Page 1

Installation, Operation, and Maintenance

Instructions

NEMA 182T – 286T, IEC 112 -180

Permanent Magnet Motors Operated On

Variable Frequency Drives (VFD)

www.leeson.com

INSTALLER: PLEASE LEAVE THIS MANUAL FOR THE OWNER’S USE

OWNER: READ AND SAVE THESE INSTRUCTIONS

SAFETY INSTRUCTIONS

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible injury

or death.

WARNING: Warning indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Caution indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTICE: Notice indicates a situation not related to personal injury which, if not

avoided, may result in motor or equipment damage.

Before installing, using, or servicing this product, carefully read and fully understand

the instructions including all warnings, cautions, & safety notice statements. To reduce

risk of personal injury, death and/or property damage, follow all instructions for proper

motor installation, operation and maintenance.

Although you should read and follow these instructions, they are not intended as a

complete listing of all details for installation, operation, and maintenance. If you have

any questions concerning any of the procedures, or if you have a safety concern not

covered by the instructions, STOP, and contact the motor manufacturer.

Page 2

Table of Contents

_________________________________________________________________________________________________________________________

1.0 SAFETY INFORMATION

1.1 Electrical Safety

1.2 Mechanical Safety

1.3 Environmental Safety

2.0 RECEIVING & INSPECTION

2.1 Initial Inspection

2.1.1 Packing List & Inspect

2.1.2 Turn Motor Shaft

2.1.3 Check Nameplate

2.2 Handling

2.2.1 Lifting Angle Limitations

2.3 Storage

2.3.1 Bearing Lubrication

2.3.2 Shaft Rotation

2.3.3 Damp or Humid Storage Locations

3.0 INSTALLATION AND OPERATION

3.1 Location

3.1.1 Selecting a Location

3.1.2 Ambient Temperature Limits

3.1.3 Construction Selection per Location

3.1.3.1 Totally Enclosed

3.1.3.2 Hazardous Locations Motors

3.2 Mounting Motor

3.2.1 Rigid Base (Footed)

3.2.2 Rigid Base Hole Selection -6 or 8 Hole Bases

3.2.3 Vertical Mounting

3.3 Application Assembly to Motor

3.3.1 General: Proper Alignment

3.3.2 Direct Coupling

3.3.3 Direct Connected

3.3.4 Belted

3.3.4.1 Sheave Diameter Requirements

3.3.4.2 Number of Belts

3.3.4.3 Sheave Location

3.3.4.4 Belt Tension

3.3.5 Permanent Magnet Motor VFD Operation

3.3.5.1 Overspeed Capability

3.3.5.2 Cable Lengths

3.3.5.3 VFD Grounding

3.3.5.4 Stray Voltage On Accessory Leads

3.3.6 Accessories

3.3.6.1 General

3.3.6.2 Brake Motors

3.3.6.3 Space Heaters

3.3.6.4 Thermal Protection

3.3.6.5 RTD Alarm & Trip Settings

3.3.7 Guards

3.4 Electrical Connections

3.4.1 Power Supply / Branch Circuit

3.4.1.1 Fuses, Breakers, Overload Relays

3.4.1.2 AC Power Supply Limits

3.4.2 Terminal Box

3.4.2.1 Conduit opening

3.4.3 Lead Connections

3.4.4 Ground Connections

3.4.4.1 Electrical Interference

3.4.5 Start Up

3.4.5.1 Start Up – No Load Procedure

3.4.5.2 Start Up – Load Connected Procedure

4.0 MAINTENANCE

4.1 General Inspection

4.1.1 Ventilation

4.1.2 Insulation

4.1.3 Electrical Connections

4.1.4 Seal Condition

4.1.5 Safety Labels

4.2 Lubrication and Bearings

4.2.1 Grease Type

4.2.2 Bearing Operating Temperature

4.2.3 Lubrication Interval

4.2.4 Lubrication Procedure

4.2.5 Lubrication Example

4.3 Trouble Shooting

4.3.1 General Trouble-Shooting Warnings

1.0 SAFETY INFORMATION

1.1

ELECTRICAL SAFETY

WARNING:

Electrical connections shall be made by a qualified electrician in

accordance with all applicable codes, ordinances and sound practices.

Failure to follow these instructions could result in serious personal

injury, death and/or property damage. Only qualified personnel who

are familiar with the applicable National Code (USA = NEC) and local

codes should install or repair electrical motors and their accessories.

WARNING:

motor and variable frequency drive in accordance with the drive

manufacturer’s documentation may result in serious injury, death,

and/or property damage.

WARNING:

Do not touch electrically live parts. Disconnect, lockout and tag input

power supply before installing or servicing motor (includes accessory

devices). Use a voltmeter to verify that power is off before contacting

conductors.

WARNING:

Shaft rotation produces voltage in PM motors even when motor is

disconnected from power source. Do not open terminal box or touch

unprotected terminals while the motor shaft is rotating. Failure to do so

may cause serious injury or death to personnel.

WARNING:

Shaft rotation produces voltage in PM motors even when motor is

disconnected from power source. Do not operate the motor or allow

equipment to back drive the motor above the maximum RPM listed on

the motor nameplate. Failure to do so may cause serious injury or

death to personnel or damage the motor or system equipment.

WARNING:

Failure to properly ground motors, per the National Electrical Code

(NEC) Article 430 and local codes may cause serious injury or death to

ELECTRICAL SHOCK HAZARD

ELECTRICAL HAZARD: Failure to connect

ELECTRICAL LIVE CIRCUIT HAZARD

ELECTRICAL SHOCK HAZARD

ELECTRICAL HAZARD

ELECTRICAL GROUNDING HAZARD

personnel. For general information on grounding refer to NEC Article

250. (Also see “Ground Connections section 3.4.4“).

WARNING:

Permanent magnet motor rotors, when removed from the stator,

expose surrounding personnel and equipment to powerful magnetic

fields which may cause serious health hazards to persons with

pacemakers, hearing aids, or other implanted electronic medical

devices and may impact other electronic devices such as mobile

phones, credit cards, etc.

MAGNETIC FIELD HAZARD

NOTICE:

Permanent magnet (PM) motors can only be operated by a PM motor

compatible VFD (Variable Frequency Drive). Connecting directly to

line power may result in motor damage.

1.2

Before starting the motor, remove all unused shaft keys and loose

rotating parts to prevent them from flying off. Failure to follow these

instructions could result in serious personal injury, death and/or

property damage.

Keep extremities, hair, jewelry and clothing away from moving parts.

Failure to follow these instructions could result in serious personal

injury, death and/or property damage. See section 3.3.7.

Due to powerful magnetic fields, disassembly and assembly of

permanent magnet motors should only be performed by the

manufacturer or specialized personnel authorized by the manufacturer.

Only qualified personnel who are familiar with the applicable national

codes, local codes and sound practices should install or repair electric

motors and their accessories. See the Magnetic Field Hazard in

section 1.1.

MOTOR NOT SUITED FOR OPERATION ON LINE POWER

MECHANICAL SAFETY

WARNING:

WARNING:

WARNING:

LOOSE PARTS HAZARD

ROTATING PARTS HAZARD

DO NOT DISASSEMBLE:

Page 3

1.3

ENVIRONMENTAL SAFETY

WARNING:

The NEC and the local authority having jurisdiction must be consulted

concerning the installation and suitability of motors for use in

Hazardous Locations, in accordance with NEC Article 500. The local

authority having jurisdiction must make the final determination of what

type of motor is required. The application and operation is beyond the

control of the motor manufacturer. Failure to do so may cause serious

injury or death to personnel.

HAZARDOUS LOCATIONS

2.0 RECEIVING AND INSPECTION

2.1

INITIAL INSPECTIONS

WARNING:

Shaft rotation produces voltage at motor leads and connected

equipment even when motor is disconnected from power source. Do

not open terminal box or touch unprotected terminals while the motor

shaft is rotating. Failure to do so may cause serious injury or death to

personnel.

2.1.1

packaging to make certain no damage has occurred in shipment.

If there is visible damage to the packaging, unpack and inspect

the motor immediately. Claims for any damage done in shipment

must be made by the purchaser against the transportation

company.

2.1.2

above) by hand to be certain that it rotates freely. Note: Motor will

not turn freely if leads are shorted together. User may feel small

pulsations when turning shaft due to the magnets in rotor. Shaft

seals and bearing seals may add drag.

keyways. Finger or ring contact may cause injury.

2.1.3

order requirements and compliance with power supply and control

equipment requirements.

2.2

HANDLING

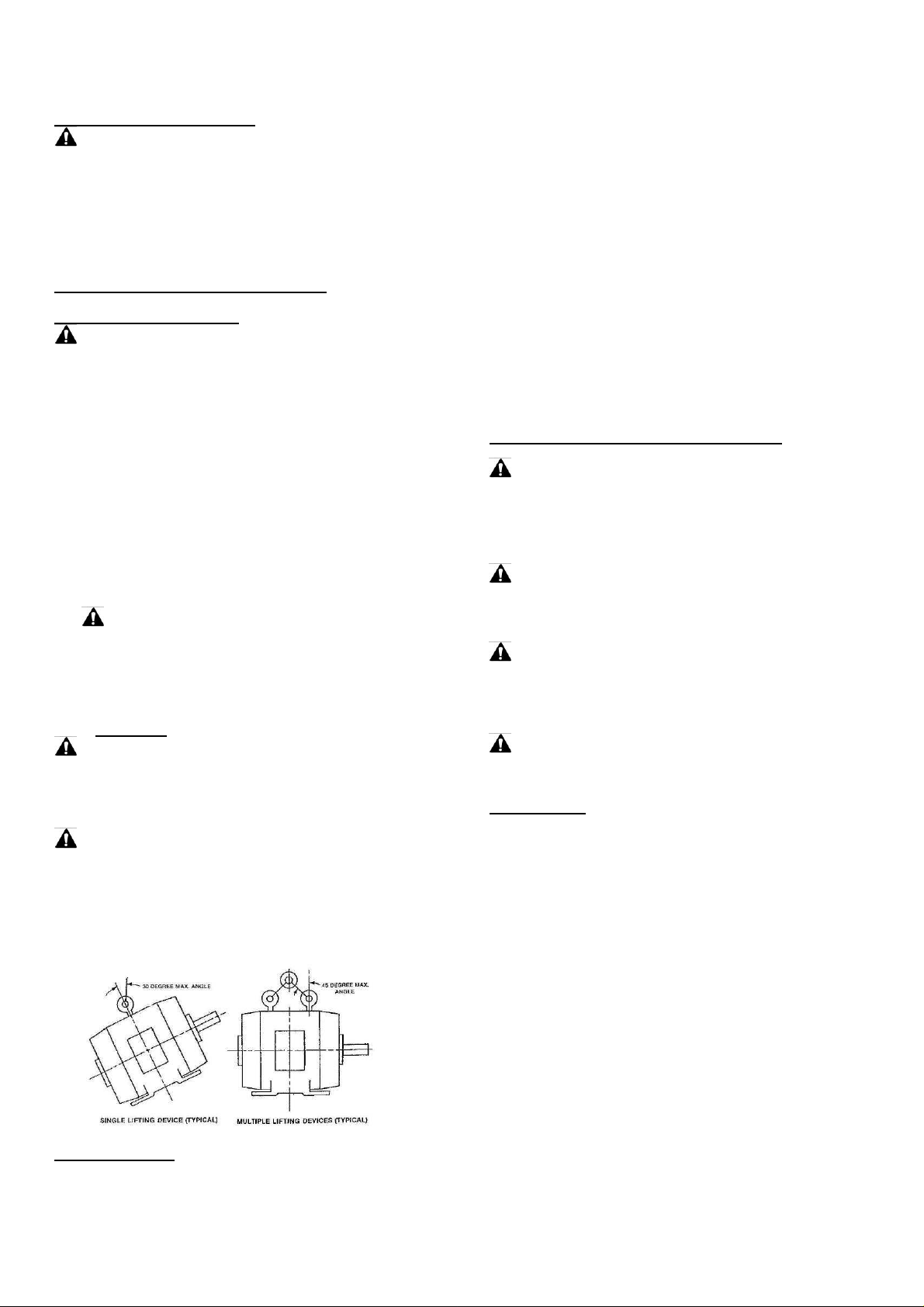

WARNING:

Eyebolts or lifting lugs, where provided, are intended for lifting only the

motor and accessories mounted by the motor manufacturer (unless

specifically stated otherwise on the motor). Utilizing the motor lifting

provision to lift other components such as pumps and gear boxes

could result in serious personal injury, death and/or property damage.

WARNING:

Before using the lifting provision, check the eyebolts and/or other lifting

means to assure they are not bent or damaged and are completely

threaded, seated & secured to the motor. Equipment to lift motor must

have adequate lifting capacity. While lifting the motor, DO NOT stand

under or in the vicinity of the motor. Failure to follow these instructions

could result in serious personal injury, death and/or property damage.

2.2.1 LIFTING ANGLE LIMITATIONS

2.3 STORAGE:

be stored indoors in a clean, dry location. Avoid locations with large

temperature swings that will result in condensation. Motors must be

ELECTRICAL SHOCK HAZARD

CHECK PACKING LIST AND INSPECT

TURN MOTOR SHAFT

(see Electrical Shock Hazard

CAUTION:

CHECK NAMEPLATE

Observe caution when working near threads or

for conformance with purchase

FALLING OBJECT HAZARD

FALLING OBJECT HAZARD

Motors, not put into service immediately, must

the

covered to eliminate airborne dust and dirt.

exhibits high vibration, place isolation pads under motor to minimize

damage to motor bearings.

2.3.1

BEARING LUBRICATION:

packed at the factory; relubrication upon receipt of motor or while

in storage is not necessary. If stored more than one year, add

grease per lubrication instructions (Table 4-4) before start-up.

2.3.2

SHAFT ROTATION:

Warning in section 2.1) It is recommended that the motor shaft be

rotated 5 to 10 rotations every three months to distribute the

grease in the bearings. This will reduce the chance for corrosion

to form on the bearing rolling elements and raceways. Note: User

may feel small pulsations when turning shaft due to the magnets

in rotor. Shaft seals and bearing seals may add drag.

2.3.3

DAMP OR HUMID STORAGE LOCATIONS:

unpainted flanges, shafts, and fittings with a rust inhibitor. Apply

appropriate power to the motor’s space heaters (if so equipped).

If the storage location

Bearings are grease

(see Electrical Shock Hazard

Treat

3.0 INSTALLATION AND OPERATION

WARNING:

Only qualified personnel who are familiar with and understand the

appropriate national codes, local codes and sound practices should

install or repair electrical motors and their accessories. Installation

should conform to the appropriate national code as well as local codes

and sound practices. Failure to follow these instructions could result in

serious personal injury, death and/or property damage.

WARNING:

Do not touch electrically live parts. Disconnect, Lockout and Tag input

power supply before installing or servicing motor (includes accessory

devices). Use a voltmeter to verify that power is off before contacting

conductors.

WARNING:

Shaft rotation produces voltage at PM motor leads and connected

equipment even when motor is disconnected from power source. Do

not open terminal box or touch unprotected terminals while the motor

shaft is rotating. Failure to do so may cause serious injury or death to

personnel.

WARNING:

Refer to Section 1.0 for additional warnings before proceeding with

installation and operation.

3.1

LOCATION

3.1.1

given to environment and ventilation. Motors should be installed

in an area that is protected from direct sunlight, corrosives,

harmful gases or liquids, dust, metallic particles, and vibration. A

motor with the proper enclosure for the expected operating

condition should be selected. Provide accessible clearance for

cleaning, repair, service, and inspections (See section 3.1.3 for

construction clearances). The location should be considered for

possible future motor removal or motor handling. The free flow of

air around the motor should not be obstructed.

3.1.2

temperatures of the air inlet to the motor should not exceed 40°C

(104°F) or be less than -30°C (-22°F) unless the mo tor nameplate

specifically states an ambient temperature outside of these limits.

The ambient inside an enclosure built around the motor shall not

exceed the nameplate ambient. For ambient temperatures outside

of these limits consult the motor manufacturer.

NOTICE:

Insulation at high temperatures ages at an accelerated rate. Each

10°C increase in temperature reduces the insulation life by one

half.

ELECTRICAL SHOCK HAZARD

ELECTRICAL LIVE CIRCUIT HAZARD

ELECTRICAL SHOCK HAZARD

ELECTRICAL SAFETY

SELECTING A LOCATION:

Consideration should be

AMBIENT TEMPERATURE LIMITS:

INSULATION DEGRADATION WARNING

The ambient

Page 4

3.1.3

Max

Location 1 and 3 holes for short frame:

CONSTRUCTION SELECTION PER LOCATION

3.1.3.1

TOTALLY ENCLOSED MOTORS are suitable for

indoor or outdoor standard service applications. Severe duty

construction is recommended for severe service applications.

TEAO or AOM (Totally Enclosed Air Over) motors must be

mounted in the air stream. When the motor nameplate states

a minimum airflow the motor must be mounted in an air

stream meeting this minimum value.

TEFC (Totally Enclosed Fan Cooled) motors must meet a

minimum distance equal to ½ the shaft height between the

fan guard grill openings and the nearest obstruction.

3.1.3.2

motors covered by this manual are intended for hazardous

duty locations. Motors intended for hazardous duty locations

are labeled with the division and class.

Hazardous Locations motors are intended for installations in

accordance with NEC Article 500. For all installations involving

Hazardous Locations motors, consult the applicable national

codes, local codes, and the authority having jurisdiction. Failure

to do so may cause serious injury or death to personnel.

Division 2 Installations – Class I only: Use only motors

that are CSA Certified and bear the CSA Certification Mark.

These motors include a phrase on the main motor

nameplate that indicates the motor is CSA Certified for Class

I, Division 2 / Zone 2 locations.

A motor should never be placed in an area with a hazardous

process or where flammable gases or combustible materials

may be present unless it is specifically designed and

nameplated for this type of service. Hazardous Locations

motors are intended for installations in accordance with NEC

Article 500. For all installations involving Hazardous Locations

motors, consult the NEC, local codes, and the authority having

jurisdiction. Failure to follow these instructions could result in

serious personal injury, death and/or property damage. (For

other limitations see section 1.3).

3.2

MOUNTING MOTOR

3.2.1

securely installed to a rigid foundation or a mounting surface to

minimize vibration and maintain alignment between the motor

shaft and the load’s shaft. The mounting surfaces of the four

mounting pads must be flat within 0.01 inches for 210 frame &

smaller; 0.015 inches for 250 frame & larger. [IEC 0.25 mm for

130 frame & smaller, 0.38 mm for 160 frame & larger]. This may

be accomplished by shims under the motor feet. For special

isolation mounting, contact manufacturer for assistance.

HAZARDOUS LOCATIONS MOTORS: Not all

WARNING:

WARNING:

RIGID BASE (FOOTED):

HAZARDOUS LOCATIONS

EXPLOSION HAZARD

The motor must be

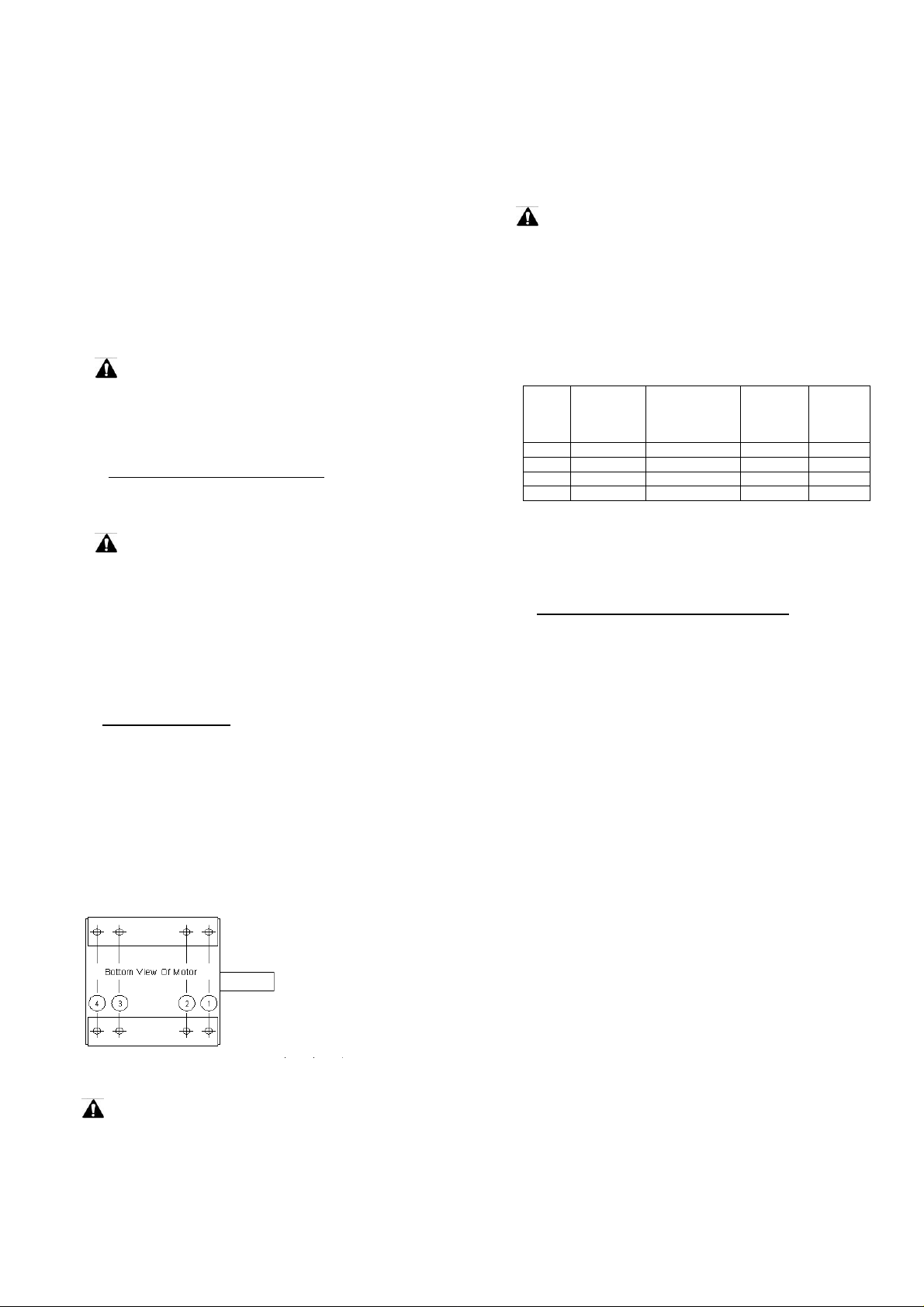

3.2.2

RIGID BASE HOLE SELECTION -6 OR 8 HOLES

(NEMA) 182, 213, 254, 284

(IEC) 112S, 132S, 160M, 180M

Location 2 holes are for F1,

F2 Conversion (if provide)

Location 1 and 4 holes for long frames:

(NEMA) 184, 215, 256, 286

(IEC) 112M, 132M, 160L, 180L

3.2.3

VERTICAL MOUNTING

WARNING:

The lifting provision on standard horizontal footed motors is not

designed for lifting the motor in a vertical shaft up or shaft down

position. (see Diagram 2.2.1). Doing so may cause the motor to

fall. Lifting method / provisions for mounting a rigid base (footed)

motor vertically is the responsibility of the installer.

FALLING OBJECT HAZARD

VERTICAL SHAFT DOWN: Most standard horizontal motors

through 449 Fr. (excluding brake motors) can be mounted in a

vertical shaft down orientation. For vertical brake motors see

section 3.3.6.2.

VERTICAL SHAFT UP:

WARNING:

MOUNT: Hazardous locations motors must NOT be mounted

vertically shaft up without approval by the motor manufacturer.

Without proper retaining provisions the rotor may move axially

and contact components, creating a spark hazard.

HAZARDOUS LOCATIONS VERTICAL

Belted or Radial Load when mounted vertically

following frame sizes / constructions with applied (axial) down

loads within the limit stated are acceptable when mounted vertical

shaft up.

Table 3-1 Belted or Radial Load Applications (All speeds)

Frame

Notes:

The max applied down load is any applied load external to the

motor, including such things as sheave weight, fan loads, axial

belt force, pump load, etc. If the application is direct drive with

no applied radial load or is beyond the limits listed, consult the

motor manufacturer.

3.3

NOTICE:

Do not connect or couple motor to load until correct rotational direction

is established.

3.3.1

and driven equipment minimizes vibration levels, maximizes

bearing life, and extends the overall life of the machinery. Consult

the drive or equipment manufacturer for more information.

NOTICE:

During assembly do NOT force components onto the shaft.

Striking or hammering the component may result in bearing

damage.

3.3.2

possible.

For applications that apply radial, axial or moment loading on the

motor shaft see section 3.3.3.

NOTICE:

Unless approved by the motor manufacturer, do NOT direct

couple a vertical shaft up motor or roller bearing motor. Direct

coupling a vertical shaft up motor or a motor with a roller bearing

may result in bearing damage.

3.3.3

connected equipment (gears, fans etc.) must be approved by the

motor manufacturer unless within the maximum overhung load

limits (Table 3-2). Combined loading (axial, radial and/or

moments) must be approved by motor manufacturer. For belted

loads see section 3.3.4.

Enclosure Construction

Size

180 TEFC All Yes 35 lbs

210 TEFC All Yes 40 lbs

250 TEFC All Yes 40 lbs

280 TEFC Cast Iron Yes 30 lbs

APPLICATION ASSEMBLY TO MOTOR

EQUIPMENT DAMAGE

GENERAL: PROPER ALIGNMENT

BEARING FAILURE

DIRECT COUPLING:

BEARING FAILURE

Use flexible couplings if

DIRECT CONNECTED:

Shaft Up

OK

Radial loading for direct

: The

Applied

Down

Load2

of the motor

Page 5

Table 3-2 Maximum Radial Load (pounds force) @ Middle

of the Shaft Extension Length

NEMA

Frame

182T 187 230 261 287

184T 193 237 273 301

213T 319 317 470 510

215T 327 320 480 533

254T 500 631 729 793

256T 510 631 736 820

284T - 866 990 1100

286T - 871 1005 1107

Values based on 26,280 hrs B-10 Life

For “End of Shaft” Load multiply value by 0.88

3600 1800 1200 900

Motor Rated RPM

3.3.4

BELTED

The goal of any belted system is to efficiently transmit the

required torque while minimizing the loads on the bearings and

shafts of the motor and driven equipment. This can be

accomplished by following four basic guidelines:

1. Use the largest practical sheave diameter.

2. Use the fewest number of belts possible.

3. Keep sheaves as close as possible to support bearings.

4. Tension the belts to the lowest tension that will still transmit

the required torque without slipping. V-belts may squeal

initially in high starting torque applications.

3.3.4.1

In general, smaller sheaves produce greater shaft stress and

shaft deflection due to increased belt tension. See Table 3-3

(next page) for recommended minimum sheave diameters.

Using larger sheaves increases the contact with belts which

reduces the number of belts required. It also increases the belt

speed, resulting in higher system efficiencies. When selecting

sheaves, do not exceed the belt manufacturer's recommended

maximum belt speed, typically 6,500 feet per minute for cast

iron sheaves. Determine belt speed by the following formula:

Sheave Diameter Guidelines

Figure 1

Figure 2

3.3.4.4

Excessive belt tension may lead to bearing failure and/or shaft

failure. Failure to properly tension belts may result in serious

personal injury, death, and/or property damage. Belt tension

must be adjusted using a belt tension gage. Adjusting belt

tension by "feel" (i.e., pushing on belt with fingers or hand) may

result in excessive belt tension.

In general, belt tensions should be kept as loose as possible

while still transmitting the required torque without slipping. Belt

tensions must be measured with a belt tension gage. These

inexpensive gages may be obtained through belt

manufacturers or distributors. V-belts may squeal initially in

high starting torque applications.

Proper belt tension is determined by measuring the force

required to deflect the center of the belt a given distance. The

proper deflection (in inches) is determined by dividing the belt

span in inches by 64. Calculate the proper deflection and then

see Table 3-3 (next page) for the required “Average Deflected

Force” to achieve that deflection.

Belt Tension

WARNING:

EQUIPMENT FAILURE

BELT SPEED (Ft/min) =

12

inches Dia Sheavex 3.14 x RPM Shaft )(

3.3.4.2

In general, use the fewest number of belts that will transmit the

required torque without slipping. See Table 3-3 (next page) for

recommended maximum number of belts. Each belt adds to

the tension in the system, which increases load on the shafts

and bearings. Belts are most efficient when operated at or

near their rated horsepower.

If the sheaves have more grooves than the number of belts

required, use the grooves closest to the motor.

Number of Belts

3.3.4.3 Sheave Location

Install sheaves as close to the housing as possible to increase

the bearing life of the motor and driven equipment.

After tensioning the belt, rotate the sheaves for several

rotations or operate the system for a few minutes to seat belts

into the grooves, then re-tension the belts. New belts will

stretch during use, and should be retensioned after the first

eight hours of use.

3.3.5

PERMANENT MAGNET MOTOR VFD (Variable

Frequency Drives) OPERATION

CAUTION:

Placing power factor correction capacitors between the motor and

VFD may cause personal injury and significant damage to the

VFD. Power factor correction capacitors should never be

installed between the VFD and the motor and should not be

installed at VFD input unless approved by VFD manufacturer.

NOTICE:

POWER

PM motors can only be operated by a PM motor compatible VFD.

Connecting directly to line power may result in motor damage.

Consult VFD installation and operation manual for additional

instructions and safety information.

Power Factor Correction Capacitors

MOTOR NOT SUITED FOR OPERATION ON LINE

Page 6

Table 3-3 Recommended Minimum Sheave Diameters, Belt Type, Number of Belts and Deflected Force

1200 rpm

1800 rpm

3600 rpm

1 2.4 3VX 1 4.0 2.2 3VX 1 3.1 2.2 3VX 1

1.5 2.4 3VX 2 3.1 2.4 3VX 2.2 3VX 1 2.5

2 2.4 3VX 3 2.8 2.4 3VX 2 2.9

2.4 3VX

3 3.0 3VX 2 3.3 2.4 3VX 3 2.9 2.4 3VX 2 2.3

5 3.0 3VX 3 4.0 3.0 3VX 3 3.7 2.4 3VX 3 2.5

7.5 3.8 3VX 4 4.7 3.0 3VX 4 4.1 3.0 3VX 2 4.2

10 4.4 3VX 4 5.4 3.8 3VX 4 4.3 3.0 3VX 3 3.8

15 4.4 3VX 5 5.4 4.4 3VX 4 5.4 3.8 3VX 3 4.4

20 5.2 3VX 6 6.0

4.4 3VX 6 4.8 4.4 3VX 3 5.0

25 6.0 3VX 7 5.6 4.4 3VX 7 5.2 4.4 3VX 4 4.7

30 6.8 3VX 7 5.9 5.2 3VX 7 5.3

Frame Size

230V

460 V

575 V

Min

Sheave

Motor Hp

Notes:

1. The ratings listed above assume normal frame size assignments per NEMA MG-1 (2009) Table 13.2.

Horsepower is the nameplate motor horsepower, and RPM is the motor (driver) speed.

2. Minimum sheave diameters are from NEMA standards where applicable.

3. For variable speed applications or values outside these recommendations, consult motor manufacturer.

4. Selections are based on a 1.4 belt service factor, 5 to 1 speed reduction and various Power Transmission Manufacturers’ catalogs.

5. These selections are for Narrow V-belt sections only. Consult motor manufacturer for details on conventional V-belt sections (A, B, C, D and E), or

other belt types.

6. “Average Deflected Force” is per section 3.3.4.4 of this document and is the force required to deflect the center of a belt 1/64 of the belt span

distance. Tolerance on this force is ±1 lbf for forces ≤10 lbs, and ±2 lbs for forces >10 lbs as measured utilizing a belt tension gage.

7. When more than one belt is required, the belts must be a matched set (matched for length).

8. If possible, the lower side of the belt should be the driving side to increase the length of wrap on the sheave.

9. Do not exceed nameplate maximum RPM.

_________________________________________________________________________________________________________________________

Dia (in) Belt

Type

NOTICE: VFD / Motor Setup

It is the responsibility of the startup personnel during set up of the

VFD / motor system to properly tune the drive to the motor for the

specific application per the VFD user manual. The correct voltage

boost, volts per hertz, and overload current level settings are

application dependent and unique to each motor design. Current

setting shall not exceed nameplate service factor amps. Failure to

connect over temperature devices (when provided) will void the

warranty.

3.3.5.1 Overspeed Capability

Do not exceed nameplate maximum RPM without first contacting

manufacturer.

WARNING:

Shaft rotation produces voltage in PM motors even when motor is

disconnected from power source. Do not operate the motor or

allow equipment to back drive the motor above the maximum

RPM listed on the motor nameplate. Failure to do so may cause

serious injury or death to personnel or damage the motor or

system equipment.

ELECTRICAL HAZARD

3.3.5.2 Cable Lengths:

insulation system designed for use with variable frequency

drives. For optimum insulation life, limit VFD to motor cable

lengths as documented in Table 3-5. For additional information,

or for installations requiring longer cable runs, please contact the

motor manufacturer

Table 3-5 Max Cable Lengths

These values are based on 3 kHz carrier frequency. Add

suitable VFD output-side filters when exceeding the listed

values.

NEMA 180-280

IEC 112-180

.

3.3.5.3 VFD Grounding:

3.3.5.4 Stray Voltage on Accessory Leads

VFDs will couple stray voltage to accessories such as

RTDs, thermistors, thermostats and space heaters. The

leads of these elements must be properly insulated and

control input circuits must be designed to withstand this

voltage.

Max

#

of

Belts

These motors are equipped with an

2000 ft. 2000 ft. 650 ft.

600 m. 600 m. 200 m.

See Grounding section 3.4.4

Avg.

Deflected

Force

(lbs)

Sheave

Dia (in) Belt

Min

Type

Max

#

of

Belts

3.3.6

3.3.6.1 General:

manufacturer’s instructions, supplied with motor. Contact the

manufacturer for additional information.

3.3.6.2 Brake Motors

Failure of the brake may put people in the vicinity of the motor at

risk for serious personal injury or death, or cause damage to

nearby equipment. If people or equipment will be in the vicinity of

the motor, a backup system should be supplied.

Motors with brakes that are designed for vertical applications are

equipped with springs to support the brake pressure plate.

Mounting a horizontal brake motor vertically shaft up or down

may require a pressure plate spring modification. Failure to

modify the brake for the vertical application may result in

premature brake failure, creating a risk of serious personal injury

or death and/or equipment damage. If in question, consult brake

literature or brake manufacturer.

the output of a VFD. The brake solenoid must be wired to 50/60

Hz line power for proper operation. Failure to do so may result in

brake damage, potentially leading to serious injury, death, or

equipment damage.

3.3.6.3

Motors provided with space heaters have two leads that are

brought into the conduit box or into an auxiliary box. These leads

are marked”H1”, “H2” (”H3”, “H4” if a second space heater is

supplied). See the space heater nameplate on motor for heater

rating.

The space heater temperature rating when used in Class I,

Division 2 motors shall NOT exceed 80% of the auto ignition

temperature of the hazardous gas or vapor. See the space

heater nameplate on motor for heater Temperature Code and

heater rating. Failure to follow this instruction could result in

serious personal injury, death and/or property damage.

Avg.

Deflected

Force

(lbs)

Min

Sheave

Dia (in) Belt

Type

ACCESSORIES / PROVISIONS

Carefully read and understand the accessory

WARNING

WARNING

WARNING

: Backup Brake System

: Vertical

: DO NOT CONNECT BRAKE SOLENOID to

Motor

Premature Brake Failure

Space Heaters

WARNING:

DIVISION 2 EXPLOSION HAZARD

Max

#

of

Belts

Avg.

Deflected

Force

(lbs)

Page 7

3.3.6.4

Temperature

General Information: When thermal protection is provided,

“WITH OVERHEAT PROTECTIVE DEVICE” will be stamped on

the nameplate. The motor is provided with an overheat

protective device that does not directly open the motor circuit.

Motors nameplated with this phrase have either thermostats,

thermisters or RTDs. The leads to these devices are routed into

the motor conduit box or into an auxiliary box. The lead markings

are defined on the nameplate.

THERMOSTAT: The circuit controlled by the thermostats must

be limited to a maximum of 600 volts and 360 volt-amps. See

connection decal provided inside the terminal box cover. Failure

to connect these over temperature devices (when provided) will

void the motor warranty.

THERMISTERS OR RESISTANCE TEMPERATURE

DETECTORS (RTDs)

These sensors are to be connected to a solid state resistance

monitoring device designed for use with thermistors or RTDs

Failure to connect these over temperature devices (when

provided) will void the motor warranty.

3.3.6.5

Tables 3-6 & 3-7 are suggested initial RTD alarm and trip

settings. For motors found to operate significantly below these

values the settings may be reduced accordingly.

Thermal Protection

RTD Alarm & Trip Settings

Table 3-6 Winding RTD – Temperature Limit (8888C)

40 8888C Max Ambient

(degrees C)

Alarm Trip

130 140

Table 3-7 Bearing RTD – Temperature Limit (8888C)

40 8888C Max Ambient

Bearing Type

Standard bearings 110 115

Motors specified

with heat stabilized

bearings to 150 C

3.3.7

GUARDS

WARNING:

When devices are assembled to the motor shaft, be sure to install

protective devices such as belt guards, chain guards, and shaft

covers. These devices must protect against accidental contact with

extremities, hair, and clothing. Consider the application and provide

guarding to protect personnel. Remove all unused shaft keys and

loose rotating parts to prevent them from flying off and causing

bodily injury. Failure to follow this warning could result in serious

personal injury, death and/or property damage.

3.4

Before proceeding read Section 1.1 on Electrical Safety. Failure to

follow the instructions in Section 1.1 could result in serious personal

injury, death and/or property damage

be present at the motor terminals even after the motor has stopped

rotating. To assure there is no voltage at motor, remove input power

from VFD and follow VFD manufacture documentation for voltage

decay time before servicing motor. Failure to follow this instruction

could result in serious personal injury or death.

ELECTRICAL CONNECTIONS

WARNING:

WARNING:

ROTATING PARTS HAZARD

ELECTRICAL HAZARDS

ELECTRICAL SHOCK HAZARD: Voltage may

Alarm Trip

130 135

NOTICE: MOTOR NOT SUITED FOR OPERATION ON LINE

POWER

Permanent magnet motors can only be properly operated by a

variable frequency drive (VFD). Attempting to run in bypass mode

(across the line) may cause motor damage.

3.4.1

WARNING:

HAZARD

Check power supply to make certain that voltage, frequency and

current carrying capacity are in accordance with the motor

nameplate and VFD. Connecting the VFD to the wrong power

source could result in serious personal injury, death and/or property

damage.

WARNING:

Motor and control wiring, fusing, overload protection, disconnects,

accessories and grounding must always conform to the applicable

electrical codes as well as local codes and sound practices.

POWER SUPPLY / BRANCH CIRCUIT

POWER SUPPLY INCOMPATIBILITY

BRANCH CIRCUIT SUPPLY HAZARD

3.4.1.1

3.4.2

Shaft rotation produces voltage in PM motors even when motor is

disconnected from power source. Do not open terminal box or

touch unprotected terminals while the motor shaft is rotating.

Failure to do so may cause serious injury or death to personnel.

3.4.3

Electrical connections are to be made per nameplate connection

diagram or separate connection plate. In making connections follow

the applicable electrical code as well as local codes and practices.

Failure to correctly connect the motor leads and grounding

conductor can result in serious personal injury or death. Motor lead

connections can short and cause damage or injury if not well

secured and insulated.

3.4.4

For general information on grounding (USA) refer to NEC Article

250. Improper grounding of an inverter fed motor may result in

frame voltages in excess of 500 Volts. In making the ground

connection, the installer must make certain that a good electrical

connection is obtained between motor and grounding lead. Failure

to properly ground motors, per the applicable national code (such

as NEC Article 430) and local codes may cause serious injury or

death to personnel.

Fuses, Breakers, Overload Relays

Consult variable frequency drive (VFD) operating manual and

applicable electric codes for branch circuit protection sizing.

WARNING:

DO NOT bypass or disable these or other protective devices.

Protection removal could result in serious personal injury, death

and/or property damage.

3.4.1.2

PM motors are designed to operate with variable frequency

drives with rated input voltage 600 VAC or less. Drive RMS

output voltage should not exceed motor nameplate voltage for

which the motor is connected.

NOTICE:

Operation outside of these limits will degrade motor performance

and increase operating temperature.

TERMINAL BOX

WARNING:

3.4.2.1

For ease of connections, motors are typically provided with large

terminal boxes. Most motors have conduit access in 90 degree

increments, the terminal box conduit opening is typically provided

via knockouts, holes with covers, or the terminal box is rotateable. Fabricated conduit boxes may have a removable plate for

the installer to provide correctly sized hole(s).

WARNING:

PROTECTIVE DEVICE DISABLED HAZARD

AC Power Supply Limits

REDUCED MOTOR PERFORMANCE

ELECTRICAL SHOCK HAZARD

Conduit Opening

LEAD CONNECTIONS

ELECTRICAL CONNECTION HAZARD

GROUND CONNECTION(S)

WARNING:

ELECTRICAL GROUNDING HAZARD

Page 8

Equalize ground potential between the motor and driven equipment

if the driven equipment and motor are not mounted to the same

metallic base plate.

3.4.4.1 Electrical Interference

Due to high switching frequencies of variable frequency drives,

use a low resistance ground cable that is low impedance at high

frequencies. A shielded motor power cable with a complete

circumferential braided or copper film ground jacket around the

power leads is recommended to minimize electrical interference.

Secure this ground to both the motor’s primary ground and the

variable frequency drive ground.

Primary “Internal” Ground: A grounding conductor must be

connected to the grounding terminal provided in the terminal

housing. This grounding terminal is either a ground screw,

ground lug, or a tapped hole to be used with a separately

provided ground screw. The internal grounding feature is

accessible inside the terminal housing and must be used as the

primary grounding connection.

Secondary “External” Ground: Some motors are provided with

a supplemental grounding terminal located on the external

surface of the motor frame or feet. This external terminal is for

supplemental grounding connections where local codes permit or

require such connection.

3.4.5

WARNING:

Before proceeding read Section 1.2 on Mechanical Safety. Failure

to follow the instructions could result in serious personal injury,

death and/or property damage.

WARNING:

Shaft rotation produces voltage in PM motors even when motor is

disconnected from power source. Do not open terminal box or

touch unprotected terminals while the motor shaft is rotating.

Failure to do so may cause serious injury or death to personnel.

WARNING:

Be certain that all connections are secure and the conduit box cover

is fastened in place before electrical power is applied. Failure to

follow these instructions could result in serious personal injury,

death, and/or property damage.

WARNING:

HAZARDOUS LOCATIONS

Motors with the temperature code stated on the nameplate are

designed to operate within this limit. Improper application or

operation can cause the maximum surface temperature to be

exceeded. A motor operated in a Hazardous Location that exceeds

this surface temperature limit increases the potential of igniting

hazardous materials. Therefore, motor selection, installation,

operation, and maintenance must be carefully considered to ensure

against the following conditions: (1) Motor load exceeds service

factor value, (2) Ambient temperature above nameplate value, (3)

Voltages outside of limits in Section 3.4.1.2, (4) Loss of proper

ventilation, (5) VFD operation exceeding motor nameplate rating,

(6) Altitude above 3300 feet / 1000 meters, (7) Severe duty cycles,

(8) Repeated starts, (9) Motor stall, (10) Motor reversing, and (10)

Single phase operation. Failure to follow these instructions could

result in serious personal injury, death and/or property damage.

CAUTION:

Normal motor surface temperatures may exceed 90 ° C (194° F).

Touching the motor frame may cause discomfort or injury. Surface

temperatures should only be measured with suitable instruments

and not estimated by hand touch.

START UP

LOOSE & ROTATING PARTS HAZARD

ELECTRICAL LIVE CIRCUIT HAZARD

ELECTRICAL SHOCK HAZARD

EXCESSIVE SURFACE TEMPERATURE

USER CONTACT OF HOT SURFACE

3.4.5.1

Incorrect motor rotation direction can cause serious or fatal injury

or equipment damage. Verify rotation direction before coupling to

driven equipment.

1. Check Instructions:

understand these instructions including all warnings, cautions,

and safety notice statements.

Start Up - No Load Procedure

WARNING:

ROTATION HAZARD

Before startup carefully read and fully

2. Motor out of storage after more than three months:

C

heck winding insulation integrity with a Megger. If winding

resistance to ground is less than 1.5 Meg-ohms consult the local

authorized service shop before energizing the motor.

3. Check Installation:

bolts and nuts. Manually rotate the motor shaft to ensure motor

shaft rotates freely. Note: Motor will not turn freely if power

leads are shorted together. User may feel small pulsations

when turning shaft due to the magnets in rotor. Shaft & bearing

seals will add drag.

Electrical - Inspect all electrical connections for proper

terminations, clearance, mechanical tightness and electrical

continuity. Be sure to verify connections are made per the

nameplate connection diagram or separate connection plate.

Replace all panels and covers that were removed during

installation before energizing the motor.

4. Energize Motor:

If practical, check motor rotation before coupling to the load. If

motor has a rotational arrow, only operate the motor in the

rotation identified. Energize VFD and momentarily jog motor to

verify direction of rotation. If opposite rotation is required, (a)

select reverse rotation from VFD or (b) de-energize VFD,

remove power, then reconnect motor leads for reverse rotation.

Repeat jog cycle and ensure proper rotation.

5. Record No Load Amps, Watts & Voltage:

Recommend - To establish a baseline value check and record

the no load amps, watts, and voltage.

3.4.5.2

Start Up – Load Connected Procedure

1. Check Instructions:

understand these instructions including all warnings, cautions, &

safety notice statements.

2. Coupling Installation:

is properly aligned and not binding. Check that all guards and

protective devices are properly installed.

3. Energize Motor:

machine, apply power and verify that the load is not transmitting

excessive vibration back to the motor though the shaft or the

foundation. Verify that motor amps are within nameplate rating.

The equipment can now be fully loaded and operated within

specified limits as stated on the nameplate.

Mechanical - Check tightness of all

Check Rotation

Before startup carefully read and fully

Check that the connected equipment

When all personnel are clear of the

4.0 MAINTENANCE

WARNING:

present at the motor terminals even after the motor has stopped rotating.

Disconnect power to the VFD and verify VFD DC output voltage is zero

before performing service or maintenance. Failure to follow this

instruction could result in serious personal injury or death.

WARNING:

Electrical connections are to be made by a qualified electrician in

accordance with all applicable codes, ordinances and sound practices.

Failure to follow these instructions could result in serious personal injury,

death and/or property damage. Only qualified personnel who are familiar

with the applicable national codes, local codes and sound practices

should install or repair electric motors and their accessories.

WARNING:

Do not touch electrically live parts. Disconnect, lockout and tag input

power supply before installing or servicing motor (includes accessory

devices).

WARNING:

Shaft rotation produces voltage in PM motors even when motor is

disconnected from power source. Do not open terminal box or touch

unprotected terminals while the motor shaft is rotating. Failure to do so

may cause serious injury or death to personnel.

WARNING:

Due to powerful magnetic fields, disassembly and assembly of

permanent magnet motors should only be performed by the

manufacturer or specialized personnel authorized by the manufacturer.

WARNING:

Permanent magnet motor rotors contain powerful magnetic fields.

Exposure to magnetic field may cause serious health hazards to persons

ELECTRICAL SHOCK HAZARD: Voltage may be

ELECTRICAL SHOCK HAZARD

ELECTRICAL LIVE CIRCUIT HAZARD

ELECTRICAL LIVE CIRCUIT HAZARD

DISASSEMBLY APPROVAL REQUIRED

MAGNETIC FIELD HAZARD

Page 9

with pacemakers, hearing aids, or other implanted electronic medical

Operating Speed

– RPM (See Table 3.4 for Maximum Operating Speed)

<7200

<5400

<4500

<3600

<1800

<1200

Severity of

Maximum Ambient

devices and may impact other electronic devices such as mobile phones,

credit cards, etc.

WARNING:

Refer to Section 1.0 for additional warnings before proceeding with

maintenance.

4.1

GENERAL INSPECTION

Inspect the motor approximately every 500 hours of operation or every

three months, whichever occurs first. Keep the motor clean and the

ventilation and fin openings clear. The following steps should be

performed at each inspection:

4.1.1

exterior of the motor are free of dirt, oil, grease, water, etc, which

can accumulate and block motor ventilation. If the motor is not

properly ventilated, overheating can occur and cause early motor

failure.

ELECTRICAL SAFETY

VENTILATION

: Check that the ventilation openings and/or

4.1.2

INSULATION

motor from the VFD and use a “Megger” to take periodic readings.

Record the Megger readings. If winding resistance to ground is less

than 1.5 Meg-ohms consult the local authorized service shop before

re-energizing the motor.

4.1.3

ELECTRICAL CONNECTIONS:

motor stopped, check all electrical connectors to be sure that they

are tight.

4.1.4

of shaft seals and replace if necessary.

4.1.5

Inspect and clean safety labels to maintain visibility. Replace labels

if they are no longer readable.

SEAL CONDITION:

SAFETY LABELS:

: To monitor motor insulation, disconnect

With all power off and

When supplied, check the condition

Do not remove or cover safety labels.

_________________________________________________________________________________________________________________________

4.2

LUBRICATION & BEARINGS

The lubricating ability of grease (over time) depends primarily on the

type of grease, the size of the bearing, the speed at which the bearing

operates and the severity of the operating conditions. Longer bearing

life can be obtained if the listed recommendations are followed:

NOTE: If lubrication instructions are provided on the motor nameplate,

the nameplate instructions will supersede these instructions. Motors

marked “Permanently Lubricated” do not require additional service”.

NOTICE:

Lubricant should be added at a steady state of moderate pressure. If

added under heavy pressure, bearing shield(s) may collapse. Over

greasing bearings greatly increases bearing friction and can cause

premature bearing and/or motor failure.

BEARING / MOTOR DAMAGE

4.2.1

GREASE TYPE

Nameplate Ambient Temperature between -30°C (-22°F) to 65°C

(150°F) inclusive: Recommended grease for standard service

conditions is Polyrex EM (Exxon Mobil). Equivalent and compatible

greases include: Texaco Polystar RB, Rykon Premium #2, Pennzoil

Pen 2 Lube, Chevron SRI & Mobil SHC 100.

Nameplate Ambient Temperature below -30°C (-22°F ): Special

low temperature grease is recommended, such as Aeroshell 7 or

Beacon 325 for ball bearings and Mobil SHC 100 for roller bearings.

Nameplate Ambient Temperature above 65°C (150°F ): Dow

Corning DC44 or equivalent, a special high temperature grease is

required. Note that Dow Corning DC44 grease does not mix with

other grease types.

(unless nameplate states otherwise)

4.2.2

CAUTION:

The external surface temperature of the end shield (bracket)

bearing hub may reach 100° C (212° F) during normal operation.

Touching this surface may cause discomfort or injury. Surface

temperatures should only be measured with suitable instruments

and not estimated by hand touch.

For RTD settings see Table 3-7.

BEARING OPERATING TEMPERATURE

HOT SURFACE

4.2.3

LUBRICATION INTERVALS (For motors with regreasing provisions)

Eq. 4.2 Lubrication Interval = [(Table 4-1) hrs] x [Interval Multiplier (Table 4-2)] x [Construction Multiplier (Table 4-3)]

Recommended lubrication intervals are shown in Table 4-1. These values are based on average use.

Table 4-1 Lubrication Intervals

NEMA / [IEC] Frame Size

180 [110] 2500 Hrs. 4000 Hrs 5000 Hrs 6000 Hrs. 17000 Hrs. 20000 Hrs.

210-250 [130-160] 2500 Hrs 4000 Hrs 5000 Hrs. 12000 Hrs. 16000 Hrs.

280 [180] 2000 Hrs 3000 Hrs 4000 Hrs. 10000 Hrs. 14000 Hrs.

Seasonal Service: If motor remains idle for more than six months, Lubricate at the beginning of the season, then follow lubrication interval.

Do not exceed maximum safe operating speed without manufacturer’s approval

Use highest level Multiplier

Service

Standard Less than 40° C (104° F) Clean, Slight Co rrosion, indoors, less than 16 hrs per day

Severe

Extreme

Temperature

Above 40° C (104° F) to 50°

Greater than 50° C or

Class H Insulation

: Maximum Ambient Temperature and Contamination are independent factors

C

_______________________________________________________________________________

Table 4-2 Service Conditions

Atmospheric Contamination Multiplier

Moderate dirt or Corrosion or outdoors or more than 16 hrs

per day

Severe dirt or Abrasive dust or Corrosion

1.0

0.5

0.2

Page 10

Construction

Multiplier

Frame Size

Volume

NEMA

IEC Cu. In.

Fluid oz

ml

Issue

Likely Cause

Corrective Action

Motor fails to start upon initial installation

E

Table 4-3 Construction Multiplier

Table 4-4 Relubrication Amounts

Angular Contact or Roller Bearing 0.5

Vertical Motor 0.5

All others 1.0

180 110 0.50 0.28 8.0

210 130 0.75 0.42 12.5

250 160 1.00 0.55 16.0

280 180 1.50 0.83 25.0

For regreasing while operating multiply volume by 125%.

_______________________________________________________________________________________________________________________

4.2.4

LUBRICATION PROCEDURE

(For Motors with Regreasing Provisions)

NOTICE:

Added grease must be compatible with the original equipment’s

grease. If a grease other than those stated in 4.2.1 is to be

utilized, contact the motor manufacturer. Nameplate information

supersedes section 4.2.1 (GREASE TYPE). New grease must be

free of dirt. Failure to follow these instructions and procedure

below may result in bearing and/or motor damage.

NOTICE:

Old grease may completely block the drain opening and must be

mechanically removed prior to regreasing. Forcing a blocked

drain open by increased greasing pressure may collapse bearing

shields and / or force excess grease through the bearings and

into the motor.

For an extremely dirty environment, contact the motor

manufacturer for additional information.

LUBRICATION PROCEDURE:

1.

2.

3.

4.

BEARING DAMAGE WARNING

GREASE DRAIN PLUGGED

Clean the grease inlet plug or zerk fittings prior to regreasing.

(If present) Remove grease drain plug and clear outlet hole

blockage.

Add grease per Table 4-4

Re-install grease inlet and drain plugs (if removed).

4.2.5

Assume - NEMA 286T (IEC 180), 1750 RPM Vertical motor

driving an exhaust fan in an ambient temperature of 43° C and

the atmosphere is moderately corrosive.

1. Table 4-1 list 10,000 hours for standard conditions.

2. Table 4-2 classifies severity of service as “Severe” with a

multiplier of 0.5.

3.

Table 4-3 lists a multiplier value of 0.5 for “Vertical”

4.

(Eq. 4.2) Interval = 10,000 hrs x 0.5 x 0.5 = 2500 hrs

5.

Table 4-4 shows that 1.5 cubic inch of grease is to be added.

Relubricate every 2,500 hrs of service with 1.5 cubic inch of

recommended grease.

EXAMPLE: LUBRICATION

4.3 TROUBLE-SHOOTING

WARNING:

Before trouble-shooting a motor, carefully read and fully understand

the warnings, cautions, & safety notice statements in this manual.

Failure to do so could cause severe injury, death, and/or equipment

damage.

4.3.1

WARNINGS:

1. Disconnect power to the VFD and verify VFD DC output

voltage is zero before performing service or

maintenance.

2. Always keep hands, hair, and clothing away from

moving parts.

3. Be sure required safety guards are in place before

starting equipment.

4. If the problem persists, contact the manufacturer.

READ INSTRUCTIONS:

GENERAL TROUBLE SHOOTING

Motor Trouble-shooting Cause / Corrective Action - Table 4-5

Before conducting any trouble-shooting, be sure to read and follow all safety warnings and

instructions. Failure to do so could cause severe injury, death, and/or equipment damage.

Low or no input voltage to VFD.

A

Motor leads are not connected or miswired in

B

conduit box or at VFD output terminals.

Driven load exceeds motor/VFD capacity. VFD

C

may trip on overload fault.

Load is jammed or motor is binding. VFD trips on

D

overload fault.

Acceleration time set too short. Increase acceleration to maximum acceptable time for the application.

VFD programmed incorrectly. VFD trips on

F

overload fault.

(1) Ensure that rated input voltage is present at VFD. Ref. Section 3.4.1.2.

(2) Check line fuses. Ref. Section 3.4.1.1.

(1) Match motor lead wiring to motor nameplate connection diagram for operating

voltage. Ref. Section 3.4.3.

(2) Check continuity between VFD and motor terminals. Ref. Section 3.4.5.

(1) Verify that VFD current / torque limit setting equals motor rated service factor amps

(these parameters may be set to zero at the factory for safety purposes). Ref Section

3.3.5

(2) Verify that motor and VFD rating are adequate for application.

(1) Verify that motor & load turn freely. Ref. Section 3.4.5.

(2) Disconnect motor from load & ensure motor turns freely. Ref. Section 3.4.5.

(3) Verify that motor starts when disconnected from load. Ref. Section 3.4.5.

(4) Remove excessive / binding load if present.

(1) Repeat checks listed above.

(2) Consult VFD service manual. Ref. Section 3.3.5.

Page 11

Motor has been running, then slows down, stalls, or fails to restart

C

D

(2) Program direction change in VFD.

VFD trips repeatedl

y on overload or motor over

-

temperature fault

(3) Disconnect motor from load & ensure motor turns freely. Ref. Section 3.4.5.

A

complete set of matched belts. Ref. Section 3.3.4.

Drive has faulted.

A

Supply voltage to VFD has drooped or has

B

become severely unbalanced.

Motor is overloaded. VFD trips on overload.

Motor bearings are seized.

Load Is jammed. VFD trips on overload.

E

VFD will not restart motor after tripping.

F

Rotor magnets have been partially demagnetized

G

due to excessive heat or excessive current.

Check fault codes on VFD and follow VFD troubleshooting procedures. Ref Section

3.3.5.

(1) Check fuse or reset circuit breaker. Ref. Section 3.4.1.1.

(2) Verify that rated and balanced supply voltage has been restored at VFD input before

restarting motor. Measure VFD input voltage after motor has reached set speed during

restart. Ref. Section 3.4.1.2.

(1) Verify that motor & load turn freely. Ref. Sections 3.3.5 and 3.4.5.

(2) Disconnect motor from load & ensure motor turns freely. Ref. Section 3.4.5.

(3) Verify that motor starts when disconnected from load. Ref. Section 3.4.5.

(4) Remove excessive / binding load if present.

(5) Motor may have overheated. Check thermostats and if tripped, allow motor to cool

before attempting to restart. Ref. Section 3.3.6.4.

(1) Check fault codes on VFD and follow VFD troubleshooting procedures.

(2) Verify that VFD input voltage is balanced and within limits. Ref. Section 3.4.1.

(3) Remove excessive mechanical load if present.

To diagnose, motor must be cooled to room temperature. Disconnect motor shaft from

load and motor leads from VFD. Ref. Section 4.0. Connect AC volt meter across T1

and T2 motor leads. Drive motor at a speed below rated speed and measure both

voltage generated and actual RPM. The voltage per 1000 rpm should match the

nameplate value within 10%.

Motor takes too long to accelerate

Acceleration rate set too long.

A

Supply voltage has drooped or become severely

B

unbalanced.

Load exceeds motor/VFD capability.

C

(1) Decrease acceleration setting in VFD.

(2) Make sure motor is wired to match VFD output voltage.

(3) Verify motor nameplate voltage matches VFD output voltage. Ref. Section 3.4.1.2.

Ensure that steady state supply voltage at VFD input terminals is within limits. Ref.

Section 3.4.1.2. Correct as needed.

(1) Verify the motor rating and VFD current capability are sized correctly for the load.

(2) Set current / torque limit setting to match the maximum motor capability. Ref.

Section 3.4.5.

(3) Disconnect motor from load & ensure motor turns freely. Ref. Section 3.4.5.

Motor rotates in the wrong direction

Motor lead wiring is reversed or commanded

A

direction is reversed at VFD.

(1) Interchange any two motor leads between motor and VFD output terminals. Ref.

Section 4.0.

Load exceeds motor/VFD capability.

A

Ambient temperature too high.

B

Motor cooling fins and/or vent openings blocked.

C

Insufficient Air Flow.

D

Load acceleration time is set too short. Increase acceleration time as needed.

E

Start/stop time (duty cycle) is too short or too

F

frequent.

Motor Vibrates

Motor misaligned to load. Realign load.

Load out of balance.

B

Uneven tension on multiple belts.

C

Driven load operating at resonant point / natural

D

frequency.

(1) Verify the motor rating and VFD current capability are sized correctly for the load.

(2) Set current / torque limit setting to match the maximum motor capability. Ref.

Section 3.4.5.

Confirm that ambient at motor does not exceed value stamped on motor nameplate.

Reduce ambient as needed. Ref. Section 3.1.2.

Remove foreign materials – clear vent openings, fan guard air inlets and frame fins

(TEFC motors). Ref. Section 4.1.1.

TEAO (Totally Enclosed Air Over) motors: Measure airflow next to motor surface and

obtain minimum requirements from motor manufacturer. Ref. Section 3.1.3.1.

(1) Increase acceleration/deceleration times.

(2) Reduce the number of start/stop cycles.

(1) Ensure that load is dynamically balanced.

(2) Verify that motor shaft is not bent. Uncouple motor from load and inspect motor

shaft. Rule of thumb is 0.002” runout for shafts extension lengths up to 3.00”. Add

0.0005” per every additional inch of shaft length beyond 3.00”.

(1) Belts are not evenly worn. Realign motor to load and replace all belts. Ref. Section

3.3.4.

(2) A mix of new and used belts is used. Replace multiple belt applications with a

(1) De-energize motor and record vibration as load coasts from 100% speed to 0 RPM.

If vibration drops immediately, vibration source is electrical. If levels do not drop

immediately, source is mechanical.

(2) If electrical sources, program skip frequencies to bypass resonant points.

(3) If mechanical, redesign system to operate below the resonant point.

Page 12

Uneven, weak or loose mounting support. Shim, strengthen or tighten where required.

also cause

(3) Check run

-

out of mating components, such as a C

-

face and pump flange.

Disconnect leads at motor conduit box and Megger motor leads to ground. Ref. Section

x producing braking torque. Isolate all

E

Motor bearings worn.

F

Motor out of balance.

G

Bearings repeatedly fail

Load to motor may be excessive or unbalanced.

A

Uncouple motor from load and rotate shaft by hand. Ref section 2.1.2. If you hear

noise or feel roughness, have bearings replaced. Ref Section 4.0. For motors with

regreasing provisions, add grease per relubricating instructions. Ref. Section 4.2.3. If

noise persists contact motor manufacturer.

Motor is balanced at the factory and will remain balanced in operation. If motor balance

is in question, remove motor from application and send to a motor manufacturer

authorized service shop for inspection. Do not attempt to disassemble motor in the

field.

(1) If belt drive, check system per section 3.3.4.

(2) Other than belting, check loading on motor shaft. An unbalanced load will

the bearings to fail.

Bearings contaminated.

B

Incorrect grease or bearings for ambient extremes. See section 4.2.1.

C

Motor enclosure not suitable for environment. Replace with correct enclosure

construction.

Motor makes a rubbing, grinding, or squealing noise

Contact between rotating and stationary

A

components.

Isolate motor from load. To locate point of contact turn motor shaft by hand. Ref.

Section 2.1.2. If point of contact is not located, contact motor manufacturer authorized

service shop.

VFD trips on Ground Fault

VFD trips at low speed during starting. Voltage

A

boost is set too high.

Condensation forms on motor winding.

B

Motor winding is shorted to ground.

C

Reduce boost, repeat auto tune.

Remove source of moisture. Dry out motor. Add space heaters to motor. Ref. Section

3.3.6.3 and 4.0.

4.1.2. If resistance is less than 1.5 mega-ohms, remove motor from service. Service

shop must check for excessive moisture or contamination on windings or short to

ground.

Motor shaft cogs

Shaft cogs when turned by hand.

A

Shaft cogs when operated by VFD. Voltage boost is excessive. Reduce boost. Repeat auto tune.

B

VFD trips during deceleration

VFD cannot absorb regenerated power.

A

Deceleration time is set too fast. VFD’s dynamic

B

braking circuit overloads.

Motor leads are shorted together inside conduit bo

leads and repeat shaft turning by hand. Ref. Section 3.4.5.1.

(1) Add dynamic brake resistors or change VFD to line-regenerative design. For multidrive installations, connect drives in common bus configuration to share regenerated

power.

(2) Increase capacity of dynamic braking circuit.

Increase deceleration time to reduce regenerated energy.

2100 Washington St. • Grafton, WI 53024

Ph: (262) 377-8810 • Fax: (262) 377-9025

A Regal Beloit Company

www.leeson.com

Form 5968L

7/2011 R1

Loading...

Loading...