Page 1

USER MANUAL HEADLINES

Unpacking 2

Warnings 2

User responsibility 2

1. Speaker damage

2. Speaker output hazard.

3. Radio interference.

Introduction 3

1. Front panel

2. Rear panel

Installation 4

1. Mounting

2. Cooling

3. Operating voltage

4. Grounding

5. Power consumption

6. Input connections

7. Connecting speakers

8. Impedance matching (MLS-switches)

Operation modes 7

1. Stereo

2. Tandem mono

3. Bridged mono

4. Stereo reverse

Operation 8

1. Operation precautions

2. Powering up -Soft start

3. Input attenuators

4. Gain switch

5. Indicators

Protections 9

1. Clip-limiter

2. Thermal protection

3. VHF protection

4. Short circuit protection

5. AC mains voltage protection

6. D.C. protection

USER MANUAL

LAB 2002

Design features 10

• Cooling

• Light weight

• Regulated power supply

• Safety approvals

• EMC approvals

Specifications 11

•

EMC-declaration

Appendix A 12

•

Mains voltage selection

Maintenance 12

Troubleshooting 12

Warranty and disclaimers 13

• General

• International

Technical assistance and services 13

• International

• Factory services

1

Page 2

Unpacking

Carefully open the shipping carton and check for

any noticeable damage. Every LAB.GRUPPEN

amplifier is tested and inspected before leaving the

factory and should arrive in perfect condition. If

found to be damaged, notify the shipping company

immediately. Only the consignee may institute a

claim with the carrier, for damage incurred during

shipping. Be sure to save the carton and packing

materials for the carrier's inspection.

It is also advisable, to save the carton and packing

material, even if the amplifier is undamaged.

Should you ever need to ship the amplifier, use the

original packing.

Warnings

Read this before you are operating your amplifier:

• Do not use this amplifier if the power cord is

broken or frayed.

• Always operate the unit with the chassis

ground wire connected to the electrical safety

earth.

• Do not parallel or series connect an amplifier

output, with any other amplifier output. Do not

connect the amplifier output to any other

voltage source, such as battery, mains source,

or power supply, regardless of whether the

amplifier is turned on or off.

• Do not run the output of any amplifier back

into another channel's input.

• Do not block the air intake or exhaust ports.

Do not operate the amplifier near heat

producing devices such as radiators, stoves etc.

• Do not spill water or other liquids into or on

the unit. Do not operate the amplifier if

suspected or standing in liquid.

• Do not remove top or bottom covers. Removal

of the cover will expose hazardous voltages.

There is no serviceable parts inside and

removal may void warranty.

• Keep this manual for future reference.

User responsibility

1. Speaker damage

Your amplifier is very powerful and can be

potentially dangerous to both loudspeakers and

humans alike. Many loudspeakers can be easily

damaged or destroyed by overpowering, especially

with the high power available from a bridged

amplifier. Always check the speakers continuous

and peak power capabilities.

Even if the gain is reduced by using the amplifier's

front panel attenuator, it is still possible to reach

full output power, if the input signal level is high

enough.

2. Speaker output hazard

Power amplifiers are capable of producing

hazardous output voltages. To avoid electrical

shock, do not touch any exposed speaker wiring,

while the amplifier is operating. See page 6 about

outputs for proper connection of speakers.

3. Radio interference

This product has been tested, and complies with the

limits for the European Electro Magnetic

Compatibility (EMC) directive. These limits are

designed to provide reasonable protection against

harmful interference between electrical equipment.

This product uses radio frequency energy, and if

not used or installed in accordance with the

operating instructions, it may cause interference to

other equipment, such as radio receivers. However,

there is no guarantee for no interference even if the

amplifier is EMC approved.

If the amplifier cause interference, which can be

easily determined by turning the amplifier on and

off, the user can correct the interference by one or

more of the following steps:

1. Increase the proximity between the equipment.

2. Connect the AC cord to an outlet on a different

circuit from that to which the affected unit is

connected.

3. If a radio receiver is interfered (normally

amplitude modulation); reorient the antenna.

4. Check if the affected unit complies with the

EMC limits for immunity, (CE-labelled).

If not, address the problem with the manufacturer

or supplier. All electrical products sold in the EC

must be approved for immunity against

electromagnetic fields, high voltage flashes, and

radio interference.

2

Page 3

-80-40-

-

-12-

Introduction

Thank you for purchasing a LAB.GRUPPEN power amplifier. The amplifier you have chosen is the culmination

of many years of Research and Development. This amplifier makes amplification more controllable instead of

the traditional "Boring black box" you have become accustomed to.

Please take some time and read this manual to familiarize yourself with the advanced features of this amplifier.

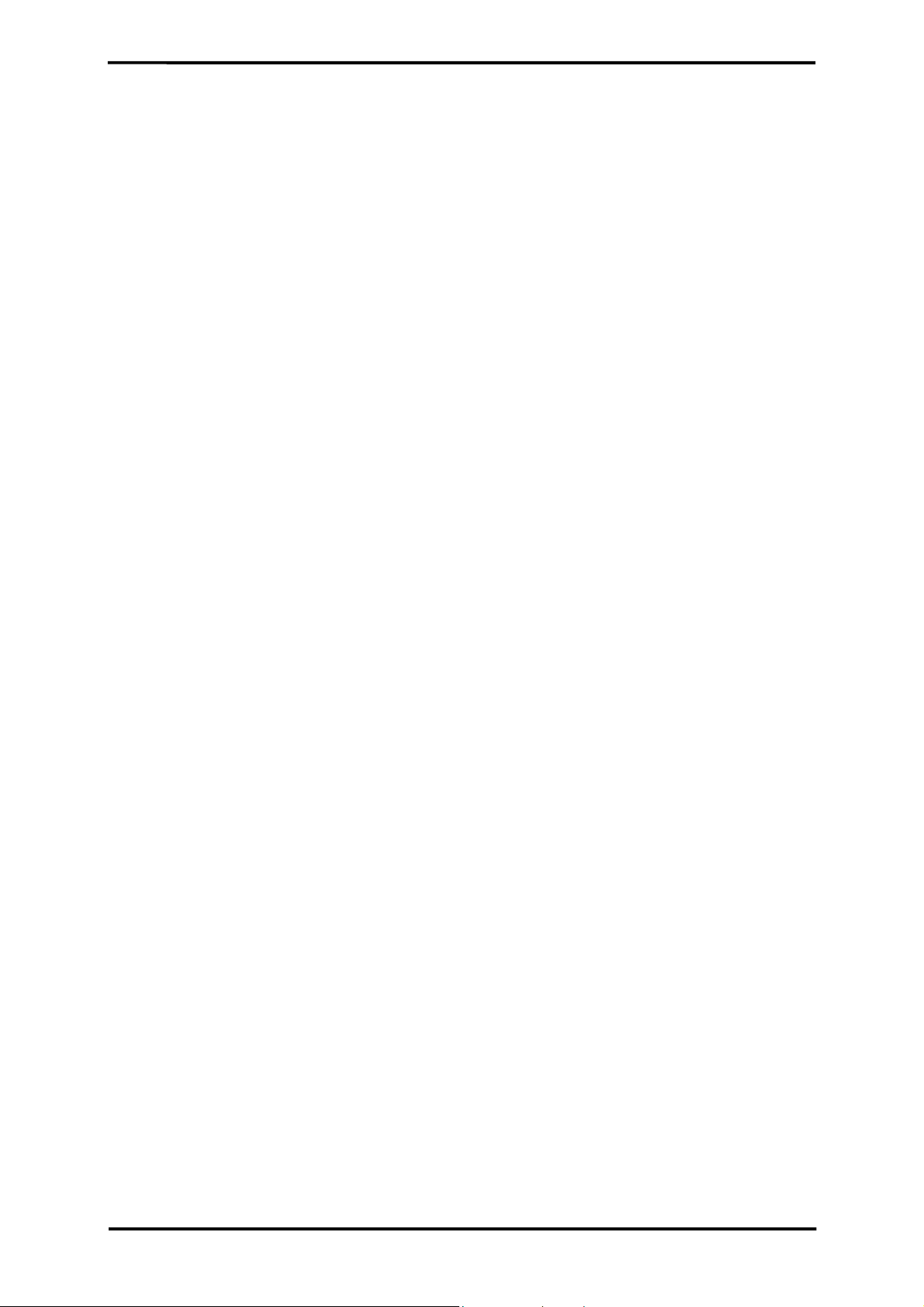

The front panel

6

-20

4

3

CH. A

-10

-7

-12

-5

-16

-3

-1

-40

-80

0

dB

VHF

TEMP

CLIP

-5

-10

-15

-20

-25

ON

2002

5

CH. B

10

-7

16

-5

-3

20

-1

0

dB

CONVERTIBLE POWER AMPLIFIER

6

1

2

Figure 1. Front panel

1. Carry/protection handle

Both handles can be used to carry the amplifier, they

also act as protection for the front panel. If so desired

they can be removed (by removing the screws behind

the front panel) for fixed installations, or racks where

the front covers are to shallow.

2. Input level attenuators

These controls are used to alter the signal level

entering the amplifier. They are calibrated in dB to

help set up active loudspeaker systems or cut down

unwanted noise from the input signal.

(See page 8).

3. Over temperature protect indicator.

This indicator is lit if the amplifier tries to operate

o

above its maximum operating temperature(90

C).

The indicator first comes on as a warning to either

turn down the input level or check the cooling

arrangements after which point the amplifier will

mute the input signal. When the cooling fans have

returned the output heat sinks to the normal operating

temperature the input signal is unmuted.

The rear panel

1

4

5

6

2

7

4. VHF protect indicator

This indicator lights when constant signals, above 12

kHz at full power, are present at the output terminals.

When this happens the input signal is muted and the

process cycles until the VHF signal is no longer

present. (See page 9).

5. Clip/limit indicator

This indicator tells when the amplifier output is

clipping or limiting. The two different states can be

told apart:

• When the clip limiter is engaged it flickers

briefly. (See page 9).

• When the clip limiter is not engaged it lights for

a longer period.

6. Fan grill filter.

A foam filter is located behind the front panel to

prevent dust entering the amplifier.

7. Power actuator

This is used to start the amplifier.

(See page 4 and 8)

8

5

7

4 1

INPUT

OUTPUT CH.B

1+ CH.B+

1- CH.B-

2

CH. B

B

.

l

o

P

1/4“

230V AC 40-4 40Hz

Power consumption: 1700 watts

l

a

m

r

o

N

h

c

t

S

i

L

w

S

M

B

d

0

-2

-4

-5

On

Clip LimiterClip Limiter

Off

Made in Sweden

XLR

Pin 1 Gnd Sleeve

2 Po s Tip

3 Ne g Ring

Must be grounded

3

B

.

l

o

P

e

s

o

r

e

e

r

v

e

t

e

S

R

Mono Bridge

CH. A

B

B

d

d

B

9

8

+

2

3

A

n

n

k

i

i

n

a

a

i

L

G

G

On

Off

Clip Limiter

Clip Limiter

SE 9003426

Patents

2002

9

EP 0483094

US 5200711

3 2

Ser. N:o

Removed!

OUTPUT CH.A

h

c

t

S

i

L

w

S

M

B

d

0

-2

-4

1+ CH.A+

-5

1- CH.A-

Figure 2. Rear panel

3

Page 4

Please refer to diagram on page 3

1. Speaker connector

This type of speaker connector may be unfamiliar to

some users. A full description is found in the

operation section. (See page 6).

2. Minimum load selector (MLS™) switches

These switches are used to select the minimum

nominal speaker impedance the amplifier is going

to drive. (See page 7).

3. Clip limiter switch.

Turns the clip limiter on and off. (See page 9).

4. Input jack

Alternative to using input XLR or for linking inputs

with other amplifiers. (See page 6).

Installation

1. Mounting

The amplifier is two rack units high (2U) and will

mount in a standard EIA 19 inch rack. Amplifiers

may be stacked directly on top of each other. There

is no need for spacing between units. If it is the

intention to fill a rack with amplifiers, we

recommend racking is started from the bottom of

the rack. It is also recommended that rear supports

are used for amplifiers mounted in the middle of the

rack, especially if used as part of a portable system.

2. Cooling

Your amplifier uses forced air cooling system to

maintain a low and even operating temperature. All

LAB.GRUPPEN amplifier, which are fan

ventilated, have front to rear cooling. There are

several reasons for this, one is that there's usually

cooler air outside the rack than inside and therefore

the amplifiers can run at higher continuos power

levels without thermal problems. Never try to

reverse the air flow, as the Intercooler® need a

pressure chamber between the fans and heat sink,

and this only works in one direction of the air flow

(see Design features on page 8).

Should a heat sink get too hot, its sensing circuit

will mute the hot channel. If the power supply

overheats, another sensing circuit will mute all

output channels, until it cools down to a safe

operating temperature.

Make sure that there is an adequate air supply in

front of the amplifier and that the rear of the

amplifier has sufficient space to allows the exhaust

to escape. If the amplifier is rack mounted, do not

use covers or doors on the front or rear of the rack.

For fixed installations with a central cooling

system, usually found in fixed installations with a

dedicated rack room, it may be necessary to

calculate the maximum heat emission. Refer to

Power consumption on page 5.

5. Input signal XLR (See page 5).

6. Phase reverse switch for channel B

For reversing the input signal phase of channel B to

allow bridged operation. (See page 7).

7. Link switch

Allows a single input to drive both channels

simultaneously. (See page 7).

8. Gain select switch

Allows amplifier gain to be switched between 29dB

and its normal gain at 0.775mV input sensitivity.

(See page 8).

9. AC line cord (See this page )

3. Operating voltage

A label just below the mains cable on the rear of

the amplifier indicates the AC mains voltage, for

which the amplifier is wired. Connect the power

cable only to the AC source referred to on the label.

The warranty will not cover damage caused by

connecting to the wrong type of AC mains.

For converting a 230 volt amplifier to 115 volt or

vice-versa, see Appendix A.

LAB.GRUPPEN switch mode amplifier use

primary switching, i.e. the mains is rectified

directly before the transformer, which means that

the power supply is insensitive to the mains

frequency and will operate from DC to 400 Hz.

The amplifier is supplied with an approved European

AC line connector. If this connector is not

appropriate for your country, it can be cut off and

wired to a suitable connector in the following way :

BROWN LIVE

BLUE NEUTRAL

GREEN/YELLOW EARTH

Once the AC connector is connected to a suitable AC

supply, the amplifier can be started with the AC

actuator. When you power up the amplifier it takes a

couple of seconds to check its circuits (this is known

as the "soft start" or "slow start" sequence), the fans

then blow at high speed before going onto "idle" and

the 2 bottom green LED’s come on to show the

output circuits are receiving the correct rail voltage.

4

Page 5

4. Grounding

There is no ground lift switch or terminal on this

amplifier. The signal ground is always floating via a

resistor to chassis and the grounding system is

automatic. If a potential above 0.6V presents itself

between signal ground and chassis ground, a short

circuit is introduced between the two, thereby

enabling electrical protection. If a unit in the system

is faulty, its mains fuse will blow, due to this

automatic ground system.

If however you wish to tie the signal ground to

chassis, connect the XLR-connector’s shell lug to

pin 1. In the interest of safety never disconnect the

earth pin on the AC cord.

For all units that are EMC approved (radio

interference), there is an AC mains filter. This filter

needs the chassis ground for reference, otherwise a

current loop is formed via the signal ground.

Use the balanced input to avoid hum and

interference.

5. Power consumption

There are three ways to determine the

power/current consumption of the amplifier:

First, the peak current draw at full output

power. Under this condition the power will trip the

wall breaker within 30 second and the amplifier

will operate for less than 2 minutes before

thermally limiting. During this time, the

temperature of the power supply will be stabilised

at a temperature that will have no effect on the

insulation rating of the AC line cord.

Secondly, the maximum expected average

current under worst case program material which is

1/3 of full power according to the FTC-standard. At

this level the music will be in the state of constant

clip and is therefore the highest power level one

can obtain without completely obliterating the

program.

At last, the "normal operating power", as

measured according to the safety standard IEC 65

and used by a majority of safety agencies. The

normal operating power is measured using pink

noise, with an average output power equal to 1/8 of

full power. The one eighth of the total power is as

loud as you can play music while making some

attempt to avoid obvious clipping. It also

corresponds to a headroom of 9dB, which is very

low for an audio program.

In 2 ohms operation, the protection of the amplifier

circuit will not permit long term current draw and

the component temperature rise will stabilises well

below the rating.

MAX OUTPUT POWER MAINS INPUT POWER

Power Full Power 1/3 Power 1/8 Power Idle

sine wave note 1 note 2

LAB 2002

note 1

8 ohms 2X 1100 3100 1300 700 130

4 ohms 2X 1400 4300 1700 900 130

2 ohms 2X 1400 4700 1700 900 130

Average power with music as program source Normal" music power with 9dB headroom,

The amplifier driven to clip level

note 2

IEC standard power rating.

Table 1.

The current draw can be calculated by dividing the mains input power by the mains voltage.

We recommend you to design the power distribution for at least the current at 1/8 power and 1/3 power for

heavy duty demands like discos etc.

The heat power can be calculated as the following example:

We consider a headroom of at least 9dB and a 4 ohms load on an amplifier producing 1400 watts per channel.

The 1/8 power per channel is then; 1400 / 8 = 175 watts, total output; 2 x 175 = 350 watts.

The power consumption according to the chart above is then 900 watts.

The heat power produced is the difference between the power consumption and output power;

900 - 350 = 550 watts per amplifier.

6. Input connections

XLR Input connectors are balanced and wired

according to the IEC 268, that is pin 2 hot, and wired

in the following way:

PIN 1 GROUND/SHIELD

PIN 2 HOT

PIN 3 COLD

Figure 3. XLR input connector pinout

5

Page 6

There are also TRS jacks for linking etc. They are

wired as follows:

TIP HOT

RING COLD

SLEEVE SHIELD/GROUND

balanced line. To minimize hum in the audio, use

balanced inputs whenever possible.

Figure 4. TRS phone plug

The input impedance is high enough (20 kohms

balanced) to allow ”daisy-chaining”, or multiple

parallel input connections. To daisy chain, use the

TRS jacks provided on each channel. The input

circuits also have a high enough headroom, to accept

the maximum output level from virtually any low

level signal source.

XLR

Pin 1 G nd Sleeve

2 Pos Tip

3 Neg Ring

Must be grounded

Figure 5. Rear panel connectors

CH. B

1/4“

B

.

l

o

P

l

a

m

r

o

N

Mono Bridge

230V AC 40-4 40Hz

Power consumption: 1700 watts

INPUT

B

.

l

o

P

e

s

o

r

e

e

r

v

e

e

t

S

R

CH. A

B

B

d

d

B

9

8

+

2

3

A

n

n

k

i

i

n

a

a

i

G

L

G

2002

Do not use XLR and TRS jacks on the same

channel simultaneously for mixing or other

purposes.

Figure 6. Balanced line

To connect an unbalanced source, tie pin 3 (ring on

TRS jack) down to the shield of the connector. If you

leave one pin disconnected, you will lose 6 dB in

gain.

Figure 7. Unbalanced line connection

A more optimal method for handling unbalanced

sources is shown in Figure 8.This is similar to the

connection for balanced lines, but pin 3 is tied down

to shield, at the source side instead. The hum and

noise rejection for the cable is equivalent to that for a

Fi

gure 8. Balanced line with unbalanced equipment

7. Connecting speakers

Speaker connections are made via the two Neutrik

NL4FC Speakon connectors (1).

They are the only connectors currently available to

meet the EC safety requirements. They are wired in

the following manner:

Pin -1 Speaker ground.

Pin +1 Speaker positive.

Pin -2 No connection.

Pin +2 No connection.

Figure 9. Speakon connector

Please note that this is the standard wiring

convention for Speakon connectors adopted worldwide.

Never connect either output terminal to ground

or to some other output or input terminal (see

warning on page 2).

For normal two-channel operation, connect each

speaker load across the outputs positive and ground

terminals. Pay attention to speaker polarity;

loudspeakers connected out of polarity degrade

sound quality and may be damaged as a

consequence.

Keep the speaker cable wires as short as possible,

and use a good quality stranded speaker cable. Do

not use shielded wire, such as microphone or guitar

cable. Remember that the speaker cable robs the

power of the amplifiers in two ways:

Increases the load impedance and introduces

resistive power losses, so called I

2

R losses.

6

Page 7

8. Impedance matching (MLS-switches)

The MLS switches is located on the rear panel. The

MLS ( Minimum load select ) switches offer a

impedance matching, so you can drive the

LAB 2002 in 2 ohms without increased heat losses.

Utilising higher MLS

TM

positions when connected to lower impedance's

As stated earlier

1100 watts into any impedance between 1.5 and 8

ohms. This is done with the aid of the MLS

switches ( 2 ).

The fixed positions shown in Table 2. guarantee

1400 watts but higher powers can be achieved

see Table 2.

As you can see from Table 2 the LAB 2002 can produce in excess of

1400 watts.

LAB 2002

LOAD CONFIGURATIO N -5 dB -4 dB -2 dB 0 dB

16 ohms Stereo (2 channel) 160 W 180 W 340 W 520 W

8 ohms Stereo (2 channel) 300 W 350 W 650 W 1100 W

4 ohms Stereo (2 channel) 570 W 680 W 1100 W 1400 W

2 ohms Stereo (2 channel) 1040 W 1200 W 1200 W 1400 W [ 1]

16 ohms Bridged mono 600 W 700 W 1300 W 2000 W

8 ohms Bridged mono 1200 W 1400 W 2200 W 2800 W

4 ohms Bridged mono 2100 W 2400 W 2400 W

MLS SWITCH SETTING

1400 W [2] 2900 W [2]

1900 W [2]

2800 W

1

the LAB 2002 can produce at least

OUTPUT CH.B

h

c

t

S

i

L

w

S

M

B

d

0

-2

1+ CH.B+

1- CH.B-

-4

-5

TM

[1] Component tolerance dependent

[2] Continuous power, one channel driven or peak power both channels driven.

(Thermal protection may occur at high continuous power).

Power in watts (EIA 1 kHz, 1% THD)

Table 2.

TM

MLS

positions can be different for each channel

and a variety of combinations can be achieved see

Table 3.

Channel Impedance MLS Power Comments

A 8 -2dB 650W Power

B 8 -2dB 650W reduction

A 4 0dB 1900W High peak

B 4 0dB 1900W power

A 8 0dB 1100W Power

B 2 -4dB 1200W matching

A 8 -2dB 650W Power

B 4 0dB 1900W sharing

Table 3.

Operation modes

1. Stereo operation

For stereo (dual channel ) operation, leave the Link

and Phase reverse switches in the undepressed

position. In this mode, both channels operate

independently of each other, with their level

attenuators controlling their respective levels.

Never connect either output terminal to ground

or in parallel. The recommended minimum

nominal impedance, for stereo or tandem operation,

is 2 ohms per channel.

2. Tandem mono

For tandem ( dual channel-single input) operation ,

depress the Link switch. Both channels can now be

driven by a signal, at either input connector. The

output connection is the same as in stereo mode.

Figure 10. MLS switches on rear panel

The way to find the best MLSTM position for your

application is by experimentation, the amplifier is

very well protected (even down to 0.3 ohms), but

where speed is of essence stick to the fixed positions.

The thing to remember with the LAB 2002 that it is a

power converter and when you select MLS

TM

positions you are allocating a portion of power from

3000 watts.

You can use either TRS connectors for linking out

etc. Do not use the remaining XLR and TRS

connectors for mixing or other purposes. Both

level attenuators are active, allowing you to set

different levels for each channel.

Never connect either output terminal to ground

or in parallel.

3. Bridged mono

To bridge the amplifier, depress the Link switch (7)

and Phase reverse switch (6). Both channels are then

driven by a single signal at either input. You can

use any remaining input connectors for linking etc.

Do not use the remaining XLR and TRS as input

jacks simultaneously for mixing or other purposes.

7

Page 8

T

To obtain an output, connect the speaker leads to pin

+1 on channel A Speakon to speaker positive

terminal and pin +1 on channel B Speakon to

speaker negative terminal . Do not connect either

of the -1 (negative) pins of the Speakons. Do not

connect speakers to channel A or B in the normal

manner in bridge mode, as this can cause serious

damage.

The recommended minimum nominal impedance

for bridged mono is 4 ohms (equivalent to driving

both channels at 2 ohms).

Driving bridged loads of less than 4 ohms may cause

a thermal overload.

Figure 11. Bridge mono connection

Both level attenuators must be at the same position.

We recommend you to put them in the 0 dB (full)

position.

4. Stereo reverse

This mode is similar to the Tandem mono mode.

Apart from depressing the Link switch , you also

depress the Phase reverse switch, like in the Bridge

mono. Channel B is now phase reversed. To

compensate for that, connect pin +1 on channel B

Speakon to speaker negative terminal and pin -1

on channel B to speaker positive terminal.

Figure 12. Stereo reverse mode

Channel A output is connected as in the normal

stereo mode. By having channel A and B operating

in opposite polarity, the energy storage in the

power supply is more efficient. This means that the

amplifier can deliver up to 10% more power than in

tandem mono mode. This is significant for signals

below 100 Hz (sub bass etc.).

Operation

1. Operation precautions

• Make sure that the power switch is off before

making any input or output connections or

operating the switches on rear panel. See pages

4-6 about installation.

• Make sure that the AC mains is correct and the

same as that is printed on the rear panel of the

amplifier. See pages 4-5 , about operating

voltage and power consumption.

• Make sure that the switches on the rear panel

for operation modes ,clip limiters, and the

MLS™ switches are in the correct position.

See pages 6-7, about operation modes, page 9

about clip limiters and page 7 for the MLS

switches.

• It is always a good idea to turn down the gain

controls during power up, to prevent speaker

• damage, if there is a high signal level at the

input.

2. Powering up -Soft start

When you power up the amplifier it takes a couple of

seconds to check its circuits (this is known as the

"soft start" or "slow start" sequence), the fans then

blow at high speed before going onto "idle" and the

two bottom green LED’s come on to show the output

circuits are receiving the correct rail voltage.

3. Input attenuators

The two input level attenuators on the front panel,

alter the signal level for their respective amplifier

channel in all modes. They are calibrated in dB to

help setting up active loudspeaker systems or cutting

down unwanted noise from the input signal.

In bridged mode, both controls must be in the same

position, so that the speaker load will be shared

equally between the channels.

4. Gain switch

The gain switch located on rear panel is for changing

the input sensitivity of the amplifier. This can be

handy when using low or high nominal input signals

e.g. most professional mixing consoles operate at a

nominal level of +4dBu therefore use the 29dB

position (depressed switch), to give you plenty of

fader movement. On the other hand, for a disco

mixer that operates at a nominal level of 0dBu, use

the upper position setting, which has a sensitivity of

0 dB for full power in 4 ohms.

VHF

EMP

CLIP

-5

-10

-15

CH. A

-10

-12

-16

-20

-40

-7

-80

0

dB

-20

-25

ON

-5

-3

-1

2002

CH. B

-10

-12

-16

-20

-40

-7

-5

-3

-80

-1

0

dB

8

Page 9

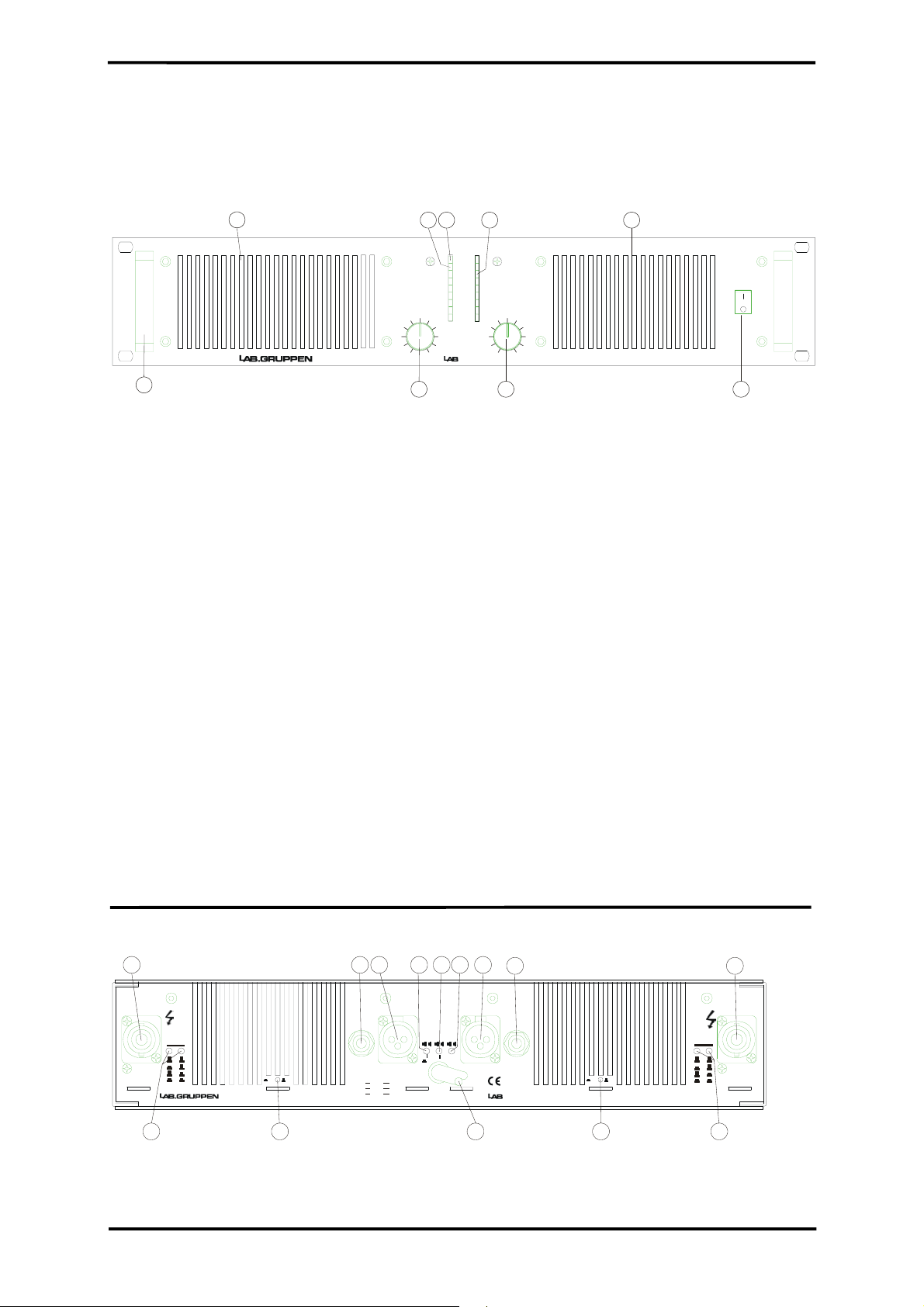

Figure 13. Front indicators

5. Indicators

The two bottom green ”ON” LEDs indicate that the

output circuits are receiving the correct rail voltage.

The ”-25 dB” LEDs glow when the output signal is

greater than -25dB, 0dB is referenced to full output

power. These LEDs also act as signal present

indicators.

The rest of the green LEDs forms a bar for output

levels from -20dB to -5dB.

Protection features

Each LAB.GRUPPEN amplifier has many advanced

protection features, that will protect both the

amplifier and the speakers connected to it, should a

fault condition arise. Under normal use these features

are inaudible. All protection circuits are independent.

Clip limiter

The clip limiter is included to prevent dangerous clip

signals reaching the speaker and damaging it. It

works by monitoring the output and comparing the

distortion produced between the input and output of

the amplifier. If the distortion exceeds 1%THD for

any reason ( voltage or current clipping), the limiter

reduces the input signal proportionally. Note that, if

the signal is distorted or clipped before it reaches the

amplifier, the clip limiter will not be activated.

Under normal operation the clip limiting is inaudible.

The limiter can be turned On or Off by depressing

the relevant clip limit switch (2). Some

manufacturers of Loudspeaker processors do not

recommend the use of clip limiters in amplifiers, as

they tend to upset the tracking of the processor’s

limiters.

Apart from this one exception, LAB.GRUPPEN

recommend leaving the clip limiters switched "on"

(button depressed).

As a by-product, when the amplifier comes out of a

protect condition, the output level has a slow rise

time -the effect is like turning the gain up slowly.

Thermal protection

When the amplifier is driven very hard into low

impedance, the cooling fans go into high speed. If the

conditions that cause this continue, the temperature

indicator(s) will light as an indication that the

amplifier will soon thermal out.

After five seconds the amplifier will go into thermal

protect, by muting the input signal. After 15-20

seconds the amplifier will cool down the

Intercooler

Thermal protection starts when the Intercooler

reaches a temperature above 900 C

®

and the cycle will begin again.

®

The Clip/limit indicator tells when the amplifier

output is clipping or limiting. The two different states

can be told apart:

• When the clip limiter is engaged it flickers

briefly.

• When the clip limiter is not engaged it lights for

a longer period.

The remaining yellow LEDs indicate if any

protection circuits are activated. These are described

below.

VHF protection

When a signal of more than 12kHz, at full output

power, is present at the output connectors for more

than five seconds, the VHF protection mutes the

input signal (this is indicated on the front panel (4)

labeled VHF). After five seconds the cycle starts

again.

This is a useful feature as there are currently no

commercially available compression drivers that can

take 500 watts of power at 10 kHz!! this circuit is

inaudible under normal use, however it can be turned

off.

If the VHF protection is required to be turned off i.e.

for studio monitors, please consult your supplier, as

this is a non-user adjustment.

Short circuit protection

All LAB.GRUPPEN amplifiers are completely

short circuit protected. The protection circuit

permits very high peak currents, but still holds the

output devices within the safe operation area. If a

short circuit is maintained, the channel affected will

eventually go into thermal protection and the cycle

will start again.

AC mains voltage protection

If the AC mains voltage is outside the allowed

operation voltage ( over or under voltage) , the

power supply will shut down itself. When the

mains voltage is above the minimum start voltage

and below its maximum operating voltage the

amplifier will restart again.

It takes a couple of seconds to check its circuits (this

is known as the "soft start" or "slow start" sequence),

the gain will slowly and gradually raised back to

normal, and the fans then blow at high speed before

going onto "idle". The two green ”ON” LED’s

indicate when then power supply is operating

properly.

D.C. protection

There are two types of DC protection:

Fuses on the supply branches of each channel (this is

an IEC 65 requirement).

A Crowbar bar protection that shorts the output. Both

these circuits come into effect once a DC level of 10

volts or more is detected on either channel.

9

Page 10

Design features

Cooling

The LAB.GRUPPEN amplifier runs very cool due

to a patented heat sink called Intercooler

output devices (bi-polar) are mounted directly on a

copper heat sink thereby avoiding thermal losses

normally found when using mica washers (the heat

sink is mounted horizontally in front of a pressure

chamber) The air flow is constant along the whole

heat sink,

thanks to a horizontal pressure chamber in front of it,

(in a conventional tunnel design the end of the heat

sink opposite to the fan invariably gets hotter than

that directly in front of the fan). When cool air hits

the geometric fins of the Intercooler

produced thereby enabling efficient cooling.

Light weight

The switch mode amplifiers has a very good power

to weight ratio, (280w/Kg) making it one of the most

powerful 2u amplifiers available.. The light weight is

achieved not only by the PSU, but the Intercooler

and the 9 piece anodized alloy chassis contribute

greatly, rear rack supports are unnecessary in most

applications.

Switch mode power supply (SMPS)

Switch mode power supplies are the modern

solution to the problems of size and weight.

However, early examples of SMPS used in power

amplification were not ground breaking, and l

literally adopted the type of supply found in many

computers today. The LAB.GRUPPEN SMPS is

different in that it is regulated.

How is this achieved? In contrast to other designs,

that use push pull or series resonant converters we

have managed to produce a SMPS that has the

same characteristics as a conventional supply. We

have avoided the pitfalls of push-pull converters,

by eliminating the need for limiting on the

secondary side of the switch transformer. This is

achieved by using sense windings, injecting a

magnetic pulse from the AC- line during a pulse

time segment which is separated from the output

charge current pulse.

TM

. The

TM

, turbulence is

TM

90

80

70

60

50

40

Voltage [V]

30

20

10

0

0 5 10 15 20 25 30 35 40 45 50

Figure 14. Current-voltage characteristic of different power

supply topologies.

1) Conventional power supply show voltage drop due to

internal resistance

2) Regulated power supply used by LAB.

3) Unregulated switch mode power supply with current

limiting.

Current [A]

2

1

3

Whilst the SMPS may sound complex it is actually

very straight forward with high reliability. The net

result is good bass and fast response. Because the

supply is regulated, the power amplifier will

produce the same power output even if the AC line

falls by more than 20% !

Efficiency is also assured, and in the case of the

LAB 2002 this is especially apparent ; its power

supply draws only 4 kW and yet it produces 2 x

1400 W (in a conventional amplifier this would

yield only 2 x 650 W- nearly 3 kW are wasted as

heat.

Traditional PSU’s behave erratically at certain

frequencies, during low frequency cycles (bass),

particularly in clip conditions, their output

impedance's rise thereby producing uncontrollable

speaker cone movement. Under these conditions clip

states are more audible.

LAB.GRUPPEN SMPS produces its rated power

output at all frequencies regardless of speaker

demands and AC line conditions.

Minimum Load Switches (MLS

(TM)

)

Thanks to the regulated SMPS, the maximum

power available for the output stages can be

adjusted without increased heat dissipation or

efficiency loss. This allows users to match the

output power with the loudspeaker impedance.

The LED bargraph is also adjusted to give a correct

reading. Because the amount of power delivered into

a load is dictated by its impedance (at 2 ohms you

use the least voltage but use the most current), you

can cheat with the MLS switches thereby enabling

powers in excess of the normal power rating to be

produced.

10

Page 11

Safety approvals

LAB.GRUPPEN amplifiers are designed to meet the

IEC65 (now called EN 60 065), a stringent electrical

safety approval from the International Electro-

technical Commission. The IEC65 is recognized

world-wide with most countries having an

equivalent.

EMC approvals

EMC stands for Electro Magnetic Compatibility. This

implies that the equipment should have low emission

of radio frequencies, directly as electromagnetic fields

in the air, and as conducted from the cables from and

to the unit. The unit should also be able to handle

electromagnetic fields, high voltage flashes, and radio

interference, coming into the unit via the air or cables.

Emission

The regulation now cover the frequency range from

150 kHz to 300 MHz. The maximum level radiated

from a unit has to be below 100 µV, ( 0.0001 V ).

Immunity

The equipment should be able to handle three

different types of interference:

EMC-declaration

This audio power amplifier conforms with the

EMC-directive and relates to the following

standards:

EN 55 103-1, E3

• Electrostatic discharges up to 8 kV, hitting the

chassis or cables.

• Transients and bursts up to 1 kV, conducted

through the cables to the unit.

• Electromagnetic fields up to 3 V/m, radiated on

the unit and the cables in the frequency range of

27 - 500 MHz.

We have extended the tests in two cases and chosen a

standard used for heavy industrial situations. First, we

have tested conducted disturbances in the frequency

range 150 kHz - 80 MHz, by injecting 3V amplitude

modulated (80%) signals into all the cables ( inputs,

outputs and mains ). This covers noise from AM

transmitters, which are still in use in some areas.

Secondly, we have extended the range for

electromagnetic fields to 26 - 1000 MHz, with a level

of 6 V/m and 80% AM modulated.

In the range 895 - 905 MHz, we test with a field

strength of 35 V/m and 100% pulse modulation.

emulate the signals from a mobile phone close to the

unit. In all cases the noise plus distortion is below 1%,

at normal operation level, ( normal operation level is

1/8 of full power or -9 dB under clip point according

to IEC 65).

EN 55 103-2, E3

EN 60 065, class I

This

11

Page 12

Appendix A

Mains voltage selection

LAB 2002 is normally shipped for 230 volt AC

operation only. For export there is a 115/230 volt

AC option available. To check if the amplifier is

equipped with this option, please follow these

steps:

1. Make sure that the LAB 2002 is unplugged

from the mains voltage.

2. Remove the top and bottom cover.

3. If the four electrolytic capacitors close to the

front are rated 385VDC, the amplifier is for

230 volt operation only

4. If the four electrolytic capacitors close to the

front are rated 200VDC, the amplifier has the

115/230 volt option.

5. Locate the jumper(s) on the solder side of the

circuit board close to the mains switch.

6. To select the desired mains voltage, install the

jumpers as shown in Figure 15.

7. For 230 volt operation; use a T 15A fuse (slow

blow), for 115 volt change to a T 30 A fuse

(slow blow).

8. Replace the amplifier top and bottom cover.

9. For 115 volt operation; stick a ”115 VAC”

label on top of the 230 VAC label on rear

panel.

Maintenance

Under normal use the amplifier should give years

of trouble free service. The only user maintenance

required from the user is to vacuum the front grill

periodically.

In some extreme cases it may be necessary for

your supplier to clean the inside of the amplifier.

These conditions usually occur after prolonged use

in environments using "cracked- oil" smoke

machines.

If you are using your amplifier for heavy duty use

i.e. concert touring or industrial music it is

recommended that you have your amplifier

serviced every 3 years, purely as a preventative

measure

Troubleshooting

These are typical things to check if you think your

amplifier is faulty:

Fault: No output.

If the output bargraph is functioning there is

nothing wrong with the amplifier, and the likely

cause is an unsecured Speakon.

Check that the VHF protection is not activated. If

it is, remove possible high frequency oscillations

from the relevant input.

115V

230V

115V

Figure 15. 230VAC or 115 VAC selection

Warning: This modification should only

be made of an experienced service

technician.

Fault: The amplifier goes into thermal protection

when driven at low level.

Check that your loudspeaker has not got a short

circuit in its windings, (this can occur when the

speaker coil gets warm).

Fault: The amplifier goes into protect with power

indicators off.

Check that the AC line voltage is not outside the

amplifier’s operating range (130-260 volts).

Over/under-voltage protection may have occurred.

If the amplifier is connected by mistake to a 3

phase supply (415v), an internal non-resetable fuse

or resistor may have blown. Then return the

amplifier to your supplier.

Fault: The amplifier does not respond even after

checking above items.

In the unlikely event, that there is a non-user

rectifiable fault, return the amplifier to your

supplier or an approved service centre.

Lab Gruppen cannot be held responsible for

damage or injury, as a result of the top cover

being removed.

12

Page 13

Warranty and disclaimers

• General

This product is manufactured by LAB.GRUPPEN

and is warranted to be free from defects in

components and factory workmanship under

normal use and service, for a period of one year

from the date of original purchase.

During the warranty period, LAB.GRUPPEN or its

nominated agents, will undertake to repair, or at its

option, replace this product at no charge to its

owner, when failing to perform as specified,

provided the unit is returned undamaged and

shipping pre-paid, to factory or authorised service

facility.

No other warranty is expressed or implied.

This warranty shall be null and void, if the product

is subjected to:

1) Repair work or alteration by person other than

those authorised by LAB.GRUPPEN or its agents.

2) Shipping accidents, war, civil insurrection,

misuse, abuse, operation with incorrect AC voltage,

operation with faulty associated equipment and

normal wear and tear. Units, on which the serial

number has been removed or defaced, will not be

eligible for warranty service.

3) LAB.GRUPPEN shall not be responsible for

any incidental or consequential damages, with

respect to the products warranted.

LAB.GRUPPEN reserve the right to make changes

or improvements in design or manufacturing,

without assuming any obligation to change or

improve products previously manufactured.

• International

Please contact your supplier for this information, as

rights and disclaimers may vary from country to

country.

Technical assistance and services

• International

If your LAB.GRUPPEN product needs repair,

contact your LAB.GRUPPEN dealer or distributor,

or contact LAB.GRUPPEN by fax, to obtain the

location of the nearest authorised service centre.

• Factory services

In the event that your LAB.GRUPPEN product

needs factory service, you shall contact

LAB.GRUPPEN service department for return

instructions and a Return Authorisation number.

Please note on product return:

1. Use the original packing

2. Include a copy of the sales receipt, your name,

return address, phone number, fax number and

defect description.

3. Mark the Return Authorisation number on the

outside of the packing.

4. Ship the product prepaid to:

LAB.GRUPPEN

Gullregnsvägen 16

434 44 Kungsbacka

SWEDEN

Telephone: +46 300 562800

Fax +46 300 562899

e-mail info@labgruppen.com

13

Loading...

Loading...