Page 1

TASKALFA-250CI, 300CI, 400CI, 500CI, 552CI, FS-C8500DN

TROUBLESHOOTING GUIDE

KDE PRODUCT ENGINEERING

Revision 4

Page 2

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

TROUBLESHOOTING GUIDE INDEX PAGE 2

Faint printing issue / Drum pin hole issue (New Firmware ver. 13.01) Page 3

Preventing wrapped paper into the transfer belt (Measure against J31/J4X) Page 4

Preventing wrapped paper into the fixing unit (Measure against C6000, J4X/J50) Page 6

Measure against the Service Call C2810 Page 9

Prevention of the DV toner dropping Page 13

Transferbelt cleaning failure Page 16

Appendix Page 17

TASKalfa-XYZ Troubleshooting Guide 2

Page 3

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

TROUBLESHOOTING GUIDE

Faint printing issue / Drum pin hole issue (New Firmware) PAGE 3

In case of a color stability issue:

Before the machine wakes up from sleep mode the developer rotates for approx. 20sec. This is related to the toner

deterioration and color stability. We have reduced this time to approx. 5Sec.

The firmware includes two new engine version

Engine FW (400ci 500ci) 2H7 1000.C05.001 (NEW)←

Engine FW (250ci 300ci) 2JZ_1000.C05.001 (NEW)←

Depending on the coverage, mode 2 can be used as well.

The customized engine firmware includes these automatic settings.

U147>Set Operation Mode>Mode 1 (Default: Mode0)

U147>BK Density>0 (Default: 1)

3

(Detailed information you will find in SB 2H7-0094-C295)

Page 4

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

TROUBLESHOOTING GUIDE

Preventing wrapped paper in transfer (Measure against J31/J4X) PAGE 4

Phenomenon :

Paper may be wrapped around the primary transfer belt after primary transfer process, and then J31 (Misfeed round the transfer belt)

or J4X (Misfeed in fuser section: X is the paper feeding source No.) may be displayed depending on the paper properties (weak stiffness/upward curl/thinness).

Therefore, the following are changed.

Contents of change:

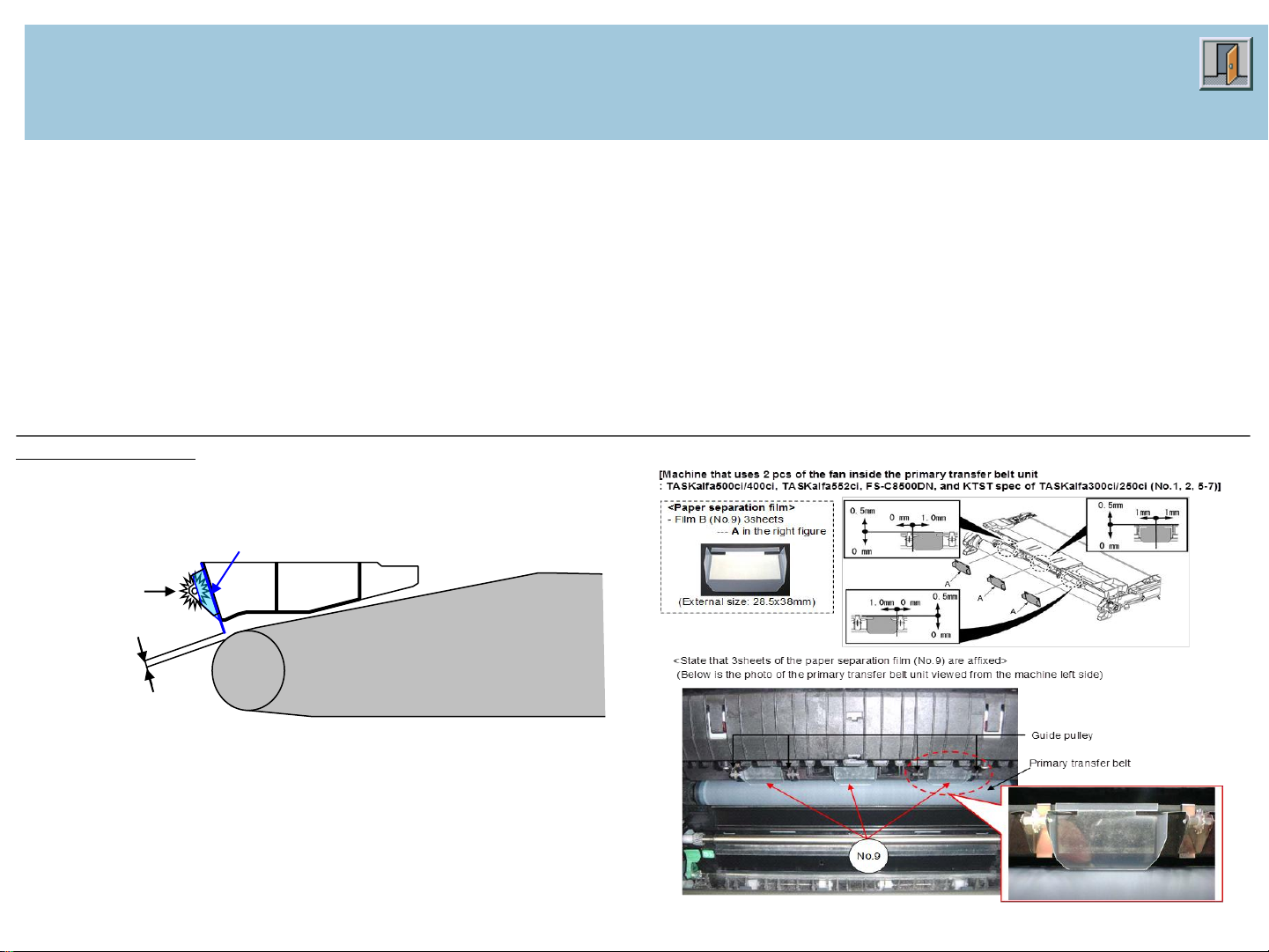

To prevent J31/J4X and the paper wrapping around the primary transfer belt, the paper separation films (No.8, 9) are affixed in between the guide pulleys at

the machine left side of the primary transfer belt.

The paper separation film (2 each sheets of No.8, 9 or 3 sheets of No.9) and the instruction leaflet are bundled in the primary transfer belt unit for service

(No.1-7) and MK kit A.

State after affixing the paper separation film (No.8, 9)

Papr separation film: below is the state that the film is affixed in 0mm of the

vertical alignment. (Please refer to the page 3, 4 for the alignment.)

Guide pulley

About 1.35mm

(Detailed information you will find in SB 2H7-0072-A283)

Primary transfer belt

Page 5

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

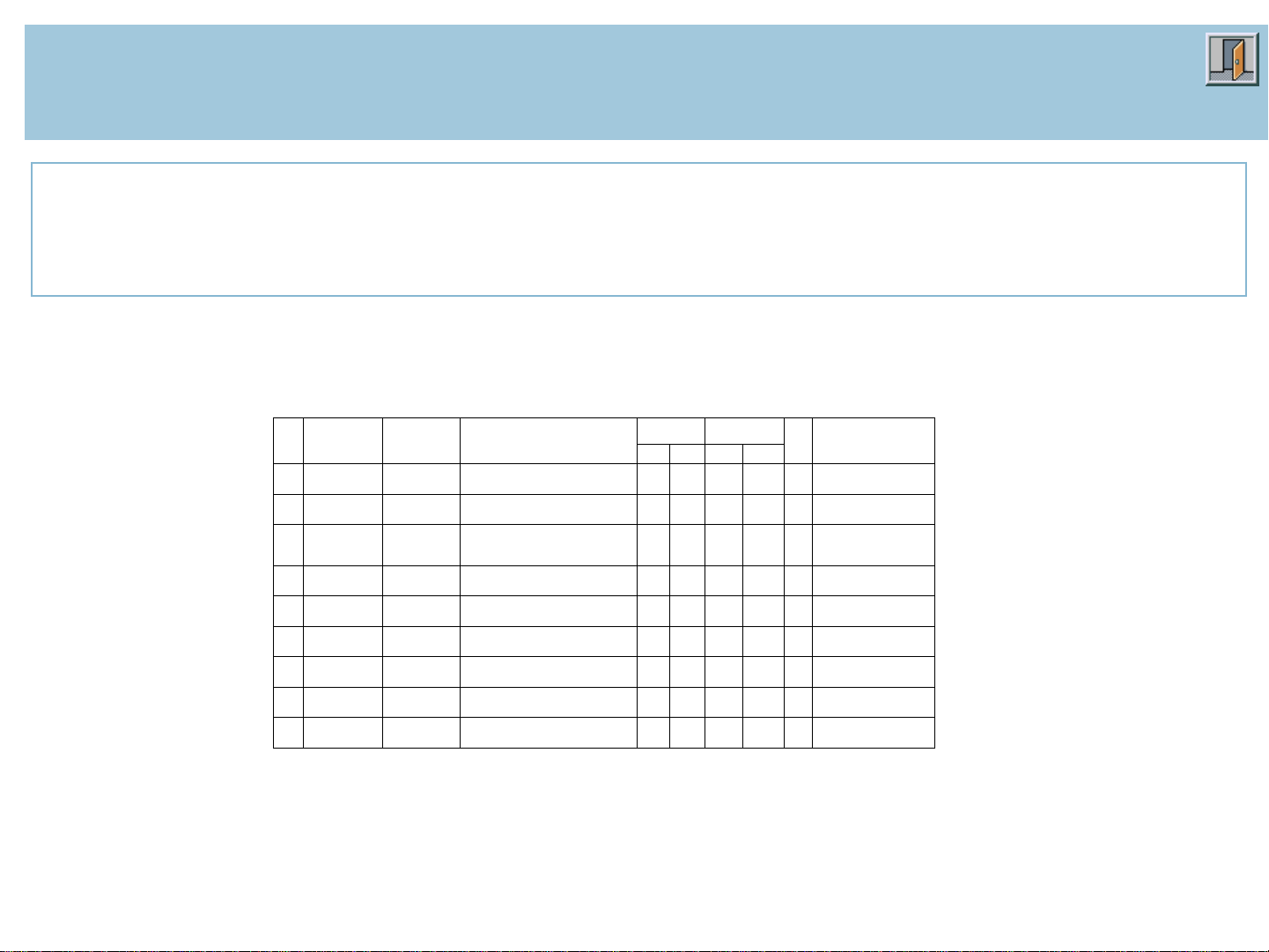

Field Measure:

When the phenomena described in the previous page occur, please affix the paper separation film (No.8, 9) after cleaning the

(When affixing the film, please remove the fuser unit and slightly pull the primary transfer belt unit leftward.)

And, when replacing the primary transfer belt unit or MK kit A, please clean the affixing position with alcohol and affix the

that is bundled.

[Note] Please check if the paper separation film does not contact the primary transfer belt after affixing the film.

No.

Old Part

No.

New Part

No.

Description

Q’

ty

Com

bi

pati

lity

SP

Remarks

Old

New

Old

New

1

302H793226

2H793226

302H793227

2H793227

PARTS TRANSFER BELT H

UNIT

1

1

X O O

500ci/400ci

(Except KMKR)

2

302H79K226

2H79K226

302H79K227

2H79K227

PARTS TRANSFER BELT H

UNIT

1

1

X O O

500ci/400ci

(KMKR)

3

302JZ93076

2JZ93076

302JZ93077

2JZ93077

PARTS TRANSFER BELT L

UNIT

1

1

X O O

300ci/250ci

(Except

KTST/KMKR spec)

4

302JZ9K076

2JZ9K076

302JZ9K077

2JZ9K077

PARTS TRANSFER BELT L

UNIT

1

1

X O O

300ci/250ci

(KMKR spec)

5

302JZ93246

2JZ93246

302JZ93247

2JZ93247

PARTS TRANSFER BELT L J

UNIT

1

1

X O O

300ci/250ci

(KTST spec)

6

302KY93151

2KY93151

302KY93152

2KY93152

PARTS TRANSFER BELT

UNIT

1

1

X O O

*1

(Except KMKR spec)

7

302KY9K151

2KY9K151

302KY9K152

2KY9K152

PARTS TRANSFER BELT

UNIT

1

1

X O O

*1

(KMKR spec)

8

------------

302H721670

2H721670

+FILM GUIDE BELT A

-

(*2)

- O -

9

------------

302H721680

2H721680

+FILM GUIDE BELT B

-

(*2)

- O -

Parts with “O” indicates regular maintenance parts. "+" Mark at the head of the description means it is a components parts.

(*) As for the primary transfer belt unit for service (No.1-7) and MK kit A, the paper separation film (2 each sheets of the film

(No.8, 9) or 3 sheets of No.9) and the instruction leaflet A/B that directs affixing the paper separation film (the attached

leaflet) are bundled.

*1: 552ci, FS-C8500DN

*2: - Primary transfer belt unit (No.3, 4): 2 each sheets of the film A (No.8) and the film B (No.9) are affixed. (Total 4 sheets)

- Primary transfer belt unit (No.1, 2, 5-7): 3 sheets of the film (No.9) are affixed.

TROUBLESHOOTING GUIDE

Preventing wrapped paper in transfer (Measure against J31/J4X) PAGE 5

affixing position of the primary transfer belt with alcohol.

paper separation film (No.8, 9) after fitting the guide pulley

When the paper is wrapping around the upper side of the primary transfer belt, if the end user does not notice the paper and only opens and

closes the cover, the paper is not removed because only the paper jam indication disappear by opening/closing the cover. If continuing drive

in that state, the paper may enter into the inner part of the primary transfer belt and then the cleaning failure at the primary transfer belt

may occur.

5

(Detailed information you will find in SB 2H7-0072-A283)

Page 6

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

TROUBLESHOOTING GUIDE

Preventing wrapped paper into the FK (Measure against C6000, J4X/J50)

PAGE 6

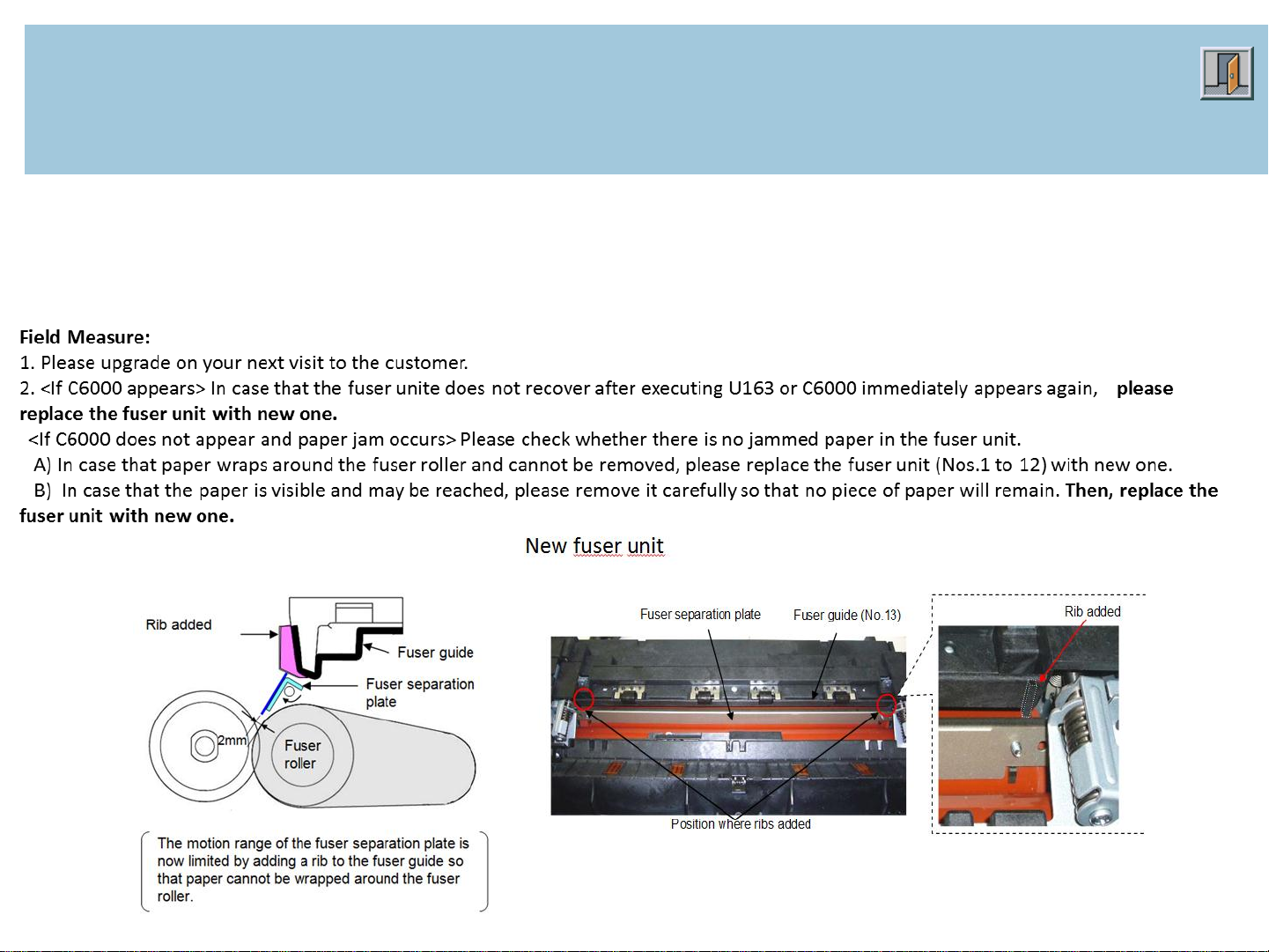

Phenomenon:

In case that a paper jam occurs at the fuser section and the job separator (*), the next fed paper might be pleated when it hits the jammed paper or a piece of torn paper

remaining after clearing the paper jam. Then, the trailing edge of this paper may wrap around the fuser roller.

If the phenomenon described above arises, it is difficult to clear the paper jam and C6000 (Service call detecting fuser problems) may appear. Therefore, the following

changes were made.

(*: J4x/J5x is detected.)

6

(Detailed information you will find in SB 2H7-0075-A333)

Page 7

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

<Fitting procedures of the new fuser guide (No.13)>

*Please handle the fuser unit after cooling it down as it is hot.

1. Fit the new fuser guide (No.13) and fix it by tightening the screws (x3).

2. Check if there is gap between the fuser separation plate and the two ribs added to the fuser guide after the new

fuser guide (No.13) was attached.

3. In case that there is no gap, please add the washer (No.14).

* The method above is how to check the rib on the machine front side. Please check the rib on the machine rear

side by the same way.

Rib added

Fuser separation plate

Please confirm the

gap in the method

described above.

<Plate to check the gap>

Please use the plate which

indicates the size of papers in

cassette.

Please insert the plate between the fuser separation plate and

the ribs added to the fuser guide. In case that there is no gap,

please add the washer (No.14) to the following position.

Fuser guide (No.13)

TROUBLESHOOTING GUIDE

Preventing wrapped paper into the FK (Measure against C6000, J4X/J50)

PAGE 7

7

(Detailed information you will find in SB 2H7-0075-A333)

Page 8

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

Serial Nos. of the Affected Machines:

TASKalfa500ci

KME

UTAX/TA

QHW0Y02513-

Next production

TASKalfa400ci

KME

UTAX/TA

QJA0Y04486-

QES0Y01114-

TASKalfa300ci

KME

UTAX/TA

QJE0Y06328-

QER0Y01758-

TASKalfa250ci

KME

UTAX/TA

QJK0Y28959-

QEQ0Y11614-

TASKalfa552ci

KME

UTAX/TA

QXG0Y00242-

Q4W0Y00082-

<Serial number of the MK kit>

MK-855A for TASKalfa500ci/400ci (KME): From QJR0Y02021 (S/N of FK unit: from MCL0Y00022-)

MK-865A for TASKalfa300ci/250ci (KME): From QJP0Y01914 (S/N of FK unit: from MCM0Y00066-)

TROUBLESHOOTING GUIDE

Preventing wrapped paper into the FK (Measure against C6000, J4X/J50)

PAGE 8

8

(Detailed information you will find in SB 2H7-0075-A333)

Page 9

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

Content of Changes

1) The tolerance for frictional wear of the brush was improved by changing the motor from a different vender.

2) Due to the change above, the shape of the motor holder was changed.

* The holder shape was changed due to the motor change.

As the countermeasure against the Service Call C2810, it is necessary to replace the old PARTS ICL

MOTOR UNIT with the new one (No. 1, 2).

3) Due to the change above, the wire alignment of the motor was changed. (Please refer to the next page.)

No.1,2

No.3

GEAR WORM /48390M0062 A4

(5MVG115DB002)

No.4

<Difference between the old and new PARTS ICL MOTOR UNIT

(Nos.1 and 2)>

White marking added on the new holder

(Nos.1 and 2)

TROUBLESHOOTING GUIDE

Change of the Waste Toner Motor (Measure against the Service Call C2810)

PAGE 9

Phenomenon:

When excessive electrical current was applied to the waste toner motor by short circuit, the engine PWB might be damaged or C2810 (waste

toner motor error) might appear. Therefore, the following changes were made.

Accordingly, some attention is required when replacing the parts. Please refer to <Field Measure> below.

Field Measure:

Please replace the assembly (new No.1, 2) with the new motor and the new holder when the phenomenon described above occurs with

the machine from the October 2009 production up to the one with the serial numbers listed below. (*No problem is expected from the

machines from the September 2009 production and before.)

Serial Numbers list of the Reworked Machines you can find in SB 2H7-0081-B022

9

(Detailed information you will find in SB 2H7-0081 (B022)

Page 10

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

A) Affected models : TASKalfa500ci/400ci/300ci/250ci

(Old) (New)

B) Affected models: TASKalfa552ci, FS-C8500DN

(Old) (New)

1) The position to fit the wire saddle (X) was changed.

2) Do not pass the wire through the wire saddle (Y).

Wire saddle (Z)

Wire saddle (Z)

Do not pass the wire through the wire saddle (Z).

Only the wire of the fan passes through the wire saddle

(Z).

No.1,2

Wire saddle(X)

Wire saddle (Y)

No.1,2

Wire saddle(X)

Wire saddle (Y)

TROUBLESHOOTING GUIDE

Change of the Waste Toner Motor (Measure against the Service Call C2810)

PAGE 10

10

(Detailed information you will find in SB 2H7-0081 (B022)

Page 11

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

TROUBLESHOOTING GUIDE

Change of the Waste Toner Motor (Measure against the Service Call C2810)

PAGE 11

11

(Detailed information you will find in SB 2H7-0081 (B022)

• "+" Mark at the head of the description indicates that it ismponent part.

*1: The old No.4 will be continuously supplied as toner replenishing motor (4

pcs. used). Please use the new Nos.1 and 2 when the waste toner a comotor

is replaced since the new individual waste toner motor is not supplied to

prevent the wrong use as the toner replenishing motor.

Page 12

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

TROUBLESHOOTING GUIDE

Change of the Waste Toner Motor (Measure against the Service Call C2810)

PAGE 12

12

(Detailed information you will find in SB 2H7-0081 (B022)

Page 13

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

TROUBLESHOOTING GUIDE

Prevention of the DV toner dropping PAGE 13

Phenomenon:

Depending on the operating environment (*), the cohesive materials of the deteriorated toner and the additives peeled off from

the toner may accumulate on the topside of the Bk developer magnet cover and it may interrupt air flow of the developer cooling

fan. If the deteriorated toner accumulates on the cohesive materials and adheres to the magnet/sleeve roller, Bk toner smudge

may appear. Therefore, following are changed.

(*) Bk toner smudge easily appear if the temperature inside the machine rises due to driving for a long time, or the originals/data

of low print coverage are continuously printed out in monochrome mode.

(The above causes the increase of the deteriorated toner)

Content of changes:

(Refer to next page for details)

1) Bk developer units for preventing the

toner smudge (No.1-4) are set and

supplied for the field.

Bk developer units for preventing the toner

smudge are not brought to the machine

produced in the factory because use of

these units is accompanied with the

restriction.

Following are the changed points from the

normal Bk developer unit.

(Refer to the next page for restriction.)

Image sample

2) Firmware is upgraded as below.

3) According to setting the parts No. of the Bk developer unit for

preventing the toner smudge in the above 1), indication and check

box of [DV-855B], [DV-865B] and [DV-856B] are added to the

packing case that is commonly used with the normal developer unit

(DV-855/865/856 for four colors).

13

(Detailed information you will find in SB 2H7-0080 (B010)

Page 14

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

TROUBLESHOOTING GUIDE

Prevention of the DV toner dropping PAGE 14

Changed point:

Firmware changes:

14

(Detailed information you will find in SB 2H7-0080 (B010)

Page 15

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

Please recognize the following because use of the Bk developer unit for preventing the toner smudge (No.1-4)

is accompanied with the restriction.

Content for restriction

Related change

(Refer to the previous page)

1

Please explain the sound that is heard when the coupling of the main

machine side and the developer side mesh with each other for reversely

rotating the developer drive to the user for acquiring the user's approval. (*1)

<Changed point 3>

Firmware upgrade

(*1) If the user does not approve the content of restriction 1, please use the normal Bk developer unit.

(These units are only for supply to the field.)

No.

Old Part

No.

New Part

No.

Description

Q’

ty

Com

bi

pati

lity

Remarks

Old

New

Old

New

1

------------

302H793710

2H793710

PARTS DLP K UNIT B

-

1

-

O

*1,

DV-855B (Except KMKR)

2

------------

302H79K710

2H79K710

PARTS DLP K UNIT B

-

1

-

O

*1,

DV-855B (For KMKR)

3

------------

302JZ93410

2JZ93410

PARTS DLP K L UNIT B

-

1

-

O

*2,

DV-865B (Except KMKR)

4

------------

302JZ9K410

2JZ9K410

PARTS DLP K L UNIT B

-

1

-

O

*2,

DV-865B (For KMKR)

5

------------

302H794830

2H794830

PARTS SEAL FRONT DRUM

SET SP

-

1

-

O

Seal kit for replacing the

drum unit, *3

*1: TASKalfa500ci/400ci (Normal Bk developer unit --- For all spec except KMKR: 302H79317_/For KMKR: 302H79K17_)

*2: TASKalfa300ci/250ci (Normal Bk developer unit --- For all spec except KMKR: 302JZ9319_/For KMKR: 302JZ9K19_)

*3: Bundled items of No.5 (That are same as the parts that are bundled in No.1-4 in <Changed point 4> mentioned in the

previous page) --- Sponge (L), sponge (S), seal and affixing procedure leaflet

* Developer drive gear of the normal developer unit is individually supplied. However, the developer drive gear (The shape is

changed from the gear of the normal developer unit in <Changed points> 3) of the Bk developer unit for preventing the toner

smudge (No.1-4) is not set as the individual supply parts.

TROUBLESHOOTING GUIDE

Prevention of the DV toner dropping PAGE 15

Restriction

Developer unit for preventing the toner smudge and seal kit

15

(Detailed information you will find in SB 2H7-0080 (B010)

Page 16

TASKALFA- 250ci, 300ci, 400ci, 500ci, 552ci, FS-C8500DN

TROUBLESHOOTING GUIDE

Transferbelt cleaning failure PAGE 16

Phenomenon:

Abnormal image (offset image) may be

printed out caused by the cleaning failure on

the transfer belt due to the cleaning ability.

(New fur brush)

Counter measure:

When the above phenomenon occurs,

please replace with the new fur brush as it is

shown in the Service Bulletin (2H7-0092-

C274).

Parts information:

PARTS BRUSH FUR B SP (302KY94370)

16

(Refering to SB 2H7-0092-C274)

Page 17

This technical publication is confidential information that is the property of Kyocera Document Solutions. It is solely

for the use of Kyocera Document Solutions authorized dealers. This information may not be published, reproduced,

sold, or copied in any media. This document contains published service bulletin information; it is to help you

troubleshoot specififc problems. Using the troubleshooting guide does not release you from your responsibility as

a technician to abide by the country laws and company regulations that you are already bound to.

We can not be held liable for any action on your part that is not strictly specified in this document.

©KYOCERA Document Solutions Europe B.V.

Published by:

PRODUCT ENGINEERING

Technical Documentation

Released: 23 January 2013

Loading...

Loading...