Page 1

Installation and Operation Instructions Document 1170F

Installation and Operation

Instructions for

TM

Rheos

Modulating Boiler

Model RHCH

Modulating Water Heater

Model RHCV

U.S. Patent No. 6,644,393

Canada Patent Pending

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in ue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not

followed exactly, a re or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

ammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the re department.

Installation and service must be performed

by a qualied installer, service agency, or gas

supplier.

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualié ou

par le fournisseur de gaz.

AVERTISSEMENT

H2300300F

Page 2

Page 2

TABLE OF CONTENTS

SECTION 1.

General Information

1.1 Introduction ........................................................ 3

1.2 Model Identication ............................................ 3

1.3 Warranty ............................................................ 4

1.4 Dimensions ........................................................ 4

1.5 Outdoor Installations .......................................... 6

1.6 Locating the Appliance ....................................... 6

1.7 Locating Pump-Mounted Water

Heater with Respect to Storage Tank(s) ............ 6

1.8 Locating Pump-Mounted Boiler with

Respect to Return/Supply Header ..................... 6

1.9 Locating Appliance for Correct Vent Distance

From Outside Wall or Roof Termination ............. 6

SECTION 2.

Venting and Combustion Air

2.1 Combustion Air .................................................. 7

2.1.1 Combustion Air From Room .............................. 7

2.1.2 Intake Combustion Air ........................................ 7

2.2 Venting ............................................................... 9

2.3 Locating Vent & Combustion Air Terminals ........ 9

2.3.1 Side Wall Vent Terminal ..................................... 9

2.3.2 Side Wall Combustion Air Terminal ...................11

2.3.3 Vertical Vent Terminal .......................................11

2.3.4 Vertical Combustion Air Terminal ..................... 15

2.4 Common Vent Test – Boilers ............................ 15

SECTION 3.

Gas Supply and Piping

3.1 Gas Supply and Piping .................................... 15

SECTION 4A.

Water Connections – Rheos Boiler

4A.1 Heating System Piping:

Hot Supply Connections – Boiler ..................... 18

4A.2 Cold Water Make-Up – Boiler .......................... 18

4A.3 Water Flow Requirements – Boiler .................. 18

4A.4 Freeze Protection – Boiler ............................... 19

SECTION 4B.

Water Connections – Rheos Water Heater

4B.1 Water System Piping – Water Heater .............. 19

4B.2 Hot Water Supply Piping – Water Heater ......... 19

4B.3 Water Flow Requirements – Water Heater ...... 20

4B.4 Combined Water (potable)

Heating and Space Heating ............................. 20

4B.5 Freeze Protection — Water Heater .................. 20

LAARS Heating Systems

5.5.1 Temperature Setpoint ...................................... 24

5.5.2 Differential Setting ............................................ 24

5.5.3 Offset ............................................................... 24

5.5.4 Throttling Range .............................................. 24

5.5.5 Minimum Output Setting .................................. 24

5.5.6 Integration Constant ........................................ 24

5.6 External Control Connections .......................... 25

5.7 Wiring Diagrams .............................................. 25

SECTION 6.

Operating Instructions

6.1 Filling the Boiler System .................................. 38

6.2 Operating the Burner and Set Up .................... 38

6.3 Shutting Down the Rheos ................................ 40

6.4 To Restart the Rheos ....................................... 40

SECTION 7.

Maintenance

7.1 System Maintenance ....................................... 40

7.2 Appliance Maintenance and

Component Description ................................... 40

7.2.1 Burner .............................................................. 41

7.2.2 Filter ................................................................. 41

7.2.3 Modulating Gas Valve ...................................... 41

7.2.4 Safety Gas Valve ............................................. 41

7.2.5 Manual Reset High Limit Control ..................... 41

7.2.6 Temperature Control ........................................ 41

7.2.7 Ignition Control ................................................. 41

7.2.8 Ignitor / Flame Sensor Assembly ..................... 42

7.2.9 Transformers .................................................... 42

7.2.10 Blower............................................................ 42

7.2.11 Flow Switch .................................................... 42

7.2.12 Heat Exchanger Coil...................................... 42

7.2.13 Normally Open Vent Valve ............................. 43

7.2.14 Motorized Safety Valve .................................. 43

7.2.15 Gas Pressure Switches ................................. 44

SECTION 8.

Trouble Shooting

8.1 Sequence of Operation .................................... 45

8.2 Resolving Lockouts .......................................... 45

8.3 Delayed Ignition – Possible Causes ................ 45

8.3.1 High Lockup Pressure (LP Appliances)

- Occurs on Start-up ........................................ 45

8.3.2 Gas Valve Regulation ...................................... 45

8.3.3 Defective Burner - Occurs on

Startup or at Burner Shutdown ........................ 46

8.4 Short Cycling – Boiler ...................................... 46

8.5 Short Cycling – Water Heater .......................... 46

8.6 High Gas Consumption .................................... 46

SECTION 5.

Electrical Connections

5.1 Main Power ...................................................... 21

5.2 Pump Connections .......................................... 21

5.3 Temperature Control – Boiler ........................... 21

5.4 Temperature Control – Water Heater ............... 21

5.4.1 Remote Water Heater Temperature Control .... 21

5.4.2 Internal Water Heater Temperature Control ..... 22

5.5 Temperature Control Features ......................... 22

SECTION 9.

Replacement Parts

9.1 General Information ......................................... 46

9.2 Parts List .......................................................... 47

Tables Listing ................................................................. 56

Figures Listing .............................................................. 56

Page 3

Rheos Boiler and Water Heater

Page 3

SECTION 1.

General Information

USING THIS MANUAL – Because the Rheos

Boilers and Rheos Water Heaters are identical

appliances, with the exception of materials of

manufacture, labels and ultimate use application,

this manual provides information for the proper

installation, operation and maintenance of both

products. Where differences exist between the

application of the appliances and their operation,

the sections pertinent to only one appliance or the

other will be so identied.

WARNING

The Rheos hydronic, boiler or water heater must be

installed in accordance with the procedures detailed

in this manual, or the Laars Heating Systems

warranty will be voided. The installation must

conform to the requirements of the local jurisdiction

having authority, and, in the United States, to the

latest edition of the National Fuel Gas Code, ANSI

Z223.1/NFPA54. In Canada, the installation must

conform to the latest edition of CSA B149.1 Natural

Gas and Propane Gas Installation Code, and/or

local codes. Where required by the authority having

jurisdiction, the installation of Rheos boilers must

conform to the Standard for Controls and Safety

Devices for Automatically Fired Boilers, ANSI/ASME

CSD-1. Any modications to the boiler, its gas

controls, or wiring may void the warranty. If eld

conditions require modications, consult the factory

representative before initiating such modications.

1.1 Introduction

This manual provides information necessary for

the installation, operation, and maintenance of Laars

Heating Systems Rheos (copper tube or cupronickel

tubes) appliances. Read it carefully before installation.

All application and installation procedures

should be reviewed completely before proceeding

with the installation. Consult the Laars Heating

Systems factory, or local factory representative, with

any problems or questions regarding this equipment.

Experience has shown that most operating problems

are caused by improper installation.

The Rheos appliance is protected against over

pressurization. A pressure relief valve is tted to all

appliances. It is installed inside the jacket, at the water

outlet of the unit.

IMPORTANT: The inlet gas pressure to the appliance

must not exceed 13" W.C. (3.2kPa).

All installations must be made in accordance

with 1) American National Standard Z223.1/NFPA54Latest Edition “National Fuel Gas Code” or 2) CSA

B149.1 “Natural Gas and Propane Installation Code”

and with the requirement of the local utility or other

authorities having jurisdiction. Such applicable

requirements take precedence over the general

instructions contained herein.

All electrical wiring is to be done in accordance

with the local codes, or in the absence of local codes,

with: 1) The National Electrical Code ANSI/NFPA No.

70-latest Edition, or 2) CSA STD. C22.1 “Canadian

Electrical Code - Part 1”. This appliance must be

electrically grounded in accordance with these codes.

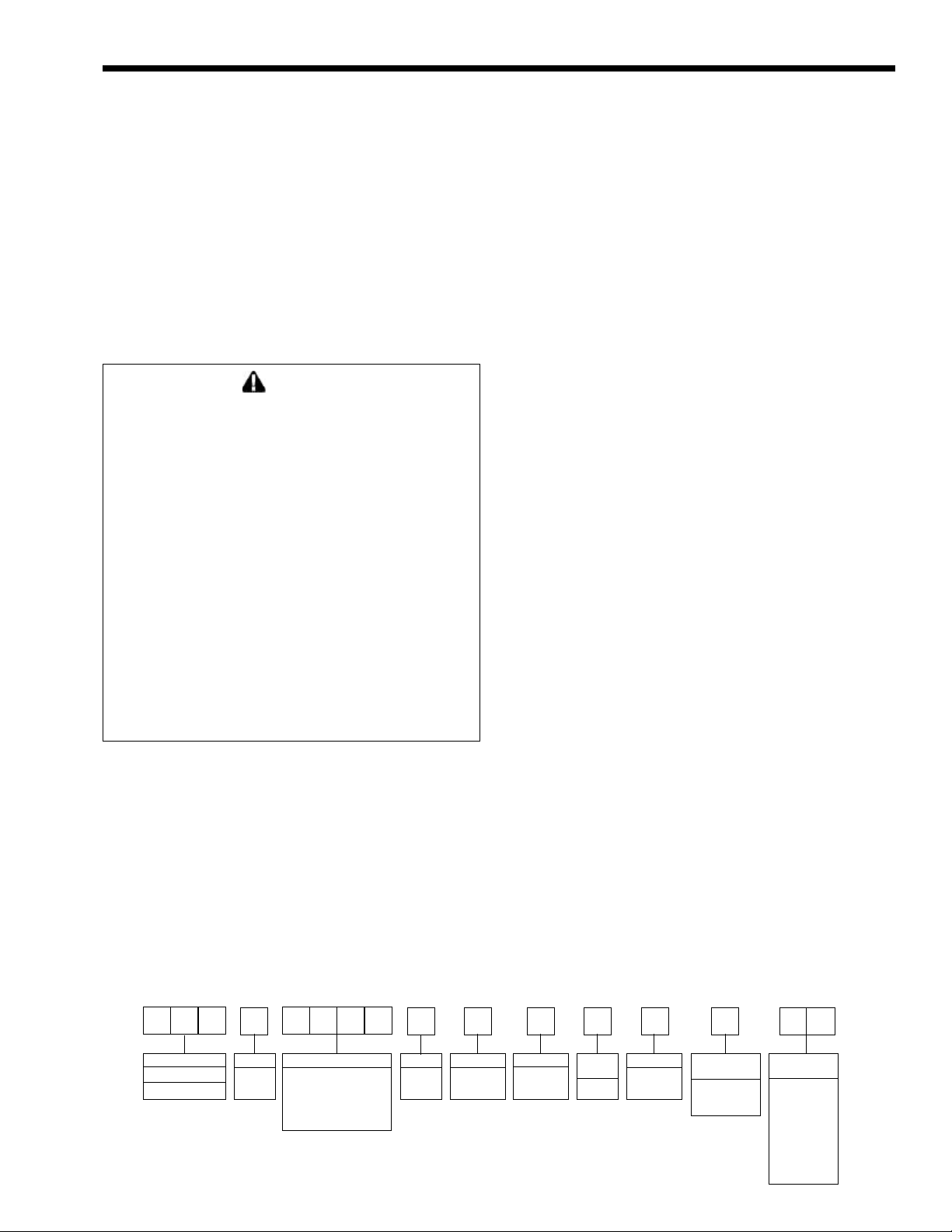

1.2 Model Identication

Consult the rating plate on the unit. The

following information describes the model number

structure.

(1-2) Model Series Designation

R H = Rheos mid-sized commercial

(3) Model Efciency

C = Mid Efciency (non-condensing)

H = High Efciency (condensing)

(4) Usage

H = Hydronic

V = Volume Water

(5-8) Size

1 2 0 0 = 1,200,000 BTU/hr input

1 6 0 0 = 1,600,000 BTU/hr input

2 0 0 0 = 2,000,000 BTU/hr input

2 4 0 0 = 2,400,000 BTU/hr input

Model Designation

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

R H 0 0 A F

SERIES

R H C

H

USAGE

H

V

1 6 0 0

2 0 0 0

2 4 0 0

SIZE

1 2 0 0

FUEL

N

P

ALTITUDE

A

LOCATION

I

C

FIRING

MODE

F

REVISION

1

2

HEAT

EXCHANGER

E

F

OPTION

CODES

X X

A H

B N

C S

D

E

F

G

Page 4

Page 4

LAARS Heating Systems

(9) Fuel

N = Natural Gas

P = Liquid Propane

(10) Altitude

A = Universal Altitude (0' to 10,000') (0m to 3050m)

(11) Location

C = Indoor and Outdoor (for non-condensing units)

I = Indoor (for condensing units)

(12) Firing Mode

F = Modulating

(13) Revision

1 = First version

2 = Second version

(14) Heat Exchanger

E = Glass-lined steel with copper tubes

F = Glass-lined steel with cupronickel tubes

(15) Control Option Code

X = Standard, meets CSD-1 boiler standard

A = Control Pack A: CSD-1, CA, FM, IL, IRI,

Alarm Bell

B = Control Pack B: CSD-1, CA, FM, IL, LDS, MN

C = Control Pack C: with 200°F (93°C) max.

control (KY)

D = Control Pack A with 200°F (93°C) max. control

E = Control Pack B with 200°F (93°C) max. control

F = Non CSD-1

G = Non CSD-1 with 200°F (93°C) max. control

(16) Pump Options

X = No Pump

H = Pump mounted, hard water pump

N = Pump mounted, normal pump

S = Pump mounted, soft water pump (volume

water, high efciency (condensing) model only)

1.3 Warranty

Laars Heating Systems’ Rheos appliances are

covered by a limited warranty. The owner should ll

out the warranty registration card and return it to Laars

Heating Systems.

All warranty claims must be made to an

authorized Laars Heating Systems representative or

directly to the factory. Claims must include the serial

number and model (this information can be found

on the rating plate), installation date, and name of

the installer. Shipping costs are not included in the

warranty coverage.

Some accessory items are shipped in separate

packages. Verify receipt of all packages listed on

the packing slip. Inspect everything for damage

immediately upon delivery, and advise the carrier of

any shortages or damage. Any such claims should be

led with the carrier. The carrier, not the shipper, is

responsible for shortages and damage to the shipment

whether visible or concealed.

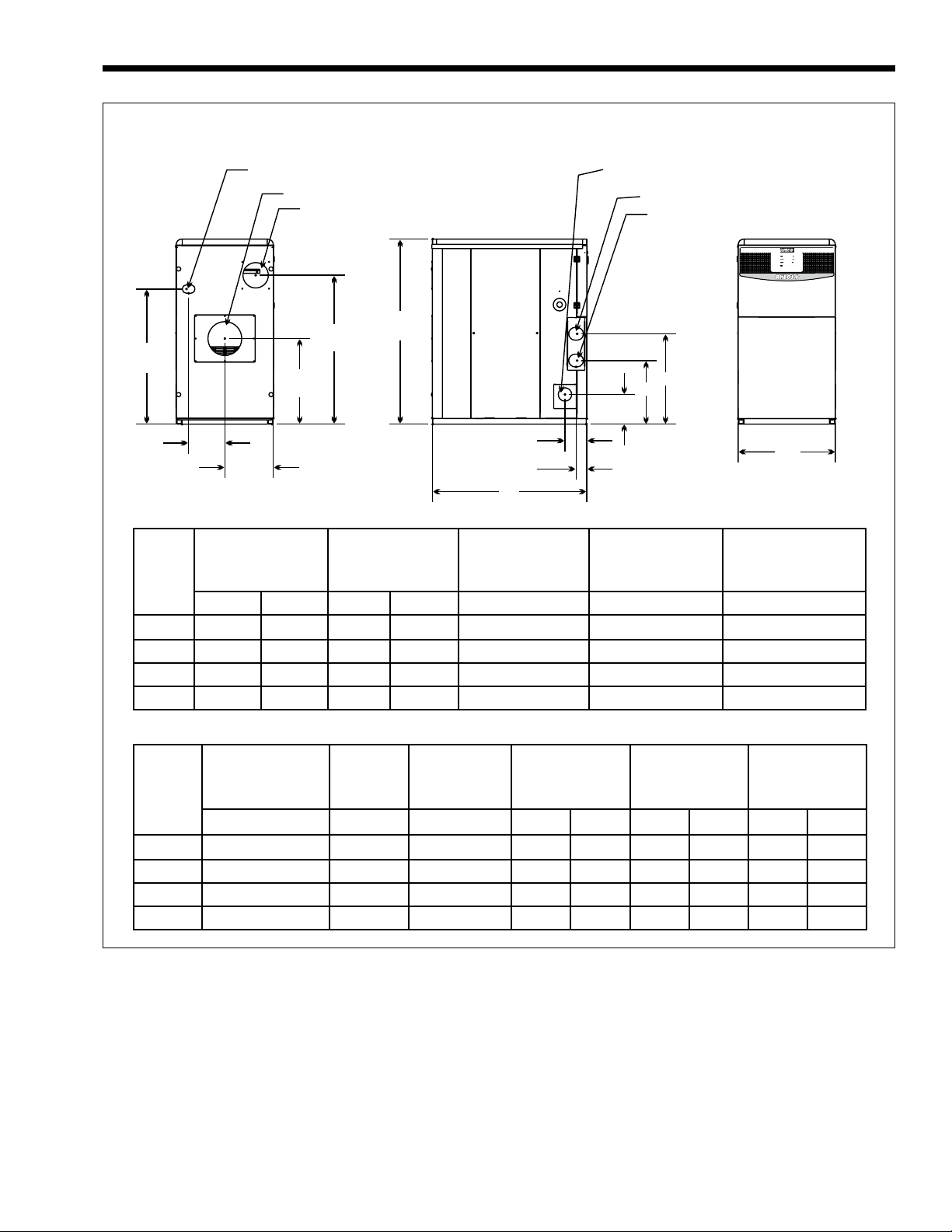

1.4 Dimensions

The overall dimensions are 34.5" (88cm)

wide, 65.75" (167cm) tall, 55" (140cm) deep. Other

dimensions can be found in Figure 1.

Page 5

Rheos Boiler and Water Heater

3.75

10

65.75

167

55

140

C

B

D

7.75

20

"S" WATER OUTLET

"W" WATER INLET

NON-PUMP-MOUNTED UNIT

"P" WATER INLET PUMP-MOUNTED UNIT

13

33

48

122

17.25

44

30.5

77

53

135

"G" GAS CONNECTION

"A" AIR INLET

WITH AIR FILTER

"V" FLUE VENT (CAT. IV) OUTLET

34.5

88

Page 5

Dimensions shown in inches cm.

Model "V" Vent Outlet

Connection

inches

1200 6

1600 6

2000 7

2400 10

cm

15

15

18

25

Model "G" Gas Con-

nects. Std/Control

Pk A Nat/LP

NPT NPT NPT inches

1200 1" 1-1/2" 1-1/2" 34-1/4

1600 1-1/2" 2" 2" 34-1/4

2000 1-1/2" 2" 1" 34-1/4

2400 1-1/2" 2" 2" 32

Figure 1. Dimensional Drawing.

"A" Air Inlet Con-

nection

inches

6

8

8

8

Control

Pk B & E

cm

15

20

20

20

Control

Pk B & E

Nat

"W" Inlet Water

Connection Non-

Pump-Mounted

"P" Inlet Water

Connection Pump-

Mounted

NPT NPT NPT

2-1/2" 2-1/2" 2-1/2"

2-1/2" 3" 2-1/2"

3" 2-1/2" 3"

3" 3" 3"

"B" "C" "D"

LP

cm

87

87

87

81

inches

27-3/4

25-1/2

24-3/4

22-1/2

"S" Outlet Water

Connection All

Models

cm

70

65

63

57

inches

9-3/4

10-1/2

9-3/4

10-1/2

cm

25

27

25

27

Page 6

Page 6

LAARS Heating Systems

1.5 Outdoor Installations

Attach the appropriate termination and appliance

adaptor to the vent outlet (see Table 1). Units are

shipped with a louvered cover over the ducted air

connection. Do not remove this cover, and/or add any

piping to the ducted air connection. The unit will take

its combustion air through the louvers in the jacket.

WARNING

The outdoor terminal gets hot. Unit must be

installed in such a way as to reduce the risk of

burns from contact with the vent terminal.

Model (Size) Termination Appliance Adapter

1200 D2008300 D2008500

1600 D2008300 D2008500

2000 D2008400 D2008600

2400 D2007500 D2007600

Table 1. Terminals for Outdoor Installation.

In installations where the air temperature may

go below 15°F (-9°C), a valve heater kit, part number

R2010100, must be installed on the operating gas

valve. Instructions for the installation of the valve

heater are included with the kit.

NOTE: Units built with control packs B and E

have two actuators. Therefore, two heater kits must be

used.

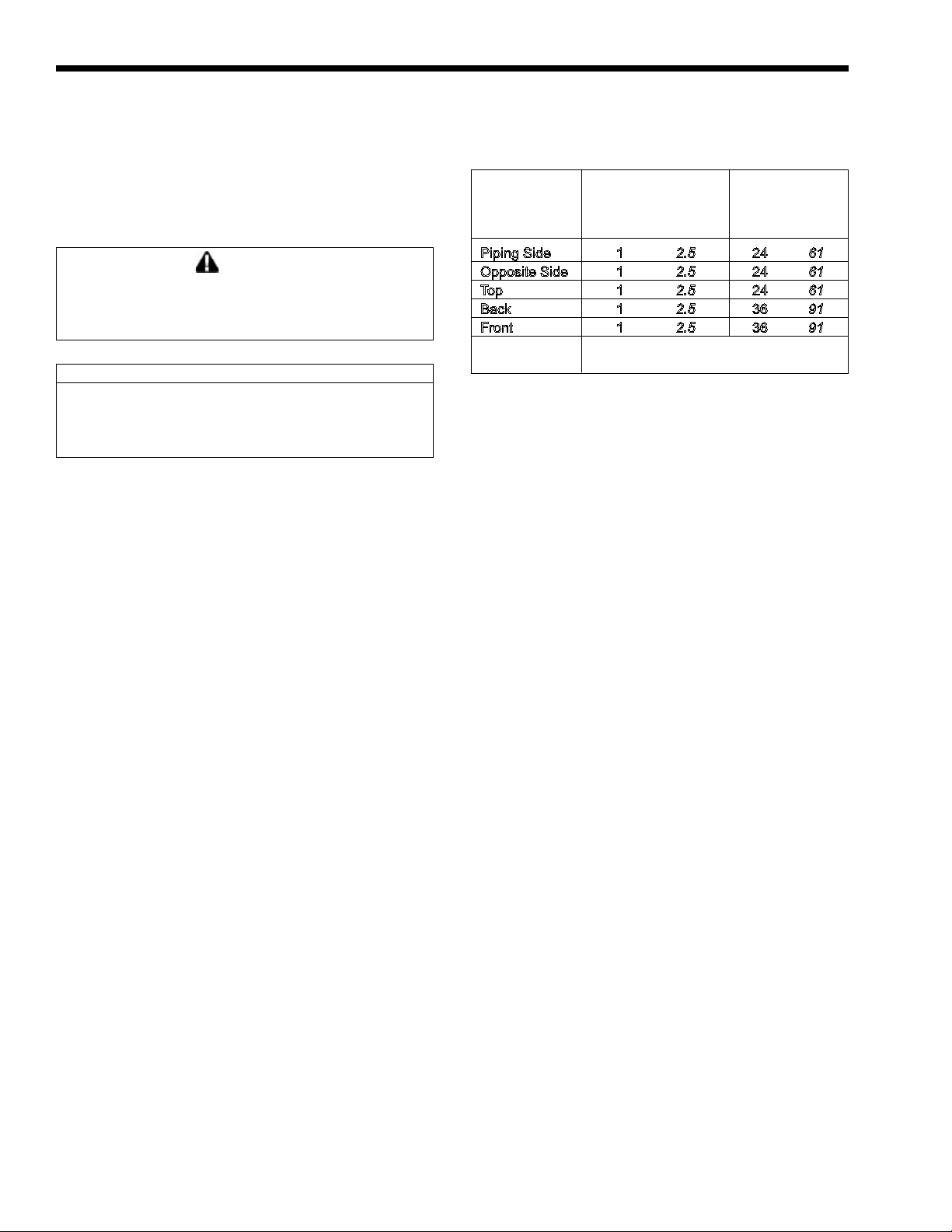

1.6 Locating the Appliance

The appliance should be located to provide

clearances on all sides for maintenance and inspection.

It should not be located in an area where leakage of

any connections will result in damage to the area

adjacent to the appliance or to lower oors of the

structure.

When such a location is not available, it is

recommended that a suitable drain pan, adequately

drained, be installed under the appliance.

The appliance is design certied by CSAInternational for installation on combustible ooring;

in basements; in closets, utility rooms or alcoves.

Rheos Boilers or Water Heaters must never be

installed on carpeting. The location for the appliance

should be chosen with regard to the vent pipe lengths

and external plumbing. The unit shall be installed such

that the gas ignition system components are protected

from water (dripping, spraying, rain, etc.) during

operation and service (circulator replacement, control

replacement, etc.). When vented vertically, the Rheos

must be located as close as practical to a chimney

or gas vent. If the vent terminal and/or combustion

air terminal terminate through a wall, and there is

potential for snow accumulation in the local area, both

terminals should be installed at an appropriate level

above grade.

The dimensions and requirements that are shown

in Table 2 should be met when choosing the locations

for the appliance:

Required Suggested

Clearance From Service

Appliance Combustible Material Clearance

Surface inches cm inches cm

Piping Side 1 2.5 24 61

Opposite Side 1 2.5 24 61

Top 1 2.5 24 61

Back 1 2.5 36 91

Front 1 2.5 36 91

Vent per UL1738 venting system

supplier's instructions

Table 2. Clearances.

1.7 Locating Pump-Mounted Water Heater

with Respect to Storage Tank(s)

For best results a pump-mounted Rheos water

heater should be located within 15 feet (4.6m) of the

storage tank(s). The pump is sized for 30 feet (9.1m)

of piping.

Water heater pumps are sized for water hardness;

7.6 to 17 grains per gallon for normal water, and

greater than 17 grains per gallon for hard water. If

the system has soft water (1 to 7.5 grains per gallon

hardness), but the Rheos has a normal water pump

mounted in it, please consult the factory for assistance.

If the appliance must be installed with longer

piping runs, then larger diameter pipe or tubing may be

able to be used, in some instances. Consult the factory

for assistance.

1.8 Locating Pump-Mounted Boiler with

Respect to Return/Supply Header

For the best results a pump-mounted Rheos

Boiler should be located within 15 feet (4.6m) of

the supply and return headers. The pump is sized for

30 feet (9.1m) of piping, in most cases, enough for

primary-secondary piping systems.

If the appliance must be installed with longer

piping runs, then larger diameter tubing may be able

to be used, in some instances. Consult the factory for

assistance.

1.9 Locating Appliance for Correct Vent

Distance From Outside Wall or

Roof Termination

The forced draft combustion air blower in the

appliance has sufcient power to vent properly when

the guidelines in Table 3 are followed.

NOTE: When located on the same wall, the Rheos

combustion air intake terminal must be installed

a minimum of 12" (30cm) below the exhaust vent

terminal and separated by a minimum of 36 inches

(91cm) horizontally.

Page 7

Rheos Boiler and Water Heater

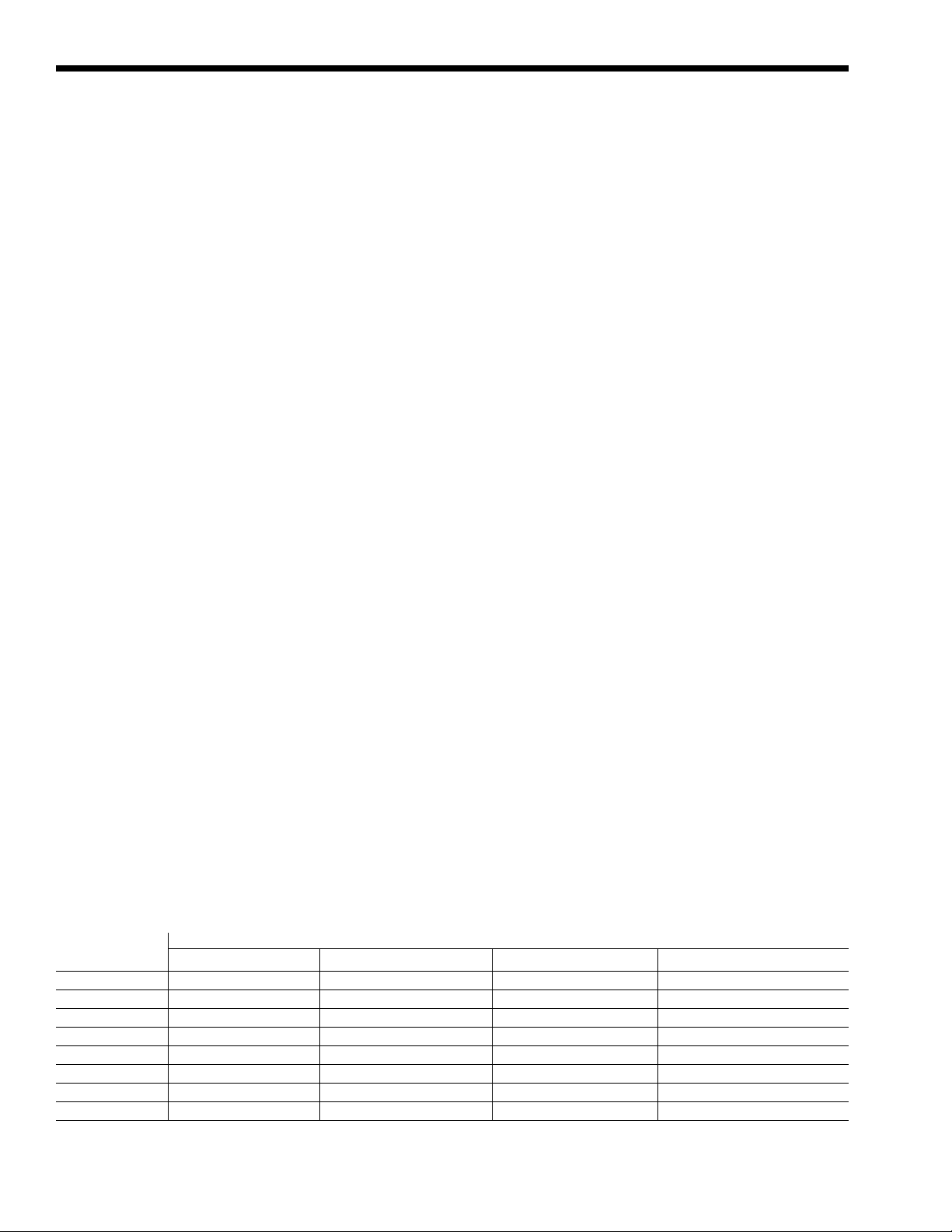

Model Intake Exhaust Intake Exhaust

Size Size Maximum Run Maximum Run

1200 6" (15 cm) dia. 6" (15 cm) dia. 50 linear feet with 5 elbows 50 linear feet with 5 elbows

1600 8" (20 cm) dia. 6" (15 cm) dia. 50 linear feet with 5 elbows 50 linear feet with 5 elbows

2000 8" (20 cm) dia. 7" (18 cm) dia. 50 linear feet with 5 elbows 50 linear feet with 5 elbows

2400 8" (20 cm) dia. 10" (25 cm) dia. 50 linear feet with 5 elbows 50 linear feet with 5 elbows

Table 3. Vent / Air Pipe Sizes.

Page 7

SECTION 2.

Venting and Combustion Air

2.1 Combustion Air

Rheos boilers and water heaters must have

provisions for combustion and ventilation air in

accordance with section 5.3, Air for Combustion and

Ventilation, of the National Fuel Gas Code, ANSI

Z223.1, or Sections 7.2, 7.3 or 7.4 of CSA B149.1,

Installation Codes, and applicable provisions of the

local building codes.

A Rheos unit can take combustion air from the

space in which it is installed, or the combustion air can

be ducted directly to the unit. Ventilation air must be

provided in either case.

2.1.1 Combustion Air From Room

In the United States, the most common

requirements specify that the space shall communicate

with the outdoors in accordance with method 1 or 2,

which follow. Where ducts are used, they shall be of

the same cross-sectional area as the free area of the

openings to which they connect.

Method 1: Two permanent openings, one

commencing within 12" (300mm) of the top and one

commencing within 12" (300mm) of the bottom, of

the enclosure shall be provided. The openings shall

communicate directly, or by ducts, with the outdoors

or spaces that freely communicate with the outdoors.

When directly communicating with the outdoors, or

when communicating to the outdoors through vertical

ducts, each opening shall have a minimum free area

of 1 square inch per 4000 Btu/hr (550 square mm/kW)

of total input rating of all equipment in the enclosure.

When communicating to the outdoors through

horizontal ducts, each opening shall have a minimum

free area of not less than 1 square inch per 2000 Btu/hr

(1100 square mm/kW) of total input rating of all

equipment in the enclosure.

Method 2: One permanent opening, commencing

within 12" (300mm) of the top of the enclosure, shall

be permitted. The opening shall directly communicate

with the outdoors or shall communicate through a

vertical or horizontal duct to the outdoors or spaces

that directly communicate with the outdoors and shall

have a minimum free area of 1 square inch per 3000

Btu/hr (734 square mm/kW) of the total input rating of

all equipment located in the enclosure. This opening

must not be less than the sum of the areas of all vent

connectors in the conned space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform

to the requirements in the applicable codes listed

above.

In Canada, consult local building and safety

codes or, in absence of such requirements, follow

CAN/CGA B149.

2.1.2 Intake Combustion Air

The combustion air can be taken through the

wall, or through the roof. When taken from the wall, it

must be taken from out-of-doors by means of the Laars

horizontal wall terminal, shown in Table 4. See Table 3

to select the appropriate diameter air pipe. When taken

from the roof, a eld-supplied rain cap or an elbow

arrangement must be used to prevent entry of rain

water (see Figure 2).

Use single-wall galvanized pipe for the

combustion air intake (see Table 5), sized per Section

1.8. Route the intake to the heater as directly as

possible. Seal all joints with tape. Provide adequate

hangers. The unit must not support the weight of the

combustion air intake pipe. Maximum linear pipe

length allowed is 50 feet (15.2m). Up to ve elbows

can be used with the 50 feet of pipe. Subtract 10

allowable linear feet for every additional elbow used.

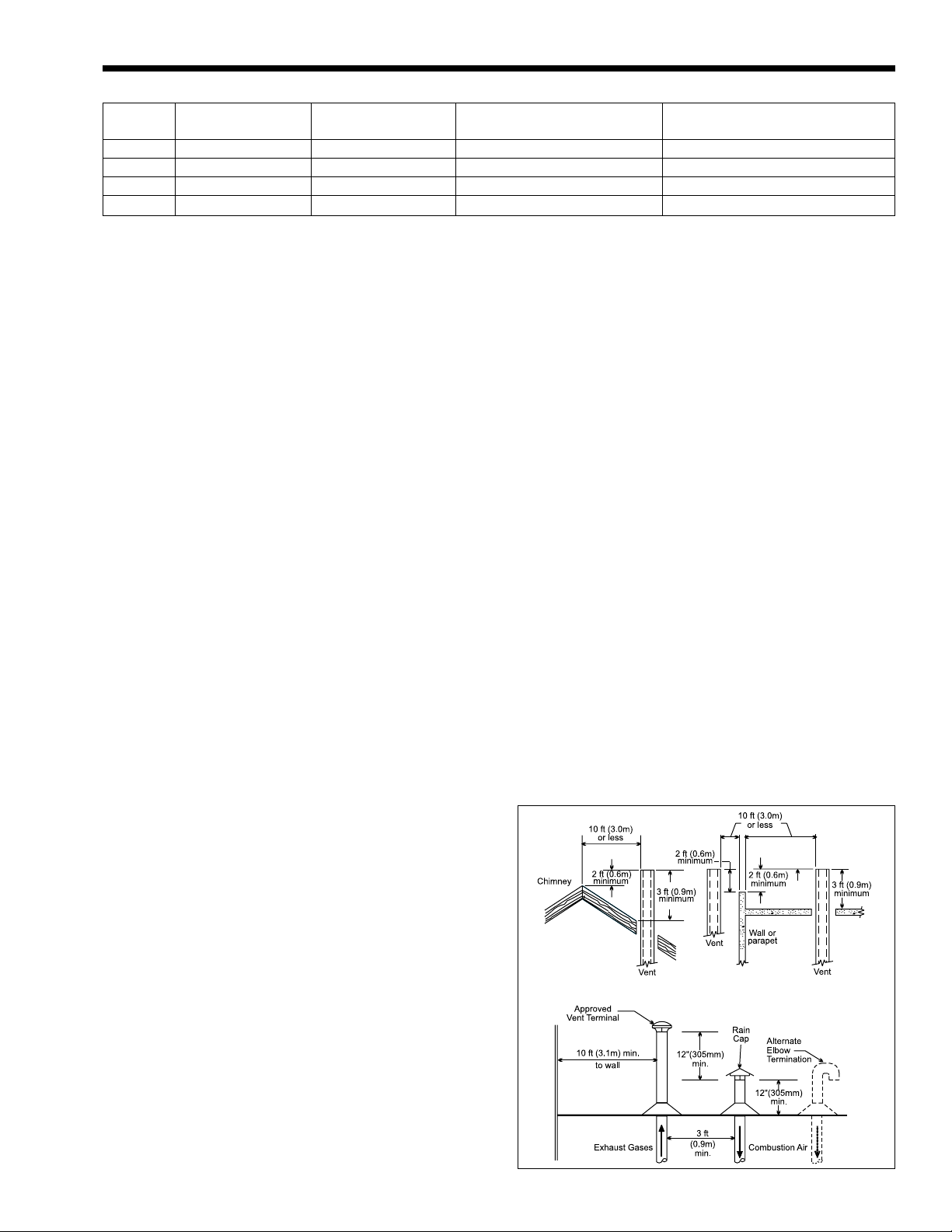

Figure 2. Combustion Air and Vent Through Roof.

Page 8

Page 8

LAARS Heating Systems

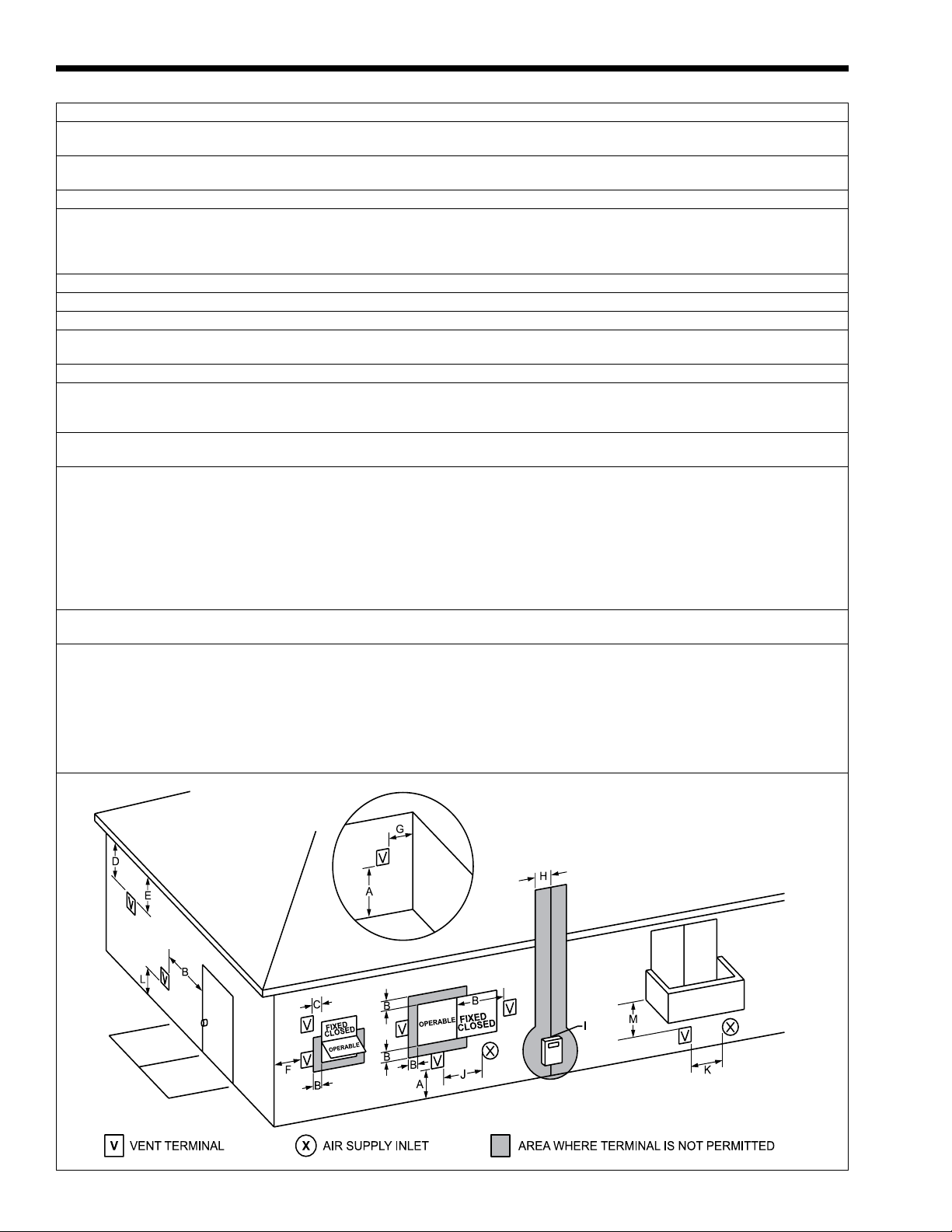

A= Clearance above grade, veranda, porch, 12 inches (30 cm) 12 inches (30 cm)

deck, or balcony

B= Clearance to window or door that may be 4 feet (1.2 m) below or to side of opening; 36 inches (91 cm)

opened 1 foot (30 cm) above opening

C= Clearance to permanently closed window See note 4 See note 5

D= Vertical clearance to ventilated soft located

above the terminal within a horizontal See note 4 See note 5

distance of 2 feet (61cm) from the center line

of the terminal

E= Clearance to unventilated soft See note 4 See note 5

F= Clearance to outside corner See note 4 See note 5

G= Clearance to inside corner See note 4 See note 5

H= Clearance to each side of center line 3 feet (91 cm) within a height 15 feet above

extended above meter/regulator assembly See note 4 the meter/regulator assembly

I= Clearance to service regulator vent outlet See note 4 3 feet (91 cm)

J= Clearance to nonmechanical air supply inlet

to building or the combustion air inlet to 4 feet (1.2 m) below or to side of opening; 36 inches (91 cm)

any other appliance 1 foot (30 cm) above opening

K= Clearance to a mechanical air supply inlet 3 feet (91 cm) above if within 10 feet (3 m) 6 feet (1.83 m)

horizontally

Vent termination not allowed in this location for

Vent termination not allowed in this location category IV appliances. A vent shall not

L= Clearance above paved sidewalk or paved for category IV appliances. For Category III terminate directly above a sidewalk or paved

driveway located on public property appliances, vent must terminate at least 7 driveway that is located between two single

feet (2.13m) above the sidewalk or driveway. family dwellings and serves both dwellings.

For Category III appliances that do not violate

the previous condition, vent must terminate at

least 7 feet (2.13m) above the sidewalk or

driveway.

M= Clearance under veranda, porch, deck, See note 4 12 inches (30 cm) (see note 3)

or balcony

Notes:

1. In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code.

2. In accordance with the current CAN/CGA-B149 Installation Codes.

3. Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the oor.

4. For clearances not specied in ANSI Z223.1 / NFPA 54, clearance is in accordance with local installation codes and the requirements of the

gas supplier.

5. For clearances not specied in CAN/CGA-B149, clearance is in accordance with local installation codes and the requirements of the gas

supplier.

U.S. Installations (see note 1)

Canadian Installations (see note 2)

Figure 3. Combustion Air and Vent Through Side Wall.

Page 9

Rheos Boiler and Water Heater

Page 9

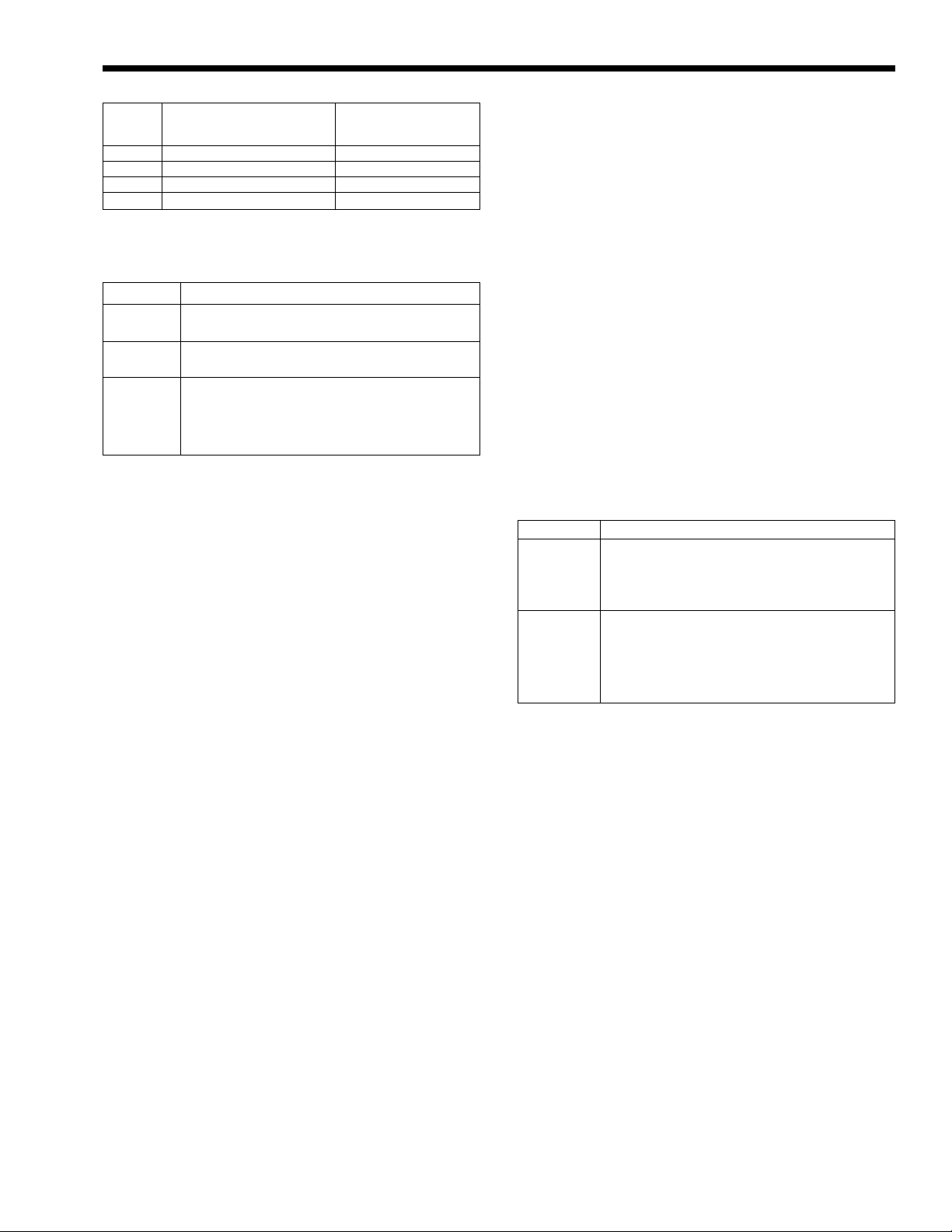

Model

1200 20260701 D2004500

1600 20260703 D2004500

2000 20260703 D2004600

2400 20260703 D2006200

Term Description

Pipe Single-wall galvanized steel pipe, 24 gauge

Joint Permanent duct tape or aluminum tape

Sealing

Insulation Not required, but recommended R5 insulation

Table 5. Required Combustion Air Piping Material.

Horizontal Combustion

Table 4. Horizontal Vent and Air Terminals

Air Terminal

For Indoor Installations.

minimum (sized per section 1.9)

for cold installations (consult American Society

of Heating, Refrigerating, and Air Conditioning

Engineers (ASHRAE) handbook)

Horizontal Vent

Terminal

The connection for the intake air pipe is in the

back of the unit. Take the plate off the back to reveal

the collar on the lter box. Run a bead of silicone

around the collar and slide the pipe over the collar.

Secure with sheet metal screws.

In addition to air needed for combustion, air

shall also be supplied for ventilation, including all air

required for comfort and proper working conditions

for personnel. The Rheos loses less than 1 percent of

its input rating to the room, but other heat sources may

be present.

allowable linear feet for every additional elbow used.

IMPORTANT NOTE ABOUT COMMON VENTING:

A single vent that is shared by multiple Rheos

units MUST be engineered by a competent venting

specialist, and involves the selection of draft inducing

equipment, hardware and controls to properly balance

ue gas pressures. Do not common vent Rheos

units unless the vent system meets this requirement.

Rheos units are never permitted to share a vent with

Category I applliances.

For outdoor applications, see Section 1.5.

Condensate Drain Connection: A condensate

drain connection shall be provided on the rst section

of venting attached to the boiler. Connect a clear

plastic tube between that drain connection on the

vent and a oor drain (or optional condensate pump

if a oor drain is not accessible). The plastic tube

shall be formed into a loop (trap) to drain condensate

that collects in the vent system without permitting

ue gases to escape. The condensate drain must be

installed so as to prevent accumulation of condensate.

Consult local codes for disposal method.

Term Description

Venting Heat-Fab®, Inc. Saf-T Vent®GC or CI,

System Metal-Fab®, Inc. Corr/Guard, or

equivalent sealed stainless steel

system certied to UL1738.

Insulation Not required, but recommended R5

insulation with protective cover for cold

installations (consult American Society of

Heating, Refrigerating, and Air Conditioning

Engineers (ASHRAE) handbook)

2.2 Venting

The Rheos is a Category IV appliance and must

be installed with a stainless steel venting system

that complies with the UL 1738 Standard (see Table

6). It must be installed per this installation manual

and the venting system manufacturer’s Installation

Instructions. The unit’s vent can terminate through the

roof, or through an outside wall. It can be installed

through walls that are from 3" (7.6cm) to 12" (30cm)

in thickness.

See Table 3 to select the appropriate vent pipe

diameter. The rst section of venting attached to the

boiler must include a condensate drain tting and

condensate trap. Route the vent pipe to the heater

as directly as possible. Seal all joints and provide

adequate hangers as required in the venting system

manufacturer’s Installation Instructions. Horizontal

portions of the venting system must be supported to

prevent sagging and may not have any low sections

that could trap condensate. The unit must not support

the weight of the vent pipe. Horizontal runs must slope

upwards not less than ¼ inch per foot (21mm/m) from

the unit to the vent terminal. Up to ve elbows can

be used with the 50 feet (15.2m) of pipe. Subtract 10

Table 6. Required Venting Material.

2.3 Locating Vent & Combustion Air

Terminals

2.3.1 Side Wall Vent Terminal

The appropriate Laars side wall vent hood must

be used, and is listed in the installation and operation

manual. The terminal provides a means of installing

the vent piping through the building wall, and must

be located in accordance with ANSI Z223.1/NFPA 54

and applicable local codes. In Canada, the installation

must be in accordance with CSA B149.1 or .2 and

local applicable codes. Consider the following when

installing the terminal:

1. The gure in this addendum shows the

requirements for mechanical vent terminal

clearances for the U.S. and Canada.

2. Vent terminals for condensing appliances or

appliances with condensing vents are not

permitted to terminate above a public walkway,

or over an area where condensate or vapor could

create a nuisance or hazard.

Page 10

Page 10

LAARS Heating Systems

3. Locate the vent terminal so that vent gases cannot

be drawn into air conditioning system inlets.

4. Locate the vent terminal so that vent gases cannot

enter the building through doors, windows,

gravity inlets or other openings. Whenever

possible, locations under windows or near doors

should be avoided.

5. Locate the vent terminal so that it cannot be

blocked by snow. The installer may determine

that a vent terminal must be higher than the

minimum shown in codes, depending upon local

conditions.

6. Locate the terminal so the vent exhaust does

not settle on building surfaces or other nearby

objects. Vent products may damage such

surfaces or objects.

7. If the boiler or water heater uses ducted

combustion air from an intake terminal located

on the same wall, locate the vent terminal at least

3 feet (0.9m) horizontally from the combustion

air terminal, and locate the vent terminal at least

1 foot (0.3m) above the combustion air terminal.

From Massachusetts Rules and Regulations

248 CMR 5.08:

(a) For all side wall horizontally vented gas

fueled equipment installed in every dwelling,

building or structure used in whole or inpart

for residential purposes, including those

owned or operated by the Commonwealth and

where the side wall exhaust vent termination

is less than seven (7) feet above nished grade

in the area of the venting, including but not

limited to decks and porches, the following

requirements shall be satised:

1. INSTALLATION OF CARBON MONOXIDE

DETECTORS.

At the time of installation of the side wall

horizontal vented gas fueled equipment, the

installing plumber or gastter shall observe that

a hard-wired carbon monoxide detector with

an alarm and battery back-up is installed on

the oor level where the gas equipment is to be

installed. In addition, the installing plumber or

gastter shall observe that a battery operated or

hard-wired carbon monoxide detector with an

alarm is installed on each additional level of the

dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment.

It shall be the responsibility of the property

owner to secure the services of qualied licensed

professionals for the installation of hard-wired

carbon monoxide detectors.

a. In the event that the side wall

horizontally vented gas fueled equipment is

installed in a crawl space or an attic, thehardwired carbon monoxide detector with alarm

and battery back-up may be installed on the

next adjacent oor level.

b. In the event that the requirements of

this subdivision cannot be met at the time of

completion of installation, the owner shall

have a period of thirty (30) days to comply

with the above requirements; provided,

however, that during said thirty (30) day

period, a battery operated carbon monoxide

detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE

DETECTORS.

Each carbon monoxide detector as required

in accordance with the above provisions shall

comply with NFPA 720 and be ANSI/UL 2034

listed and IAS certied.

3. SIGNAGE.

A metal or plastic identication plate shall be

permanently mounted to the exterior of the

building at a minimum height of eight (8) feet

Model and

Gas Type 0-50 feet 0-15m 50-100 feet 15-31m 100-200 feet 31-61m 200-300 feet 61-91m

1200 natural 2" 5.1cm 2-1/2" 6.4cm 2-1/2" 6.4cm 3" 7.6cm

1200 propane 1-1/2" 3.8cm 2" 5.1cm 2" 5.1cm 2-1/2" 6.4cm

1600 natural 2-1/2" 6.4cm 2-1/2" 6.4cm 3" 7.6cm 3" 7.6cm

1600 propane 2" 5.1cm 2" 5.1cm 2-1/2" 6.4cm 2-1/2" 6.4cm

2000 natural 2-1/2" 6.4cm 3" 7.6cm 3" 7.6cm 3-1/2" 8.9cm

2000 propane 2-1/2" 6.4cm 2-1/2" 6.4cm 2-1/2" 6.4cm 3" 7.6cm

2400 natural 2-1/2" 6.4cm 3" 7.6cm 3" 7.6cm 3-1/2" 8.9cm

2400 propane 2" 5.1cm 2-1/2" 6.4cm 2-1/2" 6.4cm 3" 7.6cm

Notes: 1. These gures are based on 1/2" 0.12kPa water column pressure drop.

2. Check supply pressure and local code requirements before proceeding with work.

3. Pipe ttings must be considered when determining gas pipe sizing.

Distance from Gas Meter or Last Stage Regulator

Table 7. Gas Piping Sizes.

Page 11

Rheos Boiler and Water Heater

Page 11

above grade directly in line with the exhaust vent

terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall

read, in print size no less than one-half (½) inch

in size, “GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION.

The state or local gas inspector of the side

wall horizontally vented gas fueled equipment

shall not approve the installation unless, upon

inspection, the inspector observes carbon

monoxide detectors and signage installed in

accordance with the provisions of 248 CMR

5.08(2)(a) 1 through 4.

(b) EXEMPTIONS: The following equipment is

exempt from 248 CMR 5.08(2)(a) 1 through 4:

1. The equipment listed in Chapter 10 entitled

“Equipment Not Required To Be Vented” in the

most current edition of NFPA 54 as adopted by

the Board; and

the manufacturer:

1. The identication of each “special venting

system” shall include either the listing of the

website, phone number or manufacturer’s address

where the venting system installation instructions

can be obtained; and

2. The “special venting systems” shall be Product

Approved by the Board, and the instructions

provided with that system shall include a parts

list and detailed installation instructions.

(e) A copy of all installation instructions for the

Product Approved side wall horizontally

vented gas fueled equipment, and all the

venting instructions, parts lists, and/or design

instructions for the venting system shall

remain with the appliance or equipment at the

completion of the installation.

Manufacturers' websites where venting system

installation instructions may be obtained is

located on the Laars website at: http://www.

laars.com.

2. Product Approved side wall horizontal vented gas

fueled equipment installed in a room or structure

separate from the dwelling, building or structure

used in whole or in part for residential purposes.

(c) MANUFACTURER REQUIREMENTS

– GAS EQUIPMENT VENTING SYSTEM

PROVIDED. When the manufacturer of

Product Approved side wall horizontally

vented gas equipment provides a venting

system design or venting system components

with the equipment, the instructions provided

by the manufacturer for installation of the

equipment and the venting system shall

include:

1. Detailed instructions for the installation of the

venting system design or the venting system

components; and

2. A complete parts list for the venting system

design or venting system.

(d) MANUFACTURER REQUIREMENTS –

GAS EQUIPMENT VENTING SYSTEMNOT

PROVIDED. When the manufacturer of a

Product Approved side wall horizontally

vented gas fueled equipment does not

provide the parts for venting the fuel gases,

but identies “special venting systems”, the

following requirements shall be satised by

2.3.2 Side Wall Combustion Air Terminal

The Laars side wall combustion air terminal (see

Table 4) must be used when the heater takes air from a

side wall. Consider the following when installing the

terminal:

1. Do not locate the air inlet terminal near a source

of corrosive chemical fumes (e.g., cleaning uid,

chlorine compounds, etc.)

2. Locate the terminal so that it will not be subject

to damage by accident or vandalism. It must be at

least 7 feet (2.1m) above a public walkway.

3. Locate the combustion air terminal so that it

cannot be blocked by snow. The National Fuel

Gas Code requires that it be at least 12 inches

(30cm) above grade, but the installer may

determine it should be higher, depending upon

local conditions.

4. If the Rheos is side-wall vented to the same wall,

locate the vent terminal at least 3 feet (0.9m)

horizontally from the combustion air terminal,

and locate the vent terminal at least 1 foot (0.3m)

above the combustion air terminal (see Figure 3).

2.3.3 Vertical Vent Terminal

When the unit is vented through the roof, the

vent must extend at least 3 feet (0.9m) above the point

at which it penetrates the roof. It must extend at least

2 feet (0.6m) higher than any portion of a building

within a horizontal distance of 10 feet (3.0m), and high

enough above the roof line to prevent blockage from

snow. When the combustion air is taken from the roof,

the combustion air must terminate at least 12" (30cm)

below the vent terminal (see Figure 2).

Page 12

Page 12

SYSTEM

BOILER CIRC.

PUMP

SYSTEM PUMP

THERMOMETER

GLOBE VALVE

CHECK VALVE

PRESSURE REDUCING VALVE

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALV E

TEMPERATURE

SENSOR

3-WAY VALV E

PURGE

VALV E

C

COLD WATER

MAKE-UP

OPTIONAL PUMP MOUNTED UNIT AVAILABLE

C

RETURN

SYSTEM

SUPPLY

INSTALLAIR VENTS AT HIGH POINTS IN SYSTEM

PIPING&SIZING OF EXPANSION TANK

PER TANK MANUFACTURER'S INSTRUCTIONS

PRIMARY/SECONDARY MANDITORY FOR ALL

VARIABLE FLOW SYSTEMS

DIMENSION ''C'' TO BE4PIPE DIAMETERS

BOILER CIRC. PUMP SIZED FOR FLOW THROUGH BOILER

BOILER CIRC. PUMP TO BE USED WITH EM

DOTTED DEVICES INDICATE ALTERNATE LOCATIONS

BOILER CIRCUIT PIPING MUST BE EQUAL TO

BOILER WATER CONNECTION SIZE

SYSTEM TEMP. INTERLOCK REQUIRED

MULTIPLE STAGE BOILERS RECOMMENDED

2

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VA LVING. CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS.

D D

DIMENSION ''D'' TO BE 18" MINIMUM

THERMOMETER

GLOBE VA LVE

CHECK VA LVE

PRESSURE REDUCING VA LVE

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALV E

TEMPERATURE

SENSOR

3-WAY VALV E

PURGE

VALV E

SYSTEM

RETURN

SYSTEM

SUPPLY

INSTALLAIR VENTS AT HIGH POINTS IN SYSTEM

PIPING&SIZING OF EXPANSION TANK

PER TANK MANUFACTURER'S INSTRUCTIONS

PRIMARY/SECONDARY MANDITORY FOR ALL

VARIABLE FLOW SYSTEMS

BOILER CIRC. PUMP SIZED FOR FLOW THROUGH BOILER

BOILER CIRC. PUMP TO BE USED WITH EM

DOTTED DEVICES INDICATE ALTERNATE LOCATIONS

BOILER CIRCUIT PIPING MUST BE EQUAL TO

BOILER WATER CONNECTION SIZE

SYSTEM TEMP. INTERLOCK REQUIRED

MULTIPLE STAGE BOILERS RECOMMENDED

2

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VA LVING. CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS.

BOILER CIRC.

PUMP

C

A

B

T1

ADJUSTMENT PROCEDURE TO MAINTAIN 130°FINLET TEMP.

1. Turn on heater and open valves A&B

3. If T1 is greater than 130° F, slowly

close valve A until T1 dropsto 130° F

4. Check after system operating temperature has

2. After steady-state operation, if T1 is less than

130° F, slowly close valve B until T1 climbs to 130° F

stabilized. Make final adjustments

OPTIONAL PUMP MOUNTED

UNIT AVAILABLE

COLD WATER

MAKE-UP

SYSTEM PUMP

B

C

A

B

T1

D

D

DIMENSION ''C'' TO BE4PIPE DIAMETERS

DIMENSION ''D'' TO BE 18" MINIMUM

LAARS Heating Systems

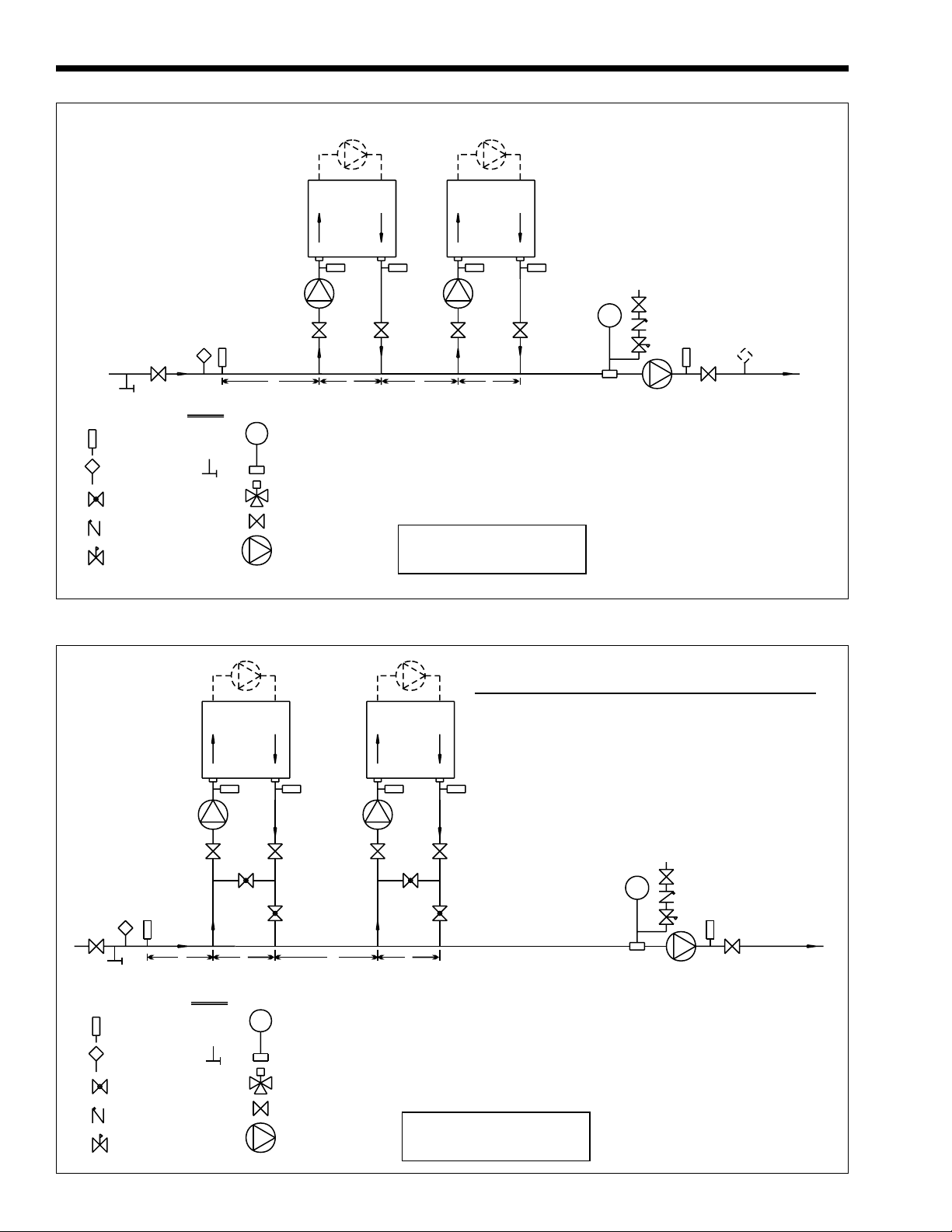

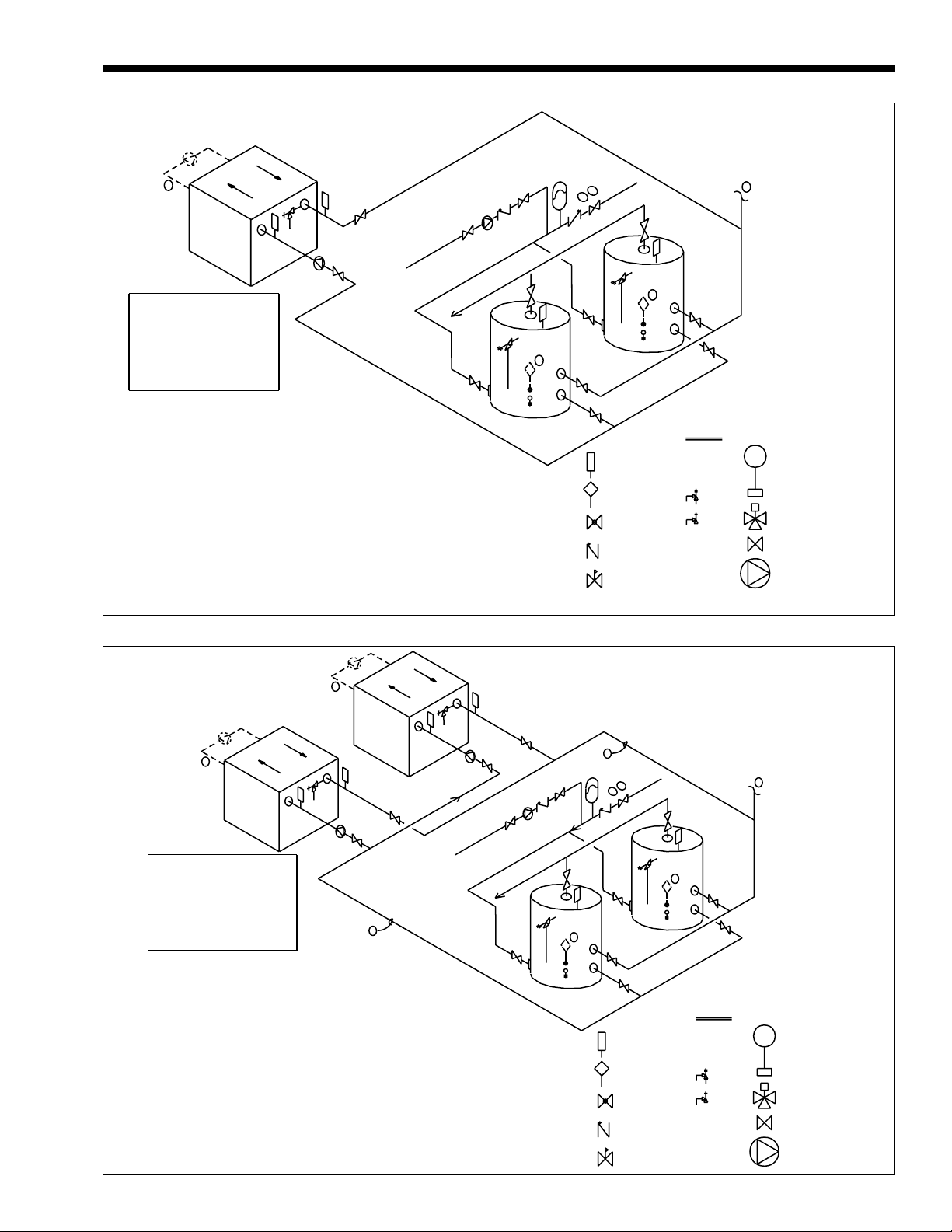

Figure 4. Hydronic Piping — Multiple Boilers, Primary Secondary System.

Figure 5. Hydronic Piping — Multiple Boilers, Low Temperature System.

Page 13

Rheos Boiler and Water Heater

THERMOMETER

GLOBE VA LVE

CHECK VA LVE

PRESSURE REDUCING VA LVE

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALV E

TEMPERATURE

SENSOR

3-WAY VALV E

PURGE

VALV E

INSTALLAIR VENTS AT HIGH POINTS IN SYSTEM

PIPING&SIZING OF EXPANSION TANK

PER TANK MANUFACTURER'S INSTRUCTIONS

PRIMARY/SECONDARY MANDITORY FOR ALL

VARIABLE FLOW SYSTEMS

BOILER CIRC. PUMP SIZED FOR FLOW THROUGH BOILER

BOILER CIRC. PUMP TO BE USED WITH EM

DOTTED DEVICES INDICATE ALTERNATE LOCATIONS

BOILER CIRCUIT PIPING MUST BE EQUAL TO

BOILER WATER CONNECTION SIZE

SYSTEM TEMP. INTERLOCK REQUIRED

MULTIPLE STAGE BOILERS RECOMMENDED

2

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VA LVING. CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS.

BOILER CIRC.

PUMP

SYSTEM PUMP

C

C

C

180° F

180° F

140° F

120° F

NOTES:

1. BOILER LOOP TO BE MAINTAINED AT 180° F.

2. ZONE THERMOSTATSTOBE INTERLOCKED WITH BOILER.

BOILER TO FIRE UPON CALL FOR HEAT FROM ANY ZONE.

3. ZONE PIPING AND INTERLOCK WIRING TO BE

DESIGNED BY SYSTEM DESIGNER.

COLD WATER

MAKE-UP

OPTIONAL PUMP MOUNTED UNIT AVAILABLE

C

D

D

D

DIMENSION ''C'' TO BE4PIPE DIAMETERS

DIMENSION ''D'' TO BE 18" MINIMUM

Page 13

Temperature Rise in Degrees (°F/°C)

20°F 11°C 25°F 14°C 30°F 17°C

Model Flow H/L Flow H/L Flow H/L Flow H/L Flow H/L Flow H/L

(Size) gpm feet lpm m gpm feet lpm m gpm feet lpm m

1200 104 18 395 5.5 84 12 316 3.7 70 8 264 2.4

1600 139 22 527 6.7 111 14 422 4.3 93 10 351 3.0

2000 174 20 659 6.1 139 13 527 4.0 116 9 439 2.7

2400 209 18 791 5.5 167 12 632 3.7 139 8 527 2.4

NOTE: Maximum temperature rise is 30°F (17°C), as shown. Headloss is for boiler’s heat exchanger only.

Table 8. Water Flow Requirements, RHCH (Boiler).

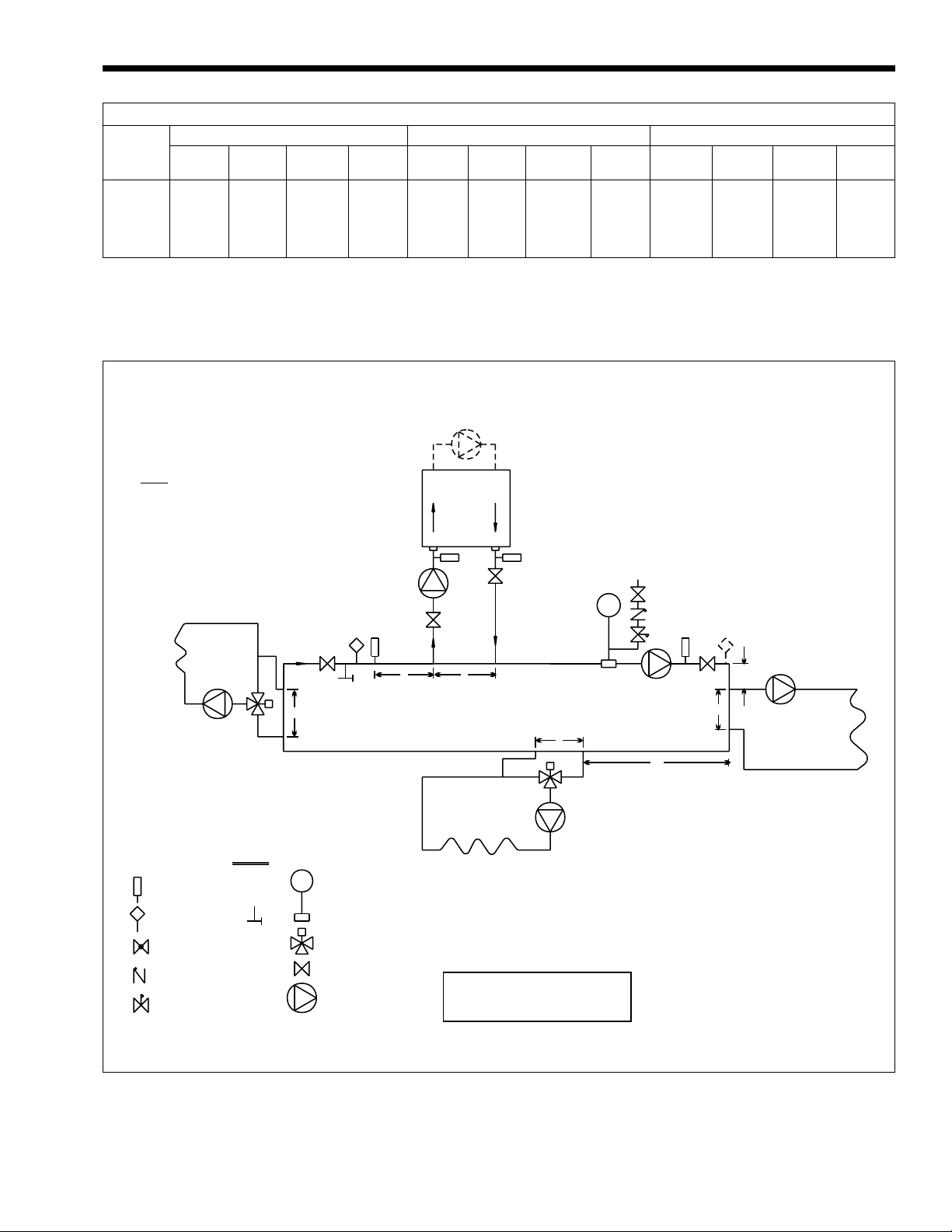

Figure 6. Hydronic Piping — One Boiler, Multi-Temperature System.

Page 14

Page 14

OPTIONAL PUMP MOUNTED UNIT AVALIABLE

BOILER CIRC.

PUMP

COLD WATER

MAKE-UP

SYSTEM PUMP

SYSTEM

RETURN

SYSTEM

SUPPLY

C

THERMOMETER

GLOBE VA LVE

CHECK VA LVE

PRESSURE REDUCING VALV E

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALV E

TEMPERATURE

SENSOR

3-WAY V ALV E

PURGE

VALV E

INSTALLAIR VENTS AT HIGH POINTS IN SYSTEM

PIPING&SIZING OF EXPANSION TANK

PER TANK MANUFACTURER'S INSTRUCTIONS

PRIMARY/SECONDARY MANDITORY FOR ALL

VARIABLE FLOW SYSTEMS

BOILER CIRC. PUMP SIZED FOR FLOW THROUGH BOILER

BOILER CIRC. PUMP TO BE USED WITH EM

DOTTED DEVICES INDICATE ALTERNATE LOCATIONS

BOILER CIRCUIT PIPING MUST BE EQUAL TO

BOILER WATER CONNECTION SIZE

SYSTEM TEMP. INTERLOCK REQUIRED

MULTIPLE STAGE BOILERS RECOMMENDED

PUT BOILER CONTROL SENSOR IN THE OUTLET

WHEN USING THIS PIPING STYLE

2

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VALVING. CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS.

DIMENSION ''C'' TO BE4PIPE DIAMETERS

DIMENSION ''D'' TO BE 18" MINIMUM

D

OPTIONAL PUMP MOUNTED UNIT AVALIABLE

BOILER CIRC.

PUMP

COLD WATER

MAKE-UP

SYSTEM PUMP

SYSTEM

RETURN

SYSTEM

SUPPLY

ADJUSTMENT PROCEDURE TO MAINTAIN 130°FINLET TEMP.

1. Turn on heater and open valves A&B

2. After steady-state operation, if T1 is less than

130° F, slowly close valveBuntil T1 climbs to 130° F

3. If T1is greater than 130° F, slowly

close valve A until T1 dropsto 130° F

4. Check after system operating temperature has

stabilized. Make final adjustments.

A

B

A

B

THERMOMETER

GLOBE VA LVE

CHECK VA LVE

PRESSURE REDUCING VALV E

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALV E

TEMPERATURE

SENSOR

3-WAY V ALV E

PURGE

VALV E

INSTALLAIR VENTS AT HIGH POINTS IN SYSTEM

PIPING&SIZING OF EXPANSION TANK

PER TANK MANUFACTURER'S INSTRUCTIONS

PRIMARY/SECONDARY MANDITORY FOR ALL

VARIABLE FLOW SYSTEMS

BOILER CIRC. PUMP SIZED FOR FLOW THROUGH BOILER

BOILER CIRC. PUMP TO BE USED WITH EM

DOTTED DEVICES INDICATE ALTERNATE LOCATIONS

BOILER CIRCUIT PIPING MUST BE EQUAL TO

BOILER WATER CONNECTION SIZE

SYSTEM TEMP. INTERLOCK REQUIRED

MULTIPLE STAGE BOILERS RECOMMENDED

PUT BOILER CONTROL SENSOR IN THE OUTLET

WHEN USING THIS PIPING STYLE

2

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VALVING. CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS.

DIMENSION ''C'' TO BE4PIPE DIAMETERS

DIMENSION ''D'' TO BE 18" MINIMUM

CD

LAARS Heating Systems

Figure 7. Hydronic Piping - Alternate System.

Figure 8. Hydronic Piping - Alternate Low Temperature System.

Page 15

Rheos Boiler and Water Heater

2.3.4 Vertical Combustion Air Terminal

When combustion air is taken from the roof, a

eld-supplied rain cap or an elbow arrangement must

be used to prevent entry of rain water (see Figure 2).

The opening on the end of the terminal must be at least

12" (30cm) above the point at which it penetrates the

roof, and high enough above the roof line to prevent

blockage from snow. When the vent terminates on the

roof, the combustion air must terminate at least 12"

(30cm) below the vent terminal.

2.4 Common Vent Test — Boilers

NOTE: This section does not describe a method for common

venting Rheos units. It describes what must be done when a unit is

removed from a common vent system. Rheos units require special

vent systems and fan for common vent. Contact the factory if you

have questions about common venting Rheos units.

When an existing boiler is removed from a

common venting system, the common venting system

is likely to be too large for proper venting of the

appliances remaining connected to it.

At the time of removal of an existing boiler, the

following steps shall be followed with each appliance

remaining connected to the common venting system

placed in operation, while the other appliances

remaining connected to the common venting system

are not in operation.

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper

size and horizontal pitch and determine there is

no blockage or restriction, leakage, corrosion and

other deciencies which could cause an unsafe

condition.

3. Insofar as it is practical, close all building doors

and windows and all doors between the space in

which the appliances remaining connected to the

common venting system are located and other

spaces of the building. Turn on clothes dryers

and any appliance not connected to the common

venting system. Turn on any exhaust fans, such

as range hoods and bathroom exhausts, so they

will operate at maximum speed. Do not operate a

summer exhaust fan. Close replace dampers.

4. Place in operation the appliance being

inspected. Follow the lighting instructions.

Page 15

Adjust thermostat so appliance will operate

continuously.

5. Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use

the ame of a match or candle, or smoke from a

cigarette, cigar or pipe.

6. After it has been determined that each appliance

remaining connected to the common venting

system properly vents when tested as outlined

above, return doors, windows, exhaust fans,

replace dampers and any other gas burning

appliance to their previous conditions of use.

7. Any improper operation of the common venting

system should be corrected so that the installation

conforms to the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and/or CSA B149.1, Installation

Codes. When resizing any portion of the common

venting system, the common venting system

should be resized to approach the minimum size

as determined using the appropriate tables in Part

II of the National Fuel Gas Code, ANSI Z223.1

NFPA 54 and/or CSA B149.1, Installation Codes.

SECTION 3.

Gas Supply and Piping

3.1 Gas Supply and Piping

Gas piping should be supported by suitable

hangers or oor stands, not the appliance.

Review the following instructions before

proceeding with the installation.

1. Verify that the appliance is tted for the proper

type of gas by checking the rating plate. Laars

Heating Systems appliances are normally equipped

to operate at elevations up to 2000 feet (610m).

However, the appliance will function properly

without the use of high altitude modication at

elevations up to 10,000 feet (3050 m).

2. The maximum inlet gas pressure must not exceed

13" W.C. (3.2kPa). The minimum inlet natural

gas pressure is 4" W.C. (1.0kPa) and minimum

inlet propane gas pressure is 6" (1.5kPa).

3. Refer to Table 7, size supply.

Model Flow H/L Temp Flow H/L Temp Flow H/L Temp Flow H/L Temp Flow H/L Temp Flow H/L Temp

(Size) gpm feet Rise (°F) lpm m Rise (°C) gpm feet Rise (°F) lpm m Rise (°C) gpm feet Rise (°F) lpm m Rise (°C)

1200 119 20 18 449 6.1 10 93 12 23 351 3.7 13 65 6.0 32 246 1.8 18

1600 161 29 17 609 8.8 10 132 20 21 500 6.1 12 89 8.9 31 336 2.7 17

2000 182 22 19 690 6.7 11 149 15 23 565 4.6 13 100 6.6 35 379 2.0 19

2400 237 23 18 898 7.0 10 186 14 23 703 4.3 13 129 6.9 32 488 2.1 18

Note: Soft Water: 1 to 7.5 grains per gallon Note: Headloss is for heater’s heat exchanger only.

Normal Water: 7.6 to 17 grains per gallon

Hard Water: More than 17 grains per gallon

Hard Water Normal Water Soft Water

Table 9. Water Flow Requirements, RHCV (Water Heater).

Page 16

Page 16

THERMOMETER

GLOBE VALVE

CHECK VALVE

PRESSURE REDUCING VALVE

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALV E

TEMPERATURE

SENSOR

3-WAY VALV E

NOTES:

7. CAUTION: PUMP SIZING MUST BE BASED UPON WATER HARDNESS AT JOB SITE

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATIONAND VALV ING CHECK

PRV

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS

WATER CATEGORY GRAIN

HARDNESS PER GALLON

S=SOFT 1 THROUGH 7.5

N=NORMAL 7.6 THROUGH 17

H=HARD OVER 18

17.1PARTS PER MILLION

=1GRAIN HARDNESS PER GALLON

KEY:

2

SUPPLY

RECIRC.

CWMU

1. OPTIONAL CWMU&RECIRC. LINE LOCATION.

2. WHEN USING INTERMITTENT PUMP AND EM LOCATE REMOTEAQUASTAT

WELL IN LOWER 1/3OFTANK WITH HEAT SENCEING COMPOUND.

3. BACK FLOW PREVENTER MAYBE REQUIRED CHECK LOCAL CODES.

4. THERMAL EXPANSION TANK MAYBE REQUIRED CHECK LOCAL CODES.

5. WHEN USING OPTIONAL FACTORY MOUNTED PUMP, MAX PIPE LENGTH

30'TOTAL, 6-90° ELBOWS,FULL PIPE SIZE.

6. THIS DRAWING DEPICTS A TWO-PASS HEAT EXCHANGER.

5

TPRV

3

4

2

1

THERMOMETER

GLOBE VA LVE

CHECK VA LVE

PRESSURE REDUCING VA LVE

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALV E

TEMPERATURE

SENSOR

3-WAY VALV E

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATIONAND VA LVING CHECK

PRV

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONALREQUIREMENTS

WATERCATEGORY GRAIN

HARDNESS PER GALLON

S=SOFT1THROUGH 7.5

N=NORMAL 7.6 THROUGH 17

H=HARD OVER18

KEY:

TPRV

6. THIS DRAWING DEPICTS ATWO-PASS HEAT EXCHANGER.

30'TOTAL, 6-90° ELBOWS ,FULL PIPE SIZE.

5. WHENUSINGOPTIONALFACTORY MOUNTED PUMP,MAX PIPE LENGTH

4. THERMAL EXPANSION TA NK MAYBEREQUIRED CHECK LOCAL CODES.

3. BACK FLOWPREVENTER MAYBEREQUIRED CHECK LOCAL CODES.

WELL IN LOWER 1/3 OF TA NK WITH HEAT SENCEING COMPOUND.

2. WHENUSINGINTERMITTENT PUMP ANDEMLOCATE REMOTEAQUASTAT

1. OPTIONAL CWMU&RECIRC. LINELOCATION.

8. CAUTION: PUMP SIZING MUSTBE BASED UPON WATER HARDNESS AT JOB SITE

NOTES:

2

5

SUPPLY

CIRC.RETURN

2

3

CWMU

4

1

5

7. COMMON PIPING MUST BE SIZEDFOR MAXIMUM COMBINED HEATER FLOW.

7

7

17.1PARTS PER MILLION

=1GRAIN HARDNESS PER GALLON

LAARS Heating Systems

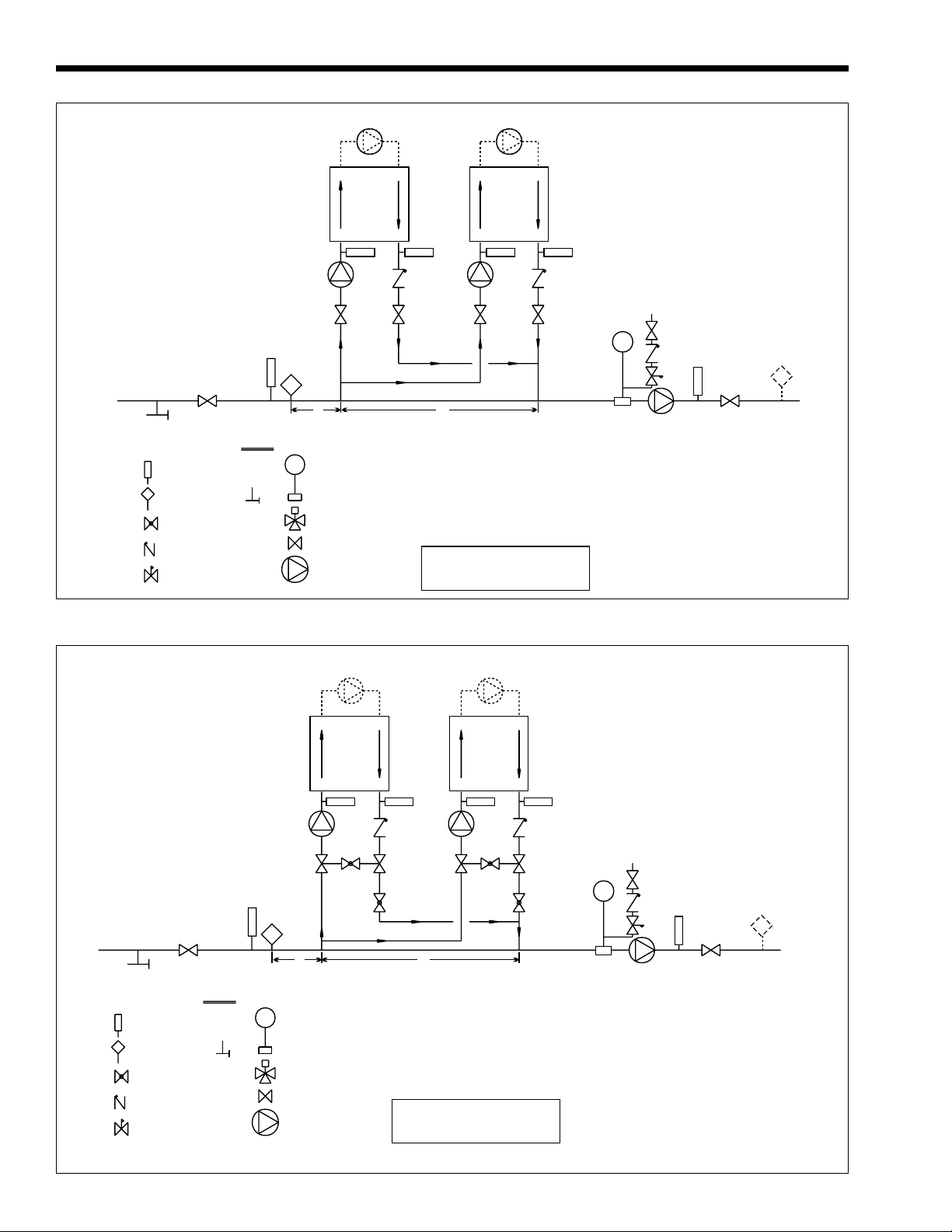

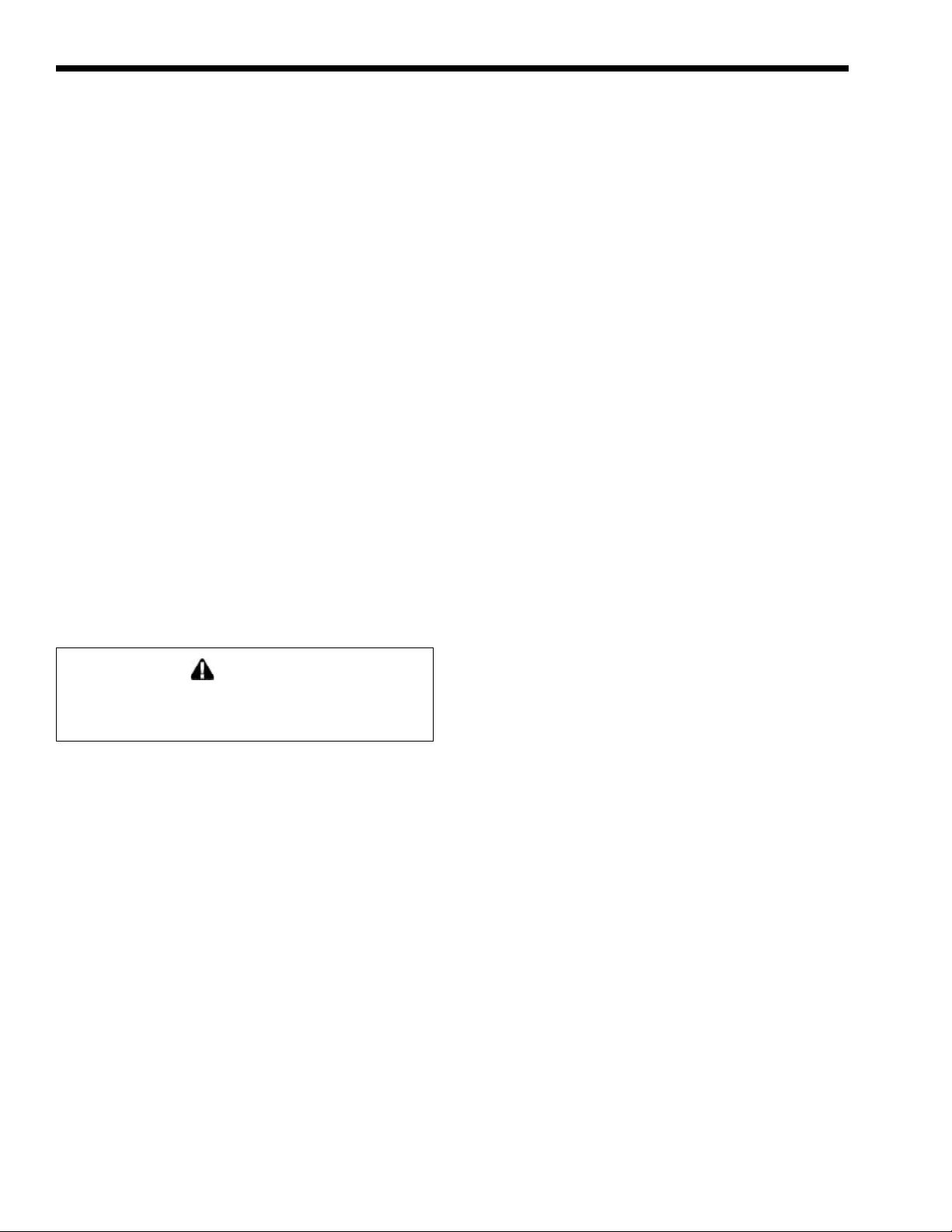

Figure 9. Water Heater Piping — One Heater, One Tank.

Figure 10. Water Heater Piping — Multiple Heaters, One Tank.

Page 17

Rheos Boiler and Water Heater

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VA LVING CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS

THERMOMETER

GLOBE VA LVE

CHECK VA LVE

PRESSURE REDUCING VA LVE

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALV E

TEMPERATURE

SENSOR

3-WAY VALV E

PRV

TPRV

6. THIS DRAWING DEPICTS A TWO-PASS HEAT EXCHANGER.

30'TOTAL, 6-90° ELBOWS,FULL PIPE SIZE.

5. WHEN USING OPTIONAL FACTORY MOUNTED PUMP, MAX PIPE LENGTH

4. THERMAL EXPANSION TANK MAYBE REQUIRED CHECK LOCAL CODES.

3. BACK FLOW PREVENTER MAYBE REQUIRED CHECK LOCAL CODES.

WELL IN LOWER 1/3OFTANK WITH HEAT SENCEING COMPOUND.

2. WHEN USING INTERMITTENT PUMP AND EM LOCATE REMOTE AQUASTAT

1. OPTIONAL CWMU&RECIRC. LINE LOCATION.

7. COMMON PIPING MUST BE SIZED FOR MAXIMUM COMBINED HEATER FLOW.

8. CAUTION: PUMP SIZING MUST BE BASED UPON WATER HARDNESS AT JOB SITE

NOTES:

2

5

SUPPLY

CIRC. RETURN

2

2

3

CWMU

4

1

5

7

7

WATER CATEGORY GRAIN

HARDNESS PER GALLON

S=SOFT 1 THROUGH 7.5

N=NORMAL 7.6 THROUGH 17

H=HARD OVER 18

17.1PARTS PER MILLION

=1GRAIN HARDNESS PER GALLON

KEY:

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATIONAND VALV ING CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS

THERMOMETER

GLOBE VALVE

CHECK VALVE

PRESSURE REDUCING VALVE

W/ FAST FILL BYPASS

EXPANSION TANK

WITH AIR SCOOP AND

AUTO AIR VENT

PUMP

LEGEND

VALV E

TEMPERATURE

SENSOR

3-WAY VALV E

PRV

TPRV

6. THIS DRAWING DEPICTS A TWO-PASS HEAT EXCHANGER.

30'TOTAL, 6-90° ELBOWS,FULL PIPE SIZE.

5. WHEN USING OPTIONAL FACTORY MOUNTED PUMP, MAX PIPE LENGTH

4. THERMAL EXPANSION TANK MAYBE REQUIRED CHECK LOCAL CODES.

3. BACK FLOW PREVENTER MAYBE REQUIRED CHECK LOCAL CODES.

WELL IN LOWER 1/3OFTANK WITH HEAT SENCEING COMPOUND.

2. WHEN USING INTERMITTENT PUMP AND EM

1. OPTIONAL CWMU&RECIRC. LINE LOCATION.

7. CAUTION: PUMP SIZING MUST BE BASED UPON WATER HARDNESS AT JOB SITE

NOTES:

2

5

1

2

CIRC. RETURN

2

CWMU

SUPPLY

3

4

WATER CATEGORY GRAIN

HARDNESS PER GALLON

S=SOFT 1 THROUGH 7.5

N=NORMAL 7.6 THROUGH 17

H=HARD OVER 18

17.1PARTS PER MILLION

=1GRAIN HARDNESS PER GALLON

KEY:

Page 17

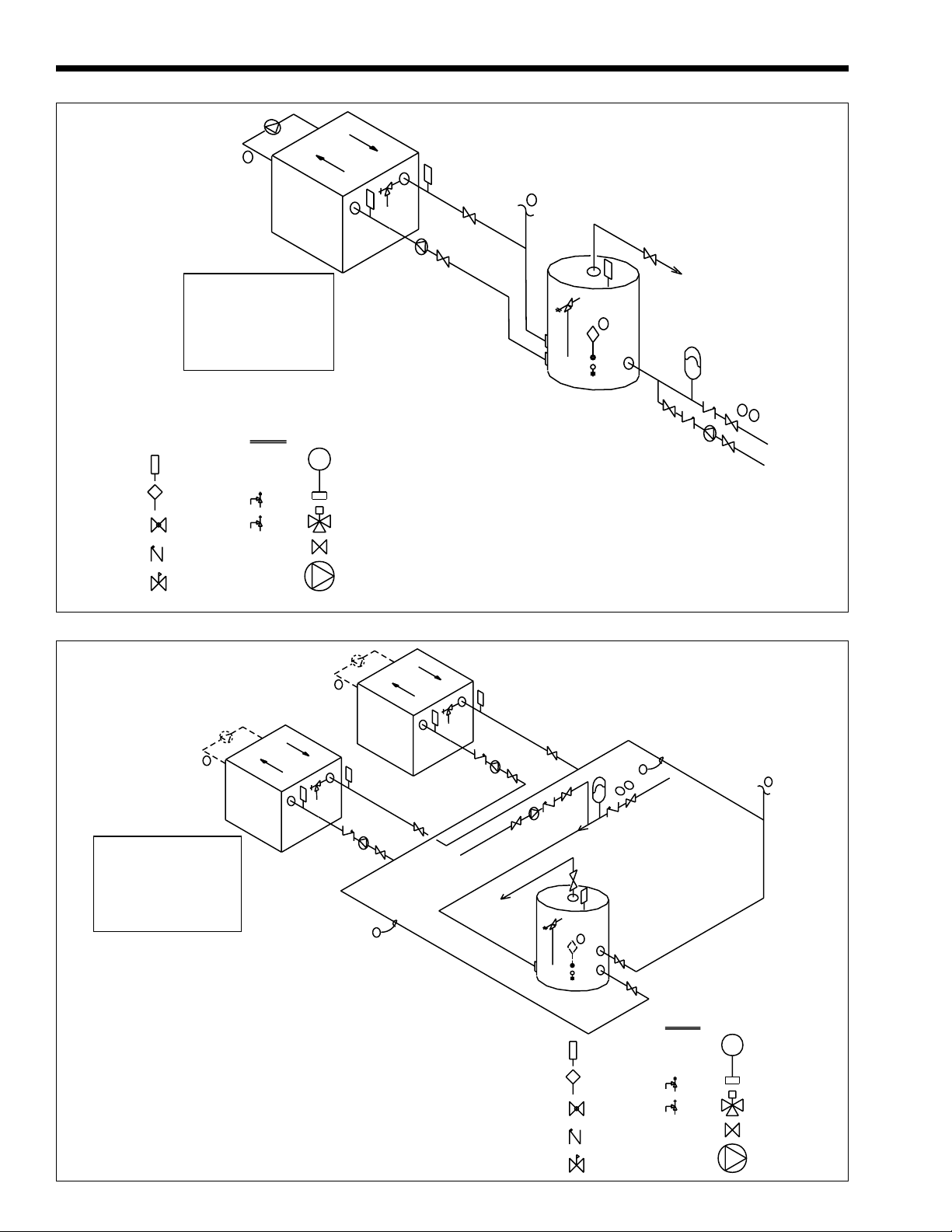

Figure 11. Water Heater Piping — One Heater, Multiple Tanks.

Figure 12. Water Heater Piping — Multiple Heaters, Multiple Tanks.

Page 18

Page 18

LAARS Heating Systems

4. Run gas supply line in accordance with all

applicable codes.

Note: If you have a boiler/water heater with a

normally open vent valve, install a vent line from

the vent valve to an outside location as required

by your installation code or IRI requirement. Do

not remove 3/4 inch pipe plug from the vent

valve if venting from the normally open vent

valve is not required by your installation code.

5. Locate and install manual shutoff valves in

accordance with state and local requirements.

6. A sediment trap must be provided upstream of

the gas controls.

7. All threaded joints should be coated with

piping compound resistant to action of liqueed

petroleum gas.

8. The appliance and its individual shutoff valve

must be disconnected from the gas supply piping

during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3.45kpa).

9. The unit must be isolated from the gas supply

system by closing its individual manual shutoff

valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 1/2 PSIG (3.45kpa).

10. The appliance and its gas connection must be

leak tested before placing it in operation.

11. Purge all air from gas lines.

WARNING:

Open ame can cause gas to ignite and result in

property damage, severe injury, or loss of life.

NOTE: The Rheos appliance and all other gas

appliances sharing the gas supply line must be ring

at maximum capacity to properly measure the inlet

supply pressure. The pressure can be measured at

the supply pressure port on the gas valve. Low gas

pressure could be an indication of an undersized

gas meter, undersized gas supply lines and/or an

obstructed gas supply line. A bleed line from the

diaphragm-type automatic valve shall be vented per

local code requirements. Rheos units are equipped

with low and high gas pressure switches that are

integrally vent limited. These types of devices do not

require venting to atmosphere.

SECTION 4A.

Water Connections — Rheos Boiler

4A.1 Heating System Piping:

Hot Supply Connections — Boiler

NOTE: This appliance must be installed in a closed

pressure system with a minimum of 12 psi (82.7kPa)

static pressure at the boiler.

Hot water piping should be supported by suitable

hangers or oor stands. Do not support piping with

this appliance. Due to expansion and contraction of

copper pipe, consideration should be given to the type

of hangers used. Rigid hangers may transmit noise

through the system resulting from the piping sliding in

the hangers. It is recommended that padding be used

when rigid hangers are installed. Maintain 1" (2.5cm)

clearance to combustibles for hot water pipes.

Pipe the discharge of the relief valve (full size)

to a drain or in a manner to prevent injury in the event

of pressure relief. Install an air purger, an air vent,

a diaphragm-type expansion tank, and a hydronic

ow check in the system supply loop. Minimum ll

pressure must be 12psig (82.7kPa). Install shutoff

valves where required by code.

Suggested piping diagrams are shown in Figures

4, 5, 6, 7 and 8. These diagrams are meant only as a

guide. Components required by local codes must be

properly installed.

4A.2 Cold Water Make-Up — Boiler

1. Connect the cold water supply to the inlet

connection of an automatic ll valve.

2. Install a suitable back ow preventer between the

automatic ll valve and the cold water supply.

3. Install shut off valves where required.

NOTE: The boiler, when used in connection with a refrigeration

system, must be installed so the chilled medium is piped in parallel

with the boiler with appropriate valves to prevent the chilled

medium from entering the boiler.

The boiler piping system of a hot water heating

boiler connected to heating coils located in air

handling appliances where they may be exposed to

refrigerated air circulation must be equipped with ow

control valves or other automatic means to prevent

gravity circulation of the boiler water during the

cooling cycle.

A boiler installed above radiation level, or as

required by the authority having jurisdiction, must be

provided with a low water cutoff device either as a part

of the boiler or at the time of boiler installation.

4A.3 Water Flow Requirements — Boiler

A hydronic heating (closed loop) application

recirculates the same uid in the piping system. As a

result, no new minerals or oxygen is introduced into

the system. To ensure a proper operating temperature

leading to long boiler life, a ow rate has been

established based on the uid temperature rise for this

specic size boiler.

Pump-mounted boilers can be ordered for use in

primary secondary piping systems. The pumps used

are sized for the headloss through the heater, plus 30

Page 19

Connector

Module

Dial

Setpoint Adjustment

Differential

Adjustment

Energized

Relay

LED Indicator

Relay

VDC

COM

24V

SEN

Jumper Block

Position

Heating

Cooling

Note: Jumper must

be in “Heating” mode,

or Rheos will not

operate properly.

Rheos Boiler and Water Heater

Figure 13. Temperature Control.

feet (9.1m) of full-sized piping and a normal number

of ttings.

Table 8 species water ow rates for boilers,

which will enable the user to size a pump. The

headloss shown is for the heater only, and the user

will need to add the headloss of the system piping to

properly size the pump.

The minimum inlet water temperature for the

Rheos is 130°F (54°C) to avoid condensing on the

copper coils.

4A.4 Freeze Protection – Boiler

Proper precautions for freeze protection are

recommended for boiler installations in areas where

the danger of freezing exists.

Power outage, interruption of gas supply, failure

of system components, activation of safety devices,

etc., may prevent a boiler from ring. Any time a

boiler is subjected to freezing conditions, and the

boiler is not able to re, and/or the water is not able

to circulate, there is a risk of freezing in the boiler

or in the pipes in the system. When water freezes,

it expands. This can result in bursting of pipes in the

system, or damage to the boiler, which could result in

leaking or ooding conditions.

a mixture of minimum 50% water and maximum

50% properly inhibited HVAC glycol, which contains

an antifoamant, is the preferred method of freeze

protection for Rheos boilers. Percentage of glycol

used in the Rheos boiler must not exceed 50%.

Typically, this mixture will serve as burst protection

for temperatures down to approximately –35°F (30°C). To get the desired temperature rise across the

boiler when this mixture is used, increase the water

ow by 15% above the original recommendation.

Do not use automotive anti-freeze. Maintaining

Page 19

Increase the head loss requirement by 20%.

IMPORTANT NOTES: Different glycol products

may provide varying degrees of protection. Glycol

products must be maintained properly in a heating

system, or they may become ineffective. Consult the

glycol specications, or the glycol manufacturer, for

information about specic products, maintenance

of solutions, and set up according to your particular

conditions.

SECTION 4B.

Water Connections —

Rheos Water Heater

4B.1 Water System Piping —

Water Heater

Hot water piping should be supported by suitable

hangers or oor stands. Do not support piping with

this appliance. Due to expansion and contraction of

copper pipe, consideration should be given to the type

of hangers used. Rigid hangers may transmit noise

through the system resulting from the piping sliding in

the hangers. It is recommended that padding be used

when rigid hangers are installed.

The Rheos can be used with several different

types of readily available storage tanks. A pump draws

water from the storage tank and pumps the water

through the heater and back into the tank. Pumpmounted units have a circulating pump built into the

water heater.

Pipe the outlet from the heater’s relief valve

such that any discharge from the relief valve will be

conducted to a suitable place for disposal when relief

occurs. Do not reduce line size or install any valves in

this line. The line must be installed to allow complete

drainage of both the valve and the line.

Suggested piping diagrams are shown in Figures

9, 10, 11 and 12. These diagrams are meant only as a

guide. Components required by local codes must be

properly installed.

The minimum inlet water temperature for the

Rheos is 130°F (54°C) to avoid condensing on the

copper coils.

4B.2 Hot Water Supply Piping —

Water Heater

Follow the tank manufacturer’s guidelines for

completion of the hot water system connections.

Page 20

Page 20

V C

I

Cover Screws

(Quantity=4)

Integration

DIP Switch

is setto

“Medium” at

thefactory.

See Section

5.5.6for

descriptions

of other

settings.

LED Indicator

(Percent of

Output)

Module

Connector

THROT

RANGE

MIN

OUTPUT

OFFSET

Reverse

Acting

Direct

Acting

Operation Mode

Jumper Positions

NOTE: A listed temperature and pressure relief

valve listed as complying with the Standard for

Relief Valves and Automatic Gas Shutoff Devices

for Hot Water Supply Systems, 1). ANSI Z21.22

latest edition, or 2). CSA 4.4, of suitable discharge

capacity must be installed in the separate storage

tank system.

water supply system, such as one having a backow

preventer in the cold water supply line, the relief valve

may discharge periodically, due to thermal expansion.

Means (such as a properly-sized expansion tank) shall

be provided to control thermal expansion. Contact the

water supplier or local plumbing inspector on how to

control this situation.

4B.3 Water Flow Requirements —

Water Heater

new water is constantly being introduced. With the

new water comes a fresh supply of minerals that can

be deposited on the unit’s heat exchanger. This is

commonly known as scaling. The amount of minerals

will depend upon the hardness of the water. Water can

also be aggressive, and can erode metals, including

copper, if the water is moved too quickly. The water

ow requirements for the Rheos water heater are based

upon the hardness of the water. The water ow is kept

high enough to prevent scaling, but low enough to

prevent tube erosion. For extremely soft or hard water,

cupro-nickel tubes are available. Contact a Laars

Representative if you have questions or concerns about

water quality.

with standard pumps for soft or normal water or with

pumps for hard water. The pumps used are sized for

the headloss through the heater, plus 30 feet (9.1m) of

full-sized piping and a normal number of ttings.

heaters, which will enable the user to size a pump.

The headloss shown is for the heater only, and the user

will need to add the headloss of the piping system to

properly size the pump.

4B.4 Combined Water (potable) Heating

NOTE: These systems are not allowed in the

Commonwealth of Massachusetts.

heater for the space heating application shall be

suitable for use with potable water.

treatment, shall not be introduced into the potable

water used for space heating.

water shall not be connected to any heating system

If the Rheos water heater is installed in a closed

In a water heating application (an open system),

Pump-mounted water heaters can be ordered

Table 9 species water ow rates for water

and Space Heating

Piping and components connected to this water

Toxic chemicals, such as used for boiler

This water heater when used to supply potable

LAARS Heating Systems

Note: Jumper must be in “Reverse Acting” mode, or Rheos will not operate properly.

Figure 14. Proportional Control.

or component(s) previously used with a non-potable

water heating appliance.

When the system requires water for heating at

temperatures higher than required for other uses,

an anti-scald mixing or tempering valve shall be

installed to temper the water for those uses in order

to reduce scald hazard potential.

4B.5 Freeze Protection – Water Heater

Although Rheos water heaters are design-

certied for outdoor installations, such installations

are not recommended in areas subject to freezing

temperatures unless proper precautions are taken.

Power outage, interruption of gas supply, failure

of system components, activation of safety devices,

etc., may prevent a heater from ring. Any time a

heater is subjected to freezing conditions, and the

heater is not able to re, and/or the water is not

able to circulate, there is a risk of freezing in the

heater or in the pipes in the system. When water

freezes, it expands. This can result in bursting of pipes

in the system, or damage to the heater, which could

result in leaking or ooding conditions.

Page 21

Rheos Boiler and Water Heater

Page 21

SECTION 5.

Electrical Connections

WARNING

The appliance must be electrically grounded in

accordance with the requirements of the authority

having jurisdiction or, in the absence of such

requirements, with the latest edition of the National