Kyocera TASKalfa 250, FS-C8500DN, TASKalfa300, TASKalfa400, TASKalfa500ci SERVICEBULLETINS 2H7 0083 B093 1

(Revised issue 1)

Service Bulletin Ref. No.

(Page.1/5)

2H7-0083 (B093)

<Date> April 18, 2012

Prevention of Peeling off of the Stopper Rubber for the Primary

Subject

Transfer Belt (Bundling of the Waste Toner Lump Breaking

Spring in the Primary Transfer Unit)

Model

This time, the description with (-->) was revised from the previous information.

<Number of changes: 2> The serial numbers of the affected models were added (P5).

Topic

The following phenomena might occur if the stopper rubber to prevent the primary transfer belt side from slipping

peeled off from the seam during the machine was driving in case that adhesive strength of the double-sided tape

decreases which affixes the stopper rubber (marked X in the figure below) on the inner side edge of the primary

transfer belt in the operation environment with high temperature and high humidity.

- Image failure if the transfer belt is torn after the rubber runs over the edge of the drive roller

- Abnormal noise and jam (JAM31) if the transfer belt drive is locked after the rubber rolls up along the driver

roller and gear

Content of Changes

1) The seam section of the stopper rubber (X) was fixed with glue to prevent the rubber from peeling off.

2) The waster toner lump breaking spring (No.8) (*), which was added to the upper stream of the waste tonner

nozzle in July 2010, is now bundled in the primary transfer unit (No.1-7) together with the installation procedures

leaflet. This is to enhance the field measures against coming off of the ICL screw bushing cap or the service

call error C2810 (waste toner motor error).

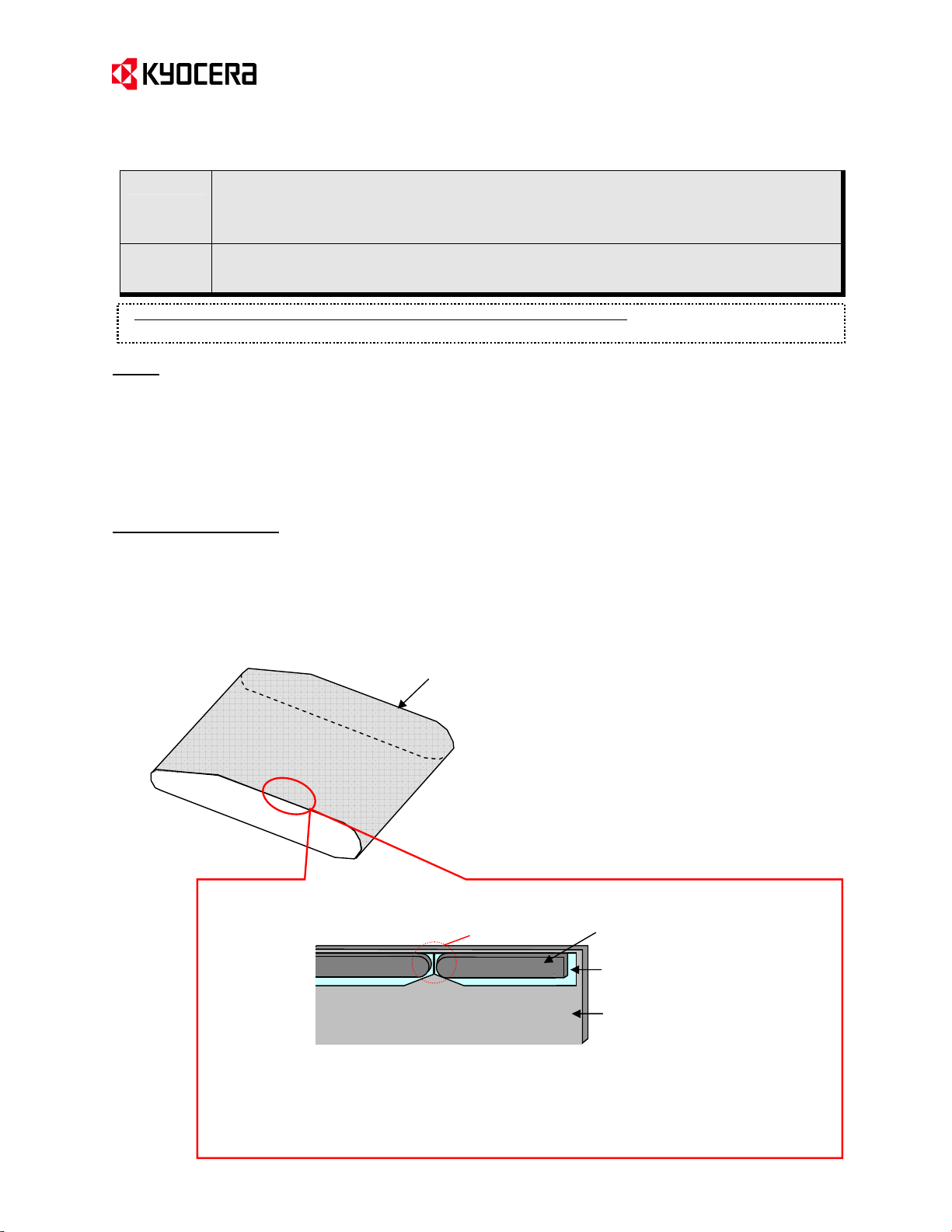

<Position of the stopper rubber (X)>

TASKalfa 500ci, TASKalfa 400ci, TASKalfa 300ci,

TASKalfa 250ci, TASKalfa 552ci, FS-C8500DN

(*) Informed by the service bulletin SB-2H7-0068-A210

Transfer belt

[View from inside of the transfer belt edge at the machine front side as marked with the red circle

above]

*The stopper rubber is first affixed on the film with the double-sided tape and then to the inner

edge of the primary transfer belt. In case that adhesive strength of the double-sided tape

between the film and the rubber decreases, the stopper rubber might peel off at the seam

section. Accordingly, seam section of the stopper rubber is now fixed with glue to the film in

order to prevent it from peeling off. (The transfer belt edge on the machine rear side has also

the stopper rubber and film as shown in the figure above.)

(Machine front side)

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Seam section

Stopper rubber (X)

Film

Transfer belt

Q’

Com

bi

p

ati-

Bundled with the

leaflet

(Revised issue 1)

Service Bulletin Ref. No.

(Page.2/5)

2H7-0083 (B093)

<Date> April 18, 2012

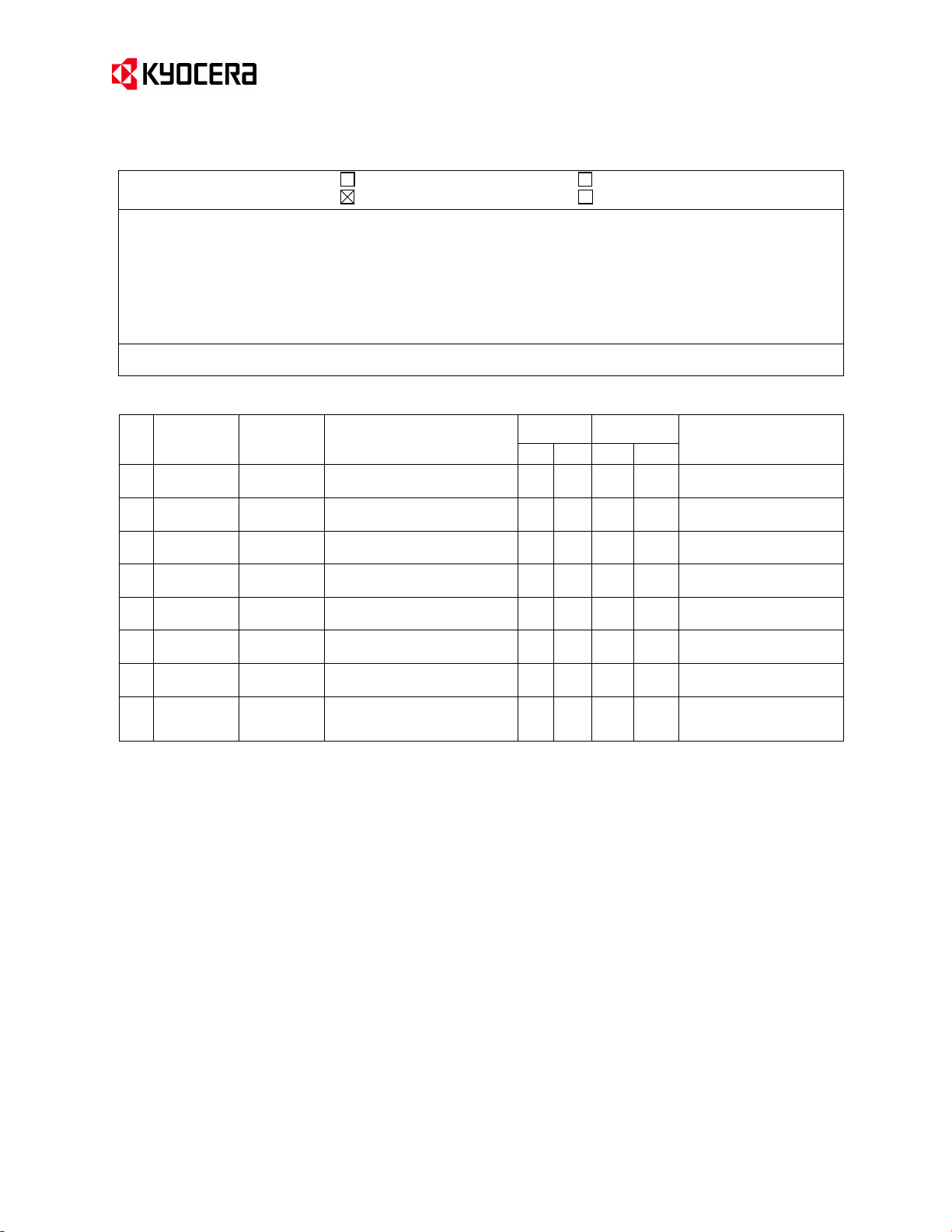

KMC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measure:

Please replace the primary transfer unit (No.1-7) with the new one when the phenomena described above

occur.

Please attach the waste toner lump breaking spring (No.8) in the upper stream of the waste toner nozzle at

the same time. (This is to be applied to the March production part without the waste toner lump breaking

spring.)

Please pay attention to the direction of the spring (No.8) when attaching it.

Please refer to the procedures on the next page or the bundled leaflet for installation procedures.

Serial Nos. of the Affected Machines: (-->) Please refer to the page 4.

Old Part

No.

1

2

3

4

5

6

7

8 ------------

No.

302H793228

2H793228

302H79K228

2H79K228

302JZ93078

2JZ93078

302JZ9K078

2JZ9K078

302JZ93248

2JZ93248

302KY93153

2KY93153

302KY9K153

2KY9K153

New Part

No.

302H793229

2H793229

302H79K229

2H79K229

302JZ93079

2JZ93079

302JZ9K079

2JZ9K079

302JZ93249

2JZ93249

302KY93154

2KY93154

302KY9K154

2KY9K154

302H723280

2H723280

Description

PARTS TRANSFER BELT H

UNIT

PARTS TRANSFER BELT H

UNIT

PARTS TRANSFER BELT L

UNIT

PARTS TRANSFER BELT L

UNIT

PARTS TRANSFER BELT L J

UNIT

PARTS TRANSFER BELT

UNIT

PARTS TRANSFER BELT

UNIT

+SPRING SCREW W T - 1

ty

Old New Old New

1 1

1 1

1 1

1 1

1 1

1 1

1 1

lity

X O

X O

X O

X O

X O

X O

X O

- O

Remarks

*1 (Except KMKR)

*1 (For KMKR)

*2 (Except KMKR/KTST)

*2 (For KMKR)

*2 (For KTST)

*3 (Except KMKR)

*3 (For KMKR)

installation procedures

*1: TASKalfa 500ci/400ci

*2: TASKalfa 300ci/250ci

*3: TASKalfa 552ci and FS-C8500DN

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Loading...

Loading...