Kyocera TASKalfa 250, TASKalfa300, TASKalfa400, TASKalfa500ci SERVICEBULLETINS 2H7 026

Service Bulletin

SB Number:

Subject:

SB 2H7-026

Instructions when performing installation or maintenance

Model: TASKalfa250ci/300ci/400ci/500ci

Contents of

changes

Item 1 details Subject

Please note the following when setting up the machine or when performing maintenance:

1. Perform the colour registration adjustment and auto halftone adjustment after installing the

machine.

2. Avoid hot-swapping of the connection wire between the DP and the machine.

3. Remove the transfer unit, before removing the developer unit when replacing the parts.

Perform the colour registration adjustment and auto halftone adjustment after installing the

machine.

Phenomena

1. The colour registration may be shifted.

2. Colour variation may occur.

Creation Date: 10/12/2009

Causes

1. Vibration during transit from the set-up point or dealer site to the user site.

2. Floor levelness of the installed place of the user site.

3. Temperature and humidity at the installed place of the user site.

4. Improper paper type has been used.

Solutions

1. Colour registration adjustment procedure

1.1. Press the (system menu) key to select (adjustment/maintenance) on the touch screen.

Press (color calibration), then (next) and (execute).

1.2. Press (system menu) key to select (adjustment/maintenance) on the touch screen.

Press (colour registration), then (next), (chart) and (print).

In case the color shift is observed, press (registration), then (next) to change each

adjustment value according to the color registration shift and press (execute).

2. Auto halftone adjustment procedure

2.1. Select the maintenance mode U410.

2.2. Select (continuous adjustment), then (start) key to print the PG test pattern.

2.3. Place the PG test pattern on the contact glass* and then A4 size paper stack

(20 sheets) on it.

Press (start) key after closing the original cover.

2.4. “print’ appears when scanning for the automatic adjustment is complete.

Press (start) key to print the next PG test pattern.

2.5. Repeat the procedures of 2.3 and 2.4 3 times.

2.6. After the 3rd scanning for the automatic adjustment, conrm “ALL COMP” appears

at “result” on the touch panel and then press the (stop) key.

*Ensure that the PG test pattern is aligned along with the scale, and avoid any shifting when

placing it.

KMIS Service Department, Kyocera Mita Europe 8967 / SB 2H7-026

Page 1 of 2

Item 2 details Subject

hot-swapping of the connection wire between the DP and the machine.

Phenomenon

Service call error C9080 (communication problem between DP and CIS) may occur.

Cause

The 24V fuse on the low voltage power supply may be burnt, due to hot-swapping of the

connection cable between the DP and the machine.

Solution

Do not remove the connection cable between the DP and the machine, when the main switch is

set to ON.

Service Bulletin

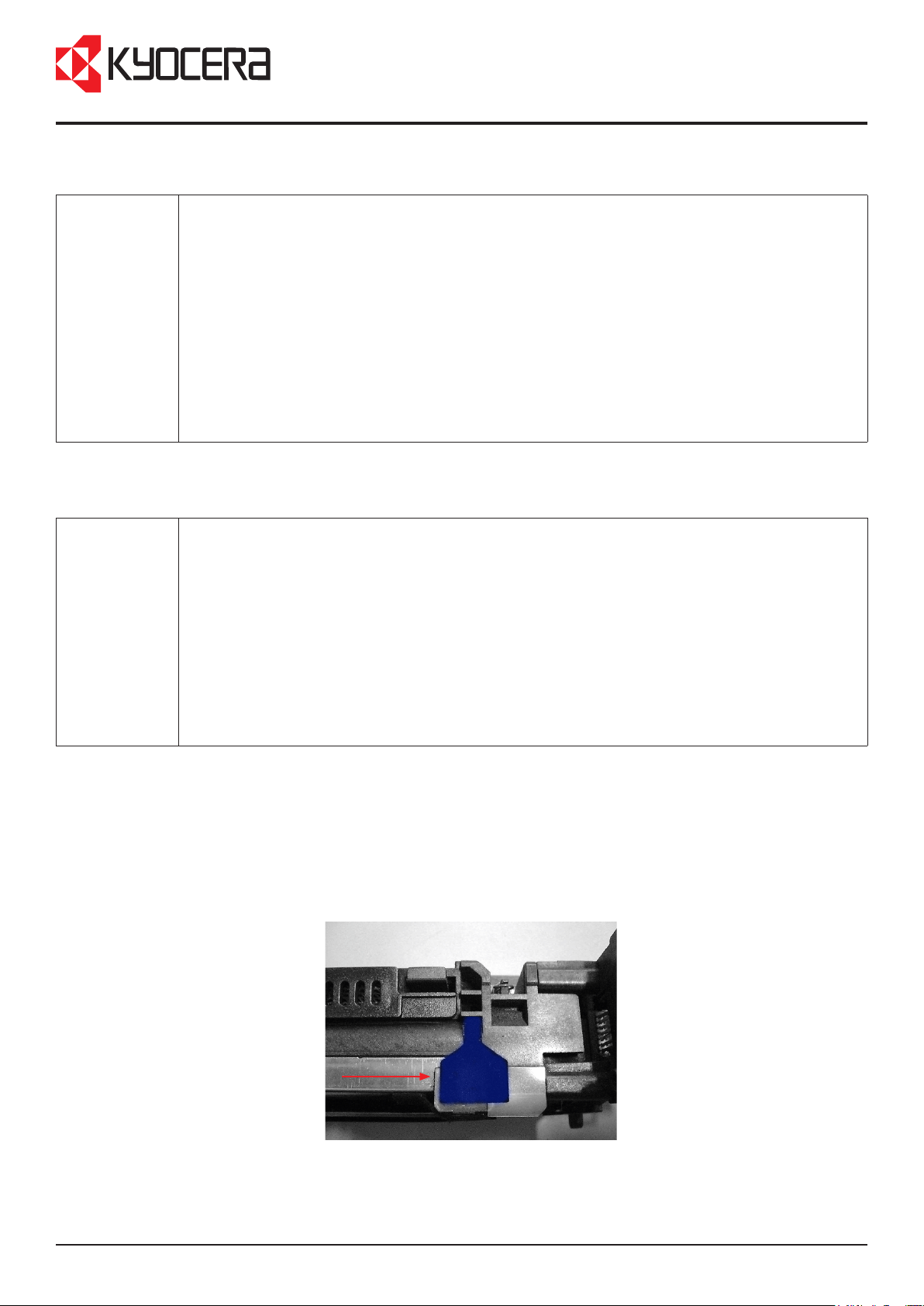

Item 3 details Subject

Remove the transfer unit, before removing the developer unit when replacing the parts.

Phenomenon

The transfer belt has been scratched.

Cause

When removing the developer unit, the seal on top of the developer unit may damage the transfer

belt.

Solution

Remove or pull the transfer unit away from the machine, before removing the developer unit.

Top of the developer unit.

The seal on the developer unit may damage the

transfer belt.

KMIS Service Department, Kyocera Mita Europe 8967 / SB 2H7-026

Page 2 of 2

Loading...

Loading...