Page 1

MICRO SERIES DYNAMIC BRAKING OPTION

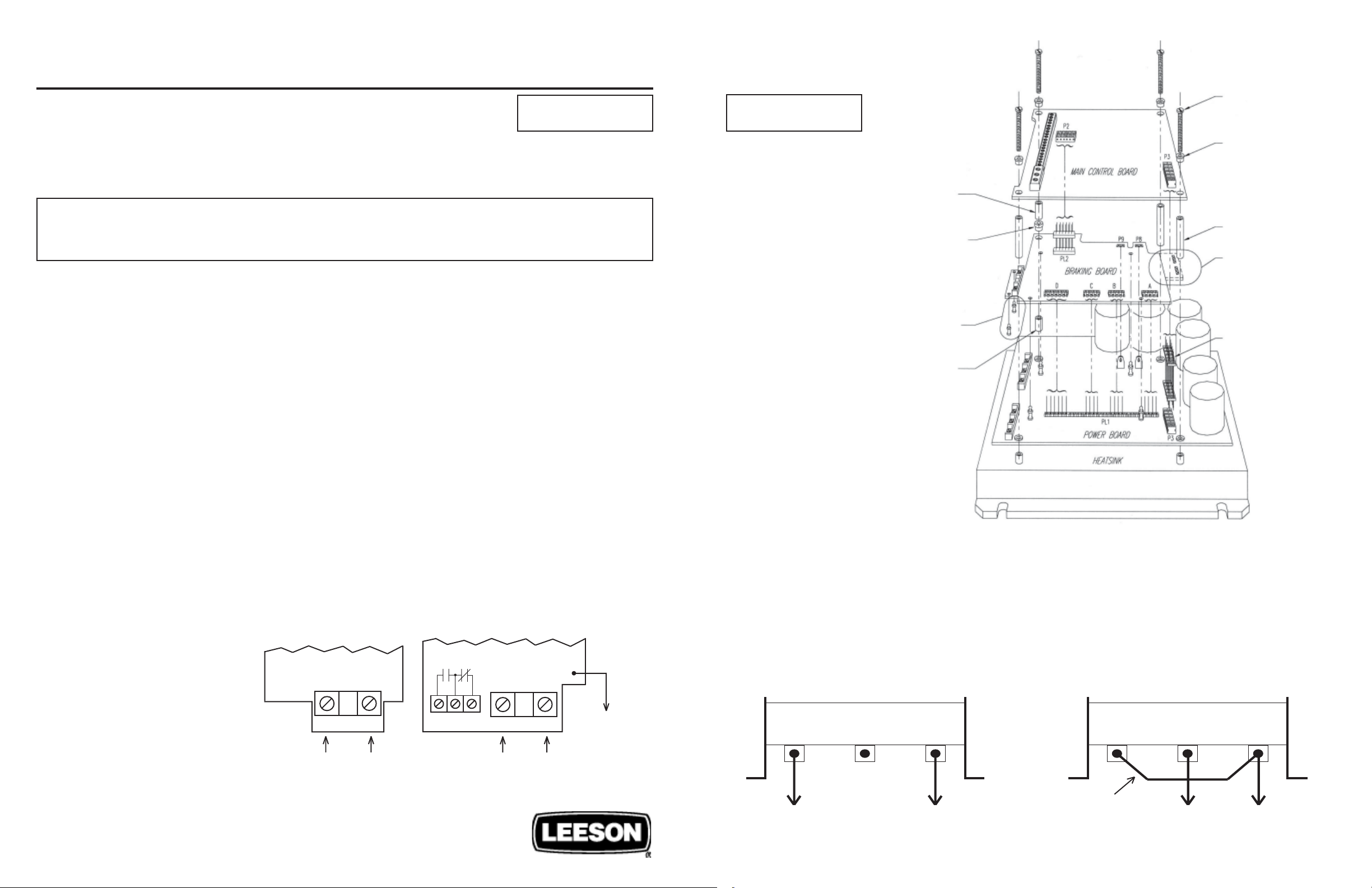

1.4 EXPLODED VIEW

INSTALLATION INSTRUCTIONS (Manual Number: MDB-6-A)

1.0 INSTRUCTIONS FOR KITS: 174184.00, 174185.00, and 174193.00

0.5 - 5 HP @ 240 Vac and

1 - 7.5 HP @ 480 & 590 Vac

1.1 PARTS LIST

(1) Dynamic Braking Board (9935-XXX or 9956-XXX) (1) Resistor assembly (if ordered)

(1) 7/16” Nylon sleeve standoff (1) 3/4” Nylon sleeve standoff

(2) Nylon “snap-in” standoff (7.5 HP kits only) (1) Nylon shoulder washer

Hazard of electric shock! Remove power from the drive and wait three minutes before attempting this procedure. DC Bus capacitors retain charge after power is removed.

The internal components of the Micro Series can be damaged by electrostatic discharge (ESD)! Use an antistatic wrist strap with the ground clip attached to the drive

ground lug when attempting this procedure. Always place components on antistatic surfaces or in antistatic bags when they are not being handled during this procedure.

WARNING!

1.2 PROCEDURE

NOTE: Refer to 1.4 Exploded View while performing this procedure. Be careful when removing and installing boards, as there are many pins that can be easily bent.

1. With drive cover removed, remove the keypad assembly. On NEMA 1 units, this is done by prying one end of the bracket up and out. On NEMA 4 or 12 units,

remove the screws that hold the bracket in place. Then unplug the keypad ribbon cable from the Main Control Board (9933A-XXX or 9019-XXX).

2. Remove the Main Control Board by removing the four screws (one at each corner), and carefully lifting the board straight up and out.

Remove the 1-5/16” nylon sleeve standoff from the lower left-hand corner screw, and replace it with the 3/4” nylon sleeve standoff from the kit.

There is a 2 x 6 pin connector that connects the P3 plug on the Main Control Board to the P3 plug on the Power Board below. Leave this plugged into the P3 plug

on the Power Board.

3. Under the Main Control Board is the Driver Board (9926-XXX) which must be removed to install the DB Board. Remove the Driver Board by pinching the flared

top of each nylon standoff while gently lifting up on the board (leave the standoffs snapped into the Power Board underneath).

NOTE: On 7.5 Hp, 480 Vac and 590 Vac drives only, remove and save the 2 x 6 pin connector that is plugged into PL2 on the Driver Board (another 2 x 6 connector

may be included in the DB kit; only one is needed).

4. Slide the nylon shoulder washer through the 3/16” hole near the lower left-hand side of the DB Board, and slide the 7/16” nylon sleeve standoff onto the shoulder

washer from the bottom side of the board.

NOTE: On 9956-XXX boards (kit 174193.00), install the two nylon “snap-in” standoffs into the holes at the bottom near the DB1 and DB2 terminals.

5. Snap the DB Board into place where the old Driver Board was, onto the same nylon standoffs that held the Driver Board in place. Make sure that the PL1 pin

connector and the P8 and P9 spade connectors make positive contact with their respective plugs.

NOTE 1: The 9956-XXX board (kit 174193.00) also has a P11 connector on the bottom of the board. Make sure that the P11 connector makes positive contact

to the pins on the Power Board below.

NOTE 2: On 9956-XXX boards (kit 174193.00), install the 2 x 6 pin connector in PL2.

6. Re-install the Main Control Board. Make sure that the PL2 and P3 pin connectors make positive contact through the bottom of the Main Control Board.

7. Re-install the keypad assembly and drive cover.

Applies to kits: 174184.00, 174185.00, and 174193.00

0.5 - 5 HP @ 240 Vac and

SCREW (TYPICAL 4 PLCS.)

1 - 7.5 HP @ 480 & 590 Vac

SHOULDER WASHER

(TYPICAL 4 PLCS.)

3/4" STANDOFF

1 5/16" STANDOFF

SHOULDER WASHER

STANDOFFS ONLY

PRESENT IN 7.5 HP KIT

(9956-XXX DB BOARD)

7/16" STANDOFF

(TYPICAL 3 PLCS.)

LOCATION OF P8 & P9 ON 7.5

HP DB BOARD (9956-XXX)

2 X 6 PIN CONNECTOR

1.5 RESISTOR CONFIGURATIONS

When the Dynamic Braking Kit is ordered separately from the Micro Series drive, the resistor assembly will be shipped in the 480 Vac and 590 Vac configuration. For 240

Vac units, the resistor configuration must be modified, as shown below, using the hardware included with the kit.

NOTE: If the Dynamic Braking option is ordered with the drive, the resistor assembly will be shipped in the proper configuration, and no modification is required.

1.3 WIRING AND PROGRAMMING

Refer to the appropriate diagram to the right for wiring.

The Dynamic Braking board for 7.5 Hp, 480 Vac and

590 Vac drives (kit 174193.00) also contains the

Additional Form C Relay option.

To enable Dynamic Braking, set DYN BRAKE

(parameter 14) to ON.

To enable the Additional Form C Relay, set TB-14 OUT

(parameter 52) to the desired status indication.

Refer to the drive's Installation and Operation Manual

for more info on programming.

Dynamic Braking Board

(kits 174184.00, 174185.00)

DB1 DB2

RED

WIRE

From Resistor Assembly

BLUE

WIRE

DB & Form C Relay Board

(kit 174192.00)

19 20 21

DB1 DB2

RED

WIRE

From Resistor Assembly

BLUE

WIRE

YELLOW WIRE

To TB-14 on Main

Control Board

480 Vac & 590 Vac 240 Vac

123 123

RED BLUE RED BLUE

Add jumper wire between Tab #1 and Tab #3, and move the RED wire to Tab #2.

JUMPER

WIRE

Page 2

2.0 INSTRUCTIONS FOR KITS: 174192.00

2.1 PARTS LIST

7.5 - 30 HP @ 240 Vac and

10 - 60 HP @ 480 & 590 Vac

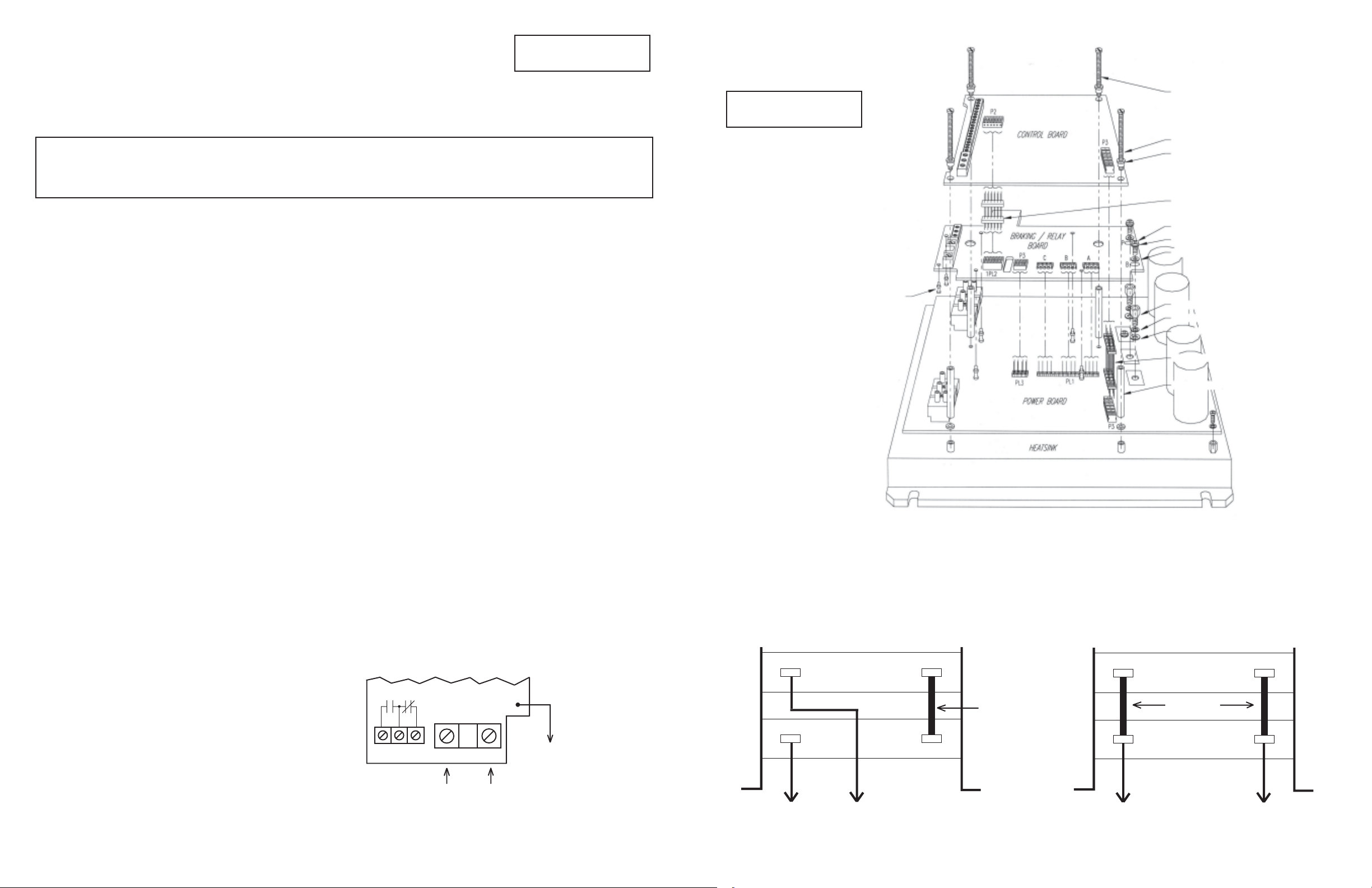

2.4 EXPLODED VIEW

Applies to kits: 174192.00

(1) Dynamic Braking & Additional Form C Relay Board (9955-XXX) (1) Resistor assembly (if ordered)

(2) Screw with captive lockwasher (2) Metal “male-female” standoff

(2) Large flat washer (2) Small flat washer

(2) Lockwasher (2) Nylon “snap-in” standoff

WARNING!

Hazard of electric shock! Remove power from the drive and wait three minutes before attempting this procedure. DC Bus capacitors retain charge after power is removed.

The internal components of the Micro Series can be damaged by electrostatic discharge (ESD)! Use an antistatic wrist strap with the ground clip attached to the drive

ground lug when attempting this procedure. Always place components on antistatic surfaces or in antistatic bags when they are not being handled during this procedure.

2.2 PROCEDURE

NOTE: Refer to 2.4 Exploded View while performing this procedure. Be careful when removing and installing boards, as there are many pins that can be easily bent.

1. Remove the drive cover.

2. Remove the keypad assembly. On NEMA 1 units, this is done by prying one end of the bracket up and out. On NEMA 4 or 12 units, remove the screws that hold

the bracket in place. Then unplug the keypad ribbon cable from the Main Control Board (9933A-XXX or 9019-XXX).

3. Remove the Main Control Board by unscrewing the four screws (one at each corner) and lifting the Main Control Board straight up and out.

There is a 2 x 6 pin connector that connects the P3 plug on the Main Control Board to the P3 plug on the Power Board below. Leave this plugged into the P3 plug

on the Power Board.

4. Under the Main Control Board is the Driver Board (9941-XXX) which must be removed to install the DB & Relay Board. Remove the Driver Board by pinching the

flared top of each nylon standoff while gently lifting up on the board (leave the standoffs snapped into the Power Board underneath).

Remove and save the 2 x 6 pin connector (refer to the diagram) that is plugged into PL2 on the Driver Board (another 2 x 6 pin connector may be included in the DB

& Relay kit; only one is needed).

7.5 - 30 HP @ 240 Vac and

10 - 60 HP @ 480 & 590 Vac

SNAP-IN STANDOFF

(TYPICAL 4 PLCS.)

1 5/8" SCREW (TYPICAL 2 PLCS.)

2 5/8" SCREW (TYPICAL 2 PLCS.)

SHOULDER WASHER

(TYPICAL 4 PLCS.)

2 X 6 PIN CONNECTOR

SCREW (TYPICAL 2 PLCS.)

CAPTIVE LOCK WASHER (TYPICAL 2 PLCS.)

SMALL FLAT WASHER (TYPICAL 2 PLCS.)

METAL STANDOFF (TYPICAL 2 PLCS.)

LOCK WASHER (TYPICAL 2 PLCS.)

LARGE FLAT WASHER (TYPICAL 2 PLCS.)

2 X 6 PIN CONNECTOR

1 7/8" STANDOFF (TYPICAL 4 PLCS.)

Once the Driver Board is removed, examine the Power Board. There will be three screws in a row between the Bus Capacitors and the PL1 connector. Some units will also

have two standoffs labeled "P" and "B" located below the row of screws. If the Power Board has the "P" and "B" standoffs, go to Step 7. If not, continue with Step 5.

5. There are three screws in a horizontal row located between the Bus Caps and the PL1 connector on the Power board. Remove and discard the middle and right

screws (which are the middle and bottom screws as viewed on Diagram B).

6. Install the two metal “male-female” standoffs where the screws were removed in Step 5, using the large flat washers and lockwashers.

7. Install the two nylon “snap-in” standoffs into the holes at the bottom of the DB & Relay Board near the DB1 and DB2 terminals.

8. Snap the DB & Relay Board into place where the old Driver Board was, onto the same nylon standoffs that held the Driver Board in place. Make sure that the PL1

and PL3 pin connectors make positive contact through the bottom of the DB & Relay Board.

9. Install the two screws with captive lockwashers at the top of the DB & Relay Board at the positions marked "P" and "B", using the small flat washers.

10. Install the 2 x 6 pin connector in PL2 on the DB & Relay Board.

11. Re-install the Main Control Board. Make sure that the PL2 and P3 pin connectors make positive contact through the bottom of the Main Control Board.

12. Re-install the keypad assembly and drive cover.

2.3 WIRING AND PROGRAMMING

Refer to the diagram to the right for wiring.

The Dynamic Braking board for kit 174192.00 also contains the Additional

Form C Relay option.

To enable Dynamic Braking, set DYN BRAKE (parameter 14) to ON.

To enable the Additional Form C Relay, set TB-14 OUT (parameter 52) to

the desired status indication.

Refer to the drive's Installation and Operation Manual for more info on

programming.

19 20 21

DB & Form C

Relay Board

DB1 DB2

RED

WIRE

From Resistor Assembly

BLUE

WIRE

YELLOW WIRE

To TB-14 on Main

Control Board

2.5 RESISTOR CONFIGURATIONS

When the Dynamic Braking Kit is ordered separately from the Micro Series drive, the resistor assembly will be shipped in the 480 Vac and 590 Vac configuration. For 240

Vac units, the resistor configuration must be modified, as shown below, using the hardware included with the kit.

NOTE: If the Dynamic Braking option is ordered with the drive, the resistor assembly will be shipped in the proper configuration, and no modification is required.

480 Vac & 590 Vac 240 Vac

12

SCREW

12

RED BLUE

Connect each Tab #1 together with screw provided (copy the configuration of the #2 tabs), and move the BLUE wire to Tab #2.

12

SCREW

12

RED BLUE

Loading...

Loading...