LAARS NeoTherm NTH Installation Manual

VARI-PRIME

TM

Document 7031Installation Kit

®

VARI-PRIME

TM

Installation Kit for

N

EOTHERM

Modulating Boilers with EMEA Display

Model NTH. Sizes 285–850 MBTU/h

FOR YOUR SAFETY: This procedure must be performed by a professional service technician, qualied in

hot water boiler installation. Improper connections could create an electrical hazard, which could cause

serious injury, property damage, or death.

VARI-PRIMETM: A variable pump control that, when used with a variable speed pump, maintains a user-chosen temperature rise

between the inlet and outlet of the boiler.

GENERAL PCB OPERATION:

1. The desired Delta T can be set to any of the following values by moving or adding jumpers to the (JP2) terminal on the control:

See Figure 2.

15 deg F/8 deg C 20 deg F/10 deg C 25 deg F/13 deg C 30 deg F/ 16 deg C

By adding a second jumper, one on “15 deg F” and one on “20 deg F”, it is possible to achieve 35 deg F /19 deg C.

By adding a second jumper, one on “15 deg F” and one on “25 deg F”, it is possible to achieve 40 deg F/22 deg C.

2. As shipped, the VARI-PRIME has a jumper on the (JP4) terminal, to operate a 0-10 VDC output. If a 4-20 mA output is needed,

move the jumper to the (JP5) terminal.

3. VARI-PRIME can operate in °F or °C. A jumper on the (JP1) terminal has set the default to °F. Remove that jumper for °C.

4 If Main Gas valve is “OFF” AND a call for heat is “TRUE” then the PCB overrides the PID control and runs the pump

output at 100% (10 VDC, or 20 mA).

5. Once the Main Gas valve is energized the PCB will maintain pump output at 100% for 60 seconds to allow the system to stabilize.

Once the 60 second timer has expired, the PCB will then run the pump output speed based on the jumper setpoint.

6. When“T-T”issatised,thePCBwillrunpumpat100%outputforthedurationofthepumpoverruntime.

7. The VARI-PRIMEPCBhasalowendcaptopreventnuisancelowowtrips.Thecapisfactoryprogrammedto2VDC.

8. Factory settings are: Degrees - Fahrenheit Output Signal - 0 -10VDC

INSTALLATION INSTRUCTIONS

P.I.D. CONTROL ADJUSTMENT:

With Variable Speed Pumping, the boiler control P.I.D. needs to be adjusted.

• These settings are found in your NeoTherm controls under:

AdvancedSetup>CHCong>CHCong

It is recommended to start with:

P = 20 I =15 D = Factory set-point

Depending on pump sizing and application requirements; these P.I.D. settings may

needtobeusedtone-tuneboilerperformance.

• Once you have adjusted the P.I.D. contols, then disconnect power source from boiler.

• Remove front panels from boiler.

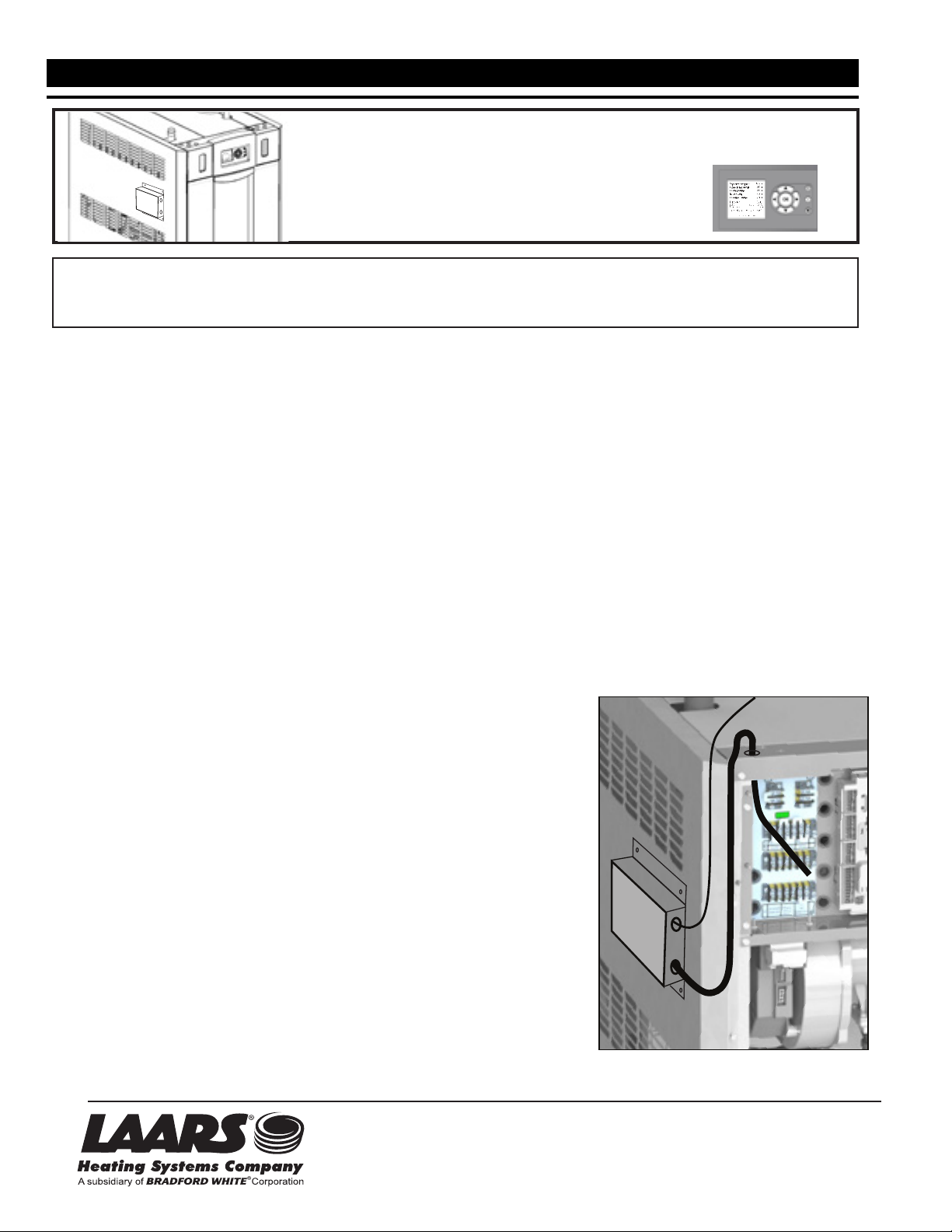

• Mount the VARI-PRIME control box in desired location. The side of the boiler is an

acceptable mounting location.

Important: Ensure there is nothing on the back side of the jacket before mounting.

• Run the wires from the VARI-PRIME control box, through the chosen ‘knock-out’ hole

and into the boiler. See Figure 1. Power wires must be run through conduit from the

VARI-PRIME box to the boiler. The Black and White wires are for the 120V pump contact.

Customer Service and Product Support: 800.900.9276 • Fax 800.559.1583

Headquarters: 20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com Litho in U.S.A. © Laars Heating Systems 1405 Document 7031

Figure 1

H2368400

pg 1 of 4

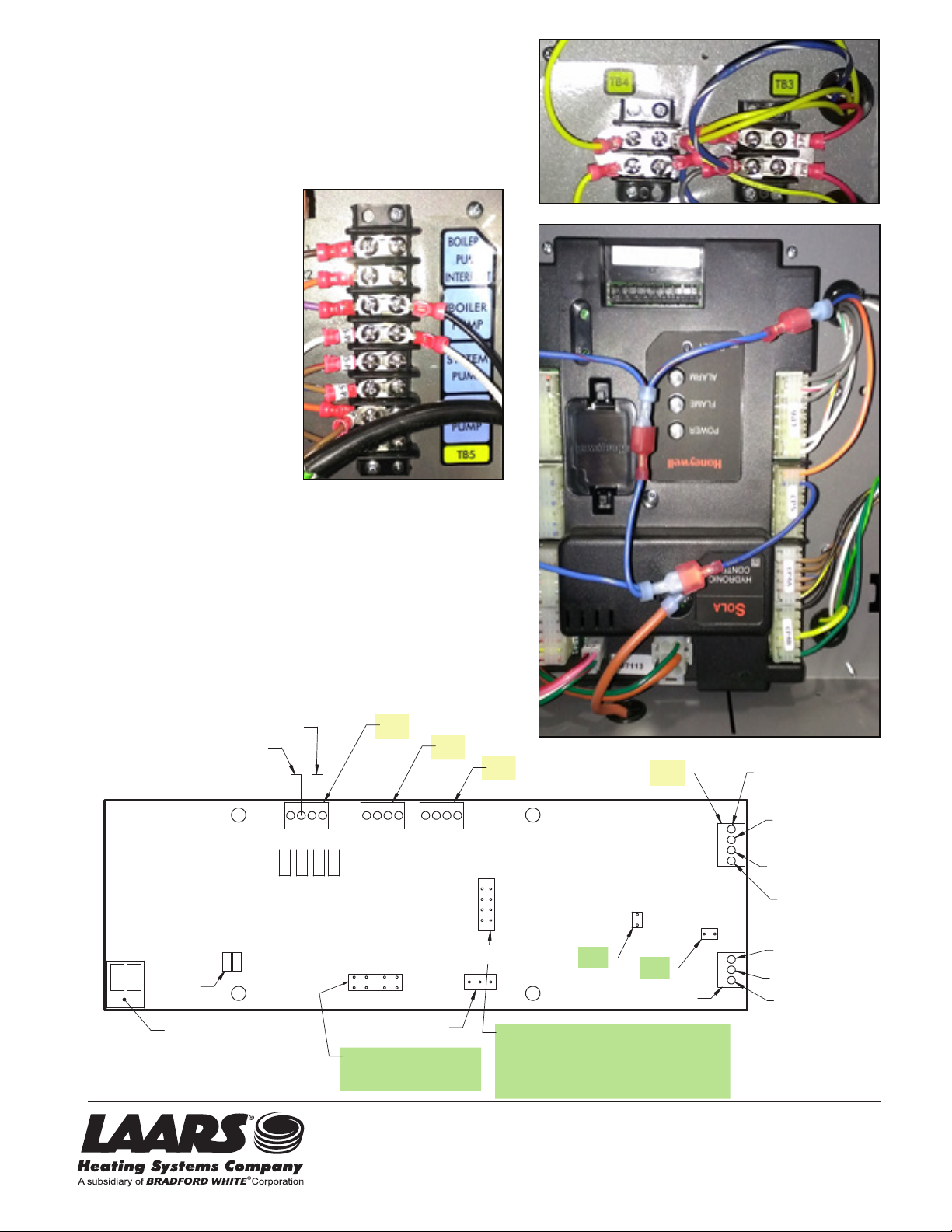

POWER CONNECTIONS:

FIRMWARE SETTINGS

P = 20

I = 10

D = 0

ANTI RESET WINDUP = 600

CONTROL ERROR = 70

10K

R14 C12 R13 C11

2

4

V

INLET

SENSOR

1

2

3

4

1

2

3

4

1

2

3

2

3

4

4

1

1

2

3

2

4

6

8

1

3

5

7

1

3

5

7

+

2

4

V

6

8

SENSOR

2

4

10K OUTLET

JP5

TB1

7&8 = F

1&2 = SPARE JUMPER

TB2

TB5

TB4

TB6

PCB

DIGITIZED

P/N E2345200

LED1

JP1

7&8 = (Delta T) 30 DEG F / 16 DEG C

TB3

JP4

JP2

1&2 = (Delta T) 15 DEG F / 8 DEG C

3&4 = (Delta T) 20 DEG F / 10 DEG C

5&6 = (Delta T) 25 DEG F / 13 DEG C

JP3

N/C

COM

4-20MA(-)

4-20MA(+)

0-10VDC(+)

0-10VDC(-)

N/O

• Connect the Blue wire anywhere on the

24V+ boiler Terminal Block (TB3).

• Connect the Yellow wire anywhere on the

24V Neutral boiler Terminal Block (TB4).

• Connect the White wire to the

boiler pump connections on

boiler Terminal Block (TB5)

across from the other white wire.

• Connect the Black wire to the

other boiler pump connection on

boiler Terminal Block (TB5).

• Locate the Blue Gas Valve power wire coming from the Sola control.

Trace the wire through where it passes into the back panel, and locate

therstwire.Disconnectthemale/femalespadeconnection.Insertthe

VARI-PRIME connections as shown.

FIELD CONNECTIONS:

• Remove VARI-PRIME Cover.

• Remove the VARI-PRIME control box from the packaging and

familiarize yourself with each connection point.

See Figure 2

Terminal

Blocks

Figure 2

Headquarters: 20 Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com Litho in U.S.A. © Laars Heating Systems 1405 Document 7031

Jumpers

Customer Service and Product Support: 800.900.9276 • Fax 800.559.1583

H2368400

pg 2 of 4

Loading...

Loading...