Page 1

User's Manual Document 1374

User's Manual for

™

PENNANT

includes

Hydronic Boiler

Model PNCH

Water Heater

Model PNCV

Sizes 500-2000

U.S. Reg. 2,765,423

'LOW TEMP PENNANT'

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualied in hot water boiler installation and maintenance. Improper installation and/or operation could

create carbon monoxide gas in ue gases which could cause serious injury, property damage, or death.

Improper installation and/or operation will void the warranty. For indoor installations, as an additional

measure of safety, Laars strongly recommends installation of suitable Carbon Monoxide detectors in the

vicinity of this appliance and in any adjacent occupied spaces.

WARNING

If the information in this manual is not

followed exactly, a re or explosion may

result causing property damage, personal

injury or loss of life.

Do not store or use gasoline or other

ammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the re department.

Installation and service must be performed

by a qualied installer, service agency, or gas

supplier.

Assurez-vous de bien suivres les instructions

données dans cette notice pour réduire au

minimum le risque d’incendie ou d’explosion

ou pour éviter tout dommage matériel, toute

blessure ou la mort.

Ne pas entreposer ni utiliser d’essence ni

d’autres vapeurs ou liquides inammables dans

le voisinage de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ:

• Ne pas tenter d’allumer d’appareils.

• Ne touchez à aucun interrupteur. Ne pas vous

servir des téléphones dansle bâtiment où vous

vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions du

fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le sservice des incendies.

L’installation et l’entretien doivent être assurés par

un installateur ou un service d’entretien qualié ou

par le fournisseur de gaz.

AVERTISSEMENT

H2380000-

Page 2

Page 2

TABLE OF CONTENTS

LAARS Heating Systems

SECTION 1 Caring For Your Pennant ....................... 3

1.A General Care ............................................3

1.B Annual Inspection of Flue and Vents ........3

1.C In the Event of a Power Failure ................3

1.D Full Service Every Three (3) Years ...........3

SECTION 2 Touchscreen and System Ops ...............4

2.A The Home Screen ....................................4

2.A.1 Home Screen Status Window...................4

2.A.2 Home Screen Active Icons .......................5

2.B Lock/Unlock Display Screen .....................6

2.C Keypad Operations ...................................7

2.D Quick Start ..............................................8

2.D.1 CH /DHW .................................................8

2.D.1.a CH1 /DHW11 ............................................ 8

2.D.1.b CH2/DHW2 2 ............................................8

2.D.2 DHW/DHW3 ............................................9

2.D.3 Outdoor Reset .........................................9

2.D.4 Warm Weather Shut Down ...................... 9

2.D.5 Anti-Short Cycle .....................................10

2.D.6 Time & Date ........................................... 10

SECTION 3 Electrical Connections ..........................11

3.A Installation Warnings ...............................11

3.B Line Voltage Connections ........................11

3.B.1 Main Power..............................................11

3.B.2 Pump Power ............................................11

3.B.3 Boiler/Heater Pump ................................11

3.B.4 Auxiliary Power Output ............................11

3.C Low Voltage Connections ....................... 12

3.C.1 Field Wiring - Inputs................................12

3.C.1.a Safety Interlocks .....................................12

3.C.1.b PNCH/PNCV Heat Demands .................12

3.C.1.c Field Inputs (Open/Closed)..................... 12

3.C.1.d Temperature Sensors ............................. 12

3.C.2 Field Wiring - Outputs ............................13

3.C.2.a Dry Contacts ...........................................13

3.C.1.e Analog (BAS) Input .................................13

3.C.2.b Cascade RS485 .....................................14

3.C.2.c BAS RS485 ............................................ 14

3.C.2.d 24VAC .................................................... 14

3.D Cascade Wiring Connections .................15

SECTION 4 Burner Set Up ......................................15

4.A Set Up for 0 to 2500 Feet Altitude ..........15

4.B Set Up for High Altitude

( >2500 Feet ) .........................................16

Page 3

Pennant (500-2000), User's Manual

SECTION 1 Caring For Your

Pennant

Your Pennant will require very little

Maintenance. However, as with any ne appliance

there are certain steps that should be taken to ensure

continuing optimum performance.

Page 3

WARNING

Do not use this boiler if any part has been

under water. Immediately call a qualied

service technician to inspect the boiler and to

replace any part of the control system and any

gas control which has been under water.

1.A General Care

Keep the area around the Pennant clean and

free from combustible materials, gasoline and other

ammable liquids and vapors.

The Pennant must be completely isolated and

protected from any source of corrosive chemical fumes

such as trichlorethylene, perchlorethylene, chlorine,

etc.

Keep grille openings on the boiler free for proper

ventilation of interior components.

Do not obstruct or block a free ow of air to the

boiler to ensure proper ventilation.

If desired, clean the jacket surfaces with a damp

cloth and mild detergent. Do not use ammable

cleaning materials.

If sidewall vented, keep the vent terminal clear

of obstructions — do not pile snow against the vent

terminal. Clean the air lter(s) often, and then develop

an appropriate maintenance schedule.

1.B Annual Inspection of Flue and Vents

Visually inspect the vent pipe once a year. Should

any deterioration exist, have the affected parts replaced

by a qualied service person.

WARNING

Should overheating occur or the gas supply

fail to shut off, do not turn off or disconnect the

electrical supply to the pump. Instead, shut

off the gas supply at a location external to the

boiler.

FOR SERVICE

Contact your installing contractor, gas utility,

Laars dealer, or call Laars for the nearest

authorized representative in your area.

1.C In the Event of a Power Failure

The Pennant can not be operated during an

electrical power outage. If there is an extended power

outage with danger from freezing, then the Pennant

(and all other water systems) should be drained

completely. When draining the boiler, turn off main

electrical disconnect switch. When placing back in

service, refer to start-up instructions in the Installation

and Operation Manual for lling and purging.

Draining and lling shall only be done by a qualied

service person.

1.D Full Service Every Three (3) Years

In addition to the annual visual inspections, a

qualied service agency should conduct a detailed

inspection of all ue product carrying areas of the

boiler and its venting system.

Page 4

Page 4

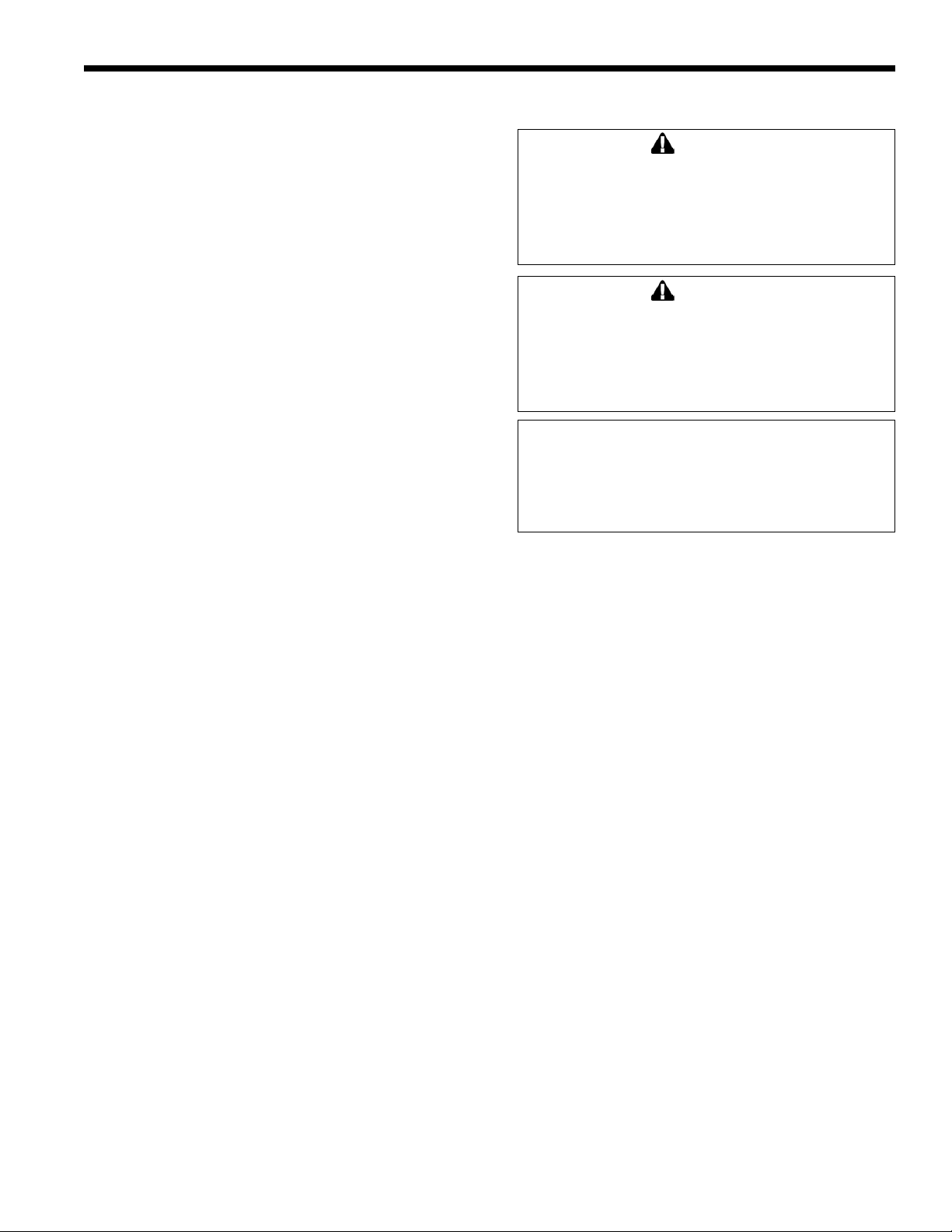

Icon

Description

Setpoint

CSP:

CH1:

CH2:

DHW:

Heat Demand

Setpoints

NOTE: The heat

demand set point

will turn green in

color when active.

Pumps

Boiler:

System:

DHW:

Pump Status

(On/Off)

Boiler Status

B1: Running

B2: Running

Stage 1:

Stage 2:

Stage 3:

Stage 4:

Blower 1:

Blower 2:

OAT:

Pennant Status:

• Burner Bank 1

• Burner Bank 2

• Staging (on/off)

• Blower Speed

(high/low)

• OAT - Outdoor

Ambient

Temperature

(when

connected)

SECTION 2 Touchscreen and System Operations

2.A The Home Screen

Figure 1. The Home Screen

LAARS Heating Systems

2.A.1 Home Screen Status Window

The central area of the home screen displays the

current status information for the unit.

Heat Demand Setpoints.

Pump Status.

Boiler Status (Boiler Bank).

System Temp.

and DHW Temp (if installed)

Heat Demand Setpoints.

NOTE: The heat demand set point will

turn green in color when active

Model Stages

Low Temp On/Off

500 - 750 2

1000 3

1250 - 2000 4

Table 1. Stages per Model

Inlet & Outlet Temperature.

Figure 2. The Status Display Area, dened.

Pump Status.

System Supply /

Return Temperature

(when connected).

DHW

Temperature

(when connected).

Page 5

Pennant (500-2000), User's Manual

2.A.2 Home Screen Active Icons

Name Icon Description

Page 5

Security

Quick Start

Congure

Service

Messages

Active

Demands

Navigation

Bar

Displays the current lock status. Touch the lock icon to lock or unlock the

Touchscreen Display.

Provides quick touch access to the most commonly used parameters for easy

installation.

Will take you to ALL of your congurations and parameters for a detailed setup of

the unit. This is the largest group of menu screens.

Allows the service technician to access the basic diagnostic and troubleshooting

information.

Will show an 'Exclamation' when there is a message.

Clicking onto the Message icon will take you to the message itself.

The USB functionality will show the USB Icon at this location, if

being used.

Will show icons that indicate the active parameters that are

currently in demand.

The Navigation Bar is the constant indicator of where you are as you

navigate into and out of the touchscreens. See Screen 2 on page 7

ERROR Codes also show in the Navigation Bar when there is one of several unit

errors or shut-downs that have occured.

Date &

Time

Table 2. The Active Icons on the Home Screen, and what they do.

For Display Only. To change date and time, go to the

Conguration menu.

Page 6

Page 6

2.B Lock / Unlock Display Screen

Password Protection:

To change parameters, a password is required.

The control system includes three levels of password

protection.

-OEM Password: Setup and parameter changes

available only to the factory.

-INSTALLER Password: Setup and parameter

changes made during the initial setup and

commissioning. The installer password is 17.

-USER Password: Non-critical adjustments and

functions. The user password is lhs.

Logout. Allows the user to log out of the

password.

Password Unlocked. The lock will change

states depending on the Password level that was

entered. The inside of the Lock Icon will also change

between O, I, or U to denote what level you are logged

into. O= OEM; I= Installer; U= User.

There are 2 ways you can navigate to the

Password Entry screen.

a. By pressing the “Lock” icon on the center of the

top bar of any screen.

b. By navigating to “Congure”, then by pressing

the “Login” button on the lower right hand corner

of the “Congure” screen.

LAARS Heating Systems

Screen 1. Sign in Screen

Password Locked. If the password

is “Locked”, the user is automatically logged out after

a certain amount of time of inactivity on the screen. If

the password is “Unlocked” then the user will not be

automatically logged off. You can set this time interval

in Service -> Screen -> Auto Lock Timeout.

This screen works just like a normal “Qwerty”

keyboard. After entering in the correct password

needed, select “Enter” to unlock the appropriate

control settings.

Page 7

Pennant (500-2000), User's Manual

2.C Keypad Operations

As you navigate in, you will nd that all screens have either

a numeric keypad to enter in your customizable parameters OR

selection buttons to choose the device of your conguration.

NOTE: You can always tell exactly where you have navigated to by

looking at the icons in the

In this example you are in

Home/Congure/Central Heat/Central Heat One

Navigation Bar.

Page 7

Shows the current setting

of the Parameter.

These windows will reect the

allowable ranges that the setting

can be adjusted to.

To delete the current setting before

entering in the new value.

“Up and Down” arrows are used to

increment the setting accordingly.

Screen 2. A typical numeric keypad entry screen.

Screen 3. A Typical selection screen.

The “Enter” button is used to accept

the new value that was just entered.

This is the indicator that will be shown when

the correct password has been entered to

allow the setting to change.

The highlighted button (orange)

shows which one is selected.

Some screens may only allow you

to set one or the other, while some

other screens (example: pump

selection) will allow you to select

any or all of the options.

The “Back” button jumps to the

previous screen.

Page 8

Page 8

2.D Quick Start

To navigate to the Quick Start Screen, touch the

Quick Start Icon in the lower left-hand portion of the

Home Screen.

Screen 4. Home Screen

LAARS Heating Systems

Touching CH1/DHW1 navigates to the CH1/

DHW1 Quick Start Screen

1

2.D.1.a CH1 /DHW1

Screen 7. CH1/DHW1 Quick Start Screen

Screen 5. Quick Start Screen

CH is Central Heat DHW is Domestic Hot Water

2.D.1 CH /DHW

On the Quick Start Screen, touch the CH/DHW

thermometer icon to navigate to the CH Selection

Screen

There are two identical heat demands, CH1/DHW1

and CH2/DHW2, each with independent control

algorithms and independent inputs on the input

terminal strip.

NOTE: CH1 applies to hydronic units (PNCH),

while DHW1 applies to volume water units (PNCV).

• Enable/Disable – This allows CH1/DHW1 to be

enabled/disabled. The default setting is Enabled.

• Set Point – This is the temperature that this heat

demand will control to.

2

2.D.1.b CH2/DHW2

To navigate to the CH2/DHW2 Quick Start Screen,

touch the CH2 Icon on the CH/DHW Quick Start

Selection Screen.

Screen 8. CH2/DHW2 Quick Start Screen

Screen 6. CH/DHW Quick Start Selection Screen

NOTE: CH2 applies to hydronic units (PNCH),

while DHW2 applies to volume water units (PNCV).

Page 9

Pennant (500-2000), User's Manual

Page 9

2.D.2 DHW/DHW3

To navigate to the DHW/DHW3 Quick Start

Screen, touch the DHW faucet icon on the Quick Start

Screen.

Screen 9. DHW/DHW3 Quick Start Screen

The DHW/DHW3 Quick Start Screen allows

adjustment of the following parameter:

• Enable/Disable – This allows DHW/DHW3 to be

enabled/disabled. The default setting is Enabled.

• Set Point – This is the temperature that this heat

demand will control to.

temperature at which the Pennant will maximize the

boiler outlet temperature to the Maximum Water

Temperature.

NOTE: Outdoor functionality is applicable to

hydronic units only, and is explained in Installation

Manual (Doc 1373)

2.D.4 Warm Weather Shut Down

To navigate to the Warm Weather Quick Start

Screen, touch the Warm Weather Icon on the Quick

Start Screen.

NOTE: A DHW/DHW3 heat demand can be

initiated by an aquastat or sensor, see Sections 5.3.1.2

and 5.3.1.4 respectively.

2.D.3 Outdoor Reset

To navigate to the Outdoor Quick Start Screen,

touch the Outdoor Icon on the Quick Start Screen.

Screen 10. Outdoor Quick Start Screen

The Outdoor Quick Start Screen allows the

adjustment of the following parameters:

• Enable/Disable – This allows Outdoor Reset to

be enabled/disabled. The default setting is Enabled.

• Maximum Ambient Temperature – The

outdoor temperature at which the Pennant will limit

the boiler outlet temperature to the Minimum Water

Temperature.

• Minimum Ambient Temperature – The outdoor

Screen 11. Warm Weather Quick Start Screen

The Warm Weather Quick Start Screen allows

adjustment of the following parameters:

• Temp Min – Upon an active warm weather

shutdown condition, this is the temperature at which

the Pennant will reset the shutdown condition to

satisfy a heat demand.

• Temp Max – This is the temperature at which the

warm weather shutdown condition will occur.

• Feature Options – This parameter provides the

ability to either disable warm weather shutdown or

upon a warm weather condition, congure the Pennant

to shut down immediately or to shut down after the

current heat demand is satised.

Page 10

Page 10

LAARS Heating Systems

2.D.5 Anti-Short Cycle

To navigate to the Anti-Short Cycle Quick Start

Screen, touch the Anti-Short Cycle Icon on the Quick

Start Screen.

Screen 12. Anti-Short Cycle Quick Start Screen

The Anti-Short Cycle Quick Start Screen allows

adjustment of the following parameter:

• Cycle Time – The amount of time after a heat

demand is satised that the Pennant will wait to satisfy

the next active heat demand.

NOTE: Anti-Short Cycle Time does not apply to

DHW/DHW3 heat demands.

2.D.6 Time & Date

To navigate to the Time & Date Quick Start

Screen, touch the Time & Date Icon on the Quick Start

Screen.

Screen 13. Time & Date Quick Start Screen

The Time & Date Quick Start Screen allows

adjustment of the following parameters:

• Hour – The hour that will be displayed in the

upper banner on each screen, and the time captured in

the date/time stamp for lock-out conditions displayed

on the history screen.

• Minute – The minute that will be displayed in the

upper banner on each screen, and the time captured in

the date/time stamp for lock-out conditions displayed

on the history screen.

• Month – The month that will be displayed in the

upper banner on each screen, and the date captured in

the date/time stamp for lock-out conditions displayed

on the history screen.

• Day – The day that will be displayed in the upper

banner on each screen, and the date captured in the

date/time stamp for lock-out conditions displayed on

the history screen.

• Year – The month that will be displayed in the

upper banner on each screen, and the date captured in

the date/time stamp for lock-out conditions displayed

on the history screen.

Page 11

Pennant (500-2000), User's Manual

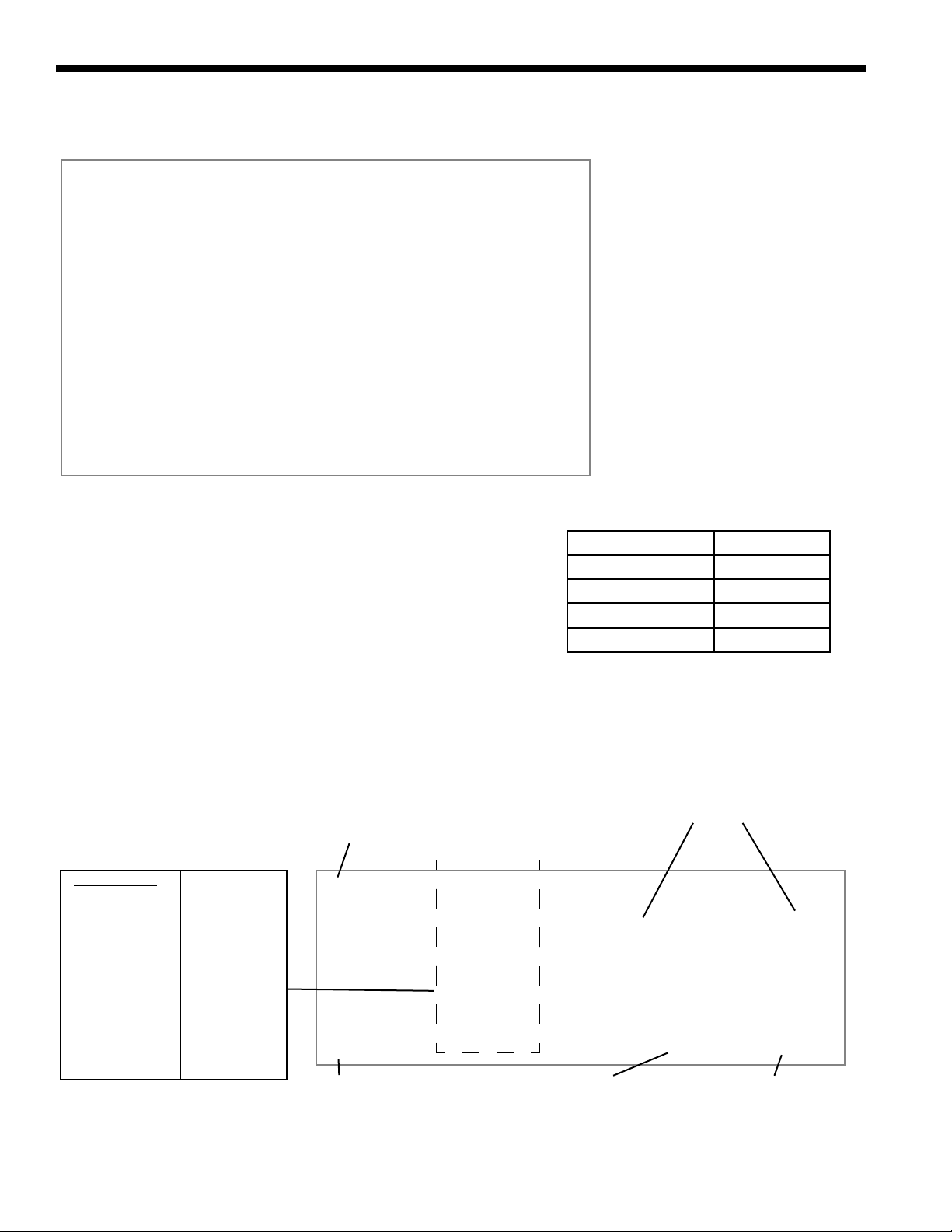

Over Current Recommendations (Amps)

Pennant

Pump Only

Size

Without

Pump

With

Pump

Taco

B & G

500

15

20

15

15

750

15

20

15

15

1000 20

25 –Taco

30 – B & G

15 15

1250

25

30

15

15

1500

25

30

15

15

1750

25 – 15

20

2000

25 – 20

20

SECTION 3 Electrical Connections

3.A Installation Warnings

WARNING

This appliance must be electrically grounded

in accordance with the requirements of the authority

having jurisdiction or, in the absence of such

requirements, with the latest edition of the National

Electrical Code, ANSI/NFPA 70, in the U.S. and with

the latest edition of CSA C22.1 Canadian Electrical

Code, Part 1, in Canada. Do not rely on the gas

or water piping to ground the metal parts of the

boiler. Plastic pipe or dielectric unions may isolate

the boiler electrically. Service and maintenance

personnel, who work on or around the boiler may

be standing on wet oors could be electrocuted by

an ungrounded boiler. Electrocution can result in

severe injury or death.

Single pole switches, including those of safety

controls and protective devices, must not be wired in

a grounded line.

All electrical connections are made at the

power terminals, which are located at the rear of the

appliance, or at the input/output terminal strips which

are located on the right side of the appliance.

All internal electrical components have been

prewired. No attempt should be made to connect

electrical wires to any other location except the

terminal blocks.

Page 11

3.B.2 Pump Power

The pump circuit is identied by three 12 AWG

wires: black with a white stripe (L2), white (N2), and

green (Ground).

If desired, an installer can change the pump

mounted single service units to use a separate circuit

for the pump. Instructions to make this change are

found in the Installation Manual (Doc 1373)

Table 3. Circuit Protection

3.B Line Voltage Connections

Incoming power must be protected by the

appropriate circuit breaker (fuse) and installed by a

qualied electrician or authorized/qualied personnel.

Recommended over current protection ratings are

shown in Table 3.

3.B.1 Main Power

All non-pump mounted Pennants require a

single 120-volt supply. Pump mounted Pennant

sizes 500-1500 also use a single 120-volt supply, and

Pennant sizes 1750-2000 require two separate 120-volt

supplies.

Pennant sizes 500-1500 main power (L1, N1, and

Ground) shall be connected to the three wires supplied.

This main power circuit is identied by three solid

colored wires (10 AWG) – black (L1), white (N1), and

green (Ground).

Pennant sizes 1750-2000 main power (L1,

N1, and Ground) is identied by three solid colored

wires (10 AWG) – black (L1), white (N1), and green

(Ground). The pump circuit is identied by three 12

AWG wires.

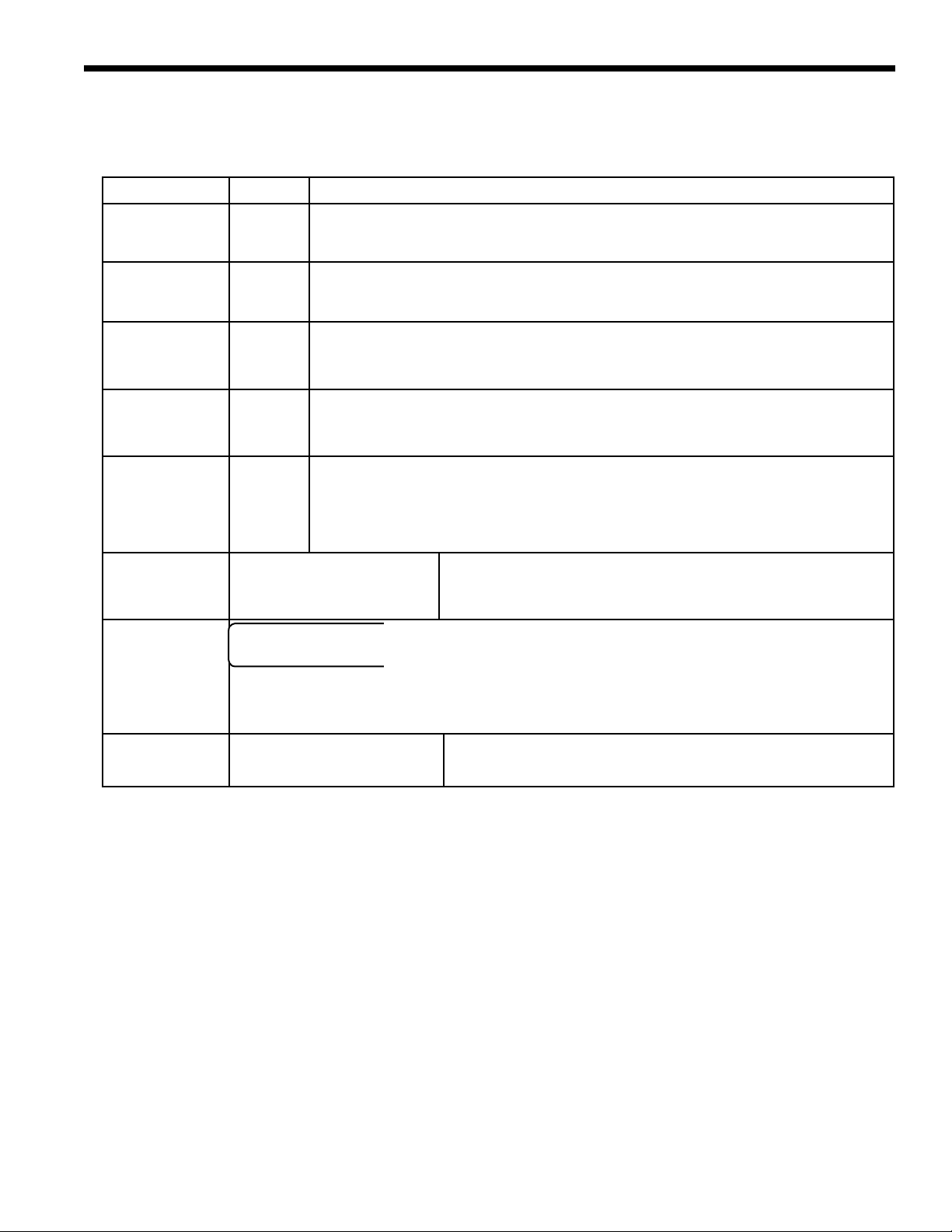

3.B.3 Boiler/Heater Pump

Conversion to a separate pump circuit requires

bringing in a separate circuit for the pump and

removing the three jumper wires within the internal

wiring of the 120-volt portion of the Pennant (see

Figure 3). This action should only be performed by

qualied personnel, with the power disconnected from

the unit.

To rewire the pump circuit, bring in a separate

120-volt circuit (L2, N2, and Ground). Remove

the jumper wires shown in Figure 3. Connect the

incoming line voltage (L2) to the main power switch

using a ¼” female insulated push on terminal. From

the other side of the main power switch, connect to

the main power terminal block, in the rear of the unit,

using a ¼” female insulated push on terminal. This

will be in the same position where the line voltage

jumper terminated. Connect N2 and Ground to the

main terminal block, in the rear of the unit, using ¼”

female insulated push terminals. These connections

will also be the same positions where the neutral and

ground jumpers were terminated.

Page 12

Page 12

terminals 7 and 8 of the input terminal strip.

DHW/DHW3: Connect the aquastat or end switch

(isolated contact only) wires to terminals 5 and 6 of the

input terminal strip. If preferred, a DHW tank sensor

can be used in lieu of an aquastat to generate a heat

demand, refer the Installation Manual (Doc 1373)

NOTE: The heat demand contacts must be dry

contacts. The Pennant controller heat demand voltage

is 24VDC.

3.C.1.c Field Inputs (Open/Closed)

Field Input 1: Field Input 1, if used, is connected

across terminals 9 and 10 of the input terminal strip.

When connected, Field Input 1 controls the Auxiliary

Dry Contact. If Field Input 1 is open, the Auxiliary

Dry Contact is open. If Field Input 1 is closed, the

Auxiliary Dry Contact is closed. Only dry contacts

can be connected to Field Input 1.

LAARS Heating Systems

Figure 3. Removing Jumpers.

3.B.4 Auxiliary Power Output

The Auxiliary Power Output, if used, is controlled

by Field Input 2. When Field Input 2 is closed,

line voltage is supplied at terminal 7 and neutral on

terminal 8 of the output terminal strip. This output is

rated for 250VAC, 2.5A maximum.

3.C Low Voltage Connections

Route all wires through the knockouts on the right side

of the Pennant. Connect low voltage wiring to the

input and output terminals shown in Figure 4. Connect

all wiring as shown on the wiring diagram.

3.C.1 Field Wiring - Inputs

3.C.1.a Safety Interlocks

Field Interlock: If the Field Interlock is utilized,

remove the jumper from the terminals 1 and 2 of the

input terminal strip and wire the interlock to these

terminals. Only dry contacts can be connected to the

Field Interlock terminals.

NOTE: Safety chain voltage is 24VDC.

3.C.1.b PNCH/PNCV Heat Demands

CH1/DHW1: Connect the thermostat/aquastat or end

switch (isolated contact only) wires to terminals 3 and

4 of the input terminal strip.

CH2/DHW2: Connect an additional thermostat/

aquastat or end switch (isolated contact only) wires to

Field Input 2: Field Input 2, if used, is connected

across terminals 11 and 12 of the input terminal strip.

When connected, Field Input 2 controls the Auxiliary

Power Output. If Field Input 2 is open, the Auxiliary

Power Output is off. If Field Input 2 is closed, the

controller turns power on at the Auxiliary Power

Output.

NOTE: The controller applies 24VDC to the Field

Inputs to detect the status of the contacts.

3.C.1.d Temperature Sensors

System Supply: The system supply sensor, if used, is

connected to terminals 14 and 15 of the input terminal

strip. When connected, the controller automatically

detects the presence of this sensor. If installed, the

Pennant controls the staging of the burners to maintain

the system supply temperature to the heat demand set

point. The system supply temperature is shown on

the home screen above the red system input arrow, see

Figure 1 on page 4. This sensor is supplied loose

with the Pennant and is installed in the piping or tank

per the suggested piping diagrams.

System Return: The system return sensor, if used, is

connected to terminals 16 and 17 of the input terminal

strip. When connected, the controller automatically

detects the presence of this sensor. There is no control

logic associated with this sensor. When connected,

this temperature is shown on the home screen above

the blue system output arrow. This sensor is supplied

loose with the Pennant and is installed in the piping or

tank per the suggested piping diagrams.

Domestic Hot Water (DHW): The DHW sensor, if

used, is connected to terminals 18 and 19 on the input

Page 13

Pennant (500-2000), User's Manual

Figure 4. Input and Output Terminal Strips

Page 13

Detail

3.C.2 Field Wiring - Outputs

3.C.2.a Dry Contacts

terminal strip. When connected, the Pennant will use

this sensor to perform the DHW thermostat function.

The controller automatically detects the presence

of this sensor and initiates a call for heat when the

DHW temperature drops below the DHW set point

by the value of the DHW On Hysteresis (DHW Set

Point – DHW On Hysteresis = DHW heat demand).

The DHW heat demand is satised when the DHW

temperature rises above the DHW set point by the

value of the DHW Off Hysteresis (DHW Set Point +

DHW Off Hysteresis = DHW heat demand satised).

When connected, this temperature is shown on the

home screen below the faucet icon. This sensor is

supplied loose with the Pennant and is installed in the

tank per the suggested piping diagrams.

Outdoor: The outdoor sensor, if used, is connected to

terminals 20 and 21 of the input terminal strip. When

connected, the controller automatically detects the

presence of this sensor. If installed, options such as

outdoor reset and warm weather shutdown can be

enabled through the display.

3.C.1.e Analog (BAS) Input

Building Automation System (BAS): The BAS input,

if used, is connected to terminals 22 and 23 of the

input terminal strip. When making the connection,

adhere to the polarity designations shown on the label

or wiring diagram. The input signal can be

0 – 10 VDC or 4 – 20 mA, and can be used to control

the ring rate or set point.. The factory default setting

is for a 0 – 10VDC signal. Congure for 4 – 20 mA

by placing a jumper on CN20 on the control board, see

Figure 5.

Run: These contacts, when used, are connected to

terminals 1 (common), 2 (normally closed), and 3

(normally open) of the output terminal strip. The

controller closes the normally open set of contacts

whenever the Pennant is running. This is typically

used by a BAS to verify the Pennant is satisfying a heat

demand. Contact ratings are 250VAC, 0.6A maximum.

Alarm: These contacts, when used, are connected

to terminals 4 (common), 5 (normally closed), and

6 (normally open) of the output terminal strip. The

controller closes the normally open set of contacts

whenever the Pennant is locked out or power is turned

off. Contact ratings are 250VAC, 0.6A maximum.

DHW Pump: When connecting a domestic hot water

(DHW) pump, use terminals 9 and 10 of the output

terminals strip. As this is a dry contact, the DHW

pump contact must be wired with either the DHW

pump supply voltage or DHW pump relay coil voltage.

DHW pump functionality is congured using the touch

screen. Contact ratings are 250VAC, 1.5A maximum.

System Pump: When connecting a system pump, use

terminals 11 and 12 of the output terminal strip. As

this is a dry contact, the system pump contact must

be wired with either the system pump supply voltage

or the system pump relay coil voltage. System pump

functionality is congured using the touch screen.

Contact ratings are 250VAC, 1.5A maximum.

AUX: These contacts, when used are connected to

terminals 13 and 14 of the output terminal strip. The

controller closes this contact when Field Input 1 is

closed; otherwise, this contact remains open. Contact

ratings are 250VAC, 1.5A maximum.

Page 14

Page 14

LAARS Heating Systems

JUMPER

4 - 20mA

ANALOG

INPUTS

NO JUMPER

0 - 10VDC

JUMPERS

4-20 mA

JUMPERS

0 - 10VDC

ANALOG OUTPUTS

Figure 5. Analog Input and Output Jumper Placement

3.C.2.b Cascade RS485

Prior to wiring Pennant units for cascade operations,

select one Pennant as the lead boiler/heater. Other

Pennants connected to the lead boiler/heater will be

referred to as lag units.

Communication between lead and lag units is

accomplished using RS485. When wiring Pennant

units for cascade operations, use terminals 22 (B), 23

(A), and 24 (GND) of the output terminal strip. Use

2-wire twisted pair, shielded w/drain, communication

cable between units. Referring to Figure 6, connect

one end of the twisted pair wires to A (terminal 23),

and the other to terminal B (terminal 22), and the

drain wire to GND (terminal 24). Connect the other

end of the cable to the next Pennant, matching the

termination wiring on the previous unit, except for

GND. Only connect the drain wire to ground on one

end of the cable to avoid ground loop issues. If more

than two Pennant units are cascaded together, daisy

chain the wiring from Pennant to Pennant, keeping the

cables as short as possible.

A system supply sensor must be installed and

connected to the lead boiler, see System Supply in

Section 5.3.1.4 – Temperature Sensors. The lead

boiler will use this system supply sensor as the

temperature control sensor for cascade operations.

CH1/DHW1 terminals are used to initiate a heat

demand at the lead boiler, refer to CH1/DHW1 in Heat

Demands of the Installation Manual (Doc 1373).

3.C.2.c BAS RS485

These terminals, when used, are for RS485 serial

communication with a BAS system using BACnet

MS/TP or Modbus protocols. Use 2-wire twisted pair,

shielded w/drain, communication cable between the

BAS and Pennant.

3.C.2.d 24VAC

There are terminals for 24VAC on the output terminal

strip. These terminals are reserved for Pennant lowtemp units or a low water cuto-off option kit.

Page 15

Pennant (500-2000), User's Manual

3.D Cascade Wiring Connections

Page 15

TB2-22

TB2-24

TB2-23

TB2-22

TB2-24

TB2-23

TB2-22

TB2-24

TB2-23

Figure 6. Cascade Wiring Connections

TB2-19

TB2-21

RS485 B

RS485

GND

TB2-20

BAS

RS485 A

TB2-19

TB2-21

RS485 B

RS485

GND

TB2-20

BAS

RS485 A

TB2-19

TB2-21

RS485 B

RS485

GND

TB2-20

BAS

RS485 A

Figure 7. Cascade BAS Wiring Connections

For the complete list of wiring diagrams and logic diagrams, please see the

Installation and Operating Manual. Document 1373

SECTION 4 Burner Set Up

4.A Set Up for 0 to 2500 Feet Altitude

The Pennant appliance utilizes a modular design

to achieve its stage-ring. The setup must be

checked before the unit is put in operation.

Problems such as failure to start, rough ignition,

strong exhaust odors, etc. can be due to improper

setup. Damage to the Pennant resulting from

improper setup is not covered by the limited

warranty.

1. Using this manual, make sure the installation

is complete and fully in compliance with the

instructions.

2. Determine that the appliance and system are

lled with water and all air has been bled from

both. Open all valves.

3. Observe all warnings on the Operating

Instructions label and turn on gas and electrical

power to appliance.

4. Switch on the appliance power switch located on

the right side of the unit.

5. The Pennant will enter the start sequence, as long

as the unit is being called for heat. The blower

and pump come on for pre-purge, then the ignitor

warm-up sequence starts and after the ignitor

warm-up is complete and all safety devices are

veried, the gas valves open. If ignition doesn’t

occur, check that there is proper gas supply. Wait

5 minutes and start the unit again. During initial

start up, air in the gas line may cause the Pennant

to "lock out" during the rst few trials for ignition.

Depending on the ignition modules installed, the

manual reset button on the ignition modules may

need to be depressed to restart the Pennant.

6. With the unit running, verify the supply gas

pressure, manifold gas pressure, and CO2

according to the Table 4

Page 16

Page 16

6. With the unit running, verify the supply gas pressure, manifold gas pressure, and CO2 according to the

table below.

Natural Gas

Propane

Typical

7” w.c. (1.7kPa)

11” w.c. (2.7kPa)

Range

5” w.c. ≤ (supply pressure ) ≤ 13” w.c.

Manifold Gas Pressure

2.5” w.c. (0.62 kPa)

CO

8%

9.2%

Supply Gas

Pressure

2

Table 4. Supply Gas Pressure

7. After placing the appliance in operation, the

Burner Safety Shutoff Device must be tested.

To test:

(a) Close gas shutof

f valve with burner operating.

(b) The ame will go out and blower will continue

to run for the post pur

ge cycle. One additional

attempt to light will follow. Ignition will not occur

as the gas is off. The ignition control will lockout,

and will have to be reset before the unit will

operate.

(c) Open gas shutof

f valve. Restart the appliance.

The ignition sequence will start again and the

burner will start. The appliance will return to its

previous mode of operation.

NOTE: Sizes 1000–2000 have two ignition controls

and two ignitors, which work independently of one

another. If the ignition control for stages 1 and 2

fails to properly light the main burners for those

stages, the second ignition control will still be

active, and will be able to energize stages 3 and

4. This, of course, will only occur if all other safety

devices conrm that the unit will run in a safe

condition.

4.B Set Up for High Altitude

( >2500 Feet )

Pennant appliances may be operated at high altitude

(7700 ft., 2347 m) with a reduction in output of approximately 10%. At altitudes of less than or more than 7700

ft. (2347 m) the appliance will perform equally as well,

but with differing reductions in output. At elevations

higher than 7700 ft. (2347 m) the reduction in output

will exceed 10% and at elevations below 7700 ft. (2347

m) it will be less than 10%. High altitude adjustment

must not be made on appliances operating at elevations

below 2500 ft. (762 m).

No orice changes are required to adjust the

Pennant appliances for high altitude. High altitude

adjustment is accomplished by adjustment of the

gas valve manifold pressure and the air shutter(s).

LAARS Heating Systems

The required instruments used to assist in these

adjust-ments are a CO

or O2 Analyzer and a U-Tube

2

Manometer or other device capable of reading a

pressure of 2.5-3.0 inches w.c. (0.62-0.75 kPa).

Start the adjustment process by checking the

in the “as installed” condition. Adjust the air

CO

2

shutter(s) so that the CO

is about 8% or the O

2

about 6.8% for appliances operating on Natural Gas.

For appliances operating on LP Gas adjust the air

shutter(s) so that the CO

is about 9.2% or the O

2

about 6.8%. Appliances with two blowers should be

adjusted so that the air shutters below each blower are

open the same amount.

Once the CO

or O2 has been set, the manifold

2

pressure may be adjusted. Remove the 1/8 NPT plug

from the lower side of the gas valve that is to be

set and install a tting, hose and manometer. Start

the appliance and observe the manifold pressure.

Manifold pressure must be adjusted to 3.0 in. w.c.

(0.75 kPa) (for high altitude only, standard operating

pressure is 2.5 in. w.c. (0.62 kPa)). It is adjusted by

removing the slotted cap on the gas valve and turning

the adjustment screw (beneath the cap) clockwise to

increase pressure and replaced after the adjustments

have been completed and the tting, hose and

manometer have been removed and the 1/8" plug has

been replaced. Repeat this process until all gas valves

have been set. Note: The pressure can be set only

when the appliance is operating and only when the

particular gas valve being adjusted is energized by a

call for heat from the staging control.

After all of the gas valve manifold pressures have

been set, the CO

or O2 must be reset. CO2 or O

2

will have changed when the manifold pressure was

adjusted. Open the air shutter(s) to reduce the CO

to the values achieved previously.

O

2

The procedure is complete when all gas valves are

adjusted to a manifold pressure of 3.0 in. w

kPa) and the CO

is adjusted to 8.0% for Natural Gas

2

appliances or 9.2% for LP appliances. When using an

analyzer, the correct O2 is 6.8% for both Natural

O

2

Gas and LP appliances.

Caution

Should any odor of gas be detected, or if the

gas burner does not appear to be functioning

in a normal manner, close main shutof f valve,

do not shut off switch, and contact your heating

contractor, gas company, or factory representative.

is

2

is

2

2

2

.c. (0.75

or

Headquarters: 20 Industrial Way, Rochester, NH, USA 03867 • 603.335.6300 • Fax 603.335.3355

www.Laars.com Printed in U.S.A. © Laars Heating Systems 1710 Document 1374

Customer Service and Product Support: 800.900.9276 • Fax 800.559.1583

9 Brigden Gate, Halton Hills, Ontario, Canada L7G 0A3 (905) 203-0600 Fax: (905) 636-0666

H2380000-

Loading...

Loading...