Page 1

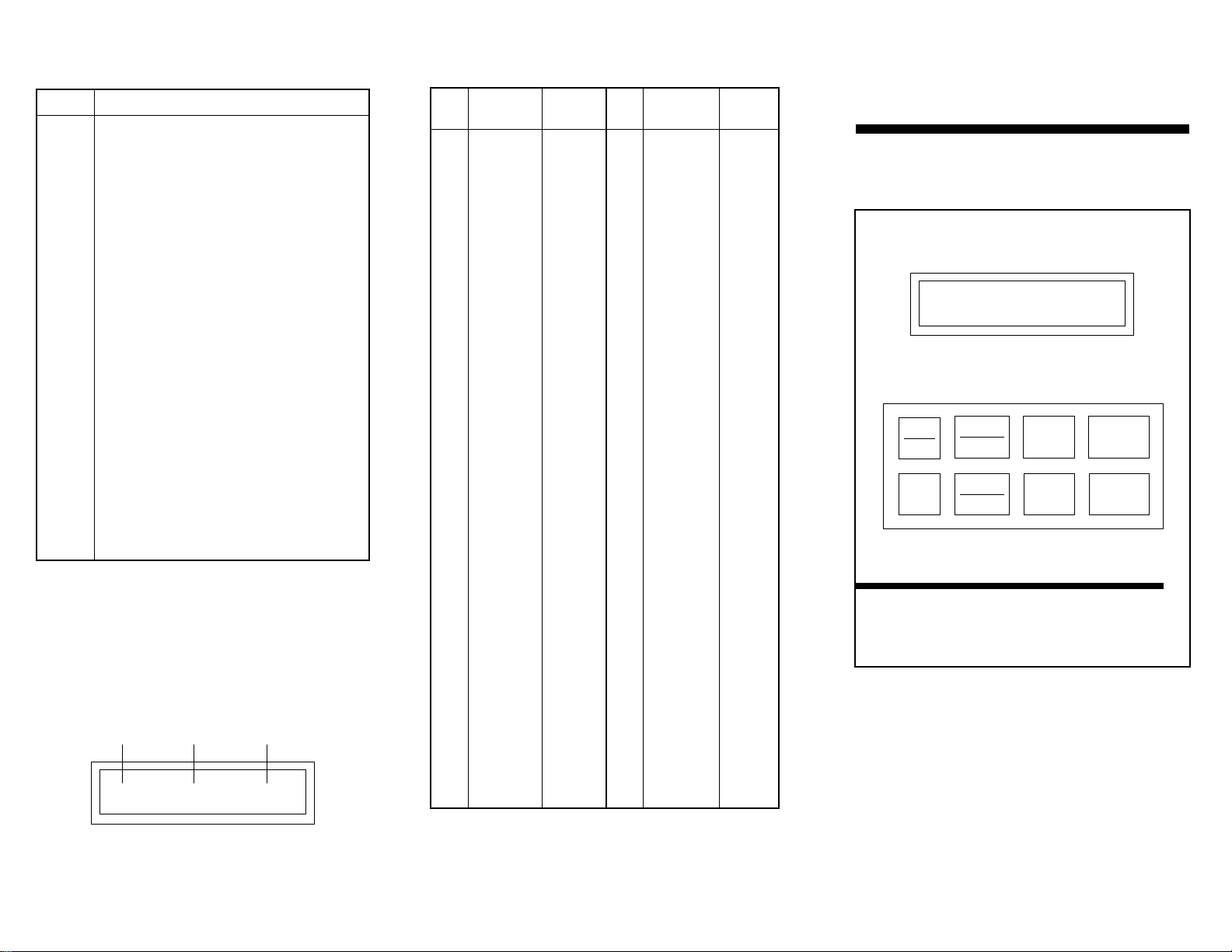

LEESON

Variable Speed AC Motor Drives

RUN 60.00 HZ

PROG

RUN

AUTO

MAN

START

ENTER

FWD

REV

STOP

Micro Series

Quick Reference Guide

NOTE: Before installing and operating the MICRO SERIES

drive, please read and become familiar with the MICRO SERIES

Installation and Operation Manual.

Adjustable Speed AC Motor Control

2 OUTPUT ACCEL

In the example above, the second fault is being viewed, which is

an OUTPUT fault that occurred while the drive was accelerating.

FAULT

NUMBER

FAULT

MESSAGE

DRIVE

STATUS

MICRO SERIES FAULT HISTORY

Parameter 70 — FAULT HISTORY stores the last eight faults that

tripped the drive. The FAULT HISTORY indicates the number of

the fault (number 1 is the most recent fault), the fault message,

and the status of the drive at the time of the fault. An example is

shown below:

FAULT DESCRIPTION

OUTPUT Output Transistor fault. Output current exceeded 200%.

May be ground fault or short circuit.

LO VOLTS Low DC Bus Voltage fault. DC bus voltage dropped below 60%

May be low line voltage.

HI VOLTS High DC Bus Voltage fault. DC Bus voltage exceeded 120%.

May be overhauling load .

HI TEMP High Temperature fault. Heatsink or ambient temperature

too high.

OVERLOAD Current Overload fault. Output current exceeded 100% for

too long. VFD may be undersized.

PWR TRAN Power Transient fault.

PWR SAG Power Sag fault: New control board installed. Perform

factory reset using Parameter 65.

LANGUAGE Language EEPROM fault.

EXTERNAL External fault: TB-130 activated (Parameter 50).

DB ERROR Dynamic Brake fault. DB Resistors overloaded.

CONTROL Control Board fault. New solfware installed. Perform factory

reset using Parameter 65.

INTERNAL Internal fault

INTERN (#) Internal fault.

MC3000 FAULT MESSAGES

PARAMETER FACTORY PARAMETER FACTORY

NO. NAME DEFAULT NO. NAME DAFAULT

0 LINE VOLTS AUTO

1 SPEED #1 20.00 Hz

2 SPEED #2 20.00 Hz

3 SPEED #3 20.00 Hz

4 SPEED #4 20.00 Hz

5 SKIP #1 .00 Hz

6 SKIP #2 .00 Hz

7 BAND WID 1.00 Hz

8 ACCEL 30.0 SEC

9 DECEL 30.0 SEC

10 MIN FRQ .50 Hz

11 MAX FRQ 60.00 Hz

12 DC BRAKE .0 VDC

13 DC TIME .0 SEC

14 DYN BRAKE OFF

16 CURRENT 180%

17 MOTOR OL 100%

18 BASE 60.00 Hz

19 FX BOOST (NOTE 1)

20 AC BOOST .0%

21 SLIP COMP .0%

22 TORQUE CONSTANT

23 CARRIER 2.5 kHz

25 START NORMAL

26 STOP COAST

27 ROTATION FORWARD

28 AUTO/MAN BOTH

29 MANUAL KEYPAD

30 CONTROL LOCAL

31 UNITS HERTZ

32 HZ MULT 1

33 UNITS DP XXXX

34 LOAD MLT 100%

35 CONTRAST HIGH

39 TB5 MIN .00 Hz

40 TB5 MAX 60.00 Hz

42 TB10A OUT NONE

43 @TB10A 60.00 Hz

44 TB10B OUT NONE

45 @TB10B 125%

47 TB13A NONE

48 TB13B NONE

49 TB13C NONE

50 TB13D FAULT

52 TB14 OUT NONE

53 TB15 OUT NONE

54 RELAY NONE

58 ADDRESS 30

61 PASSWORD 0019

63 SOFTWARE (NOTE 2)

64 MONITOR ON

65 PROGRAM RESET 60

66 HISTORY MAINTAIN

70 FAULT HIST. (NOTE 2)

NOTE 1: REFER TO THE MICRO SERIES MANUAL.

NOTE 2: THESE PARAMETERS ARE VIEW-ONLY.

MICRO SERIES PARAMETERS

Micro Series

Intelligent Drive

Digital

LEESON SPEEDMASTER

BULLETIN #2452 3/98

Page 2

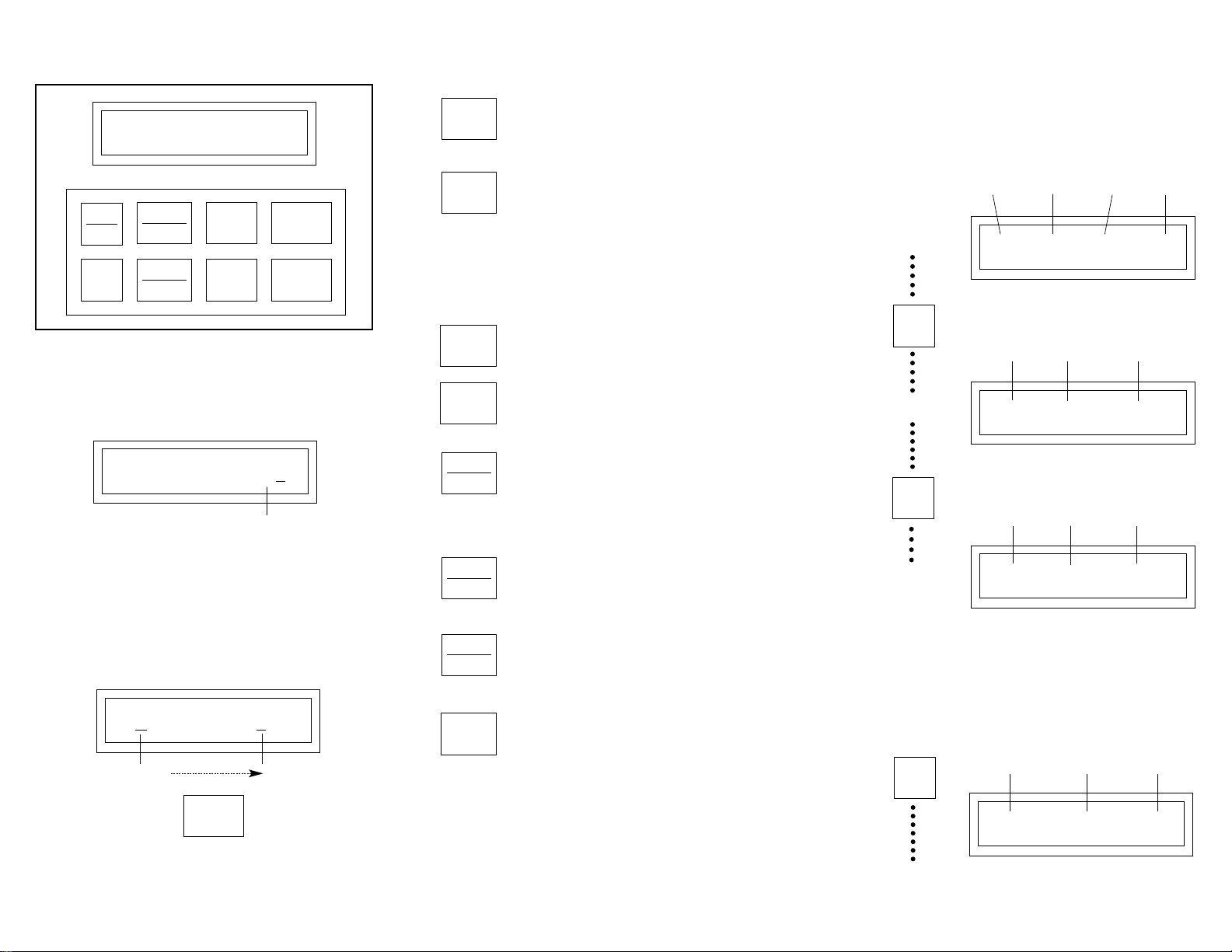

STOP 20.00 HZ

PROG

RUN

AUTO

MAN

START

ENTER

FWD

REV

STOP

Press the START key to start the drive. The START key

is only active in LOCAL mode.

PROGRAMMING THE MICRO SERIES

1. Press the PROG/RUN key. This will cause the PASSWORD

prompt to appear (unless the password protection has been disabled), as shown below:

PASSWORD 0000

CURSOR

2. Use the ARROW keys to scroll to the correct password value

(the factory default password is 0019) and press ENTER. The

PROGRAM mode will be entered at the start of the parameter

menu. Acursor will highlight the parameter name.

3. Use the ARROW keys to scroll to the desired parameter and

press ENTER. The cursor will shift from the parameter name

to the parameter value, as the example below illustrates:

ACCEL 30.0 SEC

CURSOR

ENTER

4. Use the ARROW keys to scroll to the desired parameter value,

and press ENTER to store the new value.

5. Press PROG/RUN to exit the PROGRAM mode.

START

MICRO SERIES KEYPAD FUNCTIONS

Press the STOP key to stop the drive.

NOTE: The STOP key is active in both LOCAL and

REMOTE mode.

The STOP key is also used to reset faults. If the fault

condition has passed, pressing the STOP key will clear

the fault and return the drive to a STOP condition.

STOP

UP and DOWN ARROWS — Used to change the speed

setpoint in MANUAL mode, scroll through the parameter menu, and change parameter values.

Toggles between AUTOMATIC (terminal strip) and

MANUAL (keypad) speed control.

NOTE: Parameter 28 — AUTO/MAN must be set to

BOTH for this key to be active.

AUTO

MAN

Toggles between forward and reverse directions.

ENTER key must pressed.

FWD

REV

Used to enter and exit the PROGRAM mode to set the

parameters.

PROG

RUN

ENTER

Used for: toggling the display between SPEED, LOAD,

and MOTOR VOLTAGE; confirming new parameter

values; confirming AUTO and MANUALspeed control

selections.

MICRO SERIES DISPLAYS

Shown below are examples of MICRO SERIES displays. To scroll

through the SPEED, LOAD, and MOTOR VOLTAGE displays,

press and release the ENTER key.

RUN 60.00 HZ

DRIVE

STATUS

SPEED

SETPOINT

SPEED

UNITS

RUN 85% LOAD

DRIVE

STATUS

PERCENT

LOAD

RUN 460 VAC

DRIVE

STATUS

MOTOR

VOLTAGE

MOTOR VOLTAGE

DISLAY

ENTER

ENTER

SPEED DISPLAY

LOAD DISPLAY

Press and hold the ENTER key to activate the AUXILIARY

MODE, which will toggle to a CONTROL DISPLAY. An example

is shown below:

ENTER

PRESS

& HOLD

LOCAL -- AUTO -- IDC

DRIVE

STATUS

MOTOR

VOLTAGE

SPEED

REFERENCE

SOURCE

AUXILIARY MODE

CONTROL DISPLAY

MICRO SERIES KEYPAD

ROTATION

DIRECTION

ROTATION

DIRECTION

ROTATION

DIRECTION

Loading...

Loading...