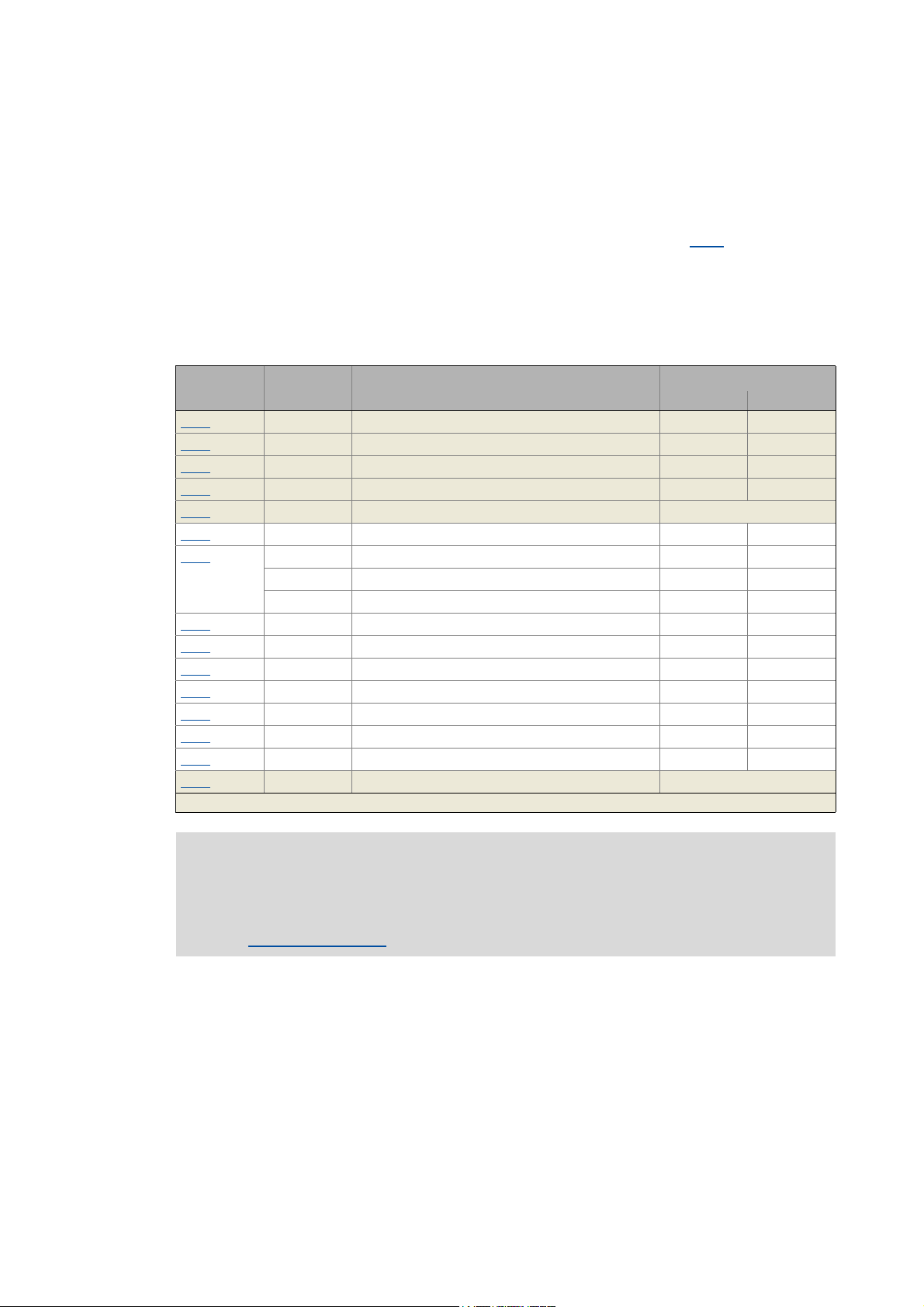

This documentation uses the following conventions to distinguish between different types of information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal separator Point The decimal point is generally used.

For example: 1234.56

Text

Version info Blue text colour All information that only applies to a certain controller

Program name » « The Lenze »Engineer« PC software ...

Window italics The Message window ... / The Options dialog box...

Variable identifier By setting bEnable to TRUE...

Control element bold The OK button... / The Copy command... / The Properties

Sequence of menu

commands

Shortcut <bold> Press <F1> to open the online help.

Hyperlink Underlined

DIP switch \

("Backslash")

Icons

Page reference ( 9) Optically highlighted reference to another page. In this

Step-by-step instructions

software version or higher is identified accordingly in this

documentation.

Example: This function extension is available from software

version V3.0!

tab... / The Name input field...

If the execution of a function requires several commands,

the individual commands are separated by an arrow: Select

Open to...

File

If a command requires a combination of keys, a "+" is placed

between the key symbols:

Use <Shift>+<ESC> to...

Optically highlighted reference to another topic. In this

documentation activated by mouse-click.

For separating the data of the DIP-Schalterbank from the

switch number, the Backlash" is used.

For instance, S2\8 indicates bank S2 and switch 8 (on the far

right).

documentation activated by mouse-click.

Step-by-step instructions are indicated by a pictograph.

Information that is only valid for or as from a certain software version of the controller are marked

accordingly in this documentation.

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 9

Page 10

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Terminology used

Term Meaning

»Engineer« Lenze PC software which supports you in "engineering" (parameterisation, diag-

Application A technology application is a drive solution equipped with Lenze's experience

ASM Asynchronous motor

CINH Abbreviation: Controller inhibit (pulse inhibit)

Code Parameter used for controller parameterisation or monitoring. The term is usu-

DC-injection braking DC injection braking is to brake and/or hold the motor. For this purpose, the

DCTRL Abbreviation: Drive control (device control)

Display code Parameter that displays the current state or value of an input/output of a sys-

EPM Memory module on which all parametes of the drive system are saved non-vola-

Function block A function block can be compared with an integrated circuit that contains a cer-

Holding brake The holding brake serves to hold the rotor by means of a mechanical unit.

LA Abbreviation: Lenze Application block

Lenze setting This setting is the default factory setting of the device.

LP Abbreviation: Lenze Port block

LS Abbreviation: Lenze System block

MCTRL Abbreviation: Motor control

Port block Block for implementing the process data transfer via a fieldbus

QSP Quick stop ("Quick stop):

Service brake The service brake serves to shutdown rotary or translatory masses in motion in

SLVC Motor control: Sensorless vector control ("SensorLess Vector Control")

SM Synchronous motor

Subcode If a code contains several parameters, the individual parameters are stored un-

System block In the application, system blocks provide interfaces to basic functions and to the

nostics and configuration) throughout the whole life cycle, i.e. from planning to

maintenance of the commissioned machine.

and know-how in which function and system blocks interconnected to a signal

flow are the basis for implementing typical drive tasks.

ally called "index".

8400 BaseLine C creates a quasi DC field at the stator of the asynchronous machine. The energy to be dissipated is converted into heat in the rotor.

tem block.

tilely. These include the parameters of the controller and communication-relevant parameters for the communication unit used.

tain control logic and delivers one or several values when being executed.

• Each function block has a unique identifier, e.g. "L_MPot_1" (motor potentiometer function)

• Example: "LA_NCtrl" – block for the "actuating drive speed" application.

• Example: "LP_Network_In" – port block for fieldbus communication.

• Example: "LS_DigitalInput" – system block for digital input signals.

The motor control is decoupled from the setpoint selection and within a parameterisable deceleration time, the motor is brought to a standstill (n

a controlled manner. The energy to be dissipated in this process is converted into

heat in the form of friction energy. This process is a regular and recurring operating mode.

der "subcodes".

This manual uses a slash "/" as a separator between code and subcode

(e.g. "C118/3").

The term is usually called "subindex".

hardware of the controller (e.g. to the digital inputs).

act

=0).

10

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 11

1 About this documentation

1.4 Definition of the notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Term Meaning

USB diagnostic adapter The USB diagnostic adapter is used for the operation, parameterisation, and di-

VFCplus Motor control: V/f characteristic control ("Voltage Frequency Control")

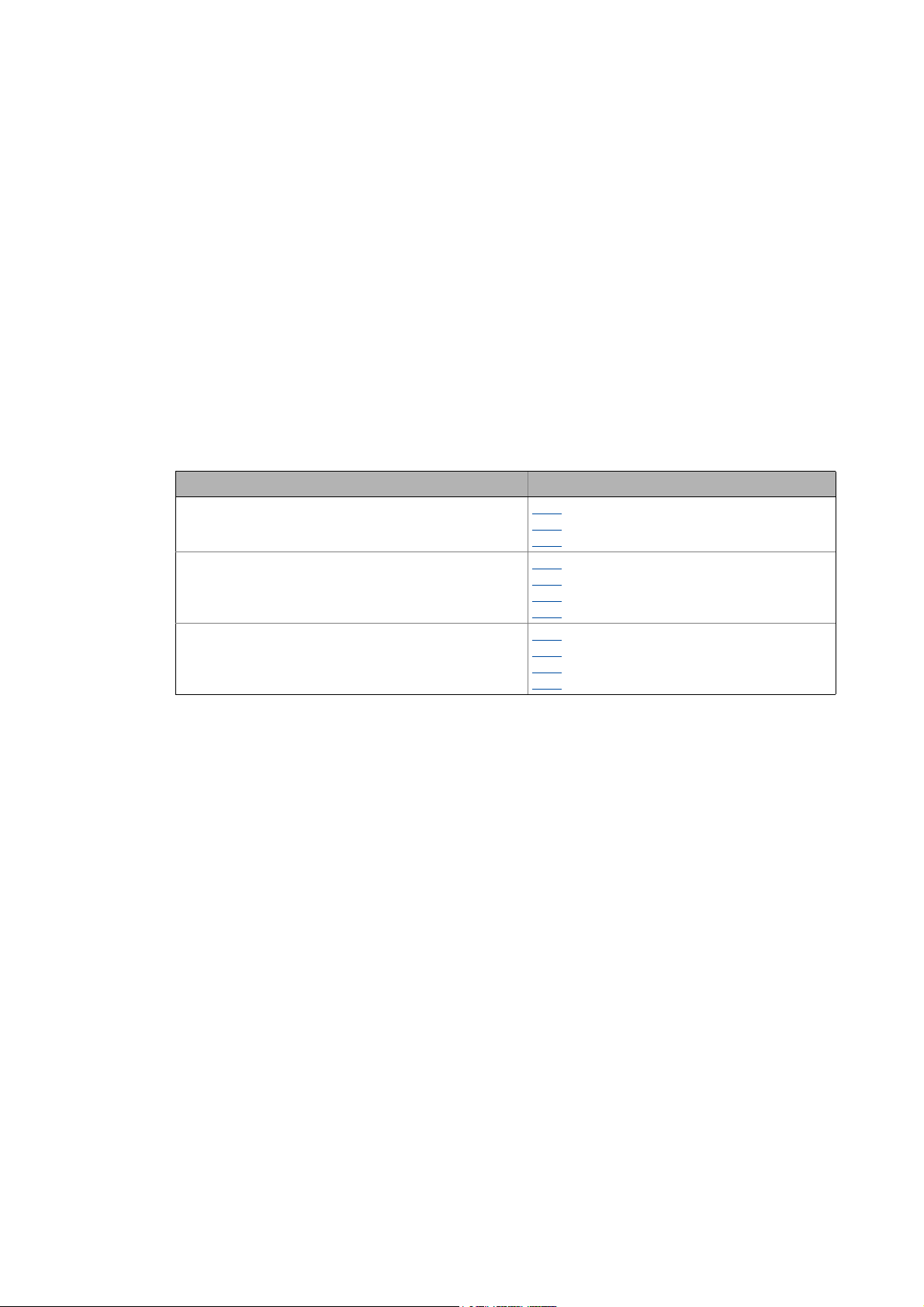

1.4 Definition of the notes used

The following signal words and symbols are used in this documentation to indicate dangers and important information:

Safety instructions

Layout of the safety instructions:

agnostics of the controller. Data are exchanged between the PC (USB connection) and the controller (diagnostic interface on the front) via the diagnostic

adapter.

• Order designation: E94AZCUS

Pictograph and signal word!

(characterise the type and severity of danger)

Note

(describes the danger and informs how to prevent dangerous situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Refere nce to an i mmin ent d ange r tha t may resu lt in deat h or serio us pe rsonal in jury

if the corresponding measures are not taken.

Refere nce to an i mmin ent d ange r tha t may resu lt in deat h or serio us pe rsonal in jury

if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the corresponding measures are not taken.

Tip! Useful tip for easy handling

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 11

Page 12

2 Introduction: Parameterising the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Introduction: Parameterising the controller

[2-1] Example configuration for parameterising the controller (here: BaseLine D)

Being a component of a machine which includes a speed-variable drive system, the controller needs

to be adjusted to its drive task and the motor. The controller is adjusted by changing parameters

which are saved in the memory module.

Danger!

The parameters can optionally be accessed from the integrated keypad, or the L-force »Engineer«,

or a master control via fieldbus communication:

In general, changing a parameter causes an immediate response in the controller!

• This may lead to undesirable behaviour on the motor shaft if the controller has been

enabled!

• Setpoint sources, for instance, may switch over all of a sudden (e.g. when configuring

the signal source for the main setpoint).

Certain device commands or settings which may cause critical states of drive behaviour

constitute exceptions. Such parameter changes are only possible if the controller is inhibited. Otherwise, a corresponding error message will be issued.

• The USB diagnostic adapter, for instance, can be used for the communication between the PC

(including the L-force »Engineer« software) and the controller, see illustration. The USB diagnostic adapter is the connection between the PC (free USB port) and the controller (diagnostic

interface).

• For fieldbus communication, the 8400 BaseLine C controller is provided with a CANopen interface.

12 Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 13

2 Introduction: Parameterising the controller

2.1 General notes on parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.1 General notes on parameters

All parameters for controller parameterising or monitoring are saved as so-called "codes".

• The codes are numbered and designated by a "C" in front of the code, e.g. "C002" in the documentation and the keypad display.

• In addition, every code has a name and specific attributes:

• Access type (read, write)

•Data type

• Limit values

• Lenze setting (factory-set scaling)

• For the sake of clarity, some codes contain "subcodes" for saving parameters.

• This manual uses a slash "/" as a separator between code and subcode (e.g. "C115/1").

• In the keypad display, the subcodes are designated by a small "c", e.g. "c001".

• According to their functionality, the parameters are divided into three groups:

Parameter group Examples

Setting parameters

Parameters for specifying setpoints and for setting device /

monitoring functions.

Configuration parameters

Parameters for configuring signal connections within the device, e.g. assignment of the digital input terminals to the

control inputs of the application.

Diagnostic/Display parameters

Parameters for displaying device-internal process factors,

current actual values, and status messages, e.g. for diagnostic purposes. These are read-only parameters.

C007: Selection of control mode

C012

: Acceleration time - main setpoint

C039

: Fixed setpoints

C620

: System connection list: 16-bit

C621

: System connection list: Bool

C700

: LA_NCtrl: Analog connection list

C701

: LA_NCtrl: Digital connection list

C052

: Motor voltage

C137

: Device status

C150

: Status word

C165

: Error info

Tip!

The terms "code" and "subcode" generally correspond to the terms "index" and "subindex"

and "parameter" and "subparameter".

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 13

Page 14

2 Introduction: Parameterising the controller

2.2 Handling the memory module

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2 Handling the memory module

Danger!

After power-off, wait at least three minutes before working on the controller. When removing the memory module, ensure that the controller is deenergised.

If the memory module has been removed and the device is switched on, the connector

pins are live and thus dangerous since the protection against contact is missing.

All parameters of the drive system are saved non-volatilely in the memory module of the controller.

This includes the parameters of the controller and parameters relevant for communication.

The plug-in version is especially suited for

• restoring an application after replacing a device.

• duplicating identical drive tasks within the 8400 BaseLine frequency inverter series, e.g. by

using the optionally available EPM Programmer.

Note!

• When the device is switched on, all parameters are automatically loaded from the memory module to the main memory of the controller.

• The 8400 BaseLine and 8400 motec controllers use the same (grey) memory module.

The memory module can be shifted between these controllers but the controller must

When handling the memory module, a distinction is drawn between the following scenarios:

Delivery status

be reparameterised afterwards.

• The memory module is not compatible with the memory modules of the

8400 StateLine and 8400 HighLine controllers.

• If the memory module has been removed, the "PS01" error message appears.

• The memory module is plugged into the EPM slot at the

front of the controller.

• The Lenze setting of the parameters is stored in the memory module.

• The memory module can be preconfigured with customerspecific data.

• The memory module is available as a spare part - without

any data.

14

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 15

2 Introduction: Parameterising the controller

2.2 Handling the memory module

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

During operation

Stop!

The memory module must not be plugged in or unplugged during operation.

• The memory module (EPM) is required for operation.

• Full functionality of the memory module is even provided if the power supply has been switched

off and only the electronic components of the controller are externally supplied by a 24 V DC voltage, e.g. via the X4/24E terminal.

• Parameter settings can be saved manually.

• Parameter settings can be loaded manually.

• Parameter changes can be saved automatically.

Replacing the controller

• In the event of a device replacement, the entire parameter data of an axis can be copied to the

replacement device by "taking along" the memory module, so that additional PC or diagnosis

terminal operations are not required.

• When replacing the controller, the versions of the old device and the new device are of importance. Before data are actually transferred, the versions are internally checked. Basically, the following applies:

• Parameter sets of old devices with V 1.0 can be processed on new devices ≥ V1.0

(downward compatibility).

• Parameters of devices with higher versions are not supported on devices with lower versions.

An error message (PS02/PS03) occurs if the parameter set versions of the two devices are not

compatible.

Saving the parameters in the memory module safe against mains failure

Controller parameter changes via the »Engineer«, the integrated keypad, or a master control via

fieldbus communication will be lost after mains switching of the controller unless the settings have

been explicitly saved.

You have various opportunities to prevent a data loss by saving the parameter settings in the memory module:

• Quick saving of all parameters at the push of a button

• Automatic saving of parameter changes

• Manual saving of parameter settings

( 49)

( 49)

( 23)

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 15

Page 16

2 Introduction: Parameterising the controller

2.2 Handling the memory module

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

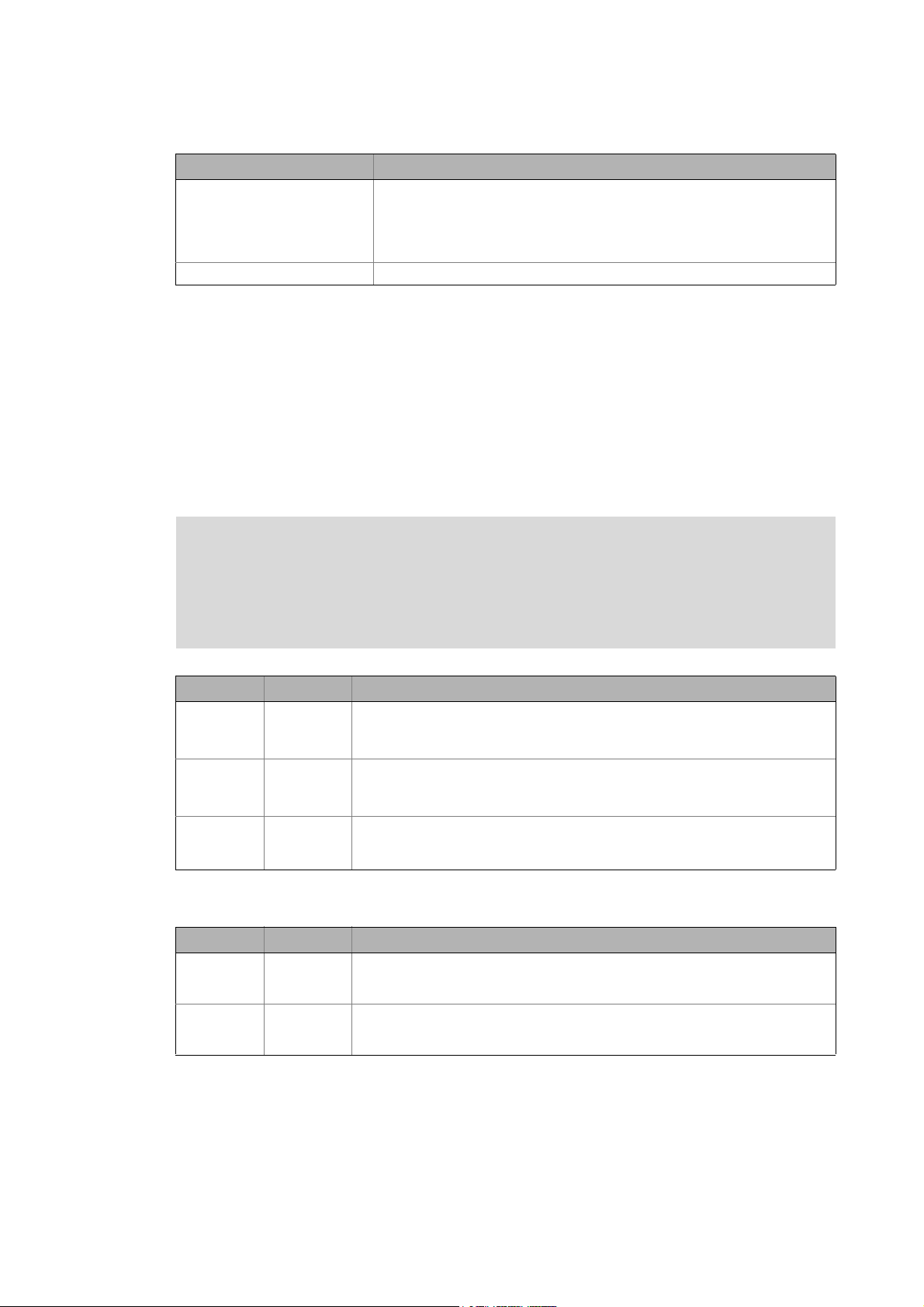

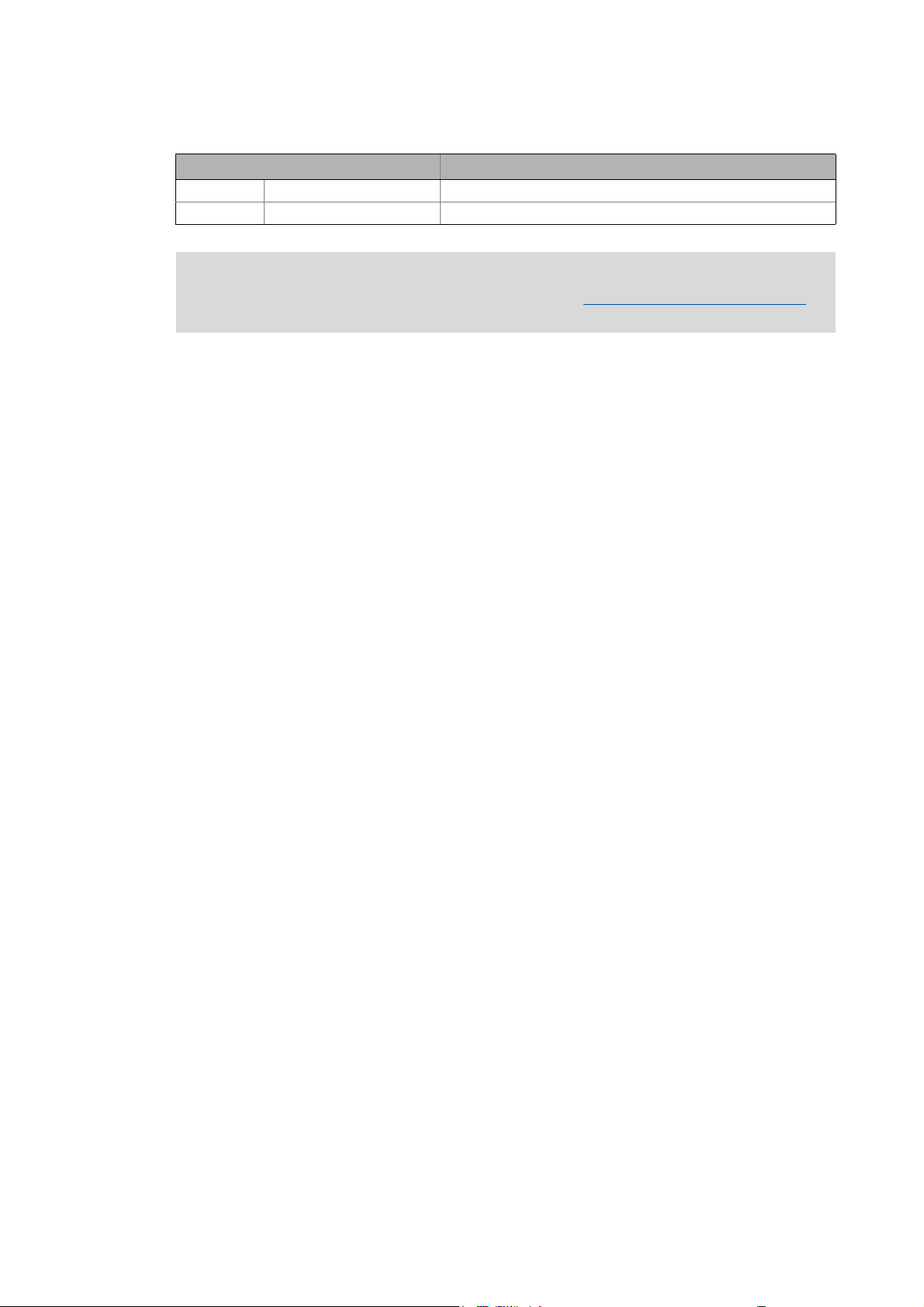

Parameter set transfer using the »Engineer«

When an online connection to the controller has been established, the following transfer functions

can directly be executed via the Toolbar or the Online menu using the L-force »Engineer«:

Symbol Menu command Shortcut

Download parameter set <F5>

Read parameter set from device <F7>

Save parameter set

Tip!

Detailed information on parameter set transfers using the »Engineer« can be found in the

»Engineer« online help.

16

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 17

2 Introduction: Parameterising the controller

8888

B

ESC

C

D

E

F

A

1

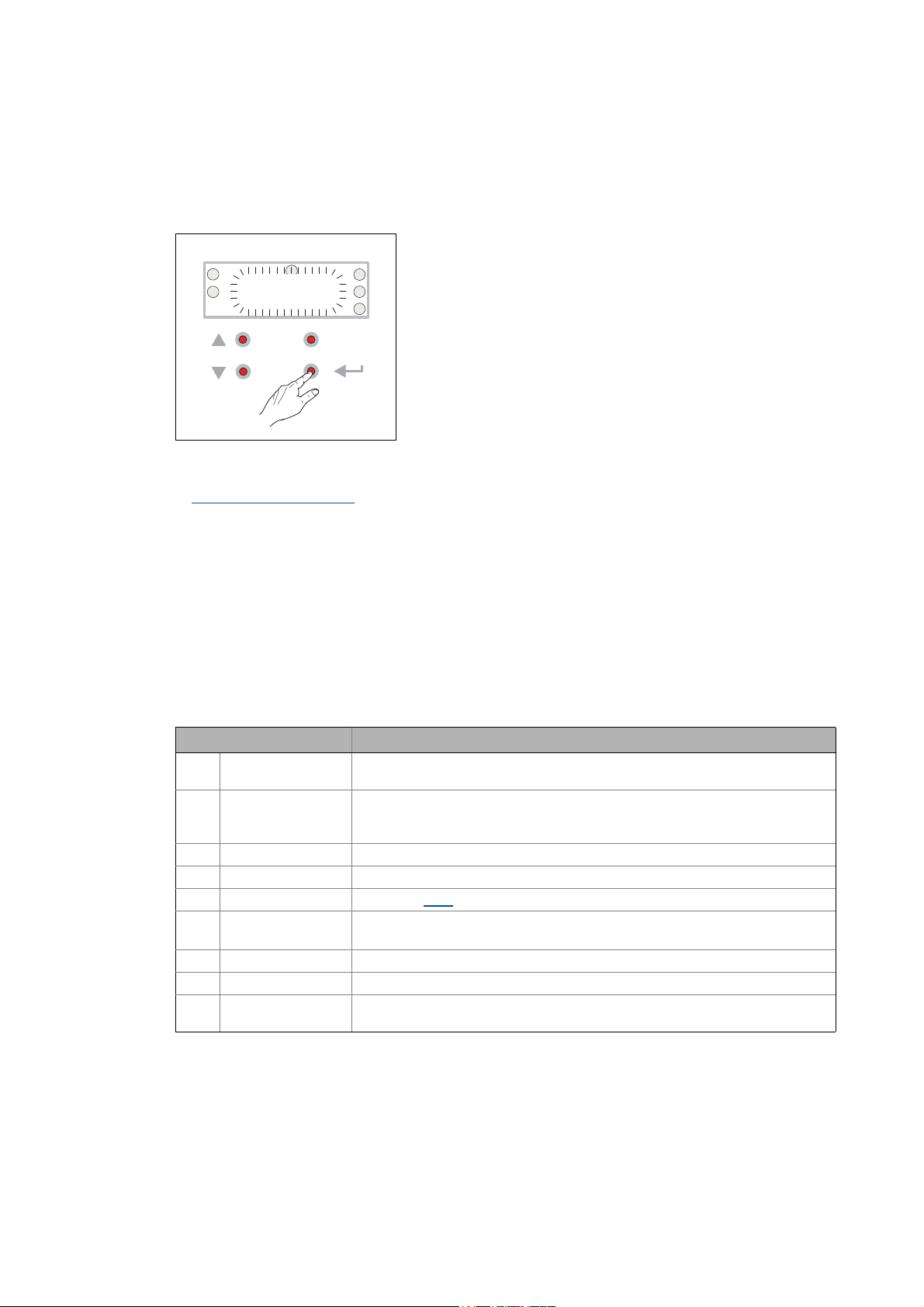

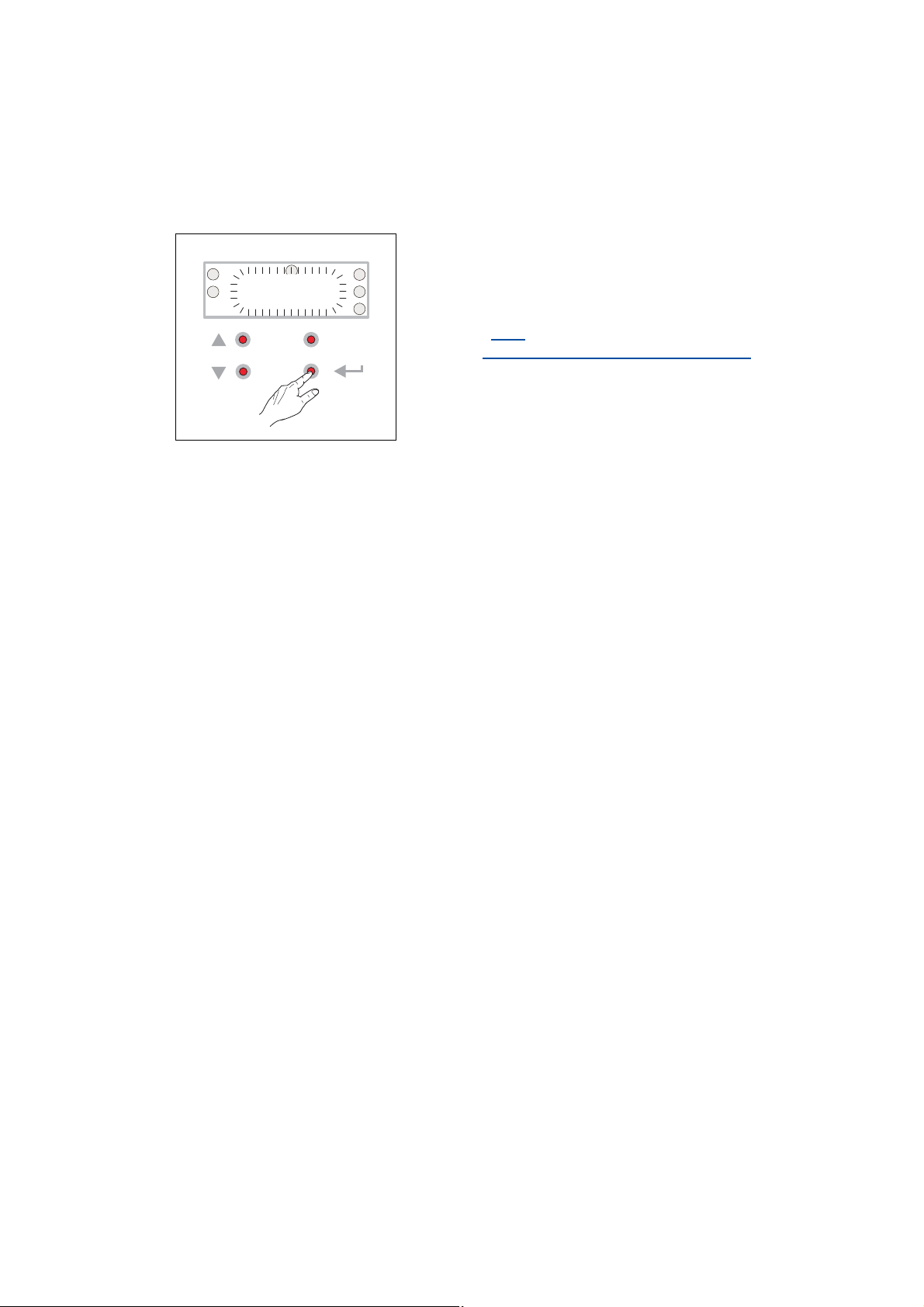

2.3 Internal Keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.3 Internal Keypad

The controller front is provided with an integrated keypad. Use the keypad for quick and simple parameter setting and for displaying current actual values and device states via the respective display

parameters.

Note!

After switching on the controller, the internal keypad performs a quick self-test. All segments of the display flash. After the self-test, the keypad shows "rdy" for a short time

and then changes to the display of the setpoint speed of the motor. The keypad is now

ready for operation.

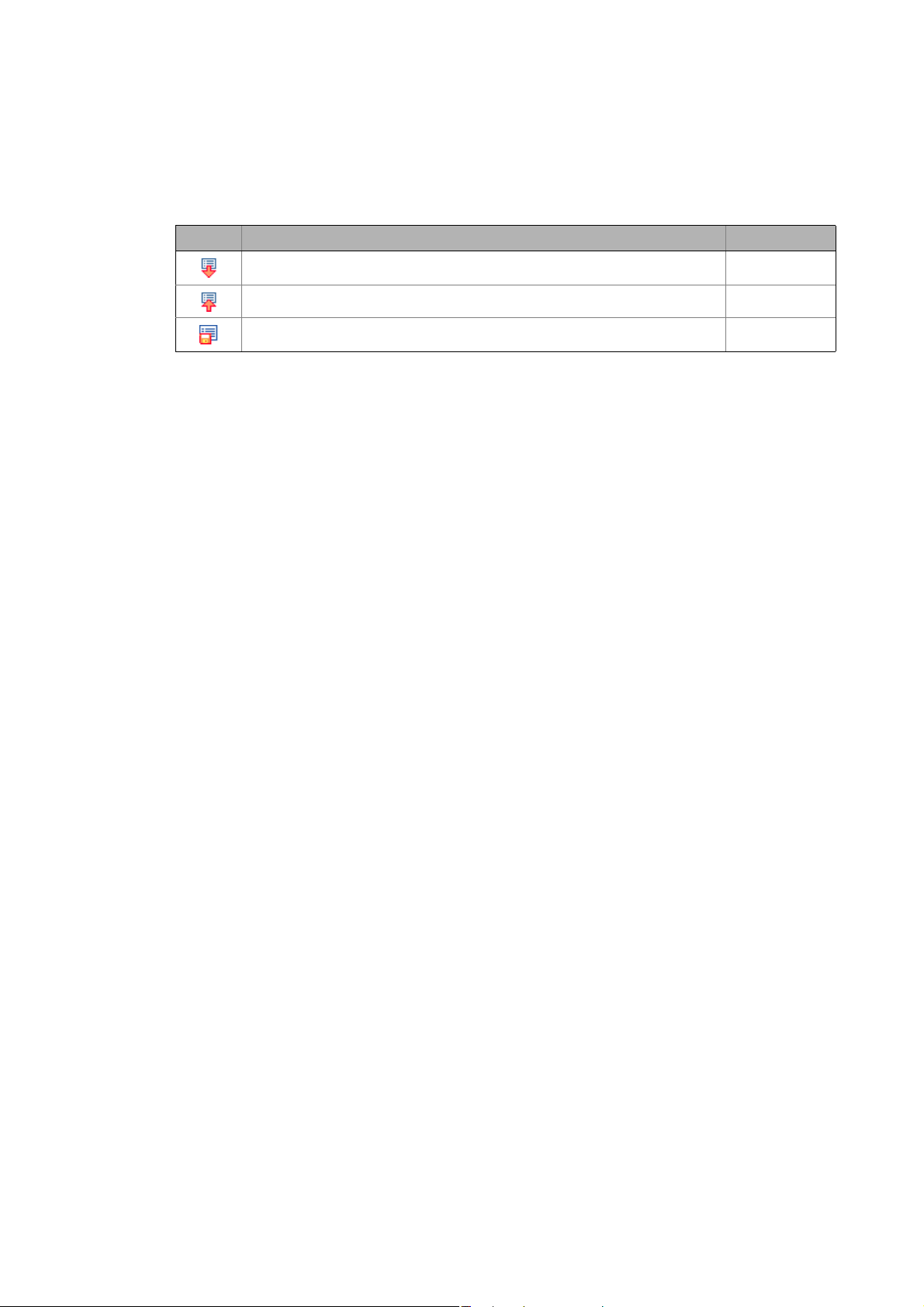

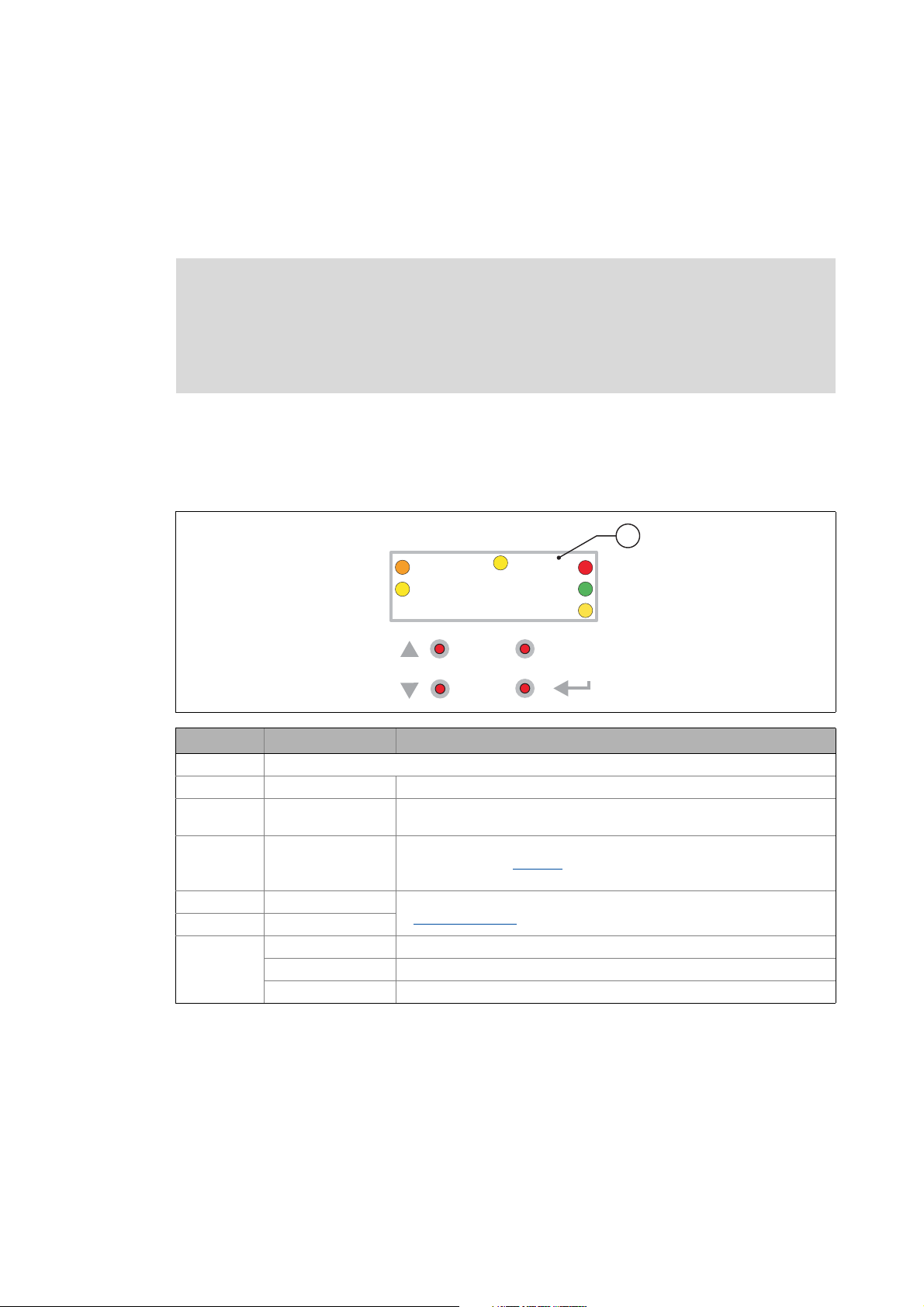

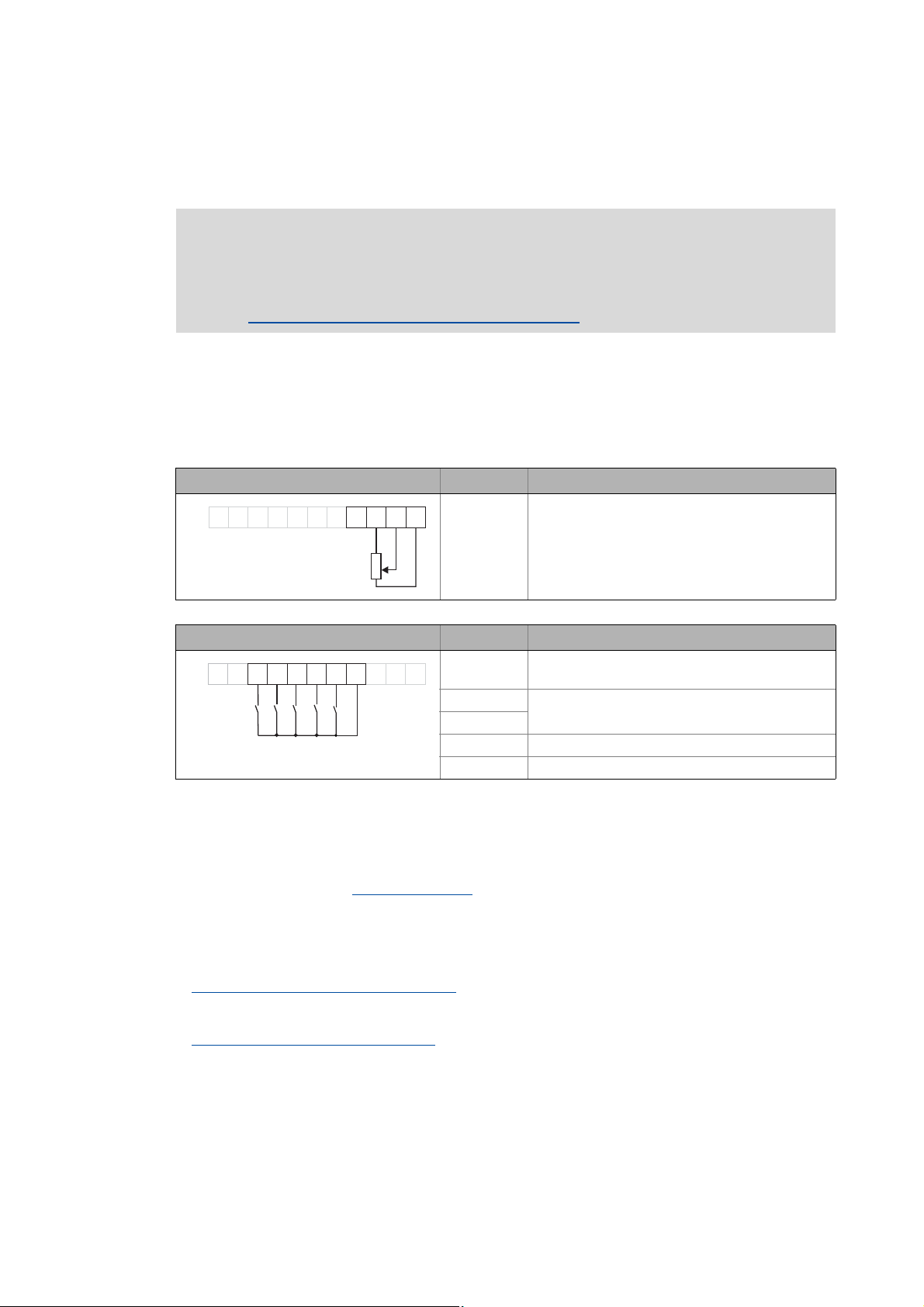

2.3.1 Display elements and control panel

Important status information of the controller is displayed optically by LEDs. The positions of the coloured LEDs are marked on the housing by letters.

Symbol Information Meaning

4-character display with LEDs (A ... F)

A orange Set current/torque limit is reached

B yellow Minus sign for identifying the negative numbers bigger than 4 characters

C yellow User LED

D red DRIVE ERROR / DRIVE READY

E green

F yellow Direction of rotation: CCW rotation

Off Direction of rotation: CW rotation

blinking Commanded direction is not equal to actual direction (e.g. during reversing)

when the rotational direction has been reversed.

•configurable via C621/42

• user-defined LED status

LED status display

( 18)

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 17

Page 18

2 Introduction: Parameterising the controller

8888

B

C

D

E

F

A

2.3 Internal Keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Control elements

Key Name Function

ESC Escape key On menu and parameter level: Back

In case of parameter processing: Abort (discard changed setting)

↵ Enter key On menu and parameter level: Next (confirm selection)

In case of parameter processing: OK (accept changed setting)

Long pressing (3 seconds): Saving of all parameters

Navigation key

upwards

Navigation key

downwards

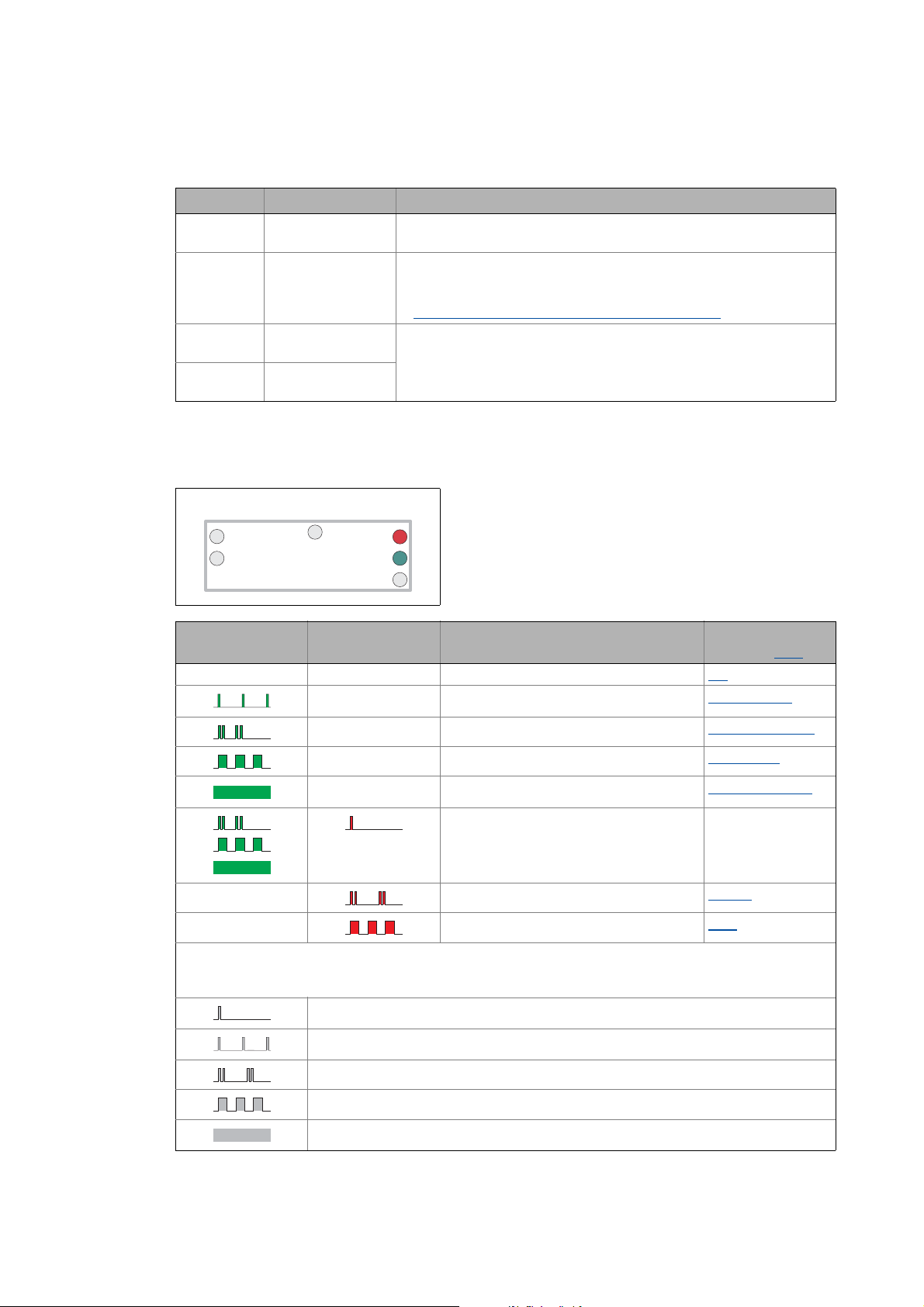

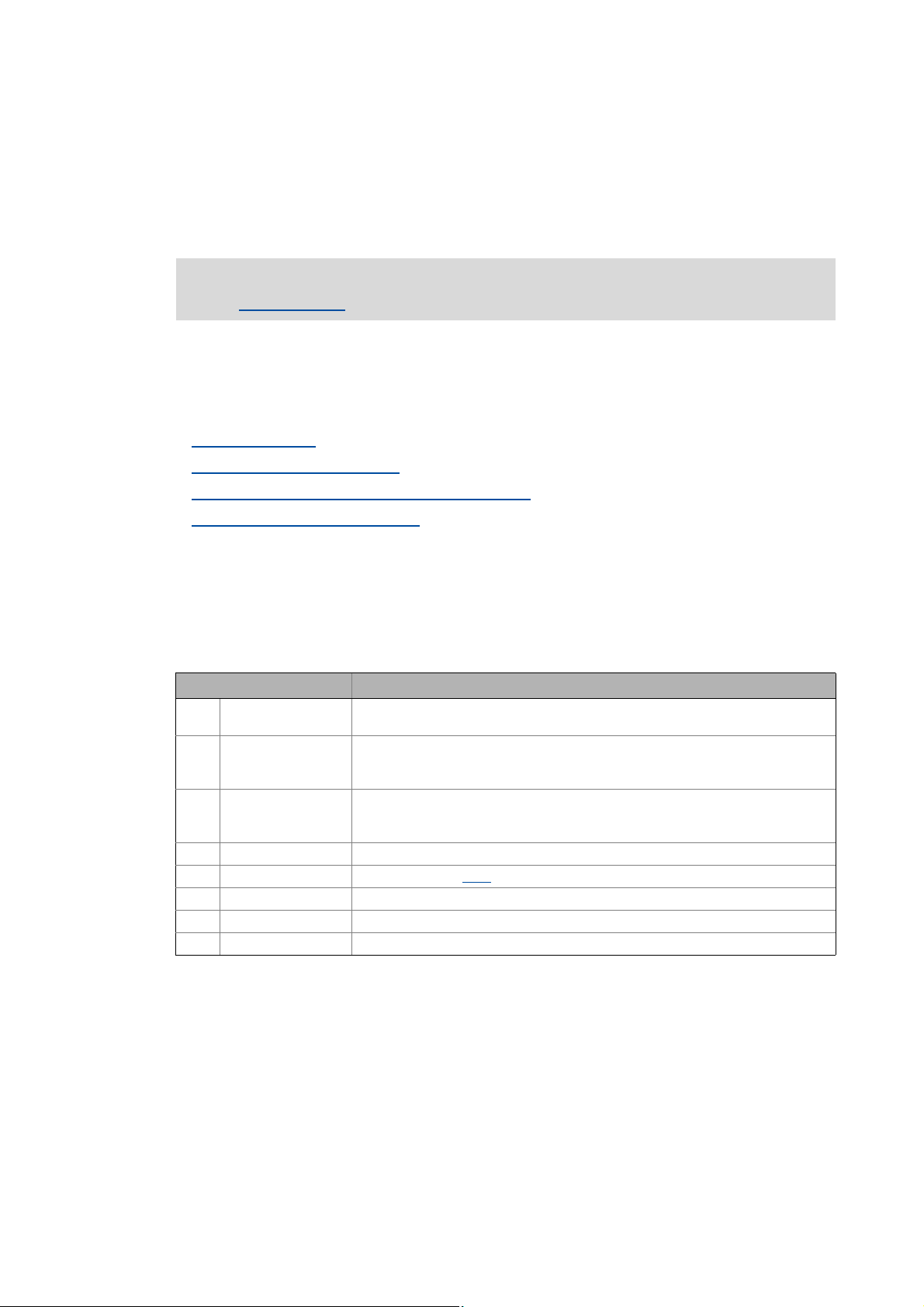

2.3.2 LED status display

Quick saving of all parameters at the push of a button

On menu and parameter level: Navigation

In case of parameter processing: Set parameter value

Long pressing (> 2 seconds): Quick scroll function

( 23)

Information on some operating states can quickly be obtained via the front D and E LEDs:

The meaning can be seen from the table below.

E

"DRIVE READY"

OFF OFF OFF or initialisation active Init

OFF Trouble is active Trouble

OFF Fault is active Fault

D

"DRIVE ERROR"

OFF Safe torque off is active SafeTorqueOff

OFF Device is ready to start ReadyToSwitchON

OFF Device is switched on SwitchedON

OFF Motor data identification/operation OperationEnabled

Description Device state

(Display in C137

The controller is ready to switch on, switched

on or the operation is enabled and a warning

is indicated.

)

18

Legend

The symbols used for indicating the LED states have the following meaning:

LED is flashing once approx. every 3 seconds (slow flash)

LED is flashing once approx. every 1.25 seconds (flash)

LED is flashing twice approx. every 1.25 seconds (double flash)

LED is blinking every second

LED is permanently on

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 19

2 Introduction: Parameterising the controller

2.3 Internal Keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.3.3 Display messages

Display Meaning

An01 constant Analog input 1: Current < 4 mA

bF blinking Identification error.

• Drive ID stored in EMP does not match the drive ID stored in the

controller.

br flashes during the hold time

of DC braking

CA06 constant CAN CRC error

CA07 constant CAN Bus Warn

CA08 constant CAN Bus Stopped

CA0b constant CAN Bus Live Time

CA0F constant CAN: Bit 14 ("SetFail") in the control word is set.

CAL blinking Identification is executed.

CAL / Err alternatively blinking Identification is not ready to start.

CAL / Stop alternatively blinking Identification is ready to start.

CE1 constant CAN: Time monitoring for RPDO1 has tripped.

CE2 constant CAN: Time monitoring for RPDO2 has tripped.

CE4 constant CAN Bus Off

CL constant Clamp: The current limit value selected in C022

dec constant Deceleration is temporarily suspended because of higher bus volta-

dF01 ... dF10 constant Internal error

dH69 constant Adjustment data error

Err blinking A wrong password has been entered.

FCL constant The current limit value selected in C022

FSt constant "Flying restart" function is executed.

ID1 constant Motor data identification error

LU constant DC bus undervoltage

OC1 constant Power section - short circuit

OC12 constant I2xt brake resistor overload

OC2 constant Power section - earth fault

OC5 constant Ixt overload

OC6 constant I2xt motor overload

OC9 constant Ixt overload - shutdown limit

OH constant Heatsink overtemperature

OU constant DC bus overvoltage

PASS 0.5 seconds on Password protection is active

PS01 constant No memory module inserted

PS02 constant Parameter set is invalid

PS03 constant Parameter set device invalid

PS31 constant Incompatible or unknown HW components have been found.

Su02 constant One mains phase is missing

DC braking is executed.

The operation is not yet enabled.

• C088

, C089 or C090 is 0.

ge

has been reached.

has been exceeded.

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 19

Page 20

2 Introduction: Parameterising the controller

2.3 Internal Keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Display Meaning

US01 constant User error 1

US02 constant User error 2

Detailed information on diagnostics using the »Engineer« and a description of possible

error messages can be found in the chapter entitled "Diagnostics & error management

( 145)

".

20

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 21

2 Introduction: Parameterising the controller

ģĤ;

MM

2#55

Ħ

(6&

(6&

%

(6&

(6&

%

(6&

ĥ

ĥ

(6&

6WDWH 3DVVZRUG 0HQX &RGH 6XEFRGH 9DOXH

2.3 Internal Keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

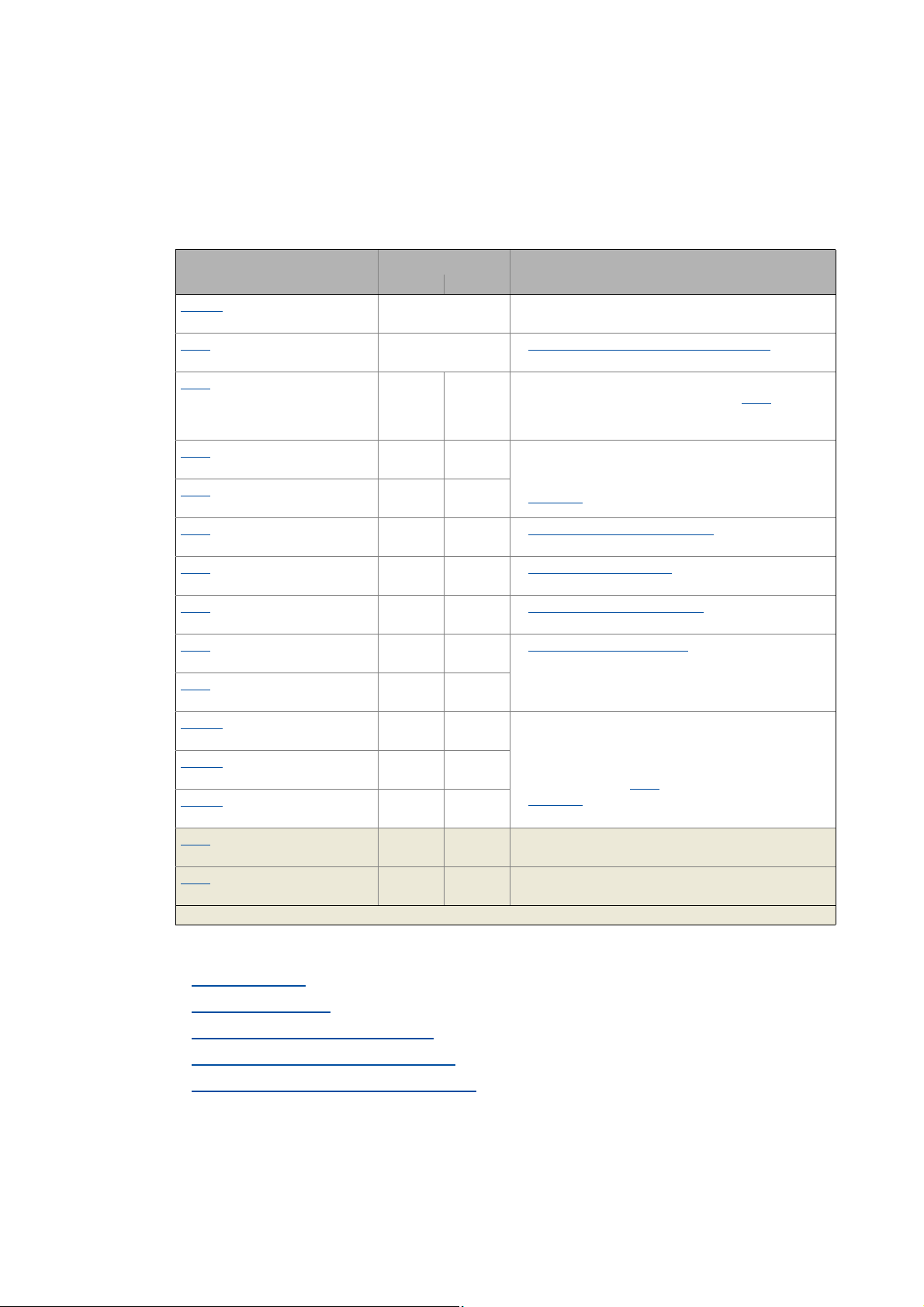

2.3.4 Menu structure

• Without active password protection, the "password" level will be skipped.

• The following applies when changing between the levels "Menu", "Code" and "Subcode":

The keypad records the last selection.

• For codes without subcodes, the "Subcode" level will be skipped.

Menu Info

-0- Access to the parameters of the user menu.

• The user menu of a device serves to create a selection of frequently used parameters to

be able to access and change these parameters quickly. User menu

-1- Access to all drive parameters.

-2- Access to parameters for quick commissioning with terminal control.

-3- Access to parameters for quick commissioning with the integrated keypad.

-4- Access to motor control parameters.

-5- Access to diagnostic/display parameters.

Note!

When the password protection is activated and no password or a wrong password is entered, only the parameters of the user menu can be accessed using the integrated keypad. All other menus/parameters require the correct password.

Password protection

( 23)

( 22)

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 21

Page 22

2 Introduction: Parameterising the controller

2.3 Internal Keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.3.5 User menu

The user menu (menu -0-) contains a selection of frequently used parameters to be able to access

and change these parameters quickly.

• The integrated keypad serves to change the preset parameter selection in C517

: Enter the codes

the user menu is to contain into the subcodes c001 ...c020. When "0" is set, no entry is displayed

in the user menu.

• The »Engineer« serves to configure the user menu on the User menu tab of the controller. Here,

additional functions are available for loading and saving the parameter selection.

The user menu contains the following parameters:

Code Subcode Info Lenze setting

Value Unit

C051 - Display of actual speed value - rpm

C053 - Display of DC-bus voltage - V

C054 - Display of motor current - A

C061 - Display of heatsink temperature - °C

C137 - Display of device status -

C011

C039

C012

C013

C015

C016

C022

C120

C087 - Rated motor speed 1460 rpm

C099 - Display of firmware version -

Highlighted in grey = display parameter

- Reference speed 1500 rpm

c001 Fixed setpoint 1 40.0 %

c002 Fixed setpoint 2 60.0 %

c003 Fixed setpoint 3 80.0 %

- Acceleration time - main setpoint 2.0 s

- Deceleration time - main setpoint 2.0 s

-V/f base frequency 50.0Hz

- Vmin boost 0.0 %

- Imax in motor mode 47.00 A

- Motor overload threshold (I2xt) 100 %

22

Note!

If the password protection is activated and no password or a wrong password is entered,

only these parameters can be accessed with the integrated keypad.

Password protection

( 23)

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 23

2 Introduction: Parameterising the controller

B

ESC

C

D

E

F

A

8888

3 sec

SAVE

2.3 Internal Keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

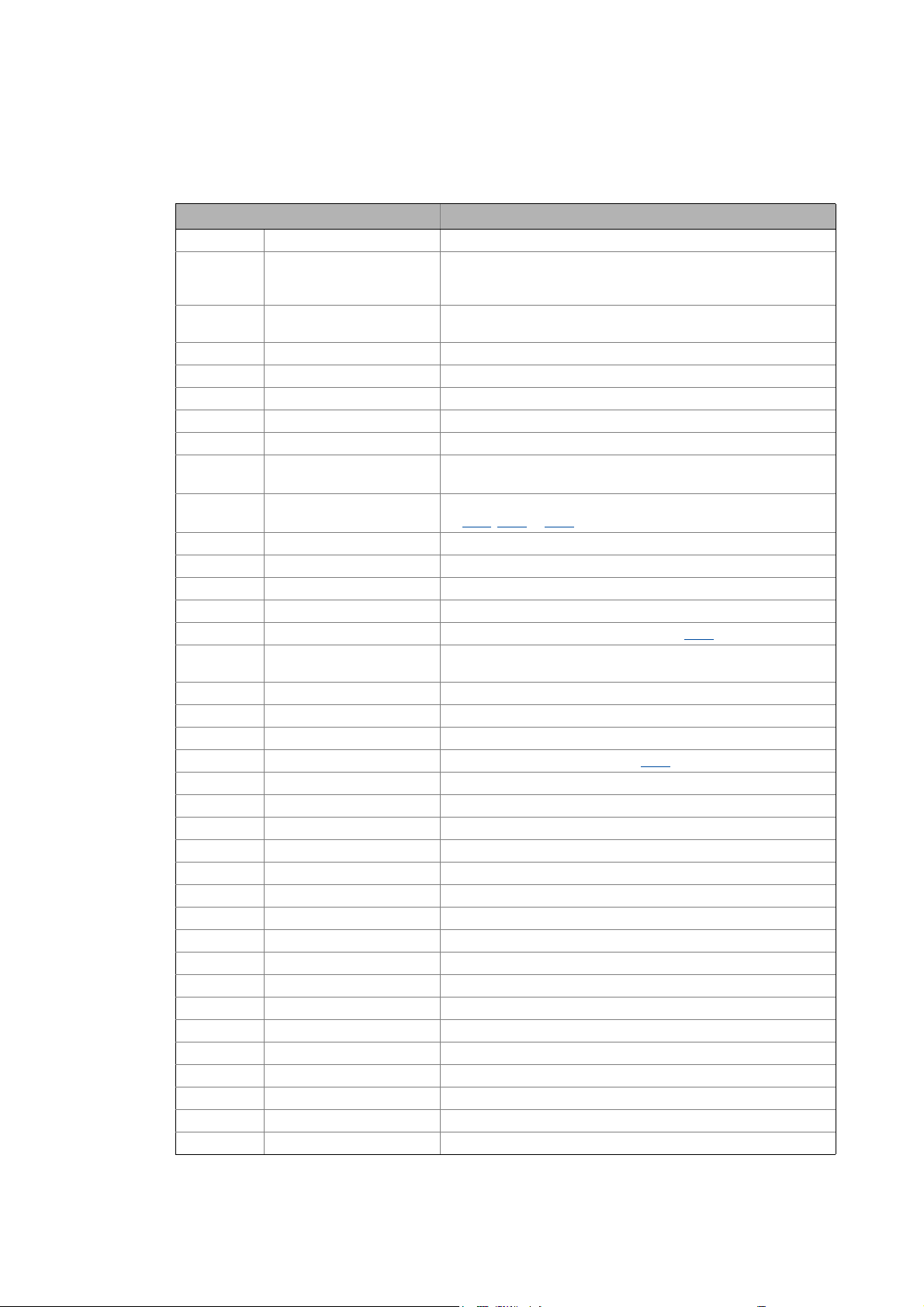

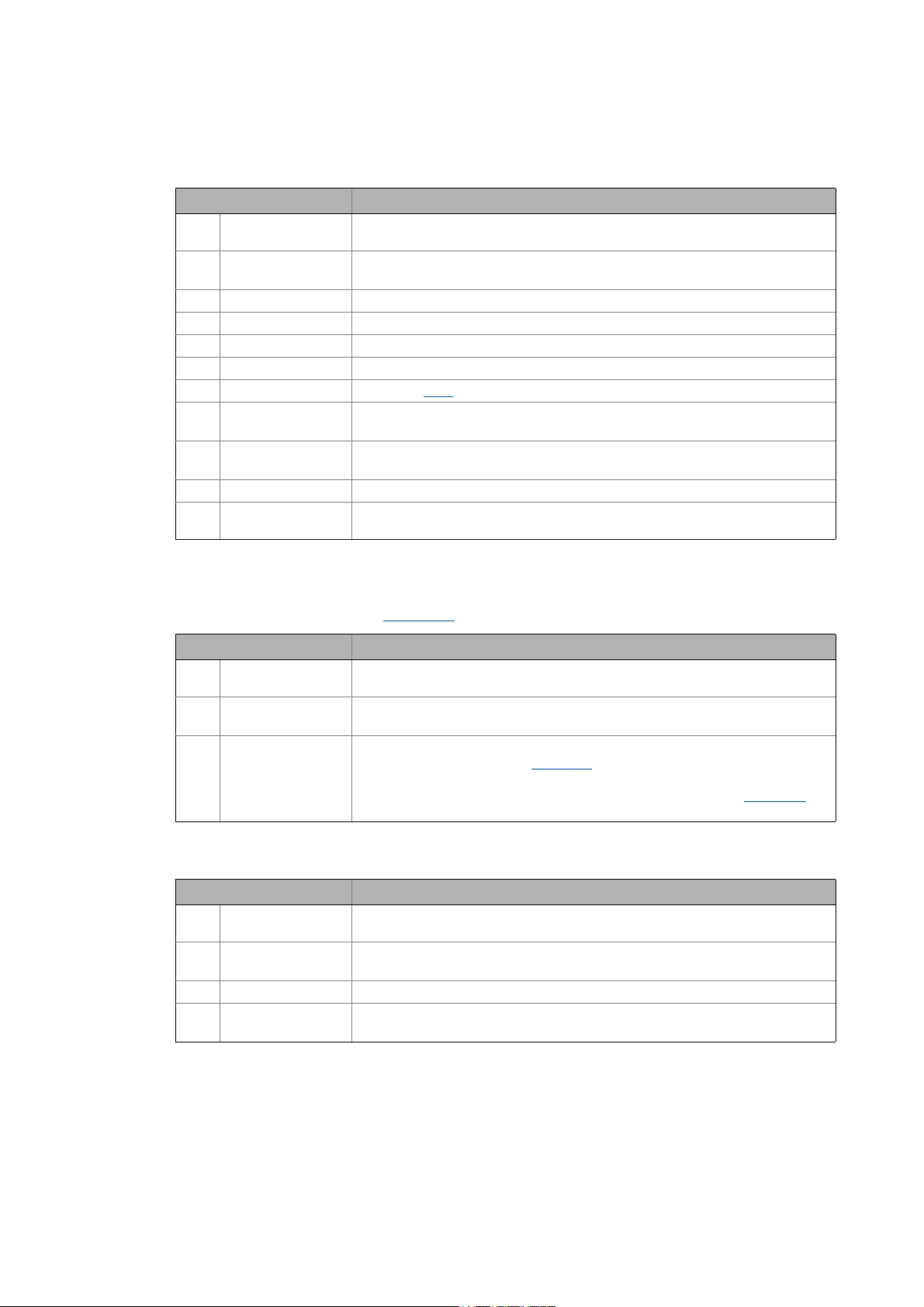

2.3.6 Quick saving of all parameters at the push of a button

Keep the entry button pressed for 3 seconds to save all parameter settings safe against mains failure.

• During the saving process, "SAVE" is blinking in the display.

• After approximately 2 seconds, "SAVE" will disappear from

the display and you can continue your work.

Related topics:

Save parameter settings

( 49)

2.3.7 Password protection

The controller offers the option to protect the unauthorised access to the menu level by assigning a

password. The following sections describe how to create, change, or delete the password protection

and how to access the menu level via the password.

Enter password and confirm it

Carry out the steps if you want to create the password protection for the first time for e.g. a controller in default status:

Step Info

1. Mains on After the mains has been switched on and the keypad self test has been completed,

2. ↵ After pressing the enter key:

3. Select menu -1- (all parameters).

4. ↵ Confirm selection.

5. Select code C094

6. ↵ Confirm selection.

7. Set the desired password ("01" ... "9999").

8. ↵ Accept password.

9. ↵ (3 seconds) Keep the entry button pressed for 3 seconds in order to save the parameter settings

"00" is displayed

Wit hout password protection you ha ve fre e acce ss from here to al l menus (and thus

all parameters).

("password").

("00" is now blinking, i.e. entry is possible.)

safe against mains failure.

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 23

Page 24

2 Introduction: Parameterising the controller

2.3 Internal Keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Change the existing password or deactivate the password protection

Step Info

1. Mains on After the mains has been switched on and the keypad self test has been completed,

2. ↵ After pressing the enter key and with existing password protection:

3. Enter password.

4. ↵ Confirm entry.

5. Select menu -1- (all parameters).

6. ↵ Confirm selection.

7. Select code C094

8. ↵ Confirm selection.

9. Change password: Set new password ("01" ... "9999").

10. ↵ Accept setting.

11. ↵ (3 seconds) Keep the entry button pressed for 3 seconds in order to save the parameter settings

"00" is displayed

"PASS" is displayed for a short time, then "0000".

("password").

(The existing password is now blinking, i.e. a change is possible.)

Deactivate password protection: Set "00".

safe against mains failure.

Access password-protected controller without knowing the password

When the password protection is activated and no password or a wrong password is entered, only

the max. 20 parameters of the user menu

Step Info

1. Mains on After the mains has been switched on and the keypad self test has been completed,

2. ↵ After pressing the enter key and with existing password protection:

3. ↵

or

↵

"00" is displayed

"PASS" is displayed for a short time, then "0000".

After direct confirmation of the value "0000":

• Only the parameters of the user menu

When the wrong password has been entered and confirmed:

• "Err" is displayed for a short time, then only the parameters of the User menu

be selected.

can be accessed.

can be selected.

can

Reach password-protected menu level with knowing the password

Step Info

1. Mains on After the mains has been switched on and the keypad self test has been completed,

2. ↵ After pressing the enter key and with existing password protection:

3. Enter password.

4. ↵ When the correct password has been confirmed:

"00" is displayed

"PASS" is displayed for a short time, then "0000".

You have free access from here to all menus (and thus all parameters).

24

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 25

3 Commissioning

3.1 Safety instructions with regard to commissioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Commissioning

The 8400 BaseLine C controller is commissioned in one of the following ways:

• Commissioning with integrated keypad

• If only a few parameters have to be adapted.

• For test/demonstration purposes.

• Commissioning with PC/»Engineer«

• The »Engineer« provides a comfortable access to all parameters of the 8400 BaseLine C controller and hence full flexibility in the commissioning process.

3.1 Safety instructions with regard to commissioning

General safety instructions

In order to prevent injury to persons or damage to material assets

• before connecting the mains voltage

• The wiring for completeness, short circuit, and earth fault

• The "emergency stop" function of the entire system

• The motor circuit configuration (star/delta) must be adapted to the output voltage of the

controller

• The in-phase connection of the motor

• Check the setting of the most important drive parameters before enabling the controller

• The V/f rated frequency must be adapted to the motor circuit configuration!

• The drive parameters relevant for your application must be set correctly!

• The configuration of the I/O terminals must be adapted to the wiring!

• Make sure that no speed setpoint is applied before controller enable

, check

:

.

Safety instructions with regard to motor operation

Danger!

• For thermal reasons, continuous operation of self-ventilated motors at a low field frequency and rated motor current is not permissible!

• If required, activate the Brake resistor monitoring (I2xt)

• With regard to the V/f base frequency (C015

controllers 8400 StateLine/HighLine/TopLine:

For the 8400 BaseLine, the reference voltage for the V/f base frequency is the rated

motor voltage (C090

tage on the supply side).

) according to motor nameplate (independent of the mains vol-

. ( 106)

), observe the following difference to the

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 25

Page 26

3 Commissioning

DI1DI2

DI3

DI4

RFR

X4

24EDO1

12I

AR

A1U

GND

0 10V...

1k

10k

W

...

W

AR

A1U

GND

DI1DI2

DI3

RFR

X4

DO1 12I24E

DI4

3.2 Preparing the 8400 BaseLine for commissioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.2 Preparing the 8400 BaseLine for commissioning

Danger!

Take all the necessary safety precautions before you carry out the following commissioning steps and switch the device on!

Safety instructions with regard to commissioning

1. Wiring the power connections

• Refer to the mounting instructions supplied with the drive controller to find help on how to

correctly design the power connections to match the requirements of your device.

2. Wire the control connections

• The following shows the wiring for the Lenze setting.

Analog input at X4 Terminal Function

A1U Setpoint selection

( 25)

• Scaling: 10 V ≡ 100 % ≡ 1500 rpm

(for 4-pole motor)

Digital inputs at X4 Terminal Function

RFR Controller enable: HIGH level

Error reset: HIGH-LOW edge

DI1 Selection fixed setpoint 1 ... 3

DI2

DI1 ... DI4: All HIGH active

DI3 Request DC-injection braking (DCB)

DI4 Request change of direction of rotation

3. Inhibit the controller:

Set terminal X4/RFR to LOW level or open contact to terminal X4/12I .

4. Switch on voltage supply of the controller.

• Information on some operating states can be quickly obtained via the LED display of the integrated keypad. LED status display

( 18)

When the green LED is blinking and the red LED is off, the controller is ready to start and you can

continue with commissioning as required:

Commissioning with integrated keypad

( 27)

or

Commissioning with the »Engineer«

( 31)

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

26

Page 27

3 Commissioning

3.3 Commissioning with integrated keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3 Commissioning with integrated keypad

Only a few parameters need to be adapted for the drive. Afterwards, the drive application can be immediately controlled via the digital and analog inputs of the controller in the preset control mode

"Terminals 0".

Information on how to use the integrated keypad can be found in the chapter entitled

"Internal Keypad

Commissioning steps

In the following, commissioning of the controller using the integrated keypad is described step by

step. Please process the chapters consecutively and execute all steps carefully. This procedure will

help you to commission the controller quickly and as safe as possible:

Load Lenze setting

Parameterise drive/application ( 28)

". ( 17)

Save parameter settings safe against mains failure

Enable controller and select speed

3.3.1 Load Lenze setting

In order to achieve a defined device configuration, it is advisable to make sure that the device is in

its original delivery state. For this purpose, the "Load Lenze setting" device command is available.

Step Info

1. Mains on After the mains has been switched on and the keypad self test has been completed,

2. ↵ After pressing the enter key:

3. Select menu -2-.

4. ↵ Confirm selection.

5. ↵ Confirm first code C002

6. ↵ Confirm subcode c001 ("load Lenze setting").

7. Set value "01" (≡ "Start").

8. ↵ Accept parameter setting to execute the "Load Lenze setting" device command.

( 29)

( 30)

"00" is displayed

Wit hout password protection you ha ve fre e acce ss from here to al l menus (and thus

all parameters).

• The menu -2- contains parameters for quick commissioning with terminal control.

("device commands") of the menu -2-.

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 27

Page 28

3 Commissioning

3.3 Commissioning with integrated keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3.2 Parameterise drive/application

The menu -2- of the integrated keypad contains all basic parameters to commission the drive/application "actuating drive speed" quickly and easily for a terminal control. When you set these parameters to suitable and sensible values, the controller can be operated properly.

Parameter Lenze setting Info

Value Unit

C002/1

Load Lenze setting

C007

Select control mode

C011

Reference speed

C012

Acceleration time - main setpoint

C013

Deceleration time - main setpoint

C015

V/f base frequency

C016

Vmin boost

C022

Current limit (in motor mode)

C087

Rated motor speed

C089

Rated motor frequency

C039/1

Fixed setpoint 1

C039/2

Fixed setpoint 2

C039/3

Fixed setpoint 3

C051

Actual speed value

C054

Current motor current

Highlighted in grey = display parameter

0: Off / ready Reset all parameters to the Lenze setting which are sa-

10: Terminals 0 Terminal assignment of the control modes

1500 rpm All speed setpoint selections are provided in % and al-

2.0 s The setpoint is led via a ramp function generator with li-

2.0 s

50.0 Hz Adapting the V/f base frequency

0.0 % Adapting the Vmin boost

47.00 A Optimising the Imax controller

1460 rpm Motor selection/Motor data

50 Hz

40.0 % A fixed setpoint for the setpoint generator can be acti-

60.0 %

80.0 %

- rpm

- A

ved in the controller firmware.

( 139)

ways refer to the reference speed set in C011

The motor reference speed is given on the motor name-

plate.

near characteristic. The ramp function generator converts setpoint step-changes at the input into a ramp.

L_NSet_1

vated instead of the main setpoint via the digital inputs

DI1 and DI2.

• The fixed setpoints are selected in [%] based on the

reference speed (C011

L_NSet_1

( 309)

( 83)

( 84)

( 85)

( 65)

).

( 309)

.

28

More detailed information on the drive application:

Drive application

Interface description

Setting parameters (short overview)

Pre-assignment of the drive application

Terminal assignment of the control modes

( 121)

( 127)

( 132)

( 133)

( 139)

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 29

3 Commissioning

B

ESC

C

D

E

F

A

8888

3 sec

SAVE

3.3 Commissioning with integrated keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3.3 Save parameter settings safe against mains failure

If parameter settings are changed in the controller, those changes will be lost after mains switching

of the controller unless the settings have been saved explicitly.

• Keep the entry button pressed for 3 seconds in order to save

the parameter settings safe against mains failure.

Tip!

In C141

Automatic saving of parameter changes

, an automatic saving can be activated.

( 49)

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 29

Page 30

3 Commissioning

3.3 Commissioning with integrated keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3.4 Enable controller and select speed

Note!

If the controller is enabled at power-on and the auto-start option is activated in C142 "In-

hibit at power-on" (Lenze setting), the controller remains in the "ReadyToSwitchON

te.

For changing to the "SwitchedON

nal X4/RFR to LOW level or open contact to terminal X4/12I.

When the controller is in the "SwitchedON" state:

1. Enable controller:

Set terminal X4/RFR to HIGH level or close contact to terminal X4/12I n.

2. Select speed:

• In the "Terminals 0" by selecting a voltage at the analog input or by selecting a fixed setpoint

via the digital inputs DI1/DI2.

" state, first deactivate the controller enable: Set termi-

" sta-

DI1 DI2 Speed selection

LOW LOW The setpoint speed is selected via the analog input 1

• Scaling: 10 V ≡ 100 % ≡ reference speed (C011

HIGH LOW The fixed setpoint 1 (C039/1

• Lenze setting: 40 % of the reference speed (C011

LOW HIGH The fixed setpoint 2 (C039/2

• Lenze setting: 60 % of the reference speed (C011

HIGH HIGH The fixed setpoint 3 (C039/3

• Lenze setting: 80 % of the reference speed (C011

) is used as setpoint speed.

) is used as setpoint speed.

) is used as setpoint speed.

)

)

)

)

Note!

Observe the actual speed value (display in C051) as well as the LED status display and

Display messages

Tip!

More control functions in the "Terminals 0" control mode:

• DI3: HIGH level ≡ request DC-injection braking

• DI4: HIGH level ≡ request change of direction of rotation

indicated in the integrated keypad.

30

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 31

3 Commissioning

3.4 Commissioning with the »Engineer«

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.4 Commissioning with the »Engineer«

Commissioning with the »Engineer« is suited for every drive task and in particular for drive tasks

with more demanding requirements/more comprehensive parameter setting.

In the following, commissioning of the controller is described step by step. Please process the chapters consecutively and execute all steps carefully. This procedure will help you to commission the

controller quickly and as safe as possible:

Preconditions for commissioning with the »Engineer«

Creating an »Engineer« project & going online

Parameterise drive/application

Save parameter settings safe against mains failure

Enable controller and select speed

3.4.1 Preconditions for commissioning with the »Engineer«

For commissioning, you need

• a PC that satisfies the following requirements:

• processor with 1.4 GHz or higher

• at least 512 MB RAM and 650 MB free hard disc space

• Microsoft® Windows® 2000 operating system (from service pack 2 onwards) or

Windows® XP

• the Lenze »Engineer« PC software

• a connection to the controller, e.g. via USB diagnostic adapter:

• Connect the USB diagnostic adapter to the diagnostic interface X6.

• Connect the USB diagnostic adapter to the PC via a free USB port.

Tip!

How to obtain/update the L-force »Engineer« software:

• Download from the Internet:

The full version of the »Engineer StateLevel« is provided free of charge. Current software

can be found on the Internet in the "Services & Downloads" area under http://

www.Lenze.com.

• Requesting the CD

Yo u c an a ls o re qu est th e L-fo rc e »Eng in eer « s epa ra tel y o n CD fr ee of c ha rge at you r L enz e

representative. See the "About Lenze" area on our homepage for e.g. the corresponding

German address.

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 31

Page 32

3 Commissioning

3.4 Commissioning with the »Engineer«

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.4.2 Creating an »Engineer« project & going online

You can find detailed information on the general use of the »Engineer« in the online help

which you can call with [F1].

• In the "Working with projects" chapter, all options of the start-up wizard are described

to create a new »Engineer« project.

The following steps describe the standard procedure of creating a project using the Select

component from catalogue option. Here, you select the single components (controller, motor, etc.)

from selection lists.

1. Start the »Engineer«.

2. Create a new project by means of the Start-up wizard and the Select component from catalogue

option:

•In the Component dialog step, select the 8400 BaseLine C controller.

• Select the other components (motor/gearbox) to be added to the project in the Other

components dialog step.

3. Go online.

• After a successful connection to the controller, the following status is displayed in the Status

line:

4. Download parameter set.

• This command serves to overwrite the current parameter settings in the controller by parameter settings of the »Engineer« project.

32

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

Page 33

3 Commissioning

3.4 Commissioning with the »Engineer«