Page 1

(Page.1/6)

Subject

Measures against the Abnormal Image (Full-page Solid Image

or Leak Image)

Model l:

FS-C5150DN, FS-C5250DN, FS-C2026MFP, FS-C2126MFP

FS-C2026MFP+, FS-C2126MFP+, FS-C2526MFP, FS-C2626MFP

KDC’s Classification Entire Stock Rework In-Field modification at next visit

In-Field modification by case No modification necessary

Field Measures: (-->) Please execute the followings when abnormal image appears.

1) Check the state of the high-voltage contact spring and put it back to the correct position if running over.

2) Attach 4 pcs. of the CASE SPACER (No.1).

(Note1) Please refer to another document [Procedure for replacing with the corrective parts] (File name is

“Procedure_D012_2KT_0019_E”) for the procedures.

(Note2) Along with this process, it is recommended to replace other corrective parts in the related sections.

For more details, please refer to another Service Bulletin SB-2KT-0019-D012.

If necessary, please apply the PARTS WASTE TONER ASSY SP (No.2) instead of performing the Step 2)

above.

Serial Nos. of the Affected Machines: (-->) Please refer to the page 4 to 5.

(The CASE SPACER and the PARTS WASTE TONER ASSY SP are service parts and no affected serial number exists.)

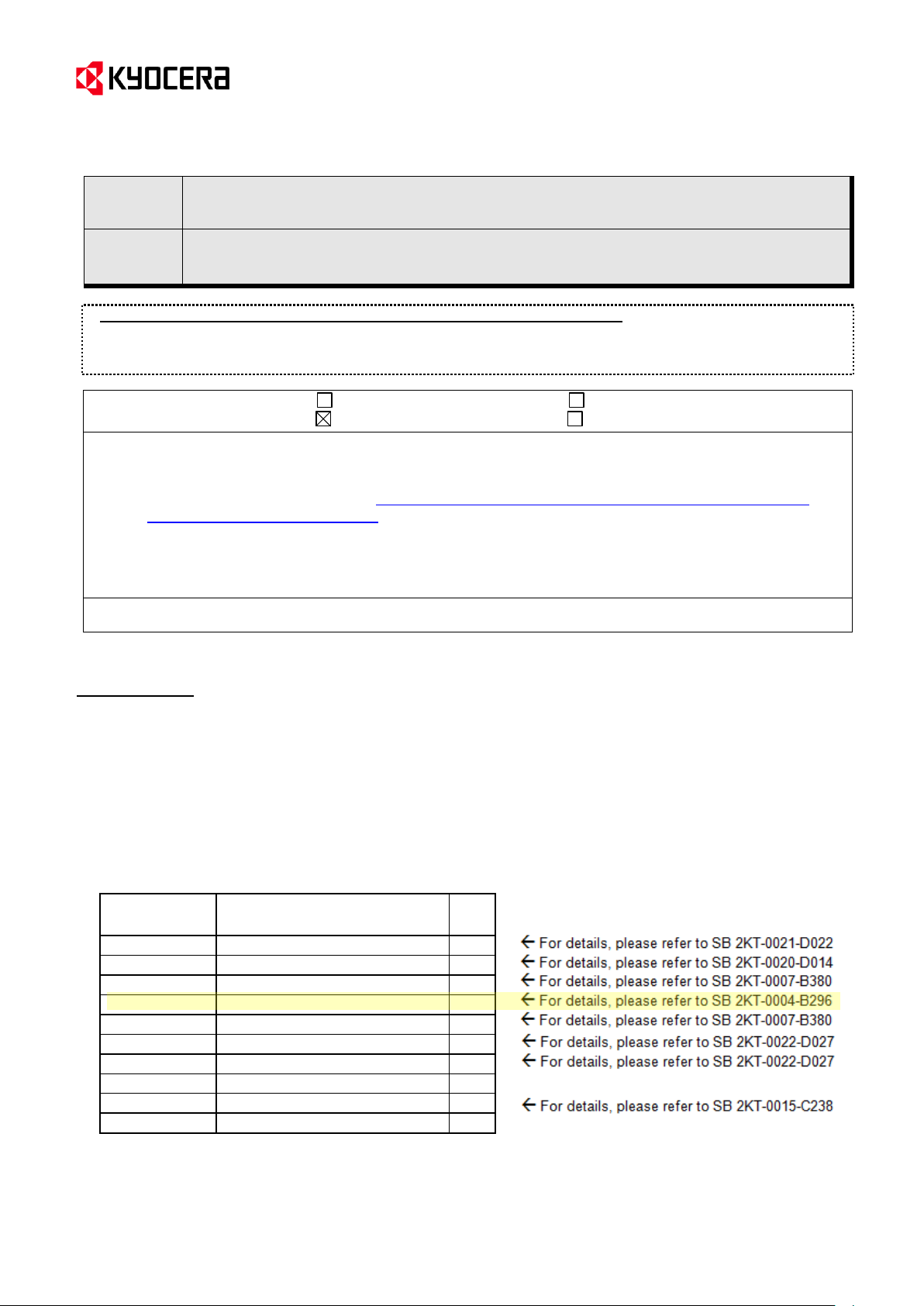

Item Number

Description

Qty.

302KV02461

CAM TONER SUPPLY

4

302KV02501

RATCHET SHUTTER

4

302KV02542

HINGE LID R

1

302KV02E50

CASE SPACER

4

302KV02532

HINGE LID L

1

302KT09111

STOPPER HOOK

1

302KT09170

SPRING STOPPER HOOK

1

302KV02170

GUIDE TOP L

1

302KV02521

LEVER INTERLOCK

1

302KW34040

LABEL SET ISU

1

Service Bulletin Ref. No. 2KV-0004 (B296)

<Date> April 23, 2013

This time, the description with (-->) was revised from the previous information.

<Number of changes: 8>

The entire content was revised due to the new descriptions regarding the field measures.

(The contents on the page 5 to 6 remain unchanged.)

To be informed:

To several issues, we have created a modification kit containing the parts in the <Table.2>.

The Item code of each modification kit is described in the <Table.3>. (Each country has a different item code!)

All latest hardware updates since January are implemented in this kit.

For more details, please refer to the Service Bulletin SB-2KT-0019-D012.

We do not recommend ordering the modification kit in every case, but the price for the kit will be lower than the

parts ordered separately ,which makes the purchase more convenient.

<Table.2> Contents of the modification kit (The yellow marked part is described in this Bulletin.)

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 2

(Page.2/6)

Material Number

in SAP

Material

Number

in AS-400

Material Description

870LCKIT2KV1AT

GEMINI MODIFICATION KIT FOR AUSTRIA

870LCKIT2KV1BE

302KV1BE

GEMINI MODIFICATION KIT FOR BELGIUM

870LCKIT2KV1CH

302KV1CH

GEMINI MODIFICATION KIT FOR SWITZERLAND

870LCKIT2KV1DE

GEMINI MODIFICATION KIT FOR GERMANY

870LCKIT2KV1DK

GEMINI MODIFICATION KIT FOR DENMARK

870LCKIT2KV1ES

GEMINI MODIFICATION KIT FOR SPAIN

870LCKIT2KV1FI

GEMINI MODIFICATION KIT FOR FINLAND

870LCKIT2KV1FR

GEMINI MODIFICATION KIT FOR FRANCE

870LCKIT2KV1GB

GEMINI MODIFICATION KIT FOR UNITED KINGD

870LCKIT2KV1IT

GEMINI MODIFICATION KIT FOR ITALY

870LCKIT2KV1NL

302KV1NL

GEMINI MODIFICATION KIT FOR NETHERLANDS

870LCKIT2KV1NO

GEMINI MODIFICATION KIT FOR NORWAY

870LCKIT2KV1PT

302KV1PT

GEMINI MODIFICATION KIT FOR PORTUGAL

870LCKIT2KV1SE

GEMINI MODIFICATION KIT FOR SWEDEN

870LCKIT2KV1ZA

302KV1ZA

GEMINI MODIFICATION KIT FOR SOUTH AFRICA

870LCKIT2KV1RU

302KV1RU

GEMINI MODIFICATION KIT FOR RUSSIA

870LCKIT2KV100

GEMINI MODIFICATION KIT FOR INT. SALES

870LCKIT2KV130

GEMINI MODIFICATION KIT FOR OLIVETTI

870LCKIT2KV120

GEMINI MODIFICATION KIT FOR TA GmbH

Service Bulletin Ref. No. 2KV-0004 (B296)

<Table.3> Item code of the modification kit

<Date> April 23, 2013

Customer Services & Support Division (CSSD)

KYOCERA Document Solutions Europe

Page 3

(Page.3/6)

Subject

Measures against the Abnormal Image (Full-page Solid Image

or Leak Image)

A guide rib was added to the circumference of the spring contact in order to prevent the spring from running over, and

a taper was added inside the guide rib so that the spring will be correctly moved back to the regular position even if

running over.

Guide rib is added

Guide rib added

Old New

Old New

(Change for M,C,Y)

(Change for BK)

Reinforcing rib is added

Reinforcing rib added

Bending direction

Bending direction

Service Bulletin Ref. No. 2KV-0004 (B296)

<Date> April 23, 2013

Topic

Abnormal full-page solid image or leak image might appear due to contact failure of the drum high-voltage board

and the drum ground failure. Therefore, the following changes were made. (Please refer to the service bulletin SB2KV-0002-B157 “Checkpoint when the full-page solid image or leak image appears”.)

(-->) Also, the PARTS WASTE TONER ASSY SP (No.2) with the new corrective measures except the CASE

SPACER was newly registered as service part in order to enable part replacement in field. Please apply it if

necessary. (For more details and the part table, please refer to the page 3.)

1. Corrective measures for the contact failure of the drum high-voltage board

Content of Changes (-->)

<Corrective measures at production line>

A guide rib was added so that the drum ground spring will not run over the circumference of the hole.

Also, the reinforcing rib was added to prevent the guide with the hole to insert the drum ground spring from

bending.

<Field measures>

The CASE SPACER I(4 pcs. of No.1) was newly registered as service part in order to prevent the guide from

bending.

(-->) <Corrective measures at production line>

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 4

(Page.4/6)

Apertures where the CASE SPACERs are

attached (Field measures)

Parts to insert the drum ground spring

(Change at production line described on page 1.)

Rib

(Fig.1)

CASE SPACER (No.1)

Groove

Rib

(Fig.2)

X

CASE SPACER (No.1)

High-voltage ground spring

Guide

(To insert the drum

ground spring)

The CASE SPACER was added to press the part of inserting the drum ground

spring towards the drum ground spring side (direction of the inner machine) in order

to prevent the part of inserting the drum ground spring on the guide securing the

high-voltage ground spring from bending.

(Fig.4: Fig.2 viewed from the machine inside)

High-voltage

ground spring

Part to insert the drum

ground spring

CASE SPACER (No.1)

Direction of

pressing the guide

Aperture of the guide

Drum ground

spring

Service Bulletin Ref. No. 2KV-0004 (B296)

<Date> April 23, 2013

(-->) (Right frame viewed from inside) (Right frame viewed from outside)

<Field measures: CASE SPACER supply> (To be attached to the apertures)

Insert the T-shape part of the CASE SPACER into the aperture of the guide behind the high voltage board

aslant so that the X side of the T-shape will be first inserted (Fig.1).

Then, secure the CASE SPACER by putting the rib at the bottom into the groove of the aperture (Fig.2).

(Fig.3: Cross section of the spring contact of the drum high-voltage board)

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 5

(Page.5/6)

No.

Old Part

No.

New Part

No.

Description

Q’

ty

Com

bi

patility

Remarks

Old

New

Old

New

1

------------

302KV02E50

2KV02E50

CASE SPACER

-

4

-

O

*1 2 ------------

302KV94470

2KV94470

PARTS WASTE TONER ASSY SP

-

1

-

O

*2

The end of SPRING LOCK DRUM

contacts the main frame for ground.

Contact with the right side of the drum shaft

Spring end cut

[PARTS WASTE TONER ASSY SP (No.2)]

(The photo below shows the side contacting the frame.)

Parts to insert the drum ground spring

(The guide ribs and the reinforcing ribs were added.)

: <1. Corrective measures for the contact failure of the

drum high-voltage board (Change at production line)>

New drum lock spring

<2. Corrective measures for the drum ground failure >

Service Bulletin Ref. No. 2KV-0004 (B296)

<Date> April 23, 2013

2. Corrective measures for the drum ground failure

Content of changes

The shape of the drum lock spring (SPRING LOCK DRUM) was changed.

Old New

SPRING LOCK DRUM

(-->) [New service part for field measures]

Upon the request from the sales company, the assembly (No.2) for <1. Corrective measure for the contact failure of

the drum high-voltage board (Change at production line)> and <2. Corrective measures for the drum ground failure>

was newly registered as service part.

(-->)

*1: Service part for field measures (Field measure at Change 1)

*2: Service part for field measures (The assembly with the Change 1 at production line and Change 2)

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 6

(Page.6/6)

Model

ITEM No.

Destination

Serial Number

1102KT3NL0

KDE

Q521821161

FS-C5150DN

1102KT3UT0

UTAX/TA

Q861Y01804

1102KT3LV0

Olivetti

NHT1900473

1102KV3NL0

KDE

Q561812452

FS-C5250DN

1102KV3UT0

UTAX/TA

Q871902481

1102KV3LV0

Olivetti

NHU1900229

Model

ITEM No.

Destination

Serial Number

1102KW3NL0

KDE

From the next production

FS-C2026MFP

1102KW3UT0

UTAX/TA

From the next production

1102KW3LV0

Olivetti

From the next production

1102KX3NL0

KDE

From the next production

FS-C2126MFP

1102KX3UT0

UTAX/TA

From the next production

1102KX3LV0

Olivetti

From the next production

1102MA3NL0

KDE

NN51901613

FS-C2026MFP+

1102MA3UT0

UTAX/TA

NNW1800426

1102MA3LV0

Olivetti

NQB1Z00001

FS-C2126MFP+

1102MB3NL0

KDE

NN91804696

1102MB3UT0

UTAX/TA

NNX1801486

1102MB3LV0

Olivetti

NQC1900001

FS-C2526MFP

1102M83NL0

KDE

NML1801244

1102M83AS0

KDAU

NMK1800041

1102M83UT0

UTAX/TA

NNU1800211

1102M83LV0

Olivetti

NQ91X00046

Model

ITEM No.

Destination

Serial Number

1102M93NL0

KDE

NN11803554

FS-C2626MFP

1102M93UT0

UTAX/TA

NNV1800481

1102M93LV0

Olivetti

NQA1800058

Service Bulletin Ref. No. 2KV-0004 (B296)

<Date> April 23, 2013

(-->) Serial Nos. of the Affected Machines

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Loading...

Loading...