Page 1

Installation and Operation Instructions Document 4126D

Installation and

Operation Instructions for

Mighty Venter

Power Vent System

Models MV1 and MV2 for

Mighty Therm Sizes 175-400

FOR YOUR SAFETY: This product must be installed and serviced by a professional service technician,

qualified in hot water boiler and vent system installation and maintenance. Improper installation and/or

operation could create carbon monoxide gas in flue gases which could cause serious injury, property

damage, or death. Improper installation and/or operation will void the warranty.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHA T TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a nearby phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or gas

supplier.

H0168800D

Page 2

Page 2

LAARS Heating Systems

TABLE OF CONTENTS

SECTION 1.

1a. General Information......................................3

1b. Vent Sizing ...................................................3

1c. Inspection and Unpacking ............................ 3

1d. Installer Information ...................................... 3

1e. Installation Restrictions.................................4

SECTION 2.

Side Wall Vent Hood Location

2a. Side Wall Vent Hood Location ...................... 4

SECTION 3.

Electrical Wiring

3a. Safety Interlock Test.....................................8

3b. Maintenance ................................................. 8

Page 3

Mighty Venter Power Vent System

Page 3

SECTION 1.

1a. General Information

WARNING

The MV1 and MV2 Mighty Venter must be installed

in accordance with the procedures outlined in these

instructions. Warranty applies only if the installation

and operating instructions applicable to the model

purchased are expressly and completely followed.

The Laars Mighty Venter, Models MV1 and

MV2, are designed to make side-wall venting possible

for Laars hot water boilers, Models HH, PH, VW and

PW, sizes 175 - 400. Both the MV1 and MV2 are

equipped with a fan-prover switch which disables the

gas valve if the Power Venter fails to operate.

The Mighty Venter installation must comply with

the latest edition of the National Fuel Gas Code, ANSI

Z223.1, and in Canada, CAN1-B149.1 or .2 and all

local codes that apply. The installation must include

the draft hood assembly shipped with the boiler,

including vent damper if required.

1b. V ent Sizing

Take into consideration the dimensions in Table 1

when designing the vent system. The vent pipe length

shown includes all vent pipe before and after the

Power Venter.

The Mighty Venter kit includes three cartons:

Carton 1. Power Venter (MV1 or MV2)

Carton 2. Vent Hood

Carton 3. Vent Reducers/Adapter

Verify the contents of each carton by checking

against the parts list on page 8.

1d. Installer Information

1. Before beginning the installation, read these

instructions completely and make sure each part

is placed to safely vent flue gases to the

outdoors.

2. Carefully read the installation instructions

located in the Side Wall Vent Hood carton.

3. Laars does not provide the vent pipe necessary

for this installation. Use Table 1 as an aid in

selecting the proper vent pipe diameter.

4. Locate the Power Venter as close as possible to

the point of termination (i.e., the wall). This will

insure the vent pipe between the boiler and the

Power Venter inlet is under negative pressure.

5. Make sure the power supply is adequate for the

Power Venter motor requirements. Do not add

the Power Venter to a circuit where the total load

is unknown.

1c. Inspection and Unpacking

Immediately upon receiving the Mighty Venter

kit, inspect the shipment packaging for damage.

Record any damage on the shipping documents.

To prevent personal injury and equipment damage,

disconnect the power supply to the hot water boiler

when working on the Power Venter.

Caution

Unpack the equipment and carefully inspect it for

obvious damage caused in shipment. If any damage is

found, YOU must file a claim with the transporter. The

transporter will not accept a claim from the shipper,

Laars Heating Systems.

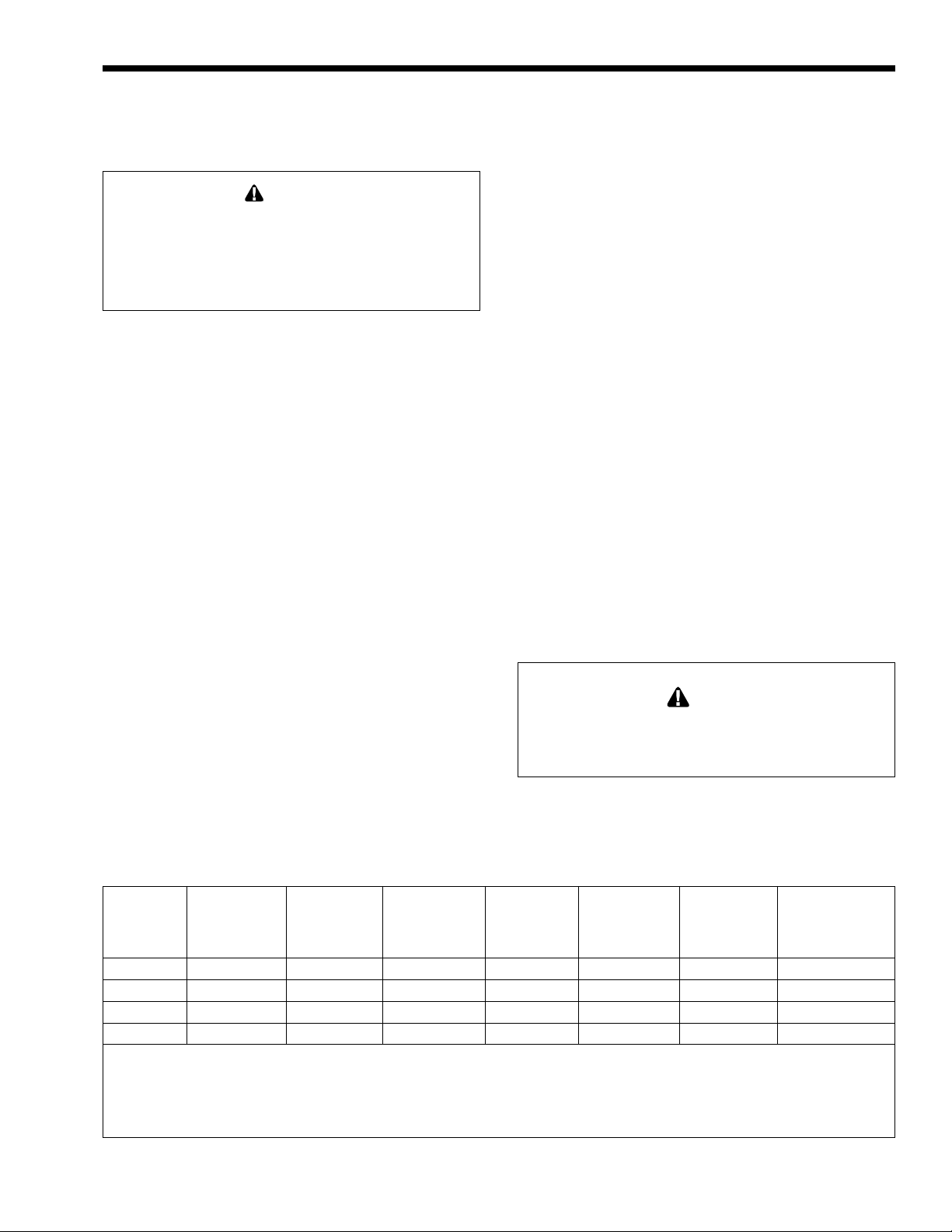

Mighty Boiler/ Mighty Venter Boiler/Heater Vent Pipe Equivalent Equivalent Mighty Venter

Venter Heater Order Number Outlet Diameter Diameter Pipe Length Pipe Length Diameter

Model Size in mm in. mm feet m feet m in mm

MV1 175 10718702 6 152 4 102 11 3.4 90 27.4 4 102

MV1 250 10718703 7 178 6 152 11 3.4 100 30.5 4 102

MV2 325 10718704 8 203 6 152 11 3.4 100 30.5 6 152

MV2 400 10718705 9 229 6 152 11 3.4 100 30.5 6 152

Notes:

1. Table 1 is for single boiler installations only.

2. To calculate the equivalent vent pipe length, add the length of the straight pipe plus 10 feet (3.0m) for every

90° elbow and 5 feet (1.5m) for every 45° elbow.

3. Vent pipe reducers will be supplied by Laars.

Minimum Maximum

Table 1. Critical Vent Sizing Data.

Page 4

Page 4

LAARS Heating Systems

1e. Installation Restrictions

1. Make sure minimum clearances from

combustible materials required by code are

maintained.

IMPORTANT: The following clearances to

combustible materials must be maintained for the

Power Venter:

Sides: 6-inches (152mm)

Back: 8-inches (203mm)

2. All vent pipe connections between the Power

Venter and the Vent Hood will be under positive

pressure during operation, and must be sealed to

prevent leakage into the building.

3. To prevent bearing wear, and for proper FanProver Switch operation, make sure the Power

Venter motor shaft is horizontal (see Fig. 1).

4. The ambient temperature surrounding the Power

Venter must not exceed 104°F (40°C).

5. The venting system must be sloped upwards not

less than 1/4 inch per foot from the boiler to the

vent terminal. The vent system must be installed

to prevent the collection of condensate where

necessary, and must be provided with a means of

drainage.

6. Condensate lines or single wall exhaust vent

shall not be run through an unheated space or

interior part of an open chimney unless the

exhaust vent is insulated.

7. The vent system must be adequately supported to

prevent sagging, but in no case shall the supports

be less than every 3 feet (0.9m).

8. Inlet and outlet piping must conform to Figure 4,

5 or 6.

9. Do not place any elbows within two feet of

venter outlet.

SECTION 2.

2a. Side Wall Vent Hood Location

If possible, locate the side wall vent hood on a

wall not normally subjected to high winds. This will

lessen the possibility of gas valve interruption during

periods when the winds are stronger than 40 MPH

(64 kmh). The Vent Hood location must comply with

the following specifications (see Fig. 2):

Caution

Flue gas temperature can exceed 150°F (66°C)

depending on the appliance being vented and the

length of the vent system. Do not terminate a side

wall vent system where vinyl siding has been

installed on the building exterior, since damage to

the vinyl siding may result.

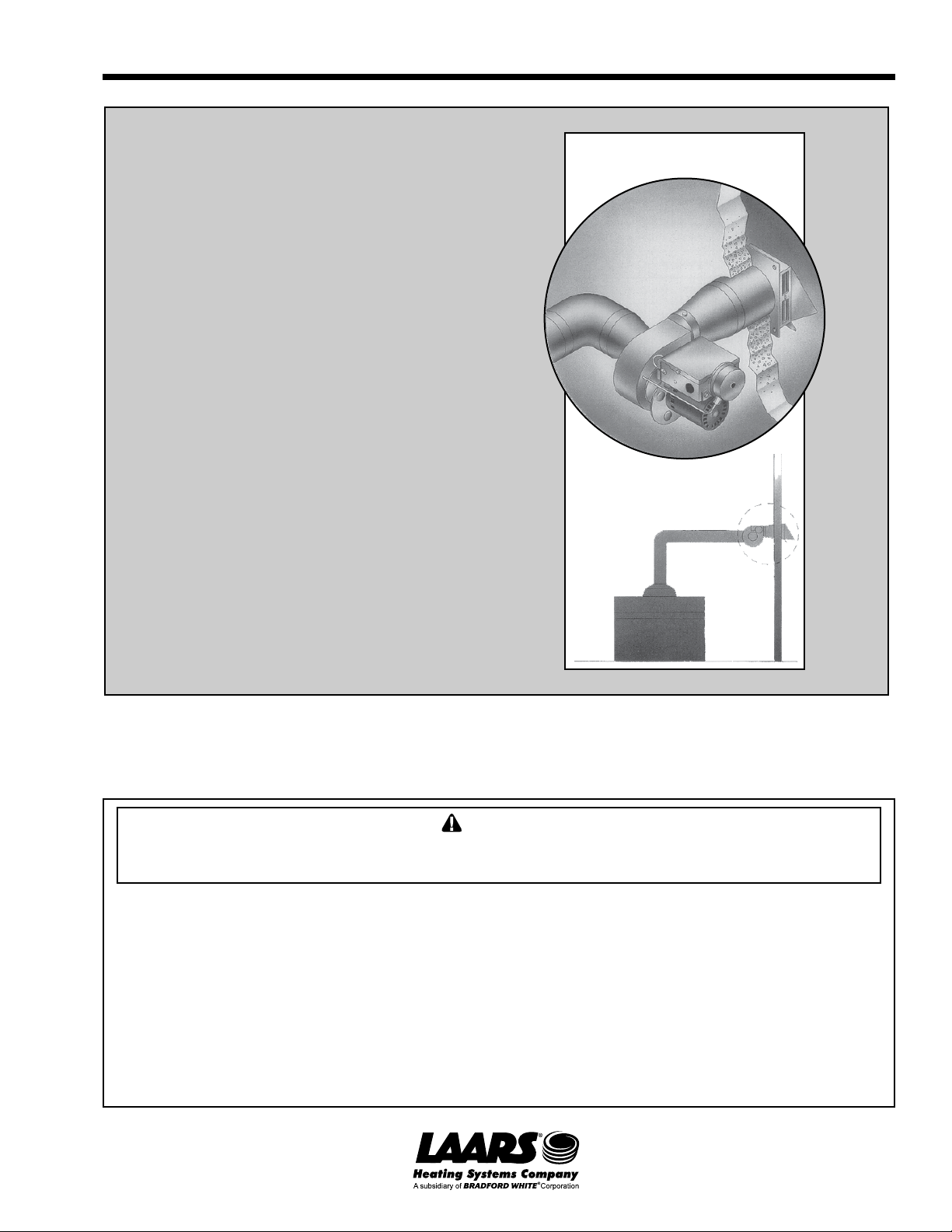

Horizontal Discharge Vertical Discharge

Figure 1. Discharge Options.

Air Pressure

Sensing Tube

Page 5

Mighty Venter Power Vent System

Page 5

1. Locate the Vent Hood a minimum of 7 feet

(2.1m) above a public walkway .

2. Locate the Vent Hood a minimum of 3 feet

(0.9m) above, or 4 feet (1.2m) below and 4 feet

(1.2m) horizontally from any door, window, or

gravity air inlet into the building. The Vent Hood

cannot terminate less than 6 feet (1.8m) above

any forced air inlet located within 10 feet (3.0m).

3. The Vent Hood must be installed at least 3 feet

(0.9m) from any other building opening or any

gas service regulator.

4. Do not install the vent hood closer than 2 feet

(0.6m) from an adjacent building.

5. Install the Vent Hood no closer than 3 feet (0.9m)

from an inside corner of an L-shaped structure.

6. Do not terminate the Vent Hood directly above a

gas utility meter or service regulator.

CODE REQUIREMENTS

The Power Venter installation must be in

accordance with the following requirements of the

National Fuel Gas Code:

All portions of the vent system under positive

pressure during operation (on the outlet side of the

Power Venter) shall be designed and installed so as to

prevent leakage of flue or vent gases into a building.

The boiler must enter the vent system on the inlet

side of the Power Venter.

Provision shall be made to interlock the

boiler(s) to prevent the flow of gas to the main burners

when the draft system is not performing so as to

satisfy the operating requirements of the equipment for

safe performance. See the “Electrical Wiring” section

in this manual for details.

Power Venter Installation

The Power Venter must be mounted with the

motor shaft horizontal to ensure proper operation of

the Fan-Prover switch and prevent motor bearing

wear (see Fig. 1). The installer must supply plumber's

strap or threaded rod with nut and washers for

mounting.

Vent Hood

7 (2.1) Minimum

Above Public

Walkway

6 (1.8) Above Any

Outside Air Intake

Within 10 (3.0)

Vent Hood

4 (1.2)

Minimum

Vent Hood

Vent Hood Must Be

Mounted At Least

4 (1.2) Below Windows

1 (0.3) Above Grade

3 (0.9) Minimum

4 (1.2)

Minimum

Vent Hood

Vent Hood Must Be

**

Mounted At Least

3 (0.9) Above Windows

and Doors

4 (1.2)

Minimum

Figure 2. Side Wall Vent Hood Locations.

Dimensions shown in feet (m).

Page 6

Page 6

LAARS Heating Systems

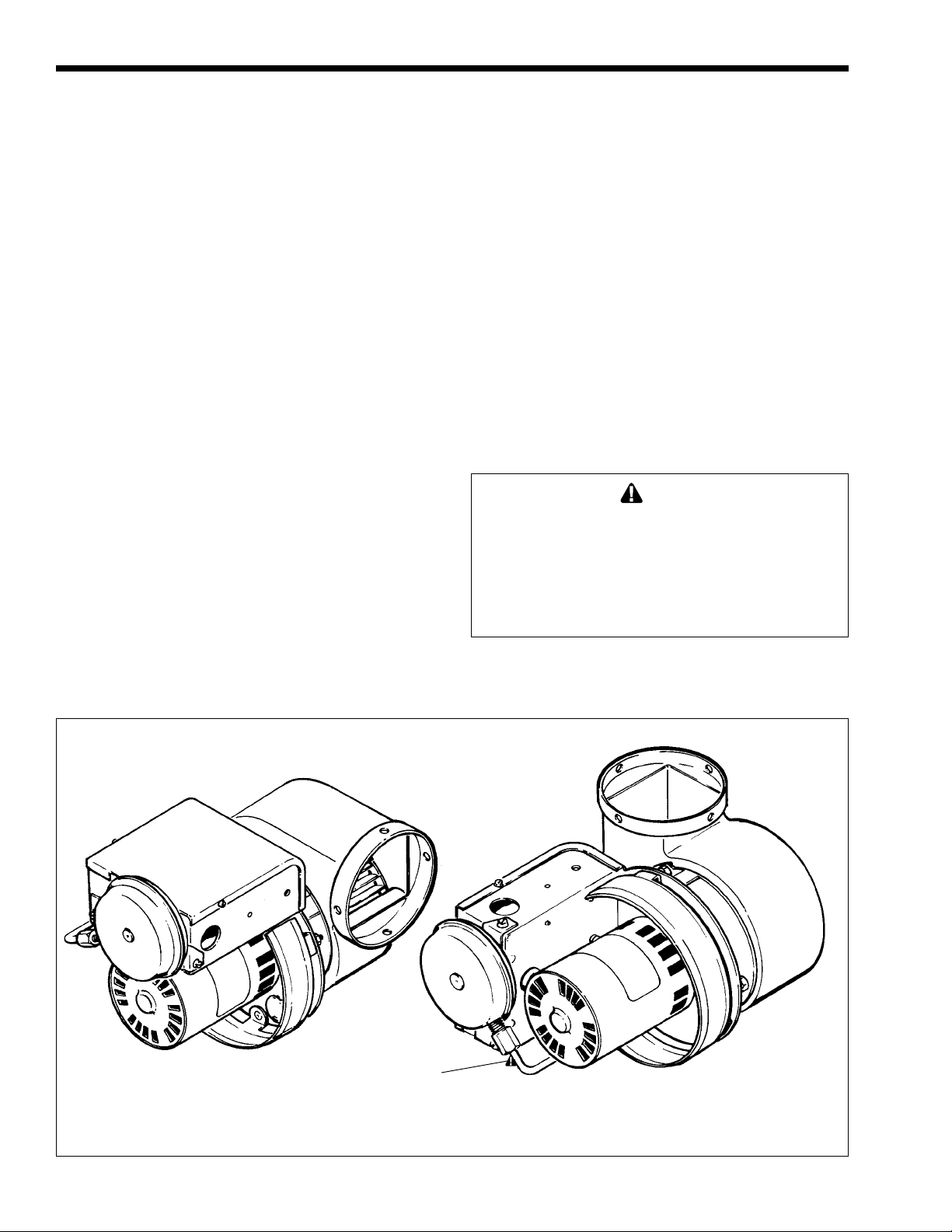

To facilitate installation and reduce vibration, 2

mounting brackets, 2 rubber isolators, and 2 rubber

grommets are included. One of the brackets can be

used as a temporary “third hand” while positioning it

for permanent installation (see Figure 3).

When installing the Power Venter for horizontal

discharge, install one of the brackets to the electrical

box using the nut/screw provided. Install the other to

the damper rod. When installing the Power Venter for

vertical discharge, only one bracket is needed. Mount

this bracket to the motor as shown in Figure 3.

SECTION 3.

Electrical Wiring

WARNING

All wiring from the Power Venter to the appliance

must comply with local codes, or in their absence,

the National Electric Code (NFPA #70) in the United

States and/or CSA C22.1 Electrical Code in

Canada.

Disconnect 115 VAC power to the appliance before

proceeding with wiring the Power Venter. The power

can be disconnected by tripping the circuit breaker

or removing the fuse protecting the appliance.

All wiring must comply with applicable codes and

ordinances. All 115 VAC wiring must be rigid or

semi-rigid metal conduit with 18 AWG, 300 VAC,

90° C rated copper wire.

Boiler Vent Vent

Fig. Boiler Draft Hood Pipe Hood Rough-in

No. Size Outlet Dia. Dia. Dim.

4 175 6" 4" 4" 8.0" Dia.

5 250 7" 6" 6" 9.0" Dia.

6 325 8" 6" 6" 9.0" Dia.

6 400 9" 6" 6" 9.0" Dia.

Table 2.

Wire the hot water boiler and the Power Venter

exactly as shown in Figure 7 and follow these steps:

1. Connect the black and white (115 VAC) wires

from the Power Venter to the boiler control box as

shown in Figure 7.

2. Connect the red, blue and yellow (24 VAC)

wires to the terminal block as shown in Figure 7.

Make sure the current capacities of the wires,

switches, etc. at 115 VAC meet the ratings in Table 3.

3. Remove factory-installed jumper from

between boiler terminals 3 and 4.

Equivalent Full Load

Power Venter Currents

Model Motor HP (Amps - 115 VAC)

MV1 1/25 1.3

MV2 1/8 4.4

Table 3. Electrical Ratings.

Figure 3. Power Venter Discharge Options.

Page 7

Mighty Venter Power Vent System

7.6"

4"

Page 7

8.6"

6"

4" x 6"

Figure 4.

Size 175

MV1

6"

4" x 6"

4" x 6"

MV1

6" x 7"

Figure 5.

Size 250

8.6"

6" x 8" for 325

6" x 9" for 400

Sizes 325-400

MV2

Figure 6.

Page 8

Page 8

LAARS Heating Systems

3a. Safety Interlock Test

1. Turn the appliance thermostat/aquastat high

enough to call for heat.

2. Verify by fan rotation that the Power Venter

begins operating before the gas valve becomes

energized.

3. With the appliance firing and the Power Venter

operating, disrupt power to the Power Venter by

removing one of the black wires from the Power

Venter relay. Make sure the appliance gas valve

turns off.

WARNING

Do not operate the boiler that does not shut off when

the Power Venter is disabled.

3b. Maintenance

1. Oil the motor every six months with 2 drops of

S.A.E. #20 oil. The oil ports are located on top of

the motor.

2. Laars recommends that the boiler system be

checked annually by a qualified service

technician. The inspection should include

checking all vent pipe and connections for

blockage and leaks, and a safety interlock test.

Parts List

Part Number Description Boiler Size

10718702 Mighty Venter Kit (MV1) 175

D2008801 Power Venter

D0019700 Vent Hood, 7.6" Dia.

D0018800 4" x 6" Reducer (Qty. 1)

10718703 Mighty Venter Kit (MV1) 250

D2008801 Power Venter

D0019800 Vent Hood, 8.6" Dia.

D0018900 6" x 7" Reducer (Qty. 1)

D0018800 4" x 6" Reducer (Qty. 2)

10718704 Mighty Venter Kit (MV2) 325

D2008802 Power Venter

D0019800 Vent Hood, 8.6" Dia.

D0019000 6" x 8" Reducer (Qty. 1)

10718705 Mighty Venter Kit (MV2) 400

D2008802 Power Venter

D0019800 Vent Hood, 8.6" Dia.

D0019100 6" x 9" Reducer (Qty. 1)

Page 9

Mighty Venter Power Vent System

Mighty Therm Mighty Venter

Page 9

Junction Box

Mighty

Venter

Color Legend

BK - Black

BL - Blue

GR - Green

R - Red

W - White

Y - Yellow

Factory Wiring

24V

115V

Field Wiring

24 V

115V

Figure 7. Wiring Diagram For Mighty Therm, Model HH, PH, VW, PW, Sizes 175 through 400.

Page 10

Page 10

LAARS Heating Systems

Page 11

Mighty Venter Power Vent System

Page 11

Page 12

Laars Heating Systems

Mighty Venter

™ Power Vent System

Your Laars Mighty Venter Power Vent System is backed by this

warranty to assure your complete satisfaction.

Laars warrants the Mighty Venter; the motor, fan prover switch and sheet metal parts

to be free of defects in materials and workmanship for 18 months from date of

purchase or 12 months from date of installation, whichever comes first.

The above warranty applies only if the installation

and operating instructions applicable to the model

purchased are expressly and completely

followed.These instructions are furnished with the

unit and are also available by writing to the Laars

factory. The liability of Laars shall not exceed the

repair or replacement of defective parts by factory

authorized technicians, and shall not include

transportation to or from factory, any labor costs,

and consequential or incidental damages. Ship

inoperative parts or complete system with Serial

number, Model number and purchase date,

transportation prepaid, directly to address below,

attention Customer Service, for evaluation and

warranty consideration.

This warranty gives you specific legal rights. You may

also have other rights which vary from state to state,

and by province. Some states and provinces do not

allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or

exclusion may not apply to you.

800.900.9276 • Fax 800.559.1583 (Customer Service, Service Advisors)

20 Industrial Way , Rochester , NH 03867 • 603.335.6300 • Fax 603.335.3355 (Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com Litho in U.S.A. © Laars Heating Systems 0907 Document 4126D

H0168800D

Loading...

Loading...