Page 1

Installation and Operation Manual

SPEEDMASTER

®

SM PLUS™ SERIES SUB-MICRO INVERTERS

Page 2

TABLE OF CONTENTS

1.0 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2.0 SM-Plus™DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4.0 SM-Plus™SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

5.0 SM-Plus™RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6.0 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7.0 INPUT AC POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . .9

8.0 POWER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

9.0 SM-Plus™POWER WIRING DIAGRAM . . . . . . . . . . . . . . . . . . .13

10.0 CONTROL WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

11.0 SM-Plus™CONTROL WIRING DIAGRAMS . . . . . . . . . . . . . . .17

12.0 INITIAL POWER UP AND MOTOR ROTATION . . . . . . . . . . .22

13.0 PROGRAMMING THE SM-Plus™DRIVE . . . . . . . . . . . . . . . . .24

14.0 PARAMETER MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

15.0 DESCRIPTION OF PARAMETERS . . . . . . . . . . . . . . . . . . . . . . .31

16.0 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

17.0 SM-Plus™DISPLAY MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . .49

APPENDIX B - PI SETPOINT CONTROL OPTION . . . . . . . . .51

Page 3

IMPORTANT NOTICE

The following , and information is supplied to you for your

protection and to provide you with many years of trouble free and safe operation of your LEESON

Electric product.

• Hazard of electrical shock! Capacitors retain charge after power is removed. Disconnect incoming

power and wait until the voltage between terminals B+ and B- is 0 VDC before servicing the drive.

• Hazard of electrical shock! Wait three minutes after disconnecting incoming power before

servicing drive. Capacitors retain charge after power is removed.

• Automatic starting of equipment may cause damage to equipment and / or injury to personnel!

Automatic start should only be used on equipment that is inaccessible to personnel.

• DRIVES MUST NOT BE INSTALLED WHERE SUBJECTED TO ADVERSE ENVIRONMENTAL CONDITIONS SUCH AS: COMBUSTIBLE, OILY, OR HAZARDOUS VAPORS

OR DUST; EXCESSIVE MOISTURE OR DIRT; VIBRATION; EXCESSIVE AMBIENT

TEMPERATURES. CONSULT LEESON ELECTRIC FOR MORE INFORMATION ON

THE SUITABILITY OF A DRIVE TO A PARTICULAR ENVIRONMENT.

• Severe damage to the drive can result if it is operated after a long period of storage or inactivity

without reforming the DC bus capacitors!

• Do not connect incoming AC power to output terminals T1, T2, or T3. Severe damage to the

drive will result.

• When operating in JOG mode, the STOP terminal (TB-1) and the STOP key (on the optional

remote keypad) WILL NO

T stop the drive. To stop the drive, remove the JOG command.

• When operating in JOG mode, the STOP terminal (TB-1), the AUXILIARY STOP function (see

setting 08), and the STOP key on the optional remote keypad WILL NOT stop the drive. To stop

the drive, remove the JOG command.

• JOG REVERSE will operate the drive in reverse rotation even if ROTATION DIRECTION

(Parameter 17) is set to FORWARD ONLY.

• DO NOT connect incoming AC power to output terminals T1, T2, and T3! Severe damage to

the drive will result. Do not continuously cycle input power to the drive more than once every

two minutes. Damage to the drive will result.

• Do not remove the EPM while power is applied to the drive. Damage to the EPM and/or drive

may result.

• Controlling the drive from the serial link without the watchdog timer could cause damage to

equipment and/or injury to personnel!

• Consult qualified personnel with questions. All electrical repairs must be performed by trained

and qualified personnel only.

Resale of Goods:

In the event of the resale of any of the goods, in whatever form, Resellers/Buyers will include the following language in

a conspicuous place and in a conspicuous manner in a written agreement covering such sale:

The manufacturer makes no warranty or representations, express or implied, by operation of law or otherwise, as

the merchantability or fitness for a particular purpose of the goods sold hereunder. Buyer acknowledges that it

alone has determined that the goods purchased hereunder will suitably meet the requirements of their intended

use. In no event will the manufacturer be liable for consequential, incidental or other damages. Even if the repair

or replacement remedy shall be deemed to have failed of its essential purpose under Section 2-719 of the Uniform

Commercial Code, the manufacturer shall have no liability to Buyer for consequential damages.

Resellers/Buyers agree to also include this entire document including the warnings and cautions above in

a conspicuous place and in a conspicuous manner in writing to instruct users on the safe usage of the

product.

Page 4

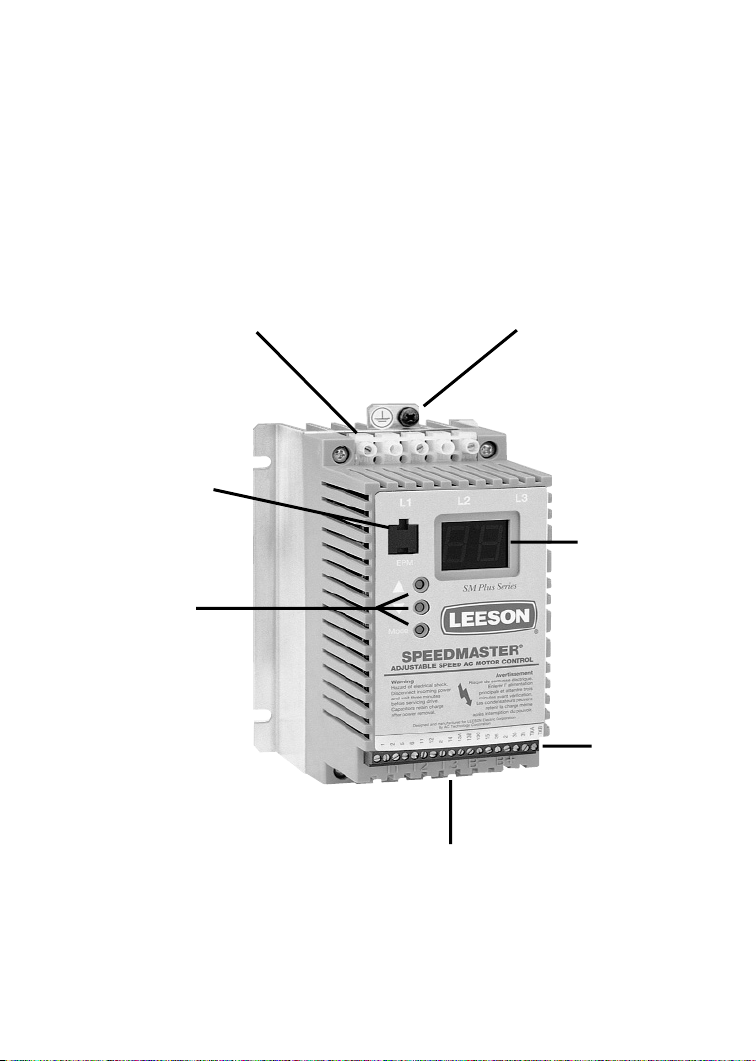

SUB-MICRO DRIVE

INPUT POWER

TERMINALS

GROUND LUG

ELECTRONIC

PROGRAMMING

MODULE (EPM)

PROGRAMMING

BUTTONS

OUTPUT (MOTOR)

TERMINALS

3-DIGIT LED

DISPLAY

CONTROL

TERMINAL

STRIP

SPEEDMASTER®SM-PLUS

™

LEESON Electric

Page 5

1.0 GENERAL

1.1 PRODUCTS COVERED IN THIS MANUAL

This manual covers the LEESON Electric SM-Plus™Variable Frequency Drive.

1.2 PRODUCT CHANGES

LEESON Electric reserves the right to discontinue or make modifications to the design of its products

without prior notice, and holds no obligation to make modifications to products sold previously.

LEESON Electric also holds no liability for losses of any kind which may result from this action.

Instruction manuals with the most up-to-date information are available for download at the LEESON

Electric website (www.leeson.com).

1.3 WARRANTY

LEESON Electric warrants the SM-Plus™AC motor control to be free of defects in material and

workmanship for a period of twelve months from the date of sale to the user, or eighteen months from

the date of shipment, which ever occurs first. If a SM-Plus™motor control, under normal use, becomes

defective within the stated warranty time period, contact LEESON’s Service Department for instructions

on obtaining a warranty replacement unit. LEESON Electric reserves the right to make the final

determination as to the validity of a warranty claim, and sole obligation is to repair or replace only

components which have been rendered defective due to faulty material or workmanship. No warranty

claim will be accepted for components which have been damaged due to mishandling, improper

installation, unauthorized repair and/or alteration of the product, operation in excess of design

specifications or other misuse, or improper maintenance. LEESON Electric makes no warranty that its

products are compatible with any other equipment, or to any specific application, to which they may be

applied and shall not be held liable for any other consequential damage or injury arising from the use of

its products.

This warranty is in lieu of all other warranties, expressed or implied. No other person, firm or

corporation is authorized to assume, for LEESON Electric, any other liability in connection with

the demonstration or sale of its products.

NOTE 1: LEESON will match mode of transportation if drive is repaired under warranty. Customer

will be invoiced for shipping if no problem is found, if the repair is non-warranty, or if the return mode

is different.

NOTE 2: There is a minimum inspection fee of $100.00 if no problem is found. There is an

additional charge of 25% for Rush Service.

1

Page 6

1.4 RECEIVING

Inspect all cartons for damage which may have occurred during shipping. Carefully unpack equipment

and inspect thoroughly for damage or shortage. Report any damage to carrier and/or shortages to

supplier. All major components and connections should be examined for damage and tightness, with

special attention given to PC boards, plugs, knobs and switches.

1.5 CUSTOMER MODIFICATION

LEESON Electric, its sales representatives and distributors, welcome the opportunity to assist our

customers in applying our products. Many customizing options are available to aid in this function.

LEESON Electric cannot assume responsibility for any modifications not authorized by its engineering

department.

2

Page 7

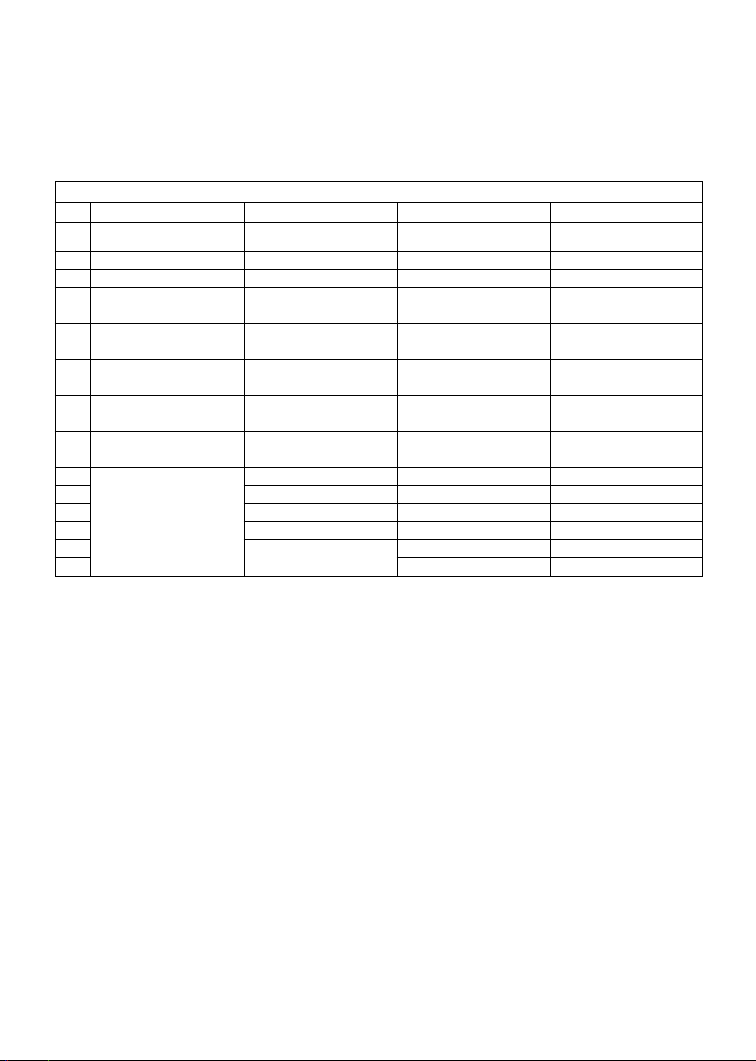

3

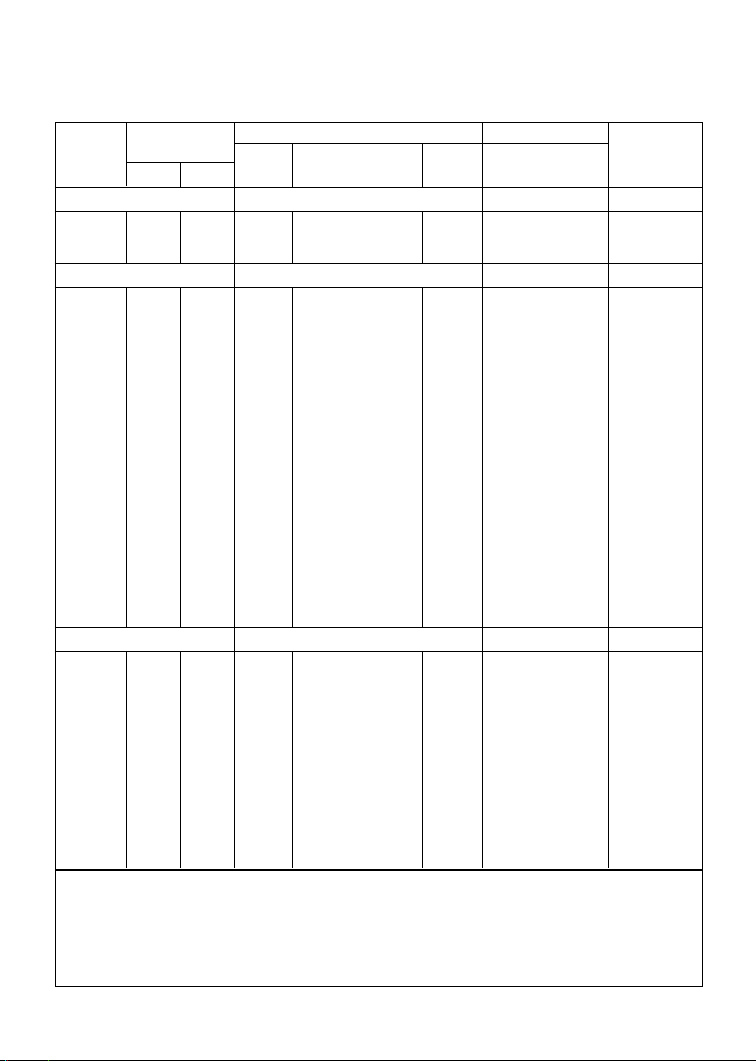

INPUT

HP kW VOLTAGE MODEL H W D P R

0.25 0.20 208 / 240 174452 5.75 (146) 2.88 (73) 3.94 (100) 0.80 (20) 4.37 (111)

0.5 0.37 208 /240 174453 5.75 (146) 2.88 (73) 3.94 (100) 0.80 (20) 4.37 (111)

400 / 480 174459 5.75 (146) 2.88 (73) 3.94 (100) 0.80 (20) 4.37 (111)

1 0.75 120/280/240 174492 5.75 (146) 3.76 (96) 5.24 (133) 1.90 (48) 4.37 (111)

208 / 240 174454 5.75 (146) 2.88 (73) 4.74 (120) 1.60 (41) 4.37 (111)

208 / 240 174455 5.75 (146) 2.88 (73) 4.74 (120) 1.60 (41) 4.37 (111)

400 / 480 174460 5.75 (146) 2.88 (73) 4.74 (120) 1.60 (41) 4.37 (111)

480 / 590 174464 5.75 (146) 2.88 (73) 4.74 (120) 1.60 (41) 4.37 (111)

1.5 1.1 120/280/240 174445 5.75 (146) 3.76 (96) 5.24 (133) 1.90 (48) 4.37 (111)

208 / 240 174493 5.75 (146) 3.76 (96) 5.24 (133) 1.90 (48) 4.37 (111)

208 / 240 174456 5.75 (146) 2.88 (73) 5.74 (146) 2.60 (66) 4.37 (111)

400 / 480 174461 5.75 (146) 2.88 (73) 5.74 (146) 2.60 (66) 4.37 (111)

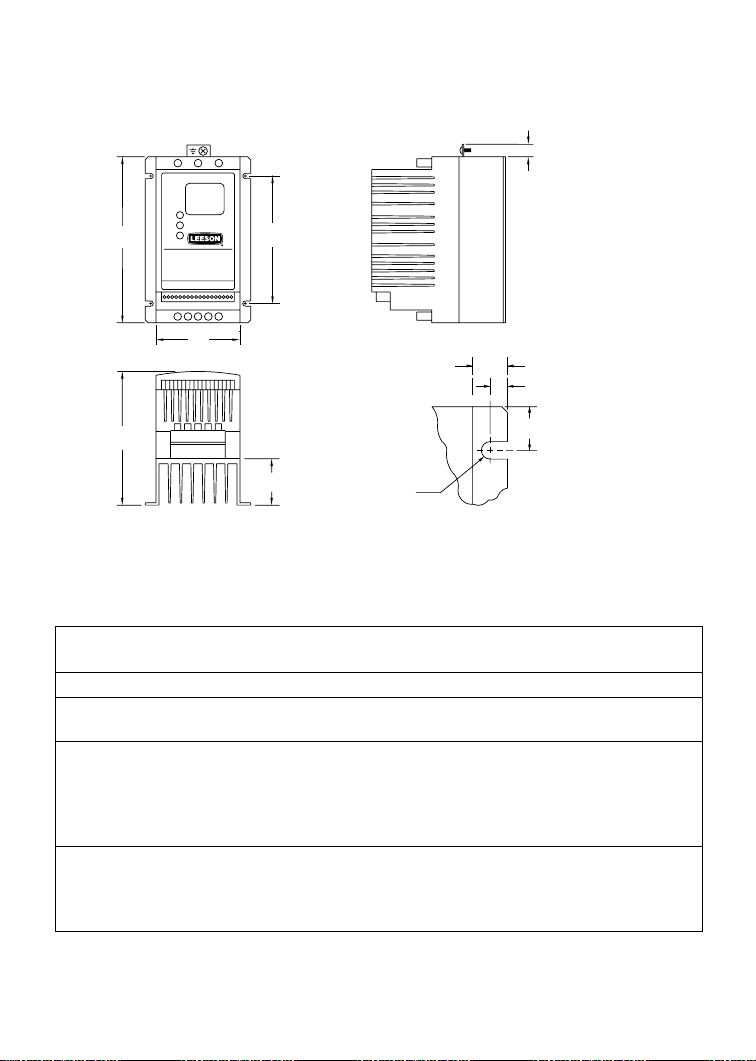

2.0 SM-Plus™DIMENSIONS

D

P

V

U

T

S

Dia. Slot

Mounting Tab Detail

H

W

R

0.38"

If R < 6.30"

S = 0.19"

T = 0.38"

U = 0.18"

V = 0.69"

If R = 6.30"

S = 0.28"

T = 0.50"

U = 0.24"

V = 0.92"

Page 8

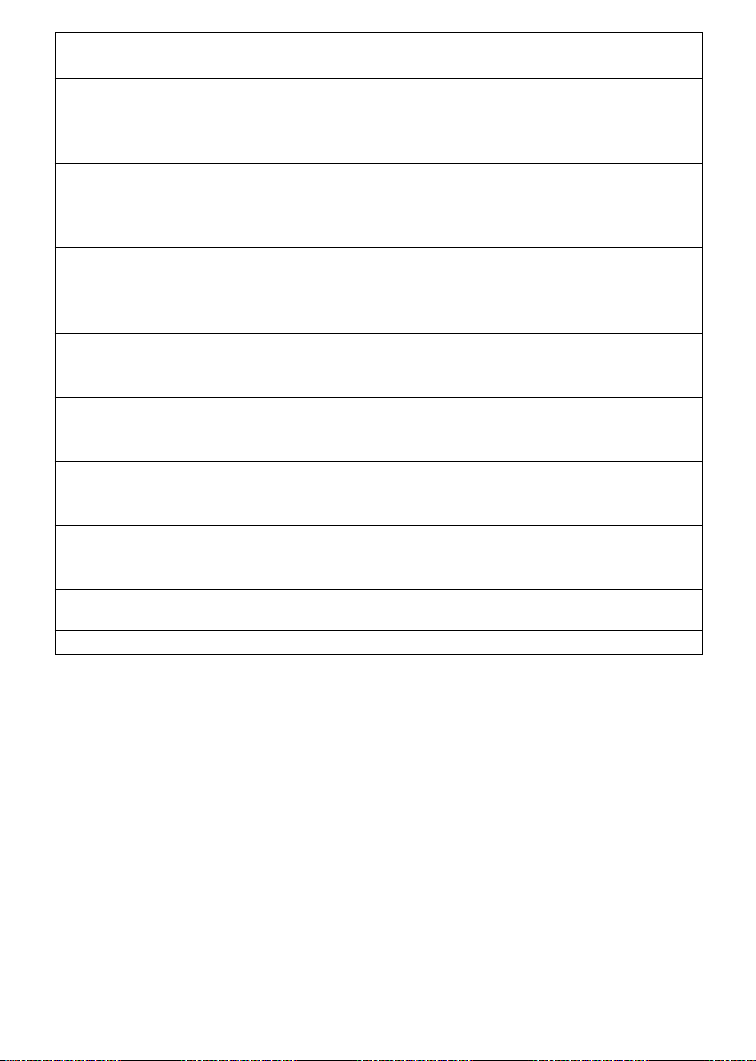

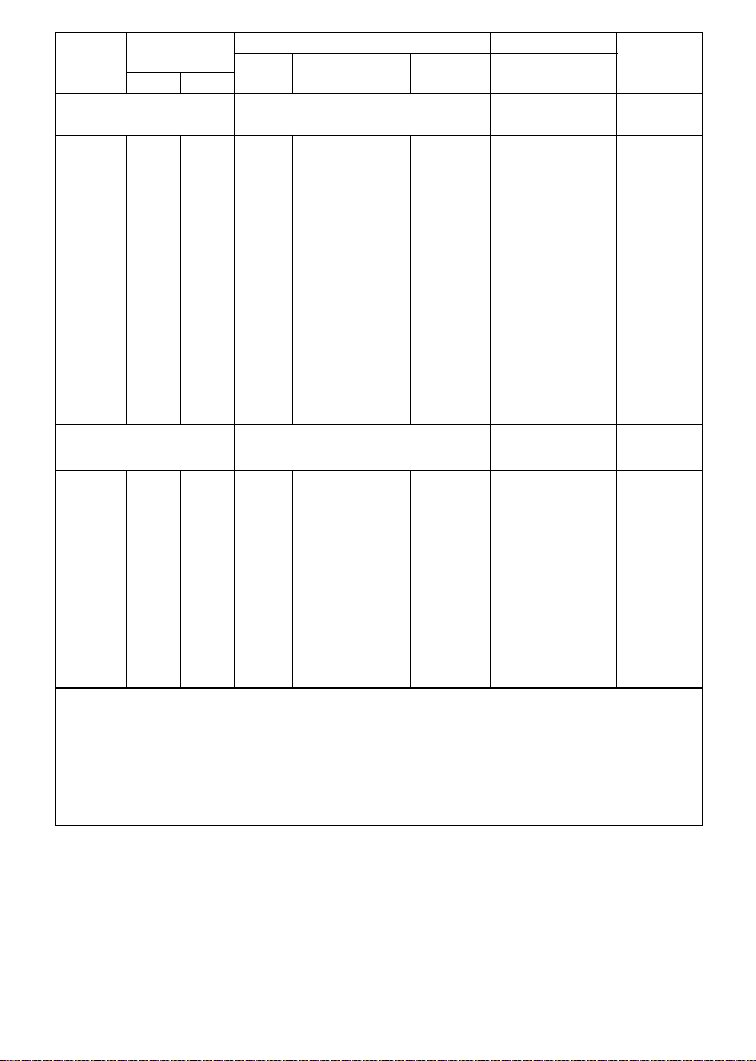

4

INPUT

HP kW VOLTAGE MODEL H W D P R

2 1.5 208 / 240 174494 5.75 (146) 3.76 (96) 6.74 (171) 3.40 (86) 4.37 (111)

208 / 240 174457 5.75 (146) 2.88 (73) 5.74 (146) 2.60 (66) 3.06 (78)

400 / 480 174462 5.75 (146) 2.88 (73) 5.74 (146) 2.60 (66) 4.37 (111)

480 / 590 174491 5.75 (146) 2.88 (73) 5.74 (146) 2.60 (66) 4.37 (111)

3 2.2 208 / 240 174495 5.75 (146) 3.76 (96) 6.74 (171) 3.40 (86) 3.25 (83)

208 / 240 174458 5.75 (146) 2.88 (73) 5.74 (146) 2.60 (66) 3.06 (78)

400 / 480 174463 5.75 (146) 2.88 (73) 5.74 (146) 2.60 (66) 3.06 (78)

480 / 590 174497 5.75 (146) 3.76 (96) 6.74 (171) 3.40 (86) 4.37 (111)

5 3.7 208 / 240 174444 7.75 (197) 5.02 (128) 7.18 (182) 3.40 (86) 4.81 (122)

208 / 240 174446 5.75 (146) 3.76 (96) 6.74 (171) 3.40 (86) 3.25 (83)

400 / 480 174447 5.75 (146) 3.76 (96) 6.74 (171) 3.40 (86) 3.25 (83)

480 / 590 174448 5.75 (146) 3.76 (96) 6.74 (171) 3.40 (86) 3.25 (83)

7.5 5.5 208 / 240 174438 7.75 (197) 5.02 (128) 7.18 (182) 3.40 (86) 4.81 (122)

400 / 480 174440 7.75 (197) 5.02 (128) 7.18 (182) 3.40 (86) 4.81 (122)

480 / 590 174442 7.75 (197) 5.02 (128) 7.18 (182) 3.40 (86) 4.81 (122)

10 7.5 208 / 240 174439 7.75 (197) 5.02 (128) 7.18 (182) 3.40 (86) 4.81 (122)

400 / 480 174441 7.75 (197) 5.02 (128) 7.18 (182) 3.40 (86) 4.81 (122)

480 / 590 174443 7.75 (197) 5.02 (128) 7.18 (182) 3.40 (86) 4.81 (122)

15 11 208 / 240 174429 9.75 (248) 6.68 (170) 8.00 (203) 3.60 (91) 6.30 (160)

400 / 480 174431 9.75 (248) 6.68 (170) 8.00 (203) 3.60 (91) 6.30 (160)

480 / 590 174434 9.75 (248) 6.68 (170) 8.00 (203) 3.60 (91) 6.30 (160)

20 15 208 / 240 174430 9.75 (248) 6.68 (170) 8.00 (203) 3.60 (91) 6.30 (160)

400 / 480 174432 9.75 (248) 6.68 (170) 8.00 (203) 3.60 (91) 6.30 (160)

480 / 590 174435 9.75 (248) 6.68 (170) 8.00 (203) 3.60 (91) 6.30 (160)

25 18.5 400 / 480 174433 9.75 (248) 6.68 (170) 8.00 (203) 3.60 (91) 6.30 (160)

480 / 590 174436 9.75 (248) 6.68 (170) 8.00 (203) 3.60 (91) 6.30 (160)

30 22 400/480 174500 9.75 (248) 6.68 (170) 8.00 (203) 3.60 (91) 6.30 (160)

Page 9

5

4.0 SM-Plus™SPECIFICATIONS

Storage Temperature -20° to 70° C

Ambient Operating Temperature 0° to 50° C (derate 2.5% per °C above 50°)

Ambient Humidity <95% (non-condensing)

Maximum Altitude 3300 ft (1000m) above sea level

(derate 5% per additional 3300 ft)

Input Line Voltages 120/208/240 VAC, 208/240 Vac, 400/480 Vac, 480/590 Vac

Input Voltage Tolerance +10%, -15%

Input Frequency Tolerance 48 to 62 Hz

Output Wave Form Sine Coded PWM

Output Frequency 0 - 240 Hz (consult Factory for higher output

frequencies)

Carrier Frequency 4 kHz to 10 kHz

(over 6 kHz requires derating; see parameter P02)

Service Factor 1.00 (up to 6 kHz carrier,

derate above 6 kHz; see parameter P02)

Efficiency Up to 98%

Power Factor (displacement) 0.96 or better

Overload Current Capacity 150% for 60 seconds, 180% for 30 seconds

Speed Reference Follower 0 - 10 VDC, 4 - 20 mA

Control Voltage 15 VDC

Power Supply for Auxiliary Relays 50 mA at 12 VDC

Analog Outputs 0 - 10 VDC or 2 - 10 VDC: Proportional to frequency

or load

Digital Outputs Open-collector outputs: 50 mA at 30 VDC

Page 10

6

MODEL FOR MOTORS INPUT (50-60 Hz) OUTPUT HEAT LOSS

NUMBER RATED INPUT CURRENT POWER CURRENT (WATTS)

HP kW PHASE (AMPS) (NOTE 1) (kVA) (AMPS) (NOTE 2)

120/208/240 VAC 0 - 230/200/230 VAC

174492 1 0.75 1 16.6/9.6/8.3 2.0 4.2/4.8/4.2 48

174445 1.5 1.1 1 24/13.9/12.0 2.9 6.0/6.9/6.0 73

208/240 Vac 0 - 200/230 Vac

174452 0.25 0.20 1 3.6/3.2 0.76 1.6/1.4 19

174452 0.25 0.20 3 1.9/1.7 0.71 1.6/1.4 19

174453 0.5 0.37 1 5.4/4.7 1.2 2.5/2.2 26

174453 0.5 0.37 3 3.1/2.7 1.1 2.5/2.2 26

174454 1 0.75 1 10.6/9.2 2.2 4.8/4.2 49

174454 1 .075 3 5.8/5.1 2.1 4.8/4.2 49

174493 1.5 1.1 1 13.9/12.0 2.9 6.9/6.0 82

174493 1.5 1.1 3 8.0/6.9 2.9 6.9/6.0 82

174494 2 1.5 1 14.8/12.9 3.1 7.8/6.8 86

174494 2 1.5 3 9.1/7.9 3.2 7.8/6.8 86

174495 3 2.2 1 19.7/17.1 4.1 11.0/9.6 130

174495 3 2.2 3 12.4/10.8 4.4 11.0/9.6 130

174444 5 3.7 1 29/26 6.1 17.5/15.2 212

174444 5 3.7 3 19.6/17.1 7.1 17.5/15.2 212

208/240 Vac 0 - 200/230 Vac

174455 1 0.75 3 5.8/5.1 2.1 4.8/4.2 41

174456 1.5 1.1 3 8.0/6.9 2.9 6.9/6.0 69

174457 2 1.5 3 9.1/7.9 3.3 7.8/6.8 78

174458 3 2.2 3 12.4/10.8 4.5 11.0/9.6 117

174446 5 3.7 3 19.6/17.1 7.1 17.5/15.2 187

174438 7.5 5.5 3 28/25 10.3 25/22 286

174439 10 7.5 3 34/32 13.1 30/28 379

174429 15 11 3 54/48 20.0 48/42 476

174430 20 15 3 65/61 25.4 58/54 648

NOTE 1: The higher current ratings are for 208 Vac input and the lower current ratings are for 240

Vac input.

NOTE 2: Values are worst-case (not typical) for 6 kHz carrier frequency at full speed and full load.

5.0 SM-Plus™RATINGS

Page 11

7

MODEL FOR MOTORS INPUT (50-60 Hz) OUTPUT HEAT LOSS

NUMBER RATED INPUT CURRENT POWER CURRENT (WATTS)

HP kW PHASE (AMPS) (kVA) (AMPS) (NOTE 2)

400/480 Vac

0 - 400/460 Vac

(NOTE 3)

174459 0.5 0.37 3 1.6/1.4 1.1 1.3/1.1 26

174460 1 0.75 3 2.9/2.5 2.1 2.4/2.1 40

174461 1.5 1.1 3 4.0/3.6 3.0 3.4/3.0 56

174462 2 1.5 3 4.6/4.0 3.3 3.9/3.4 67

174463 3 2.2 3 6.2/5.4 4.5 5.5/4.8 100

174447 5 3.7 3 9.8/8.6 7.1 8.7/7.6 168

174440 7.5 5.5 3 14.2/12.4 10.3 12.6/11.0 254

174441 10 7.5 3 18.1/15.8 13.1 16.1/14.0 310

174431 15 11 3 27/24 20.0 24/21 390

174432 20 15 3 35/31 25.8 31/27 530

174433 25 18.5 3 44/38 31.6 39/34 648

174500 30 22 3 53/45 37.4 46/40 770

480/590 Vac

0 - 460/575 Vac

(NOTE 4)

174464 1 0.75 3 2.2/2.0 1.9/2.0 1.9/1.7 40

174491 2 1.5 3 4.0/3.5 3.3/3.6 3.4/3.0 67

174497 3 2.2 3 4.7/4.7 3.9/4.8 4.2/4.2 100

174448 5 3.7 3 7.4/7.4 6.1/7.5 6.6/6.6 168

174442 7.5 5.5 3 11.2/11.2 9.3/11.4 9.9/9.9 254

174443 10 7.5 3 13.7/13.7 11.4/14.0 12.2/12.2 310

174434 15 11 3 22/22 18.3/22.5 19.0/19.0 390

174435 20 15 3 27/27 22.4/27.6 24/24 530

174436 25 18.5 3 31/31 25.8/31.7 27/27 648

NOTE 2: Values are worst-case (not typical) for 6 kHz carrier frequency at full speed and full load.

NOTE 3: The higher current ratings are for 400 Vac input and the lower current ratings are for 480

Vac input.

NOTE 4: The higher current ratings for for 480 Vac input and the lower current ratings are for 590

Vac input.

Page 12

6.0 INSTALLATION

NOTE: SM-Plus™drives are intended for inclusion within other equipment, by professional electrical

installers. They are not intended for stand-alone operation.

DRIVES MUST NOT BE INSTALLED WHERE SUBJECTED TO ADVERSE

ENVIRONMENTAL CONDITIONS SUCH AS: COMBUSTIBLE, OILY, OR HAZARDOUS

VAPORS OR DUST; EXCESSIVE MOISTURE OR DIRT; VIBRATION; EXCESSIVE AMBIENT

TEMPERATURES. CONSULT LEESON ELECTRIC FOR MORE INFORMATION ON THE

SUITABILITY OF A DRIVE TO A PARTICULAR ENVIRONMENT.

SM-Plus™models are suitable for UL pollution degree 2 environment only, and MUST be installed in

an electrical enclosure which will provide complete mechanical protection and will maintain the internal

temperature within the drive’s ambient operating temperature rating. All drives models MUST be

mounted in a vertical position for proper heatsink cooling.

Maintain a minimum spacing around the drive of at least 1 inch (25mm) on each side and 2 inches

(50mm) on the top and bottom for units rated up to 5 HP (3.7 kW). For units rated 7.5 - 25 HP (5.5-

18.5 kW), maintain at least 2 inches (50mm) on each side and 4 inches (100mm) on the top and

bottom. Allow more spacing if the drive is mounted next to other heat-producing equipment. Do not

mount drives above other drives or heat producing equipment. Fans or blowers should be used to insure

proper cooling in tight quarters.

In order to properly size an enclosure, the heat generated by the drive(s) must be known. Refer to the

HEAT LOSS columns in Section 5.0 - SM-Plus™RATINGS. An enclosure manufacturer can then

determine the required enclosure size based on the total heat generated inside the enclosure (from the

drive(s) and other heat sources), the maximum allowable temperature inside the enclosure, the maximum

ambient temperature outside the outside the enclosure, and the enclosure properties.

The SM-Plus™is UL approved for solid state motor overload protection. Therefore, a separate thermal

overload relay is not required for single motor applications.

6.1 INSTALLATION AFTER A LONG PERIOD OF STORAGE

Severe damage to the drive can result if it is operated after a long period of storage or

inactivity without reforming the DC bus capacitors!

If input power has not been applied to the drive for a period of time exceeding three years (due to

storage etc), the electrolytic DC bus capacitors within the drive can change internally, resulting in

excessive leakage current. This can result in premature failure of the capacitors if the drive is operated after

such a long period of inactivity or storage.

In order to reform the capacitors and prepare the drive for operation after a long period of

inactivity, apply input power to the drive for 8 hours prior to actually operating the motor.

8

Page 13

9

6.2 EXPLOSION PROOF APPLICATIONS

Explosion proof motors that are not rated for inverter use lose their certification when used for variable

speed. Due to the many areas of liability that may be encountered when dealing with these applications,

the following statement of policy applies:

“LEESON Electric inverter products are sold with no warranty of fitness for a particular

purpose or warranty of suitability for use with explosion proof motors. LEESON Electric accepts

no responsibility for any direct, incidental or consequential loss, cost, or damage that may arise

through the use of its AC inverter products in these applications. The purchaser expressly agrees to

assume all risk of any loss, cost, or damage that may arise from such application.”

7.0 INPUT AC POWER REQUIREMENTS

Hazard of electrical shock! Capacitors retain charge after power is removed. Disconnect

incoming power and wait until the voltage between terminals B+ and B- is 0 VDC before servicing the

drive.

The input voltage must match the nameplate voltage rating of the drive. Voltage fluctuation must not

vary by greater than 10% overvoltage or 15% undervoltage.

NOTE: Drives with dual input voltage ratings must be programmed for the proper supply

voltage (refer to Parameter 01 - LINE VOLTAGE SELECTION in Section 15.0 - DESCRIPTION OF

PARAMETERS).

The drive is suitable for use on a circuit capable of delivering not more than 5,000 RMS

symmetrical amperes at 5 HP (3.7 kW), and below, and 18,000 RMS symmetrical amperes at 7.5 HP

(5.5 kW) and above, at the drive’s rated voltage.

If the kVA rating of the AC supply transformer is greater than 10 times the input kVA rating of the

drive(s), an isolation transformer or 2-3% input line reactor must be added to the line side of the drive(s).

Three phase voltage imbalance must be less than 2.0% phase to phase. Excessive phase to phase

imbalance can cause severe damage to the drive’s power components.

Motor voltage should match line voltage in normal applications. The drive’s maximum output voltage

will equal the input voltage. Use extreme caution when using a motor with a voltage rating which is

different from the input line voltage.

Page 14

10

7.1 INPUT VOLTAGE RATINGS

Drives are rated for 120/208/240 Vac, single phase, 50-60 Hz input. The drive will function with input

voltage of 120 Vac (+10%, -15%), at 48 to 60 Hz, or with input voltage of 208 to 240 Vac (+10%,

-15%), at 48 to 62 Hz.

Drives that are rated for 208/240 Vac, three phase, 50-60 Hz input will function with input voltages of

208 to 240 Vac (+10%, -15%), at 48 to 62 Hz.

Drives that are rated for 208/240 Vac, single or three phase, 50-60 Hz input will function with input

voltage of 208 to 240 Vac (+10%, -15%), at 48 to 62 Hz.

Drives that are rated for 400/480 Vac, three phase, 50-60 Hz input will function with input voltages of

400 to 480 Vac (+10%, -15%), at 48 to 62 Hz.

Drives that are rated for 480/590 Vac, three phase, 50-60 Hz input will function with input voltages of

480 to 590 Vac (+10%, -15%), at 48 to 62 Hz.

NOTE: Parameter 01 - LINE VOLTAGE SELECTION must be programmed according to the applied

input voltage. See Section 15.0 - DESCRIPTION OF PARAMETERS.

Page 15

7.2 INPUT FUSING AND DISCONNECT REQUIREMENTS

A circuit breaker or a disconnect switch with fuses must be provided in accordance with the National

Electric Code (NEC) and all local codes. Refer to the following table for proper fuse/circuit breaker

rating and wire size.

11

INPUT FUSE / CIRCUIT BREAKER RATINGS AND WIRE SIZE REQUIREMENTS (Note 1)

208/240 Vac, 1 phase 208/240 Vac, 3 phase 400/480 Vac, 3 phase 480/490 Vac, 3 phase

Catalog Fuse Rating Wire Size Catalog Fuse Rating Wire Size Catalog Fuse Rating Wire Size Catalog Fuse Rating Wire Size

HP Number Note(2) AWG (mm

2

) Number Note(2) AWG (mm2) Number Note(2) AWG (mm2) Number Note(2) AWG (mm2)

0.25 174452 10A 14(1.5) 174452 10A 14(1.5)

0.5 174453 10A 14(1.5) 174453 10A 14(1.5) 174459 10A 14(1.5)

1 174454 15A 12(1.5)

174454

10A 14(1.5) 174460 10A 14(1.5) 174464 10A 14(1.5)

174455

1.5 174493 20A 12(2.5)

174493

12/10A 14(1.5) 174461 10A 14(1.5)

174456

2 174494 25/20A 10(2.5)

174494

15/12A 12(2.5) 174462 10A 14(1.5) 174491 10A 14(1.5)

174457

3 174495 30/25A 10(4.0)

174495

20/15A 10(4.0) 174463 10A 14(1.5) 174497 10A 14(1.5)

174458

5 174444 45/40A 10(6.0)

174444

30/25A 8(6.0) 174447 15A 14(1.5) 174448 12A 14(1.5)

174446

7.5 174438 45/40A 8(6.0) 174440 20A 12(2.5) 174442 20A 14(1.5)

10 174439 50/50A 8(10) 174441 30/25A 10(4.0) 174443 20A 12(2.5)

15 174429 80/75A 6(16) 174431 40/35A 8(6.0) 174434 30A 10(4.0)

20 174430 100/90A 4(25) 174432 50/45A 8(10) 174435 40A 8(6.0)

25 174433 70/60A 6(16) 174436 45A 8(6.0)

30 174500 80/70A 6(16)

NOTE 1: Applicable national and local electrical codes take precedence over recommendations in this table.

NOTE 2: Use UL Class CC or Class T fast-acting, current limiting type fuses. Select fuses with low I

2

T values, rated at

200,000 AIC. Recommended fuses are Bussman KTK-R, JJN, and JJS. Similar fuses with equivalent ratings by other

manufacturers may also be acceptable.

Page 16

8.0 POWER WIRING

Hazard of electrical shock! Capacitors retain charge after power is removed. Disconnect

incoming power and wait until the voltage between terminals B+ and B- is 0 VDC before servicing the

drive.

Note drive input and output current ratings and check applicable electrical codes for required wire type

and size, grounding requirements, over-current protection, and incoming power disconnect, before

wiring the drive. Size conservatively to minimize voltage drop.

Refer to Section 9.0 - SCF POWER WIRING DIAGRAM for information on torque and wire stripping

requirements for power wiring.

Input fusing and a power disconnect switch or contactor MUST be wired in series with terminals L1, L2,

and L3 for three phase input models. For 208/240 Vac single phase input models, use terminals L1 and

L2. For 120 Vac single phase input models, use terminals L1 and N. This disconnect must be used to

power down the drive when servicing, or when the drive is not to be operated for a long period of time,

but should not be used to start and stop the motor.

Repetitive cycling of a disconnect or input contactor (more than once every two minutes) may

cause damage to the drive.

8.1 WIRING FOR SINGLE PHASE OR THREE PHASE INPUT

If the drive is rated for 120/208/240 Vac single phase input, wire the input to terminals L1 and N for

120 Vac voltage, or wire to terminals L1 and L2 (do not wire to N) for 208/240 Vac input voltage. Refer

to Section 9.0 - SM-Plus™POWER WIRING DIAGRAM.

If the drive is rated for single and three phase input, wire to terminals L1 and L2 for single phase input,

or wire to terminals L1, L2, and L3 for three phase input.

If the drive is rated for three phase input, wire the input to terminals L1, L2, and L3.

All three power output wires, from terminals T1, T2, and T3 to the motor, must be kept tightly bundled

and run in a separate conduit away from all other power and control wiring.

It is not recommended to install contactors or disconnect switches between the drive and motor.

Operating such devices while the drive is running can potentially cause damage to the drive’s power

components. If such a device is required, it should only be operated when the drive is in a STOP state.

If there is potential for the device to be opened while the drive is running, the drive must be programmed

for COAST to stop (see Parameter 4 - STOP METHOD), and an auxiliary contact on the device must

be interlocked with the drive’s run circuit. This will give the drive a stop command at the same time the

device opens, and will not allow the drive to start again until the device is closed.

12

Page 17

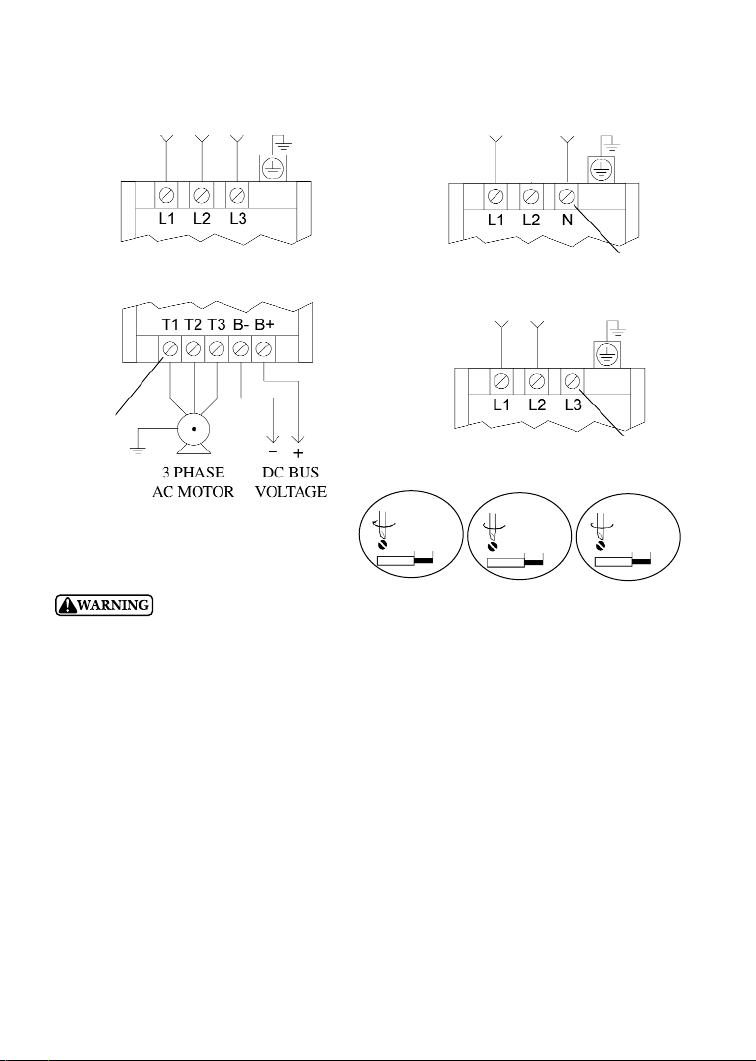

13

Do not connect incoming AC power to output terminals T1, T2, or T3. Severe

damage to the drive will result.

NOTES:

1. WIRE AND GROUND IN ACCORDANCE WITH NEC OR CEC, AND ALL APPLICABLE

LOCAL CODES.

2. Motor wires MUST be run in a separate steel conduit away from control wiring and incoming AC

power wiring.

3. Do not install contactors between the drive and the motor without consulting LEESON Electric

for more information. Failure to do so may result in drive damage.

4. Use only UL and CSA listed and approved wire.

5. Minimum wire voltage ratings: 300 V for 120, 208 and 240 Vac systems, and 600 V for 400, 480,

and 590 Vac systems.

6. Wire gauge must be based on a minimum of 125% of the rated input/output current of the drive,

and a minimum 75° C insulation rating. Use copper wire only.

9.0 SM-Plus™POWER WIRING DIAGRAM

THREE PHASE INPUT

(WHERE APPLICABLE)

OUTPUT (ALL MODELS)

120 Vac SINGLE PHASE INPUT

(WHERE APPLICABLE)

208/240 Vac SINGLE PHASE INPUT

(WHERE APPLICABLE)

WIRE STRIP & TERMINAL

SCREW TORQUE DATA

0.25 - 5 HP 7.5 - 10 HP 15 - 30 HP

(0.37 - 3.7 kW) (5.5 - 7.5 kW) (11 - 22 kW)

4.5 lb-in / 0.5 Nm 10 lb-in / 1.2 Nm 18 lb-in / 2.0 Nm

0.24 in / 6 mm 0.35 in / 9 mm 0.5 in / 13 mm

Page 18

14

10.0 CONTROL WIRING

10.1 CONTROL WIRING VS. POWER WIRING

External control wiring MUST be run in a separate conduit away from all other input and output power

wiring. If control wiring is not kept separate from power wiring, electrical noise may be generated on the

control wiring that will cause erratic drive behavior. Use twisted wires or shielded cable grounded at the

drive chassis ONLY. Recommended control wire is Belden 8760 (2-wire) or 8770 (3-wire), or equivalent.

Strip off 0.20 to 0.25 inches (5 to 6mm) of insulation for control wiring, and torque the terminals to 2

lb.-in. (0.2 Nm). Be careful not to overtorque the control terminals, as this will cause damage to the

terminal strip. This is not covered under warranty and can only be repaired by replacing the control

board.

10.2 TB-2: CIRCUIT COMMON

The TB-2 terminals are used as circuit common for the start/stop, forward/reverse, input select,

local/remote, analog input, and analog output functions. There are three TB-2 terminals

available on the terminal strip, and they are all internally connected to each other on the main control

board. If necessary TB-2 may be connected to chassis ground.

NOTE: TB-2 must be connected to chassis ground when using serial communications.

10.3 SURGE SUPPRESSION ON RELAYS

Current and voltage surges and spikes in the coils of contactors, relays, solenoids, etc, near or connected

to the drive, can cause erratic drive operation. Therefore, a snubber circuit should be used on coils

associated with the drive. For AC coils, snubbers should consist of a resistor and a capacitor in series

across the coil. For DC coils, a free-wheeling or flyback diode should be placed across the coil. Snubbers

are typically available from the manufacturer of the device.

10.4 START/STOP CONTROL

There are various control schemes that allow for 2-wire and 3-wire Start/Stop circuits. Refer to the wiring

diagrams in Section 11.0 - SM-Plus™CONTROL WIRING DIAGRAMS.

10.5 SPEED REFERENCE SIGNALS

The drive allows for three analog speed reference inputs:

SPEED POT Connect the wiper of a speed pot to terminal TB-5, and connect the high and low end

leads to terminals TB-6 and TB-2, respectively. The speed pot can be 2.5kΩ up to

10kΩ.

0-10 VDC Wire the positive to terminal TB-5 and the negative to terminal TB-2. TB-5 input

impedance is 120 kilohms.

4-20 mA Wire the positive to terminal TB-25 and the negative to terminal TB-2. TB-25 input

impedance is 100 ohms.

Page 19

15

10.6 SPEED REFERENCE SELECTION

If an analog speed reference input is used to control the drive speed, terminal TB-13A, 13B,

or 13C (Parameter 10, 11, or 12) may be programmed as the input select for the desired

analog input signal. When that TB-13 terminal is then closed to TB-2, the drive will follow the selected

analog speed reference input.

If an analog speed reference input is not selected on the terminal strip using TB-13A, 13B, or 13C,

speed control will default to STANDARD mode, which is governed by the setting of Parameter 05 STANDARD SPEED SOURCE. The STANDARD SPEED SOURCE can be the ▲ and ▼ buttons

on the front of the drive, PRESET SPEED #1(Parameter 31), a 0-10 VDC signal, or a 4-20 mA signal.

0-10 VDC and 4-20 mA INPUT SIGNALS

TB-13A, TB-13B, and TB-13C can all be programmed to select a 0-10 VDC or 4-20 mA analog speed

reference input.

PRESET SPEEDS

TB-13A can be programmed to select PRESET SPEED #1, TB-13B to select PRESET SPEED #2, and

TB-13C to select PRESET SPEED #3. There are a total of seven preset speeds, which are

activated by different combinations of contact closures between TB-13A, 13B, 13C and TB-2. Refer to

Parameters 31-37 in Section 15.0 - DESCRIPTION OF PARAMETERS.

JOG

TB-13B can be programmed to select either JOG FORWARD or JOG REVERSE. The Jog speed is set

by PRESET SPEED #2. Close TB-13B to TB-2 to JOG, and open the contact to STOP.

When operating in JOG mode, the STOP terminal (TB-1) and the STOP key (on the

optional remote keypad) WILL NOT stop the drive. To stop the drive, remove the JOG command.

JOG REVERSE will operate the drive in reverse rotation even if ROTATION

DIRECTION (Parameter 17) is set to FORWARD ONLY.

NOTE: If the drive is commanded to JOG while running, the drive will enter JOG mode and run at

PRESET SPEED #2. When the JOG command is removed, the drive will STOP.

MOTOR OPERATED POT (MOP) / FLOATING POINT CONTROL

TB-13B and TB-13C are used for this function, which controls the drive speed using contacts wired to

the terminal strip. Program TB-13B for DECREASE FREQ (05), and program TB-13C for INCREASE

FREQ (05). Closing TB-13B to TB-2 will cause the speed setpoint to decrease until the contact is

opened. Closing TB-13C to TB-2 will cause the speed setpoint to increase until the contact is opened.

The INCREASE FREQ function will only operate while the drive is running.

Page 20

16

NOTE: IfTB-13A, TB-13B, and TB-13C are all programmed to select speed references, and two or three

of the terminals are closed to TB-2, the higher terminal has priority and will override the others. For

example, if TB-13A is programmed to select 0-10 VDC, and TB-13C is programmed to select PRESET

SPEED #3, closing both terminals to TB-2 will cause the drive to respond to PRESET SPEED #3,

because TB-13C overrides TB-13A.

The exception to this is the MOP function, which requires the use of TB-13B and TB-13C. This

leaves TB-13A to be used for some other function. If TB-13A is programmed for a speed reference, and

TB-13A is closed to TB-2, TB-13A will override the MOP function.

10.7 ANALOG OUTPUT SIGNALS

Terminal TB-30 can provide a 0-10 VDC or a 2-10 VDC signal proportional to output frequency or

load, and TB-31 can provide the same signals proportional to load only. The 2-10 VDC signal can be

converted to a 4-20 mA signal using a resistor in series with the signal such that the total load resistance

is 500 Ohms. Refer to Parameters 08 and 09 in Section 15.0 - DESCRIPTION OF PARAMETERS.

NOTE: These analog output signals cannot be used with “loop-powered” devices that derive power from

a 4-20 mA signal.

10.8 DRIVE STATUS DIGITAL OUTPUTS

There are two open-collector outputs at terminals TB-14 and TB-15. The open-collector circuits are current-sinking types rated at 30 VDC and 50 mA maximum.

The open-collector outputs can be programmed to indicate any of the following: RUN, FAULT,

INVERSE FAULT, FAULT LOCKOUT, AT SPEED, ABOVE PRESET SPEED #3, CURRENT

LIMIT, AUTO SPEED MODE, and REVERSE. Refer to Parameters 06 and 13 in Section 15.0 DESCRIPTION OF PARAMETERS.

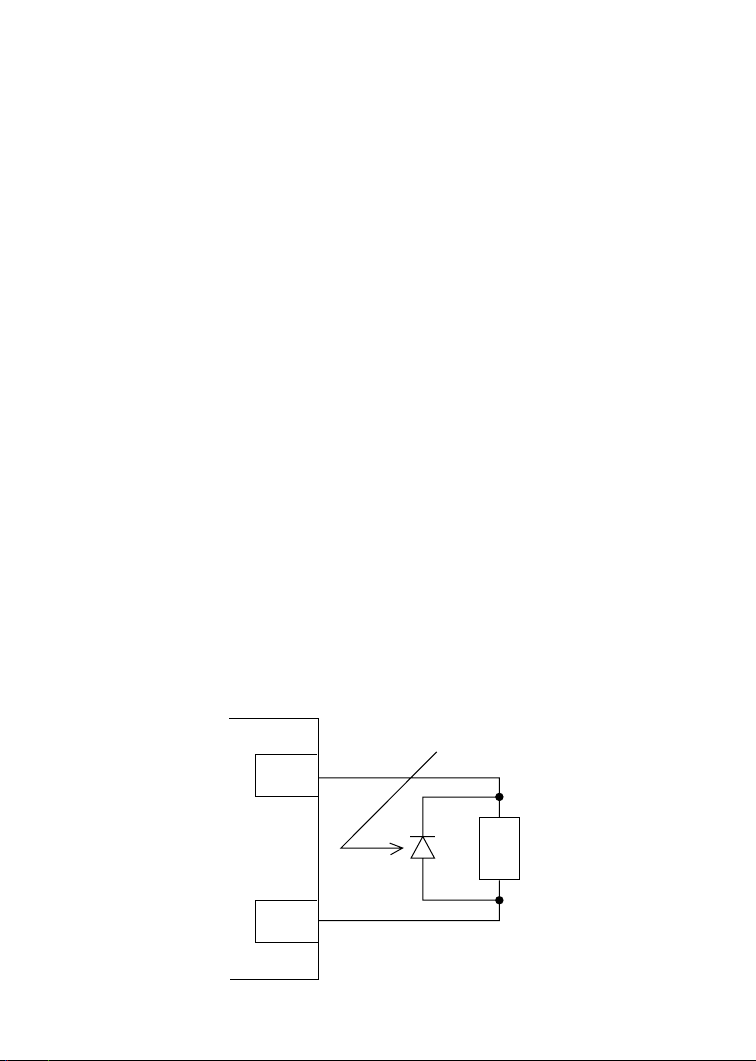

The diagram below illustrates how the 12 VDC power supply at TB-11 can be used with the open-collector output to drive an external relay:

DIODE SNUBBER

(1N4148 or Equivalent)

RELAY COIL

TB-14

TB-11

SM-PLUS™

TERMINAL STRIP

Page 21

17

11.0 SM-Plus™CONTROL WIRING DIAGRAMS

11.1 SM-Plus™TERMINAL STRIP

Shown below is the terminal strip on the main control board, along with a brief description of the

function of each terminal.

NOTE: The function of terminals TB-13A, TB-13B, TB-13C, TB-14, TB-15, TB-30, and TB-31 are

dependent on the programming of certain parameters. Refer to Section 15.0 - DESCRIPTION OF

PARAMETERS.

Additional information on operating the drive from the terminal strip can be found in Section 10.0. The

following diagrams provide a quick reference to wire the drive for the most common configurations.

STOP

12

The TB-2 terminals are internally connected to each other

5 11 12 2 14 13A 13B 13C 15 25 2 30 31 TXA TXB6

CIRCUIT COMMON

0-10 VDC SPEED REFERENCE INPUT

10 VDC SUPPLY FOR SPEED POT

12 VDC SUPPLY (50 mA MAX)

START

CIRCUIT COMMON

CIRCUIT COMMON

0-10 OR 2-10 VDC OUTPUT: FREQ. OR LOAD

0-10 OR 2-10 VDC OUTPUT: LOAD

RS-485 SERIAL

COMMUNICATIONS

OPEN-COLLECTOR OUTPUT

TB-13A FUNCTION SELECT

TB-13B FUNCTION SELECT

TB-13C FUNCTION SELECT

OPEN-COLLECTOR OUTPUT

4-20 mA SPEED REFERENCE INPUT

Page 22

18

11.2 TWO-WIRE START/STOP CONTROL

Shown below is the wiring diagram for a typical two-wire start/stop control scheme, using one maintained

contact (such as that from a PLC) for RUN and STOP commands.

NOTES:

1. Close TB-1 to TB-2 to RUN and open TB-1 to TB-2 to STOP.

2. If reverse direction is also required, ROTATION DIRECTION (Parameter 17) must be set to

FORWARD AND REVERSE (02), and TB-13A (Parameter 10) must be set to START REVERSE

(06). If reverse direction is not required, TB-12 must be wired directly to TB-2.

3. For 0-10 VDC or 4-20 mA speed control, use one of the following methods:

1. Program one of the TB-13 terminals (13A, 13B, or 13C) for 0-10 VDC (02) or 4-20 mA

(03). When that TB-13 terminal is closed to TB-2, the drive will respond to the selected speed

reference signal. If that TB-13 terminal is not closed to TB-2, the drive will respond to the

speed control source selected in Parameter 05 - STANDARD SPEED SOURCE. This

method must be used if it is necessary to toggle between two speed sources.

2. Program Parameter 05 - STANDARD SPEED SOURCE for 0-10 VDC (03) or 4-20 mA

(04). This method is preferable if only one speed source is required, as this method leaves the

TB-13 terminals free to be used for other functions.

STOP

12

The TB-2 terminals are internally connected to each other

MAINTAINED

RUN/STOP

CONTACT

5 11 12 2 14 13A 13B 13C 15 25 2 30 31 TXA TXB6

COMMON

0-10 VDC INPUT

FORWARD

COMMON

COMMON

REVERSE

0-10 VDC or 4-20 mA SELECT

4-20 mA INPUT

Page 23

19

11.3 ALTERNATE TWO-WIRE START/STOP CONTROL

Shown below is the wiring diagram for an alternate two-wire start/stop control scheme, using one

maintained contact for RUN FORWARD and another maintained contact for RUN REVERSE.

NOTES:

1. For this control scheme, TB-13A MUST be set to RUN REVERSE (05), even if REVERSE

direction is not required. Refer to Parameter 10 - TB13A FUNCTION.

2. Close TB-12 to TB-2 to RUN and open TB-12 to TB-2 to STOP.

3. If reverse direction is also required, ROTATION DIRECTION (Parameter 17) must be set to

FORWARD AND REVERSE (02). Close TB-13A to TB-2 to RUN in REVERSE, and open

TB-13A to TB-2 to STOP. If TB-12 and TB-13A are closed to TB-2, the drive will STOP.

4. For 0-10 VDC or 4-20 mA speed control, use one of the following methods:

1. Program one of the TB-13 terminals (13A, 13B, or 13C) for 0-10 VDC (02) or 4-20 mA

(03). When that TB-13 terminal is closed to TB-2, the drive will respond to the selected speed

reference signal. If that TB-13 terminal is not closed to TB-2, the drive will respond to the

speed control source selected in Parameter 05 - STANDARD SPEED SOURCE. This

method must be used if it is necessary to toggle between two speed sources.

2. Program Parameter 05 - STANDARD SPEED SOURCE for 0-10 VDC (03) or 4-20 mA

(04). This method is preferable if only one speed source is required, as this method leaves the

TB-13 terminals free to be used for other functions.

STOP

12

The TB-2 terminals are internally connected to each other

5 11 12 2 14 13A 13B 13C 15 25 2 30 31 TXA TXB6

COMMON

0-10 VDC INPUT

RUN FWD

COMMON

COMMON

RUN REV

0-10 VDC or 4-20 mA SELECT

4-20 mA INPUT

Page 24

20

11.4 THREE-WIRE START/STOP CONTROL

Shown below is the wiring diagram for a typical three-wire start/stop control scheme, using momentary

contacts (such as pushbuttons) for START and STOP commands.

NOTES:

1. Momentarily close TB-12 to TB-2 to START the drive, and momentarily open TB-1 to TB-2 to

STOP the drive.

2. If reverse direction is also required, ROTATION DIRECTION (Parameter 17) must be set to

FORWARD AND REVERSE (02), and TB-13A (Parameter 10) must be set to START REVERSE

(06). If the FWD/REV switch is changed while the drive is running, the drive will not change

direction until the START button is pushed. If reverse direction is not required, the other side of

the START pushbutton must be wired directly to TB-12.

3. For 0-10 VDC or 4-20 mA speed control, use one of the following methods:

1. Program one of the TB-13 terminals (13A, 13B, or 13C) for 0-10 VDC (02) or 4-20 mA

(03). When that TB-13 terminal is closed to TB-2, the drive will respond to the selected speed

reference signal. If that TB-13 terminal is not closed to TB-2, the drive will respond to the

speed control source selected in Parameter 05 - STANDARD SPEED SOURCE. This

method must be used if it is necessary to toggle between two speed sources.

2. Program Parameter 05 - STANDARD SPEED SOURCE for 0-10 VDC (03) or 4-20 mA

(04). This method is preferable if only one speed source is required, as this method leaves the

TB-13 terminals free to be used for other functions.

! "#

$# %&!

$# $'

! '('

"#

'$)*

'$)*

$

Page 25

21

11.5 SPEED POT AND PRESET SPEED CONTROL

Shown below is the wiring for SPEED POT and/or PRESET SPEED control, and either a two-wire or

three-wire start/stop circuit:

NOTES:

1. Program the PRESET SPEEDS (Parameters 31-37) to the desired values.

2. Program TB-13A (Parameter 10) to PRESET SPEED #1 (04). TB-13B (parameter 11) to

PRESET SPEED #2 (04), and TB-13C (Parameter 12) to PRESET SPEED #3 (04). To select a

preset speed, close the appropriate TB-13 terminal(s) to TB-2 (refer to Parameters 31-37 for the

Preset Speed Activation table).

3. If reverse rotation is also required, TB-13A cannot be used as a PRESET SPEED SELECT.

TB-13A must be programmed to select RUN REVERSE (05) or START REVERSE (06), leaving

only TB-13B and TB-13C to select preset speeds.

4. For speed pot control, program Parameter 05 - STANDARD SPEED SOURCE for 0-10 VDC

(03). If none of the preset speeds are selected (all of the TB-13 terminals are open), the drive will

respond to the speed pot.

STOP

12

The TB-2 terminals are internally connected to each other

5 11 12 2 14 13A 13B 13C 15 25 2 30 31 TXA TXB6

COMMON

0-10 VDC INPUT

START

10 VDC SUPPLY

COMMON

PRESET SPEED SELECT

PRESET SPEED SELECT

PRESET SPEED SELECT

2.5K-10K½

Page 26

22

12.0 INITIAL POWER UP AND MOTOR ROTATION

DO NOT connect incoming AC power to output terminals T1, T2, and T3! Severe

damage to the drive will result. Do not continuously cycle input power to the drive more than once every

two minutes. Damage to the drive will result.

Hazard of electrical shock! Wait three minutes after disconnecting incoming power

before servicing drive. Capacitors retain charge after power is removed.

Severe damage to the drive can result if it is operated after a long period of storage or

inactivity without reforming the DC bus capacitors!

If input power has not been applied to the drive for a period of time exceeding three

years (due to storage, etc), the electrolytic DC bus capacitors within the drive can change internally,

resulting in excessive leakage current. This can result in premature failure of the capacitors if the drive is

operated after such a long period of inactivity or storage.

In order to reform the capacitors and prepare the drive for operation after a long period of

inactivity, apply input power to the drive for 8 hours prior to actually operating the motor.

Before attempting to operate the drive, motor, and driven equipment, be sure all procedures pertaining

to installation and wiring have been properly followed.

Disconnect the driven load from the motor. Verify that the drive input terminals (L1, L2, and L3) are

wired to the proper input voltage per the nameplate rating of the drive.

Energize the incoming power line. The LED display will flash a three digit number (312 in the example

below) that identifies the parameter version contained in the drive. The display should then read “- - -”,

which indicates that the drive is in a STOP condition. This is shown below:

Apply input power

Display flashes parameter

version (300-399)

Display then reads “- - -”

Page 27

23

Follow the procedure below to check the motor rotation. This procedure assumes that the drive has been

powered up for the first time, and that none of the parameters have been changed.

1. Use the ▼ button to decrease the speed setpoint to 00.0 Hz. The left decimal point will illuminate

as the speed setpoint is decreased. If the ▼ button is held down, the speed setpoint will decrease by

tenths of Hz until the next whole Hz is reached, and then it will decrease by one Hz increments.

Otherwise, each push of the ▼ button will decrease the speed setpoint by a tenth of a Hz.

Once 00.0 Hz is reached, the display will toggle between “00.0” and “- - -”, which indicates that

the drive is in a STOP condition with a speed setpoint of 00.0 Hz.

2. Give the drive a START command. This can be done using one of several wiring methods described

in Section 11.0 - SM-Plus™CONTROL WIRING DIAGRAMS. Once the START command is

issued, the display will read “00.0”, indicating that the drive is in a RUN condition with a speed

setpoint of 00.0 Hz.

3. Use the ▲ button to increase the speed setpoint until the motor starts to rotate. The left decimal

point will light as the speed setpoint is increased. If the ▲ button is held down, the speed setpoint

will increase by tenths of Hz until the next whole Hz is reached, and then it will increase by one

Hz increments. Otherwise, each push of the button will increase the speed setpoint by a tenth of a

Hz.

4. If the motor is rotating in the wrong direction, give the drive a STOP command and remove power

from the drive. Wait three minutes for the bus capacitors to discharge, and swap any two of the

motor wires connected to T1, T2, and T3.

NOTE: The drive is phase insensitive with respect to incoming line voltage. This means that the drive

will operate with any phase sequence of the incoming three phase voltage. Therefore, to change the motor

rotation, the phases must be swapped at the drive output terminals or at the motor.

Page 28

24

13.0 PROGRAMMING THE SM-Plus™DRIVE

The drive may be programmed by one of three methods: using the three buttons and 3-digit LED

display on the front of the display, programming the Electronic Programming Module (EPM) using the

optional EPM Programmer, and through a serial link using serial communications. This section describes

programming the drive using the buttons and display, which are shown below:

To enter the PROGRAM mode to access the parameters, press the Mode button. This will

activate the PASSWORD prompt (if the password has not been disabled). The display will read “00” and

the upper right-hand decimal point will be blinking, as shown below:

Press Mode

Display reads “00”

Upper right decimal point blinks

Use the ▲ and ▼ buttons to scroll to the password value (the factory default password is “225”) and

press the Mode button. Once the correct password value is entered, the display will read “P01”, which

indicates that the PROGRAM mode has been accessed at the beginning of the parameter menu (P01 is

the first parameter). This is shown below:

Use ▲ and ▼ to scroll to the

password value

Press Mode to enter password

Parameter menus is accessed at the

first parameter

BUTTONS

Mode

DISPLAY

Page 29

25

NOTE: If the display flashes “Er”, the password was incorrect, and the process to enter the password must

be repeated.

Use the ▲ and ▼ buttons to scroll to the desired parameter number. In the example below, Parameter

19 is being displayed, which is the ACCELERATION TIME of the drive:

Use ▲ and ▼ to scroll to the desired

parameter number (the example is

Parameter 19 - ACCELERATION

TIME)

Once the desired parameter number is found, press the Mode button to display the present parameter

setting. The upper right-hand decimal point will begin blinking, indicating that the present parameter

setting is being displayed, and that it can be changed by using the ▲ and ▼ buttons.

Press Mode to display present

parameter setting (example setting

is 20.0)

Upper right decimal point blinks

Use ▲ and ▼ to change setting

(example setting changed to 30.0)

Press Mode to store new setting

Pressing the Mode will store the new setting and also exit the PROGRAM mode. To

change another parameter, press the Mode key again to re-enter the PROGRAM mode (the parameter

menu will be accessed at the parameter that was last viewed or changed before exiting). If the Mode key

is pressed within two minutes of exiting the PROGRAM mode, the password is not required access the

parameters. After two minutes, the password must be entered in order to access the parameters again.

Page 30

13.1 SETTING VALUES IN TENTHS OF UNITS ABOVE 100

Parameter settings and the keypad speed command can always be adjusted in tenths of unit increments

from 0.0 to 99.9. Above 100 however, values can be set in whole units or tenths of units, depending on

the setting of Parameter 16 - UNITS EDITING.

If Parameter 16 - UNITS EDITING is set to WHOLE UNITS (02), parameter values and the

keypad speed command can only be adjusted by whole unit increments above 100. For example,

Parameter 19 - ACCELERATION TIME could not be set to 243.7 seconds. It could only be set to 243

or 244 seconds. Likewise, the keypad speed command (set using the ▲ and ▼ buttons) could not be set

to 113.4 Hz. It could only be set to 113 or 114 Hz.

If, however, Parameter 16 - UNITS EDITING is set to TENTHS OF UNITS (01), parameter values

and the keypad speed command can be adjusted in tenths of unit increments up to a value of 1000 (above

1000, whole unit increments only). Each push of the ▲ or ▼ button will adjust the value by one tenth

of a unit. If the ▲ or ▼ button is pressed and held, the value will increment by tenths of units until the

next whole unit is reached, and then the value will increment by whole units.

When a value above 100 is being adjusted by tenths of units, the value is shifted to the left by one digit

so that the tenths portion of the value can be displayed. This results in the first digit (reading from left

to right) of the value disappearing from the display. Also, the lower decimal point will blink to indicate

that the actual value is above 100. Once the value is no longer being adjusted, the value will shift back

to the right and the tenths portion of the value will disappear.

In the example below, Parameter 19 - ACCELERATION TIME is presently set to 243.0 seconds, and is

being increased to 243.7 seconds.

Go to Parameter 19 and press Mode

to see present setting (“243” seconds)

Upper right decimal point blinks

Press ▲ button to see tenths portion

Value shifts to the left (“2” disappears)

Upper right decimal point and lower

decimal point blink

Press ▲ button to scroll up to “43.7”

Press Mode to store new value

26

Page 31

27

13.2 ELECTRONIC PROGRAMMING MODULE (EPM)

Every SM-Plus

™

drive has an Electronic Programming Module (EPM) installed on the main control

board. The EPM stores the user’s parameter settings and special OEM default settings (if programmed).

The EPM is removable, allowing it to be installed in another drive for quick set-up. For example, if a

drive is being replaced with a new one, the EPM can be taken out of the first drive and installed in the

new drive. Downtime is minimized because the new drive does not require programming - it is ready to

run when the EPM is installed.

The SM-Plus

™

drive contains two or three sets of parameter values, depending on whether the drive

has been programmed with optional OEM default settings. The first set of values is the factory default

settings, which are permanently stored on the main control board and cannot be changed. The second

set of values is the user settings, which are stored in the EPM. When the drive leaves the factory, the user

settings are the same as the factory default settings, but the user settings can be changed to configure

the drive for a particular application. The optional third set of values is the OEM default settings, which

are also stored in the EPM. OEM default settings are typically used in cases where many drives are used

for the same application, which requires that all of the drives have the same parameter settings. The OEM

default settings cannot be changed without the optional EPM Programmer. The drive can be

programmed to operate according to the user settings or the OEM default settings (see Parameter 48 in

Section 15.0).

NOTE: The drive will not operate without the EPM installed, The drive will display “F1” if the EPM is

missing or damaged.

Do not remove the EPM while power is applied to the drive. Damage to the EPM

and/or drive may result.

An EPM Programmer is available as an option from LEESON Electric, which has the ability to

quickly and easily program many SM-Plus

™

drives for the same configuration. Once a “master” EPM is

programmed with the desired parameter settings, the EPM Programmer can copy those setting to other

EPMs, allowing many drives to be configured very quickly. Please consult the EPM Programmer

Instruction Manual or contact the factory for more information.

If the OEM settings in the EPM become corrupted, the drive will operate normally, until an attempt is

made to perform a RESET OEM using Parameter 48 - PROGRAM SELECTION. The drive will then

flash “GF” to indicate that the OEM settings are no longer valid. This will require that the EPM be

re-programmed using the optional EPM Programmer.

If the OEM settings and the user settings are both corrupted, the drive will display “GF”

immediately and the drive will require a RESET 60 or RESET 50 using Parameter 48 - PROGRAM

SELECTION. Once the RESET is performed, the parameters can then be programmed

individually to match the OEM default settings. This will allow the drive to operate as if it were in

OEM mode, even though it is actually in USER mode. Refer to Parameter 48 in Section 15.0 DESCRIPTION OF PARAMETERS.

NOTE: The drive will also display “GF” if a RESET OEM or OPERATE WITH OEM SETTINGS is

attempted when the drive is not equipped with the OEM default option.

Page 32

28

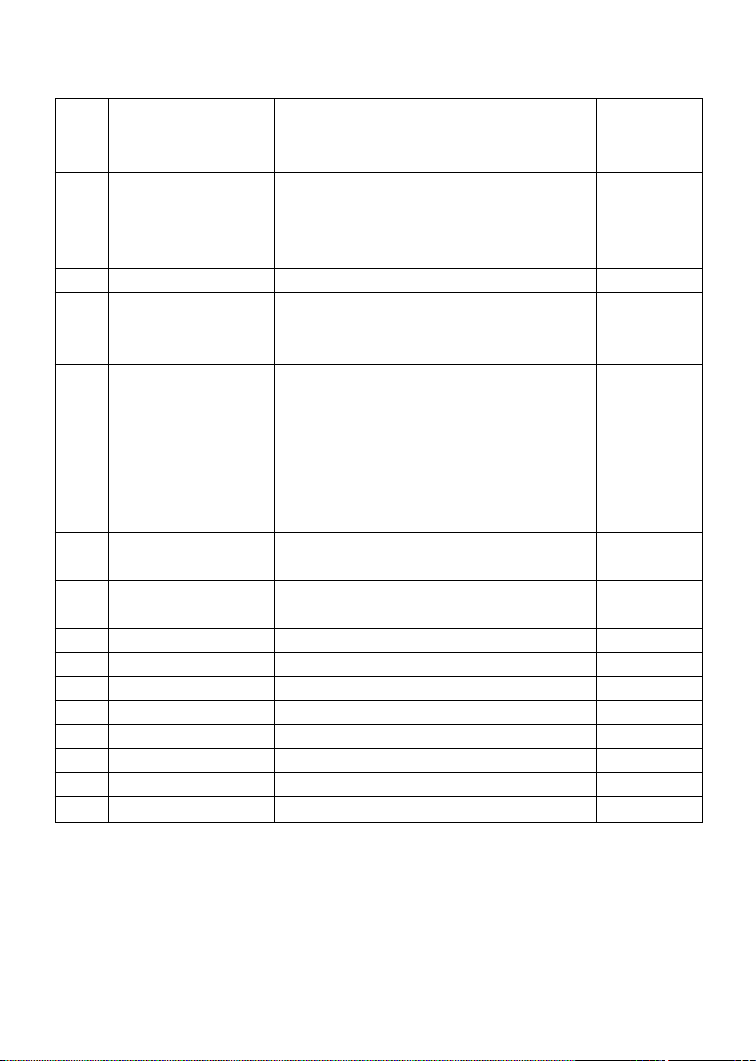

14.0 PARAMETER MENU

FACTORY

NO. PARAMETER NAME RANGE OF ADJUSTMENT DEFAULT

(NOTE 1)

01 LINE VOLTAGE HIGH (01), LOW (02) HIGH (01)

02 CARRIER FREQUENCY 4kHz (01), 6kHz (02), 8kHz (03), 10 kHz (04) 6 kHz (02)

03 START METHOD NORMAL (01), START ON POWER UP (02), NORMAL (01)

START WITH DC BRAKE (03),

AUTO RESTART WITH DC BRAKE (04),

FLYING RESTART 1 (05,) FLYING RESTART 2 (06),

FLYING RESTART 3 (07)

04 STOP METHOD COAST (01), COAST WITH DC BRAKE (02), COAST (01)

RAMP (03), RAMP WITH DC BRAKE (04)

05 STANDARD SPEED KEYPAD (01), PRESET #1 (02), KEYPAD (01)

SOURCE 0-10 VDC (03), 4-20 mA (04)

06 TB-14 OUTPUT NONE (01), RUN (02) ,FAULT (03), NONE (01)

13 TB-15 OUTPUT INVERSE FAULT (04), FAULT LOCKOUT (05), NONE (01)

AT SET SPEED (06), ABOVE PRESET #3 (07),

CURRENT LIMIT (08), AUTO SPEED (09),

REVERSE (10)

08 TB-30 OUTPUT NONE (01), 0-10 VDC FREQ (02), NONE (01)

2-10 VDC FREQ (03), 0-10 VDC LOAD (04),

2-10 VDC LOAD (05)

09 TB-31 OUTPUT NONE (01), 0-10 VDC LOAD (02), NONE (01)

2-10 VDC LOAD (03), DYNAMIC BRAKING (04)

10 TB-13A FUNCTION NONE (01), 0-10 VDC(02), 4-20mA (03), NONE (01)

SELECT PRESET SPEED #1 (04), RUN REVERSE (05),

START REVERSE (06), EXTERNAL FAULT (07),

REMOTE KEYPAD (08), DB FAULT (09),

AUXILIARY STOP (10), ACCEL/DECEL #2 (11)

11 TB-13B FUNCTION NONE (01), 0-10 VDC (02), 4-20mA (03), NONE (01)

SELECT PRESET SPEED #2 (04), DECREASE FREQ (05),

JOG FORWARD (06), JOG REVERSE (07),

AUXILIARY STOP (08)

NOTE 1: Factory defaults are shown for a 60 Hz base frequency. See Parameter 48 for 50 Hz base

frequency.

Page 33

29

FACTORY

NO. PARAMETER NAME RANGE OF ADJUSTMENT DEFAULT

(NOTE 1)

12 TB-13C FUNCTION NONE (01), 0-10 VDC (02), 4-20mA (03), NONE (01)

SELECT PRESET SPEED #3 (04), INCREASE FREQ (05),

EXTERNAL FAULT (06), REMOTE KEYPAD (07),

DB FAULT (08), ACCEL/DECEL #2 (09)

13 TB-15 OUTPUT (SEE PARAMETER 6 - TB-14 OUTPUT) NONE (01)

14 CONTROL TERMINAL STRIP ONLY (01), TERMINAL STRIP

REMOTE KEYPAD ONLY (02), ONLY (01)

TERMINAL STRIP OR REMOTE KEYPAD (03)

15 SERIAL LINK DISABLE (01), 9600, 8, N, 2

9600, 8, N, 2 WITH TIMER (02), (02)

9600, 8, N, 2 WITHOUT TIMER (03),

9600, 8, 3, 1 WITH TIMER (04),

9600, 8, E, 1 WITHOUT TIMER (05),

9600, 8, O, 1 WITH TIMER (06),

9600, 8, O, 1 WITHOUT TIMER (07)

16 UNITS EDITING TENTHS OF UNITS (01), WHOLE

WHOLE UNITS (02) UNITS (02)

17 ROTATION FORWARD ONLY (01), FORWARD

FORWARD AND REVERSE (02) ONLY (01)

19 ACCELERATION TIME 0.1 - 3600.0 SEC 20.0 SEC

20 DECELERATION TIME 0.1 - 3600.0 SEC 20.0 SEC

21 DC BRAKE TIME 0.0 - 3600.0 SEC 0.0 SEC

22 DC BRAKE VOLTAGE 0.0 - 30.0 % 0.0 %

23 MINIMUM FREQUENCY 0.0 - MAXIMUM FREQUENCY 0.0 Hz

24 MAXIMUM FREQUENCY MINIMUM FREQ - 240.0 Hz (NOTE W) 60.0 Hz

25 CURRENT LIMIT 30 - 180 % (NOTE 3) 180 %

26 MOTOR OVERLOAD 30 - 100 % 100 %

NOTE 1: Factory defaults are shown for a 60 Hz base frequency. See Parameter 48 for 50 Hz base

frequency.

NOTE 2: Maximum setting is 999.9 Hz on drives with High Output Frequency option. Consult the

factory.

NOTE 3: If LINE VOLTAGE is set to LOW, maximum setting is 150%.

PARAMETER MENU (cont)

Page 34

30

FACTORY

NO. PARAMETER NAME RANGE OF ADJUSTMENT DEFAULT

(NOTE 1)

27 BASE FREQUENCY 25.0 - 500.0 Hz (NOTE 4) 60.0 Hz

28 FIXED BOOST 0.0 - 30.0 % 1.0 %

29 ACCEL BOOST 0.0 - 20.0 % 0.0 %

30 SLIP COMPENSATION 0.0 - 5.0 % 0.0 %

31-37 PRESET SPEEDS 0.0 - MAXIMUM FREQUENCY 0.0 Hz

38 SKIP BANDWIDTH 0.0 - 10.0 Hz 0.0 Hz

39 SPEED SCALING 0.0 - 6500.0 0.0

40 FREQUENCY SCALING 3.0 -2 000.0 Hz 60.0 Hz

41 LOAD SCALING 10 - 200 % 200 %

42 ACCEL / DECEL #2 0.1 - 3600.0 SEC 20.0 SEC

43 SERIAL ADDRESS 1 - 247 1

44 PASSWORD 000 - 999 225

47 CLEAR HISTORY MAINTAIN (01), CLEAR (02) MAINTAIN (01)

48 PROGRAM USER SETTINGS (01), OEM SETTINGS (02), USER

SELECTION RESET OEM (03), RESET 60 (04), SETTINGS (01)

RESET 50 (05), TRANSLATE (06)

50 FAULT HISTORY (VIEW - ONLY) (N/A)

51 SOFTWARE CODE (VIEW - ONLY) (N/A)

52 DC BUS VOLTAGE (VIEW - ONLY) (N/A)

53 MOTOR VOLTAGE (VIEW - ONLY) (N/A)

54 LOAD (VIEW - ONLY) (N/A)

55 0 - 10 VDC INPUT (VIEW - ONLY) (N/A)

56 4-20 mA INPUT (VIEW - ONLY) (N/A)

57 TB STRIP STATUS (VIEW - ONLY) (N/A)

58 KEYPAD STATUS (VIEW - ONLY) (N/A)

59 TB-30 OUTPUT (VIEW - ONLY) (N/A)

60 TB-31 OUTPUT (VIEW - ONLY) (N/A)

NOTE 1: Factory defaults are shown for a 60 Hz base frequency. See Parameter 48 for 50 Hz base

frequency.

NOTE 4: Maximum setting is 1300.0 Hz (factory default is 999.9) on drives with High Output

Frequency option. Consult the factory.

PARAMETER MENU (cont)

Page 35

31

15.0 DESCRIPTION OF PARAMETERS

P01 LINE VOLTAGE SELECTION

This calibrates the drive for the actual applied input voltage, and can be set to HIGH (01) or LOW (02).

Refer to the table below for the proper setting depending on the input voltage.

RATED INPUT INPUT APPLIED INPUT PARAMETER

VOLTAGE PHASE VOLTAGE SETTING

120/208/240 Vac 1 110 - 120 Vac or 220 - 240 Vac HIGH (01)

1 200 - 208 Vac LOW (02)

208 / 240 Vac 1 or 3 220 - 240 Vac HIGH (01)

1 or 3 220 - 203 Vac LOW (02)

208 / 240 Vac 3 220 - 240 Vac HIGH (01)

3 200 - 208 Vac LOW (02)

400 / 480 Vac 3 440 - 480 Vac HIGH (01)

3 380 - 415 Vac LOW (02)

480 / 590 Vac 3 575 - 600 Vac HIGH (01)

3 460 - 480 Vac LOW (02)

NOTE: If this parameter is changed while the drive is running, the new value will not take effect until

the drive is stopped.

P02 CARRIER FREQUENCY

This sets the switching rate of the output IGBT’s. Increasing the carrier frequency will result in less

audible motor noise. Available settings are: 4 kHz, 6 kHz, 8 kHz, and 10 kHz.

PARAMETER CARRIER MAXIMUM OUTPUT AMBIENT OR OUTPUT

SETTING FREQUENCY FREQUENCY (NOTE 1) DERATE (NOTE 2)

01 4 kHz 240.0 Hz (400.0 Hz) 50 C or 100 %

02 6 kHz 240.0 Hz (600.0 Hz) 50 C or 100 %

03 8 kHz 240.0 Hz (999.9 Hz) 43 C or 92 %

04 10 kHz 240.0 Hz (999.9 Hz) 35 C or 82 %

NOTE 1: For drives with the High Output Frequency option, the carrier frequency also

determines the maximum output frequency (shown in parenthesis).

NOTE 2: The SM-Plus™drive is fully rated up to 6 kHz carrier frequency. If the 8 kHz or 10 kHz

carrier frequency is selected, the drive’s ambient temperature rating OR output current rating must be

derated to the value shown in the table above.

Page 36

NOTE 3: If this parameter is changed while the drive is running, the change will not take effect until

the drive is stopped. Therefore, the allowable maximum frequency for drives with the High Output

Frequency option (see NOTE 1) will not change if the carrier frequency is changed while the drive is

running.

P03 START METHOD

Automatic starting of equipment may cause damage to equipment and / or injury to

personnel! Automatic start should only be used on equipment that is inaccessible to personnel.

01 NORMAL: The drive will start when the appropriate contact is closed on the terminal strip, or

by pressing the START key on the optional remote keypad. See Parameter 14.

02 START ON POWER UP: The drive will automatically start upon application of input power.

03 START WITH DC BRAKE: When a START command is given, the drive will apply DC

BRAKE VOLTAGE (Parameter 22) for the duration of DC BRAKE TIME (Parameter 21) prior

to starting the motor to ensure that the motor is not turning.

04 AUTO RESTART WITH DC BRAKING: Upon a START command, after a fault, or upon

application of power, the drive will apply DC BRAKE VOLTAGE (Parameter 22) for the

duration of DC BRAKE TIME (Parameter 21) prior to starting (or restarting) the motor.

05 FLYING RESTART 1: LOW performance. Slowest synchronization and lowest current level.

This setting results in the smoothest synchronization.

06 FLYING RESTART 2: MEDIUM performance. Faster synchronization and higher current

level. This setting allows faster synchronization while retaining smoothness.

07 FLYING RESTART 3: HIGH performance. Fastest synchronization and highest current level.

This setting allows the fastest synchronization, but sacrifices smoothness.

The FLYING RESTART 1 - 3 settings allow the drive to start into a spinning load after a fault or upon

application of input power. They differ in the time required to find the motor and the amount of

current required to synchronize with it. The faster the drive attempts to find the motor, the more current

is required.

When programmed for auto-restart, the drive will attempt three restarts after a fault. The interval

between restart attempts is 15 seconds for setting 04, and 2 seconds for settings 05, 06 and 07. During

the interval between restart attempts, the display will read “SP” to indicate Start Pending. If all three

restart attempts fail, the drive will trip into FAULT LOCKOUT (displayed “LC”) and require a manual

reset. Refer to Section 16.0 - TROUBLESHOOTING.

NOTE: Settings 02 and 04 - 07 require a two-wire start/stop circuit to operate. The RUN contact must

remain closed for the power-up start and auto-restart functions to operate.

32

Page 37

33

P04 STOP METHOD

01 COAST TO STOP: When a STOP command is given, the drive shuts off the output to the

motor, allowing it to coast freely to a stop.

02 COAST WITH DC BRAKE: When a stop command is given, the drive will activate DC

braking (after a delay of up to 2 seconds, depending on frequency) to help decelerate the load.

Refer to Parameters: 21 - DC BRAKE TIME, and 22 - DC BRAKE VOLTAGE.

03 RAMP TO STOP: When a stop command is given, the drive will decelerate the motor to a stop

at the rate determined by Parameter 20 - DECELERATION TIME.

04 RAMP WITH DC BRAKE: When a stop command is given, the drive will decelerate the

motor down to 0.2 Hz (at the rate set by Parameter 20 - DECELERATION TIME) and then

activate DC braking according to the settings of Parameters 21 - DC BRAKE TIME and 22 DC BRAKE VOLTAGE. This is used to bring the load to a final stop, as the motor may still be

turning slightly after the drive stops.

P05 STANDARD SPEED SOURCE

This selects the speed reference source when the drive is in STANDARD speed mode. The following

speed reference can be selected.

01 KEYPAD: Use the ▲ and ▼ buttons to scroll to the desired speed.

02 PRESET SPEED #1: The drive will operate at the frequency set into Parameter 31.

03 0 - 10 VDC: The drive will respond to a 0 - 10 VDC signal wired to TB-2 and TB-5.

04 4 - 20 mA: The drive will respond to a 4-20 mA signal wired to TB-2 and TB-25.

P06 TB-14 OPEN COLLECTOR OUTPUT

This selects the status indication for the open-collector output at TB-14. The terms “open” and “close”

refer to the state of the internal transistor that activates the circuit. When the transistor is “closed”,

TB-14 is at the same potential as TB-2, allowing current to flow.

01 NONE: Disables the open-collector output.

02 RUN: Closes upon a START command. Opens if the drive is in a STOP state, the drive faults,

or input power is removed. DC braking is considered a STOP state.

03 FAULT: Closes if there is no fault condition. Opens if the drive faults, or input power is

removed.

04 INVERSE FAULT: Closes is the drive faults. Opens if there is no fault condition.

05 FAULT LOCKOUT: Closes when input power is applied. Opens if three restart attempts are

unsuccessful, or if input power is removed.

Page 38

34

06 AT SET SPEED: Closes if the drive is within ± 0.5 Hz of the speed setpoint.

07 ABOVE PRESET SPEED #3: Closes if the output frequency exceeds the PRESET SPEED #3

setting. Opens if the output frequency is equal to or less than PRESET SPEED #3 (Parameter

33).

08 CURRENT LIMIT: Closes if the output current exceeds the CURRENT LIMIT setting. Opens

if the output current is equal to or less than CURRENT LIMIT (see Parameter 25).

09 AUTOMATIC SPEED MODE: Closes if an AUTOMATIC (terminal strip) speed reference is

active. Opens if a STANDARD (Parameter 5) speed reference is active.

10 REVERSE: Closes when reverse rotation is active. Opens when forward rotation is active. (see

Parameter 17 - ROTATION DIRECTION).

P08 TB-30 ANALOG OUTPUT

Terminal TB-30 can be used as an analog output proportional to either output frequency or load.

FREQUENCY SCALING (Parameter 40) or LOAD SCALING (Parameter 41) can be used to scale

the output signal.

01 NONE

02 0-10 VDC FREQ

03 2-10 VDC FREQ

04 0-10 VDC LOAD

05 2-10 VDC LOAD

NOTE: The 2-10 VDC signal can be converted to a 4-20 mA signal by connecting a resistor in series

with the signal such that the total load resistance is 500 Ohms. However, this output cannot be used with

devices that derive power from a 4-20 mA signal.

P09 TB-31 ANALOG OUTPUT

Terminal TB-31 can be used as an analog output proportional to load, or as the control signal to activate

the optional external Dynamic Braking module. LOAD SCALING (Parameter 41) can be used to scale

the output signal when TB-31 is used as an analog output proportional to load.

01 NONE

02 0-10 VDC LOAD

03 2-10 VDC LOAD

04 DYNAMIC BRAKING: TB-31 becomes the “trigger” that activates the optional external

Dynamic Braking module. Refer to the instructions included with the Dynamic Braking option.

NOTE: The 2-10 VDC signal can be converted to a 4-20 mA signal by connecting a resistor in series

with the signal such that the total load resistance is 500 Ohms. However, this output cannot be used with

devices that derive power from a 4-20 mA signal.

Page 39

P10 TB-13A FUNCTION SELECT

This selects the function of terminal TB-13A. Closing TB-13A to TB-2 (or opening in the case of

settings 7 and 10) activates the selected function. The following functions can be selected:

01 NONE: Disables the TB-13A function.

02 0-10 VDC: Selects a 0-10 VDC signal (at TB-5) as the AUTO speed reference input.

03 4-20 mA: Selects a 4-20 mA signal (at TB-25) as the AUTO speed reference input.

04 PRESET SPEED #1: Selects PRESET SPEED #1 as the AUTO speed reference. The drive will

operate at the frequency programmed into Parameter 31.

05 RUN REVERSE: Close TB-13A to TB-2 to RUN in the reverse direction, and open to STOP.

This setting forces TB-12 to act as RUN FWD, requiring a maintained contact to RUN in the

forward direction. TB-1 must be closed to TB-2 for this function to operate.

06 START REVERSE: Momentarily close TB-13A to TB-2 to START the drive in the reverse

direction. Momentarily open TB-1 to TB-2 to STOP. This setting forces TB-12 to act as START

FWD, requiring a momentary contact to START in the forward direction.

07 EXTERNAL FAULT: Sets TB-13A as a normally closed external fault input. If TB-13A is open

with respect to TB-2, the drive will fault.

08 REMOTE KEYPAD: Selects the optional remote keypad as the control source. Refer to

Parameter 14 - CONTROL.

09 DB FAULT: Sets TB-13A as a dynamic braking fault input when using the optional dynamic

braking module. When this input is activated by the dynamic braking module, the drive will trip

into a “dF” fault and the motor will coast to a stop. Refer to the manual included with the

Dynamic Braking option.

10 AUXILIARY STOP: When TB-13A is opened with respect to TB-2, the drive will decelerate to

a STOP (even if STOP METHOD is set to COAST) at the rate set into Parameter 42 ACCEL/DECEL #2.

11 ACCEL/DECEL #2: Selects the acceleration and deceleration time programmed into Parameter

42 - ACCEL/DECEL #2.

NOTE: In order for the RUN REVERSE and START REVERSE function to operate, Parameter 17 ROTATION DIRECTION must be set to FORWARD AND REVERSE (02).

P11 TB-13B FUNCTION SELECT

This selects the function of terminal TB-13B. Closing TB-13B to TB-2 (or opening in the case of

setting 08) activates the selected function. The following functions can be selected:

35

Page 40

01 NONE: Disables the TB-13B function.

02 0-10 VDC: Selects a 0-10 VDC signal (at TB-5) as the AUTO speed reference input.

03 4-20 mA: Selects a 4-20 mA signal (at TB-25) as the AUTO speed reference input.

04 PRESET SPEED #2: Selects PRESET SPEED #2 as the AUTO speed reference. The drive will

operate at the frequency programmed into Parameter 32.

05 DECREASE FREQUENCY: Decreases the speed setpoint when using the MOP function. Refer

to Section 10.6.

06 JOG FORWARD: Jog in the forward direction. In this mode, the drive will JOG at the speed

programmed into Parameter 32 - PRESET SPEED #2.

07 JOG REVERSE - Jog in the reverse direction. In this mode, the drive will JOG at the speed

programmed into Parameter 32 - PRESET SPEED #2.

When operating in JOG mode, the STOP terminal (TB-1), the AUXILIARY STOP

function (see setting 08), and the STOP key on the optional remote keypad WILL NOT stop the drive.

To stop the drive, remove the JOG command.

JOG REVERSE will operate the drive in reverse even if ROTATION DIRECTION

(Parameter 17) is set to FORWARD ONLY.

08 AUXILIARY STOP: When TB-13B is opened with respect to TB-2, the drive will decelerate to

a STOP (even if STOP METHOD is set to COAST) at the rate set into Parameter 42 ACCEL/DECEL #2.

NOTE: If the drive is commanded to JOG when running, the drive will enter JOG mode and run at

PRESET SPEED #2. When the JOG command is removed, the drive will STOP.

P12 TB-13C FUNCTION SELECT

This selects the function of terminal TB-13C. Closing TB-13C to TB-2 (or opening in the case of

setting 06) activates the selected function. The following functions can be selected:

01 NONE: Disables the TB-13C function.

02 0-10 VDC: Selects a 0-10 VDC signal (at TB-5) as the AUTO speed reference input.

03 4-20 mA: Selects a 4-20 mA signal (at TB-25) as the AUTO speed reference input.

04 PRESET SPEED #3: Selects PRESET SPEED #3 as the AUTO speed reference. The drive will

operate at the frequency programmed into Parameter 33.

05 INCREASE FREQUENCY: Increases the speed setpoint when using the MOP function. Refer

to Section 10.6.

36

Page 41

06 EXTERNAL FAULT: Sets TB-13C as a normally closed external fault input. If TB-13C is open

with respect to TB-2, the drive will fault.

07 REMOTE KEYPAD: Selects the optional remote keypad as the control source. Refer to

Parameter 14 - CONTROL.

08 DB FAULT: Sets TB-13C as a dynamic braking fault input when using the optional dynamic

braking module. When this input is activated by the dynamic braking module, the drive will trip

into a “dF” fault and the motor will coast to a stop. Refer to the manual included with the

Dynamic Braking option.

09 ACCEL/DECEL #2: Selects the acceleration and deceleration time programmed into Parameter

42 - ACCEL/DECEL #2.

P13 TB-15 OPEN COLLECTOR OUTPUT

This selects the status indication for the open-collector output at TB-15, and has the same

selections as Parameter 6 - TB-14 OPEN COLLECTOR OUTPUT.

P14 CONTROL

This selects the source of START/STOP and direction commands.

01 TERMINAL STRIP ONLY: The drive will only respond to START/STOP and direction

commands from the terminal strip.

02 REMOTE KEYPAD ONLY: The drive will only respond to START/STOP and direction

commands from the optional remote keypad.

03 TERMINAL STRIP OR REMOTE KEYPAD: Terminal TB-13A or TB-13C can be used to

select terminal strip control or remote keypad control. See Parameters 10 and 12.

NOTE: This STOP button on the optional remote keypad is always active as long as the serial link

remains intact.

P15 SERIAL LINK

This parameter configures the drive for serial communications. The options are listed by baud rate,

number of data bits, parity, number of stop bits, and whether the watchdog timer is enabled or disabled.

The watchdog timer will stop the drive after 10 seconds of no serial activity to safeguard against a failed

serial link. During set-up or troubleshooting, it may be useful to disable the watchdog timer, but it is not

recommended to run normally without the watchdog timer.

Controlling the drive from the serial link without the watchdog timer could cause