Page 1

HD 7/250 De Tr1

59633200 08/10

Page 2

2

Page 3

Please read and comply with

these original instructions prior

to the initial operation of your appliance and

store them for later use or subsequent owners.

Contents

Safety instructions EN - 1

Function EN - 2

Environmental protection EN - 2

Proper use EN - 2

Device elements EN - 3

Operation EN - 5

Frost protection EN - 8

Maintenance and care EN - 10

Faults EN - 14

Technical specifications EN - 16

Accessories and Spare Parts EN - 17

Warranty EN - 17

CE declaration EN - 17

Safety instructions

Hazard levels

Danger

Immediate danger that can cause severe

injury or even death.

몇 Warning

Possible hazardous situation that could

lead to severe injury or even death.

Caution

Possible hazardous situation that could

lead to mild injury to persons or damage to

property.

Safety instructions

Danger

– This appliance must only be operated,

maintained and repaired by authorised,

skilled and trained personnel.

–

Only physically and mentally fit and reliable people should operate and care for

this high pressure water jets (minimum

age 18). The operator or his representative must be certain that the operator is familiar with the appliance and its

application and that he will be able to perform the assigned tasks responsibly.

– Fatigue, health issues, influence by al-

cohol or medications lead to a higher

safety risk while operating the machine.

– For safety reasons, a second person

must always be present when the appliance is being operated, in order to be

able to shut off the appliance in emergencies and to summon help if needed.

– The local and relevant accident preven-

tion directives as well as other, generally applicable safety, health and work

related regulations are to be observed.

The user is obliged to only operate the ap-

–

pliance while it is in flawless condition.

– Safety features on the appliance and

the spray unit must never be removed,

modified to made inoperable.

– Only use hose lines, spray units and ac-

cessories approved for the maximum

working pressure of the appliance.

– Hoses, pipes and connected accesso-

ries must be in good condition and installed properly.

– The application should not be operated

in explosive environments.

– If the appliance is used in hazardous ar-

eas (e.g. filling stations) the corresponding safety provisions must be

observed.

– During jet spray work, nobody besides

the operator is allowed in a radius of 10

m around the spray unit.

– Never direct the water jet on to persons,

animals, the appliance itself or electrical

components.

– Modifications of the set operating over

pressure on the appliance may only be

performed if previously agreed with the

operator of the spray unit.

– Risk of injury! The recoil pressure of the

spray pipe can throw you off-balance.

You may fall. The spray jet can fly off

and cause damage to persons. Search

a secure place to stand and hold the

gun firmly. Never hold on tightly to the

lever of the hand spray gun.

Risk of falling! Take precautions when

–

working on a scaffold, so that the person

does not fall from the scaffold due to the

recoil force generated by the appliance.

– For manual work with a spray gun, the

nozzle diameter must be selected so

that the recoil force in the longitudinal

axis does not exceed 250 N during

max. operating pressure. If the recoil

force 150 N, the spray gun must be

equipped with a body support as per

European standard prEN 1829. With recoil forces that exceed 250 N, the nozzle must be guided mechanically.+

– The recoil forces may be different if you

are using angular spray devices.

– Always monitor the displays during op-

eration. If the displayed values are not

correct, switch the appliance off immediately and remediate the cause of the

malfunction.

– If the appliance is not to be turned on,

e.g. during maintenance procedures,

you must attach a warning sign on the

switch cabinet.

– Prevent unauthorised personnel from

using the appliance by switching off the

key switch and removing the key.

– The appliance must be secured against

unauthorised use during work breaks.

– If the water stream is directed on

sound-amplifying objects, the noise

emission values may exceed the values

listed in the specifications.

– Any type of non-adherence as well as

resulting injuries to humans and damage to materials lies in the responsibility

of the operator. Failure to observe

these warnings may result in injuries or

death of the operating personnel.

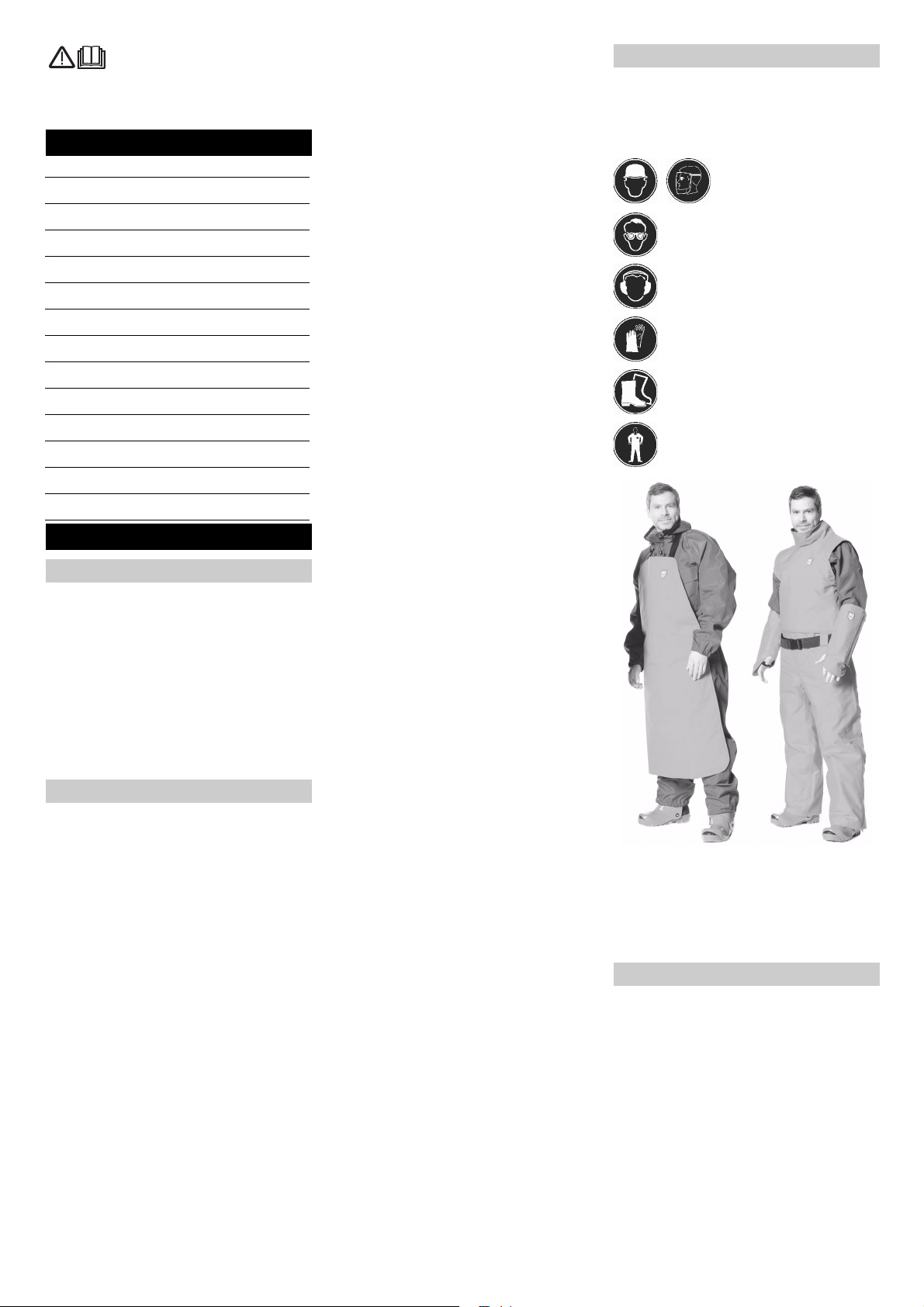

Protective clothing

Danger

When working with the appliance or when

being present near the spray unit, the following protective clothing must be worn:

Helmet with protective

shield

Safety goggles

Capsule ear protection

Protective gloves

Special safety boots and

a middle foot protection

Protective jacketprotective overalls

Note

You must use protective clothing that is

specifically intended to be used with high

pressure cleaners. Effective protective

clothing can be purchased directly from

KÄRCHER.

Safety Devices

Safety devices serve to protect the user

and must not be rendered inoperational or

their functions bypassed.

Emergency-stop button

To put all functions out of operation immediately: Press emergency-stop button.

The appliance is free of pressure.

Safety switch for appliance hood

The appliance should be used only if the

appliance hood is closed.

If the appliance hood is opened during operation, the appliance will switch off and a

fault will be displayed.

- 1

3EN

Page 4

Burst disc

If the working pressure exceeds the max.

permissible overpressure by approx. 10%,

the burst disc will be destroyed and the water will circulate inside the appliance without pressure. High pressure operation no

longer possible.

Pressure switch

The pressure switch switches off the appliance if the minimum prepressure is not

reached.

High pressure sensor

The pressure sensor monitors the pressure

buildup in the high pressure system. If the

pressure sensor detects an exceedingly

rapid pressure decrease, as might be the

case with leaks or a burst hose, as well as

if the working pressure is exceeded, the appliance will shut off.

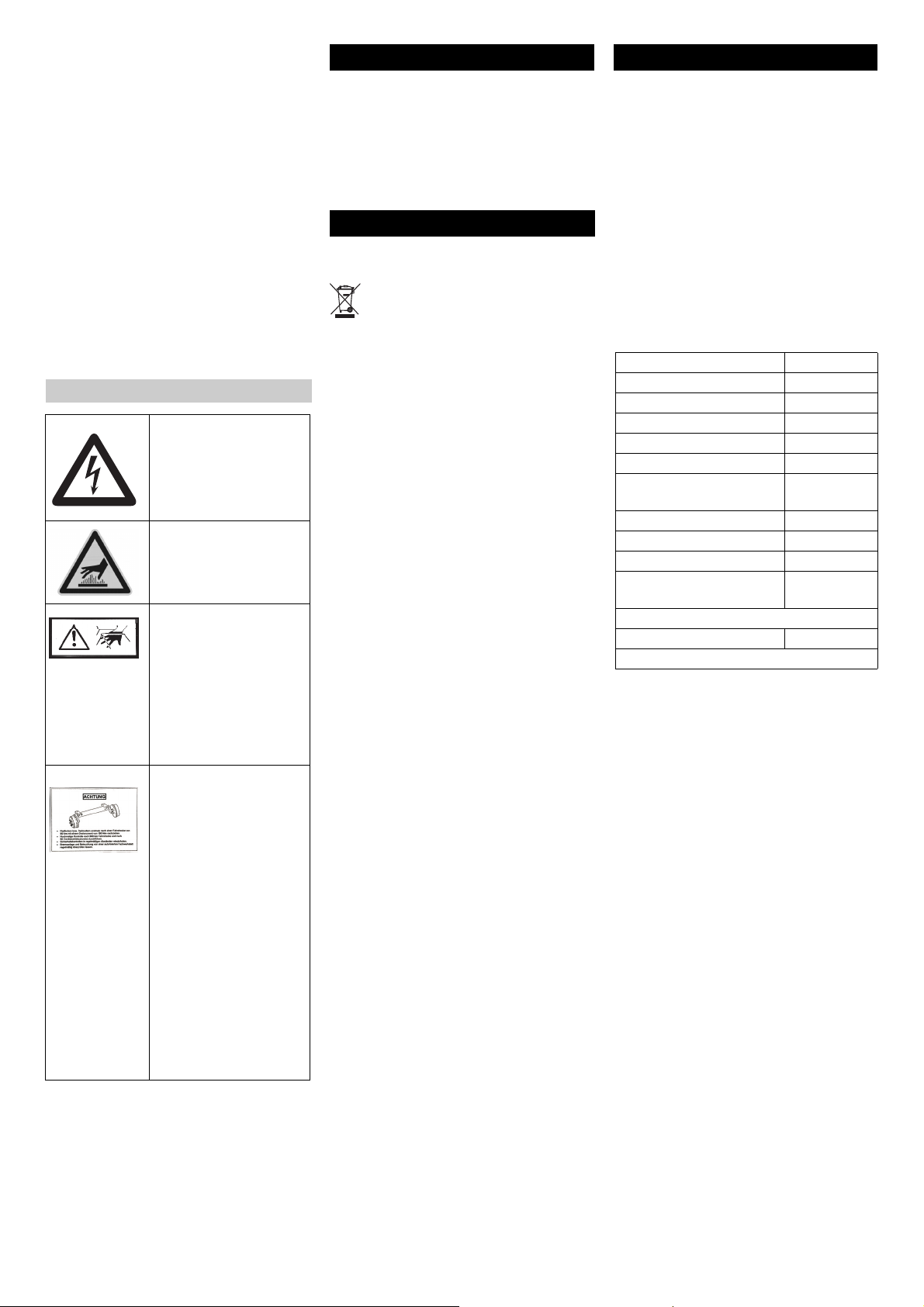

Warning and instructive signs

Danger

Risk of injury on account

of electric shock!

몇 Warning

Risk of burns on account

of hot surfaces!

몇 Warning

Danger of crushing. Do

not remove the cover

while the appliance is

running.

Do not reach near the

cooling fan and the Vbelt while the motor is

running.

Î Retighten the wheel

bolts and the wheel

nuts after driving 50

km to a torque of 100

Nm.

Î Repeat the check af-

ter 500 km have been

driven and after 50

operating hours.

Î Repeat the safety

checks at regular intervals.

Î Have the brake sys-

tem and the lighting

system checked regularly by an authorised dealer

workshop.

Keep the warning and instructive signs on

the appliance clean.

Replace damaged or missing warning and

instructive signs with new ones.

Function

The high pressure pump is driven by an intermediate gear by a diesel motor.

When the jet operation is interrupted, an

electric signal will switch the system from

hand spray gun to pressureless water circulation.

The preset operating pressure is regulated

via the motor speed.

Environmental protection

Please arrange for the proper disposal

of the old appliances

Old appliances contain valuable materials

that can be recycled; these should be sent

for recycling. Batteries, oil, and similar substances must not enter the environment.

Please dispose of your old appliances using appropriate collection systems.

Please make sure that engine and gear

oil, diesel and antifreeze

do not enter the environment. Protect the

ground and dispose of used oil as well as

fuel and antifreeze in an environmentallyclean manner.

Please do not release mineral oil containing wastewater

into the soil, surface waters or sewer systems.

Notes about the ingredients (REACH)

You will find current information about the

ingredients at:

http://www.karcher.de/de/unternehmen/

umweltschutz/REACH.htm

Proper use

Use this appliance only as directed in these

operating instructions.

– The appliance is used to clean objects

by means of a high pressure water jet

with cold water without the use of detergents.

– The appliance may only be equipped

with original accessories and spare

parts.

– The appliance is not suited for the use

in potentially explosive environments.

– The appliance is not suitable to be used

simultaneously with multiple spray

units.

– The fresh water supply must meet the

following requirements:

max. temperature 60 °C

pH value 6,5...12

Total hardness 3...30 °dH

max. iron 0.2 mg/l Fe

max. manganese 0.05 mg/l Mn

max. chloride 100 mg/l Cl

max. organic substances 12 mg/l

use

KMnO

4

max. sulphate 100 mg/l SO

max. chlorine 0,5 mg/l Cl

min. dissolved oxygen 5 mg/l O

max. abrasive hazardous

substances

free of undisolved gases

max. conductivity 1000 µS/cm

remaining values as per DIN 50930

5 mg/l

2

2

4

Furthermore, the personnel must participate in a Kärcher safety seminar.

4 EN

- 2

Page 5

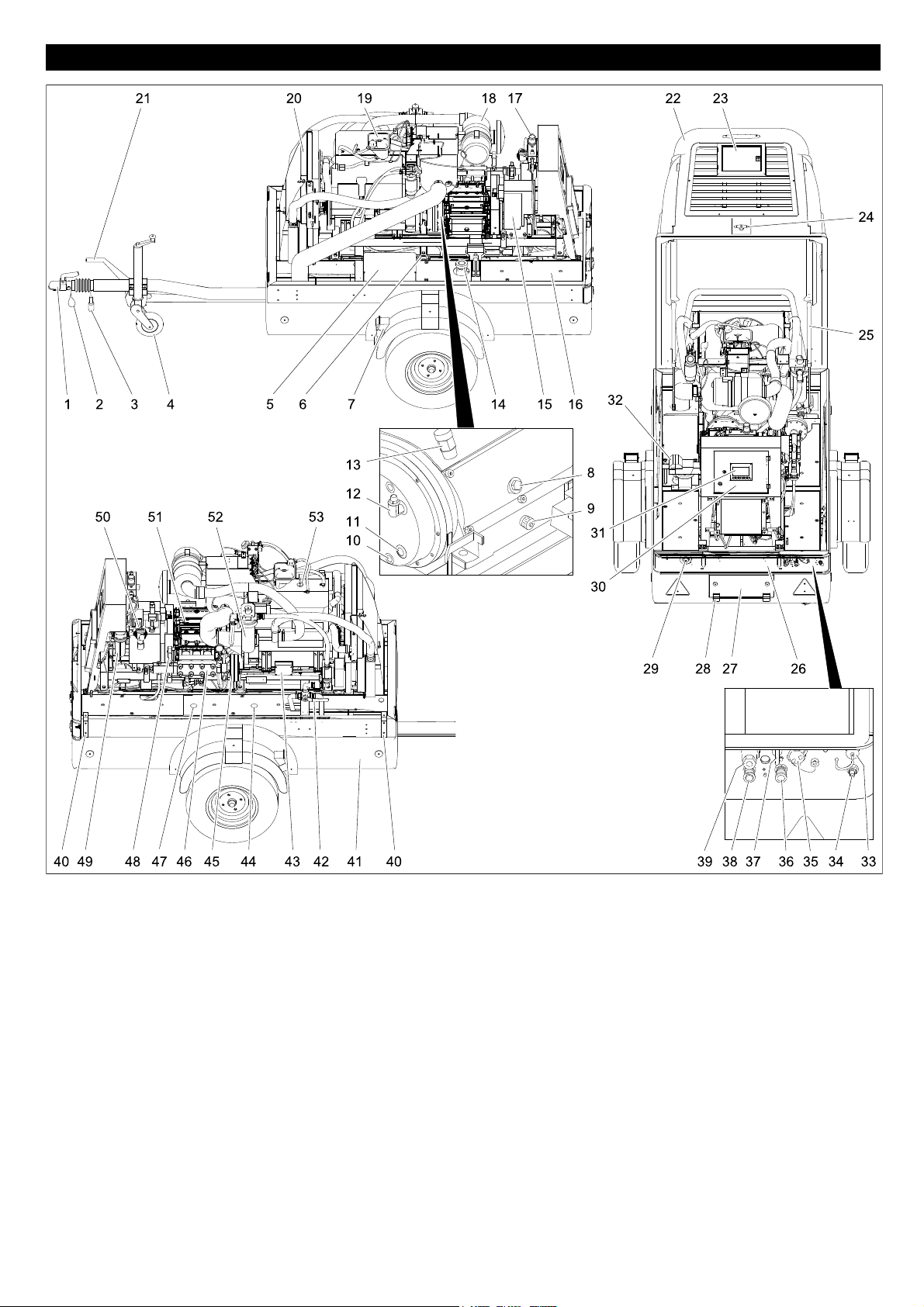

Device elements

1 Towing hitch

2 Tear-off rope

3 Connector vehicle lighting

4 Support wheel

5 Battery

6 Battery main switch

7 Block wedge

8 Oil dip pump gear

9 Covering lid, oil drain opening pump

gear

10 Oil drain screw intermediate gear

11 Oil sight glass intermediate gear

12 Ventilation screw intermediate gear

13 Ventilation end gear

14 Filling nozzle diesel tank

15 Compressor

16 Cover

17 Compressed air valve

18 Air filter

19 Equalising reservoir motor coolant

20 Radiator

21 Parking brake

22 Cover

23 Door operating panel

24 Lock of appliance hood

25 Safety support appliance hood

26 Registration plates

27 Storage compartment

28 Hinge, storage compartment

29 Emergency-stop button

30 Switch box

31 Operating field

32 Vice

33 Socket, control line

34 Exterior air connection (supply)

35 Water inlet

36 Right compressed air connection, to

connect a compressed air tool

37 Hose sock mounting

- 3

38 Left compressed air connection, to con-

nect a compressed air tool

39 High-pressure outlet

40 Lifting eyelet (option)

41 Drain tap of the water tank (inside the

appliance)

42 Ball tap, antifreeze/water tank

43 Main fuse

44 Antifreeze container

45 Switch valve

46 Pump head

47 Maintenance door water tank

48 Pressure sensor/high pressure

49 Maintenance unit, pneumatics (cyclone

separator)

50 Manometer compressed air

51 High pressure pump

52 Waterfilter

53 Filler neck motor oil

5EN

Page 6

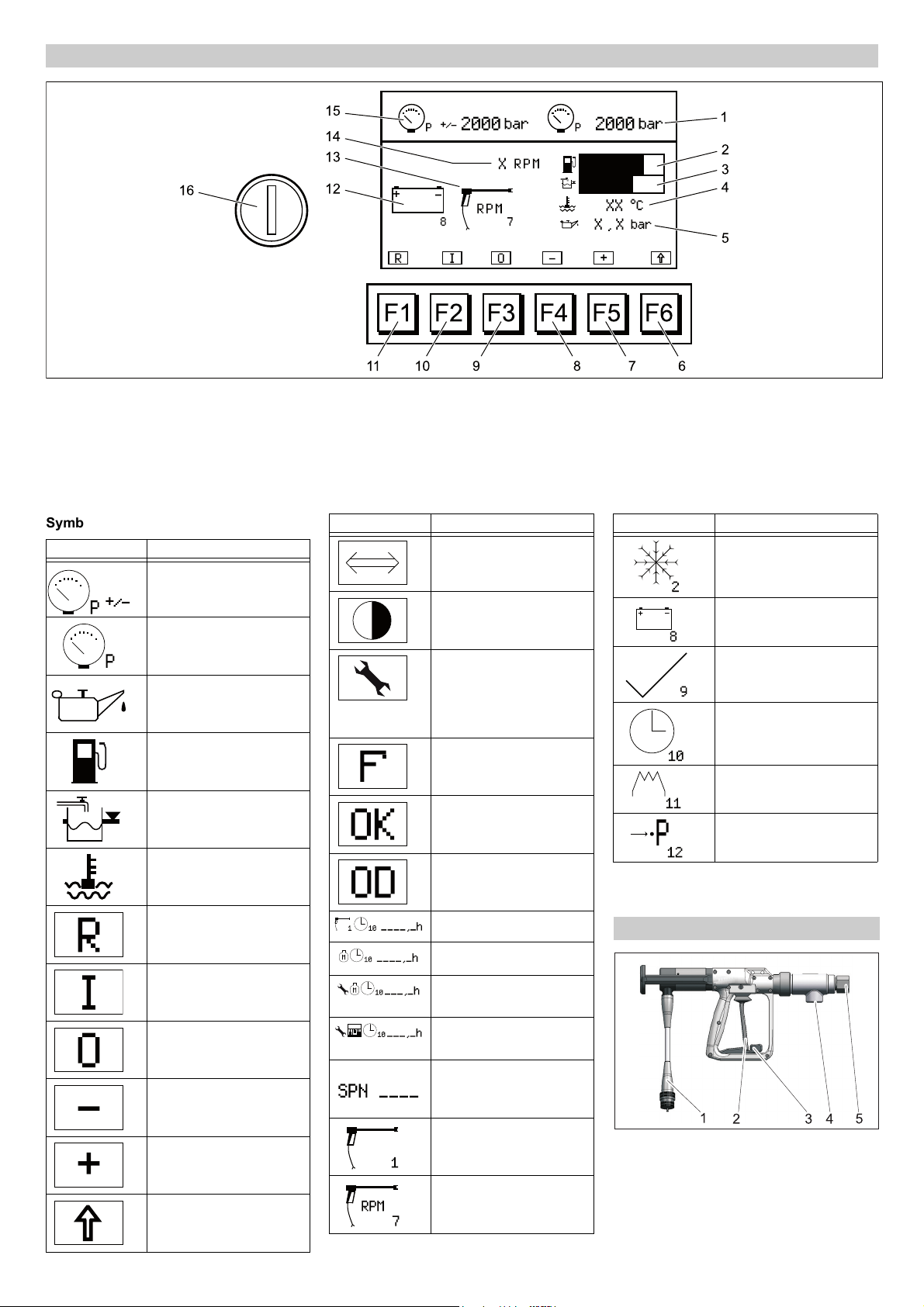

Display and operating panel

+-

87

1 Display actual pressure

2 Bar graph fuel level

3 Bar graph water level in tank

4 Display cooling water temperature

5 Display oil pressure

6 F6 key, menu preselection

Symbols on the display

Symbol Meaning

Nominal pressure

Actual pressure

Motor oil pressure

Fuel level

Water level in tank

Cool water temperature

Reset

Motor ON

Motor OFF

Reduce nominal value

7 Key F5, increase nominal value

8 Key F4, decrease nominal value

9 Key F3, motor OFF

10 Key F2, motor ON

11 Key F1, reset key (acknowledge fault)

12 Display appliance status

Symbol Meaning

Change value

Brightness and contrast

settings

Informational display for

service personnel (inputs/outputs, operating

and high pressure hourmeter)

List of faults

Confirmation

Triggering outputs

High pressure hours

Operating hours of motor

Service interval hours

motor

Service interval hours

pump

Fault code motor

13 Display operation

14 Display actual speed

15 Display nominal pressure

16 Key switch

Symbol Meaning

Antifreeze rinse operation

Load control

Display OK (control voltage ON or motor is running)

Display wait time

Preglowing (hold for 3

seconds)

Nominal pressure

reached

The symbols of the fault displays are described in the Chapter "Faults".

Hand spraygun

Increase nominal value

Menu preselection

Gun operation

Gun operation with speed

stop

6 EN

1 Coupling of the control cable

2 Lever

3Locking

4 High pressure hose connection

5 Spray pipe connection

- 4

Page 7

Operation

Please observe Chapter "Safety Instructions" and the enclosed safety instructions

for high pressure cleaners (5.063-314.0)

Transport

Trailer operation

Note

The driver, who operates the towing vehicle

with trailer on public roads must ensure that

he has the appropriate license for this.

Danger

When transporting the trailer in public traffic

with the water tank half full, the water can

swap out or the trailer could even tilt during

extreme steering manoeuvers.

Î Completely fill or empty the water tank.

Do not transport with the water tank half

full.

Î Close the appliance hood and open-

ings.

Î Adjust the height of the drawbar by

means of the support wheel to the

height of the trailer hitch of the towing

vehicle.

Î Attach the tear-off rope to the towing

vehicle.

1 Coupling lever

2 Bolt with marking

Î Hitch up the towing vehicle. Make sure

that the marking on the bolt points to the

+ symbol (Pfeil) once the coupling lever

is pushed down.

Î Connect the connector of the vehicle

lighting.

Î Rotate the support wheel up by means

of the crank.

Î Make sure that the suppport wheel

points in the direction of the trailer when

retracted.

Î Remove the chocks from underneath

the wheels and place them in their holders.

Î Release parking brake.

1 Third brake light

2 Combined brake/tail lights, right, left

3 Blinker, right/left

4 Reverse light

5 License plate lighting

6 Fog lamp

Î Check the brake lights, blinkers, tail

lights, reverse lights, fog lamp and the

license plate lighting for their function.

Î Check tire pressure (refer to technical

data).

Note

Local speed limits for vehicles with trailers

must be observed and adhered to.

Loading

The appliance must be fitted with lifting

eyelets (option) to be raised by means of a

crane. The appliance should only be lifted

by the lifting eyelets.

Setting up the appliance

1 Crank to lower the support wheel

2 Connector vehicle lighting

3 Tear-off rope

4 Support wheel

5 Parking brake

Î Lock parking brake.

Î Lower the support wheel by means of

the crank.

Î Remove the tear-off rope from the tow-

ing vehicle.

Î Disconnect the connector from the ve-

hicle lighting and insert it into the plug

storage on the drawbar.

Î Secure the machine with wheel chocks

to prevent it from rolling away.

Î Disconnect the towing vehicle.

Î Align the appliance horizontally with the

support wheel.

Caution

Risk of malfunctions and damages to the

appliance. The appliance must be in horizontal position during operation.

Preparing for start-up

Check the fill levels

Î Open the lock on the appliance cover

and swivel the appliance cover up-

wards.

Î Swivel the latch of the appliance hood

upwards to keep it from shutting inad-

vertently.

Î Align the appliance horizontally

Check oil level in the pump, intermediate

gear and motor

Î Unscrew the oil dip on the pump gear.

Î Wipe the oil dip with a lintfree cloth.

Î Reinsert the dip completely and pull it

back out.

Î If the oil level has sunken to the mark,

refill oil (see "Care and Maintenance").

Check the oil level in the intermediate

Î

gear.

Î The oil level must be in the centre of the

viewing glass. If this is not the case, re-

fill oil (see "Care and Maintenance").

Î Pull out the oil dip of the motor.

Î Wipe the oil dip with a lintfree cloth.

Î Insert the oil dip, pull it out and read it.

Î If the oil level has sunken to the mark,

refill oil (see "Care and Maintenance").

Check the fill level of the coolant in the

motor

Check the fill level of the coolant in the

Î

equalisation container of the motor cool-

ant with a cooled off motor. The liquid

level has to be between MIN and MAX.

Check the fill level of the antifreeze

Î In case of risk of frost, unscrew the lid of

the antifreeze container and check the

fill level. If required refill antifreeze.

Turning on the Appliance

Î Switch on the battery main switch.

Î Switch on the key switch on the operat-

ing panel.

Check the fill level of the diesel tank

Danger

Risk of explosion, fire, poisoning by means

of exhaust gases.

– Turn the motor off prior to fueling up.

– Do not refuel in closed rooms, ensure

sufficient ventilation.

– Never fill up in the vicinity of open

flames or sparks.

– Do not smoke during fueling.

– Immediately remove fuel that leaked

during the refuelling with cleaning

cloths and dispose of it properly.

- 5

7EN

Page 8

Caution

Do not completely deplete the fuel in the

fuel tank, otherwise, the fuel system will

have to be ventilated. Possibly suctioned

dirt from the bottom of the tank can lead to

malfunctions.

Î Check the fill level of the diesel fuel at

the bar segment display for the fuel level. If required, top off the diesel fuel.

For temperatures below 0°, only use

winter diesel.

Check the fill level in the water tank

Î Check the fill level of the water at the

bar segment display for the water level

in the tank. Top off the water tank if necessary. Connect the water supply hose

to the water inlet.

Start up

Connecting the spray pipe to the gun

1 Trigger gun

2 Pressure ring

3 Pressure screw

4 Spray lance

5 Nozzle holder

6 High pressure nozzle

Î Remove the protective caps on the

spray pipe.

Î Grease the thread on the gun side with

stainless steel screw grease (6.280-

180.0).

Î Screw the pressure ring onto the spray

pipe.

A

B

Î The sealing cone of the spray pipe must

protrude about 1-1.5 thread lengths (B)

from the pressure ring (A).

Î Rotate the pressure ring (A) by hand to

adjust the distance (left thread).

Î Insert the spray pipe all the way into the

gun.

Secure the spray pipe by tightening the

Î

pressure screw (torque approx. 100 Nm).

Connecting the nozzle

Do not perform this procedure until after the

unit has been ventilated, see "Ventilating

the high pressure system“.

Î Grease the thread on the nozzle side

with stainless steel screw grease

(6.280-180.0).

Î Grease the nozzle holder with stainless

steel screw grease (6.280-180.0) and

screw it onto the spray pipe (left

thread).

Î Grease the thread of the high pressure

nozzle with stainless steel screw

grease (6.280-180.0) and screw it onto

the nozzle holder (hexagon socket).

Connect the high pressure hose to the

gun and the appliance.

Danger

Risk of injury from leaks or water jets

emerging from leaks.

– Hoses, pipes and the spray unit must

be in good condition and installed properly.

– Check the high pressure hose daily.

– Only use original high pressure hoses

that are approved for the respective

pressure range and temperature.

– Avoid contact with chemicals.

– Do not use hoses with kinks.

– Do not use the high pressure hose any-

more if the thread is damaged or corroded.

– Stop using the high pressure hose if the

external wire layer is visible.

– Do not route the high pressure hose

across sharp edges.

– Lay the high pressure hoses in such a

way that no vehicle can drive over it.

– Do not use high-pressure hoses that

have been driven over, kinked, pressed

or bent even if there is no externally visible damage.

– Completely lay out the high pressure

hose, do not overlap.

High pressure hoses age with time. Re-

–

place high pressure hoses every 6

years, even if they are in good condition.

– High pressure hoses that have been

stored for more than 2 years, may no

longer be used.

– Store the high pressure hose so that

there is no mechanical strain. Store in a

cool, dry and dustfree place.

– Do not stretch the high pressure hose

during storage, as the high pressure

hose might change its length during operation.

– Relieve tension from the high pressure

hose after operation, purge excess water, coil it and store it properly.

Î Unscrew the protective caps from the

high pressure connection of the hand

spray gun and pull off at the high pressure hose.

Î Clean the thread and grease it with

stainless steel screw grease (6.280-

180.0).

Î Check the high pressure hose for flaw-

less condition (no damage). Only use

intact hoses.

Î Connect the high pressure hose to the

hand spray gun (procedure as described in Chapter "Connecting the

spray pipe to the gun").

Î Remove the protective cap from the

high pressure outlet of the appliance.

Î Clean the thread and grease it with

stainless steel screw grease (6.280-

180.0).

Î Connect the high pressure hose to high

pressure connection (procedure as de-

scribed in Chapter "Connecting the

spray pipe to the gun").

1 Hose sock mounting

2 Hose sock

Î When using a hose sock to protect the

high pressure hose from ripping off,

hook the hose sock into the hose sock

mount.

Connect the control line

Î Roll the control line off the winch to

hose length. Make sure that the control

line is not underneath the high pressure

hose, as the high pressure hose can

rub against it and cause a line break.

Î Pull of the protective cap or antifreeze

plug on the appliance connection side.

Î Connect the short cable end of the

winch with the socket.

Plug the protective caps together to pre-

Î

vent soiling of the protective cap insides.

Î Connect the control line on the gun side

and plug the protective caps together.

Connect the water supply

According to the applicable regulations, the appliance must never

be used on the drinking water net

without a system separator. Use a

suitable system separator manufactured by

Kärcher; or, as an alternative, a system

separator as per EN 12729 Type BA.

Note

Water with drinking water quality with a

pressure between 0.15 and 0.6 MPa (1.5 to

6 bar) is required to ensure a smooth operation of the system.

Î Remove the protective cap from the wa-

ter supply inlet of the appliance.

Î Connect the system separator to the

water inlet (option).

A If the system separator was installed,

the water inlet is on the appliance

B Water inlet on the system separator

8 EN

- 6

Page 9

Î Connect the water supply hose to the

+-

87

+-

87

MENUE

respective water inlet (arrow).

Î Open the lock on the appliance cover

and swivel the appliance cover upwards.

Î Swivel the latch of the appliance hood

upwards to keep it from shutting inadvertently.

Î Check the water filter for contamination,

clean/replace if required.

Î Check the position of the ball tap in the

antifreeze/water tank, set to the water

tank on the right.

The control voltage is switch on and the display shows the operating status.

Î Switch off the motor.

Î Install the nozzle as described in the

chapter "Connecting the nozzle".

Settings

Adjust the water pressure

Note

The water pressure can be changed right

after startup with the key switch as well as

during operation.

Î Adjust the water pressure using the F5

and F4 keys "Increase/reduce water

pressure".

The water pressure can be changed in

increments of 5 MPa (50 bar).

Î Close the drain tap of the water tank.

Î Switch on the battery main switch.

Î Tilt the safety latch of the appliance

hood toward the bottom.

Î Tilt the appliance hood downward and

lock it.

Î Open the door to the operating panel

and switch on the ignition via the keyswitch.

If the tank level is low, the water will be supplied

Start the engine

At low ambient temperatures, the preheating process will start automatically. The respective message is shown on the display.

Î Press the F2 key to start the motor.

Motor runs warm.

During the warm up time, the display will

show the clock symbol.

The set water pressure has been reached.

Adjust the brightness and contrast of

the display

Î Step 1: Press F6 key.

Note

The appliance can only be operated with

the appliance hood closed. The appliance

will switch off when the appliance hood is

opened.

Î Release emergency-stop button by

turning.

Î Open the operating panel door.

Î Turn the key switch to the right.

After the warm up time, the appliance will

be ready for high pressure operation.

Ventilating the high pressure system

Î Connect the high pressure hose, gun

and the spray pipe without nozzle as

described in chapter "Startup".

Î Activate the gun about 30 to 40 sec-

onds until a continuous water jet is emitted from the spray pipe.

- 7

Î Step 2: Press F4 key.

9EN

Page 10

Î Step 3: Press the F3 key to switch be-

0 100___

155 210___

+-

87

MENUE

+-

87

1

2

3

4

5

tween brightness and contrast.

Î You can change the brightness and

contrast levels with the F4 and F5 keys.

F4 (-) = set value decreases.

F5 (+) = set value increases.

Î By pressing the F6 key twice, you will

return to the operating display.

Retrieve the informational display for

service personnel

Î Step 1: Press F6 key.

Î By pressing the F6 key twice, you will

return to the operating display.

Operation

Note

If the appliance is protected with antifreeze,

this antifreeze must be purged from the water system (see chapter "Pumping antifreeze out of the water system“).

Remove air from the high pressure system

prior to operation!

Î Press the release of the hand spray gun

downwards.

Î Pull the lever on the handgun toward

the back.

The motor goes to operating speed.

The high pressure water stream is released.

Î To switch off the high pressure spray,

release the lever of the hand spray gun

and let the release lock.

Note

Frequent switching on and off of the high

pressure spray increase the wear and tear

on the appliance and reduce its product life.

Perform the cleaning process with as few

interruptions as possible.

Shutting down

Note

Only use the Emerg Stop key in emergencies, not to switch off the appliance. A frequent use of the emergency stop key will

increase wear and tear on the appliance.

Î To switch off the high pressure spray,

release the lever of the hand spray gun

and let the release lock.

Î Press F3 key.

Depending on the load, the motor

should somewhat longer to cool off.

Î If there is a risk of freezing tempera-

tures during the operational break, flush

the appliance with antifreeze (see

Chapter "Antifreeze") or transport the

appliance to an area protected from

frost.

Î Turn main key to "0" and remove it.

Î Close and lock the operating panel

door.

Î Open the hood and remove the key

from the battery separating switch.

Î Unscrew the high pressure hose, the

water supply hose and the control line.

Î Protect the hose connections and cou-

plings from contamination with protective caps.

Note

Do not store any objects (incl. hoses, cables and spray units) inside the appliance.

Use the storage compartment or storage

box (option) to store these items.

Frost protection

Note

Use commercially available glycol-based

antifreeze for automobiles.

Observe the manufacturer's handling instructions.

To protect from freeze damages, the appliance must be flushed with antifreeze.

– Antifreeze flushing in a circuit from the

antifreeze tank of the appliance, for preferred use on site

Antifreeze rinse in the circuit (high

pressure pump)

Î Step 2: Press F3 key.

The display will show the trailing time of the

motor with the clock symbol.

Different parameters can be read in the informational display:

U = operating voltage

RPM = motor speed

bar = operating pressure

h = operating hours

10 EN

The motor will switch off.

1 Maintenance door water tank

2 Ball tap, switchover antifreeze/water

tank

3 Backflow antifreeze

4 Antifreeze container filler neck

5 Drain tap water tank

1 Antifreeze hose

Î Unpressurize the appliance.

- 8

Page 11

Î Refill the antifreeze container with anti-

freeze. Select the mixing ratio of the

water/antifreeze as per the instructions

of the antifreeze manufacturer.

Î Align the actuation lever of the ball tap

for antifreeze/water tank vertically.

Î Unscrew the high pressure hose from

the high pressure outlet.

Î Connect the antifreeze hose between

the high pressure outlet and the antifreeze return.

Î Plug in the antifreeze plug control line.

Î Turn the key switch to the right.

The control voltage is switched on and the

display shows the antifreeze rinse operation.

Î Press the F2 key to start the motor.

Î Let the motor run until antifreeze is vis-

ible in the antifreeze hose.

The antifreeze liquid is pumped through

the appliance in a circuit.

Note

After each antifreeze flush, the antifreeze

concentration must be tested in the hose

with a commercially available antifreeze

tester in the return flow from the hose. Add

more antifreeze as needed if the concentration is too low.

Î Press the F3 key to shut off the motor.

Wait for the motor to stop trailing.

Î Remove the antifreeze hose between

the high pressure outlet and the antifreeze return.

Antifreeze motor

Î Check the coolant circuit of the motor

for sufficient antifreeze, refill antifreeze

as needed.

See Maintenance Procedures "Check and

refill the coolant“.

Battery

Î If the appliance is not used for an ex-

tended period and if there is frost, remove the battery and store it in a

location protected from frost.

Pumping antifreeze out of the high

pressure system

Note

Prior to operation, the antifreeze must be

pumped from the high pressure system

back into the antifreeze container.

Î Unpressurize the appliance.

Î Connect the antifreeze hose between

the high pressure outlet and the anti-

freeze return.

Î Create a water supply connected to the

system separator.

Î Turn the key switch to the right.

The control voltage is switch on and the

display shows the operating status.

The solenoid valve for the water supply will

open.

Î Plug in the antifreeze plug control line.

Î Press the F2 key to start the motor.

Î The antifreeze liquid is routed into the

antifreeze tank with fresh water from

the fresh water reservoir.

Î Rinse for about 2 minutes. Watch the

antifreeze hose until no more antifreeze

can be seen.

Î Press the F3 key to shut off the motor.

Wait for the motor to stop trailing.

Î Remove the antifreeze hose between

the high pressure outlet and the anti-

freeze return.

Î Swivel the actuation lever of the ball tap

for antifreeze/water tank to the right.

- 9

11EN

Page 12

Maintenance and care

Danger

Maintenance Procedures may only be

–

carried out by persons who have been instructed in the safe operation and maintenance on the high-pressure systems.

– Before carrying out any tasks on the

machine, switch the key switch off and

remove it.

Prevent inadvertent startups of the appliance during Maintenance Procedures via

third persons by attaching signs on the

appliance and the spray unit.

– If the appliance must be started up for

maintenance procedures, a second

person must be present for safety reasons.

– Water under high pressure can pene-

trate the skin and cause severe injuries

and infections. Stay away from leaks

and do not search for leaks by hand.

– Do not use flammable detergents to

clean the appliance.

– After completing the maintenace work,

check all safety devices for correct installation and proper function.

몇 Caution

Risk of damage. Do not disconnect the battery while the ignition is on or the motor is

running.

1 Waterfilter

2 Filter pot

3 Filter inlay

4 Ventilation of pump gear

5 Ventilation screw intermediate gear

6 Oil sight glass intermediate gear

7 Oil drain screw intermediate gear

8 Oil drain screw pump gear

9 Oil dip pump gear

10 Air filter

11 Air filter insert

12 Cover

13 Lock

14 Battery

15 Filler neck motor oil

12 EN

- 10

Page 13

Flow pattern

1 Compressor

2 Oil cooler module

3 Air cooler module

4 Cyclone separator

5 2/2 way solenoid valve, 2-stroke

6 Condensation drain, return to water

tank

7 Pressure relief valve

8 Silencer

9 Backflow valve

10 Pressure regulation valve

11 Ball tap

12 Safety valve

13 Pressure container

14 Compressed air filter

15 Pressure switch

16 2/2 way PN bypass valve

17 5/2 way valve

18 3/2 way valve

19 Burst disc safety

20 High pressure sensor

21 High-pressure pump

22 Internal combustion engine

23 Prepressure manometer

24 Advance pressure pump

25 Ball tap

26 Water reservoir

27 Antifreeze tank

28 2/2 way solenoid valve

29 High-pressure outlet

30 Exterior air

31 Quick coupling

32 Water filter

33 Fill level probe

- 11

13EN

Page 14

Maintenance intervals

Time Activity By whom

Prior to each drive Check the lighting. Operator

Check the tyre pressure and their state. Operator

Every 10 operating

hours or daily

Once after the first 50

operating hours

Once after the first 150

operating hours

Every 50 operating

hours or weekly

Every 100 operating

hours

Every 200 operating

hours

Every 400 operating

hours

After 750 operating

hours or once a year

Every 1500 operating

hours

Every 3000 operating

hours

Every other year Check the coolant in the motor and replace (see "Maintenance Procedures"). Customer Service/

Maintenance Works

Check the oil level on the motor and add

motor oil

Note

Only trained personnel is permitted to add

motor, gear and pump oil.

Note

Align the appliance horizontally prior to

check the oil level in order not to get a false

result.

Check the oil prior to starting the appliance

or at least 5 minutes after switching off the

engine.

Caution

Increased risk of fire! When filling the motor

oil make sure that no oil lands on hot motor

surfaces.

Check oil level in the pump gear (see "Initial startup"), refill oil if needed. Operator

Check the water filter and clean if necessary. Operator

Check coolant level in the equalisation container (see "Initial startup"), refill coolant if need-

ed.

Replace motor oil (see "Maintenance Procedures"). Customer Service

Replace oil filter insert on motor. Customer Service

Check the screw connections on the motor. Call customer service if necessary. Customer Service

Replace oil in the pump gear. Customer Service

Replace oil in the intermediate gear. Customer Service

Check pipes to see if there are any leaks. Operator

Check the V-belt tension, retension if necessary (see "Maintenance Procedures"). Customer Service/

Check hoses for wear, replace if required. Customer Service/

Check/clean the air filter insert (see "Maintenance Procedures"). Operator

Check the screw connections on the motor. Call customer service if necessary. Customer Service

Replace motor oil (see "Maintenance Procedures"). Customer Service

Replace oil filter insert on motor. Customer Service

Replace the fuel filter. Customer Service

Cleaning the water separator. Customer Service

Lubricate the brake on the drawbar (see "Maintenance Procedures"). Operator

Replace air filter insert (see "Maintenance Procedures"). Customer Service

Replace V-belt. Customer Service

Check the injection pressure at the fuel injector nozzle. Customer Service

Replace oil in the pump gear. Customer Service

Replace oil in the intermediate gear. Customer Service

Remove the oil dip, wipe it and reinsert it.

Î

Î Remove the oil dip one more time and

check the oil level.

The oil level is correct if it is within the markings (arrows) on the oil dip.

Î If the oil level is below the bottom mark,

open the filler neck lid (arrow) and add

fresh motor oil.

Î Wait five minutes, until the oil has col-

lected in the oil pan.

Î Check the oil level as described above.

Î Repeat this procedure as often as nec-

essary until the oil level is between the

markings on the oil dip.

Î After the check, insert the oil dip and

close the lid of the filler neck.

Oil change (to be performed by customer service only)

Note

Only trained personnel is permitted to add

motor, gear and pump oil.

Note

Replace the oil while the motor has operating temperature. Align the appliance horizontally prior to the oil change.

Motor

Above 25 °C SAE30 or

0 °C to 25 °C SAE20 or

Below 0 °C SAE10W or

Operator

Operator

Operator

Operator

SAE10W-30

SAE 15W-40

SAE10W-30

SAE 15W-40

SAE10W-30

SAE15W-40

14 EN

- 12

Page 15

Pump and gear

Pump Mobil D.T.E Oil AA 320

Gear Mobil D.T.E Oil AA 320

Î The oil level is correct if it is within the

markings on the oil dip.

Î After the check, insert the oil dip and

close the lid of the filler neck.

Check the coolant and refill

Note

Prior to every operation, the fill level of the

coolant in the equalisation container must

be checked.

Caution

Observe the brand of antifreeze used. The

mixture can cause a chemcial reaction and

hazardous substances can be generated.

Do not mix different antifreeze types.

몇 Warning

The motor can overheat if there is a lack of

coolant. Turn the motor off immediately and

let it cool down.

If the motor is so overheated, that water vapors escape, immediately turn the motor off

and keep a safety distance to the motor until the pressure has decreased.

Danger of burns! Never open the lid on the

cooler while the motor has operating temperature. The container is under pressure.

Î Open the lid on the equalisation con-

tainer of the motor coolant, fill in fresh

clean water and the required antifreeze.

Cleaning/replacing the air filter

Î Open both locks (arrows) on the lid.

Î Remove the lid and the dust sediments.

Î Take out the filter inlay.

Î Blow out the filter insert with com-

pressed air (max. 2 bar) from the inside.

Î Clean the inside of the air filter housing

with a cloth.

Note

Severely contaminated or defective filter inserts must always be replaced.

Î Please the filter insert into the air filter

housing with the closed side facing out.

Note

Make sure the lid fights snugly, if the lid

does not close properly, dust can get into

the combustion chamber of the motor and

damage it.

Î Replace the lid and close the locks.

Draining the compressed air system

Note

The compressed air system must be

drained in regular intervals.

During continuous operation, it might be

necessary to drain it 2 to 3 times a day.

Note

Do not drain the liquid from the system during high pressure operation. If the ball tap is

open, pressure cannot be built up in the

compressed air lines.

Î Open the ball tap. Allow the water to

drain.

Î After the drain procedure, close the ball

tap.

Compressor

Note

Maintenance work on the compressor may

only be performed by the authorised customer service.

Charge/replace battery

몇 Warning

Battery acid is very corrosive! Always wear

acid-resistant goggles, gloves and an

apron when working with battery acid.

Never charge the battery in the vicinity of

open flames or igniting sparks.

The battery may only be charged in rooms

that are sufficiently ventilated.

Depending on the battery type, the acid level might need to be checked.

The motor must be turned off to charge the

battery.

Note

Prior to connecting the charger, the connecting cables to the control must be disconnected from the battery. Otherwise, the

control could be damaged!

If the appliance is not used for an extended

period and if there is frost, remove the battery and store it in a location protected from

frost.

몇 Warning

Never connect frozen batteries to charge

them. Risk of explosion!

Prior to charging, thaw the battery and

warm to at least 16 °C.

Note

When disconnecting the battery, first disconnect the negative and then the positive

terminal.

When reconnecting the battery, first connect the positive and then the negative cable.

Do not transpose the connecting cable.

Risk of cable fire!

Î Disconnect the connecting cable from

the battery at the negative terminal.

Î Disconnect the connecting cable from

the battery at the positive terminal.

Î Connect the charger.

Î Disconnect the charger after the charg-

ing process is complete.

Î Connect the connecting cable to the

positive terminal on the battery.

Î Connect the connecting cable to the

negative terminal on the battery.

Checking the V-Belt

Note

If the V-belt is not sufficiently tensioned,

this can cause an overheating of the motor

or to an insufficient battery charge.

Î Shut off the motor and remove the key

from the key switch.

Î To check whether the V-belt is ten-

sioned, press the belt with your thumb.

If the V-belt can easily be deflected, or if it

sits loosely on the pulleys, you must order

authorised customer service to tension/replace the V-belt.

Note

Defective V-belts must be replaced immediately.

Caution

The V-belt must only be tensioned or replaced by Customer Service.

Lubricate the brake on the drawbar

Î Press lubricant into both lubrication nip-

ples (arrows) using a commercial

grease press.

- 13

15EN

Page 16

Faults

Danger

This can lead to severe injuries and possibly death. An improper startup and repair of

the appliance and the spray unit is dangerous.

Î Read the fault message on the display

and remediate the fault as per the table

below.

Î Press the reset button to acknowledge/

confirm the fault message.

Faults with display

Faults detected by the control are shown

on the display.

1 Display

2 Fault indication

3 Reset key to confirm the fault

Display/meaning Cause Remedy By whom

Emergency Stop switch depressed Unlock Emergency Stop switch Operator

Remote control not connected Create connection Operator

Plug wet Dry the plug Operator

>Malfunction<

EMERGENCY

STOP

Plug defective Replace the plug Customer Service

Switch in the hand spray gun defective Check the switch, replace Customer Service

Cable breakage Replace the cable Customer Service

Device hood open Close appliance hood Operator

Cable breakage Replace the cable Customer Service

Safety switch for appliance hood defective Check safety switches. Customer Service

>Malfunction<

Hood open

>Malfunction<

Tank level

>Malfunction<

Cooling water level

>Malfunction<

Motor oil pressure

>Malfunction<

Motor temperature

>Malfunction<

Tyre pressure

Fuel tank empty. Refill diesel fuel Operator

Level sensor defective Replace level sensor Customer Service

Cable breakage Replace the cable Customer Service

See motor operating instructions

Level of coolant too low Refill cooling water Operator

Radiator contaminated Clean the radiator Operator

V-belt tension on the ventilator too low Retension V-belt Customer Service

Thermostat defective Replace the thermostat Customer Service

Cable breakage Replace the cable Customer Service

Motor oil level too low Check the motor oil level Operator

Oil the motor has the wrong viscosity Replace engine oil. Customer Service

Oil pressure switch on motor defective Replace oil pressure switch on motor Customer Service

Cable breakage Replace the cable Customer Service

Look for more instructions in the motor's operating instructions

Coolant level in the motor too low Check coolant units Operator

Radiator contaminated Clean the radiator Operator

V-belt tension on the ventilator drive too low Check V-belt tension Operator

Tighten V-Belt Customer Service

Thermostat defective Check thermostat Customer Service

Defective temperature switch Check the temperature switch Customer Service

Cable breakage Replace the cable Customer Service

Look for more instructions in the motor's operating instructions

Ball tap of drain open Close the ball tap Operator

Water in the compressed air tank Drain water Operator

Air system leaks Seal the air system Customer Service

Compressor defective Repair the compressor Customer Service

V-belt tension on the compressor drive too low Tighten V-Belt Customer Service

Pressure switch is defective Check/replace the pressure switch Customer Service

Cable breakage Replace the cable Customer Service

16 EN

- 14

Page 17

Display/meaning Cause Remedy By whom

>Malfunction<

High pressure sensor

>Malfunction<

High pressureHochdruck > max.

>Malfunction<

High pressure decrease too slow

>Malfunction<

Water level

>Malfunction<

Water inlet pressure

below 0.15 MPa (1.5

bar)

>Malfunction<

Remote control

Cable plug of high pressure sensor loose or

short in connection

Cable breakage Replace the cable Customer Service

High pressure sensor defective Check / replace the sensor Customer Service

The permitted max. pressure is exceeded due

to small or plugged nozzle

Load speed too high Reduce load speed Customer Service

The pressure decrease is too slow after the lever of the hand spray gun is released

Cable breakage Replace the cable Customer Service

High pressure valve defective Check the high pressure valve Customer Service

High pressure sensor defective Check / replace the sensor Customer Service

Water tank empty. Inlet valve to water tank

closed (by customer)

Cross section of water supply hose too small Use a water supply hose with a larger

Level switch defective Replace the level switch Customer Service

Cable breakage Replace the cable Customer Service

Water reservoir empty Filling the Water Reservoir Operator

Water filter contaminated Clean water filter Operator

Backflow valve on the advance pump contami-

nated

Pressure switch is defective Check/replace the pressure switch Customer Service

Cable breakage Replace the cable Customer Service

Advance pump defective Check / replace the prepressure pump Customer Service

Advance pump drive defective Check/replace the main switch Customer Service

Remote control not connected Create connection Operator

Plug wet Dry the plug Operator

Plug defective Replace the plug Customer Service

Switch in the hand spray gun defective Check the switch, replace Customer Service

Cable breakage or short in the control line Check the cable, replace Customer Service

See motor operating instructions

Evaluation unit defective Replace evaluation unit Customer Service

Cable breakage Replace the cable Customer Service

Check for correct fit Operator

Check the nozzle size, install correct noz-

zle

Check the switch valve Customer Service

Check the inlet valve to the water tank Operator

cross section

Check backflow valve Customer Service

Operator

Operator

>Malfunction<

EMR fault

>Malfunction<

Compressor temperature

>Malfunction<

Water in fuel

Oil temperature too high Check the oil temperature Operator

Temperature sensor defective Replace the temperature sensor Customer Service

Cable breakage Replace the cable Customer Service

See motor operating instructions

Water in fuel Replace the fuel Operator

Cable breakage Replace the cable Customer Service

- 15

17EN

Page 18

Faults without display on the console

1Main fuse

Fault Cause Remedy By whom

Appliance stops, dis-

Main fuse is blown Replace the main fuse Operator

play switches off

No display after

switching the appliance on

Motor will not start or

Battery main switch switched off Switch on the battery main switch Operator

Battery depleted Charging battery Operator

Main fuse is blown Replace the main fuse Operator

See separate operating instructions of the motor

turns off immediately

Working pressure is

fluctuating

Air in the high pressure pump Ventilating the high pressure system Operator

Valves worn out Replace the valves Customer Service

Technical specifications

HD 7/250 DE TR1

Water connection

Max. feed temperature °C 60

Min. feed volume l/h (l/min) 1080 (18)

Feed pressure MPa (bar) 0,15...0,6 (1,5...6)

Performance data

Water flow rate l/h (l/min) 672 (11,2)

Operating pressure of water (using standard nozzle) MPa (bar) 250 (2500)

Max. excess operating pressure (safety valve) MPa (bar) 300 (3000)

Drive motor performance kW 74

Motor rpm 1/min 3000

Battery V/Ah 12/55

Nozzle size 0,6

Max. recoil force of hand spray gun N 129

Fuel

Oil quantity, intermediate gear l 0,6

Öl type, intermediate gear - Mobil D.T.E. Oil AA 320

Oil quantity, pump gear l 4,5

Oil type, pump gear - Mobil D.T.E. Oil AA 320

Oil quantity, motor l 4,5

Öl type, motor - See Maintenance tasks

Content of cooling system l 10-11

Dimensions and weights

Length x width x height mm 4068 x 1912 x 2000

Diesel tank l200

Weight without operating materials kg 1240

Weight including operating materials, approx. kg 1510

Permissible axle load kg 1800

Antifreeze container l 25

Water reservoir l200

Tyre type - 205 R 14

Tyre pressure MPa (bar) 0,45 (4,5)

Brake system - Overrun brake

Vibration total value (ISO 5349)

Hand-arm vibration value

Hand spraygun m/s

Spray lance m/s

Uncertainty K m/s

Sound pressure level L

Uncertainty K

pA

Sound pressure level L

(EN 60704-1) dB(A) 91

pA

+ Uncertainty KWA (2001/14//EC) dB(A) 111

WA

2

2

2

<2,5

<2,5

0,5

dB(A) 2

18 EN

- 16

Page 19

Accessories and Spare Parts

CEO

Head of Approbation

– Only use accessories and spare parts

which have been approved by the manufacturer. The exclusive use of original

accessories and original spare parts

ensures that the appliance can be operated safely and troublefree.

– At the end of the operating instructions

you will find a selected list of spare

parts that are often required.

– For additional information about spare

parts, please go to the Service section

at www.kaercher.com.

Warranty

The warranty terms published by the relevant sales company are applicable in each

country. We will repair potential failures of

your appliance within the warranty period

free of charge, provided that such failure is

caused by faulty material or defects in manufacturing. In the event of a warranty claim

please contact your dealer or the nearest

authorized Customer Service centre.

Please submit the proof of purchase.

CE declaration

We hereby declare that the machine described below complies with the relevant

basic safety and health requirements of the

EU Directives, both in its basic design and

construction as well as in the version put

into circulation by us. This declaration shall

cease to be valid if the machine is modified

without our prior approval.

Product: Maximum pressure cleaners

Type: 1.025-xxx

Relevant EU Directives

2006/42/EC (+2009/127/EC)

2004/108/EC

2000/14/EC

Applied harmonized standards

EN ISO 12100–1

EN ISO 12100–2

pr EN 1829-1

EN 1829 -2

EN 13309: 2000

EN 55012: 2007 + A1: 2009

Applied conformity evaluation method

2000/14/EC: Appendix V

Sound power level dB(A)

Measured: 109

Guaranteed: 111

The undersigned act on behalf and under

the power of attorney of the company management.

Authorised Documentation Representative

S. Reiser

Alfred Kärcher GmbH Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Phone: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2010/08/01

- 17

19EN

Page 20

AE Karcher FZE, P.O. Box 17416, Jebel Ali Free Zone (South),

Dubai, United Arab Emirates,

+971 4 886-1177, www.kaercher.com

AR Kärcher S.A., Uruguay 2887 (1646) San Fernando, Pcia. de

Buenos Aires

+54-11 4506 3343, www.karcher.com.ar

AT Alfred Kärcher Ges.m.b.H., Lichtblaustraße 7, 1220 Wien,

+43-1-25060-0, www.kaercher.at

AU Kärcher Pty. Ltd., 40 Koornang Road, Scoresby VIC 3179,

Victoria,

+61-3-9765-2300, www.karcher.com.au

BE Kärcher N.V., Industrieweg 12, 2320 Hoogstraten,

+32-3-340 07 11, www.karcher.be

BR Kärcher Indústria e Comércio Ltda., Av. Professor

Benedicto Montenegro no 419, Betel, Paulínia - Estado de Sao

Paulo, CEP 13.140-000

+55-19-3884-9100, www.karcher.com.br

CA Kärcher Canada Inc., 6535 Millcreek Road, Unit 67,

Mississauga, ON, L5N 2M2,

+1-905-672-8233, www.karcher.ca

CH Kärcher AG, Industriestrasse, 8108 Dällikon, Kärcher SA,

Croix du Péage, 1029 Villars-Ste-Croix,

0844 850 864, www.kaercher.ch

CN Kärcher (Shanghai) Cleaning Systems, Co., Ltd., Part F,

2nd Floor, Building 17, No. 33, XI YA Road, Waigaogiao Free

Trade, Pudong, Shanghai, 200131

+86-21 5076 8018, www.karcher.cn

CZ Kärcher spol. s r.o., Modletice c.p. 141, CZ-251 01 Ricany,

+420/323/606 014, www.kaercher.cz

DE Alfred Kärcher Vertriebs-GmbH, Friedrich-List-Straße 4,

71364 Winnenden,

+49-7195/903-0, www.kaercher.de

DK Kärcher Rengøringssystemer A/S, Helge Nielsens Allë 7 A,

8723 Løsning,

+45-70206667, www.karcher.dk

ES Kärcher, S.A., Pol. Industrial Font del Radium, Calle Josep

Trueta, 6-7, 08403 Granollers (Barcelona),

+34-902 17 00 68, www.karcher.es

F Kärcher S.A.S., 5, avenue des Coquelicots, Z.A. des Petits

Carreaux, 94865 Bonneuil-sur-Marne,

+33-1-4399-6770, www.karcher.fr

FI Kärcher OY, Yrittäjäntie 17, 01800 Klaukkala,

+358-207 413 600, www.karcher.fi

GB Kärcher (U.K.) Ltd., Kärcher House, Beaumont Road,

Banbury, Oxon OX16 1TB,

+44-1295-752-000, www.karcher.co.uk

GR Kärcher Cleaning Systems A.E., 31-33, Nikitara str. &

Konstantinoupoleos str., 136 71 Aharnes,

+30-210-2316-153, www.karcher.gr

HK Kärcher Limited, Unit 10, 17/F., Apec Plaza, 49 Hoi Yuen

Road, Kwun Tong, Kowloon,

++(852)-2357-5863, www.karcher.com.hk

HU Kärcher Hungaria KFT, Tormásrét ut 2., (Vendelpark), 2051

Biatorbagy,

+36-23-530-64-0, www.kaercher.hu

IE Kärcher Limited (Ireland), 12 Willow Business Park, Nangor

Road, Dublin 12,

(01) 409 7777, www.kaercher.ie

JP Kärcher (Japan) Co., Ltd., Irene Kärcher Building, No. 2,

Matsusaka-Daira 3-chome, Taiwa-cho, Kurokawa-gun, Miyagi

981-3408,

+81-22-344-3140, www.karcher.co.jp

KR Karcher Co. Ltd. (South Korea), 2nd Floor , Youngjae

Building, 50-1, 51-1, Sansoo-dong, Mapo-ku, Seoul 121-060,

+82-2-322 6598, www.karcher.co.kr

MX Karcher México, SA de CV, Av. Gustavo Baz Sur No. 29-C,

Col. Naucalpan Centro, Naucalpan, Edo. de México, C.P. 53000

México,

+52-55-5357-04-28, www.karcher.com.mx

MY Karcher Cleaning Systems Sdn. Bhd., 71 & 73 Jalan TPK 2/

8, Taman Perindustrian Kinrara, Seksyen 2, 47100 Puchong,

Selangor Darul Ehsan, Malaysia,

+603 8073 3000, www.karcher.com.my

NL Kärcher B.V., Postbus 474, 4870 AL Etten-Leur,

0900-33 666 33, www.karcher.nl

NO Kärcher AS, Stanseveien 31, 0976 Oslo, Norway,

+47 815 20 600, www.karcher.no

NZ Karcher Limited, 12 Ron Driver Place, East Tamaki,

Auckland, New Zealand,

+64 (9) 274-4603, www.karcher.co.nz

PL Kärcher Sp. z o.o., Ul. Stawowa 140, 31-346 Kraków,

+48-12-6397-222, www.karcher.pl

RO Karcher Romania srl, Sos. Odaii 439, Sector 1, RO-013606

BUKAREST,

+40 37 2709001, www.kaercher.ro

RU Karcher Ltd. Service Center, Leningradsky avenue, 68,

Building 2, Moscow, 125315

+7-495 789 90 76, www.karcher.ru

SE Kärcher AB, Tagenevägen 31, 42502 Hisings-Kärra,

+46 (0)31-577 300, www.karcher.se

SGP Karcher South East Asia Pte. Ltd., 5 Toh Guan Road East,

#01-00 Freight Links Express Distripark, Singapore 608831,

+65-6897-1811, www.karcher.com.sg

SK Kärcher Slovakia, s.r.o., Beniakova 2, SK-94901 NITRA,

+421 37 6555 798, www.kaercher.sk

TR Kärcher Servis Ticaret A.S., 9 Eylül Mahallesi, 307 Sokak

No. 6, Gaziemir / Izmir,

+90-232-252-0708, +90-232-251-3578, www.karcher.com.tr

TW Karcher Limited, 7/F, No. 66, Jhongijheng Rd., Sinjhuang

City, Taipei County 24243, Taiwan,

+886-2-2991-5533, +886-800-666-825, www.karcher.com.tw

UA Kärcher TOV, Kilzeva doroga, 9, 03191 Kiew,

+380 44 594 7576, www.karcher.com.ua

USA To locate your local dealer please visit our web site at

http://www.karchercommercial.com or call us at 888.805.9852

ZA Kärcher (Pty) Ltd., 144 Kuschke Street, Meadowdale,

Edenvale, 1614,

+27-11-574-5360, www.karcher.co.za

I Kärcher S.p.A., Via A. Vespucci 19, 21013 Gallarate (VA),

+39-848-998877, www.karcher.it

02/10

Loading...

Loading...