Lancer FS30 User Manual

FLAVOR SELECT 30 (FS30)

ICE BEVERAGE DISPENSER

Installation and Service Manual

LANCER

6655 Lancer Blvd.

San Antonio, Texas 78219

To order parts, call Customer Service: 800-729-1500 Warranty/Technical Support: 800-729-1550 Email: custserv@lancercorp.com

www.lancercorp.com ISO 9001:2000 Quality System Certified

Manual PN: 28-0558/04 |

“Lancer” is the registered trademark of Lancer © 2008 by Lancer, all rights reserved. |

7/18/08 |

|

|

|

|

TABLE OF CONTENTS |

|

SPECIFICATIONS.............................................................................................................................................. |

3 |

|||

FS30 FEATURES ............................................................................................................................................... |

4 |

|||

LIST OF FS30 DISPENSERS ............................................................................................................................ |

4 |

|||

ICE |

..................................................................................................................................................................... |

|

4 |

|

PRE-INSTALLATION CHECKLIST.................................................................................................................... |

5 |

|||

FS30 COUNTER CUTOUT ................................................................................................................................ |

6 |

|||

SAFETY.............................................................................................................................................................. |

|

7 |

||

1. |

|

INSTALLATION ........................................................................................................................................... |

8 |

|

|

|

1.1 |

SELECTING A LOCATION FOR THE DISPENSER .......................................................................... |

8 |

|

|

1.2 |

UNPACKING THE DISPENSER ...................................................................................................... |

10 |

|

|

1.3 |

DRAIN SPIDER................................................................................................................................ |

10 |

|

|

1.4 |

INSTALLATION OVERVIEW 1 ......................................................................................................... |

11 |

|

|

1.5 |

INSTALLATION OVERVIEW 2 ......................................................................................................... |

12 |

|

|

1.6 |

CONNECTING TO WATER SUPPLY LINES ................................................................................... |

13 |

|

|

1.7 |

CONNECTING CO2......................................................................................................................... |

14 |

|

|

1.8 |

CONNECTING TO ELECTRICAL POWER ..................................................................................... |

14 |

|

|

1.9 |

INSTALLING THE FS30 DISPENSER ............................................................................................. |

14 |

2. |

|

CLEANING AND SANITIZING ................................................................................................................. |

16 |

|

|

|

2.1 |

GENERAL INFORMATION .............................................................................................................. |

16 |

|

|

2.2 |

CLEANING AND SANITIZING SOLUTIONS ................................................................................... |

17 |

|

|

2.3 |

DAILY CLEANING ............................................................................................................................ |

18 |

|

|

2.4 |

ICE BIN CLEANING - PERFORM AT START UP AND MONTHLY ................................................. |

18 |

|

|

2.5 |

CLEANING AND SANITIZING BEVERAGE COMPONENTS - BAG-IN-BOX SYSTEMS............... |

20 |

|

|

2.6 |

ICE CHUTE CLEANING ................................................................................................................. |

20 |

3. |

HOW TO OPERATE AND ADJUST THE LANCER FS30 ........................................................................ |

21 |

||

|

|

3.1 |

NORMAL OPERATION .................................................................................................................... |

21 |

|

|

3.2 |

PROGRAMMING AND SETUP SOFTWARE................................................................................... |

21 |

|

|

3.3 |

PURGING THE CARBONATION SYSTEM ..................................................................................... |

23 |

|

|

3.4 |

PURGING THE WATER AND SYRUP SYSTEM ............................................................................. |

23 |

|

|

3.5 |

ADJUSTING WATER FLOW AND WATER TO SYRUP RATIO (BRIX)........................................... |

23 |

|

|

3.6 |

CARBONATOR PUMP MODIFICATIONS........................................................................................ |

24 |

4. |

|

TROUBLESHOOTING............................................................................................................................... |

26 |

|

5. |

ILLUSTRATIONS, PARTS LISTINGS, AND WIRING DIAGRAMS .......................................................... |

32 |

||

|

|

5.1 |

FINAL ASSEMBLY ...................................................................................................................... |

32-33 |

|

|

5.2 |

ICE CHUTE ASSEMBLY .................................................................................................................. |

34 |

|

|

5.3 |

LANCER FLOW CONTROL VALVE (LFCV) .................................................................................... |

35 |

|

|

5.4 |

PELLET ICE ASSEMBLY AND PARTS LISTING............................................................................. |

36 |

|

|

5.5 |

WIRING DIAGRAM - 115V/60HZ ..................................................................................................... |

37 |

|

|

5.6 |

PLUMBING DIAGRAM WITH VALVE WIRING ................................................................................ |

38 |

ABOUT THE FS30

The FS30 is designed using the highest quality materials and state-of-the-art technology providing our customers with consistent quality and a unique drink experience.

P.N. 28-0558/04 |

2 |

FS30 SPECIFICATIONS

DIMENSIONS |

WEIGHT |

PLAIN WATER |

|

Width: 30 in (762 mm) |

Without ice: 320 lbs (145 kg) |

Min flowing pressure: 75 PSIG |

|

Depth: 30.5 in (775 mm) |

With ice: 620 lbs (281 kg) |

(5.28 kg/cm2, 5.16 BAR) |

|

Height: 40.25 in (1022 mm) |

Shipping: 356 lbs (161 kg) |

|

|

|

|

CARBONATOR WATER SUPPLY |

|

SPACE REQUIRED |

ICE |

Min flowing pressure: 25 PSIG |

|

Left Side: 1 in (25 mm) |

Capacity: 290 lbs (132 kg) |

(1.76 kg/cm2, 1.72 BAR) |

|

Right side: 1 in (25 mm) |

Dispensable: 215 lbs (98 kg) |

Max static pressure: 50 PSIG |

|

Back: 1 in (25 mm) |

|

(3.52 kg/cm2, 3.45 BAR) |

|

Top: 6 in (152 mm) |

FITTINGS |

|

|

Optional legs: 4 in (102 mm) |

Water for carbonator inlet: |

CARBON DIOXIDE (CO2) |

|

|

3/8” barb |

||

|

Min pressure: 70 PSIG |

||

ELECTRICAL |

Plain water inlet: 3/8” barb |

||

(4.92 kg/cm2, 4.83 BAR) |

|||

115VAC/60Hz, 7AMPs, |

Brand syrup inlets: 3/8” barb |

||

Max pressure: 80 PSIG |

|||

805 Watts |

Injection flavor inlets: 1/4” barb |

||

(5.62 kg/cm2, 5.52 BAR) |

|||

|

CO2 inlet: 3/8” barb |

||

|

|

|

3 |

P.N. 28-0558/04 |

FS30 FEATURES

Cold carbonation for consistently better drink quality.

16 brands for over 112 flavor possibilities.

Add up to 12 bonus flavors to create an exceptional drink experience.

Self-contained with multiple ice fill options.

Fits in current 30” IBD footprint.

“AirMix™” nozzles blend syrup and water in mid-air for consistent drink delivery.

Large capacity removable drip tray and cuprest.

Pellet ice-capable dispense available.

Lancer LFCV valves.

Keylock switch for valves.

Field configurable.

Front connection for products.

STANDARD FS30 DISPENSERS

85-14808-12 |

ICE BEVERAGE DISPENSER, ABOVE COUNTER MULTI BRAND, |

CUBED ICE |

|

|

30 |

INCH WIDE, 8 BRANDS / 12 FLAVORS, 115V/60Hz |

|

85-14808N-12 |

ICE BEVERAGE DISPENSER, ABOVE COUNTER MULTI BRAND, |

PELLET ICE |

|

|

30 |

INCH WIDE, 8 BRANDS / 12 FLAVORS, 115V/60Hz |

|

85-14810-12 |

ICE BEVERAGE DISPENSER, ABOVE COUNTER MULTI BRAND, |

CUBED ICE |

|

|

30 |

INCH WIDE, 10 BRANDS / 12 FLAVORS, 115V/60Hz |

|

85-14810N-12 |

ICE BEVERAGE DISPENSER, ABOVE COUNTER MULTI BRAND, |

PELLET ICE |

|

|

30 |

INCH WIDE, 10 BRANDS / 12 FLAVORS, 115V/60Hz |

|

85-14812-12 |

ICE BEVERAGE DISPENSER, ABOVE COUNTER MULTI BRAND, |

CUBED ICE |

|

|

30 |

INCH WIDE, 12 BRANDS / 12 FLAVORS, 115V/60Hz |

|

85-14812N-12 |

ICE BEVERAGE DISPENSER, ABOVE COUNTER MULTI BRAND, |

PELLET ICE |

|

|

30 |

INCH WIDE, 12 BRANDS / 12 FLAVORS, 115V/60Hz |

|

85-14814-12 |

ICE BEVERAGE DISPENSER, ABOVE COUNTER MULTI BRAND, |

CUBED ICE |

|

|

30 |

INCH WIDE, 14 BRANDS / 12 FLAVORS, 115V/60Hz |

|

85-14814N-12 |

ICE BEVERAGE DISPENSER, ABOVE COUNTER MULTI BRAND, |

PELLET ICE |

|

|

30 |

INCH WIDE, 14 BRANDS / 12 FLAVORS, 115V/60Hz |

|

85-14816-12 |

ICE BEVERAGE DISPENSER, ABOVE COUNTER MULTI BRAND, |

CUBED ICE |

|

|

30 |

INCH WIDE, 16 BRANDS / 12 FLAVORS, 115V/60Hz |

|

85-14816N-12 |

ICE BEVERAGE DISPENSER, ABOVE COUNTER MULTI BRAND, |

PELLET ICE |

|

|

30 |

INCH WIDE, 16 BRANDS / 12 FLAVORS, 115V/60Hz |

|

Dispensers using cubed ice may also use pellet ice if properly configured (contact Lancer Customer Service or your Sales Representative for more information).

Lancer dispensers will not dispense shaved or flaked ice.

Do not use bagged ice. Bagged ice will damage components.

P.N. 28-0558/04 |

4 |

PRE-INSTALLATION CHECKLIST

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly inspected before shipment. At the time of shipment, the carrier accepts responsibility for the unit. Upon receiving the unit, carefully inspect the carton for visible damage. If damage exists, have the carrier note the damage on the freight bill and file a claim with carrier. Responsibility for damage to the dispenser lies with the carrier.

POST MIX ACCESSORIES:

CO2 Regulator Set

CO2 Regulator Set

Beverage Tubing

CO2 Supply

Water Booster

Oetiker Clamps/Fittings

Water Regulator

BIB SYSTEM:

BIB Rack

BIB Regulator Set

BIB Connectors - ensure you have the correct connectors for syrup lineup.

BIB Syrup Boxes

DOUBLE CHECK:

Is the countertop level?

Is the countertop level?

Is there enough space to install the dispenser? Be sure to include space for a top-mounted ice machine, if necessary.

Is there enough space to install the dispenser? Be sure to include space for a top-mounted ice machine, if necessary.

Can the countertop support the weight of the dispenser? Be sure to include the weight of an ice machine (if necessary) plus the weight of the ice.

Can the countertop support the weight of the dispenser? Be sure to include the weight of an ice machine (if necessary) plus the weight of the ice.

Does the top-mounted ice machine have a minimum clearance on all sides?

Does the top-mounted ice machine have a minimum clearance on all sides?

CONSIDER THE LOCATION OF THE FOLLOWING BEFORE INSTALLATION:

Water supply lines

Drain

Grounded electrical outlet

Heating and air conditioning ducts

Direct sunlight (avoid) or overhead lighting

5 |

P.N. 28-0558/04 |

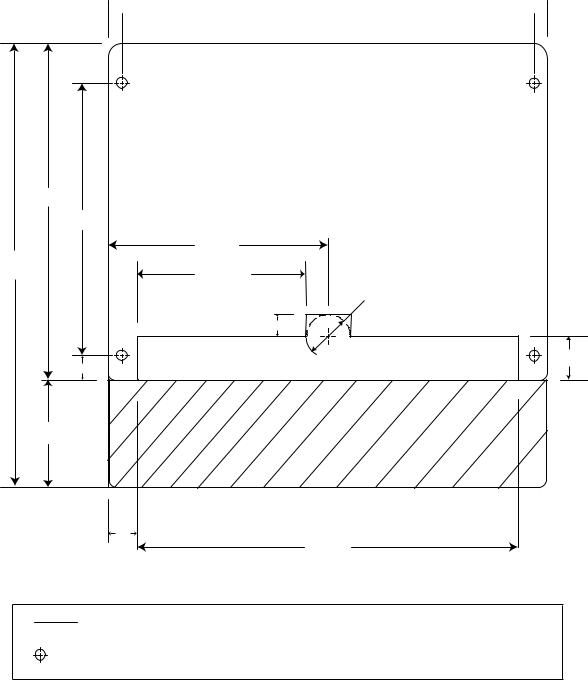

FS30 COUNTER CUTOUT

30”

30”  15/16”

15/16”

28 1/8”

28 1/8”

23” |

|

|

|

|

|

|

|

|

|

|

|

18 5/8” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15” |

|

|

|

|

|

|

30 1/2” |

|

|

|

11 1/2” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

3“ DIAMETER OPTIONAL |

|

||

|

|

|

|

|

|

1 1/2” |

|

|

|

|

|

1 5/8” |

|

|

|

|

|

|

|

|

|

|

3“ |

F |

R |

O |

N |

T |

O F |

D |

I S P E |

N |

S E |

R |

|

7 1/2” |

|

|

|

|

D R I P T R A Y |

|

|

|

|||

|

2“ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

26” |

|

|

|

|

CUT OUT DASHED AREA

OPTIONAL HOLES FOR FASTENING DISPENSER TO COUNTER WITH SCREWS

P.N. 28-0558/04 |

6 |

SAFETY

AUTOMATIC AGITATION

The dispenser is equipped with automatic agitation and will activate unexpectedly. Do not place hands or foreign objects in the ice storage compartment. Unplug the dispenser during servicing, cleaning, and sanitizing.

To avoid personal injury, do not attempt to lift the dispenser without assistance. For heavier dispensers, use a mechanical lift.

GROUNDING

The dispenser must be properly electrically grounded to avoid serious injury or fatal electrical shock. The power cord has a three-prong grounded plug. If a three-hole grounded electrical outlet is not available, use an approved method to ground the unit. Follow all local electrical codes when making connections. Each dispenser must have a separate electrical circuit. Do not use extension cords. Do not connect multiple electrical devices on the same outlet.

ALWAYS disconnect power to the dispenser before attempting any internal maintenance. The resettable breaker switch should not be used as a substitute for unplugging the dispenser from the power source to service the unit. NOTE: the keyswitch does not turn off power to the dispenser. It must be physically unplugged.

Only qualified personnel should service the internal components of the dispenser. Avoid any contact with water when plugging in the dispenser.

CARBON DIOXIDE

Carbon Dioxide (CO2) is heavier than air and displaces oxygen. CO2 is a colorless, noncombustible gas with a faintly pungent odor. High percentages of CO2 may displace oxygen in the blood. Prolonged exposure to CO2 can be harmful. Personnel exposed to high concentrations of CO2 gas will experience tremors which are followed rapidly by a loss of consciousness and suffocation. Strict attention must be observed in the prevention of CO2 gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is suspected, immediately ventilate the contaminated area before attempting to repair the leak.

The minimum/maximum ambient operating temperature for the dispenser is 40 to 90 degrees F.

The dispenser is for indoor use only.

7 |

P.N. 28-0558/04 |

1. INSTALLATION

1.1 SELECTING A LOCATION FOR THE DISPENSER

MAKE SURE THE LOCATION MEETS THESE REQUIREMENTS:

A.Access to a dedicated, grounded 20 AMP electrical outlet.

B.Convenient to an open drain with access for soda, water, and syrup lines.

C.Sufficient clearance above the dispenser for servicing.

D.Counter can support the weight of the dispenser, the weight of the ice, and if necessary, an icemaker. The total weight may exceed 800 pounds (363 kg).

E.Sufficient clearance on the sides, top and back for icemaker ventilation and air circulation. Refer to your icemaker manufacturer for specifications.

F.If an icemaker is not top-mounted on the dispenser, make sure to provide sufficient clearance (a minimum of 6 inches (40.6 cm)) to allow filling the dispenser with ice from a five gallon (19 liter) container.

G.Avoid direct sunlight and other heat sources.

THINGS TO CONSIDER:

Connecting lines can be run through the back of the dispenser or extend down through a counter cutout. The dispenser may be installed directly on the countertop or on an optional leg kit (PN 823484), if no icemaker is installed. If installed directly on the counter, the dispenser must be sealed to the countertop.

LEVELING THE DISPENSER:

In order to facilitate proper dispenser drainage and carbonation, ensure that the dispenser is level, front to back and side to side. Place a level on the top of the rear edge of the dispenser. The bubble must settle between the level lines. Repeat this procedure for the remaining three sides. Level unit if necessary.

P.N. 28-0558/04 |

8 |

FS30 DISPENSER, NO ICEMAKER

ENSURE SUFFICIENT CLEARANCE

FOR FILLING WITH ICE

ENSURE KEYSWITCH

IS ACCESSIBLE

_______________________________________________________________

FS30 DISPENSER WITH ICEMAKER Install the icemaker per manufacturer specifications. Points

of consideration include drainage, ventilation, and drop zones.

An adapter plate is required when installing an icemaker. Contact your Sales Representative or Lancer Customer Service for more information.

A bin thermostat is required in order to control the level of ice in the dispenser. Contact your icemaker manufacturer to obtain the correct bin thermostat.

Ensure the icemaker is installed properly to allow for removal of the merchandiser.

Ensure manual fill is accessible.

Clean and maintain icemaker per manufacturer’s instructions.

9 |

P.N. 28-0558/04 |

1.2UNPACKING THE DISPENSER

A.Set the shipping carton upright on the floor.

B.Cut band, remove.

C.Open the top of the carton and remove the interior packing.

D.Lift the carton up and off the dispenser.

E.Remove the wood shipping base from the bottom of the dispenser. Support dispenser while removing the shipping base to prevent damage to the dispenser.

1.3DRAIN SPIDER

The drain spider is located directly in the center of the bin under the ice shroud. The coldplate has a cavity designed to hold the drain spider. During shipment or installation, the drain spider may become dislodged from its original position.

Prior to installing the dispenser, ensure the drain spider is in the correct position. This will prevent drain clog issues. Inspect the lower bin area and reach under the shroud to ensure the drain spider is secure in the coldplate cutout. If the spider is not in place, proceed with the following steps:

A.Remove agitator clip and pin from agitator bar.

B.Remove agitator bar from paddle wheel.

C.Remove paddle wheel.

D.Remove ice shroud by lifting back then out of bin.

E.Locate drain spider and reinstall in the coldplate cavity where drain line exits (see figure above).

F.Reinstall all components. Ensure agitator clip is locked:

P.N. 28-0558/04 |

10 |

1.4 INSTALLATION OVERVIEW 1

11 |

P.N. 28-0558/04 |

1.5 INSTALLATION OVERVIEW 2

P.N. 28-0558/04 |

12 |

Loading...

Loading...