LEGRAND Plugmold 2000 Aluminum, Plugmold 2000TR Aluminum Installation Instructions Manual

Plugmold 2000 Aluminum

Legrand/Wiremold electrical systems conform to and should be properly

grounded in compliance with requirements of the current National

Electrical Code or codes administered by local authorities.

All electrical products may present a possible shock or fire

hazard if improperly installed or used. Legrand/Wiremold electrical

products may bear the mark of a Nationally Recognized Testing

Laboratory (NRTL) and should be installed in conformance with current

local and/or the National Electrical Code.

Plugmold 2000TR Aluminum

I N S T A L L A T I O N I N S T R U C T I O N S

Installation Instruction No.: 1 009 949 – February 2011

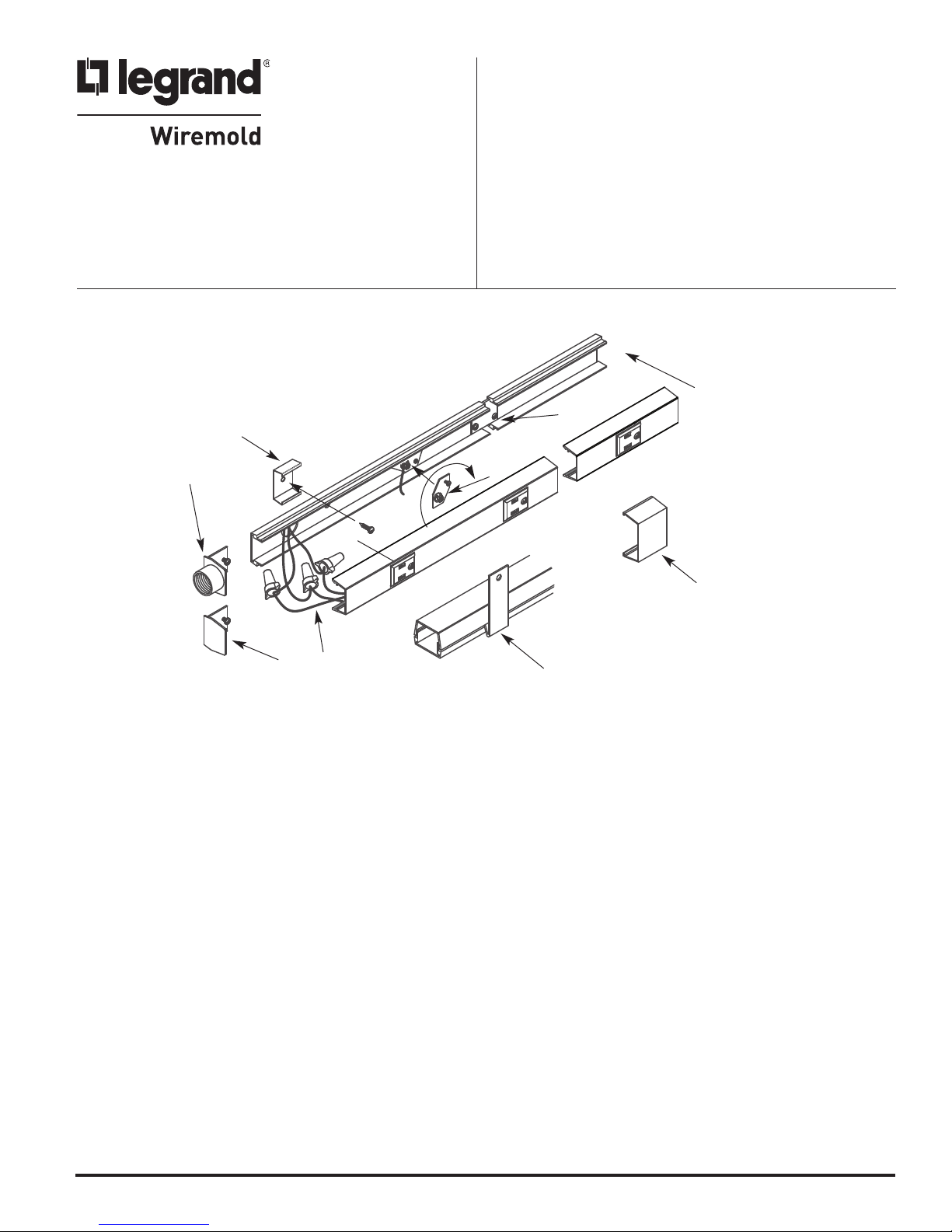

AL2000 SYSTEM PRODUCT APPLICATIONS

2

1

5

4

IMPORTANT: Please read all instructions

before beginning.

6

2

3

7

8

TO INSTALL:

1. Bring Feed into Base

a. Remove appropriate 1/2" trade size entrance knockout in base, or attach Feed End Fitting (AL2010A).

2. Install Base Section on Surface

a. Attach base section on mounting surface using AL2003 Spring Mounting Clips, or by drilling 9/32” holes in the base and use #8

set screws. Ensure holes are free from burrs.

b. If required, cut base to length and carefully debur any cut ends before mounting. If cuts have been made to the base, center the

cover section over the mounted base. Locate, mark and cut the cover ends. If the edge of any receptacle falls closer than 1 1/2"

[38mm] from the end of the unit, that receptacle must be cut out to allow sufficient space for the installation of an end fitting.

c. Connect multiple sections together using coupler (AL2001). To install, slide coupling plate into both base sections, center on joint

and tighten locking screws.

d. To install around corners, use appropriate elbows, (AL2011 - 90° Flat Elbow), (AL2017 – Internal Elbow), or (AL2017 - External Elbow)

3. Install Ground Adapter

a. Use Ground Adapter (AL2009) provided to secure ground connection. To relocate, loosen set screw and twist counter clockwise.

Position in between receptacles (to avoid interference) and assemble in reverse order.

4. Install Blank End Fitting (AL2010B)

a. At end of base raceway run, slide blank end fitting in last base sections and secure in place by tightening screw.

5. Connect wired section to feed

a. Connect feed wires to wired raceway sections. It is recommended to stagger connection points to allow room for all connections.

6. Snap raceway cover onto base

a. If necessary, snap receptacle harness into cover making sure to line up receptacle faces with pre-punched holes in the raceway cover.

b. Engage lower edge of cover over the edge of the base. Starting at one end and progressing along the unit, snap in upper edge

of the cover with the heel of the hand. Ensure that wires are pushed completely into the base before assembling the cover to

avoid pinching the wires.

7. Snap on cover clip to cover joint seams where lengths of covers come together.

8. To remove cover, insert removal tool into groove, push down and twist.

NOTE: All mounting methods must result in flush interior surface.

AL2000 RACEWAY WIRE FILL CAPACITIES FOR POWER

MAXIMUM CROSS SECTION

8 sq. in.

.

20.3mm]

.1 sq. in.

1/8"

1

29mm]

[

NOTE: Raceway may be configured in single or

1

27mm]

[

7/16"

1

37mm]

[

multiple channels to accommodate power

or communications wiring.

[

AL2000 RACEWAY WIRE FILL CAPACITIES FOR POWER

POWER WIRING 10 AWG 8

WITHOUT DEVICE 12 AWG 12

1.1 sq. in. cross section 14 AWG 24

POWER WIRING AWG 10 AWG 3

WITH DEVICE 12 AWG 6

515 amp devices 14 AWG 8

.8 sq. in. cross section

AL2003 Mounting Clip AL2006 Cover Clip

WIRE TYPE THHN/THWN

Use for external support of raceway. To install attach

AL2003 to mounting surface with screws. Snap

raceway base into AL2003.

AL2010A Feed End Fitting

AL2010B Blank End Fitting

At end of AL2000B base raceway run, slide AL2000A or

AL2000B fitting in last base section. Secure in place by

tightening screw.

le

c

pta

e

c

Re

und

d Gro

te

a

ol

s

I

line

n-

olated

G I

Gro

G Ta

I

und Re

mper-

eptac

c

Re

sis

tant I

le

n-line

AL2043I

AL2043TR

Is

To close any gaps. That occur from field cutting, snap

AL2006 Cover Clip over joints, where two adjoining

pieces come together.

AL2043 In-line Receptacle

AL2043TR Tamper-Resistant In-line Receptacle

For AL2043 Series Two 15A, 120V U-ground factory prewired

receptacles. To install slide coupler into grooves of AL2000B

end base raceway and push sections together. Connect

wires, tighten. Screws and snap in cover.

AL2040A In-line Single Pole Switch

For AL2043IG Series Two 15A, 120V Isolated ground factory

prewired receptacles. To install slide coupler into grooves

of AL2000B base raceway and push sections together.

Connect wires, tighten screws and snap in cover.

Single Pole Switch 15A. 120V. To Install slide coupler into

groove of AL2400B base raceway and push sections together.

Tighten screws and snap in cover.

Loading...

Loading...