Kyocera KM-2560 User Manual [hu]

Model R-C4/R-C4.5

(Machine Code: B205/B209/D007/D008)

SERVICE MANUAL

21 July 2006

Subject to change

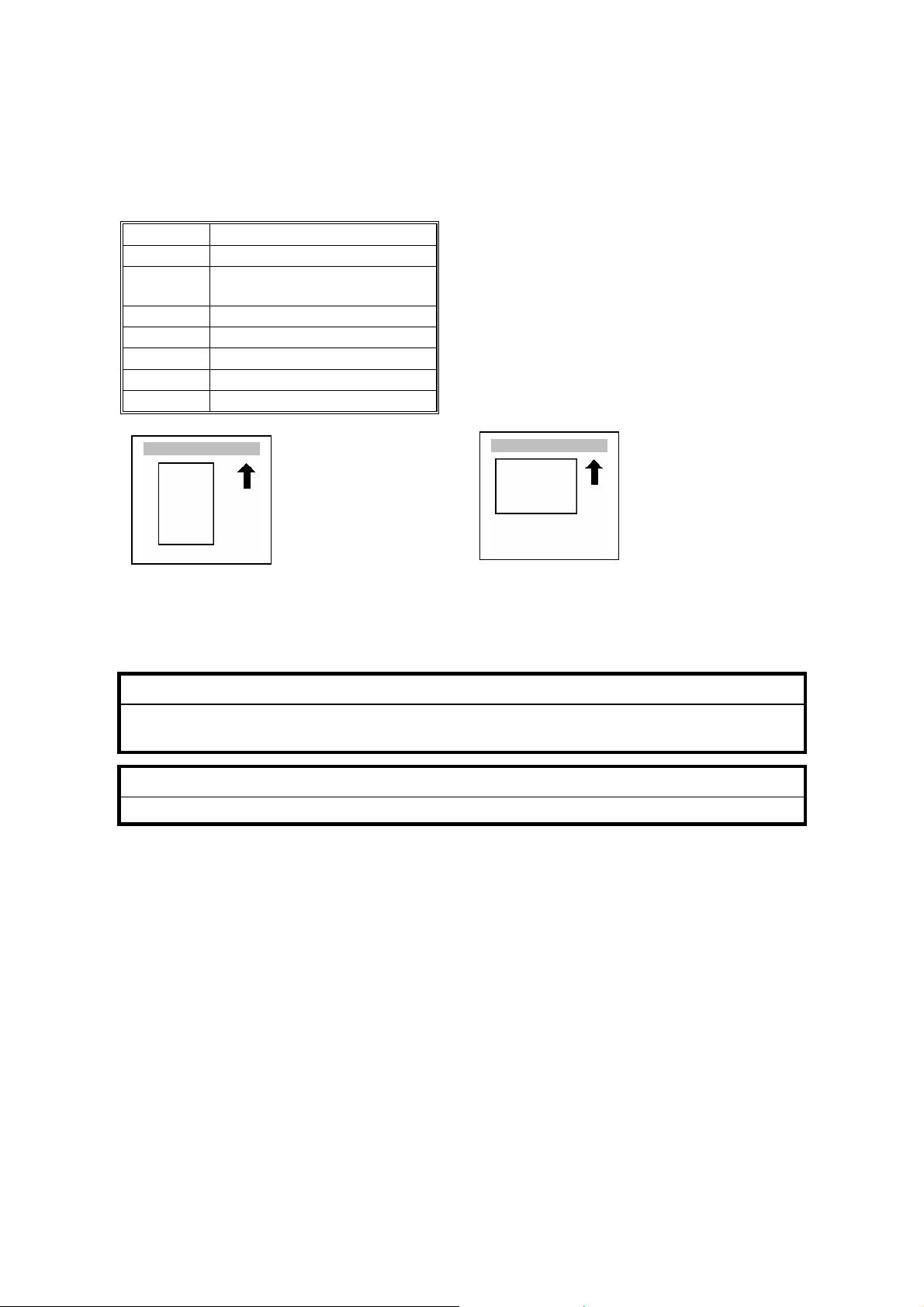

Conventions Used in this Manual

This manual uses several symbols.

Symbol What it means

=

Refer to section number

See Core Tech Manual for

details

Screw

Connector

E-ring

Clip ring

Clamp

Lengthwise, SEF

(Short Edge Feed)

Sideways, LEF

(Long Edge Feed)

Cautions, Notes, etc.

The following headings provide special information:

WARNING

FAILURE TO OBEY WARNING INFORMATION COULD RESULT IN SERIOUS INJURY OR

DEATH

.

CAUTION

Obey these guidelines to ensure safe operation and prevent minor injuries.

Important

• Obey these guidelines to avoid problems such as misfeeds, damage to originals,

loss of valuable data and to prevent damage to the machine.

IMPORTANT

LWAYS OBEY THESE GUIDELINES TO AVOID SERIOUS PROBLEMS SUCH AS MISFEEDS,

• A

DAMAGE TO ORIGINALS, LOSS OF VALUABLE DATA AND TO PREVENT DAMAGE TO THE

MACHINE

NOTE: This information provides tips and advice about how to best service the

. BOLD IS ADDED FOR EMPHASIS.

machine.

IMPORTANT SAFETY NOTICES

REVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

4. If a job has started before the copier completes the warm-up or initializing

period, keep hands away from the mechanical and electrical components

because the starts making copies as soon as the warm-up period is

completed.

5. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

6. Keep the machine away from flammable liquids, gases, and aerosols. A fire

or an explosion might occur.

HEALTH SAFETY CONDITIONS

Toner is non-toxic, but if you get it in your eyes by accident, it may cause

temporary eye discomfort. Try to remove with eye drops or flush with water as

first aid. If unsuccessful, get medical attention.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cassettes. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of toner cassettes in accordance with local regulations. (This is a

non-toxic unit.)

3. Dispose of replaced parts in accordance with local regulations.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the Controller board has a lithium battery which can explode

if replaced incorrectly. Replace the NVRAM only with an identical one. Do

not recharge or burn this battery. Used NVRAM must be handled in

accordance with local regulations.

3. The danger of explosion exists if batteries on the FCU, MBU and JBIG are

incorrectly replaced. Replace only with the same or an equivalent type

recommended by the manufacturer. Discard used batteries in accordance

with the manufacturer’s instructions.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

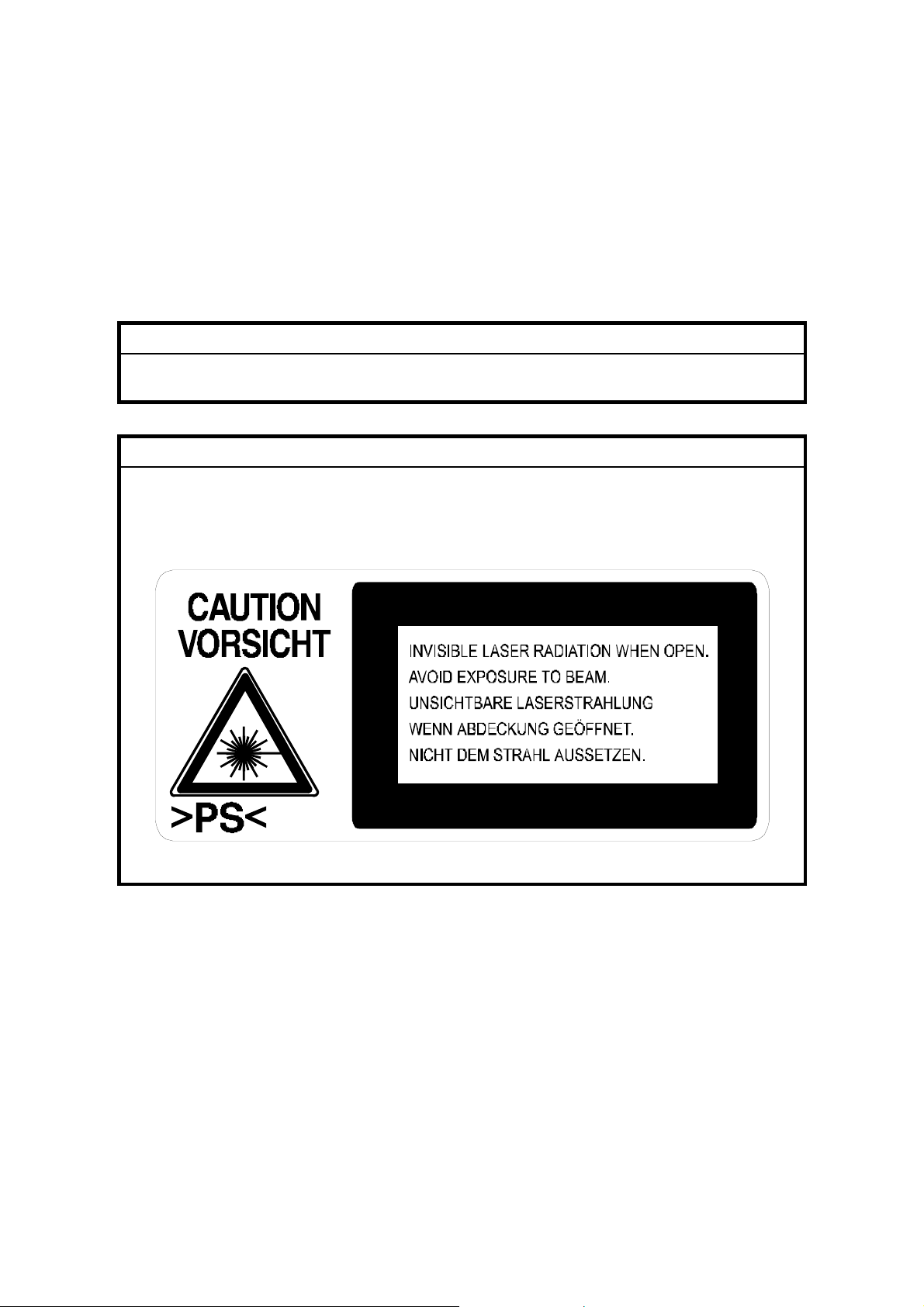

WARNING FOR LASER UNIT

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

LASER-4.WMF

Safety Precautions for This Machine

Before moving the mainframe:

• Disconnect all peripheral units (finisher, LCT, etc.) from the mainframe.

• Pull the slide handles out of the mainframe and use them to lift the mainframe.

TABLE OF CONTENTS

1. INSTALLATION PROCEDURE.................................................... 1-1

1.1 INSTALLATION REQUIREMENTS ...........................................................1-1

1.1.1 ENVIRONMENT ...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-1

1.1.3 MINIMUM SPACE REQUIREMENTS...............................................1-2

1.1.4 POWER REQUIREMENTS ..............................................................1-3

1.2 COPIER INSTALLATION ..........................................................................1-4

1.2.1 POWER SOCKETS FOR PERIPHERALS .......................................1-4

1.2.2 INSTALLATION FLOW CHART .......................................................1-5

1.2.3 ACCESSORY CHECK......................................................................1-6

1.2.4 INSTALLATION PROCEDURE ........................................................1-7

Tapes and Retainers.............................................................................1-7

Developer .............................................................................................1-8

Toner Bottle ........................................................................................1-12

Emblem, Decals.................................................................................. 1-13

1.3 PAPER TRAY UNIT INSTALLATION ......................................................1-15

1.3.1 ACCESSORY CHECK....................................................................1-15

1.3.2 INSTALLATION PROCEDURE ......................................................1-16

1.4 LCT INSTALLATION ...............................................................................1-19

1.4.1 ACCESSORY CHECK....................................................................1-19

1.4.2 INSTALLATION PROCEDURE ......................................................1-20

1.5 ARDF INSTALLATION ............................................................................1-23

1.5.1 ACCESSORY CHECK....................................................................1-23

1.5.2 INSTALLATION PROCEDURE ......................................................1-24

1.6 INTERCHANGE UNIT INSTALLATION................................................... 1-28

1.6.1 COMPONENT CHECK...................................................................1-28

1.6.2 INSTALLATION PROCEDURE ......................................................1-29

1.7 1-BIN TRAY UNIT INSTALLATION .........................................................1-31

1.7.1 COMPONENT CHECK...................................................................1-31

1.7.2 INSTALLATION PROCEDURE ......................................................1-32

1.8 SHIFT TRAY............................................................................................1-35

1.8.1 COMPONENT CHECK...................................................................1-35

1.8.2 INSTALLATION PROCEDURE ......................................................1-36

1.9 BY-PASS FEED UNIT INSTALLATION...................................................1-38

1.9.1 COMPONENTS CHECK ................................................................1-38

1.9.2 INSTALLATION PROCEDURE ......................................................1-39

1.10 DUPLEX UNIT INSTALLATION ............................................................1-41

1.10.1 ACCESSORY CHECK..................................................................1-41

1.10.2 INSTALLATION PROCEDURE ....................................................1-42

1.11 BRIDGE UNIT INSTALLATION .............................................................1-44

1.11.1 ACCESSORY CHECK..................................................................1-44

1.11.2 INSTALLATION PROCEDURE ....................................................1-45

i

1.12 1000-SHEET FINISHER INSTALLATION .............................................1-47

1.12.1 ACCESSORY CHECK..................................................................1-47

1.12.2 INSTALLATION PROCEDURE ....................................................1-48

1.13 500-SHEET FINISHER (B442) INSTALLATION....................................1-51

1.13.1 ACCESSORY CHECK..................................................................1-51

1.13.2 INSTALLATION PROCEDURE ....................................................1-52

1.14 PLATEN COVER (B406) ....................................................................... 1-54

1.15 KEY COUNTER.....................................................................................1-55

1.16 OPTICS ANTI-CONDENSATION HEATER...........................................1-57

1.17 TRAY HEATER .....................................................................................1-58

1.18 TRAY HEATER (OPTIONAL PAPER TRAY UNIT) ...............................1-60

1.19 TRAY HEATER (OPTIONAL LCT) ........................................................1-63

1.20 COPY DATA SECURITY UNIT (B770).................................................. 1-66

1.21 HDD (B773) ...........................................................................................1-68

1.22 DATA OVERWRITE SECURITY UNIT (B735) ......................................1-70

Before You Begin… ............................................................................1-70

Seal Check and Removal ...................................................................1-71

Installation...........................................................................................1-72

2. PREVENTIVE MAINTENANCE SCHEDULE ............................... 2-1

2.1 PM TABLE................................................................................................. 2-1

2.2 MAIN MOTOR DRIVE GEAR ....................................................................2-4

3. REPLACEMENT AND ADJUSTMENT ........................................ 3-1

3.1 SPECIAL TOOLS AND LUBRICANTS ................................................3-1

3.2 SPECIAL TOOLS ................................................................................3-1

3.3 LUBRICANTS............................................................................................3-1

3.4 GENERAL CAUTIONS..............................................................................3-2

3.4.1 PCU (PHOTOCONDUCTOR UNIT) .................................................3-2

3.4.2 TRANSFER ROLLER UNIT..............................................................3-2

3.4.3 SCANNER UNIT...............................................................................3-2

3.4.4 LASER UNIT ....................................................................................3-3

3.4.5 FUSING UNIT...................................................................................3-3

3.4.6 PAPER FEED...................................................................................3-3

3.4.7 OTHERS...........................................................................................3-3

3.5 SCANNER UNIT........................................................................................3-4

3.5.1 EXPOSURE GLASS.........................................................................3-4

3.5.2 SCANNER EXTERIOR/OPERATION PANEL ..................................3-5

3.5.3 LENS BLOCK ASSEMBLY...............................................................3-6

3.5.4 ORIGINAL SIZE SENSORS .............................................................3-7

3.5.5 EXPOSURE LAMP........................................................................... 3-8

3.5.6 SCANNER MOTOR/LAMP STABILIZER..........................................3-9

3.5.7 SCANNER WIRES .........................................................................3-10

3.6 LASER UNIT ...........................................................................................3-13

3.6.1 CAUTION DECAL LOCATIONS.....................................................3-13

3.6.2 LASER UNIT ..................................................................................3-14

3.6.3 POLYGON MIRROR MOTOR ........................................................3-15

3.6.4 LD UNIT..........................................................................................3-16

3.6.5 LASER SYNCHRONIZATION DETECTOR....................................3-17

ii

3.7 PHOTOCONDUCTOR UNIT (PCU) ........................................................3-18

3.7.1 PCU REMOVAL..............................................................................3-18

3.7.2 PICK-OFF PAWLS .........................................................................3-19

3.7.3 OPC DRUM ....................................................................................3-20

3.7.4 CHARGE ROLLER, CLEANING ROLLER .....................................3-21

3.7.5 CLEANING BLADE.........................................................................3-22

3.7.6 DEVELOPER..................................................................................3-23

3.7.7 AFTER REPLACEMENT OF PCU COMPONENTS....................... 3-27

3.8 TRANSFER UNIT....................................................................................3-28

3.8.1 TRANSFER ROLLER UNIT............................................................3-28

3.8.2 IMAGE DENSITY SENSOR ...........................................................3-29

3.9 FUSING/EXIT ..........................................................................................3-30

3.9.1 FUSING UNIT................................................................................. 3-30

3.9.2 THERMISTORS..............................................................................3-30

3.9.3 THERMOSTATS.............................................................................3-31

3.9.4 HOT ROLLER AND FUSING LAMP............................................... 3-33

3.9.5 PRESSURE ROLLER/CLEANING ROLLER ..................................3-35

3.9.6 PAPER EXIT SENSOR/PAPER OVERFLOW SENSOR................3-36

3.10 PAPER FEED........................................................................................3-37

3.10.1 FEED ROLLER: TRAY 1 ..............................................................3-37

3.10.2 FEED ROLLER: TRAY 2 ..............................................................3-38

3.10.3 PAPER END SENSOR.................................................................3-39

3.10.4 PAPER TRAY LIFT MOTORS......................................................3-40

3.10.5 REGISTRATION CLUTCH ...........................................................3-41

3.10.6 PAPER FEED CLUTCHES...........................................................3-42

Lower Paper Feed Clutch ...................................................................3-42

Upper Paper Feed Clutch. ..................................................................3-42

3.10.7 RELAY CLUTCHES......................................................................3-43

3.10.8 PAPER SIZE DETECTOR............................................................3-44

3.10.9 REGISTRATION SENSOR...........................................................3-45

3.10.10 RELAY SENSORS .....................................................................3-46

Upper Relay Sensor............................................................................3-46

Lower Relay Sensor............................................................................3-46

3.10.11 DUST COLLECTION BOX .........................................................3-47

3.11 PCBS AND OTHER ITEMS...................................................................3-48

3.11.1 CONTROLLER BOARD ...............................................................3-48

3.11.2 NVRAM.........................................................................................3-49

3.11.3 SBCU BOARD.............................................................................. 3-50

3.11.4 POWER PACK .............................................................................3-51

3.11.5 MAIN MOTOR ..............................................................................3-52

3.11.6 PSU ..............................................................................................3-53

3.11.7 IPU................................................................................................3-54

3.11.8 HDD..............................................................................................3-55

Important Notes About HDD Replacement .........................................3-56

iii

3.12 COPY ADJUSTMENTS: PRINTING/SCANNING ..................................3-57

3.12.1 PRINTING ....................................................................................3-57

Registration - Leading Edge/Side-to-Side...........................................3-57

Blank Margin.......................................................................................3-58

Main Scan Magnification.....................................................................3-58

Parallelogram Image Adjustment........................................................ 3-59

3.12.2 SCANNING...................................................................................3-60

Registration: Platen Mode...................................................................3-60

Magnification.......................................................................................3-60

Standard White Density Adjustment ...................................................3-61

3.12.3 ADF IMAGE ADJUSTMENT.........................................................3-62

Registration.........................................................................................3-62

Sub Scan Magnification ...................................................................... 3-62

3.12.4 TOUCH SCREEN CALIBRATION ................................................ 3-63

4. TROUBLESHOOTING ................................................................. 4-1

4.1 SERVICE CALL CONDITIONS .................................................................4-1

4.1.1 SUMMARY .......................................................................................4-1

4.1.2 SC CODE DESCRIPTIONS .............................................................4-2

4.2 SELF-DIAGNOSTIC MODE ....................................................................4-18

4.2.1 SELF-DIAGNOSTIC MODE AT POWER ON .................................4-18

4.2.2 DETAILED SELF-DIAGNOSTIC MODE .........................................4-19

Executing Detailed Self-Diagnosis...................................................... 4-19

4.3 PAPER FEED TROUBLESHOOTING.....................................................4-21

4.4 SKEWED IMAGE ....................................................................................4-22

4.5 IMAGE PROBLEMS ................................................................................4-23

4.5.1 SKEWED, TRAPEZOID AND PARALLELOGRAM IMAGES..........4-23

Skewed Images ..................................................................................4-23

Trapezoid Images ............................................................................... 4-23

Parallelogram Images .........................................................................4-24

4.5.2 CHECKING IMAGES WITH THE TRIMMING PATTERN...............4-25

4.5.3 CORRECTING THE IMAGES ........................................................4-26

Correcting Skewed Images.................................................................4-26

Correcting Trapezoid Images..............................................................4-29

Correcting Parallelogram Images .......................................................4-30

4.6 ELECTRICAL COMPONENT DEFECTS ................................................4-31

4.6.1 SENSORS ......................................................................................4-31

4.6.2 SWITCHES.....................................................................................4-33

4.7 BLOWN FUSE CONDITIONS .................................................................4-34

iv

5. SERVICE TABLES....................................................................... 5-1

5.1 SERVICE PROGRAM MODE....................................................................5-1

5.1.1 SERVICE MODE LOCK/UNLOCK....................................................5-1

5.1.2 SERVICE PROGRAM MODE OPERATION.....................................5-2

Entering and Exiting SP mode ..............................................................5-2

SP Mode Button Summary ...................................................................5-3

Switching Between SP Mode and Copy Mode for Test Printing ...........5-4

Selecting the Program Number.............................................................5-4

5.1.3 SERVICE PROGRAM MODE TABLES............................................ 5-5

SP1XXX: Feed......................................................................................5-6

SP2XXX: Drum ...................................................................................5-15

SP4-XXX: Scanner .............................................................................5-27

SP5XXX: Mode...................................................................................5-38

SP6XXX: Peripherals..........................................................................5-74

SP7XXX: Data Log .............................................................................5-76

SP8-xxx: Data Log2............................................................................5-81

5.1.4 TEST PATTERN PRINTING (SP2902-3) .....................................5-115

5.1.5 INPUT CHECK .............................................................................5-116

Main Machine Input Check (SP5803) ...............................................5-116

ARDF Input Check (SP6007)............................................................5-119

Finisher Input Check (SP6117).........................................................5-120

5.1.6 OUTPUT CHECK .........................................................................5-122

Main Machine Output Check (SP5804).............................................5-122

ARDF Output Check (SP6008) .........................................................5-124

Finisher Output Check (SP6118) ...................................................... 5-124

5.1.7 SMC DATA LISTS (SP5990) ........................................................5-125

5.1.8 MEMORY ALL CLEAR (SP5801) ................................................. 5-126

5.1.9 APS OUTPUT DISPLAY (SP4301)...............................................5-127

5.1.10 DF APS SENSOR OUTPUT DISPLAY (SP6901)....................... 5-128

5.1.11 NIP BAND WIDTH MEASUREMENT (SP1109) ......................... 5-129

5.2 FIRMWARE UPDATE ...........................................................................5-130

5.3 SOFTWARE RESET .............................................................................5-131

5.4 SYSTEM SETTINGS AND COPY SETTING RESET............................5-131

5.4.1 SYSTEM SETTING RESET .........................................................5-131

5.4.2 COPIER SETTING RESET ..........................................................5-132

5.5 USER TOOLS .......................................................................................5-133

5.5.1 HOW TO USE UP MODE.............................................................5-133

UP Mode Initial Screen: User Tools/Counter Display........................5-133

System Settings................................................................................5-133

Copier/Document Server Features ...................................................5-133

Printer, Facsimile, Scanner Settings................................................. 5-134

Inquiry ...............................................................................................5-134

Counter .............................................................................................5-135

5.6 LEDS .....................................................................................................5-136

Controller ..........................................................................................5-136

SBCU................................................................................................5-136

v

5.7 DIP SWITCHES.....................................................................................5-136

Controller ..........................................................................................5-136

SBCU................................................................................................5-136

5.8 USING THE DEBUG LOG..................................................................... 5-137

5.8.1 SWITCHING ON AND SETTING UP SAVE DEBUG LOG ...........5-137

5.8.2 RETRIEVING THE DEBUG LOG FROM THE HDD.................... 5-141

5.8.3 RECORDING ERRORS MANUALLY ...........................................5-141

5.8.4 NEW DEBUG LOG CODES .........................................................5-142

SP5857-015 Copy SD Card-to-SD Card: Any Desired Key .............. 5-142

SP5857-016 Create a File on HDD to Store a Log ...........................5-142

SP5857-017 Create a File on SD Card to Store a Log .....................5-142

6. DETAILS....................................................................................... 6-1

6.1 OVERVIEW ...............................................................................................6-1

6.1.1 MECHANICAL COMPONENTS........................................................6-1

6.1.2 PAPER PATH...................................................................................6-3

6.1.3 ELECTRICAL COMPONENT DESCRIPTIONS ...............................6-4

6.1.4 DRIVE LAYOUT ...............................................................................6-7

6.2 BOARD STRUCTURE............................................................................... 6-8

6.2.1 OVERVIEW ......................................................................................6-8

6.2.2 CONTROLLER BOARD .................................................................6-10

6.3 COPY PROCESS....................................................................................6-13

6.4 SCANNING..............................................................................................6-15

6.4.1 OVERVIEW ....................................................................................6-15

6.4.2 SCANNER DRIVE .......................................................................... 6-16

6.4.3 ORIGINAL SIZE DETECTION: PLATEN MODE ............................6-17

6.5 IMAGE PROCESSING ............................................................................6-19

6.5.1 OVERVIEW ....................................................................................6-19

6.5.2 SBU (SENSOR BOARD UNIT)....................................................... 6-20

6.5.3 AUTO IMAGE DENSITY.................................................................6-21

6.5.4 ORIGINAL TYPE SETTINGS .........................................................6-22

6.5.5 IPU (IMAGE PROCESSING UNIT).................................................6-23

Overview.............................................................................................6-23

Image Processing Path.......................................................................6-24

SP Modes for Each Image Processing Step .......................................6-25

Auto Shading ......................................................................................6-30

Pre-Filtering ........................................................................................6-30

Main Scan Magnification/Reduction....................................................6-30

Mirroring for ADF Mode ......................................................................6-30

Characteristic Detection......................................................................6-31

Filtering ...............................................................................................6-31

Background Erase ..............................................................................6-32

ID Gamma (g) Correction....................................................................6-32

Gradation Processing .........................................................................6-32

Line width correction........................................................................... 6-33

6.5.6 VIDEO CONTROL UNIT (GAVD) ................................................... 6-34

Fine Character and Image (FCI) .........................................................6-34

vi

6.6 LASER EXPOSURE................................................................................6-35

6.6.1 OVERVIEW ....................................................................................6-35

6.6.2 AUTO POWER CONTROL (APC).................................................. 6-36

6.6.3 LD SAFETY SWITCH .....................................................................6-37

6.7 PHOTOCONDUCTOR UNIT (PCU) ........................................................6-38

6.7.1 OVERVIEW ....................................................................................6-38

6.7.2 DRIVE.............................................................................................6-39

6.8 DRUM CHARGE .....................................................................................6-40

6.8.1 OVERVIEW ....................................................................................6-40

6.8.1 CHARGE ROLLER VOLTAGE CORRECTION ..............................6-41

Correction for Environmental Conditions ............................................6-41

6.8.2 ID SENSOR PATTERN PRODUCTION TIMING............................ 6-42

6.8.3 DRUM CHARGE ROLLER CLEANING ..........................................6-43

6.9 DEVELOPMENT .....................................................................................6-44

6.9.1 OVERVIEW ....................................................................................6-44

6.9.2 DRIVE.............................................................................................6-45

6.9.3 DEVELOPER MIXING ....................................................................6-46

6.9.4 DEVELOPMENT BIAS ...................................................................6-47

6.9.5 TONER SUPPLY............................................................................6-48

Toner bottle replenishment mechanism ..............................................6-48

Toner supply mechanism....................................................................6-49

6.9.6 TONER DENSITY CONTROL ........................................................6-50

Overview.............................................................................................6-50

Toner density sensor initial setting......................................................6-52

Toner density measurement ...............................................................6-52

Vsp/Vsg detection............................................................................... 6-52

Toner supply reference voltage (Vref) determination..........................6-52

Toner supply determination ................................................................6-52

Toner Supply Motor On Time Determinations.....................................6-53

6.9.7 TONER SUPPLY IN ABNORMAL SENSOR CONDITIONS...........6-54

ID sensor ............................................................................................6-54

TD Sensor...........................................................................................6-54

6.9.8 TONER NEAR END/END DETECTION AND RECOVERY............6-54

Toner Near End Detection ..................................................................6-54

Toner Near End Recovery ..................................................................6-55

Toner End Detection........................................................................... 6-55

Toner End Recovery ...........................................................................6-55

6.10 DRUM CLEANING AND TONER RECYCLING.....................................6-56

6.10.1 DRUM CLEANING........................................................................6-56

6.10.2 TONER RECYCLING ...................................................................6-57

vii

6.11 PAPER FEED........................................................................................6-58

6.11.1 OVERVIEW ..................................................................................6-58

6.11.2 PAPER FEED DRIVE MECHANISM ............................................6-59

6.11.3 PAPER FEED AND SEPARATION MECHANISM........................6-60

6.11.4 PAPER LIFT MECHANISM ..........................................................6-61

6.11.5 PAPER END DETECTION ...........................................................6-63

6.11.6 PAPER HEIGHT DETECTION .....................................................6-64

6.11.7 FEED PRESSURE ADJUSTMENT FOR PAPER SIZE................6-66

Overview.............................................................................................6-66

Paper Size Thresholds........................................................................6-66

Feed Pressure Adjustment .................................................................6-67

Effect of the Amount of Remaining Paper...........................................6-67

6.11.8 PAPER SIZE DETECTION...........................................................6-69

6.11.9 SPECIAL PAPER SETTING.........................................................6-70

6.11.10 SIDE AND END FENCES...........................................................6-71

Side Fences........................................................................................6-71

End Fence ..........................................................................................6-71

6.11.11 PAPER REGISTRATION............................................................6-72

6.12 IMAGE TRANSFER AND PAPER SEPARATION .................................6-73

6.12.1 OVERVIEW ..................................................................................6-73

6.12.2 IMAGE TRANSFER CURRENT TIMING......................................6-74

6.12.3 TRANSFER ROLLER CLEANING................................................6-75

6.12.4 PAPER SEPARATION MECHANISM...........................................6-76

6.13 IMAGE FUSING AND PAPER EXIT......................................................6-77

6.13.1 OVERVIEW ..................................................................................6-77

6.13.2 FUSING DRIVE AND RELEASE MECHANISM ...........................6-78

6.13.3 FUSING ENTRANCE GUIDE SHIFT MECHANISM .....................6-79

6.13.4 PRESSURE ROLLER...................................................................6-80

6.13.5 CLEANING MECHANISM ............................................................6-81

6.13.6 FUSING TEMPERATURE CONTROL..........................................6-82

Temperature Control...........................................................................6-82

Fusing Lamp Control...........................................................................6-83

6.13.7 OVERHEAT PROTECTION .........................................................6-84

6.13.8 PAPER EXIT ................................................................................6-85

6.14 ENERGY SAVER MODES ....................................................................6-86

6.14.1 OVERVIEW ..................................................................................6-86

6.14.2 ENERGY SAVER MODE..............................................................6-87

Entering the energy saver mode.........................................................6-87

What happens in energy saver mode .................................................6-87

Return to stand-by mode ....................................................................6-87

6.14.3 AUTO OFF MODE........................................................................6-88

Entering off stand-by and off modes ...................................................6-88

Off Stand-by mode.............................................................................. 6-88

Off Mode .............................................................................................6-88

Returning to stand-by mode................................................................6-88

viii

7. OVERALL MACHINE INFORMATION......................................... 7-1

7.1 SPECIFICATIONS.....................................................................................7-1

7.2 MACHINE CONFIGURATION ...................................................................7-4

7.2.1 SYSTEM COMPONENTS ................................................................7-4

7.2.2 OPTIONS TABLE .............................................................................7-6

Copier options.......................................................................................7-6

Fax option .............................................................................................7-6

Printer/scanner options .........................................................................7-6

ix

21 July 2006 INSTALLATION REQUIREMENTS

1. INSTALLATION PROCEDURE

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range:

2. Humidity Range:

3. Ambient Illumination:

4. Ventilation:

5. Ambient Dust:

6. Avoid an area which is exposed to sudden temperature changes. This includes:

1) Areas directly exposed to cool air from an air conditioner.

2) Areas directly exposed to heat from a heater.

7. Do not place the machine in an area where it will be exposed to corrosive

gases.

8. Do not install the machine at any location over 2,000 m (6,500 ft.) above sea

level.

9. Place the copier on a strong and level base. (Inclination on any side should be

no more than 5 mm.)

10. Do not place the machine where it may be subjected to strong vibrations.

10°C to 32°C (50°F to 89.6°F)

15% to 80% RH

Less than 1,500 lux (do not expose to direct sunlight.)

Room air should turn over at least 30 m3/hr/person

Less than 0.10 mg/m3

Installation

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: With in 5 mm (0.2") of level

1-1

INSTALLATION REQUIREMENTS 21 July 2006

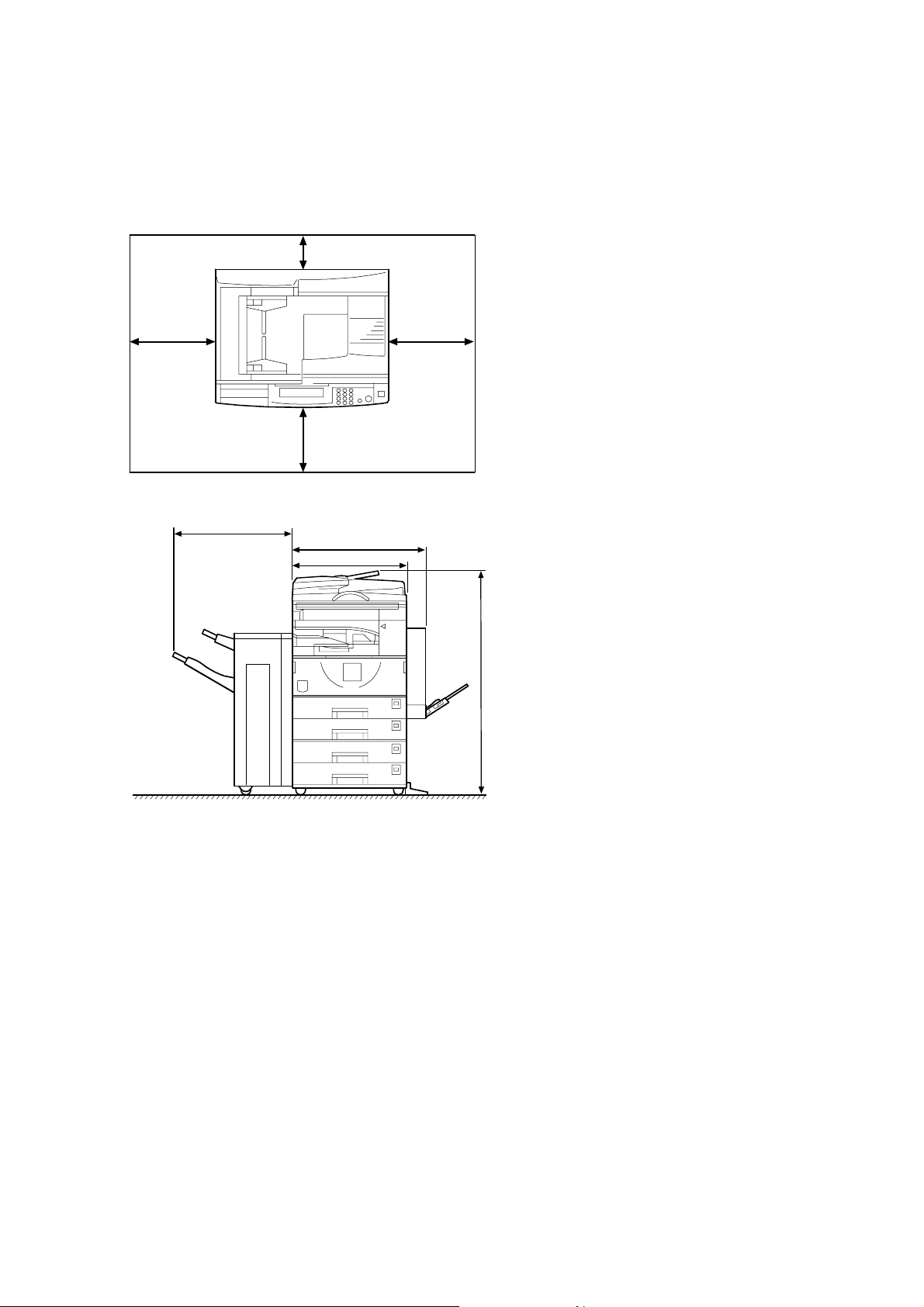

1.1.3 MINIMUM SPACE REQUIREMENTS

Place the copier near the power source, providing clearance as shown:

C

A: In Front: Over 750 mm (29.6")

B: Left: Over 100 mm (0.4")

C: To Rear: Over 100 mm (0.4")

D: Right: Over 100 mm (0.4")

B

A

B089I201.WMF

E

F

G

D

E: 620 mm (24.4")

F: 640 mm (25.2")

G: 550 mm (21.7")

H: 1137 mm (44.8")

H

B089I202.WMF

NOTE: The 750 mm recommended for the space at the front is only for pulling out

the paper tray. If an operator stands at the front of the copier, more space

is required.

1-2

21 July 2006 INSTALLATION REQUIREMENTS

1.1.4 POWER REQUIREMENTS

CAUTION

1. Make sure that the wall outlet is near the copier and easily accessible.

Make sure the plug is firmly inserted in the outlet.

2. Avoid multi-wiring.

3. Be sure to ground the machine.

1. Input voltage level: 120 V, 60 Hz: More than 12 A

220 V ~ 240 V, 50 Hz/60 Hz: More than 7 A

110V, 50 Hz/60 Hz: More than 13 A

2. Permissible voltage fluctuation: ±10 %

3. Do not set anything on the power cord.

Installation

1-3

COPIER INSTALLATION 21 July 2006

1.2 COPIER INSTALLATION

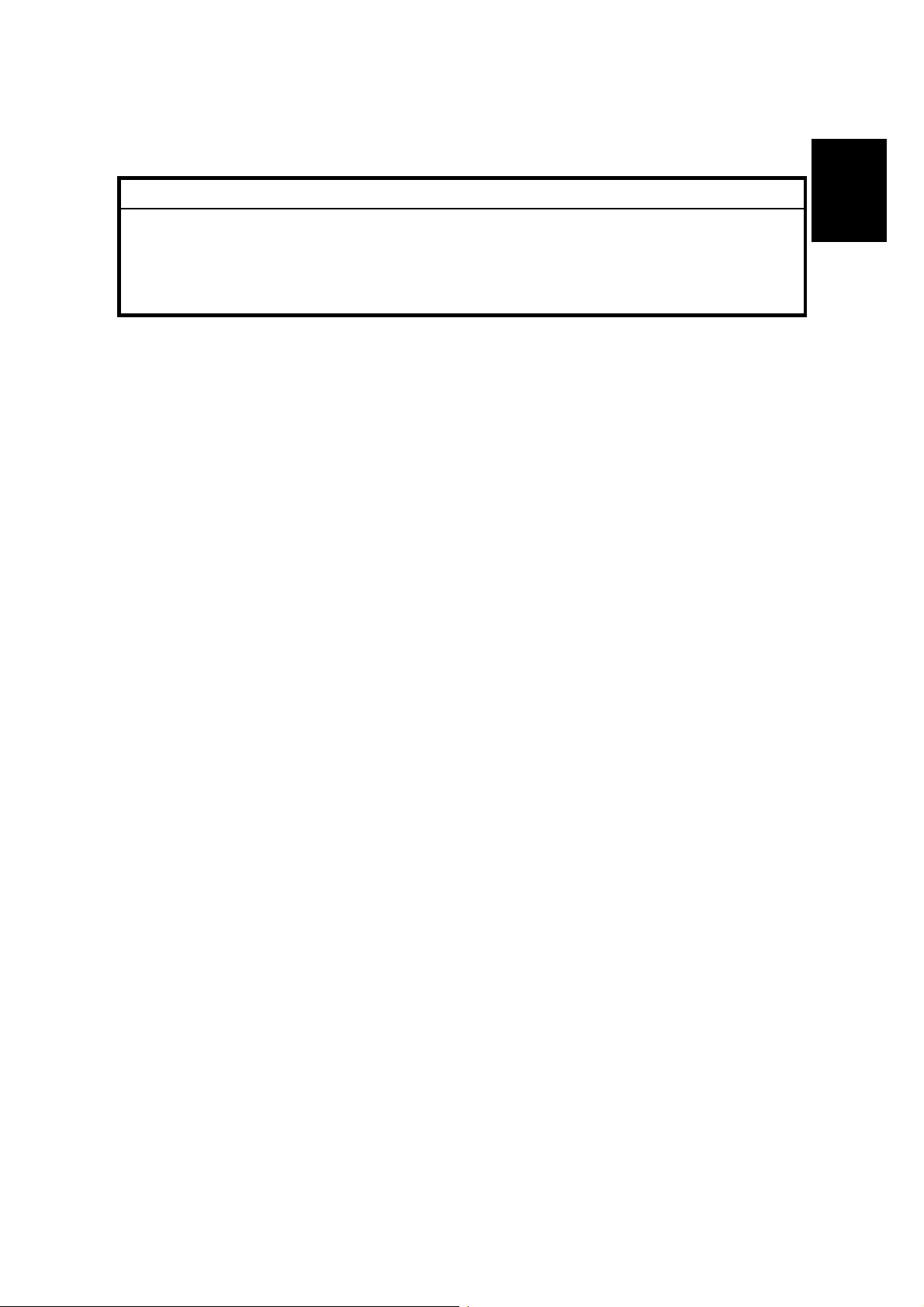

1.2.1 POWER SOCKETS FOR PERIPHERALS

CAUTION

Rating voltage for peripherals.

Make sure to plug the cables into the correct sockets.

1. Rating voltage output connector

for accessory Max. DC24 V

1. ADF

2. Bridge Unit or Shift Tray

1. Rating voltage output connector

for accessory Max. DC24 V

B205I107.WMF

1. Rating voltage output connector

for accessory Max. DC24 V

3. Duplex Unit

1. Rating voltage output connector

for accessory Max. DC24 V

4. By-pass Tray

1-4

21 July 2006 INSTALLATION REQUIREMENTS

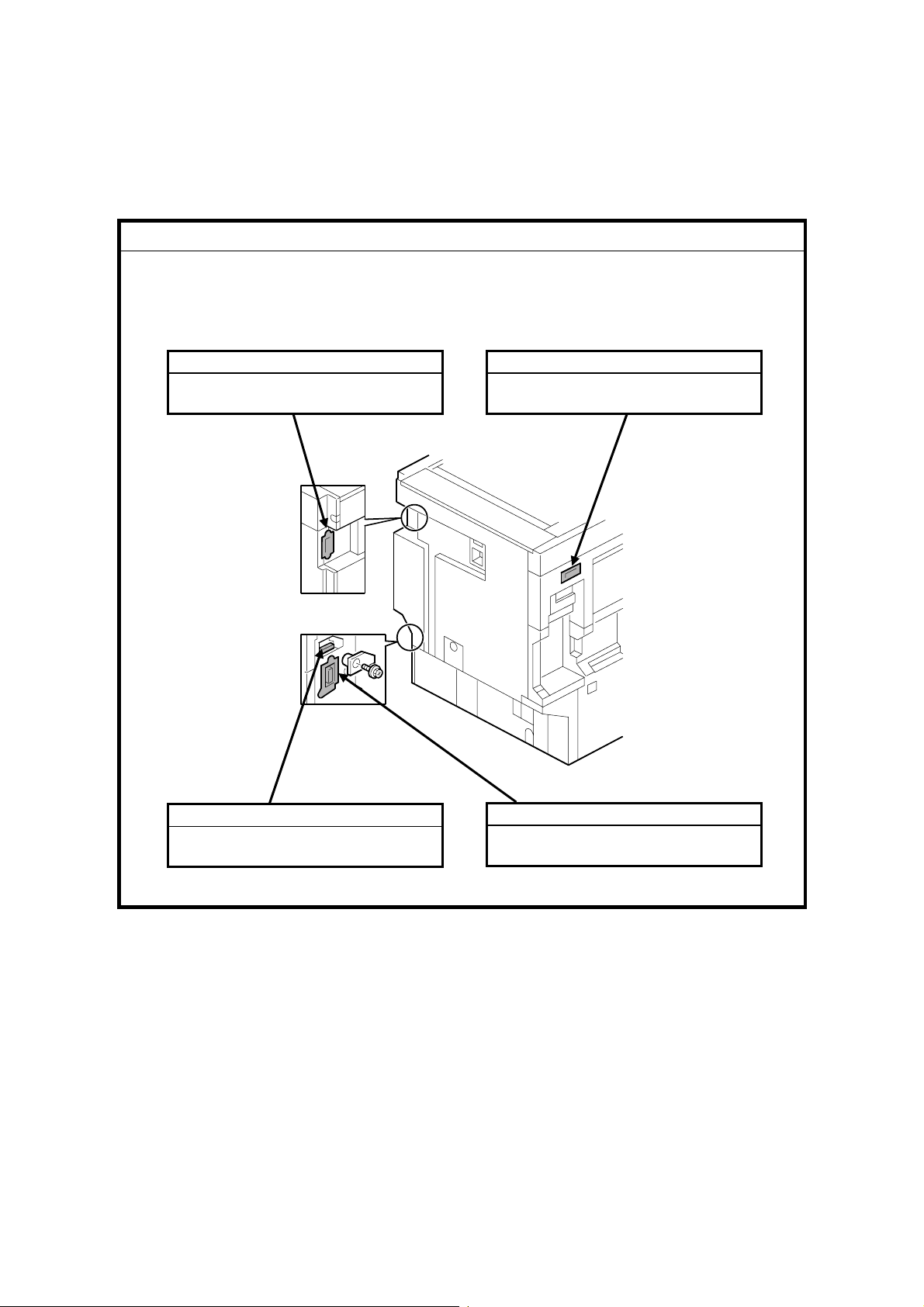

1.2.2 INSTALLATION FLOW CHART

The following flow chart shows how to install the optional units more efficiently.

Unpack the copier

Does the user require the Paper Tray Unit, LCT, or Finisher?

Yes No

Place the copier on the Paper Tray Unit or LCT

Install the Paper Tray Unit or LCT

Install the copier

Does the user require the Memory Unit?

Yes No

Install the Memory Unit

Does the user require the By-pass Tray?

Yes No

Install the By-pass Tray

Installation

Does the user require the Shift Tray?

Yes No

Install the Shift Tray

Does the user require the Finisher?

Yes No

Install the Bridge Unit

Install the Finisher

Does the user require the Duplex Unit and/or 1-bin Tray Unit ?

Yes No

Install the Interchange Unit

Install the Duplex Unit and/or 1-bin Tray Unit

Install the ARDF or Platen Cover (if required)

B089I513.WMF

1-5

COPIER INSTALLATION 21 July 2006

1.2.3 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q'ty

1. Paper Tray Decal.................................................................1

2. Emblem Cover.....................................................................1

3. Emblem ...............................................................................1

4. Model Name Decal ..............................................................1

5. End Fence ...........................................................................1

6. HDD Caution Decal (-17, -29, -57 only) ...............................1

7. Operating Instructions – System Setting..............................1

8. Operating Instructions – Copy Reference............................1

1-6

21 July 2006 INSTALLATION REQUIREMENTS

1.2.4 INSTALLATION PROCEDURE

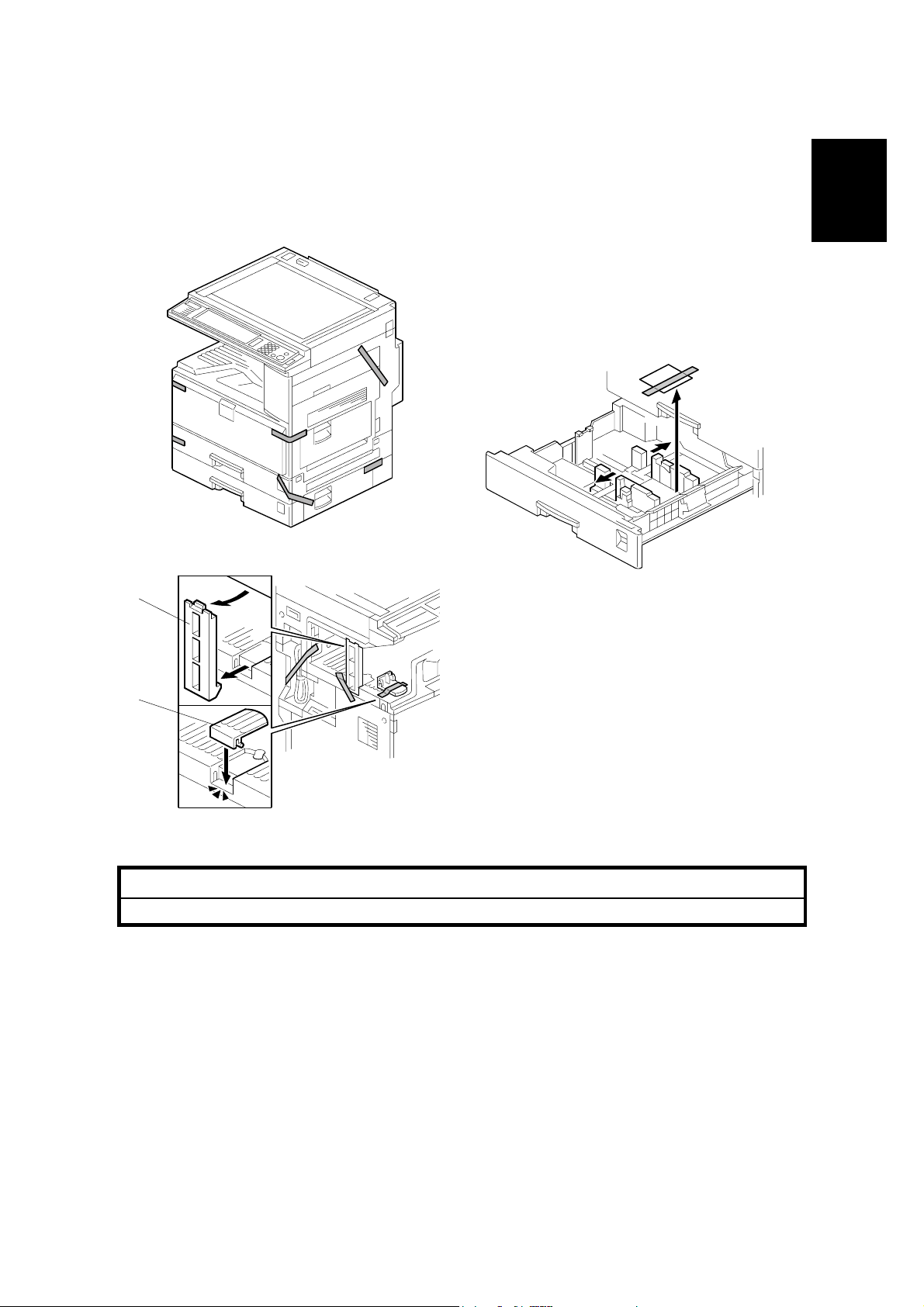

Tapes and Retainers

[A]

Installation

B205I104.WMF

B205I904.WMF

[B]

B205I905.WMF

CAUTION

Unplug the machine power cord before starting the following procedure.

If the optional paper tray or the optional LCT is going to be installed now, put the

copier on the paper tray unit or the LCT first, then install these options, then install

the copier.

NOTE: Keep the shipping retainers after installing the machine. They will be

reused if the machine is moved to another location in the future.

1. Remove the tapes and the shipping retainer [A] on the exterior of the copier.

2. Install the end fence [B].

1-7

COPIER INSTALLATION 21 July 2006

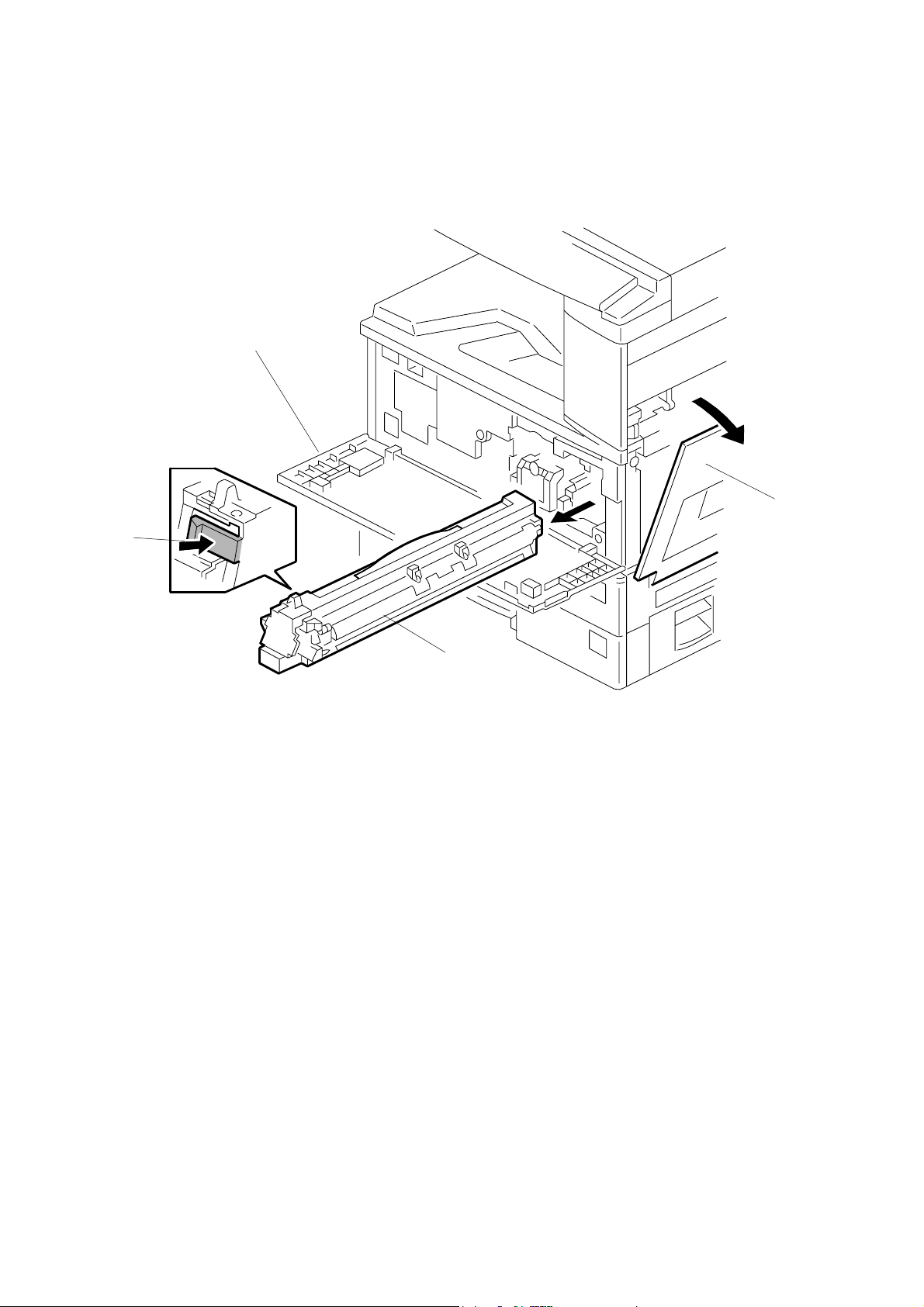

Developer

[B]

[C]

[A]

[D]

B205I920.WMF

1. Spread the vinyl sheet provided with the developer kit on a flat surface.

2. Open the right door [A]

3. Open the front door [B].

4. Push the latch [C] and remove the PCU [D].

1-8

21 July 2006 INSTALLATION REQUIREMENTS

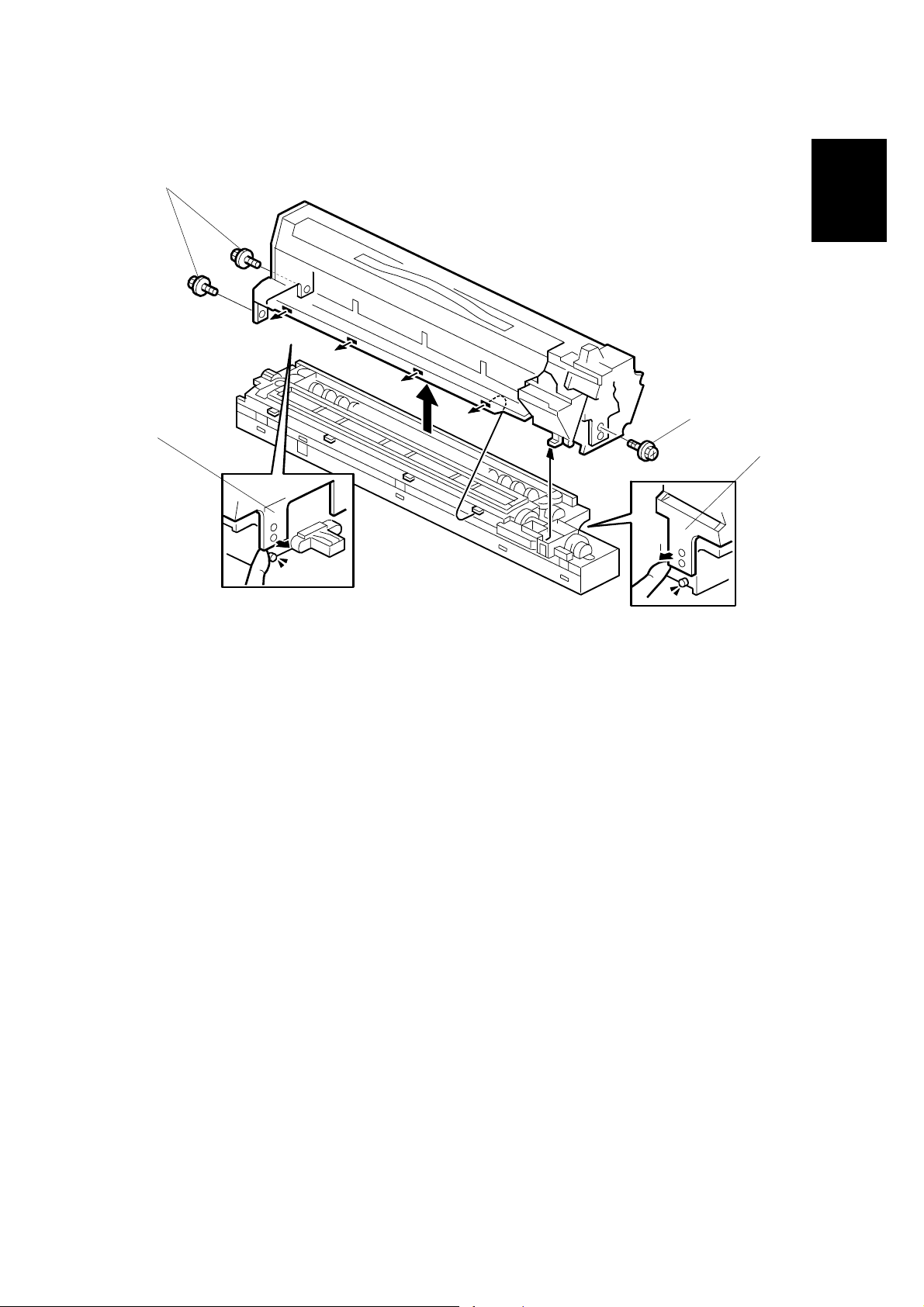

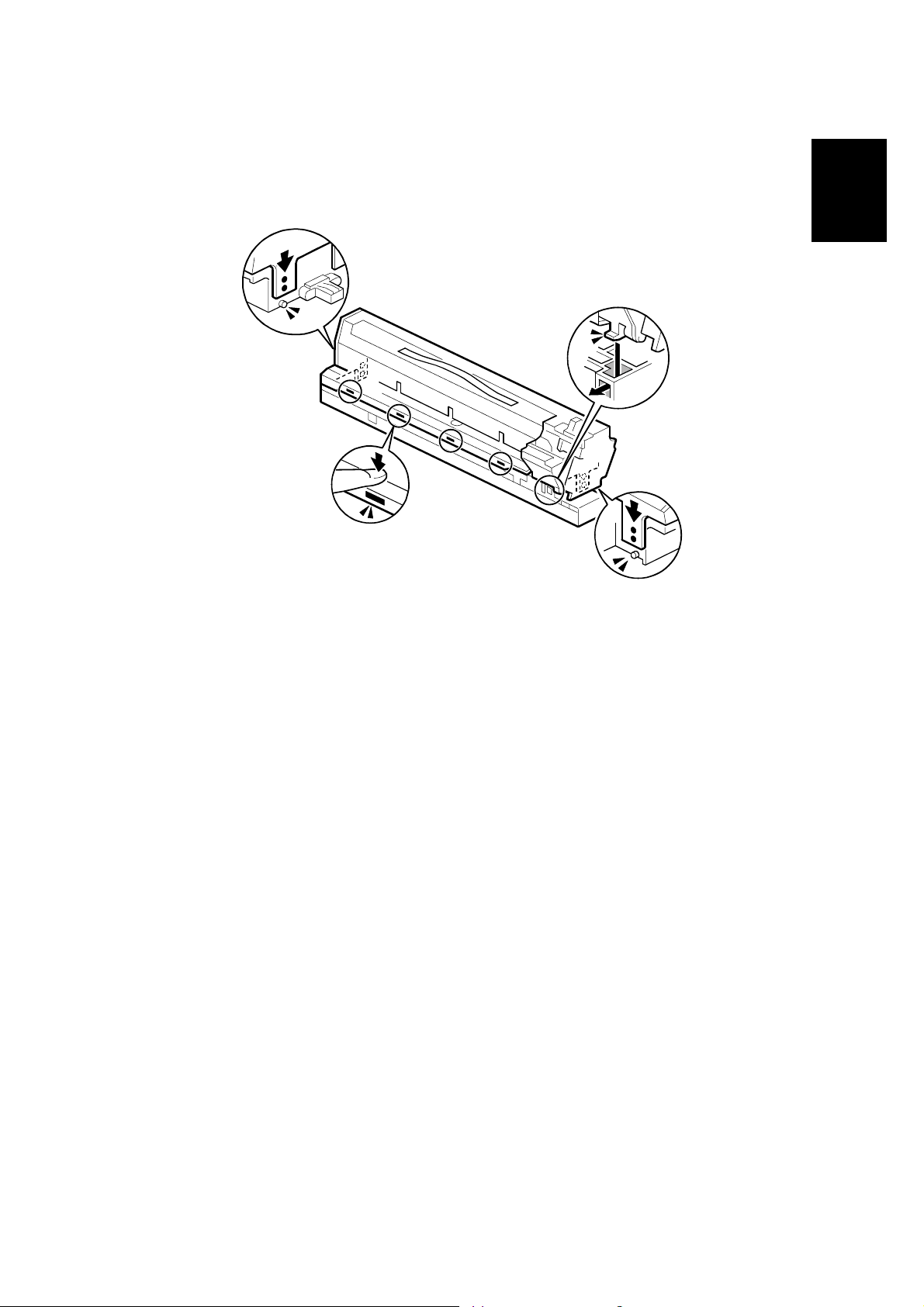

[B]

[A]

[C]

[D]

Installation

B205I102A.WMF

5. Remove the front screw [A] ( x1)

6. Remove the rear screws [B] ( x2)

7. Release the rear tab [C] then front tab [D], then separate the top and bottom.

Important: Be sure to release the rear tab first and the front tab second.

1-9

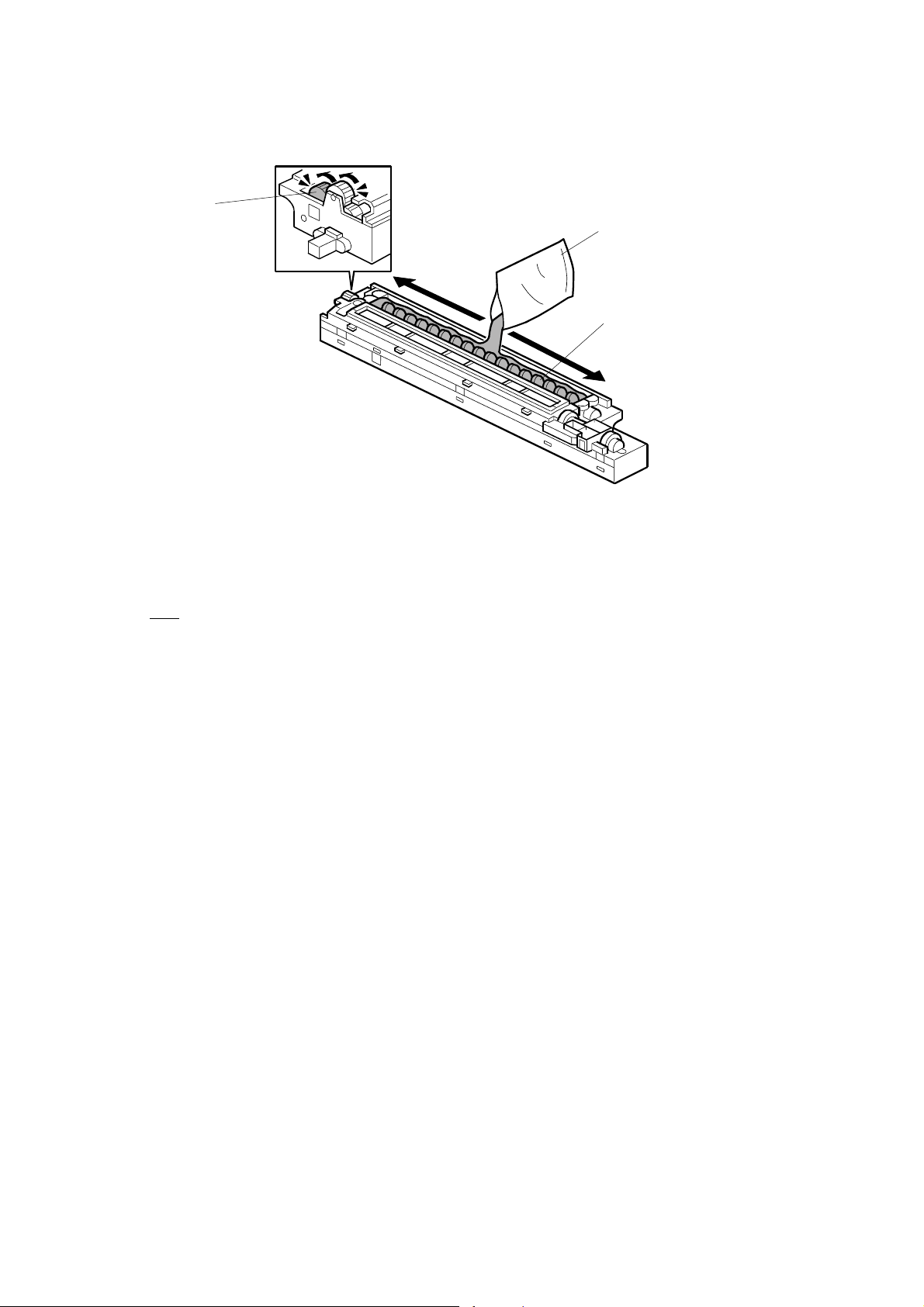

COPIER INSTALLATION 21 July 2006

[B]

[A]

[C]

B205I103.WMF

8. Open the developer pack [A].

9. While turning the black gear [B], slowly move the pack left and right and pour

half of the developer over the auger [C].

10. Continue to turn the black gear until the developer is level.

11. While continuing to turn the black gear, slowly move the pack left and right and

pour the remaining half of the developer over the auger until the developer is

level.

Important

• Be careful. Do not spill developer on the gears and sponges.

• If you accidentally spill developer on the gears or sponges, remove it with a

magnet or the tip of a magnetized screwdriver.

1-10

21 July 2006 INSTALLATION REQUIREMENTS

Re-assembly

Installation

B205I920B.WMF

1. Make sure that all of the holes and tabs on are engaged at , , , and .

Then push down to lock the tabs on the front and rear end of the PCU.

2. Make sure that the holes for the screws on the front and rear end of the PCU

are aligned correctly. If the holes are not aligned correctly, make sure that the

tabs at the front, rear, and left side of the PCU are engaged correctly.

Important

• Reattach the rear screws ( x2) first, then reattach the front screw ( x1).

• Do not push down on the top of the PCU when you attach the rear and front

screws

1-11

COPIER INSTALLATION 21 July 2006

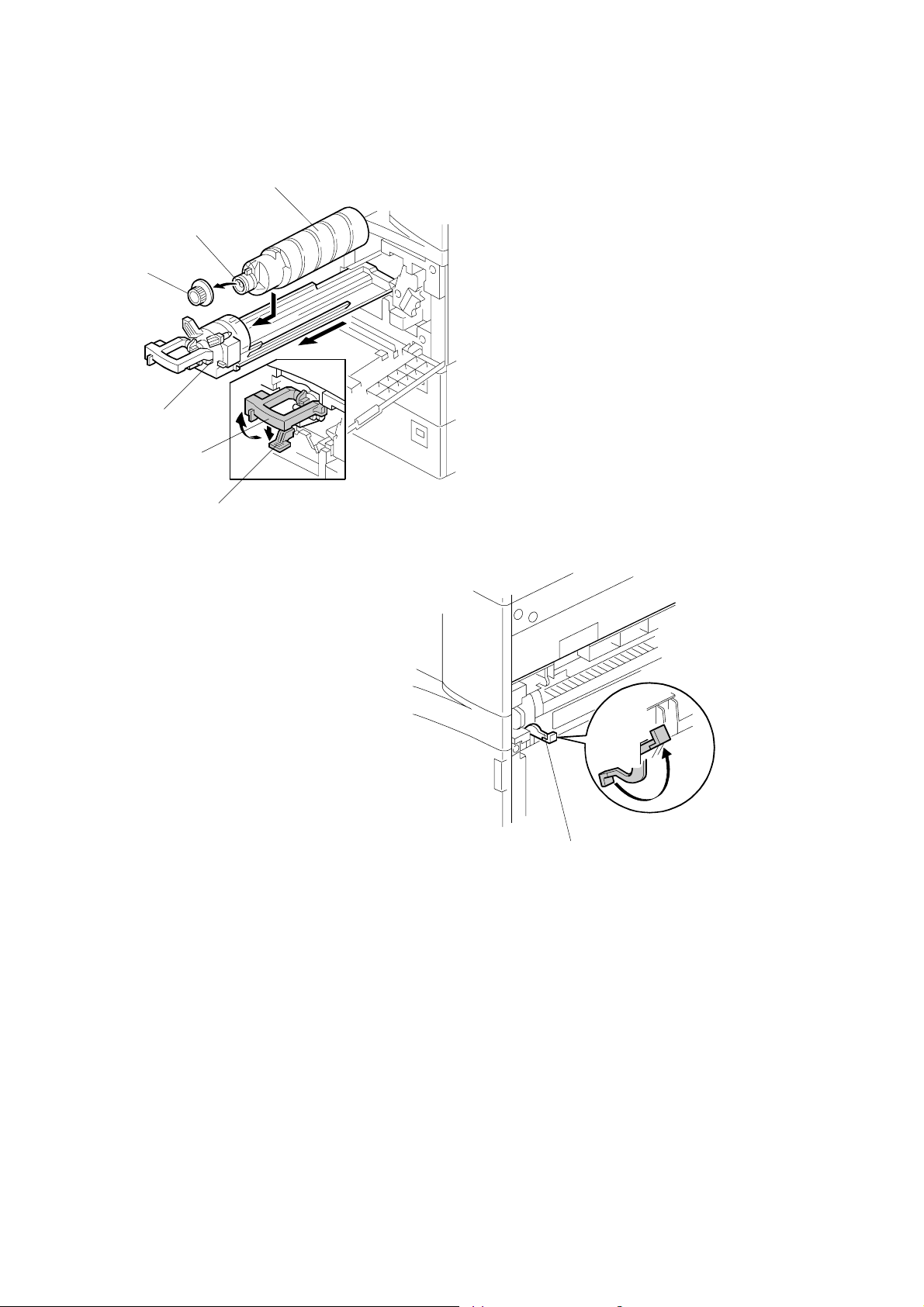

Toner Bottle

[F]

[E]

[C]

[A]

[B]

[D]

B205I907.WMF

[G]

B089I500.WMF

1. Raise the toner bottle holder lever [A], push lever [B] down, and pull the toner

bottle holder [C] out.

2. Shake the toner bottle [D].

NOTE: Do not remove the toner bottle cap [E] until after shaking.

3. Unscrew the bottle cap [E] and insert the bottle into the holder.

NOTE: Do not touch the inner bottle cap [F].

4. Reposition the holder and press down the holder lever to secure the bottle.

5. Open the right cover.

6. Rotate the green fusing pressure lever [G] to the up position.

1-12

21 July 2006 INSTALLATION REQUIREMENTS

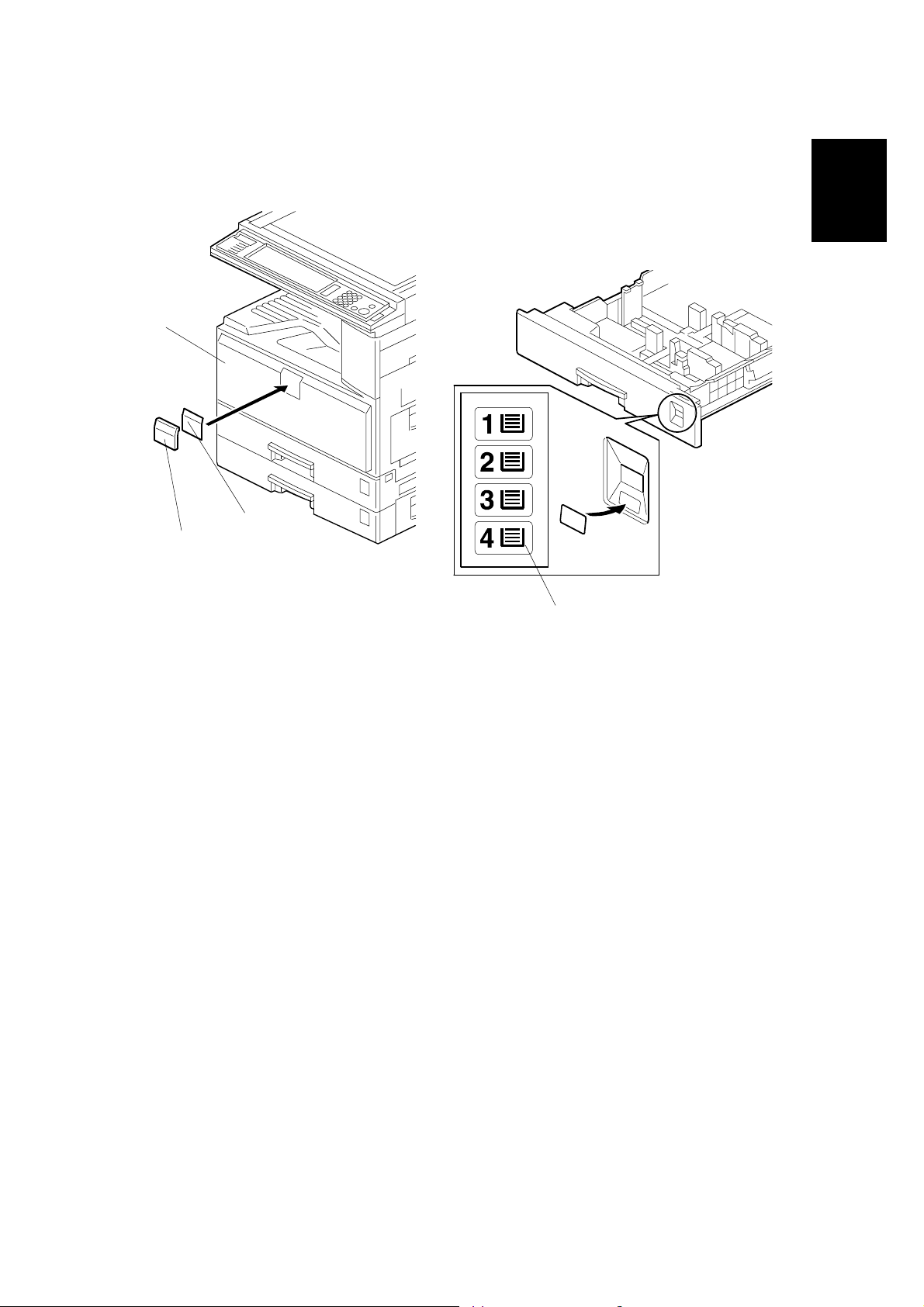

Emblem, Decals

[C]

[A]

[B]

Installation

B205I105.WMF

[D]

B205I909.WMF

1. Attach the emblem [A] and panel [B] to the front door [C].

NOTE: Push the panel in until the emblem and panel move into their positions.

You will hear a click.

2. Pull the paper tray out and turn the paper size dial to select the appropriate size.

Adjust the side guides and end guide to match the paper size.

NOTE: To move the side guides, first pull out the tray fully, then push down the

green lock at the rear of the tray.

3. Attach the appropriate paper tray number decal [D] to each paper tray.

NOTE: Paper tray number decals are also used for the optional paper tray or

the optional LCT. Keep any remaining decals for use with these

optional units.

1-13

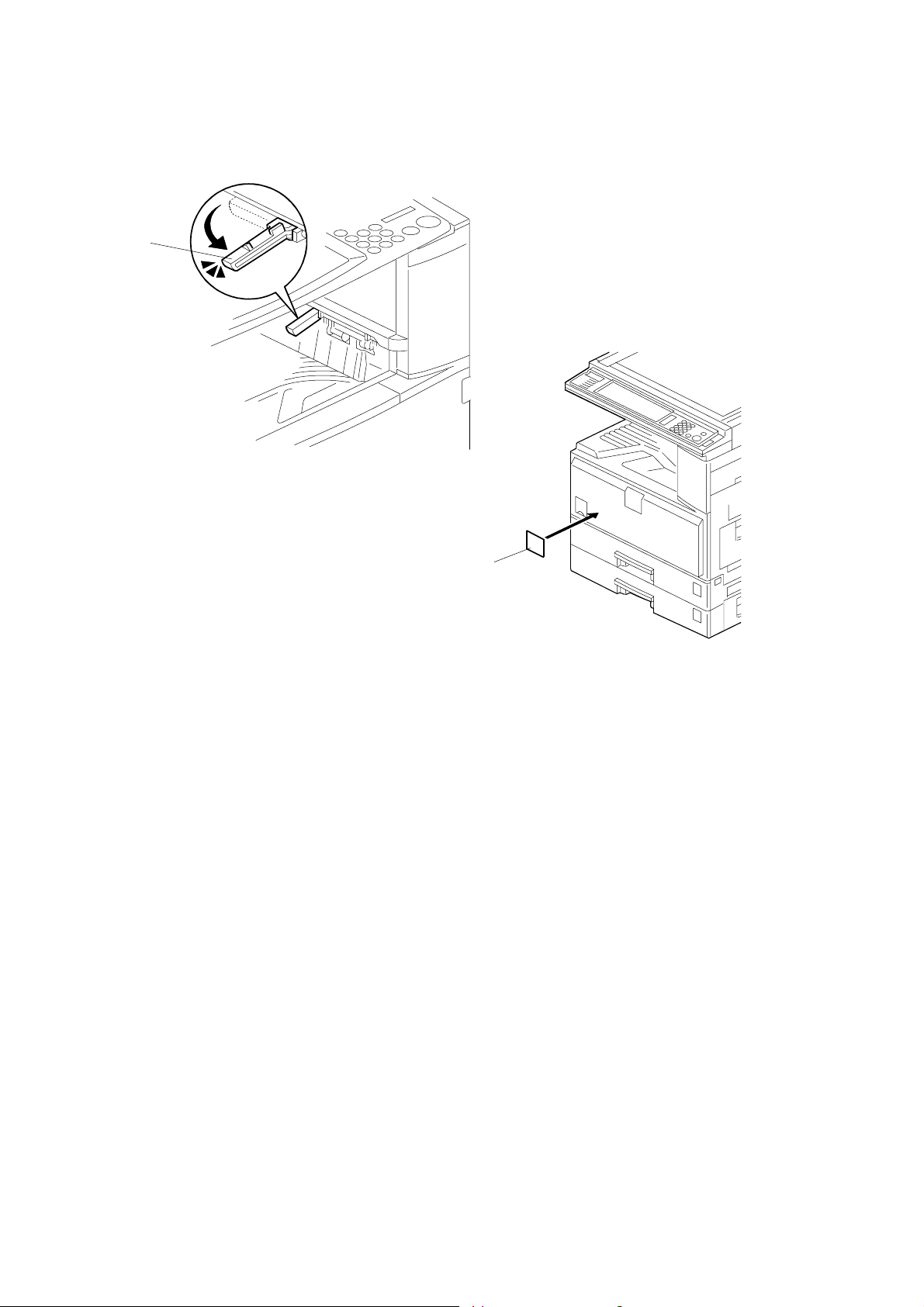

COPIER INSTALLATION 21 July 2006

[A]

B205I910.WMF

[B]

B205I108.WMF

4. If the optional bridge unit will not be installed, swing the sensor feeler [A] out.

5. Install the optional ARDF or the optional platen cover (see "ARDF Installation"

(1.5) or "Platen Cover Installation" (1.14)).

6. If the HDD will be installed for a –17, -29, –57 model, attach the HDD caution

decal [B] to the front cover.

7. Connect the copier and turn the machine on.

8. Go into the SP mode and do SP2801 (Developer Initialization).

9. Do some test copies to make sure that the machine operates correctly.

1-14

21 July 2006 INSTALLATION REQUIREMENTS

1.3 PAPER TRAY UNIT INSTALLATION

1.3.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

Description Q’ty

1. Securing Bracket .................................................................2

2. Screw – M4 x 10..................................................................4

Installation

1-15

PAPER TRAY UNIT INSTALLATION 21 July 2006

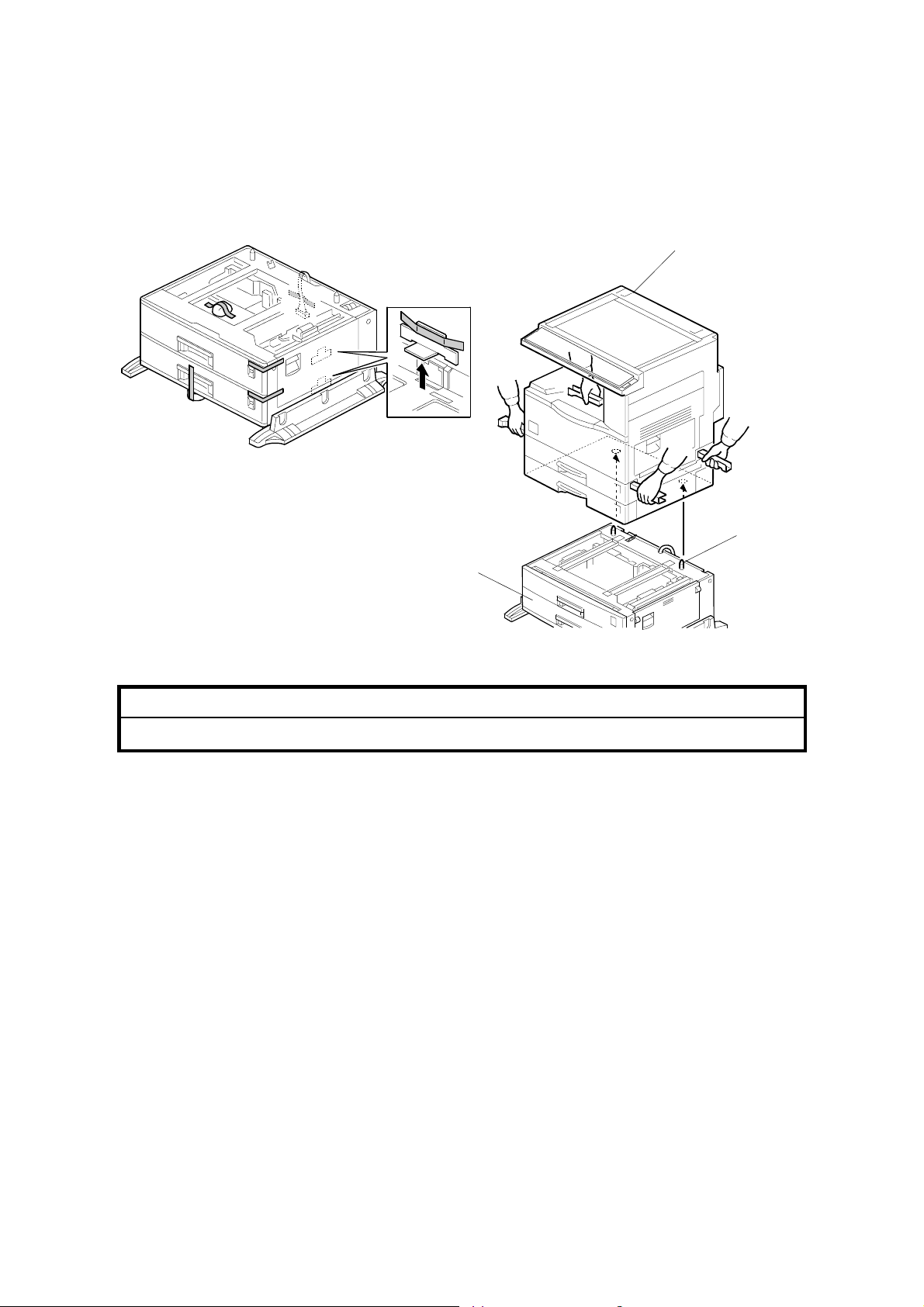

1.3.2 INSTALLATION PROCEDURE

[A]

B390I603.WMF

[C]

[B]

B390I601.WMF

CAUTION

Unplug the machine power cord before starting the following procedure.

1. Remove the strips of tape.

2. Set the copier [A] on the paper tray unit [B].

NOTE: When installing the copier, be careful not to pinch the cable [C].

1-16

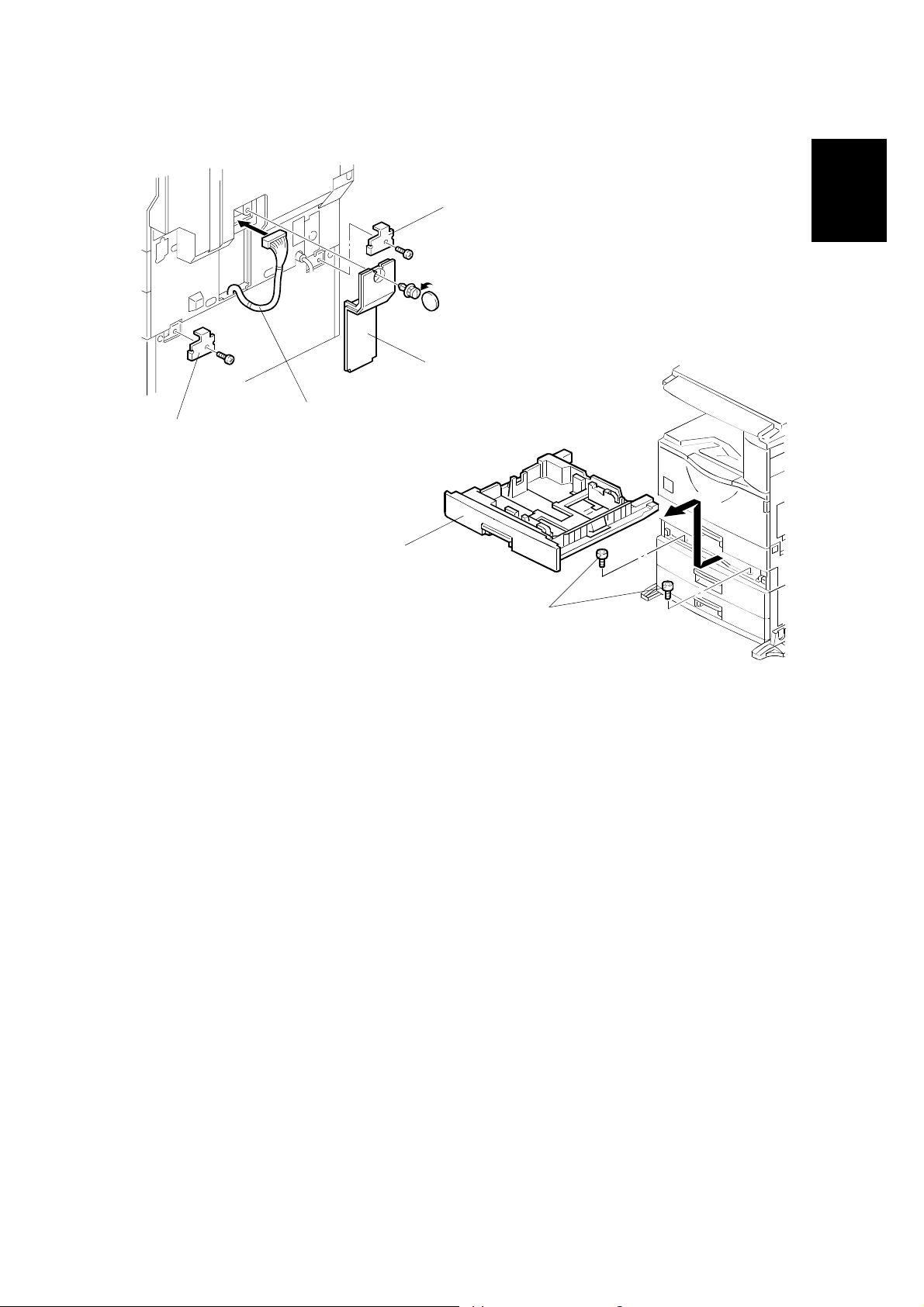

21 July 2006 INSTALLATION REQUIREMENTS

[C]

[A]

Installation

[B]

[C]

B390I604.WMF

[D]

[E]

B390I600.WMF

3. Remove the connector cover [A] ( x 1).

4. Connect the cable [B] to the copier, as shown.

5. Attach a securing bracket [C] to each side of the paper tray unit, as shown ( x

1 each).

6. Re-install the connector cover.

7. Remove the 2nd paper tray [D] and secure the paper tray unit [E] ( x 2).

1-17

Loading...

Loading...