Page 1

RM CoolClamp Electronically Cooled

Universal Cassette Clamp

INHECO article number: 7900100

LEICA article number: 14 0502 46537

Operating Manual

Revision status V1.1

July 2011

Always keep this manual with the instrument.

Read carefully before working with the instrument.

BA_RM CoolClamp_11-07-15_7900100RM CoolClamp_V1 1_English.doc Printed in Germany

Page 2

Page 3

RM CoolClamp

INHECO GmbH reserves the right to modify its products in order to improve

their quality. These modifications are usually not documented.

This operating manual and the information contained in it have been compiled

according to the best of our knowledge. INHECO GmbH assumes no liability in

the event of printing errors or damage that is caused by printing errors.

Trademarks and product names in this operating manual are registered brand

names and each belongs to the corresponding owner.

INHECO GmbH 3

Page 4

Contact

INHECO GmbH

Fraunhoferstr. 11

82152 Martinsried

Germany

Phone – Sales

Phone – Technical Hotline

089/899593-101

089/899593-201

Fax

E-mail – Sales

E-mail – Technical Hotline

Internet

089/899593-499

sales@inheco.com

techhotline@inheco.com

www.inheco.com

Contact:

This manual belongs to

To be filled out by the customer:

Series:

Serial number.

Year of manufacture:

Order number:

INHECO GmbH 4

Inventory number

Location of instrument setup

Page 5

RM CoolClamp

Significance of this Operating Manual

This operating manual is part of the RM CoolClamp and must

remain at the RM CoolClamp until its final destruction.

be passed on if the RM CoolClamp is sold or lent.

Please contact the manufacturer in the event that you do not understand the

operating manual or portions of it.

Your opinion regarding the operating manual gives us valuable insights into how

we can continue to serve you best. Please do not hesitate to send us your

remarks; see the address or telephone numbers on page 4.

The safety instructions must be read with the greatest care and attentiveness.

They must be understood and observed in order to ensure safe handling of the

instrument.

Insufficient or lacking knowledge of the contents of the operating manual

relieves INHECO GmbH of liability. Therefore the operator should request an

orientation from the distributor, Leica Biosystems Nussloch GmbH.

INHECO GmbH 5

Page 6

Contents

Contents

1 SYMBOLS IN THE TEXT AND THEIR MEANINGS ............................................................... 7

2 SAFETY NOTES ...................................................................................................................... 8

3 INSTRUMENT SETUP ........................................................................................................... 10

4 ATTACHING TO ROTARY MICROTOMES OF THE LEICA RM22/23.. SERIES WITH

QUICK CHANGE SYSTEM ................................................................................................... 15

5 FINE ADJUSTMENT OF THE FORCE BALANCE ............................................................... 16

6 MAINTENANCE WORK TO BE CARRIED OUT BY THE USER ......................................... 17

7 TECHNICAL DATA ................................................................................................................ 18

8 DECLARATION OF CONFORMITY ...................................................................................... 19

APPENDIX A: ABBREVIATION GLOSSARY................................................................................. 20

APPENDIX B: INDEX OF FIGURES ............................................................................................... 20

APPENDIX C: TABLES INDEX ....................................................................................................... 20

APPENDIX D: DOCUMENT HISTORY ........................................................................................... 20

INHECO GmbH 6

Page 7

Symbols in the Text and Their Meanings

!

1 Symbols in the Text and

Their Meanings

Notice: Warning! Safety hazard!

Warning of a potential hazard with a low risk of injury. This symbol also warns

you of property damage.

This symbol indicates useful information for installation, etc.

This arrow is for indicating steps and bullet points.

INHECO GmbH 7

Page 8

Safety Notes

2 Safety Notes

General use

The RM CoolClamp complies with the current technical requirements. The

manufacturer has placed the greatest value on user safety.

The following rules apply for the user:

Rules for accident prevention

General rules for technical safety

The respective specific directives of the EU and other countries

General use includes handling according to the operating

manual.

Operation of this unit is intended only for dry ambient conditions without

precipitation of liquids.

Defective instruments must not be used.

It must be possible for the user to shut off the power supply to the

instrument via the power supply unit instantly, if necessary.

The following applies in general: Handling specimen head or knife / blade

holder, always lock handwheel in place. Release locking mechanism only

for sectioning and use knife guard

Failure to adjust the force balance may result in injury while working

The unit must not be operated in rooms with danger of explosion.

The RM CoolClamp must be operated only in the installation orientation and

position prescribed for it.

It must be ensured that no liquids ingress into the unit.

The instrument may be operated indoors only.

To keep the thermomechanical stress on the TEC as minimal as possible,

the RM CoolClamp should be switched on only once per day and then

remain in operation.

Who is permitted to operate this unit?

Only instructed and trained personnel are permitted to operate this unit.

INHECO GmbH 8

Page 9

Safety note

Intended use

The RM CoolClamp is an electric cooling specimen holder for the universal

cassettes and the paraffin-embedded specimens in the cassettes. It is attached

with the specimen holder to the rotary microtomes of the RM22/23.. series. Any

other use is improper and therefore not permitted.

Technical modifications

For safety reasons, no technical modifications to this instrument are

permitted. Any change or modification that the manufacturer has not

approved causes the warranty to be voided.

Original parts are specially designed for the RM CoolClamp. Parts from

other manufacturers have not been tested and therefore have not been

approved and permitted by INHECO GmbH.

No liability shall be accepted for any use other than the intended use.

Biosafety in the laboratory environment

When using the RM CoolClamp in a laboratory environment with biosafety, the

user is responsible for labeling the RM CoolClamp according to the WHO

Laboratory Biosafety Manual (ISBN 92 4154650 6). In addition, when using the

RM CoolClamp the user is responsible for adhering to the rules and regulations

depending on the biosafety level with respect to the WHO Laboratory Biosafety

Manual.

The safety rules and regulations in force for the respective lab must be

monitored constantly while work is being carried out with the unit.

Malfunctions

Report any malfunctions that occur to the person responsible for the

instrument immediately.

Make sure that the unit has been secured against misuse and abuse.

Any safety-related parts that have been removed must be reattached and

checked prior to instrument setup.

Servicing the RM CoolClamp

The unit is not intended to be serviced. Servicing is accomplished by

replacement. No repairs may be carried out by the user.

Disposing of the unit

Dispose of the unit in accordance with the respective environmental directives

of the respective country.

In the event of contamination, comply with the safety instructions.

The RM CoolClamp is RoHS-compliant.

INHECO GmbH 9

Page 10

Instrument Setup

3 Instrument Setup

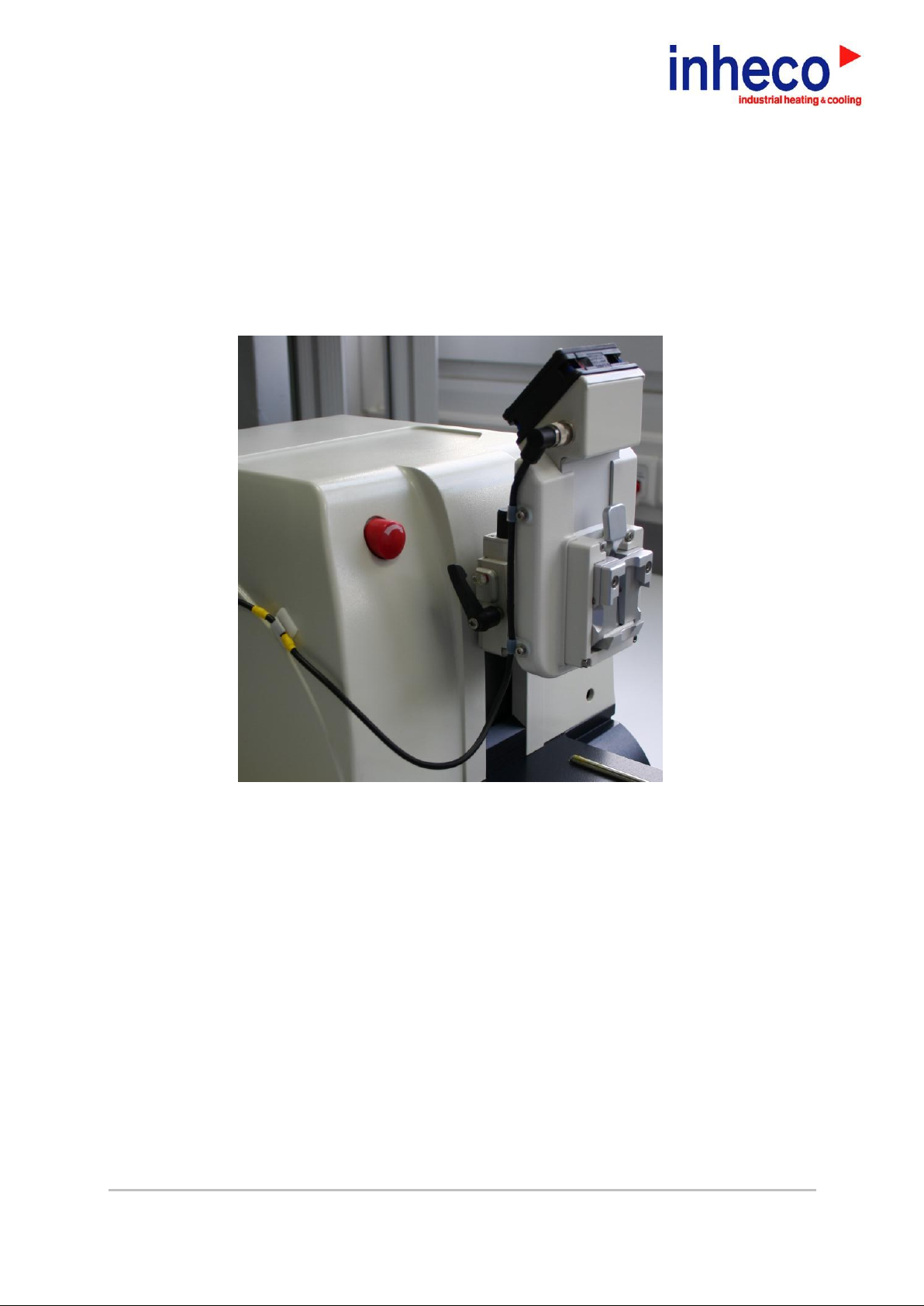

Standard delivery

Prior to instrument setup, make sure that the shipment is complete and no part

is damaged. The following components should be included in each shipment:

RM CoolClamp

Power pack with EU, UK, USA and Australia adapters

Cable holders for attaching to the microtome (not shown in the figure)

Operating manual as a book with 3 languages and on CD with

16 languages (not shown in the figure)

Figure 1: Standard delivery

The RM CoolClamp can be used only together with the quick change

system on the rotary microtomes of the Leica RM22/23.. series.

INHECO GmbH 10

Page 11

Instrument Setup

Ventilation

openings, outlet

Ventilation

openings, inlet

General operating instructions

To prevent injury and damage, provision must be made for an

unobstructed air supply; refer also to the cleaning instructions on

page 17. The fan must not be blocked and the air outlet must not be

obstructed. Please check before each use that the fan rotates freely. To

prevent damage to the RM CoolClamp, the maximum permissible ambient

temperature must not be exceeded; for additional information, refer to the

specifications on page 18.

Figure 2: Ventilation openings

When operating the RM CoolClamp , condensation on the clamp occurs. This is

a natural physical process.

INHECO GmbH 11

Page 12

Instrument Setup

Cable holder position

20 cm high

6 cm lateral

The cable of the RM CoolClamp must be routed to prevent possible

severing of the cable when operating the microtome. For this purpose,

attach the cable holder to the microtome and then insert the cable into the

cable duct.

INHECO GmbH 12

Figure 3: Position of the cable duct

Page 13

Instrument Setup

Potential pinching

areas

It is possible for fingers to become pinched in the specimen holder in the

event of improper handling.

Figure 4: Potential pinching areas

Select the appropriate adapter for the power supply.

To insert or remove the corresponding adapter, the unlocking button must

be pressed.

INHECO GmbH 13

Figure 5: Power pack with EU, UK, USA and Australia adapters

Page 14

Instrument Setup

!

Prerequisite for sectioning the specimens

Prerequisite for using the RM CoolClamp:

To use it with the rotary microtomes of the RM22/23.. series, a vertical travel

range of at least 70mm and an adjustable force balance are necessary.

To use the non-directional specimen fixture or the directional specimen fixture

(fine or only XY), bring the specimen fixture into the zero position.

The embedded tissue samples to be sectioned must be precooled to -5 °C

[+23 °F] using ice or a cooling plate prior to sectioning.

After the RM CoolClamp's precooling phase of 30 min., the universal cassette

can be inserted and the sections carried out.

Permitted maximum sectioning speed 420 mm/s

Section thickness range 0.5 – 600 µm

Operating concept

Installation on a rotary microtome of the RM22/23.. series:

The following applies in general: Handling specimen head or knife / blade

holder, always lock handwheel in place. Release locking mechanism only

for sectioning and use knife guard; see Safety Notes on page 8.

For a microtome that is already configured – remove knife / blade holder with

base and specimen clamp. Bring the specimen head into the rear end position

(home position). Lock the handwheel in place and, where appropriate, check

whether the handbrake has been activated.

We recommend working with the non-directional specimen holder fixture – if

you will be working with the directional specimen fixture (XY or fine), it must be

brought into the zero position.

Push the RM CoolClamp with adapter into the dovetail guide of the quick

change system for specimen clamps and tighten it using a size 4 Allen key.

To carry out the force balancing, please observe the operating manual of the

respective microtome under the Operation chapter, Fine Adjustment of the

Force Balance. The specimen head must not fall into the knife after being

stopped/released.

Reinstall the knife / blade holder with base and select the desired clearance

angle.

Attach the cable holder to the microtome; cable holders are included in the

standard delivery of the RM CoolClamp.

INHECO GmbH 14

Page 15

Attaching to the Rotary Microtome of the Leica RM22/23.. Series with Quick Change System

12

60

63

61

62

4 Attaching to Rotary Microtomes

of the Leica RM22/23.. Series

with Quick Change System

The RM CoolClamp is attached the same way as changing the universal

cassette clamp; for additional information, also refer to the operating

manual of the respective rotary microtomes.

There are two versions of the specimen holder fixture, one with and one without

specimen orientation. The two versions can be interchanged.

The specimen orientation allows for simple position correction of the specimen

surface when the specimen is clamped into place.

To do so, proceed as follows:

Move the specimen holder fixture (60) to the upper end position by turning

the handwheel (12) and engage the handwheel lock.

To release the clamping system, turn the screw (61) counterclockwise using

a size 4 Allen key.

Push the guide (63) of the RM CoolClamp (62) from the left into the

specimen holder fixture (60) as far as it will go.

To clamp the specimen clamp, turn the screw (61) clockwise as far as it will

go.

Figure 6: Attaching the RM CoolClamp

INHECO GmbH 15

Page 16

Fine Adjustment of the Force Balance

5 Fine Adjustment of the Force

Balance

Installing the RM CoolClamp necessitates performance of a force balance;

for additional information, also refer to the operating manuals of the

respective rotary microtomes.

If another accessory of a different weight is mounted on the specimen head (33),

you must check whether it is necessary to readjust the force balance.

Checking the correct setting:

Attaching a new accessory and clamping a specimen

Set the specimen head to half the height of the vertical travel range by

turning the handwheel (Figure 7) (9:00 position).

If the specimen head remains in this exact position, the setting is correct.

If the specimen head moves, i.e. it is raised or lowered, fine adjustment is

necessary.

Failure to adjust the force balance may result in injury while working; see

the Safety Notes on page 8.

The force balance is adjusted using the screw (34), which can be accessed by

removing the section waste tray on the bottom of the base plate of the microtome.

Use the Allen key provided, size 5 (with handle!) for the adjustment.

If the specimen head moves downwards, turn the screw (34) clockwise.

If the specimen head moves upwards, turn the screw (34) counterclockwise.

Continue this procedure until the specimen head no longer moves once

released.

Figure 7: Fine adjustment of the force balance

INHECO GmbH 16

Page 17

Maintenance Work to be Carried Out by the User

6 Maintenance Work to be Carried

Out by the User

Cleaning

Before beginning to clean the RM CoolClamp, make sure that the power pack

has been unplugged and all surfaces have cooled down to below +50 °C

[+122 °F].

Clean the RM CoolClamp using paraffin remover only. Xylene and other

solvents are not permitted. Wait to reactivate it until all the liquid has

evaporated.

Make sure that no liquid ingresses into the instrument (ventilation slots). Use

only enough liquid as is absolutely necessary. The assembly group is not suited

for cleaning by dipping into liquid.

To guarantee that the RM CoolClamp functions flawlessly, make sure that the

fan rotates and is not blocked. In addition, make sure that the ventilation

openings are free before and during use; see page 11.

No cleaning in the incubator is permitted.

The RM CoolClamp must not be disassembled for cleaning.

Decontamination

No units may be sent back to INHECO if contaminated. Potential harm to the

recipient's health must be precluded. The most common decontamination

method is disinfection using formaldehyde or ethylene oxide gas.

The surface decontamination may include wiping the surface. A solution of 70%

alcohol is the conventional method for effectively removing organisms.

Make sure that no moisture gets inside the unit!

Spare parts

Spare parts for the unit must be ordered through Leica Biosystems Nussloch

GmbH. Only original parts are permitted for use.

INHECO GmbH 17

Page 18

7 Technical Data

Electrical data for the RM CoolClamp

Operating voltage

7.5 V DC

Maximum input power

18 W

Electrical data for the power pack

Nominal voltage

100 to 240 V AC

Nominal current

0.4 to 0.8 A maximum

Nominal frequency

47 to 63 Hz

Maximum output power

22.5 W

Output operating voltage

7.5 V DC

Additional data for the RM CoolClamp

Operating temperature

+10 °C to +35 °C [+50 °F to +95 °F],

relative humidity:

10% to 80% (non-condensing)

Transport and storage conditions

-10 °C to +60 °C [+14 °F to +140 °F],

relative humidity:

10% to 80% (non-condensing),

elevation: 0 – 2000m

Temperature difference between

operating temperature and tensioning

clamp

20K±3K

LxWxH with power pack plug

Dimensions:

80mm x 115mm x 205mm

Weight without power pack but with

plug

0.65 kg

Weight including power pack

0.9 kg

Technical Data

Table 1: Technical Data

INHECO GmbH 18

Page 19

Declaration of Conformity

Standards and date of issue

EN 61010-1: 2004

UL 61010-1: 2004

CSA C22.2.61010.1: 2004

Safety requirements for electrical

equipment for measurement, control

and laboratory use - Part 1: General

requirements.

EN 61010-2-101: 2002

Safety requirements for in vitro

diagnostics instruments.

EN 60601-1-2: 2007

Electrical equipment for medical use.

EMC requirements.

EN 61326-1: 2006

Electrical equipment for measurement,

control and laboratory use. EMC

requirements.

City

Martinsried / Munich

Date

May, 2010

Signature

Name, position

Günter Tenzler, Managing Director

8 Declaration of Conformity

INHECO GmbH

Fraunhoferstr. 11

82152 Martinsried

Germany

Confirms that the following product,

RM CoolClamp,

fulfills the essential requirements of the following directive(s) and their relevant

part(s) of the standards and their related documents of the European Union:

This product fulfills the directives 98/79/EC for in vitro diagnostics medical

devices, 2002/96/EC WEEE, and 2002/95/EC RoHS.

INHECO GmbH 19

Page 20

Appendix

Abbreviation

Description

°C

Degrees Celsius

°F

Degrees Fahrenheit

K

Kelvin

LxWxH

Length x Width x Height

kg

Kilograms

Hz

Hertz [1/s]

V AC

AC voltage

V DC

DC voltage

A

Amperes

TEC

Peltier element

SW

Version

Date

Name

Reason

1.0

05.05.2010

TBU

Created

1.1

15.07.2011

TBU

Expanded standard delivery

Appendix A: Abbreviation Glossary

Table 2: Abbreviation Glossary

Appendix B: Index of Figures

Figure 1: Standard delivery _______________________________________ 10

Figure 2: Ventilation openings _____________________________________ 11

Figure 3: Position of the cable duct _________________________________ 12

Figure 4: Potential pinching areas __________________________________ 13

Figure 5: Power pack with EU, UK, USA and Australia adapters___________ 13

Figure 6: Attaching the RM CoolClamp ______________________________ 15

Figure 7: Fine adjustment of the force balance ________________________ 16

Appendix C: Tables Index

Table 1: Technical Data __________________________________________ 18

Table 2: Abbreviation Glossary ____________________________________ 20

Appendix D: Document History

INHECO GmbH 20

Loading...

Loading...