Kyocera FS-C8500DN SERVICEBULLETINS 2H7 0095 C338

(Page.1/3)

Subject

Change of the Transfer Belt Unit (Improvement of the Cleaning

Function and the Rubber Fixation)

Model l:

TASKalfa 500ci, TASKalfa 400ci, TASKalfa 300ci,

TASKalfa 250ci, TASKalfa 552ci, FS-C8500DN

KDC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measures:

When offset image appears and the rubber peels off, please replace the transfer belt unit (No.1 to No.2) with

the new one. However, if only offset image appears, it can be recovered by replacement of the corrective fur

brush (No.3).

Please refer to another Service Bulletin SB-2H7-0092-C274 for the procedures how to replace the fur brush.

Serial Nos. of the Affected Machines:

MFP and Printer : Currently no production

MK kit and the transfer belt unit for service: From the available timing in the December 2012 production

Service Bulletin Ref. No. 2H7-0095 (C338)

<Date> January 7, 2013

Topic

The followings changes were made in order to improve the performance of the primary transfer belt unit.

Content of Changes

1) Measure against offset image (Please refer to the Service Bulletin SB-2H7-0092-C274.)

→ The corrective fur brush (No.8) supplied to field as individual parts is now applied to the transfer belt unit

for service (No.1 to No.7) and MK kit. (Note 1)

2) Improvement of the rubber fixation to prevent transfer belt skew

(Please refer to the Service Bulletin SB-2H7-0083-B093 for the previous measures.)

→ The following changes were made in order to further improve the adhesive strength of the rubber affixed

on the backside of the transfer belt. (Note 2)

2-1) The thickness of the rubber was reduced from 1.5 mm to 1.0 mm in order to reduce the loads applied

to the rubber.

2-2) The double-sided tape to affix the rubber to the transfer belt was changed in order to increase the

adhesive strength.

2-3) The following changes were made in order to prevent the loads applied when the rubber runs over the

guide pulley attached to the both sides of the idle roller in the primary transfer belt unit.

- The circumference of the rubber was reduced from 887.5 mm to 885 mm.

- The shape of the guide pulley was changed (refer to the page 3), and its outer diameter was

increased from 28.6 mm to 29.4 mm.

- The PET film applied between the transfer belt and the rubber was abolished.

(Note 1) The corrective fur brush harder than the current one is effective to avoid cleaning ability

deterioration of the fur brush caused by prolonged use of the machine.

(The abnormal image (offset image) caused by the transfer belt cleaning failure may appear due

to the cleaning ability deterioration.)

(Note 2) When the rubber peels off due to the adhesive strength deterioration depending on the operating

environment, or the toner scatters inside of the machine, the transfer belt may be torn or lock up

after the rubber runs over or rolls up along with other parts. Also, it may cause image failure,

abnormal noise or paper jam (JAM31).

As the corrective measures implemented before, the seam section of the rubber has been fixed

with glue.

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

(Page.2/3)

No.

Old Part

No.

New Part

No.

Description

Q’

ty

Com

bi

patility

Remarks

Old

New

Old

New

1

302H793229

2H793229

302H79322B

2H79322B

PARTS TRANSFER BELT H

UNIT

1

1

O

O

TASKalfa 500ci/400ci

(Except KDKR)

2

302JZ93079

2JZ93079

302JZ9307B

2JZ9307B

PARTS TRANSFER BELT L

UNIT

1

1

O

O

TASKalfa 300ci/250ci

(Except KDKR/KDCN)

3

302KY93154

2KY93154

302KY93156

2KY93156

PARTS TRANSFER BELT

UNIT

1

1

O

O

TASKalfa 552ci

LS/FS-C8500DN

(Except KDKR)

4

-----------

302KY94370

2KY94370

+PARTS BRUSH FUR B SP

-

1

-

O

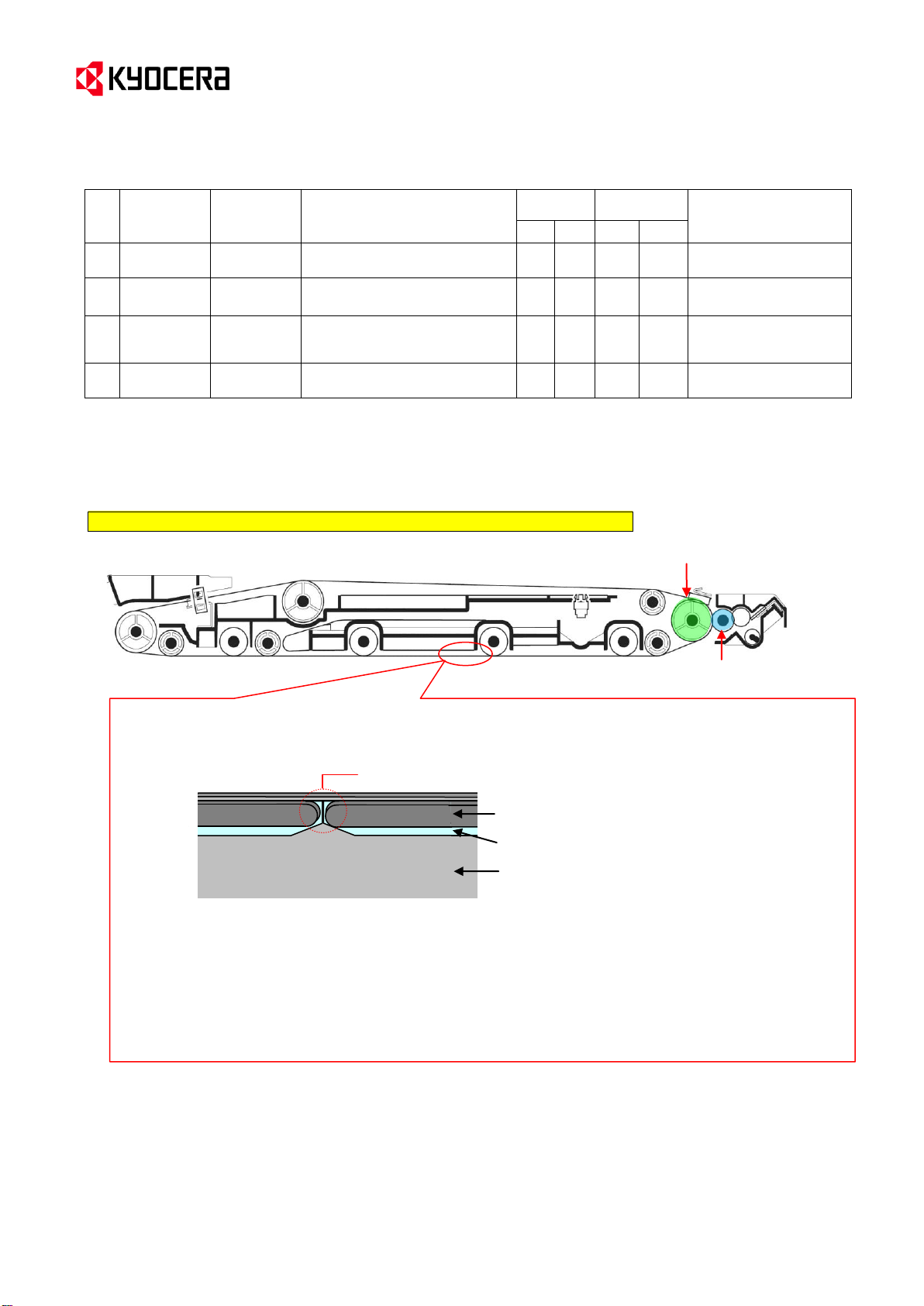

Idle roller (Changed the guide pulleys attached to the both ends of this roller.)

Fur brush (Changed its material.)

<Rubber to prevent transfer belt skew

: The rubbers are affixed to the front and rear edges of the transfer belt backside.>

(The illustration below shows the machine front edge of the transfer belt backside.)

Seam section where the glue was added as the previous change.

Transfer belt

PET film (abolished this time)

Rubber

(Notes) Currently, the rubber is first affixed to the PET film with the double-sided tape, and then PET film

with the rubber is affixed to the edge of the transfer belt backside. If the adhesive strength

between the PET film and the rubber is decreased depending on the operating environment, etc.,

the seam section of the rubber may peel off from the PET film. Therefore, the seam section of

the rubber has been fixed with glue since the previous change.

This time, the rubber and the guide pulley at the both sides of the idle roller were changed as the

further improvement. Also, the PET film was abolished since the rubber is now directly affixed to

the transfer belt due to this change.

Service Bulletin Ref. No. 2H7-0095 (C338)

"+" mark at the beginning of the part name indicates that it is a component part.

(Notes) The units with A as the last digit of the part number of No.1 and No.2 and with 5 as the last digit of the part number of

No.3 do not exist.

Cross section of the primary transfer belt unit from the machine front side

<Date> January 7, 2013

KYOCERA Document Solutions Europe

Technical Customer Service Division (TCSD)

Loading...

Loading...