Page 1

Version 1.0

English

Leica TM6100A

User Manual

Page 2

Introduction

Introduction

Purchase Congratulations on the purchase of a TM6100A instrument.

2TM6100A

Product

identification

This manual contains important safety directions as well as instructions for setting

up the product and operating it. Refer to

tion.

Read carefully through the User Manual before you switch on the product.

The type and the serial number of your product are indicated on the type plate.

Enter the type and serial number in your manual and always refer to this information

when you need to contact your agency or Leica Geosystems authorized service workshop.

Type: _______________

Serial No.: _______________

"6 Safety Directions" for further informa-

Page 3

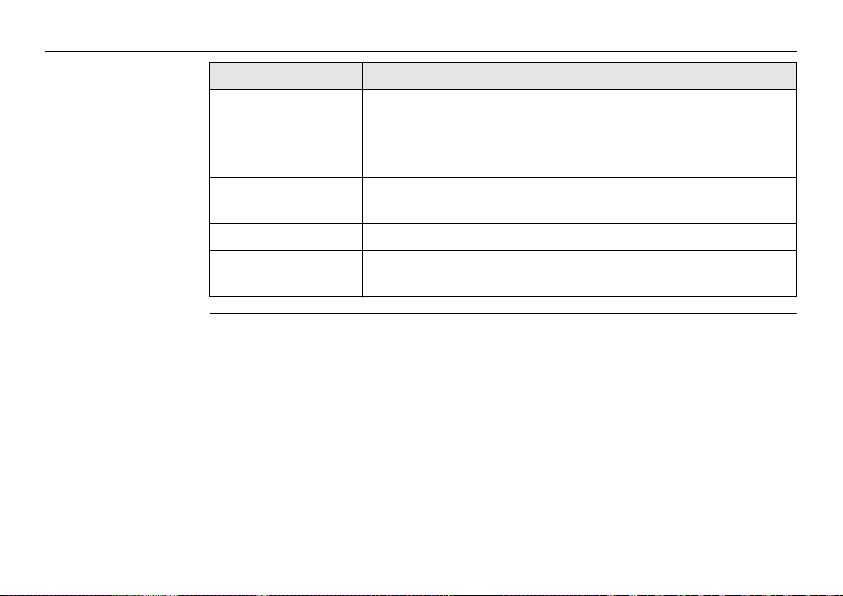

Symbols The symbols used in this manual have the following meanings:

Type Description

Danger Indicates an imminently hazardous situation which, if not

Warning Indicates a potentially hazardous situation or an unintended use

Caution Indicates a potentially hazardous situation or an unintended use

Trademarks • CompactFlash and CF are trademarks of SanDisk Corporation

• Bluetooth is a registered trademark of Bluetooth SIG, Inc

All other trademarks are the property of their respective owners.

avoided, will result in death or serious injury.

which, if not avoided, could result in death or serious injury.

which, if not avoided, may result in minor or moderate injury

and/or appreciable material, financial and environmental

damage.

Important paragraphs which must be adhered to in practice as

they enable the product to be used in a technically correct and

efficient manner.

Validity of this

manual

Introduction TM6100A 3

General This manual applies to all TM6100A instruments.

Description

Page 4

Introduction

4TM6100A

Available

documentation

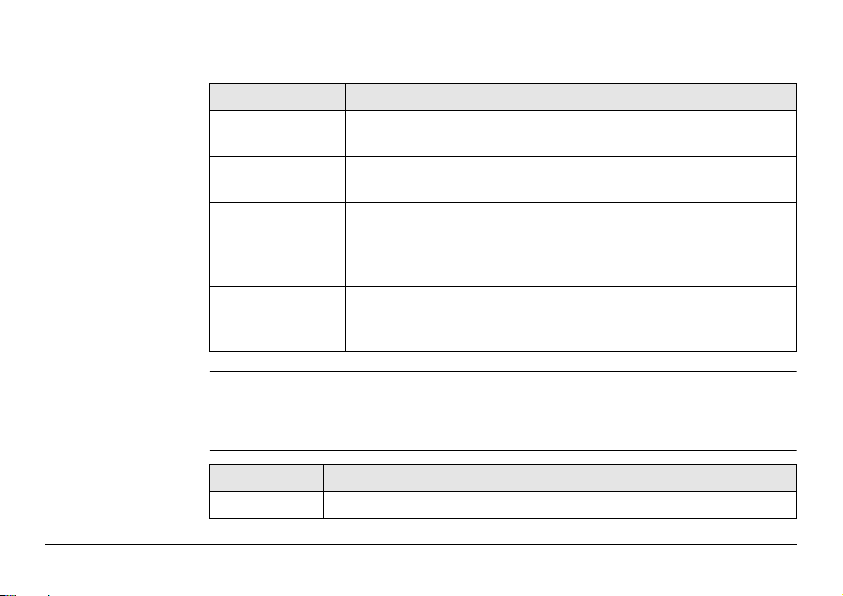

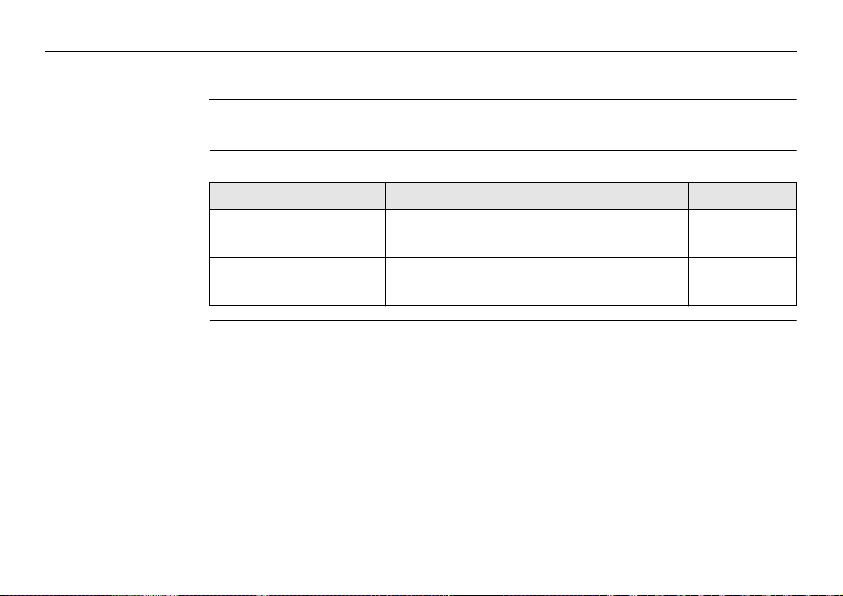

Name Description and Format

User Manual All instructions required in order to operate the product

Name Description and Format

System

Field Manual

Technical

Reference

Manual

Refer to the following resources for all TM6100A documentation and software

• the TPS6000 Product CD

• http://metrology.leica-geosystems.com/en/Downloads_6843.htm

to a basic level are contained in the User Manual.

Provides an overview of the product together with

technical data and safety directions.

Describes the general working of the product in

standard use and specific onboard application

programs. Intended as a quick reference field guide.

Overall comprehensive guide to the product and

program functions. Included are detailed descriptions

of special software/hardware settings and software/hardware functions intended for technical

specialists.

Page 5

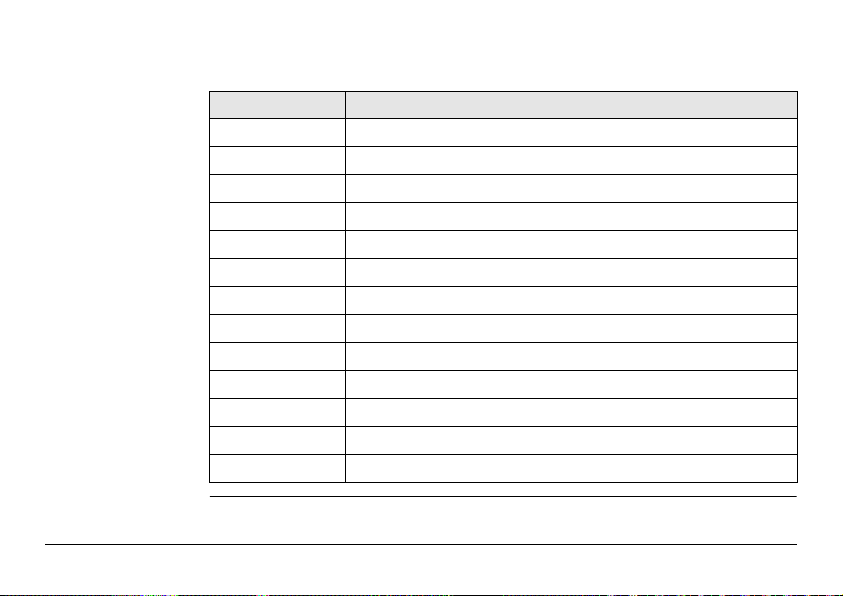

Table of Contents

In this manual Chapter Page

1 Description of the System 8

1.1 System Components 8

1.2 System Concept 11

1.2.1 Software Concept 11

1.2.2 Data Storage and Data Conversion Concept 13

1.2.3 Power Concept 15

1.3 Container Contents 16

1.4 Instrument Components 17

2 User Interface 20

2.1 Keyboard 20

2.2 Hot Key Assignments 24

2.3 Screen 27

2.4 Operating Principles 29

2.5 Icons 35

3 Operation 37

3.1 Instrument Setup 37

3.2 Battery 40

3.2.1 Operating Principles 40

Table of Contents TM6100A 5

Page 6

Table of Contents

6TM6100A

3.2.2 Instrument Battery 41

3.3 Working with the CompactFlash Card 43

3.4 Accessing Survey Application Program 46

3.5 Built-in autocollimation device 49

3.6 Connection to Application Computer 51

3.7 Limitation of the horizontal and vertical movements 55

4 Check & Adjust 60

4.1 Overview 60

4.2 Preparation 63

4.3 Combined Adjustment (l, t, i and c) 65

4.4 Tilting Axis Adjustment (a) 69

4.5 Adjusting the Circular Level of the Instrument and Tribrach 74

4.6 Adjusting the Circular Level of the Prism Pole 76

4.7 Inspecting the Laser Plummet of the Instrument 77

4.8 Servicing the Tripod 79

4.9 Adjustment of the autocollimation reticule 80

5 Care and Transport 82

5.1 Transport 82

5.2 Storage 84

5.3 Cleaning and Drying 85

5.4 Maintenance 87

Page 7

6 Safety Directions 88

6.1 General Introduction 88

6.2 Intended Use 89

6.3 Limits of Use 91

6.4 Responsibilities 92

6.5 Hazards of Use 93

6.6 Laser Classification 99

6.6.1 General 99

6.6.2 Laser Plummet 101

6.7 Electromagnetic Compatibility EMC 104

6.8 FCC Statement, Applicable in U.S. 107

7 Technical Data 110

7.1 Angle Measurement 110

7.2 Conformity to National Regulations 111

7.2.1 Communication side cover with Bluetooth 111

7.3 General Technical Data of the Instrument 112

8 International Limited Warranty,

Software License Agreement 119

Table of Contents TM6100A 7

Page 8

Description of the System

1 Description of the System

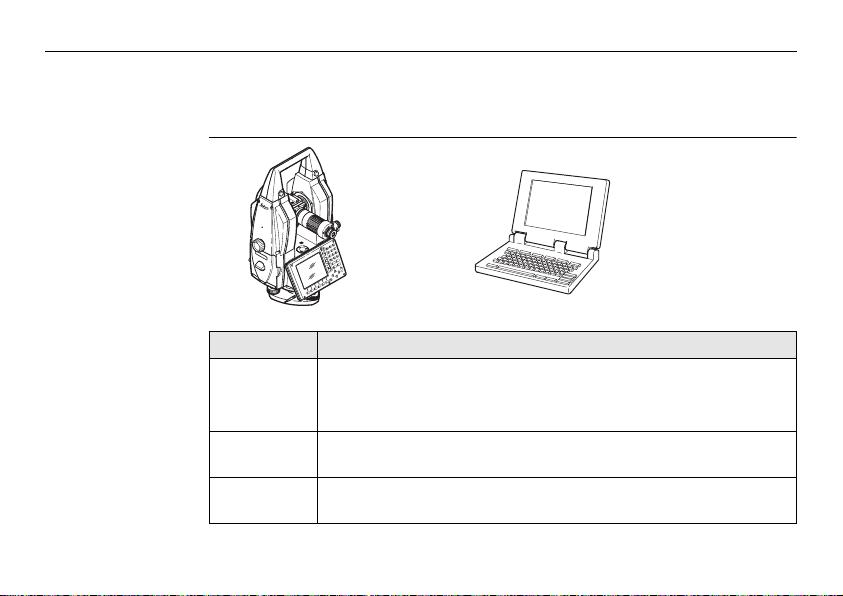

1.1 System Components

Main components

1 - 8TM6100A

TM6100A_001

Component Description

TM6100A • an instrument of highest accuracy for measuring, calculating

Application

Software

LGO Tools An office software consisting of a suite of standard and extended

TM6100A

and capturing data.

• connected with LGO Tools to view, exchange and manage data.

Third party metrology software with an interface to the TM6100A

for acquisition, analysis, management and reporting of data.

programs for the viewing, exchange and management of data.

Page 9

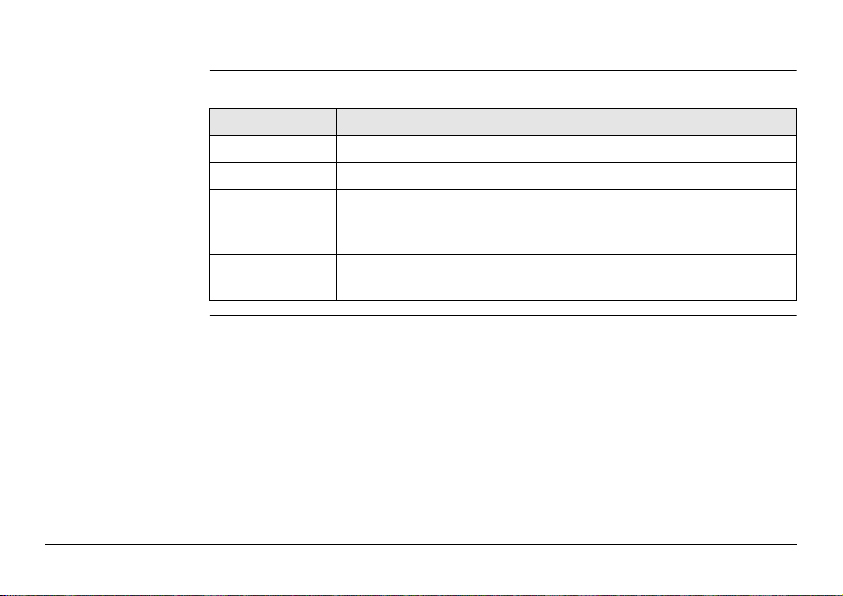

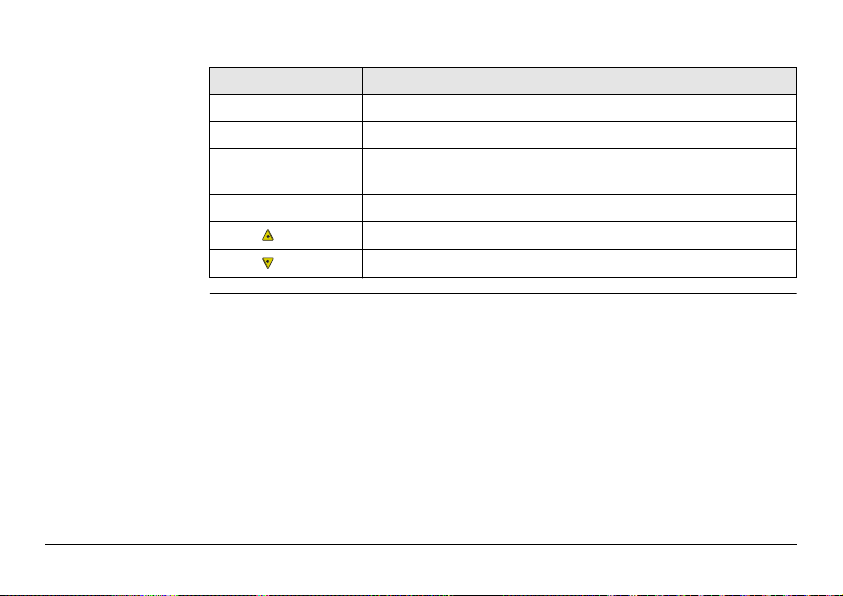

Terminology The following terms and abbreviations may be found in this manual:

Term Description

TPS Total Station Positioning System

LGO Tools LEICA Geo Office Tools

Motorised TM6100A instruments are fitted with internal motors, enabling

Communication

side cover

Description of the System TM6100A 1 - 9

automatic horizontal and vertical turning are referred to as

Motorised.

Communication side cover with integrated Bluetooth is a component with external devices, i.e. laptop with application software.

Page 10

Description of the System

Instrument models

Model Description

TM6100A Electronic theodolite, motorised, 0.5" accuracy.

1 - 10TM6100A

LEICA Geo Office

Tools

• LGO Tools supports TM6100A instruments. It also supports all other Leica TPS

instruments.

• LGO Tools is based on a graphical user interface with standard Windows® operating procedures.

• LGO Tools provides the following functionality:

Functionality Description

Standard

Functionality

• Supported operating systems: Windows® XP, Windows® 2000.

• Refer to the online help of LGO Tools for additional information.

Includes data exchange between computer and instrument, data

management including viewing and editing, reporting, creation

and management of codelists, creation and use of format files for

data conversion, uploading and deleting of system software and

application programs.

Page 11

1.2 System Concept

1.2.1 Software Concept

Description TM6100A instruments support the following types of software.

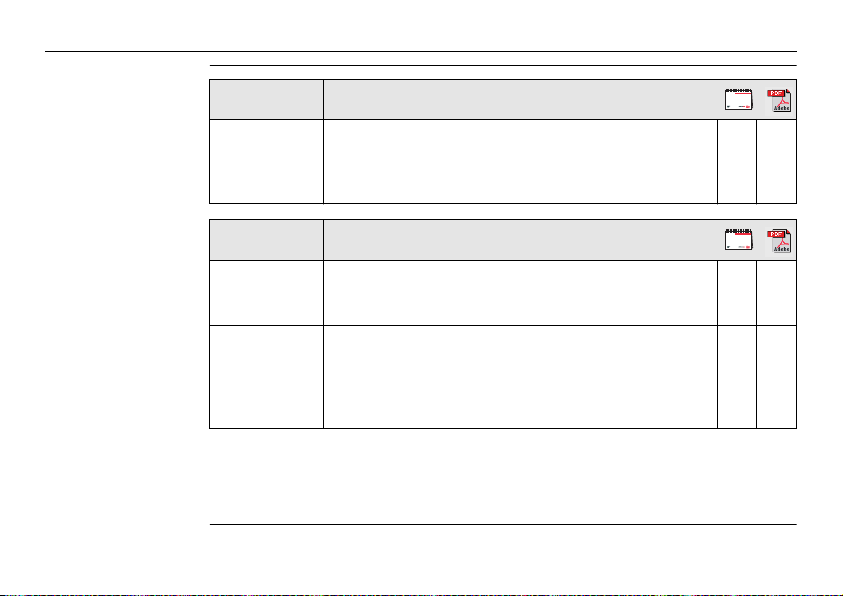

Software type

Description of the System TM6100A 1 - 11

Software type Description

System

software

Language

software

This software comprises the central functions of the instrument.

It is also referred to as firmware.

The programs Survey and Setup are integrated into the firmware

and cannot be deleted.

The English language is integrated into the firmware and cannot

be deleted.

Numerous languages are available for the TM6100A instruments.

This software is also referred to as system language.

The system software enables a maximum of three languages

which can be stored at any one time - the English language and

two other languages. The English language is the default

language and cannot be deleted. One language is chosen as the

active language.

Page 12

Description of the System

Software type Description

Application

programs

Third party application programs

Customised

application

programs

1 - 12TM6100A

A suite of optional specific application programs are available for

the instrument.

Some of the programs are activated freely and require no license

key and others require purchasing and are only activated with a

license key.

There are various third party applications available for the

TM6100A, onboard or computer based software. Please contact

your Leica Geosystems representative for details.

Customised software specific to user requirements can be developed using the GeoC++ development kit. Information on the

GeoC++ development environment is available on request from a

Leica Geosystems representative.

Software upload All instrument software is stored in the System RAM of the instrument. The software

can be uploaded onto the instrument using the following methods:

• Using LGO Tools the software is transferred via the serial interface to the

CompactFlash card in the instrument, which is then stored to the System RAM.

• By connecting the CompactFlash card directly to the computer either via an

internal card slot housing or an external OMNI drive, the software is transferred

to the card, which is then stored to the System RAM.

Page 13

1.2.2 Data Storage and Data Conversion Concept

Description Data is stored within a job in a database on a memory device. This is either a

Memory device

Description of the System TM6100A 1 - 13

CompactFlash card or an internal memory.

CompactFlash card: A CompactFlash card housing is standard. A CompactFlash

Internal memory: An internal memory is always fitted. It resides inside the

Unplugging connecting cables or removing the CompactFlash card during the measurement may cause loss of data. Always return to TM6100A Main Menu before

removing the CompactFlash card and switch off the instrument before removing

cables.

card can be inserted and removed. Available capacity:

256 MB and 1 GB.

instrument. Available capacity: 256 MB.

Whilst other CompactFlash cards may be used,

Leica recommends Leica CompactFlash cards

and cannot be held responsible for data loss or

any other error that may occur when using a

non-Leica card.

Page 14

Description of the System

Data conversion Export

Data can be exported from a job in a wide range of ASCII formats. A standard set of

Export Formats is delivered with the system. Customized export format can defined

in Format Manager which is a PC tool in

help of LGO Tools for information on creating format files.

Data can also be exported from a job in DXF or LandXML format.

Import

Data can be imported from ASCII, DXF, GSI8 or GSI16 format.

1 - 14TM6100A

LEICA Geo Office Tools. Refer to the online

Transfer raw data

LGO Tools

to

Raw data can be transferred between the database on the CompactFlash card or the

internal memory of the instrument and

• From the CompactFlash card or the internal memory directly via a serial interface

to a project in

• From the CompactFlash card using for example an OMNI drive as supplied by Leica

Geosystems to a project in LGO Tools on a PC.

CompactFlash cards can be used directly in an OMNI drive as supported by Leica

Geosystems. Other PC card drives may require an adapter.

LGO Tools on a PC.

LGO Tools in two ways:

Page 15

1.2.3 Power Concept

General Use the Leica Geosystems batteries, chargers and accessories or accessories recom-

Power options Instrument

Description of the System TM6100A 1 - 15

mended by Leica Geosystems to ensure the correct functionality of the instrument.

Power for the instrument can be supplied either internally or externally. An external

battery is connected to the instrument using a LEMO cable.

Internal battery: One GEB241 battery fitted into the battery compartment.

External battery: One GEB171 battery connected via cable

Page 16

Description of the System

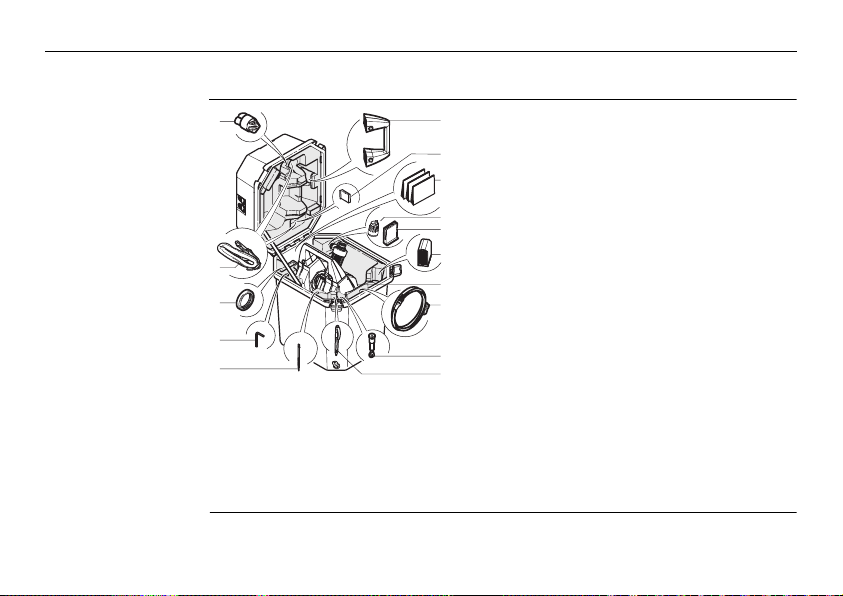

1.3 Container Contents

1 - 16TM6100A

Container for

instrument and

delivered

accessories

a

b

c

d

e

TM6100A_039

a) Protective cover for instrument and

f

sunshade for objective lens

b) Container straps

g

c) Counterweight for diagonal eyepiece or

h

i

j

k

l

m

zenith eyepiece - optional

d) Allen key

e) Spare stylus

f) Room for normal handle

g) Compact Flash card with cover

h) User manual

i) Autocollimation lamp AL51 - optional

j) CompactFlash card adapter with cover -

n

o

optional

k) Internal battery GEB241 - optional

l) Instrument with supplied stylus and

tribrach

m) Data transfer cable GEV218 - optional

n) Diagonal eyepiece GFZ3 or zenith

eyepiece GOK6 (eyepiece for steep

sighting) - optional

o) Ball pen - optional

Page 17

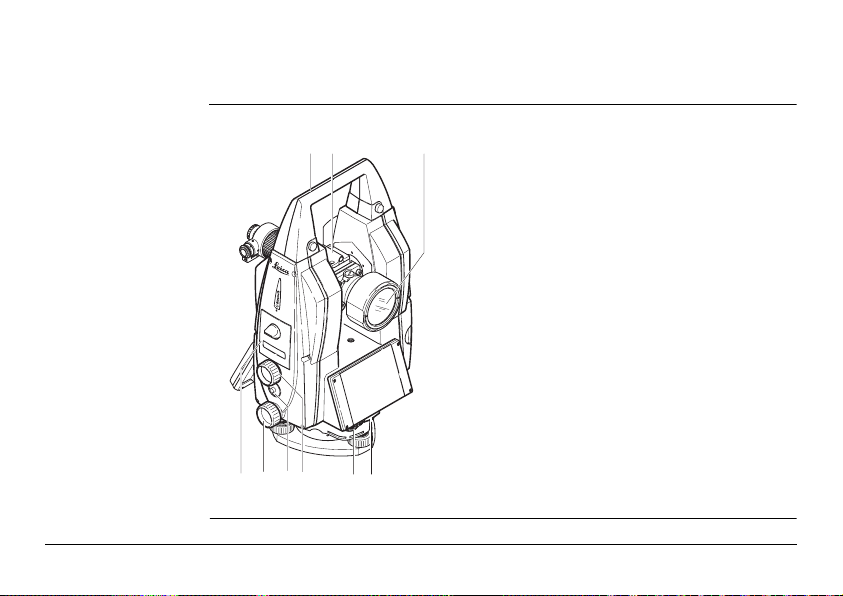

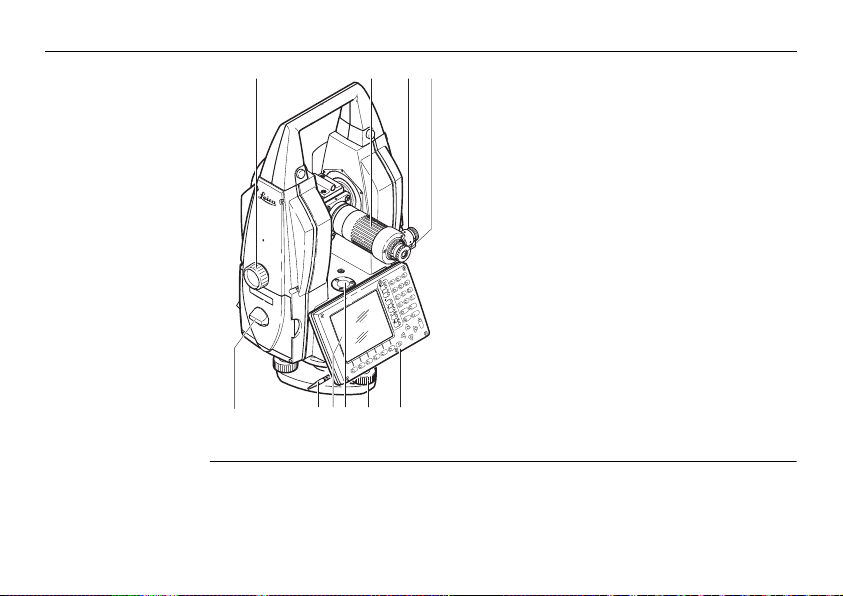

1.4 Instrument Components

Instrument

components

part 1 of 2

The instrument components of a TM6100A instrument are shown below.

a b c

a) Carry handle

b) Optical sight

c) Panfocal telescope

d) CompactFlash card compartment

e) Horizontal drive

f) User defined SmartKey

g) Vertical drive

TM6100A_002

f

d

ge

h i

h) Lemo connector

i) Tribrach

Description of the System TM6100A 1 - 17

Page 18

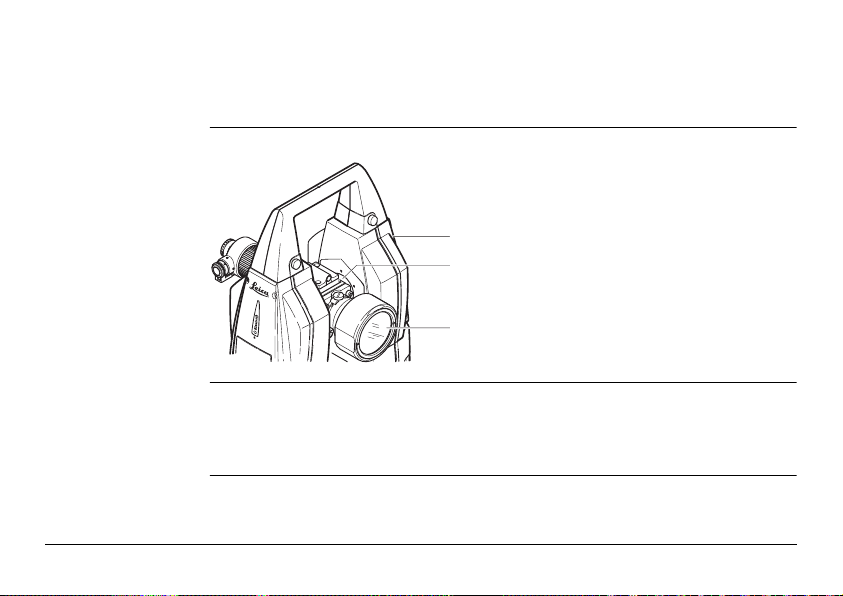

Description of the System

Instrument

components

part 2 of 2

TM6100A_003

j k l m

n

q r spo

1 - 18TM6100A

j) Vertical drive

k) Focusing ring

l) Autocollimation device

m) Interchangeable eyepiece

n) Battery compartment

o) Stylus for touch screen

p) Screen

q) Circular level

r) Footscrew

s) Keyboard

Page 19

Internal target An internal target GUS29 may be factory fitted to the telescope of the TM6100A to

facilitate the mutual accurate collimation of two theodolites. Depending on the

measurement task, the internal target can be rotated into or out of position.

a

b

a) TM6100A

c

TM6100A_004

b) Knob to rotate internal target GUS29

c) Panfocal telescope

Description of the System TM6100A 1 - 19

The internal target GUS29 is rotated into the visible positions when the marker line

on the knob is perpendicular to the line of sight.

When the marker line on the knob is parallel to the line of sight, the internal target

GUS29 is out of sight.

Page 20

User Interface

2 User Interface

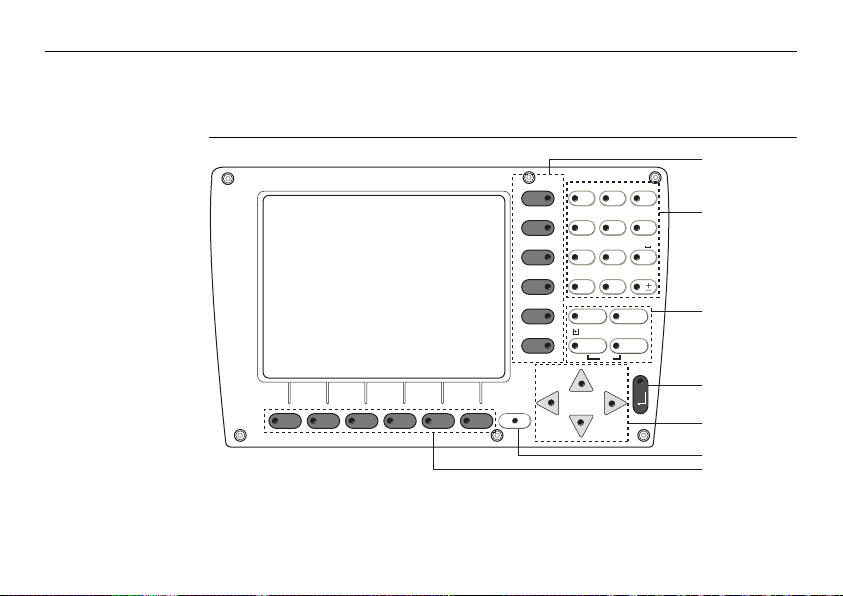

2.1 Keyboard

20TM6100A

Keyboard

TM6100A_005

F2F1 F3 F4 F5 F6

a

ABC DEF GHI

789

F12

JKL MNO PQR

456

F11

STU VWX YZ

F10

123

/$%_

PgUp

@&*?!

0.

CE ESC

USER PROG

ON

OFF

PgDn

F9

F8

F7

SHIFT

b

c

d

e

f

g

Page 21

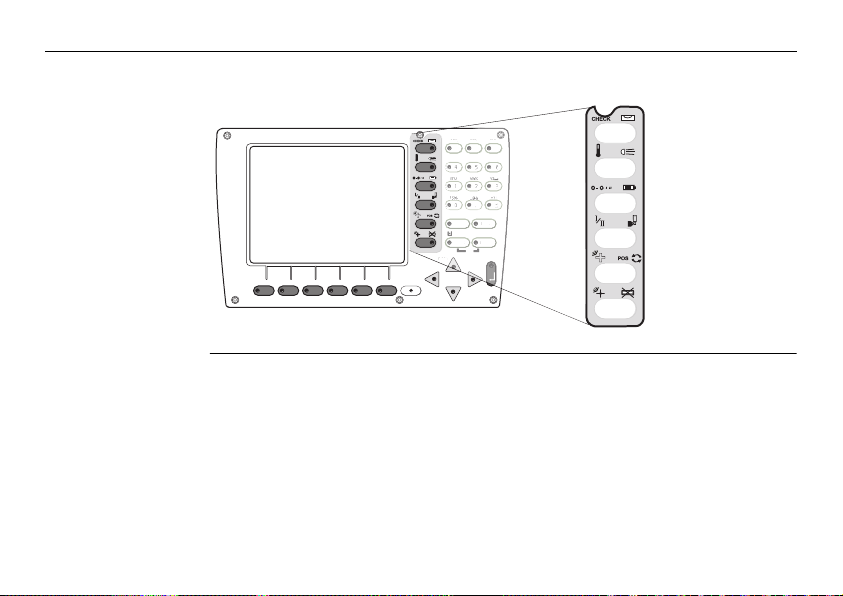

a) Hot keys F7-F12

b) Alphanumeric keys

c) CE, ESC, USER, PROG

d) ENTER

e) Arrow keys

f) SHIFT

g) Function keys F1-F6

Keys H

User Interface TM6100A 21

Key Description

Hot keys F7-F12 • Pre-defined keys to execute commands or access chosen

Alphanumeric keys • To type letters and numbers.

CE • Clears all entry at the beginning of user input.

ESC • Leaves the current menu or dialog without storing

USER • Calls the user defined menu.

PROG (ON) • If the instrument is off: to turn instrument on.

screens.

• The hot key F13, the user defined SmartKey, is located

between the horizontal and vertical drive on the right

hand side cover.

• Clears the last character during user input.

changes made.

• If the sensor is on: press at any time to select an application program.

Page 22

User Interface

22TM6100A

Key Description

ENTER • Selects the highlighted line and leads to the next logical

dialog/menu.

• Starts the edit mode for edit fields.

• Opens a list box.

SHIFT • Changes between the first and the second level of func-

tion keys.

Arrow keys • Move the focus on the screen.

Function keys F1-F6 • Correspond to the six softkeys that appear on the bottom

of the screen when the screen is activated.

Page 23

Key combinations

User Interface TM6100A 23

Keys Description

PROG plus USER Turns instrument off.

SHIFT F12 Calls STATUS Level & Laser Plummet.

SHIFT F11 Calls CONFIGURE Lights, Display, Beeps, Text, Lights

SHIFT USER Calls QUICK SET Change Settings to:.

SHIFT

SHIFT

page.

Pages up.

Pages down.

Page 24

User Interface

2.2 Hot Key Assignments

24TM6100A

General TM6100A instruments contain two standard configurations at delivery. Two more

configurations are available on the Factory CD.

Configuration Set Description Angle Unit

TM6100A BT Standard configuration set for Bluetooth

Degree

connection

TM6100A Cable Standard configuration set for Cable

Degree

connection

Page 25

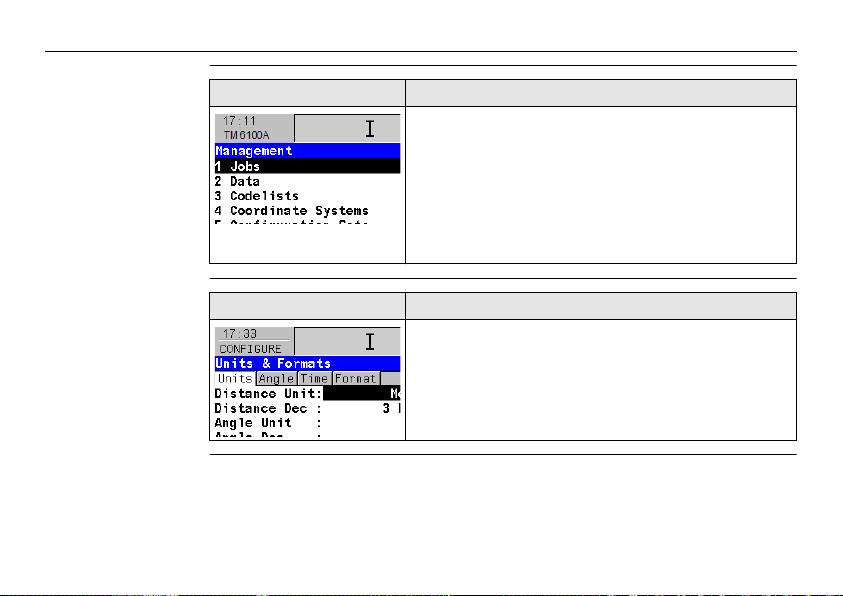

Hot Keys All default configurations contain the following Hot Key & Shift Hot Key assignments:

Key Description

F7 Autocollimation lamp On/Off

F8 Reticule illumination On/Off

F9 Change face

F10 Position Hz/V

F11 TPS Correction (Environmental Parameters)

F12 Check & Adjust

F13 (Trigger Key) Rec (Take an angle measurement)

Shift - F7 Compensator functions

Shift - F8 Telescope accessories

Shift - F9 Units & Formats

Shift - F10 Battery & Memory Status

Shift - F11 Lights & Display Settings

Shift - F12 Electronic Level & Plummet

User Interface TM6100A 25

Page 26

User Interface

PgUp

CEESC

USERPRO

8

9

ABC

DEFGHI

JKLMNO

PQR

ON

OFF

Keyboard Overlay A self adhesive keyboard overlay is available for the default Hot Key assignments. The

keyboard overlay can be affixed to the keyboard as shown below if required.

ABC DEF GHI

789

F12

JKL MNO PQR

F11

F10

F9

CE ESC

F8

USER PROG

F7

F2F1 F3 F4 F5 F6

SHIFT

TM6100A_006

G

ON

OFF

PgUp

PgDn

26TM6100A

Page 27

2.3 Screen

Screen

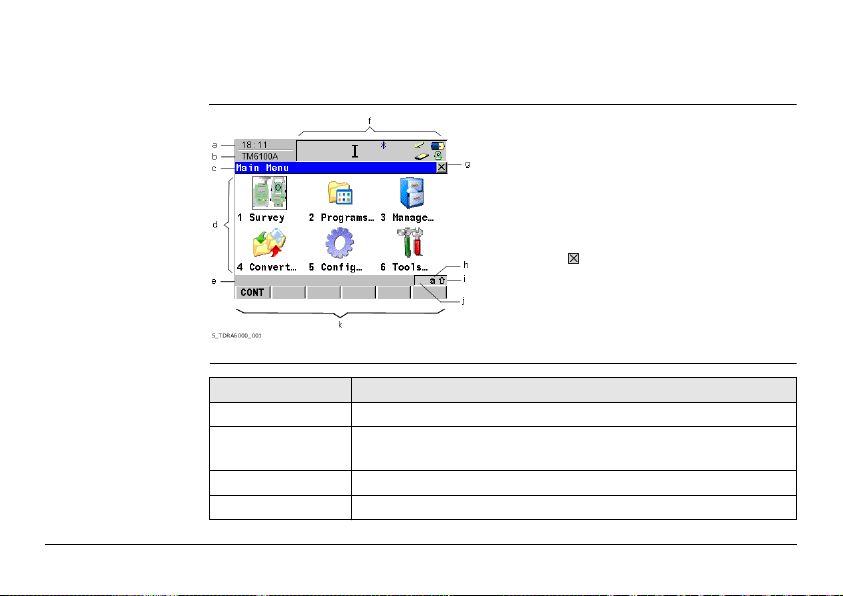

a) Time

b) Caption

c) Title

d) Screen area

e) Message line

f) Icons

g) ESC

h) CAPS

i) SHIFT icon

j) Quick coding icon

k) Softkeys

Elements of the

screen

User Interface TM6100A 27

Element Description

Time The current local time is shown.

Caption Shows location either in Main Menu, under PROG key or USER

key.

Title Name of the screen is shown.

Screen area The working area of the screen.

Page 28

User Interface

Element Description

Message line Messages are shown for 10 s.

Icons Shows current status information of the instrument. Refer to

ESC

CAPS The caps mode for upper case letters is active.The caps mode

SHIFT icon Shows the status of the SHIFT key; either first or second level

Quick coding icon Shows the quick coding configuration. Can be used with touch

Softkeys Commands can be executed using F1-F6 keys. The commands

Scroll bar

"2.5 Icons". Can be used with touch screen.

Can be used with touch screen. Same functionality as the fixed

key ESC. The last operation will be undone.

is activated and deactivated by pressing UPPER (F5) or LOWER

(F5) in some screens.

of softkeys is selected. Can be used with touch screen and has

the same functionality as the fixed key SHIFT.

screen to turn quick coding on and off.

assigned to the softkeys are screen dependent. Can be used

directly with touch screen.

Scrolls the screen area up and down.

28TM6100A

Page 29

2.4 Operating Principles

Keyboard and

touch screen

Turn instrument on Press and hold PROG for 2 s.

Turn instrument

off step-by-step

Lock/Unlock

keyboard

User Interface TM6100A 29

The user interface is operated either by the keyboard or by the touch screen with

supplied stylus. The workflow is the same for keyboard and touch screen entry, the

only difference lies in the way information is selected and entered.

Step Description

Option Description

Lock To lock the keyboard press and hold SHIFT for 3 s. The message ’Keyboard

Unlock To unlock the keyboard press and hold SHIFT for 3 s. The message

The instrument can only be turned off in TM6100A Main Menu.

1. Press and hold both USER and PROG simultaneously.

OR

Press ESC for more then 2 s.

2. Press YES (F6) to continue or NO (F4) to cancel.

locked’ is momentarily displayed on the Message Line.

’Keyboard unlocked’ is momentarily displayed on the Message Line.

Page 30

User Interface

30TM6100A

Selecting

from a menu

Selecting a page

Appearance Description

To select an item from a menu, do one of the following:

Move the focus to the item. ENTER or CONT (F1).

OR

Type the complete selection number in front of the

item. ENTER or CONT (F1) are not required.

OR

Tap on the item with the stylus.

Appearance Description

To select a page in a screen, do one of the following:

PAGE (F6).

OR

Tap on the page tab with the stylus.

Page 31

Edit an entire value

in input fields

Appearance Description

1. Highlight the field.

2. Type numeric and/or alphanumeric characters to

overwrite.

3. ENTER or tap outside of the field.

Edit an individual

character in input

fields

User Interface TM6100A 31

Appearance Description

A character can be inserted or overwritten. The procedure is the same for both cases.

1. Highlight the field.

2. For the keyboard: ENTER. The edit mode is activated where additional functions like insert and

overwrite are available.

3. For the touch screen: Highlight the characters to be

changed.

4. Type numeric and/or alphanumeric characters.

5. ENTER or tap outside of the field.

Page 32

User Interface

Access special

alphanumeric

characters for

input

32TM6100A

Step Description

1. Highlight the input field.

2. For the keyboard: ENTER.

3. Toggle to the desired special character set by using the up/down arrow

keys.

4. Press the function key assigned to the required character group.

5. Press the function key with the required character.

6. Repeat step 4. and 5. for entering more special characters of the same

character set.

7. ENTER.

Appearance and

selection from a

choicelist

Choicelists have various appearances.

Closed choicelist

Appearance Description Selection

Triangles on the right indicate further available

choices.

Use the arrow keys

change through the list or

tap the triangles on the

screen.

to

Page 33

ENTER or tap on the field to access the choicelist. Opening a choicelist reveals either

a simple listbox or a comprehensive listbox dialog.

Simple listbox

.

Appearance Description Selection

• Choicelist shows items

to select.

• A search field is shown

if necessary.

• A scroll bar is shown if

necessary.

• Highlight the item and

ENTER.

• To exit without

changes ESC, tap

or

outside the simple

listbox.

User Interface TM6100A 33

Page 34

User Interface

Listbox dialog

.

Appearance Description Selection

• Choicelist fills the

whole screen.

• A search field is

shown.

• A scroll bar is shown if

• Highlight the item and

CONT (F1).

• To exit without

changes press ESC or

tap

necessary.

• The functionality

comprise adding,

editing and deleting of

items.

• Listbox dialogs are

explained in detail at

appropriate places in

the manuals.

34TM6100A

.

Page 35

2.5 Icons

Description The screen icons display the current status information of the instrument.

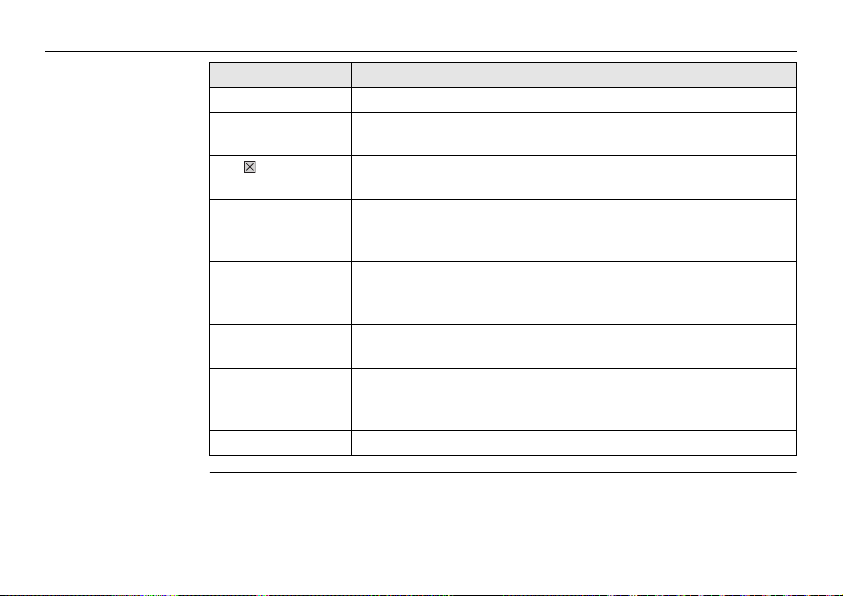

Position of the

icons on the screen

a) Compensator/face I&II

b) Bluetooth

c) CompactFlash card/internal memory

d) Battery

e) SHIFT

f) Quick coding

Icons

User Interface TM6100A 35

Icon Description

Reflector The currently active reflector is displayed.

Compensator/face I&II Compensator off, out of range or face I&II icon is

displayed.

Page 36

User Interface

Icon Description

Bluetooth The status of each Bluetooth port and any Bluetooth

CompactFlash

card/internal memory

Battery The status and source of the battery is displayed. The

SHIFT The status of the SHIFT key is displayed.

Quick coding Shows the quick coding configuration. Can be used with

connection is displayed.

The status of the CompactFlash card and internal

memory are displayed.

• For the CompactFlash card, the capacity of used

space is shown in seven levels.

• For the internal memory, the capacity of used

memory is shown in nine levels.

percentage of remaining power capacity for all batteries

are displayed numerically and graphically. For internal

and external battery being attached at the same time the

internal battery is used until it is empty and then the

external battery is used.

touch screen to turn quick coding on and off.

36TM6100A

Page 37

3 Operation

3.1 Instrument Setup

Description This topic describes an instrument setup over a marked ground point using the laser

Operation TM6100A 37

plummet. It is always possible to set up the instrument without the need for a

marked ground point.

Important features:

• It is always recommended to shield the instrument from direct sunlight and

avoid uneven temperatures around the instrument.

• The laser plummet described in this topic is built into the vertical axis of the

instrument. It projects a red spot onto the ground, making it appreciably easier

to centre the instrument.

• The laser plummet cannot be used in conjunction with a tribrach equipped with

an optical plummet.

Page 38

Operation

Setup step-by-step

38TM6100A

SHIFT

F12

3

2

7

6

1

TM6100A_007

Step Description

Shield the instrument from direct sunlight and avoid uneven temperatures

around the instrument.

1. Extend the tripod legs to allow for a comfortable working posture. Position

the tripod over the marked ground point, centring it as well as possible.

2. Fasten the tribrach and instrument onto the tripod.

1

1

5

4

5

5

Page 39

Step Description

3. Turn on the instrument by pressing PROG for 2 s. Press SHIFT (F12) to

access STATUS Level & Laser Plummet, activating the laser plummet.

4. Move the tripod legs (1) and use the tribrach footscrews (6) to centre the

plummet (4) over the ground point.

5. Adjust the tripod legs to level the circular level (7).

6. By using the electronic level turn the tribrach footscrews (6) to precisely

level the instrument.

7. Centre the instrument precisely over the ground point (4) by shifting the

tribrach on the tripod plate (2).

8. Repeat steps 6. and 7. until the required accuracy is achieved.

Operation TM6100A 39

Page 40

Operation

3.2 Battery

3.2.1 Operating Principles

40TM6100A

Primary use/charging

• The battery must be charged prior to using it for the first time because it is delivered with an energy content as low as possible.

• For new batteries or batteries that have been stored for a long time (> three

months), it is effectual to make only one charge/discharge cycle.

• For Li-Ion batteries, a single discharging and charging cycle is sufficient. We

recommend carrying out the process when the battery capacity indicated on the

charger or on a

battery capacity available.

• The permissible temperature range for charging is between 0°C to +40°C/+32°F

to +104°F. For optimal charging we recommend charging the batteries at a low

ambient temperature of +10°C to +20°C/+50°F to +68°F if possible.

• It is normal for the battery to become warm during charging. Using the chargers

recommended by

temperature is too high.

Operation/Discharging

• The batteries can be operated from -20°C to +55°C/-4°F to +131°F.

• Low operating temperatures reduce the capacity that can be drawn; very high

operating temperatures reduce the service life of the battery.

Leica Geosystems product deviates significantly form the actual

Leica Geosystems, it is not possible to charge the battery if the

Page 41

3.2.2 Instrument Battery

Change battery

step-by-step

7

1

4

2

6

TM6100A_008

Step Description

1. Face the instrument on the side with the single finedrive. The battery

compartment is located just below. Turn the knob to the vertical position,

opening the lid of the battery compartment.

2. Pull out the battery housing.

3. Pull the battery from the battery housing.

Operation TM6100A 41

3

5

Page 42

Operation

42TM6100A

Step Description

4. A pictogram of the battery is displayed inside the battery housing. This is

a visual aid to assist in placing the battery correctly.

5. Place the battery into the battery housing, ensuring that the contacts are

facing outward. Click the battery into position.

6. Place the battery housing into the battery compartment. Push the battery

housing in until it fits completely into the battery compartment.

7. Turn the knob to lock the battery compartment. Ensure that the knob is

returned to its original horizontal position.

Page 43

3.3 Working with the CompactFlash Card

Insert and remove

a CompactFlash

card step-by-step

Operation TM6100A 43

• Keep the card dry.

• Use it only within the specified temperature range.

• Do not bend the card.

• Protect the card from direct impacts.

Failure to follow these instructions could result in data loss and/or permanent

damage to the card.

7

1

2

6

TM6100A_009

3

5

4

Page 44

Operation

44TM6100A

Step Description

1. Face the instrument so that the CompactFlash card compartment is on the

right side of the instrument. Turn the knob to the vertical position, opening

the lid of the CompactFlash card compartment.

2. Open the lid of the CompactFlash card compartment.

3. Pull the front of the CompactFlash card up and take the card out of the lid.

4. Place the lower end of the CompactFlash card at the lower end of the

CompactFlash card compartment. The extended edge of the card has to be

on the upper side as shown on the pictogram in the CompactFlash card

compartment.

5. Press the card down on the lid.

6. Close the lid.

7. Turn the knob to lock the CompactFlash card compartment. The lid is

closed correctly when the knob is turned to a horizontal position.

Page 45

Format a

CompactFlash card

step-by-step

Operation TM6100A 45

Formatting the CompactFlash card before starting to store data is required if a

completely new CompactFlash card is used or if all existing data needs to be deleted.

Step Description

1. Main Menu: Tools...\Format Memory Device.

2. TOOLS Format Memory Device

<Memory Device: CF Card>

<Format Method: Format Quick>

Select the memory device to be formatted.

By activating the format command all data will be lost. Make sure that all

important data on the CompactFlash card has been backed up before

formatting the card. Before formatting the internal memory make sure

that all important data is first transferred to the PC.

To exit the screen without formatting the memory device, press ESC. This

returns to the previous screen without execution of any command.

3. CONT (F1).

4. YES (F4) to complete the formatting of the CompactFlash card.

NO (F6) to abort the formatting of the CompactFlash card and return to

TOOLS Format Memory Device.

5. Once the formatting of the CompactFlash card is completed the system

returns to TM6100A Main Menu.

Page 46

Operation

3.4 Accessing Survey Application Program

Access Select Main Menu: Survey.

OR

Press PROG. Highlight Survey. CONT (F1).

SURVEY

Survey Begin

CONT (F1)

To accept changes and access the

subsequent screen. The chosen

settings become active.

CONF (F2)

To access SURVEY Configuration.

SETUP (F3)

Opens SETUP Station Setup to set

station and orientation.

CSYS (F6)

To select a different coordinate

system. Not available for <Use Auto

CrdSys: Yes> configured in

CONFIGURE Additional Rover

Settings.

46TM6100A

Page 47

Description of fields

Field Option Description

<Job:> Choicelist The active job. All jobs from Main Menu:

<Coord System:> Output The coordinate system currently attached to the

<Codelist:> Choicelist No codes are stored in the selected <Job:>. All

Output Codes have already been stored in the selected

<Config Set:> Choicelist The active configuration set. All configuration

Operation TM6100A 47

Manage...\Jobs can be selected.

selected <Job:>. Cannot be edited for <Use

AutoCrdSys: Yes> configured in CONFIGURE

Additional Rover Settings.

codelists from Main Menu:

Manage...\Codelists can be selected.

<Job:>. If codes had been copied from a System

RAM codelist, then the name of the codelist is

displayed. If codes have not been copied from a

System RAM codelist but typed in manually, then

the name of the active job is displayed.

sets from Main Menu: Manage...\Configura

tion Sets can be selected.

-

Page 48

Operation

Field Option Description

The instrument has numerous user configuration

parameters and functions. This allows a variety

of preferences to be addressed. The configura

tion of the parameters and functions for an individual measuring technique are combined in a

configuration set.

<Reflector:> Choicelist Displays the active reflector. All reflectors from

Main Menu: Manage...\Reflectors. All listed

reflectors can be selected.

<Add. Constant:> Output Displays the additive constant stored with the

chosen reflector.

Next step

CONT (F1) to access SURVEY Survey: Job Name, where measurements can be

performed with ALL (F1) or DIST (F2) and/or REC (F3).

48TM6100A

-

Page 49

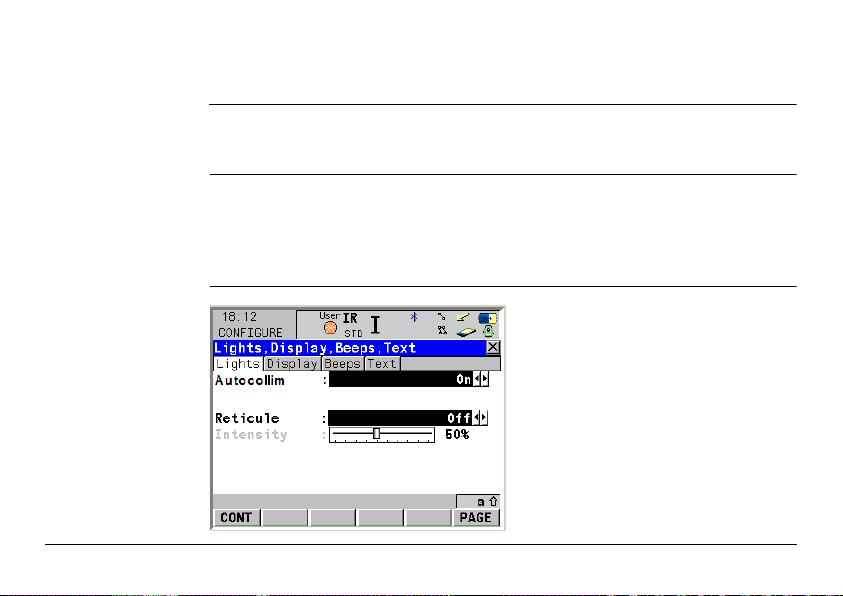

3.5 Built-in autocollimation device

AL51 plug-in lamp The TM6100A is equipped with a built-in autocollimation device. To illuminate the

Illumination To switch the illumination on or off select SHIFT (F11) to access CONFIGURE Lights

Operation TM6100A 49

autocollimation reticule and project it to an autocollimation mirror, plug the AL51

plug-in lamp into the socket on the telescope.

Display, Beeps, Text. Highlight the line Autocollim, toggle On or Off and press to

CONT (F1) to continue.

The brightness of the autocollimation lamp may be adjusted by turning the knob on

the autocollimation lamp.

Page 50

Operation

50TM6100A

a

TM6100A_041

a) Intensity actuator

Page 51

3.6 Connection to Application Computer

Connection types There are three basic connection types to connect a TM6100A to an application

Operation TM6100A 51

computer:

• Cable connection via T-LINK

• Cable connnection via USB Download Cable GEV218 or Y-Cable GEV220

• Wireless Bluetooth connection

Page 52

Operation

T-LINK The connection via T-LINK connects up to 8 TM6100A to an application computer. The

connection requires the following components:

• T-LINK

• Data Cable GEV86-I (20 m)

• Data transfer cable to RS232 port of the application computer.

TM6100A_010

It is not recommended to upload any firmware or software via the T-LINK and the 20

m data cable. Use the short data cable or the USB Download Cable GEV218.

52TM6100A

Page 53

Direct cable

connection

The direct cable connection connects a single instrument to an application computer.

The connection requires the following components:

• USB Download Cable GEV218 or Y-Cable GEV220

TM6100A_011

Operation TM6100A 53

Page 54

Operation

Bluetooth connection

54TM6100A

A Bluetooth connection to an application computer can be established through the

internal bluetooth modul. The connection requires the following setup:

• Paired bluetooth communication between TM6100A and application computer.

TM6100A_012

Page 55

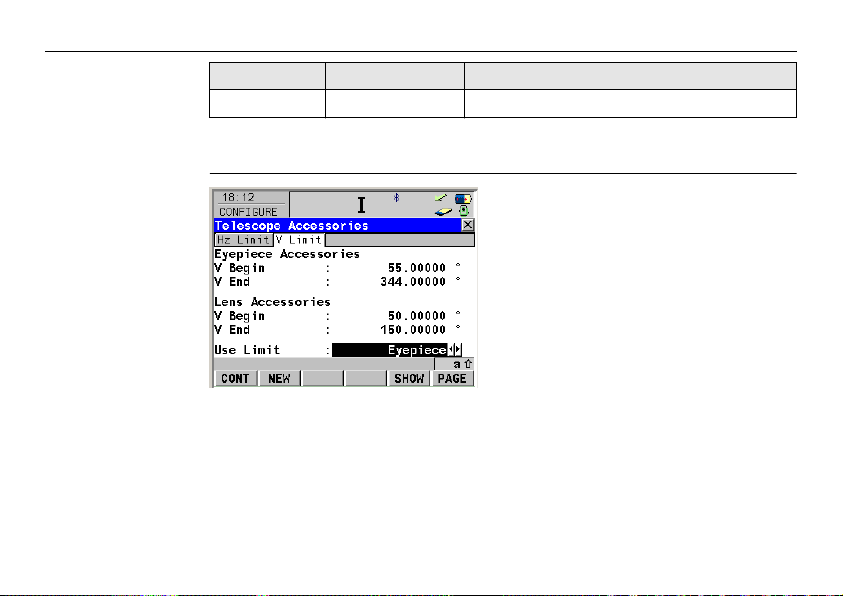

3.7 Limitation of the horizontal and vertical movements

General Due to the size of the panfocal telescope of the TM6100A a face change can only be

Vertical Limitations The default limits for vertical movements are applied as shown below.

done through the lens side. This requires a turning restriction for the vertical movement of the telescope.

In addition the motorized horizontal movements can be restricted because of accesssories attached, i.e. Diode Laser DL2/3.

If a turning restriction is defined, the TM6100A will not pass or enter a certain vertical

or horizontal sector.

Telescope side Range Value

Eyepiece V Begin 55 gon

V End 344 gon

Lens V Begin n/a

V End n/a

Use Limit Eyepiece

Operation TM6100A 55

Page 56

Operation

56TM6100A

Free turning range for eyepiece:

Zenith

Lens

Eyepiece

55 gon

TM6100A_042

Lens

Eyepiece

344 gon

Custom limitations In case of additional accessories used on the telescope, Individual limitations can be

applied to the horizontal and vertical movements.

Access Select Main Menu: Config...\Instrument Settings...\Telescope Accessories.

Page 57

CONFIGURE, Telescope Accessories,

Hz Limits

CONT (F1)

To accept changes and return to the

TM6100A Main Menu.

NEW (F2)

To define new horizontal limits for

motorized rotation.

SHOW (F5)

To position the telescope to its rotation limits.

PAGE (F6)

To change to another page on this

screen.

Description of fields:

Field Option Description

<Hz Begin:>

<Hz End:>

<Use Limit:>

Output/user Input The boundaries of the window within the

instrument is allowed to turn.

Yes Motorized instrument turning is restricted to

the defined window.

Operation TM6100A 57

Page 58

Operation

CONFIGURE, Telescope Accessories,

V Limits

Field Option Description

No

Next step

Instruments turns without any limitation.

PAGE (F6) to change to the V Limit page.

CONT (F1)

NEW (F2)

SHOW (F5)

PAGE (F6)

58TM6100A

To accept changes and return to the

TM6100A Main Menu.

To define new horizontal limits for

motorized rotation.

To position the telescope to its rotation limits.

To change to another page on this

screen.

Page 59

Description of fields:

Field Option Description

<V Begin:>

<V End:>

<Use Limit:>

Operation TM6100A 59

Output/user Input Vertical extent of the window in which the

instrument is allowed to turn the telescope.

None Instruments turns without any limitation.

Eyepiece The movement of the telescope is limited by

Lens

Eyepiece & Lens

the stored Eyepiece Accessories limits.

The movement of the telescope is limited by

the stored Lens Accessories limits.

The movement of the telescope is limited by

the combination of both areas with the least

vertical extent.

Do not use with TM6100A.

Page 60

Check & Adjust

4 Check & Adjust

4.1 Overview

60TM6100A

Description Leica instruments are manufactured, assembled and adjusted to the best possible

Electronic

adjustment

quality. Quick temperature changes, shock or stress can cause deviations and

decrease the instrument accuracy.

It is therefore recommended to check and adjust the instrument from time to time.

This can be done in the field by running through specific measurement procedures.

The procedures are guided and have to be followed carefully and precisely as

described in the following chapters. Some other instrument errors and mechanical

parts can be adjusted mechanically.

The following instrument errors can be checked and adjusted electronically:

l, t Compensator longitudinal and transversal index errors

i Vertical index error, related to the standing axis

c Hz collimation error, also called line of sight error

a Tilting axis error

Every angle measured in the daily work is corrected automatically if the compensator

and the Hz-corrections are activated in the instrument configuration. Select Main

Menu: Config...\Instrument Settings...\Compensator to check the settings.

Page 61

View current

adjustment errors

The currently used adjustment errors can be viewed under Main Menu:

Tools.../Check & Adjust...\Current Values.

Mechanical

adjustment

Precise

measurements

Check & Adjust TM6100A 61

The following instrument parts can be adjusted mechanically:

• Circular level on instrument and tribrach

• Laser plummet

• Optical plummet - option on tribrach

• Allen screws on tripod

To get precise measurements in the daily work, it is important:

• To check and adjust the instrument from time to time.

• To take high precision measurements during the check and adjust procedures.

• To measure targets in two faces. Some of the instrument errors are eliminated

by averaging the angles from both faces.

• Refer to "4.2 Preparation" to find more important points.

During the manufacturing process, the instrument errors are carefully determined

and set to zero. As mentioned above, these errors can change and it is highly recommended to redetermine them in the following situations:

• Before the first use

• Before every high precision survey

• After rough or long transportations

• After long working periods

Page 62

Check & Adjust

62TM6100A

• After long storage periods

• If the temperature difference between current environment and the temperature

at the last calibration is more than 20°C

Summary of errors

to be adjusted

electronically

Instrument error Effects HzEffects VElimination

c - Line of sight error ---

a - Tilting axis error ---

l - Compensator index

error

t - Compensator index

error

i - V-Index error ---

---

---

with two face

measurement

Automatically

corrected with

proper adjustment

Page 63

4.2 Preparation

Check & Adjust TM6100A 63

Before starting to work, the instrument has to become acclimatised to the ambient

temperature. Approximately two minutes per °C of temperature difference from

storage to working environment but at least 15 min should be taken into account.

Take the carry handle off the TM6100A when calibrating and measuring as the telescope may not turn to the second face with the carry handle mounted.

Generally calibration and measurement set up should be carried out with the same

instrument configuration.

Before determining the instrument errors, the instrument has to be levelledup using the electronic level.

Plummet, Level page.

The tribrach, the tripod and the underground should be very stable and

secure from vibrations or other disturbances.

The instrument should be protected from direct sunlight in order to avoid

thermal warming.

It is also recommended to avoid strong heat shimmer and air turbulence.

The best conditions are usually early in the morning or with overcast sky.

SHIFT F12 to access STATUS Level & Laser

Page 64

Check & Adjust

Next step

64TM6100A

IF the task is to THEN

adjust a combination of

instrument errors

adjust the tilting axis Refer to "4.4 Tilting Axis Adjustment (a)"

adjust the circular level Refer to "4.5 Adjusting the Circular Level of the Instru-

adjust the laser/optical

plummet

adjust the tripod Refer to "4.8 Servicing the Tripod"

Refer to "4.3 Combined Adjustment (l, t, i and c)"

ment and Tribrach"

Refer to "4.7 Inspecting the Laser Plummet of the

Instrument"

Page 65

4.3 Combined Adjustment (l, t, i and c)

Description The combined adjustment procedure determines the following instrument errors in

Combined

adjustment

procedure

step-by-step

Check & Adjust TM6100A 65

one process:

l, t Compensator longitudinal and transversal index errors

i Vertical index error, related to the standing axis

c Hz collimation error, also called line of sight error

The following table explains the most common settings.

Step Description

1. Main Menu: Tools...\Check & Adjust...

2. TOOLS Check & Adjust Menu

Select the option: Combined (l,t,i,c,ATR)

3. TOOLS Combined I

Page 66

Check & Adjust

Step Description

4.

TM6100A_013

~ * m

± 9°

66TM6100A

Aim the telescope accurately at a target

at about the usual working distance.

The target must be positioned within

± 9°/± 10 gon of the horizontal plane.

The procedure can be started in any

telescope face.

*: Typical working distance, minimum

15 meter.

Page 67

Step Description

5. MEAS (F1) to measure and to continue to the next screen.

180°

180°

TM6100A_014

6. TOOLS Combined II

MEAS (F1) to measure the same target in the other face and to calculate

the instrument errors.

Check & Adjust TM6100A 67

If one or more errors are bigger than the predefined limits, the procedure

has to be repeated. All measurements of the current run are rejected and

none of them is averaged with the results from previous runs.

TOOLS Adjustment Accuracy

7.

TM6100A are motorised instruments

and change automatically to the other

face.

The fine pointing has to be

performed manually in both faces.

Page 68

Check & Adjust

Step Description

<No.of Meas:> Shows the number of runs executed. One run consists of

a measurement in face I and face II.

<σ l Comp:> and similar lines show the standard deviations of the determined adjustment errors. The standard deviations can be calculated from

the second run onwards.

It is recommended to measure at least two runs.

8. MEAS (F5) if more runs have to be added. Continue with step 3.

OR

CONT (F1) to accept the measurements and to proceed to TOOLS

Adjustment Results. No more runs can be added later.

68TM6100A

Next step

IF the results are THEN

to be stored CONT (F1) overwrites the old adjustment errors with the new

to be determined

again

ones, if the Use status is set to Yes.

REDO (F2) rejects all new determined adjustment errors and

repeats the whole procedure. Refer to step 3. of paragraph

"Combined adjustment procedure step-by-step".

Page 69

4.4 Tilting Axis Adjustment (a)

Description This adjustment procedure determines the following instrument error:

a Tilting axis error

Determination of

tilting axis error

step-by-step

Check & Adjust TM6100A 69

The following table explains the most common settings.

Step Description

The Hz collimation error (c) has to be determined before starting this

procedure.

1. Main Menu: Tools...\Check & Adjust...

2. TOOLS Check & Adjust Menu

Select the option: Tilting Axis (a)

Page 70

Check & Adjust

Step Description

3. TOOLS Tilting-Axis Adjustment I

+ 27°

V=90°

- 27°

TM6100A_015

70TM6100A

Aim the telescope accurately at a target

at about the usual working distance. The

target must be positioned at least

27°/30 gon above or beneath the horizontal plane.

The procedure can be started in any telescope face.

Page 71

Step Description

4. MEAS (F1) to measure and to continue to the next screen.

+ 27°

V=90°

180°

TM6100A_040

5. TOOLS Tilting-Axis Adjustment II

MEAS (F1) to measure the same target in the other face and to calculate

the tilting axis error.

Check & Adjust TM6100A 71

- 27°

180°

TM6100A are motorised instruments

and change automatically to the other

face.

The fine pointing has to be

performed manually in both faces.

Page 72

Check & Adjust

Step Description

If the error is bigger than the predefined limit, the procedure has to be

repeated. The tilting axis measurements of the current run are then

rejected and not averaged with the results from previous runs.

6. TOOLS T-Axis Adjustment Accuracy

<No.of Meas:> Shows the number of runs executed. One run consists of

a measurement in face I and face II.

<σ a T-axis:> shows the standard deviation of the determined tilting axis

error. The standard deviation can be calculated from the second run

onwards.

It is recommended to measure at least two runs.

7. MEAS (F5) if more runs have to be added. Continue with step 3.

OR

CONT (F1) to accept the measurements and to proceed to TOOLS T-Axis

Adjustment Result. No more runs can be added later.

72TM6100A

Page 73

Next step

Check & Adjust TM6100A 73

IF the results are THEN

to be stored CONT (F1) overwrites the old tilting axis error with the new

to be determined

again

one.

REDO (F2) rejects the new determined tilting axis error and

repeats the whole procedure. Refer to step 3. of paragraph

"Determination of tilting axis error step-by-step".

Page 74

Check & Adjust

74TM6100A

4.5 Adjusting the Circular Level of the Instrument and Tribrach

Adjusting the

circular level

step-by-step

1

4

SHIFT

F12

2

Step Description

1. Place and secure the instrument into the tribrach and onto a tripod.

2. Using the tribrach footscrews, level the instrument with the electronic

level. SHIFT (F12) to access STATUS Level & Laser Plummet.

3. Check the position of the circular level on the instrument and tribrach.

4. a) If both circular levels are centered, no adjustments are necessary

b) If one or both circular levels are not centered, adjust as follows:

4

Page 75

Step Description

Instrument: If it extends beyond the circle, use the supplied allen key

to centre it with the adjustment screws. Turn the instrument by

gon (180°). Repeat the adjustment procedure if the circular level

200

does not stay centered.

Tribrach: If it extends beyond the circle, use the supplied allen key to

centre it with the adjustment screws.

Check & Adjust TM6100A 75

After the adjustments, all adjusting screws should have the same tightening tension and no adjusting screw shall be loose.

Page 76

Check & Adjust

1

4.6 Adjusting the Circular Level of the Prism Pole

76TM6100A

Adjusting the

circular level

step-by-step

Step Description

1. Suspend a plumb line.

2. Using a pole bipod, align the prism pole parallel to

3. Check the position of the circular level on the

4. a) If the circular level is centered, no adjustment

the plumb line.

prism pole.

is necessary.

b) If the circular level is not centered, use an

allen key to centre it with the adjustment

screws.

After the adjustments, all adjusting screws should have the same tightening tension and no adjusting screw shall be loose.

TM6100A_017

4b

2

4a

Page 77

4.7 Inspecting the Laser Plummet of the Instrument

The laser plummet is located in the vertical axis of the instrument. Under normal

conditions of use, the laser plummet does not need adjusting. If an adjustment is

necessary due to external influences, the instrument has to be returned to any Leica

Geosystems authorized service workshop.

Inspecting the

laser plummet

step-by-step

SHIFT

2

F6

3

TM6100A_018

1

F12

5

360°

Ø 2.5 mm / 1.5 m

4

≤ 3 mm / 1.5 m

6

The following table explains the most common settings.

Check & Adjust TM6100A 77

Page 78

Check & Adjust

Step Description

1. Place and secure the instrument into the tribrach and onto a tripod.

2. Using the tribrach footscrews, level the instrument with the electronic

level. SHIFT (F12) to access STATUS Level & Laser Plummet.

3. PAGE (F6) to access the Laser Plummet page. Switch on the laser

plummet. Inspection of the laser plummet should be carried out on a

bright, smooth and horizontal surface, like a sheet of paper.

4. Mark the centre of the red dot on the ground.

5. Turn the instrument through 360° slowly, carefully observing the movement of the red laser dot.

The maximum diameter of the circular movement described by the centre

of the laser point should not exceed 3 mm at a distance of 1.5 m.

6. If the centre of the laser dot describes a perceptible circular movement or

moves more than 3 mm away from the point which was first marked, an

adjustment may be required. Inform your nearest Leica Geosystems

authorized service workshop. Depending on brightness and surface, the

diameter of the laser dot can vary. At 1.5 m it is about 2.5 mm.

78TM6100A

Page 79

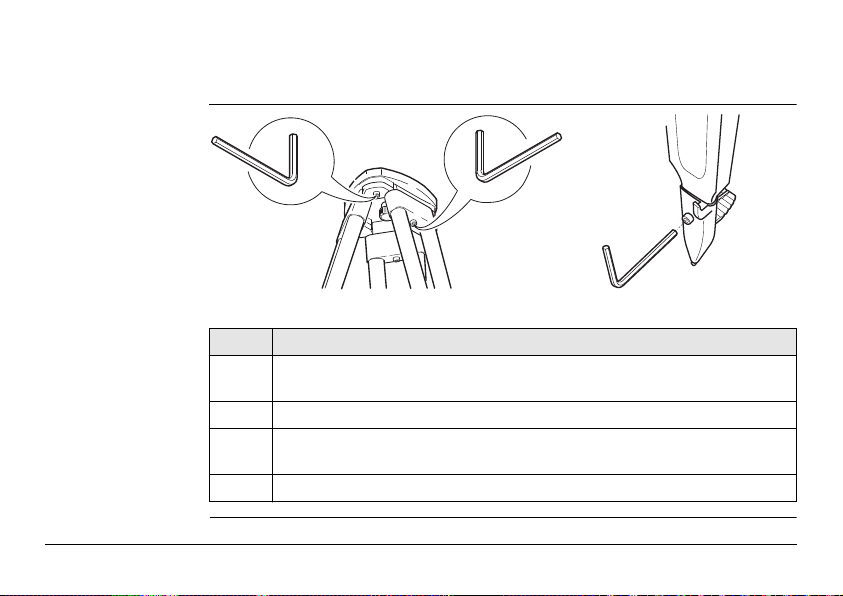

4.8 Servicing the Tripod

Servicing the tripod

step-by-step

Check & Adjust TM6100A 79

2

TM6100A_019

The following table explains the most common settings.

Step Description

The connections between metal and timber components must always be

firm and tight.

1. Tighten the leg cap screws moderately, with the supplied allen key.

2. Tighten the articulated joints on the tripod head just enough to keep the

tripod legs open when lifting the tripod off the ground.

3. Tighten the allen screws of the tripod legs.

1

3

Page 80

Check & Adjust

4.9 Adjustment of the autocollimation reticule

80TM6100A

Description The built-in autocollimation device has an additional "negative" reticle, which is

Check Set up an autocollimation mirror about 5 m (16 ft) from the instrument. Adjust the

Adjustment If the two crosshairs do not coincide. adjust by means of the four setting screws (1

projected through the telescope and observed by the linear cross of the standard

reticule.

To achieve accurate results the negative reticule must coincide to the standard reticule.

reflecting surface perpendicular to the telescope’s line of sight.

Adjust the telescope to focus on the image of the negative linear cross reflected by

the mirror, i.e. focus to double the distance between telescope and mirror. Do not

focus to infinity. The standard black reticule and the negative green linear cross

should be aligned and centered. When moving the telescope over the mirror both

reticules stay aligned.

to 4). Screws 1 and 2 move the negative reticule sideways, screws 3 and 4 move it

up and down.

These screws are paired and act reciprocal. When loosening one of a pair, immediately tighten the other one by the same amount. Do not over tighten!

To access screw 4 remove the metal cover plate by unscrewing the slotted screw.

Page 81

2

3

1

4

TM6100A_020

Check & Adjust TM6100A 81

Page 82

Care and Transport

5 Care and Transport

5.1 Transport

82TM6100A

Telescope protection cushion

To protect the telescope from damage, a protection cushion holds the telescope in

a particular position when the instrument is stored in the transport container. Position the telescope and attach the protection cushion according to the picture located

on the bottom of the transport container.

Page 83

Transport in the

field

When transporting the equipment in the field, always make sure that you

• either carry the product in its original transport container,

• or carry the tripod with its legs splayed across your shoulder, keeping the

attached product upright.

Transport in a road

vehicle

Shipping When transporting the product by rail, air or sea, always use the complete original

Shipping, transport

of batteries

Field adjustment After transport inspect the field adjustment parameters given in this user manual

Care and Transport TM6100A 83

Never carry the product loose in a road vehicle, as it can be affected by shock and

vibration. Always carry the product in its transport container and secure it.

Leica Geosystems packaging, transport container and cardboard box, or its equivalent, to protect against shock and vibration.

When transporting or shipping batteries, the person in charge of the product must

ensure that the applicable national and international rules and regulations are

observed. Before transportation or shipping, contact your local passenger or freight

transport company.

before using the product.

Page 84

Care and Transport

5.2 Storage

84TM6100A

Product Respect the temperature limits when storing the equipment, particularly in summer

if the equipment is inside a vehicle. Refer to

temperature limits.

Field adjustment After long periods of storage inspect the field adjustment parameters given in this

user manual before using the product.

Li-Ion batteries • Refer to "7.3 General Technical Data of the Instrument" for information about

storage temperature range.

• A storage temperature range of -20°C to +30°C/-4°F to +86°F in a dry environment is recommended to minimize self-discharging of the battery.

• At the recommended storage temperature range, batteries containing a 10% to

50% charge can be stored for up to one year. After this storage period the

batteries must be recharged.

• Remove batteries from the product and the charger before storing.

• After storage recharge batteries before using.

• Protect batteries from damp and wetness. Wet or damp batteries must be dried

before storing or use.

"7 Technical Data" for information about

Page 85

5.3 Cleaning and Drying

Product and

accessories

Fogging of prisms Reflector prisms that are cooler than the ambient temperature tend to fog. It is not

Damp products Dry the product, the transport container, the foam inserts and the accessories at a

Care and Transport TM6100A 85

• Blow dust off lenses and prisms.

• Never touch the glass with your fingers.

• Use only a clean, soft, lint-free cloth for cleaning. If necessary, moisten the cloth

with water or pure alcohol. Do not use other liquids; these may attack the

polymer components.

enough simply to wipe them. Keep them for some time inside your jacket or in the

vehicle to allow them to adjust to the ambient temperature.

temperature not greater than 40°C / 104°F and clean them. Do not repack until

everything is completely dry. Always close the transport container when using in the

field.

Page 86

Care and Transport

Cables and plugs Keep plugs clean and dry. Blow away any dirt lodged in the plugs of the connecting

cables.

86TM6100A

Page 87

5.4 Maintenance

Care and Transport TM6100A 87

An inspection of the product must be done in a Leica Geosystems authorized service

workshop. Leica Geosystems recommends an inspection of the product every

24 months.

As TM6100A instruments are equipped with a self-surveillance system designed for

maximum motor performance and long maintenance cycles Leica Geosystems recommends inspection of the product whenever indicated in the message line of the user

interface.

Page 88

Safety Directions

6 Safety Directions

6.1 General Introduction

88TM6100A

Description The following directions should enable the person responsible for the product, and

the person who actually uses the equipment, to anticipate and avoid operational

hazards.

The person responsible for the product must ensure that all users understand these

directions and adhere to them.

Page 89

6.2 Intended Use

Permitted use • Measuring horizontal and vertical angles.

• Recording measurements.

• Visualizing the aiming direction and vertical axis.

• Remote control of product.

• Data communication with external appliances.

• Transmission of measurement data to an external application PC.

• Transmission of coordinates from an external application PC to the product for

inspection and build measurements.

• Computing by means of software.

Adverse use • Use of the product without instruction.

• Use outside of the intended limits.

• Disabling safety systems.

• Removal of hazard notices.

• Opening the product using tools, for example screwdriver, unless this is specifically permitted for certain functions.

• Modification or conversion of the product.

• Use after misappropriation.

• Use of products with obviously recognizable damages or defects.

Safety Directions TM6100A 89

Page 90

Safety Directions

• Use with accessories from other manufacturers without the prior explicit

approval of

• Aiming directly into the sun.

• Inadequate safeguards at the working site, for example when measuring on

roads.

• Deliberate dazzling of third parties.

• Controlling of machines, moving objects or similar monitoring application without

additional control- and safety installations.

Warning Adverse use can lead to injury, malfunction and damage.

It is the task of the person responsible for the equipment to inform the user about

hazards and how to counteract them. The product is not to be operated until the user

has been instructed on how to work with it.

Leica Geosystems.

90TM6100A

Page 91

6.3 Limits of Use

Environment Suitable for use in an atmosphere appropriate for permanent human habitation: not

Danger Local safety authorities and safety experts must be contacted before working in

Safety Directions TM6100A 91

suitable for use in aggressive or explosive environments.

hazardous areas, or in close proximity to electrical installations or similar situations

by the person in charge of the product.

Page 92

Safety Directions

6.4 Responsibilities

92TM6100A

Manufacturer

of the product

Manufacturers

of non

Leica Geosystems

accessories

Person in charge

of the product

Warning The person responsible for the product must ensure that it is used in accordance with

Leica Geosystems AG, CH-9435 Heerbrugg, hereinafter referred to as Leica Geosystems, is responsible for supplying the product, including the user manual and original

accessories, in a completely safe condition.

The manufacturers of non Leica Geosystems accessories for the product are responsible for developing, implementing and communicating safety concepts for their

products, and are also responsible for the effectiveness of those safety concepts in

combination with the

The person in charge of the product has the following duties:

• To understand the safety instructions on the product and the instructions in the

user manual.

• To be familiar with local regulations relating to safety and accident prevention.

• To inform Leica Geosystems immediately if the product and the application

becomes unsafe.

• To ensure that the national laws, regulations and conditions for the operation of

radio transmitters are respected.

the instructions. This person is also accountable for the training and the deployment

of personnel who use the product and for the safety of the equipment in use.

Leica Geosystems product.

Page 93

6.5 Hazards of Use

Warning The absence of instruction, or the inadequate imparting of instruction, can lead to

Caution Watch out for erroneous measurement results if the product has been dropped or

Caution Reflectors can cause personal injury and/or mechanical damage, when dropped.

Safety Directions TM6100A 93

incorrect or adverse use, and can give rise to accidents with far-reaching human,

material, financial and environmental consequences.

Precautions:

All users must follow the safety directions given by the manufacturer and the directions of the person responsible for the product.

has been misused, modified, stored for long periods or transported.

Precautions:

Periodically carry out test measurements and perform the field adjustments indicated

in the user manual, particularly after the product has been subjected to abnormal use

and before and after important measurements.

Precautions:

Secure the reflector with a lanyard when moving the reflector.

Page 94

Safety Directions

Warning Mounting the sensor on unstable or uneven ground may cause the sensor to tip over

Danger Because of the risk of electrocution, it is very dangerous to use poles and extensions

Caution With the remote control of products, it is possible that extraneous targets will be

or cause unreliable measurement results.

Precautions:

Ensure the ground is stable and even. Do not place the sensor over cracks in the

floor.

in the vicinity of electrical installations such as power cables or electrical railways.

Precautions:

Keep at a safe distance from electrical installations. If it is essential to work in this

environment, first contact the safety authorities responsible for the electrical installations and follow their instructions.

picked out and measured.

Precautions:

When measuring in remote control mode, always check your results for plausibility.

94TM6100A

Page 95

Warning If the product is used with accessories, for example masts, staffs, poles, you may

Caution Be careful when pointing the product towards the sun, because the telescope func-

Warning During dynamic applications, for example stakeout procedures there is a danger of

Warning Inadequate securing of the measurement site can lead to dangerous situations,

Safety Directions TM6100A 95

increase the risk of being struck by lightning.

Precautions:

Do not use the product in a thunderstorm.

tions as a magnifying glass and can injure your eyes and/or cause damage inside the

product.

Precautions:

Do not point the product directly at the sun.

accidents occurring if the user does not pay attention to the environmental condi

tions around, for example obstacles, excavations or traffic.

Precautions:

The person responsible for the product must make all users fully aware of the existing

dangers.

especially at industrial installations.

Precautions:

Always ensure that the measurement site is adequately secured. Adhere to the regulations governing safety and accident prevention and road traffic.

-

Page 96

Safety Directions

Warning Only Leica Geosystems authorized service workshops are entitled to repair these

Warning If computers intended for use indoors are used in the field there is a danger of elec-

Caution If the accessories used with the product are not properly secured and the product is

Caution During the transport, shipping or disposal of batteries it is possible for inappropriate

products.

tric shock.

Precautions:

Adhere to the instructions given by the computer manufacturer with regard to field

use in conjunction with

subjected to mechanical shock, for example blows or falling, the product may be

damaged or people may sustain injury.

Precautions:

When setting-up the product, make sure that the accessories are correctly adapted,

fitted, secured, and locked in position.

Avoid subjecting the product to mechanical stress.

mechanical influences to constitute a fire hazard.

Precautions:

Before shipping the product or disposing of it, discharge the batteries by running the

product until they are flat.

When transporting or shipping batteries, the person in charge of the product must

ensure that the applicable national and international rules and regulations are

Leica Geosystems products.

96TM6100A

Page 97

observed. Before transportation or shipping contact your local passenger or freight

transport company.

Warning Using a battery charger not recommended by Leica Geosystems can destroy the

Warning High mechanical stress, high ambient temperatures or immersion into fluids can

Warning Short circuited battery terminals can overheat and cause injury or fire, for example

Warning If the product is improperly disposed of, the following can happen:

Safety Directions TM6100A 97

batteries. This can cause fire or explosions.

Precautions:

Only use chargers recommended by Leica Geosystems to charge the batteries.

cause leakage, fire or explosions of the batteries.

Precautions:

Protect the batteries from mechanical influences and high ambient temperatures. Do

not drop or immerse batteries into fluids.

by storing or transporting in pockets if battery terminals come in contact with jewel

lery, keys, metallized paper or other metals.

Precautions:

Make sure that the battery terminals do not come into contact with metallic objects.

• If polymer parts are burnt, poisonous gases are produced which may impair

health.

-

Page 98

Safety Directions

98TM6100A

• If batteries are damaged or are heated strongly, they can explode and cause

poisoning, burning, corrosion or environmental contamination.

• By disposing of the product irresponsibly you may enable unauthorized persons

to use it in contravention of the regulations, exposing themselves and third

parties to the risk of severe injury and rendering the environment liable to

contamination.

• Improper disposal of silicone oil may cause environmental contamination.

Precautions:

The product must not be disposed with household waste.

Dispose of the product appropriately in accordance with the national

regulations in force in your country.

Always prevent access to the product by unauthorized personnel.

Product specific treatment and waste management information can be downloaded

from the Leica Geosystems home page at http://www.leica-geosystems.com/treatment or received from your Leica Geosystems dealer.

Page 99

6.6 Laser Classification

6.6.1 General

General The following directions (in accordance with the state of the art - international

Safety Directions TM6100A 99

standard IEC 60825-1 (2007-03) and IEC TR 60825-14 (2004-02)) provide instruction and training information to the person responsible for the product and the

person who actually uses the equipment, to anticipate and avoid operational

hazards.

The person responsible for the product must ensure that all users understand these

directions and adhere to them.

Products classified as laser class 1, class 2 and class 3R do not require:

• laser safety officer involvement,

• protective clothes and eye wear,

• special warning signs in the laser working area

if used and operated as defined in this user manual due to the low eye

hazard level.

Products classified as laser class 2 or class 3R may cause dazzle, flashblindness and afterimages, particularly under low ambient light conditions.

Page 100

Safety Directions

Labelling

TM6100A_024

Type: TM6100A

Equip.No.: . . . . . .

Power: 12V/14,8V ---, 2,5A max

Leica Geosystems AG

CH-9435 Heerbrugg

Manufactured: . . . .

Made in Switzerland

Complies with FDA performance standards for laser

products except for deviations pursant to Laser Notice

No.50, dated June 24, 2007.

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

25

Art.No.:

576372

S.No.:

. . . . .

100TM6100A

Loading...

Loading...