Page 1

HANDMADE IN FLORENCE

GB/5

av ailab le

Ver. 1.3

Also available in UL - NSF version

FB/80

Op erati ng Manual

Page 2

GB/5 - FB/80

Chapters

Table of Contents

English

1. General Warnings and Safety Specifications

2. Definition of Available Models

3. Installation

4. Operating the Espresso Machine and Preparing Coffee

5. Preparing Other Hot Drinks

6. Preventative Maintenance and Weekly Cleaning

7. De-Commissioning and Demolition

8. History and Use of the “La Marzocco” Coffee Machines

pag 2

pag 3

pag 5

pag 7

pag 9

pag 10

pag 11

pag 12

www.lamarzocco.com V1.3

Page 3

1. General Warnings and Safety Specifications

1) This operating manual is an integral and essential part of

the product and must be supplied to users. Users are

asked to read the enclosed warnings and cautions carefully,

as they provide valuable information concerning safety

English

during installation, operation and maintenance. This

manual must be kept in a safe place and be available for

consultation to new and experienced users alike.

2) Ensure product’s integrity by inspecting the packaging,

making sure it presents no signs of damage which might

have affected the enclosed machine.

3) Check the machine’s integrity after having carefully

removed the packaging.

Note:

In case of doubt, do not go on any further and contact your

dealer or retailer immediately. They will send out specialized

personnel authorized to perform service on the espresso

machine.

4) Packaging (boxes, plastic bags, foam parts and whatever

else) must not be left around within easy reach of children,

due to the potential danger it represents, nor be discarded

in the environment.

5) Check to see that data on the rating plate corresponds to

those of the main electrical supply which the machine will

be hooked up to.

6) The installation must be performed according to local

electrical and plumbing codes and regulations. The

installation also must comply to the manufacturer’s

instructions, and must be performed by qualified and

authorized personnel.

7) Incorrect installation may cause for injury/damages to

people, animals or objects, for which the manufacturer shall

not be held responsible.

8) Safe electrical operation of this device will be achieved

only when the connection to the power outlet has been

completed correctly and in observance of all local, national,

and international electrical codes and safety regulations,

and particularly by grounding the unit. Make sure grounding

has been done properly as it represents a fundamental

safety requirement. Ensure qualified personnel check such

connection.

9) Furthermore, you must ensure that the capacity of the

available electrical system is suitable for the maximum

power consumption indicated on the espresso machine.

This device must be used exclusively for the functions it

11)

has been designed and built for. Any other application is

inappropriate and dangerous.

The manufacturer shall not be held responsible for any

damages caused by improper and/or irrational use.

12) Using any electrical device requires that certain

fundamental rules be observed. In particular:

- do not touch the device with wet or humid hands and feet;

- do not use the device while having no shoes on your feet;

- do not use extension cords in bath or shower rooms;

- do not unplug the device from the power outlet by pulling on the power

supply cable;

- do not expose the device to atmospheric agents (rain, sun, etc.);

- do not allow children or untrained people to use this device.

13) Before carrying out any maintenance and/or cleaning

operations, turn the main switch, which is located on the

front left of the machine, to the “0” or OFF position, and

disconnect the machine from the electrical network by

unplugging the cord or by switching off the relative circuit

breaker. For any cleaning operation, follow exclusively the

instructions contained in this manual.

14) In case the machine is operating in a faulty manner or

breaks down, disconnect it from the electrical network (as

described in the preceding point) and close the water

supply valve. Do not attempt to repair it. Contact a qualified

and authorized professional to perform any repair. Any

repairs must be performed exclusively by the manufacturer

or by an authorized centre using only original parts. Non

compliance with the above could compromise the safe

operation of the machine.

15) You should plan to make use of an omnipolar connector

during installation, as required by local, national, and

international electrical codes and regulations.

16) In order to avoid dangerous overheating problems, it is

recommended that the power supply cable be fully unfurled.

17) Do not obstruct air intake and exhaust grilles and, in

particular, do not cover the cup warmer tray with cloths or

other items.

18) The machine’s power supply cable must not be replaced

by users. In case the power supply cable becomes

damaged, shut off the machine and disconnect the machine

from the electctrical network by switching off the relative

circuit breaker and close off the water supply; to replace

the power supply cord, contact qualified professionals

exclusively.

10) We do not recommend using adapters, multiple plugs and/

or extension cords. If you cannot avoid using them, make

sure that they are exclusively of the kind which conforms to

local, national, and international electrical codes and safety

regulations, being careful not to exceed the power and

current ratings indicated on such adapters and extension

cords.

2

La Marzocco, S.r.l. Firenze, ItaliaV1.3

Page 4

GB/5 - FB/80

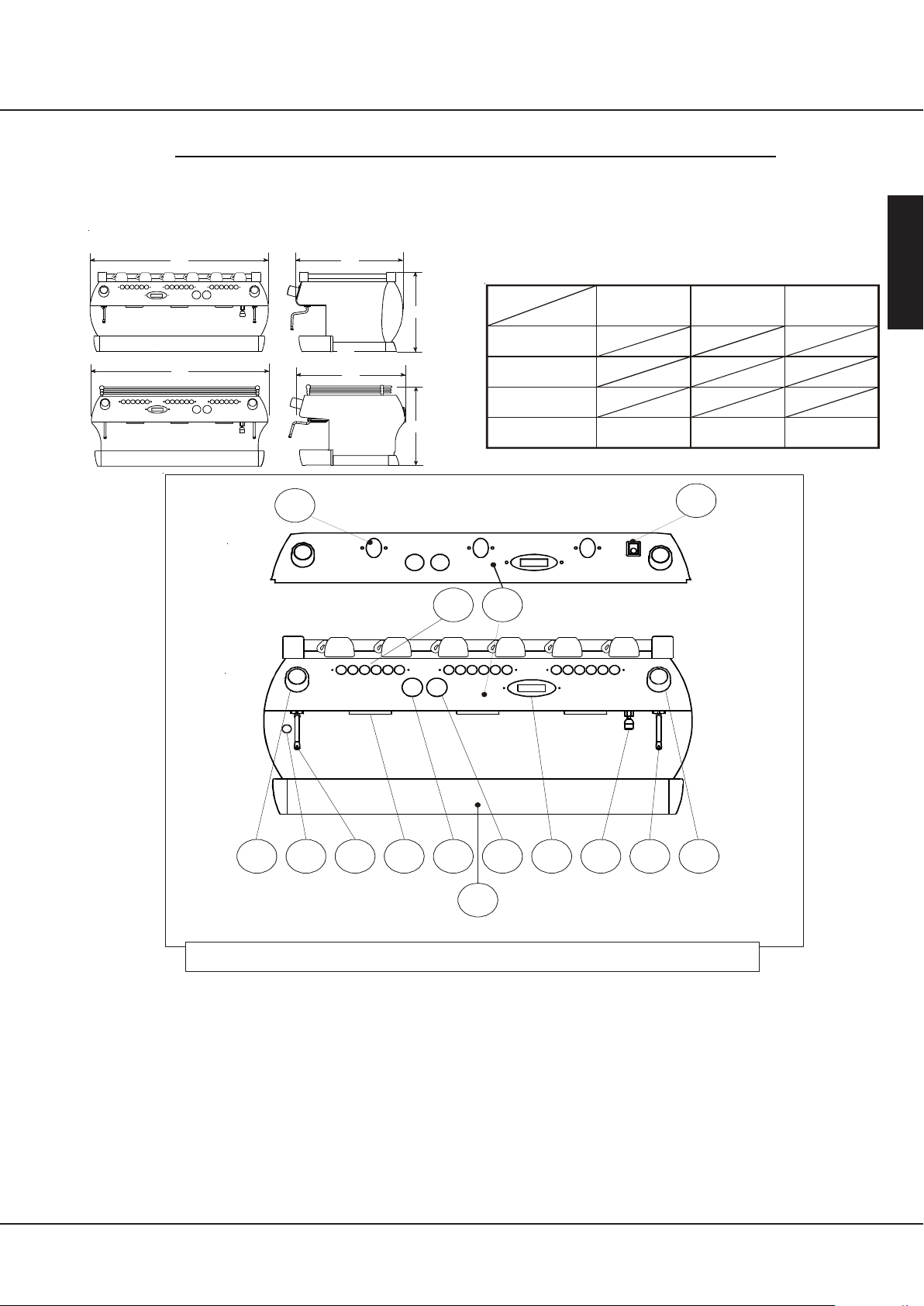

This operating manual refers exclusively to the following models, of our own manufacture:

GB/5 or FB/80, Model EE & AV into 2, 3 and 4 groups

1) Common Dimensions, Weights, and Features

C B

2. Definition of Available Models

GB/5

A

C

B

A

WEIGHT [kg]

FB/80

A [mm]

B [mm]

C [mm]

12

2 gr. 3 gr.

475

485

622

627

750 950

755

90

475

622

13

100

485

627

4 gr.

475

485

622

627

1190

1195955

130

English

EE

6 5

AV

9

1 8 4 2 3 7 10 8 9

11

Fig. 1 - Model AV & EE with 2, 3, or 4 groups

Legend

1) Main Switch

2) Pressure Gauge (Steam Water)

3) Pressure Gauge (Brew Water)

4) Brew Groups

5) Control Panel

6) Group #1 Keypad

7) Digital Display

8) Steam Wand

9) Steam Knob

www.lamarzocco.com V1.3

10) Hot Water dispense nozzle

11) Removable Drain Tray

12) Manual Brew Switch (EE model)

13) Hot Water Switch ( EE model)

For additional information on electronics, keypads,

and software programming, please see the section

entitled Software Programming your Espresso

Machine.

3

Page 5

2. Definition of Available Models

2) General Description

The machine is built in 2, 3, and 4 group versions and is

essentially composed of the following parts:

1) Steam Boiler (produces steam and hot water)

English

2) Coffee (“saturation”) boiler

3) Brewing groups

4) Exterior Cover

5) Water pump

3) Description of the various parts

• Steam Boiler

The Steam Boiler consists of a cylindrical tank, of varying

length according to the number of coffee groups, which is

made of AISI 300 series stainless steel. Each unit is

subjected to a hydraulic test, at a pressure of 6 bar, and has

an operating pressure of 1.3-1.5 bar. The following is a list

of effective volumes and power ratings according to the

number of groups installed:

2 groups 7.0 liters 2000 or 3000 Watts

3 groups 11 liters 3000 or 4000 Watts

4 groups 14,5 liters 3000/3800 or 5000 Watts

Covers are installed at either end of the cylindrical tank and

on one of them there is a housing for the water heating

element, which allows the steam boiler to operating

pressure within approximate 25 minutes. Operating

pressure is maintained by a pressure switch or a

temperature probe. The steam boiler has various fittings

used for safety devices, for supplying hot water and steam,,

and for the heating element.

• Exterior Cover

It consists of a stainless sheet steel body for the GB/5 and

painted plastic for FB/80. The structure has been the object

of specific studies to provide good aesthetics, to lower

ergonometric costs for the operator and to reduce the chance

of damage to a minimum.

• Water Pump

The water pump, is a differential pressure, “positivedisplacement” type installed on the water supply tubing and

is set-up to operate anytime the coffee groups are activated,

and through an electric level gauge whenever the steam

boiler needs to be replenished.

The Coffee Boiler and Steam Boiler contain water at elevated temperature.

Water temperature over 125 F / 52 can cause severe burns instantly or

(Coffee Boiler 200 F / 93.3 - Steam Boiler F / 127 )

゚゚C

death from scalding.

゚゚C ゚゚C

260

• Coffee Boiler

The Coffee Boiler consists of a cylindrical tank, of varying

length according to the number of coffee groups, which is

made of AISI 300 series stainless steel.

Each unit is

subjected to a hydraulic test, at a pressure of 18 bar, and

has an operating pressure of 9 bar. The following, table is a

list of effective volumes and power ratings according to the

number of groups installed:

2 groups 3.4 liters 1400 Watts

3 groups 5.0 liters 1600 or 1900 Watts

4 groups 3.4 + 3.4 liters 1400 + 1400 Watts

(2 Boilers Installed)

Covers are installed at either end of the cylindrical tank and

on one of them there is a housing for the water heating

elements. The temperature of the coffee boiler is maintained

by an electronic temperature controller (PID capable) with

an accuracy of 0.2°C. The brewing groups are installed on

the boiler.

• Brewing Groups

They consist of a precision casting made of stainless steel.

The brewing group accepts the portafilter used to hold the

ground coffee; the espresso flows through the brewing

group, through the portafilter basket, through the portafilter

spout, and into the cup(s) after the brewing button has been

pressed.

4

La Marzocco, S.r.l. Firenze, ItaliaV1.3

Page 6

GB/5 - FB/80

3. Installation

English

Expa nsion Valve

Waste/Drain

Water Pump

Motor Powe r

Cord

Power

Supply Cord

Water Pump

and Motor

Electrical Supply

Connection

Water

Filtration/Softener

Drain Grate

Drain Tray

Water Sup ply

Connection

www.lamarzocco.com V1.3

Drain Hose

Connection

5

Page 7

3. Installation

1) Accessories

Check the package to make sure that the following

accessories are included:

English

• a number of 1-dose and 2-dose portafilters

corresponding to the number of groups;

• replacement 1-dose and 2-dose filters (one of each)

• 1 tamper

• 1 blind filter

• cleaning detergent, for the groups

• 3 stainless steel braided hoses for water connections

• 1,5 mt of reinforced plastic tubing for drainage

• 1 hose clamp

In order to proceed with installation, it is necessary that the

following are available:

a) Pipes carrying drinking water with a 3/8"G (BSP) end

connection; (3/8" Compression for USA and Canada)

b) Electrical Supply according to the specification of the

espresso machine purchased:

• Single/Three phase 220VAC - 50/60 Hz electrical

connection with ground, protected socket and approved

interlock switch

• Single phase 200VAC - 50/60 Hz electrical connection with

ground, protected socket and approved interlock switch

• Three-phase, 380VAC - 50/60 Hz electrical connection with

neutral + ground, near the bench on which the machine is

installed and terminating in a suitable protected fivepole

socket equipped with an approved interlock switch

c) Waste water drain system

NOTE:

The drinking water stopcock and the terminal switches for the

electrical system need to be located in the most convenient

position for the operator to access them easily and quickly.

pump is operating, otherwise air can be introduced into the

brew boiler causing an undesireable condition.

3) Electrical Connections

a) Power Supply Cord

Before making any electrical connections make sure

that the 2 strain relief connectors are firmly secured to

the body of the machine in order to prevent inadvertent

stress on the power cables.

This is the main power supply cable that provides power to the

entire espresso machine. There are different types of cable

based upon the electrical requirements of the espresso

machine purchased

• 200/220VAC 1 Phase 3-core cable with 2.5/4/6/10mm

cross section or AWG 12/10/8 (for UL version), secured to

espresso machine via a strain relief connector

• 220VAC 3 Phase 4-core cable with 4 mm2 cross section

for versions with 1, 2 , 3 and 4 groups secured to espresso

machine via a strain relief connector

• 380 VAC 3 Phase 5-core cable with 2.5/6 mm2 cross

section for versions with 1, 2, 3 and 4 groups secured to

espresso machine via a strain relief connector

b) Water Pump Motor Power Cord

This is the power supply for the water pump motor. The internal

electronics will switch the pump motor on when needed.

• 3-core cable with 1.5 mm2 cross section or 3-core AWG

16 (for UL version) secured to espresso machine via a strain

relief connector

3) Waste Water Drain Connection

The espresso machine drain is to be connected by means of

the included reinforced plastic tubing. Connect one end of the

reinforced plastic tubing to the drain hose connection on the

left side of the espresso machine, secure with included hose

2

2) Water Supply Connection

Connect the inlet of the water filter/softener to the drinking

water supply using one of the supplied stainless steel

braided hoses. Before connecting the water pump to the

espresso machine, flush the water supply line and the

filtration system in order to eliminate any residual particles

which could otherwise get stuck in taps or valves thus

preventing them from working properly.

Connect the water supply connection of the espresso

machine to the water pump outlet using one of the supplied

stainless steel braided hoses. Then connect the water

pump inlet to the water filter/softener outlet.

NOTE: The water pump is differential pressure, volumetric

pump and has been designed to be used exclusively with

cold water. Make sure that water is always present while the

HAZARDOUS VOLTAGE DISCONNECT FROM

POWER SUPPLY BEFORE SERVICING

6

The manufacturer declines any responsibility for any event

leading to liability suits whenever has

BEEN COMPLETED

and international regulations and electrical codes, or other

electrical parts have been connected improperly.

Do Not Connect To A Circuit Op erating At Mor e Tha n

clamp. Connect the other end to a suitable waste water

collection system. In case such a system is not available,

drained liquids may be collected in a suitable bucket and any

necessary drain pipe extensions shall be made using steellined PVC tubing and suitable hose clamps.

according to current local, national,

— U.S.A. and Canada Only —

150 V T o G rou nd

GROUNDING NOT

La Marzocco, S.r.l. Firenze, ItaliaV1.3

Page 8

GB/5 - FB/80

4. Operating the Espresso Machine and Preparing Coffee

1) Starting the Espresso Machine

a) Filling the Boilers with Water

Once the installation procedures have been completed, it is

necessary to fill the boiler tanks with water. Complete the

following procedure to properly fill the boiler tanks:

• Coffee Boiler

The water flows inside the coffee boiler directly, as soon as

the water system and water filter/softener taps are opened.

Since the inflow of water will compress the air in the boiler it

will be necessary to remove or “bleed” the air from the coffee

boiler. All air must be removed in order to completely “saturate”

the coffee boiler/group assemblies. To remove the air from

the boiler, “bleed the groups”, it will be necessary to remove

the cup tray from the top of the machine. First remove the cup

tray grates from the top of the machine exposing the cup tray .

Remove the screws securing the cup tray and then remove.

Once removed the top of the groups will be exposed.

2) Waiting for the Espresso Machine to Heat to Operating

Temperature

During this time, it may happen that the pointer of the coffee

boiler pressure gauge reaches as high as 14-15 bar. This may

happen anytime that the heating element is in the on condition.

In this case it is necessary to adjust the expansion valve (Fig. 3)

in such a way that the pressure may never exceed 1 1-12 bar. In

normal operating conditions, the coffee boiler pressure gauge

can read anywhere from 0-12 bar. When brewing, the pressure

should be set to 9 bar.

When the steam boiler reaches operating temperature, the light

on the Tea dispense button will light.

AV

When the espresso machine is ready to operate all lights on

the keypads will light.

AV

3)Installing the Portafilters

Install the portafilter(s) by inserting them into the group and

rotate the handle from left to right. When the portafilters are

inserted properly , you can press any of brew buttons to st art the

EE

EE

English

Loosen the bleed screws one at a time (see picture above)

to allow air to escape until water flows from below the screw

head. Tighten the screw to stop the water from flowing. Over

tightening can cause damage to the sealing washer and the

group cover. Repeat this procedure for all groups. Once all

air is removed from the coffee boiler, reinstall the cup tray by

following the removal instructions in reverse.

• Steam Boiler

Turn the main switch (item 1 in Fig. 1) to position “1” or ON,

the automatic steam boiler level gauge will be switched on,

activating the auto-fill solenoid valve and the motor pump.

This will fill the steam boiler to a predetermined level and will

shut off when full.

Note:

It may happen that the air inside the steam boiler builds up

pressure (which may be detected through the pressure gauge

- item 2, fig. 1) when the water is allowed to flow in; this “false”

pressure must be eliminated by opening the steam valves (item

9, Fig. 1).

b)Turning the Espresso Machine On

Once you have completed these procedures, check the display .

The message “Coffee Boiler Filled?” should be displayed.

Press enter to confirm that the preceding procedures are

complete.

The installation is now complete and the espresso machine

should be heating to the operating temperatures.

Portafilter

Basket

Portafilter

Portafilter

Spout

flow of water through the portafilter. You should allow hot water

to pass through the portafilter(s) for a few seconds each time,

in order to pre-heat the portafilter.

Note:

It is important to leave the portafilters installed in the espresso

machine when not in use. The portafilter must remain heated

for the brew process to function correctly.

4)Brewing Coffee

It is now possible to remove one of the portafilters to make an

espresso beverage. Place some ground coffee in the filter

itself: 1 dose (approximately 6 g) for the small filter, 2 doses (2

approximately 10-14 g) for the larger filter. Press down on the

ground coffee with the supplied tamper and install the filter

holder up again to the bottom of the group and then press a

button to begin the brewing process.

Note:

Some barista believe it is important to press the brewing button

prior to installing the portafilter to flush any remaining coffee

oils and particles from the group. Some also flush just after

brewing to do the same. Please experiment to make the best

possible procedure for your coffee.

www.lamarzocco.com V1.3

7

Page 9

4. Operating the Espresso Machine and Preparing Coffee

1)Controlling the Brew Process Using Volumetric

Programming.

This espresso machine allows the volumetric programming of

each of the first 4 buttons on each group (numbered left to

right). Please consult the Software Programming Manual for

English

further instructions.

2) General Notes for Coffee Preparation

The potafilters must remain heated since they are at the lowest

position of the group itself, and they are partially isolated from

the same due to the rubber gasket between them. This can be

accomplished by leaving the portafilters installed in the machine

when not in use. The portafilters may also be actively heated.

This procedure may be carried out by activating one of the brew

buttons to flush hot water through the portafilter then turning off

the water flow.

It is important to remember that coffee left over in the filters

must be removed only when you need to prepare another cup,

and only at that time should you place a new dose of ground

coffee in the filter.

The size of the coffee granules is extremely important in

preparing a good cup of coffee, other than the type of coffee mix

used, quite obviously. The ideal grinding can be determined by

making various coffees using the amount of ground coffee that

you would normally use for each cup (we recommend at least

6g). The best grinding is that which allows coffee to flow out

from the filter holder spouts neither too slowly , drop by drop, nor

too quickly. A general rule is that a double dose should dispense

approximately 2 fluid oz. of espresso in approximately 25

seconds.

Do not remove the portafilter when its relative group is brewing

hot liquids. The Coffee Boiler contains water at elevated

temper ature. Water temperature over 125 F / 52 ca n cause

severe burns instantly or death from scalding.

゚゚

C

IMPORTANT

To improve the flavor profile of the espresso, the temperature of

the water in the coffee boiler, and therefore of the groups, may

eventually be raised or lowered via the digital display (please

consult the Software Programming Manual for detailed

instructions).

8

La Marzocco, S.r.l. Firenze, ItaliaV1.3

Page 10

GB/5 - FB/80

1) Steaming Milk or Other Liquids

Dip one of the 2 steam wands (part 8, fig. 1) which are connected

to the steam valve, into the liquid to be heated, turn the steam

knob (part 9, fig. 1) gradually until steam comes out at the end

of the wand.

The steam will transfer heat to the liquid raising its temperature

up to boiling point.

Be careful not to allow liquid to overflow in order to avoid severe

burns.

In order to prepare milk for making cappuccino with the right

amount of foam, go through the following steps:

• Place the container half-full of milk under the steam wand,

open the steam valve and bring the temperature of the milk

almost up to 149/158° F 65/70° C.

• Lower the container so as to bring the wand end to a point

just below the surface of the milk; at this point, move the

container up and down just enough to dip the nozzle end in and

out of the milk until you get the right amount of foam. You can

then pour this milk into a cup containing warm espresso and

you will end up with a fresh cup of cappuccino.

In order to prevent the heated liquid from being sucked

back into the steam boiler it is recommended that you

purge the steam valve and steam wand by opening the

valve for a few seconds to allow steam to escape to the

atmosphere from the end of the steam wand. Failure to

do so can cause the heated liquid to transfer from the

heated liquid container to the steam boiler (via vacuum

created from cooling parts). This condition is

undesireable and can cause contamination in the steam

boiler.

5. Preparing Other Hot Drinks

English

2) Preparing Tea and Other hot Drinks.

You may dispense hot water by using the fixed nozzle (item 10

fig 1). To dispense hot water, press the tea water button on the

right most group.

AV

This button commands the hot water delivery. The volume of

water delivered may be adjusted via the display (see the

Software Programming Manual for further instructions). The

temperature of the water dispensed may be adjusted by

adjusting the mixing valve under the right side cover of the

espresso machine.

EE

www.lamarzocco.com V1.3

9

Page 11

6. Preventative Maintenance and Weekly Cleaning

The machine must not be dipped in, nor splashed with,

water in order to clean it. For cleaning operations,

please follow the instructions listed below very carefully.

English

1) Cleaning groups and drain wells

- Put a tablespoon of detergent powder for coffee machines

into the blind filter, supplied with the machine, and tighten it

onto the group you want to clean by using a normal filter holder.

Do not remove the portafilter when its relative group is brewing

hot liquids. The Coffee Boiler contains water at elevated

temper ature. Water temperature over 125 F / 52 ca n cause

severe burns instantly or death from scalding.

゚゚

C

- Activate the automating rinsing (backflushing) routine (see

the Software Programming Manual for more detailed

instructions)

- Rinse the group using a normal filter, by running hot water

through it several times.

2) Cleaning filters and filter holders

- Put 2 or 3 teaspoons of detergent powder for coffee machines

in about 1/2 a litre of water inside a heat-resistant container

and boil.

- Dip filters and filter holders in the boiled solution and leave

them fully submerged for about 30 minutes.

- Rinse thoroughly with clean water and run hot water through

one group several times with the filters in place.

- Make one cup of coffee and discard in order to remove any

unpleasant flavor.

3) Cleaning the drain collector

Remove the drain tray grill at least twice a week and clean, pull

out the water drain collector and clean it thoroughly. Inspect

and clean the drain well also, and remove any leftover grounds.

4) Cleaning the body

Wipe the stainless steel surfaces with a soft, non abrasive

cloth in the direction of the glazing marks, if any. Do not use any

alcohol or solvents whatsoever on painted or imprinted parts in

order not to damage them.

5) Cleaning the hot water and steam nozzles

Steam nozzles must be cleaned immediately after use with a

damp cloth and by producing a short burst of steam so as to

prevent the formation of deposits inside the nozzles themselves,

which may alter the flavor of other drinks to be heated. Hot

water nozzles must be cleaned periodically with a damp cloth.

6) Cleaning the Diffuser Screen

Due to filter holder discharge operations (subsequent to coffee

brewing), a certain amount of coffee grounds may slowly build-

Group

Assembly

Diffuser

Screen

Diffuser

Screw

up on and obstruct, even partially, the diffuser screen. To clean

it, you must first remove it by unscrewing the diffuser screw.

Put 2 or 3 teaspoons of cleaning detergent for coffee machines

in about 1/2 a litre of water inside a heat-resistant container

and boil. Place the diffuser screen(s) and diffuser screw(s) in

the solution and leave them fully submerged for about 30

minutes. Rinse thoroughly with clean water. Install and run hot

water through each group several times with the screen

installed.

7) Water Pump

Whenever you are brewing coffee, and you can adjust the pump

pressure by turning the by-pass screw (below the plug located

on the side to which the pump power supply is connected)

clockwise to increase and counter-clockwise to reduce

pressure. Adjust pressure only when at least one group is

brewing coffee.

Note:

When the heating element in the coffee boiler is energized, the

water will expand increasing the start-up pressure. Once the

maximum pressure is reached, the expansion (safety) valve

should start working by discharging a few drops of water, in

order to prevent such pressure from exceeding 11-12 bar.

In case the pressure exceeds 12 bar, you must adjust the

expansion valve by unscrewing the cap slightly. If this is not

sufficient, remove the valve and clear away any calcium

deposits. This remedy is valid also in case the valve remains

open in the drain position (i.e. the pressure cannot increase to

8 bar approx.).

8) Water Filter/Softener

Please see the documentation that accompanied the water

filter/softener for the proper operating and cleaning instructions.

10

La Marzocco, S.r.l. Firenze, ItaliaV1.3

Page 12

GB/5 - FB/80

1) De-Commissioning and Demolition

Start by setting the main switch to the “0” or OFF position.

Disconnecting from the power outlet

Disconnect the espresso machine from the electrical network

by switching off the associated circuit breaker or circuit

protection device. Remove the power supply cord from the

power connection. Remove the Pump Motor Power Cord from

the water pump motor.

Disconnecting from the water system

Shut off the water supply by closing the specific tap located

upstream of the water filter/softener inlet. Disconnect the water

pipe at the water filter/softener inlet. Remove the hose

connecting the espresso machine to the water pump. Remove

the reinforced plastic tubing on the drain connection.

At this point, the machine may be removed from the bar, being

very careful not to drop it or squash your fingers.

The machine is made out of various materials and therefore, if

you do not intend to put it back in service, it must be taken to a

special disposal company which will select the materials which

can be recycled and discard the others.

7. De-Commissioning and Demolition

English

Current regulations make it illegal to discard such machine by

leaving it on public grounds or on any private property.

Recycling notice:

Warning for the protection of the environment.

Old electrical equipment is made of

valuable materials, it is not normal

domestic waste! We kindly ask that our

clients to contribute to the protection of

the environment and natural resources

by delivering this equipment to the

relevant recycling centers, if they such

centers are available in their country.

www.lamarzocco.com V1.3

11

Page 13

8. History and Use of the “La Marzocco” Coffee Machines

La Marzocco has been producing espresso coffee machines

for use in cafés since 1927.

In February of 1939, when machines being manufactured were

exclusively of the vertical boiler type, “La Marzocco” designed

and built the first horizontal boiler machines, for which it obtained

English

a “patent”.

The Second World War brought an end to production of coffee

machines, and the fact that La Marzocco was a company of just

the right size (small-medium) allowed it to keep in touch directly

with its clients and specialty “cafés”, which meant being able to

get more accurate feedback information, concerning the needs

of the final consumer and market trends, which could then be

put into practice.

Throughout time, various machines have been designed and

built: of the type operating on “Water/S team” and on the principle

of “Hydrocompression”, and of the lever operated, air and steam

type; semi-automatic and automatic, with mechanical and

electrical actuators, up until current production which consists

of machines allowing continuous “brewing” operation.

PECULIAR CHARACTERISTICS OF LA MARZOCCO COFFEE

MACHINES

The great majority of the espresso coffee machines being built

today, of almost any brand, are of the “continuous brewing”

type, whose basic concept is to use the same water in the

tubing, directly to brew coffee by increasing its pressure

mechanically and heating it in advance. This has eliminated a

particular problem encountered with older machines, which

made use of water from the boiler, consisting of the “overheating”

of the brewing groups which, at times of heavy workload, would

give coffee a particularly unpleasant burned taste.

In any case, a good cup of coffee is the result of 4 highly

interdependent components, to such extent that if only one of

them is not quite in perfect harmony with the others, the resulting

cup of coffee will turn out not quite as pleasant in taste.

The 4 basic components are:

1. coffee bean mix;

2. water;

3. coffee grinder;

4. espresso machine.

1) Coffee Mix

Independent of the various qualities of coffee that make it up,

the type of toasting, etc., the freshness of the coffee beans and

the way they are preserved is very important.

For coffee beans to be used on espresso machines, it’s a

good rule of thumb to wait at least 8-10 days after toasting, so

that the beans may re-absorb part of the humidity they lost

during the toasting process itself, and to use coffee beans

within 3-4 days of opening their container.

2) Water

Within the limits imposed by the type supplied locally, water

should be free of bad savours and “softened” using a suitable

water softener in order to avoid calcium build-up; in any case,

hardness should not exceed 3-5 grains. If water tastes like

chlorine it is recommended that you use an actived carbon

filter.

3) Coffee Grinder

It must allow you to grind coffee beans in a wide variety of

granule sizes, in the most uniform manner possible and once

you have established the amount of ground coffee required for

each cup, the grinder must guarantee a constant amount from

dose to dose. It is best to grind coffee from time to time, trying

not to leave any ground coffee in the grinder overnight and during

days off.

4) Espresso Machine

Among other things, the espresso machine must guarantee

the following qualities:

a) the most appropriate water temperature for the type of coffee

mix used, constant in time so as to ensure that a good cup of

coffee may be prepared any time, whether you have to make

several, one after the other, or one from time to time.

b) a constant water pressure through the brewing group and

the coffee mix.

As far as the quality b) is concerned, it is usually obtained by

means of the same system in all the “continuous brewing” type

machines, that is by using a positive-displacement motor pump,

while quality a) can be obtained with various systems.

The great majority of manufacturers uses systems which are

very similar to one another. The underlying principle is to heat

up the water used for brewing coffee, which comes directly

from the pipes and is pushed by the motor pump, by running it

through coils or cartridges (small containers) which are located

in the boiler. It follows that the latter must be quite large, which

entails a noticeable power consumption, and the temperature

may be controlled exclusively through a pressure switch, a

device which is specifically designed for controlling pressure

and not temperature; indeed, the temperature changes every

time the water/steam ratio in the boiler changes, and even more

so when the latter is replenished with cold water.

It is quite obvious that the coils or cartridges which supply water

to the brewing groups are very sensible to the above changes.

Furthermore, the heat exchange between the main boiler and

the coil varies greatly when, as time goes on, conduction of

heat is reduced due to calcium deposits forming on the inside

and outside of coils or cartridges. In light of the above, and to

avoid wastage of electric energy required to keep large

quantities of water at operating temperature/pressure, when

only a small part is utilized, our machines have been designed

with 2 small boilers, of the size which is most suited to the kind

of services they have to offer.

One of them, a “STEAM GENERA TOR”, is used to deliver steam

and hot water for various drinks while the other, a “HOT WA TER

GENERATOR”, is used for the coffee. The latter, therefore,

produces hot water used exclusively for brewing coffee, which

will flow out, every time the specific group is activated, thanks to

the force of the cold water (actually produced by the positivedisplacement pump). The temperature of such water is

controlled by an electronic temperature controller and a

temperature probe. This system is extremely sensitive and

has an accuracy of 0.2 C, electronically adjustable to 1/10 of a

degree in order to adapt it to the optimal temperature, depending

on the type of coffee mix being used.

The brewing groups, work like thermal “flywheels”. They are

welded directly to the coffee boiler and are thus an integral part

of the boiler itself. The boiler assembly is shaped in such a way

that each group is located at a greater height than the boiler, so

that, just like in the elements of a thermosiphon, a natural

circulation of hot water takes place within each group, at the

same temperature of the boiler and kept constant by the

electronic temperature control system described previously . The

use of these small boilers, completely independent from one

12

La Marzocco, S.r.l. Firenze, ItaliaV1.3

Page 14

GB/5 - FB/80

8. History and Use of the “La Marzocco” Coffee Machines

another, the special manifold and fastening system of the

groups to the boiler as well as the electronic temperature

control, have allowed us to:

1) achieve an excellent thermal equilibrium between the

brewing groups, both at times of discontinuous operation and

during peak times;

2) be able to control the temperature of the water running

through the brewing groups, independently of the “pressure”

and the level in the small steam boiler, and therefore to optimize

the water temperature itself in order to obtain the best possible

coffee with whatever coffee mixes are available commercially;

3) save on electrical energy by more than 30%, in many cases,

when compared to other machines.

The “GB/5” series machines are produced in the 2, 3 and 4

group versions.

CONTROL SYSTEMS AND SAFETY DEVICES BUIL T INTO

“LA MARZOCCO” COFFEE MACHINES

All models are equipped with:

- automatic level regulator;

- automatic pressure regulator;

- automatic temperature regulator;

- safety devices

spring operated safety valve;

manual reset thermostats.

In all models, coffee is brewed by opening a solenoid valve,

one for each group. For the “EE” model, the quantity of coffee

brewed is regulated manually by the operator through a switch,

while in the “AV” model the quantity is regulated automatically

in 4 different doses, which may be programmed at will for each

brewing group. This last model is equipped with control panels,

one located above each group, with 4 buttons which may be

programmed in such a way that by pressing the 1st button you

get 1 regular coffee, pressing the 2nd one you get one weak

coffee (tall), pressing the 3rd you get 2 regular coffees and by

pressing the 4th one you get 2 weak coffees. The fifth button,

which has a spiral sign, allows continuous brewing operation

which can be interrupted by pressing the very same button again.

-Hydraulic test at 18 bar performed on the ready-to-use small

boilers, at our factory;

2) Description of the Steam Boiler (C.V . )

Composed of AISI 300 series stainless steel tube.

Heating is accomplished through an immersion-type plated

heating element.

-Operating pressure of 1.3-1.5 bar, controlled automatically

through a pressure switch or a temperature probe, adjusted so

as to open the heating element supply circuit at 1.5 bar and

close it at 1.3 bar.

-The pressure is displayed by means of a pressure gauge with

a scale of 0 to 2 bar.

-Safety device, based on an expansion type mechanical valve,

with counter-acting spring adjusted to 1.8 bar.

-Testing:

a) hydraulic test at 4.5 bar performed on the ready-to-use small

boilers, at our factory;

Capacity and Power Ratings

1) C.C.

- 2 groups 3.4 litres 1400 Watts

- 3 groups 5.0 litres 1600 or 1900-(HI-Power) Watts

- 4 groups 2x3.4 litres 2x1400 Watts

2) C.V .

- 2 groups 7 litres 2000 or 3000-(HI-Power) Watts

- 3 groups 11 litres 3000 or 4000-(HI-Power) Watts

- 4 groups 14.5 litres 3000/3800 or 5000-(HI-Power)Watts

English

CONSTRUCTION DETAILS

They consist essentially of 2 small boilers, of which:

1) Coffee Boiler (hot water generator for brewing coffee)

2) Steam Boiler (steam generator for producing steam and hot

water for making tea and other hot drinks)

1) Description of the Coffee Boiler (C.C.)

Composed of an AISI 300 series stainless steel tube.

Heating is accomplished through an immersion-type plated

heating element.

-Operating temperature 95° C (adjustable), controlled

automatically by an electronic temperature controller with an

accuracy of 0.2 °C. Operating pressure of 9 bar, developed

mechanically by a special positive-displacement pump which

is activated automatically every time coffee is brewed.

-Pressure is displayed through a pressure gauge with a scale

from 0 to 15 bar.

-Safety device, based on an expansion type mechanical valve,

with counter-acting spring adjusted to 12 bar.

-Testing:

www.lamarzocco.com V1.3

13

Page 15

HANDMADE IN FLORENCE

La M a rz occ o s.r.l.

Via Bolognese 68 Pian Di San Bartolo 50010 Firenze, Italy

t: +39.055.401.390 f: +39.055.401.349

e-ma il: flor ence@lamarzoc co.com

www.lama rzocc o.com

Loading...

Loading...