Page 1

(Page 1/45)

Subject

Information on the Replacement of the Parts

(1. Measures against the Abnormal Image

2. Improvement of the Top Tray’s operability and Prevention of the Hinge

Gear Damage

3. Measures against Toner Supply Failure

4. Measures against the Display Failure of REAR COVER Opening

5. Measures against the J0501 in 250 Sheets Cassette)

Model l:

FS-C5150DN, FS-C5250DN, FS-C2026MFP, FS-C2126MFP,

FS-C2026MFP+, FS-C2126MFP+, FS-C2526MFP, FS-C2626MFP

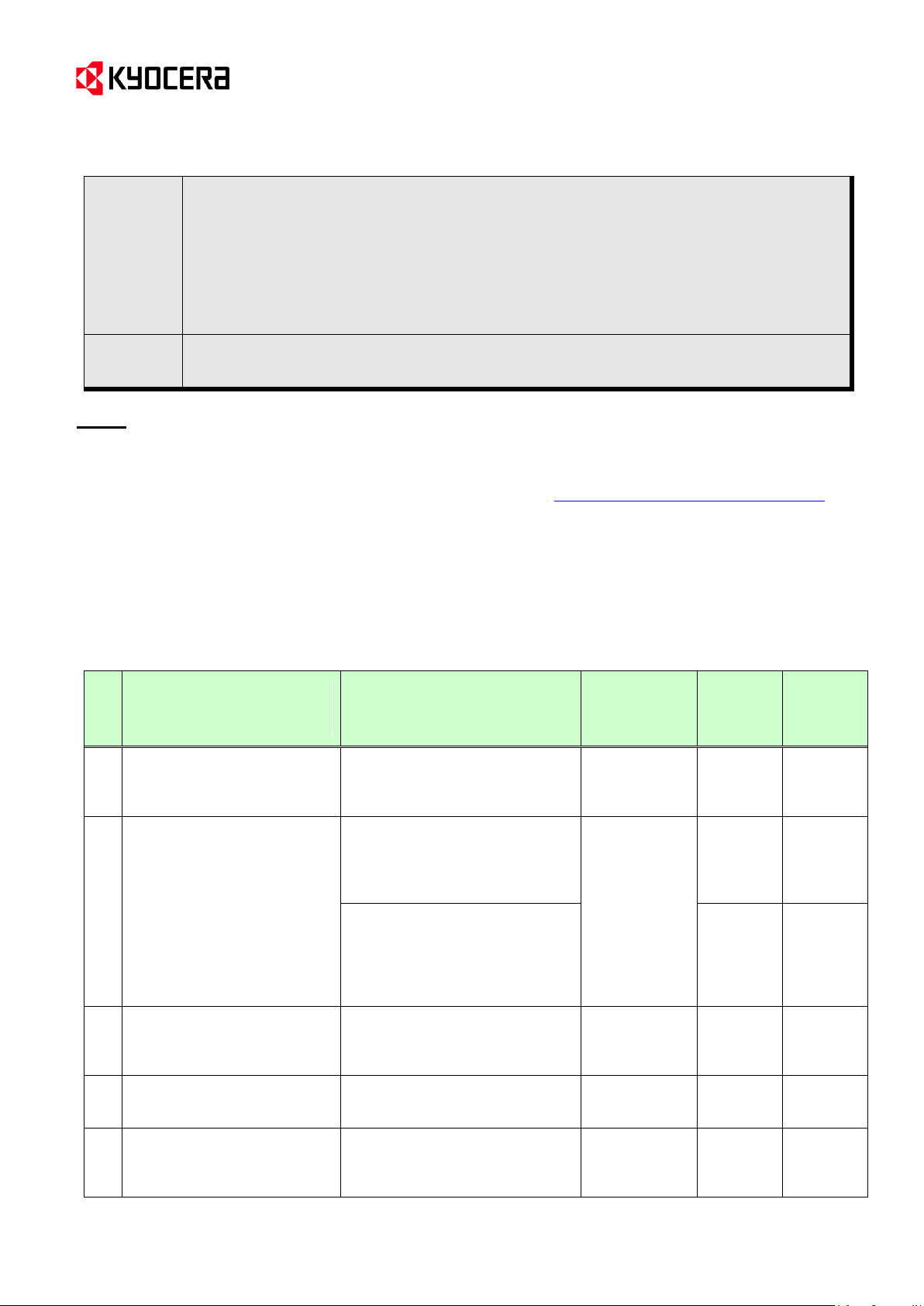

No.

Phenomenon for which the

measures are recommended

this time

Corrective Parts

Service Bulletin

No.

Product

month of

implement

ation

Procedure

No.*

1

Measures against the

abnormal image

(Full-page solid image or

leak image)

CASE SPACER (302KV02E5_)

--- 4 pcs.

SB-2KV-0004B296

(Revised Issue

1 or later)

Nov. 2011

(A)

2

Improvement of the top tray’s

operability and prevention of

the hinge gear damage

(The hinge gear’s damage

is applied to a part of

FS-C2026MFP/C2126MFP

(Note1).)

<Improvement of the top tray’s

operability>

RATCHET SHUTTER

(302KV02501)

--- 4 pcs. (Note2)

SB-2KT-0020D014

Feb. 2013

(C)

<Prevention of the hinge gear

damage>

HINGE LID R (302KV02542)

--- 1 pc.

HINGE LID L (302KV02532)

--- 1 pc.

Sep.

2010-Dec.

2010

(B)

(E)

3

Measures against the toner

supply failure (Frequent

display of the toner

replacement message)

CAM TONER SUPPLY

(302KV02461)

--- 4 pcs.

SB-2KT-0021D022

Feb. 2013

(F)

4

Measures against the display

failure of REAR COVER

opening

LEVER INTERLOCK (302KV02521)

--- 1 pc.

SB-2KT-0015C238

July 2012Aug. 2012

(D)

5

Measures against J0501 in

250 sheets cassette

STOPPER HOOK (302KT09111)

--- 1 pc.

SPRING STOPPER HOOK

(302KT09170) --- 1 pc.

SB-2KT-0022D027

Feb. 2013

(G)

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

Topic

Please find the procedure how to replace the parts with the corrective parts for the following phenomena 1 to 5.

To perform other corrective measures at the same time is recommended when executing the field measure for the

phenomenon described below.

It is recommended to watch the video showing the procedure => Improvement-KIT installation procedure

(Notes) Please refer to the <table.1> below for the corrective parts and the Service Bulletin No. of the respective

phenomena.

To solve several issues, we have created a modification kit containing the parts in the <table.2>.

The Item code of each modification kit is described in the <table.3>. (Each country has a different item code!)

All latest hardware updates since January are implemented in this kit.

We do not recommend ordering the modification kit in every case, but the price for the kit will be lower than the

separate parts together which makes the purchase more convenient.

<Table.1>

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 2

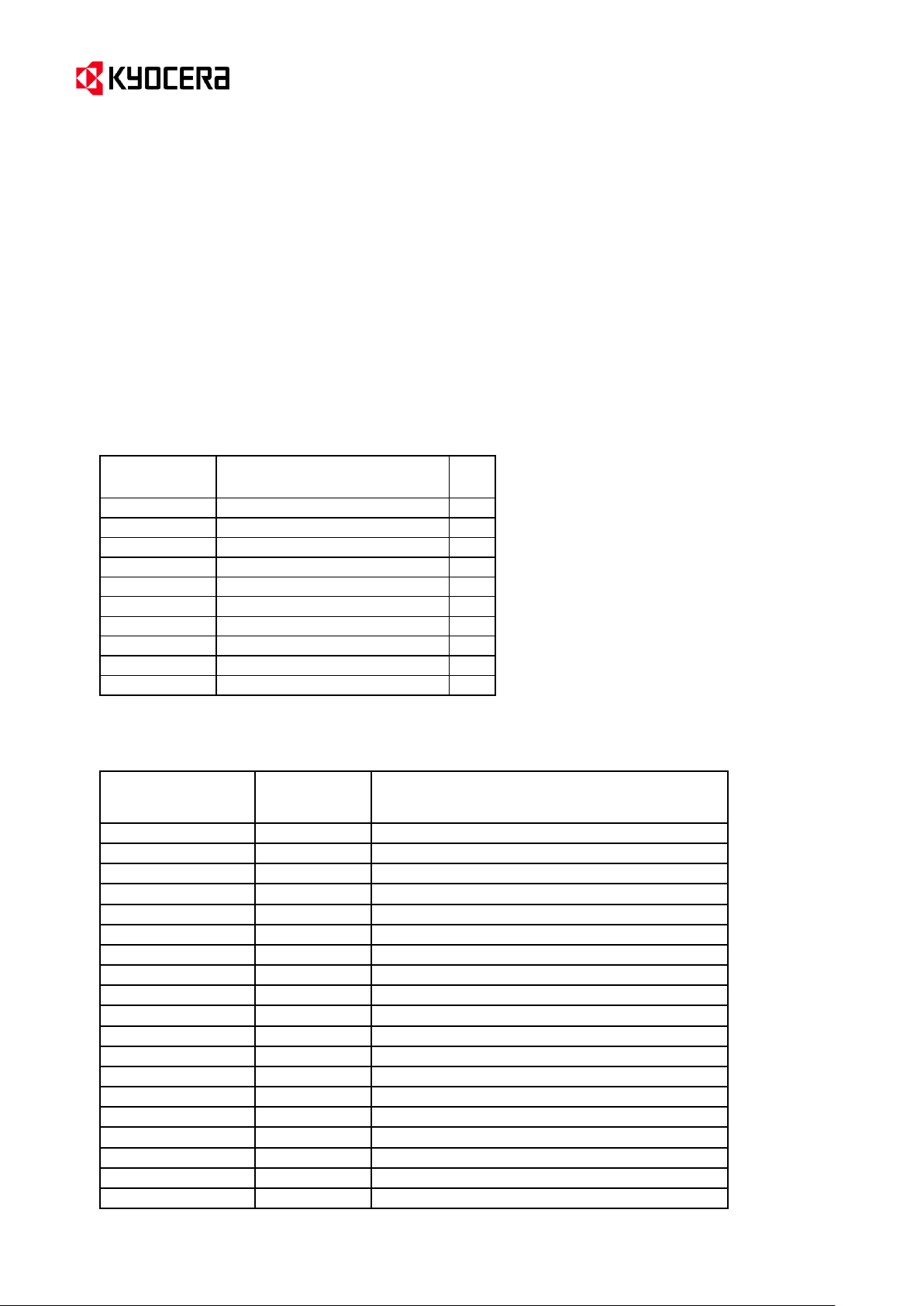

(Page 2/45)

Item Number

Description

Qty.

302KV02461

CAM TONER SUPPLY

4

302KV02501

RATCHET SHUTTER

4

302KV02542

HINGE LID R

1

302KV02E50

CASE SPACER

4

302KV02532

HINGE LID L

1

302KT09111

STOPPER HOOK

1

302KT09170

SPRING STOPPER HOOK

1

302KV02170

GUIDE TOP L

1

302KV02521

LEVER INTERLOCK

1

302KW34040

LABEL SET ISU

1

Material Number

in SAP

Material

Number

in AS-400

Material Description

870LCKIT2KV1AT

GEMINI MODIFICATION KIT FOR AUSTRIA

870LCKIT2KV1BE

302KV1BE

GEMINI MODIFICATION KIT FOR BELGIUM

870LCKIT2KV1CH

302KV1CH

GEMINI MODIFICATION KIT FOR SWITZERLAND

870LCKIT2KV1DE

GEMINI MODIFICATION KIT FOR GERMANY

870LCKIT2KV1DK

GEMINI MODIFICATION KIT FOR DENMARK

870LCKIT2KV1ES

GEMINI MODIFICATION KIT FOR SPAIN

870LCKIT2KV1FI

GEMINI MODIFICATION KIT FOR FINLAND

870LCKIT2KV1FR

GEMINI MODIFICATION KIT FOR FRANCE

870LCKIT2KV1GB

GEMINI MODIFICATION KIT FOR UNITED KINGD

870LCKIT2KV1IT

GEMINI MODIFICATION KIT FOR ITALY

870LCKIT2KV1NL

302KV1NL

GEMINI MODIFICATION KIT FOR NETHERLANDS

870LCKIT2KV1NO

GEMINI MODIFICATION KIT FOR NORWAY

870LCKIT2KV1PT

302KV1PT

GEMINI MODIFICATION KIT FOR PORTUGAL

870LCKIT2KV1SE

GEMINI MODIFICATION KIT FOR SWEDEN

870LCKIT2KV1ZA

302KV1ZA

GEMINI MODIFICATION KIT FOR SOUTH AFRICA

870LCKIT2KV1RU

302KV1RU

GEMINI MODIFICATION KIT FOR RUSSIA

870LCKIT2KV100

GEMINI MODIFICATION KIT FOR INT. SALES

870LCKIT2KV130

GEMINI MODIFICATION KIT FOR OLIVETTI

870LCKIT2KV120

GEMINI MODIFICATION KIT FOR TA GmbH

For details, please refer to SB-2KT-0021-D022.

For details, please refer to SB-2KT-0020-D014.

For details, please refer to SB-2KT-0015-C238.

For details, please refer to SB-2KT-0022-D027.

For details, please refer to SB-2KT-0022-D027.

For details, please refer to SB-2KT-0007-B380.

For details, please refer to SB-2KT-0007-B380.

For details, please refer to SB-2KT-0004-B296.

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

(Note 1) The measures against the hinge gear damage have been implemented during the mass production of the FS-

C2026MFP/C2126MFP, and since the first production of other models by improving the strength due to the material change.

As for the machines without the measures, please refer to the serial number table on the next page.

However, even on the machines with the measures, “Hinge” might be bent by the stress applied by toner shutter function. If so,

it is recommended to exchange “Hinge” at the same time with modifying the other parts.

(Note 2) The HOLDER JOINT attached with the CAM TONER SUPPLY might be contaminated by toner.

When replacing the CAM TONER SUPPLY, please clean the HOLDER JOINT or replace it with the new parts (4 pcs. of

302KV0251X).

The GUIDE TOP L (302KV02170) might also have been contaminated. In this case, it is recommended to exchange this part at

the same time.

(Note 3) After the relevant parts were replaced (after the modification kit was applied), please make sure to update the firmware

to the latest version.

<Table.2> Contents of the modification kit

*” LABEL SET ISU” is just a sticker which makes the opening position of top cover in MFP model more visible.

<Table.3> Item code of the modification kit

Customer Services & Support Division (CSSD)

KYOCERA Document Solutions Europe

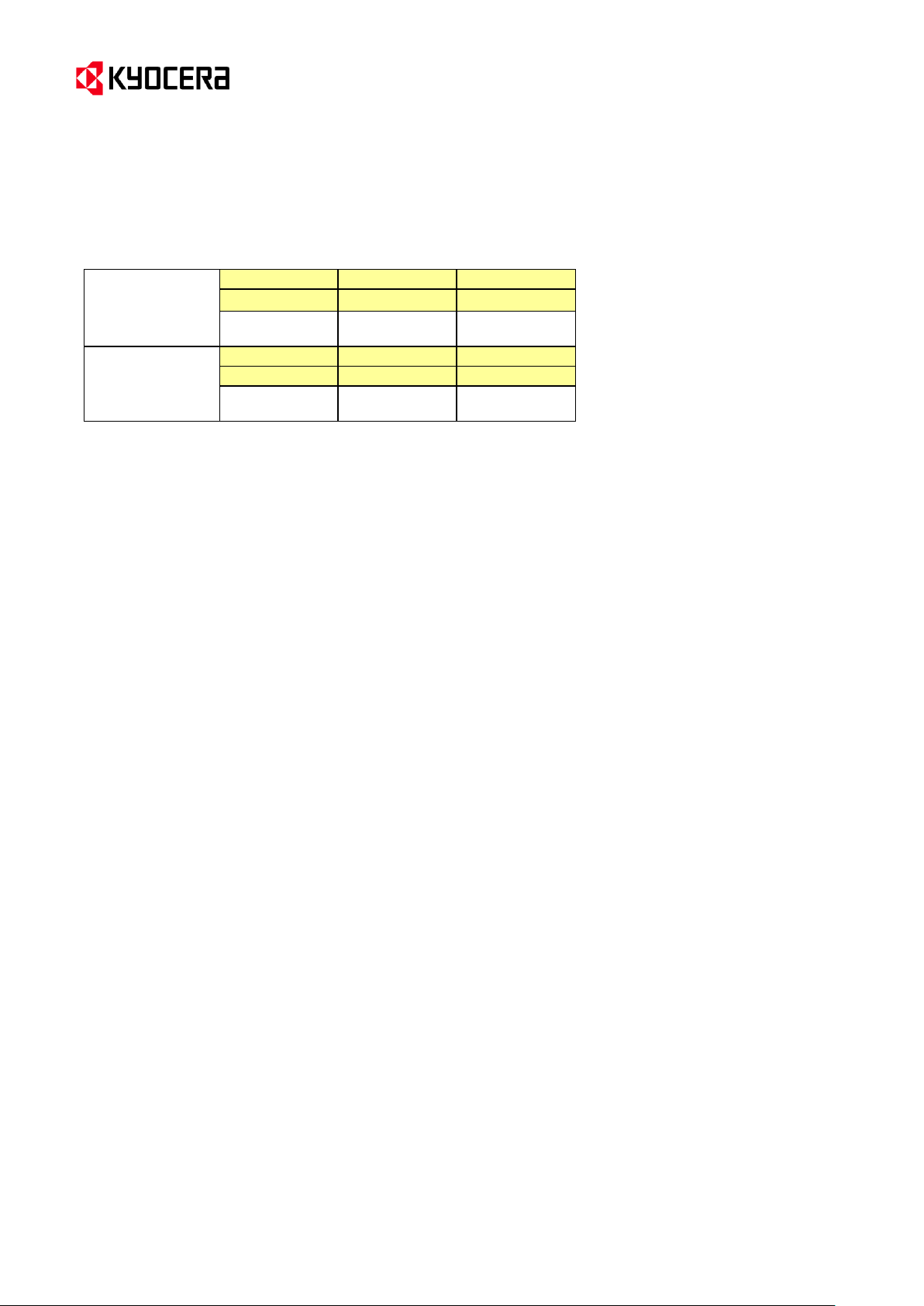

Page 3

(Page 3/45)

FS-C2026MFP

KDE

Olivetti

UTAX

1102KW3NL0

1102KW3LV0

1102KW3UT0

Q5A0500001to

Q5A0Z03378

N730900001 to

N730Z00250

Q880600001 to

Q880Z01276

FS-C2126MFP

KDE

Olivetti

UTAX

1102KX3NL0

1102KX3LV0

1102KX3UT0

Q5E0500001 to

Q5E0Z06121

N740900001 to

N740Z00260

Q890600001 to

Q890Z04602

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

[No.2: Machines with possible hinge gear damage] (Note 1 on the page 1)

*How to know the product month from serial number of machine:

For example, FS-C2026MFP S/N: Q5A0500001),

-First 3 digits ("QA5" in the example above) indicate the model code.

-Next 2 digits ("05" in the example above) indicate the product month.

("0" means year 2010, "5" means May. X=October; Y=November; Z=December)

-Next 5 digits ("00001" in the example above) are just specified numbers.

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 4

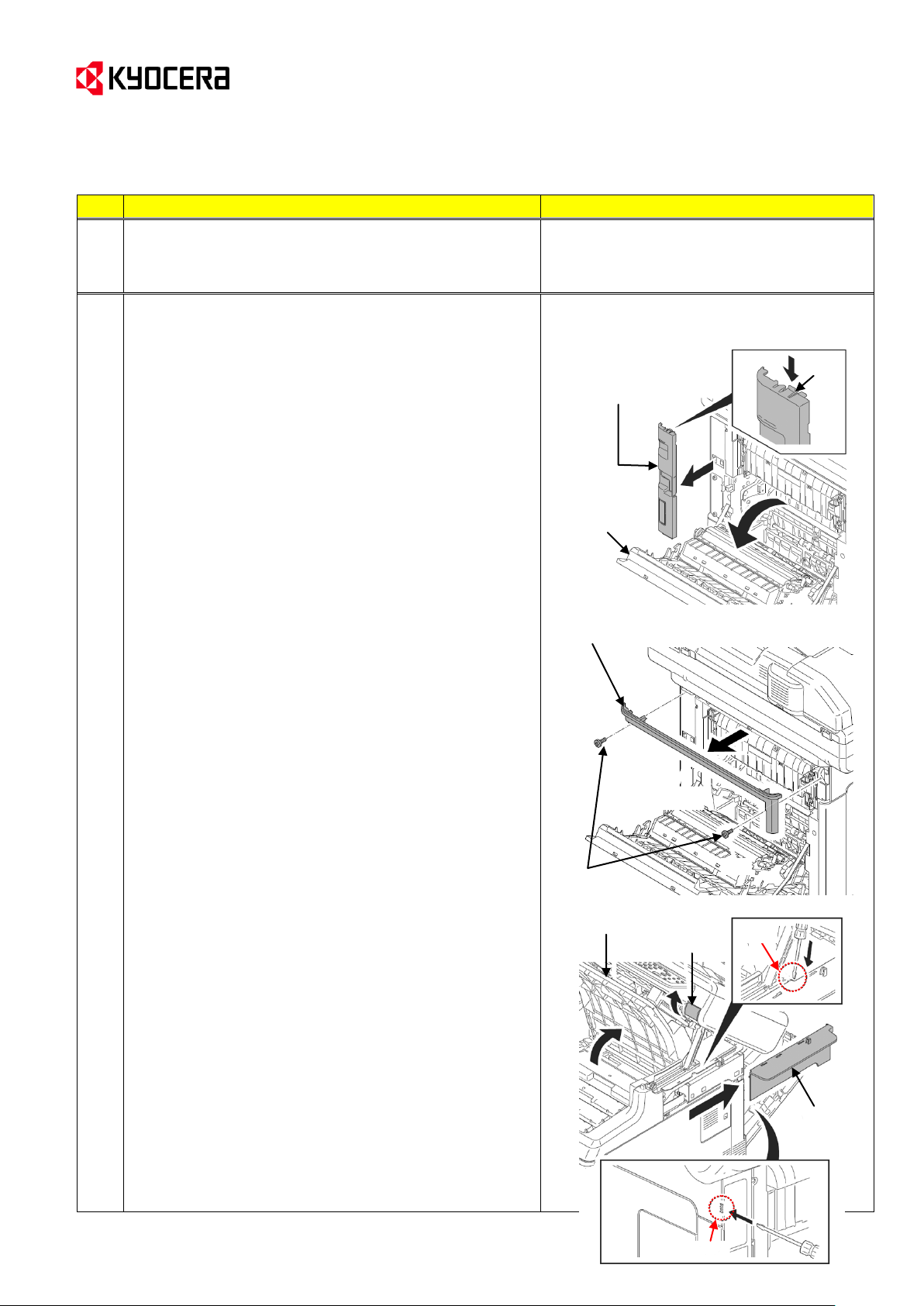

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

The Procedure 1 for the MFPs differs from the one for

printer models.

Go to the Procedure M1 below for the MFPs, and to

Procedure P1 for the printers.

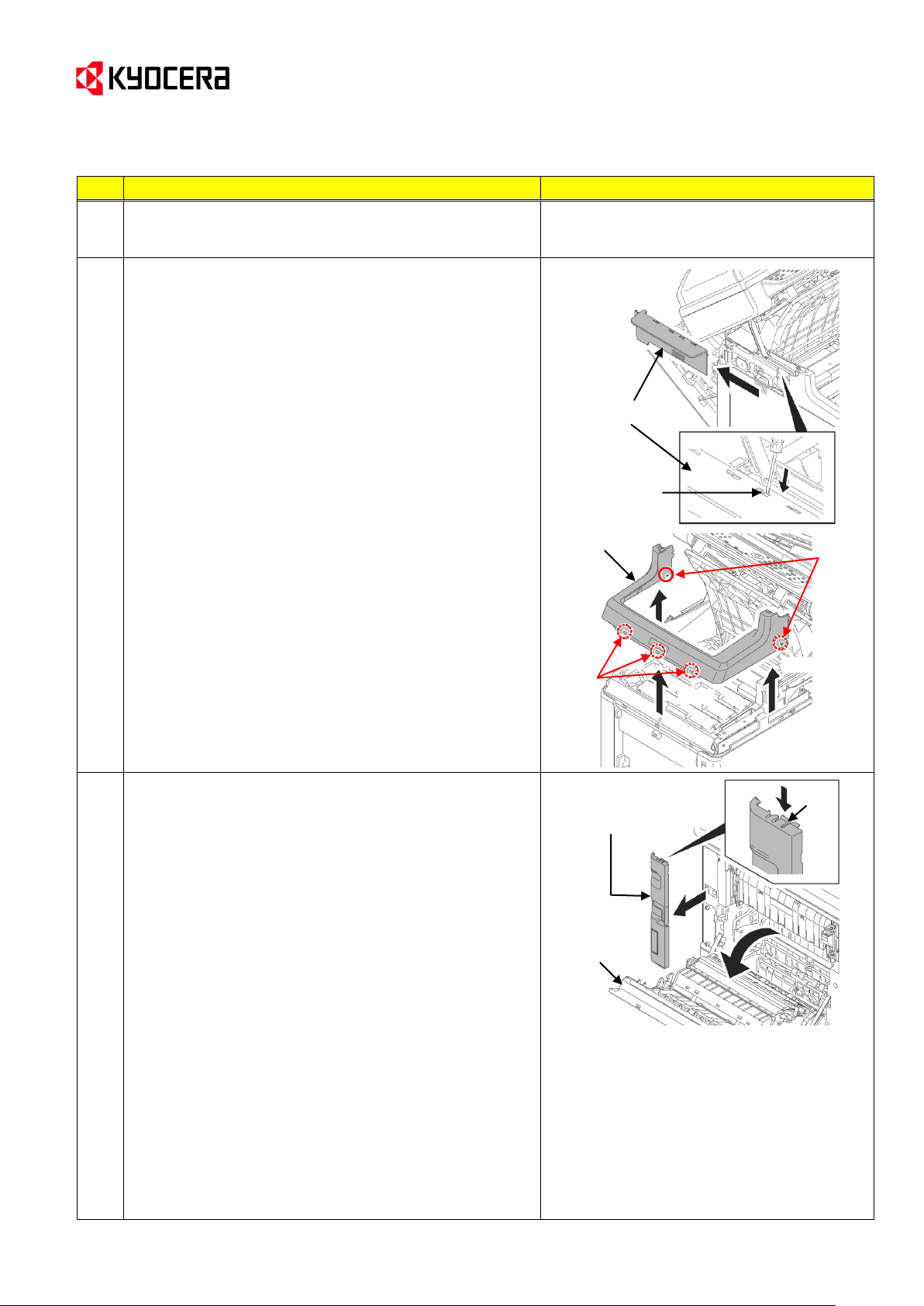

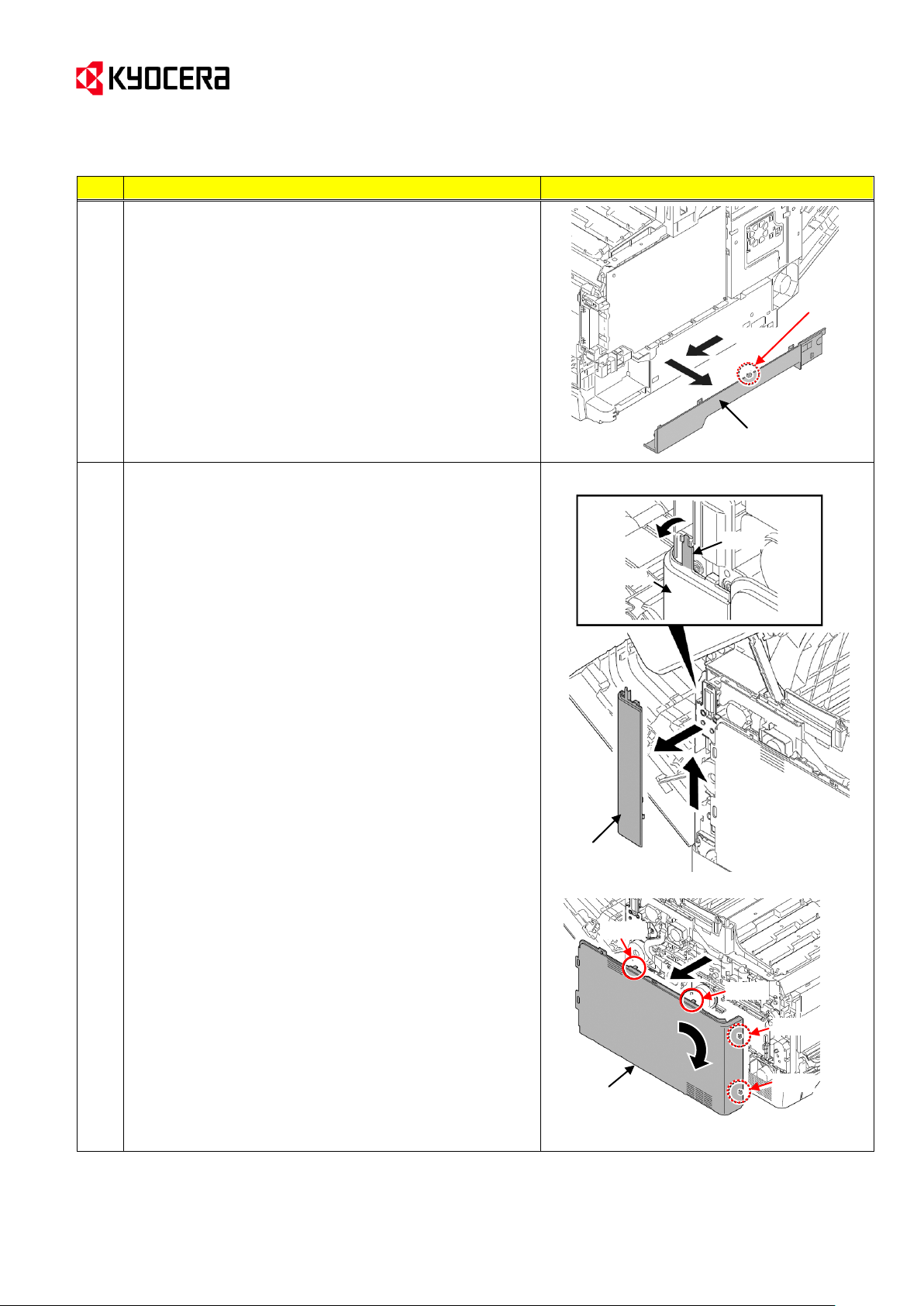

M1

[Procedures for the MFPs]

Detach the rear upper cover, right upper cover, left upper

cover and front cover.

* These procedures are described in the Service

Manual 1-5-2 [Outer covers] (1).

(Details)

M1-1. Open the paper conveying unit.

M1-2. Release the hook and then remove the IF cover.

M1-3. Remove the screw (x2). Then, remove the rear

upper cover.

M1-4. Pull the top tray lever and open the top tray.

M1-5. Release the hook (x2). Slide the right upper cover

backward and then remove it.

Hook

IF cover

Paper

conveying

unit

Screws

Rear upper cover

Right upper

cover

Top tray lever

Top tray

Hook

Hook

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 4/45)

Page 5

(Page 5/45)

No.

Procedure

Illustration/Remarks

M1

M1-6. Release the hook. Slide the left upper cover

backward and then remove it.

M1-7. Release the hook (hook A x2; hook B x3). Then,

remove the front cover.

--> Go to Procedure 2 in page 3.

P1

[Procedure for the printers]

Detach the top cover.

* These procedures are described in the

Service Manual 1-5-2 [Outer covers] (1).

(Details)

P1-1. Open the paper conveying unit.

P1-2. Release the hook and then remove the IF cover.

Left upper cover

Hook

Front cover

Hook

B

Hook A

Hook

IF cover

Paper

conveying

unit

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 6

(Page 6/45)

No.

Procedure

Illustration/Remarks

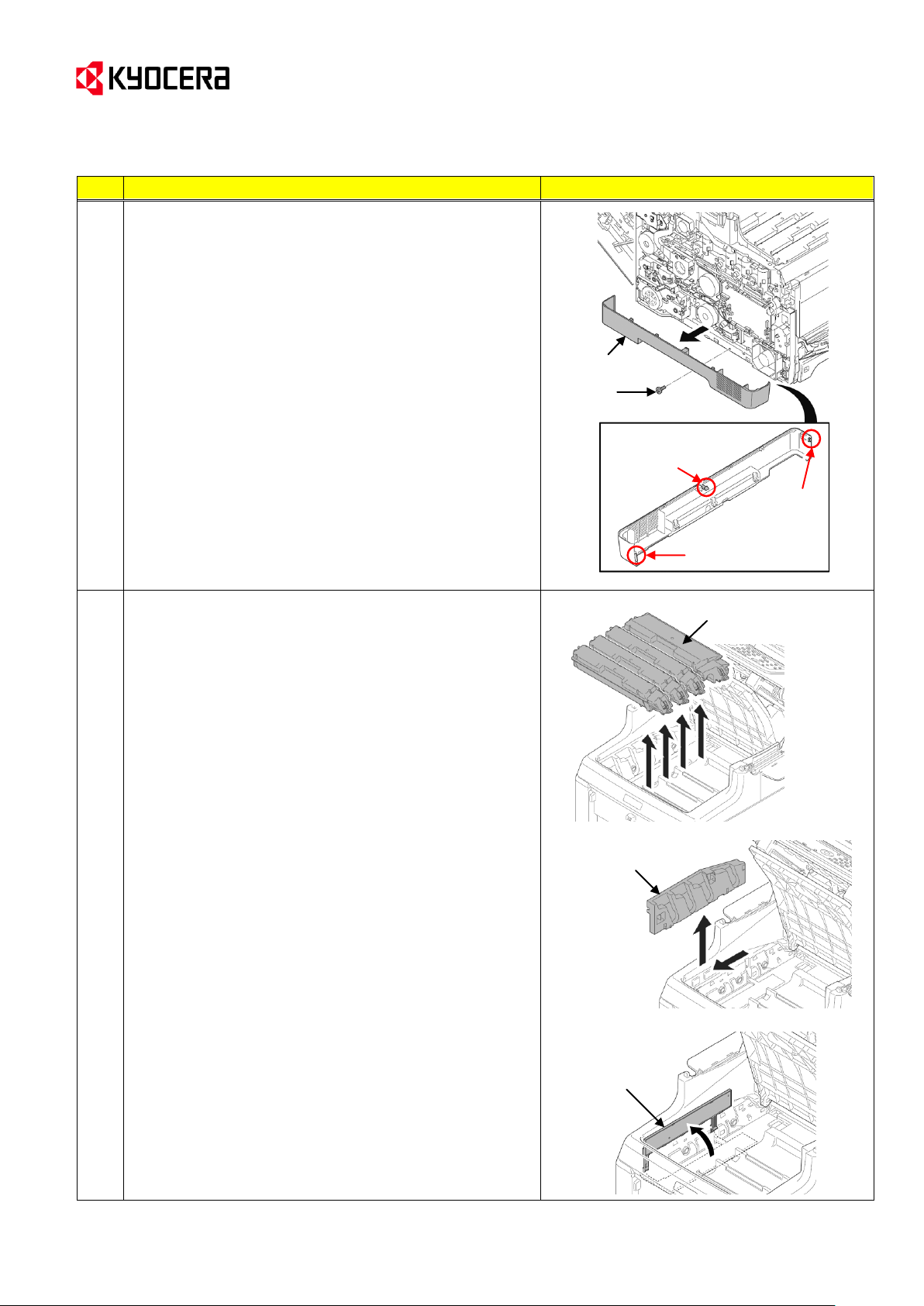

P1-3. Remove the screw (x2).

P1

P1-4. Open the top tray.

P1-5. Remove the screw (x2).

P1-6. Release the hook (x2) and then remove the top

cover.

--> Go to the following Procedure 2.

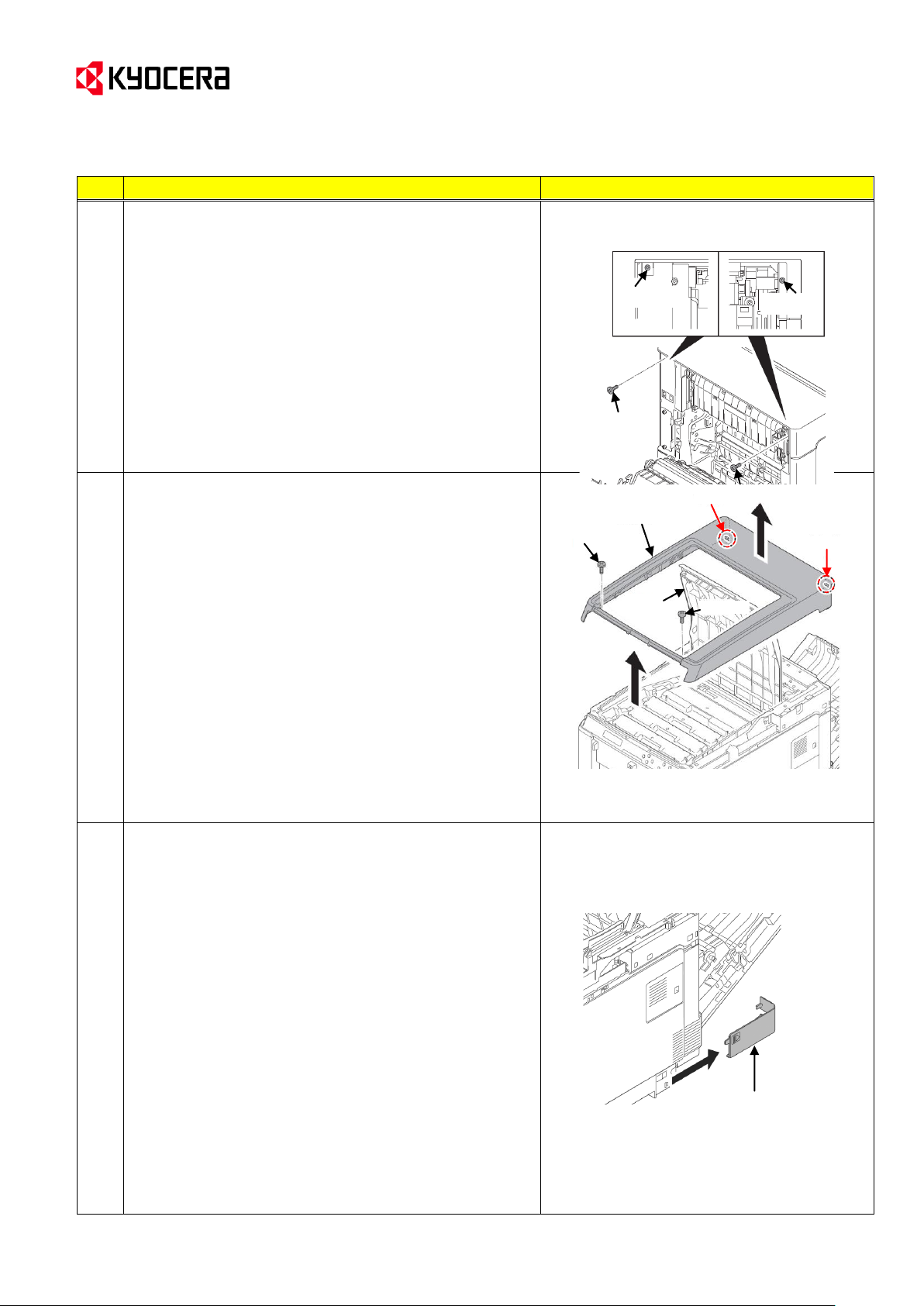

2

Detach the right rear cover, right cover and right lower

cover.

* These procedures are described in the Service

Manual 1-5-2 [Outer covers] (2).

(Details)

2-1. Slide the power source cover backward and then

remove it.

Power source cover

Screw

Screw

Screw

Screw

Screw

Top cover

Screw

Hook

Hook

Top tray

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 7

(Page 7/45)

No.

Procedure

Illustration/Remarks

2-2. Remove the screw.

2-3. Release four hooks. Slide the right rear cover

backward and then remove it.

Right rear

cover

Screw

Hooks

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

Customer Services & Support Division (CSSD)

KYOCERA Document Solutions Europe

Page 8

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

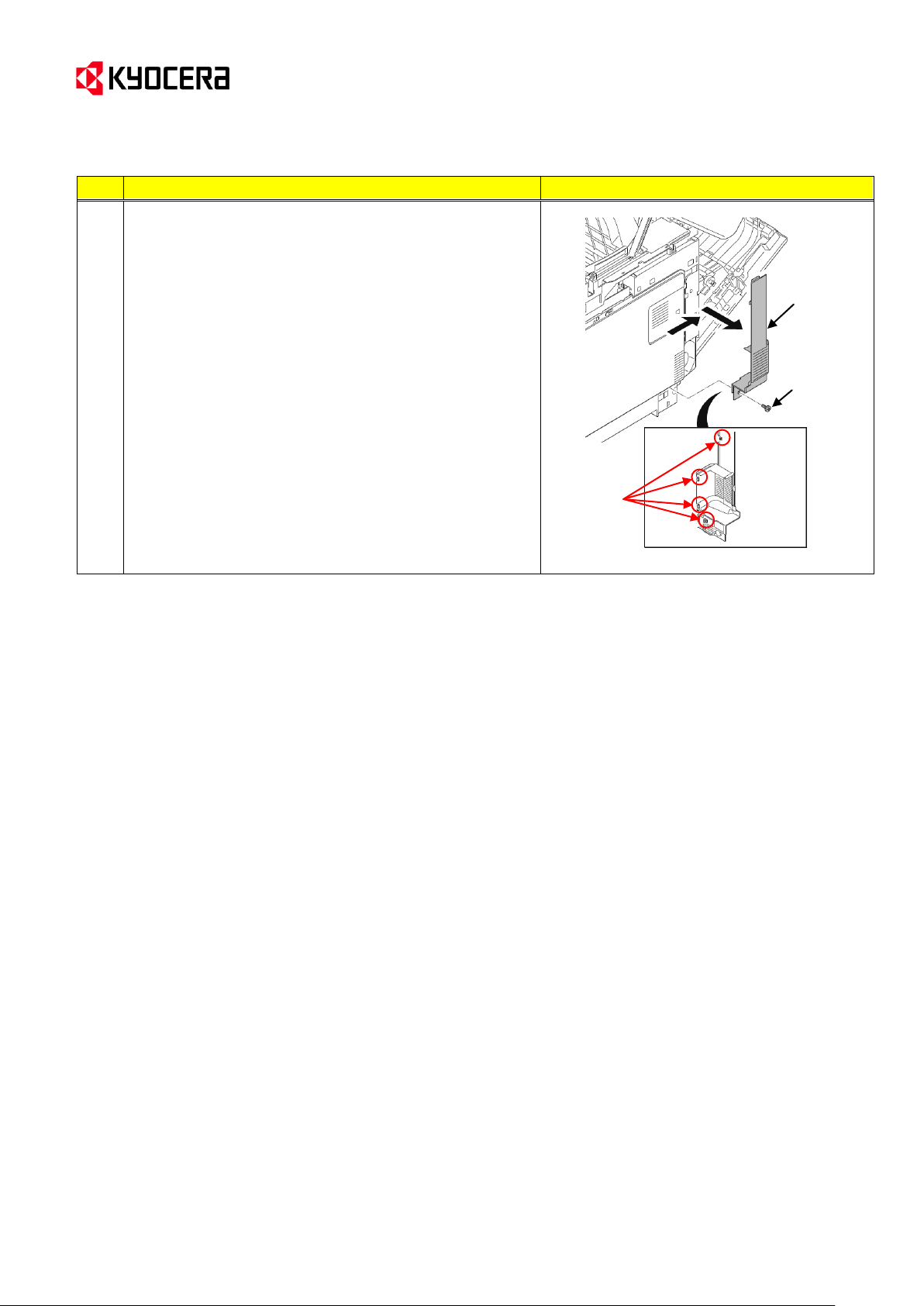

2

2-4. Open the memory cover and then remove it.

2-5. Open the waste toner cover.

2-6. Push the lock release button and then remove the

waste toner box.

(Close the cap of the waste toner box.)

2-7. Open the MP tray.

2-8. Release the hook (hook A x1 → B x1→ C x2).

Slide the right cover forward and then remove it.

2-9. Remove the waste toner cover.

Memory cover

Lock release button

Waste toner

cover

Waste toner box

Waste toner cover

Right cover

Hook A

Hook C

Hook B

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 8/45)

Page 9

(Page 9/45)

No.

Procedure

Illustration/Remarks

2

2-10. Release the hook. Slide the right lower cover

forward and then remove it.

3

Detach the left rear cover, left cover and left lower cover.

* These procedures are described in the Service

Manual 1-5-2 [Outer covers] (3).

(Details)

3-1. Release the hook. Slide the left rear cover upward

and then remove it.

3-2. Release the hook A(x2) and then release the hook B

(x2) while twisting the left cover clockwise.

Then, remove the left cover.

Left rear cover

Left rear

cover

Hook

Right lower cover

Hook

Hook A

Hook B

Left cover

Hook A

Hook B

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 10

(Page 10/45)

No.

Procedure

Illustration/Remarks

3

3-3. Remove the screw.

3-4. Release the hook (hook A → B → C) and then

remove the left lower cover.

3-5. Close the MP tray.

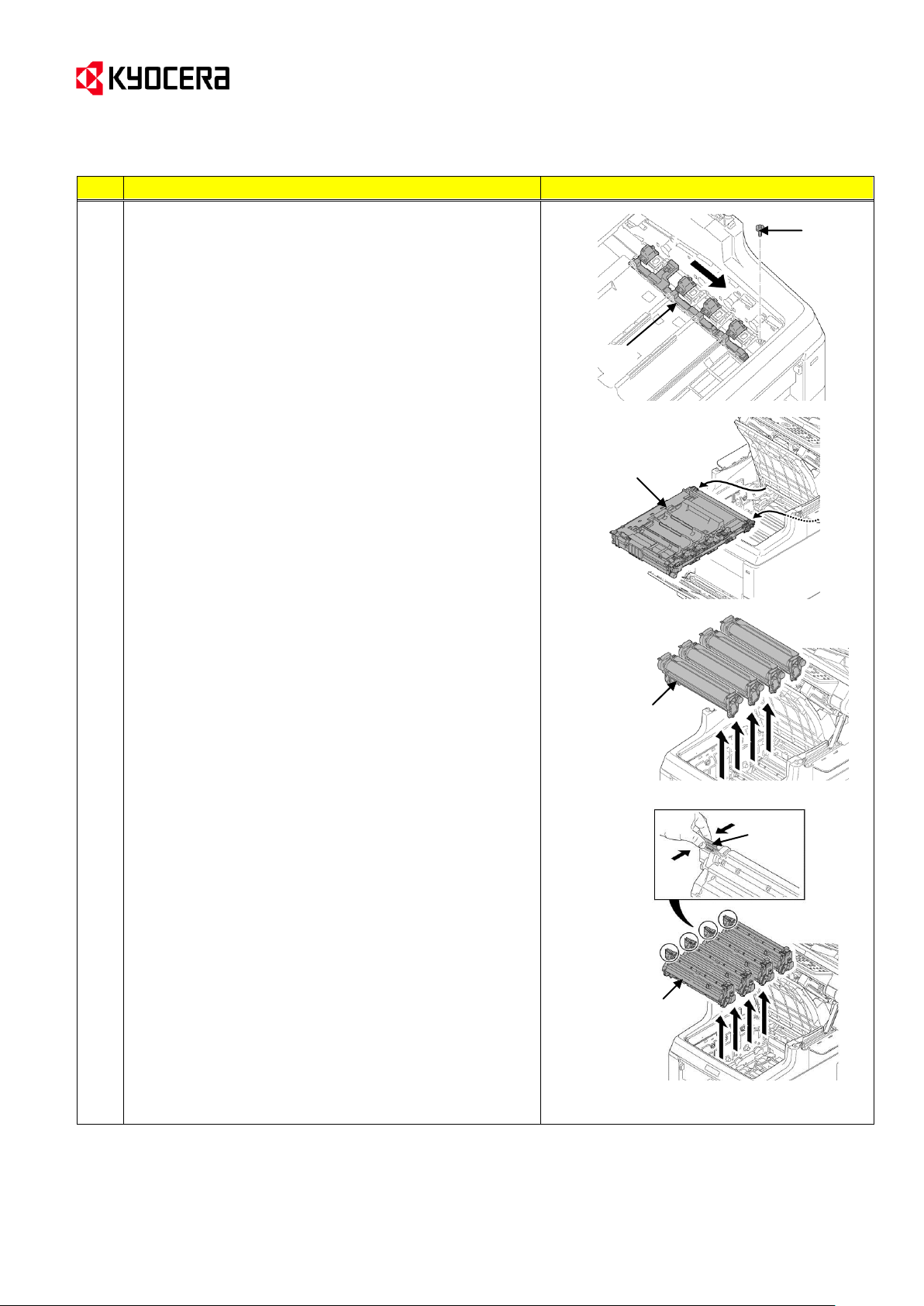

4

Detach the toner containers, the intermediate transfer units

and the drum units.

* These procedures are described in the Service

Manual 1-5-6 [(1) Detaching and refitting the

intermediate transfer unit] (3) and 1-5-5 [(1)

Detaching and refitting the drum unit].

(Details)

4-1. Remove toner containers (K, M, C, Y).

4-2. Slide the container guide forward and then remove it.

4-3. Open the RFID holder.

Toner containers

(K, M, C, Y)

RFID holder

Container guide

Left lower cover

Screw

Hook A

Hook C

Hook B

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 11

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

4

4-4. Slide the shutter forward and close the toner inlet.

4-5. Remove the screw.

4-6. Remove the intermediate transfer unit.

4-7. Remove the drum units (K, M, C, Y).

4-8. Pinch the lever of the developing unit.

4-9. Remove the developer units (K, M, C, Y)

[Note]

Please note that the machine should not be pushed

backward after removing the units from the machine

in the Procedures 4-6 to 4-9.

Shutter

Screw

Intermediate

transfer unit

Drum unit

(K, M, C, Y)

Lever

Developing unit

(K, M, C, Y)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 11/45)

Page 12

(Page 12/45)

No.

Procedure

Illustration/Remarks

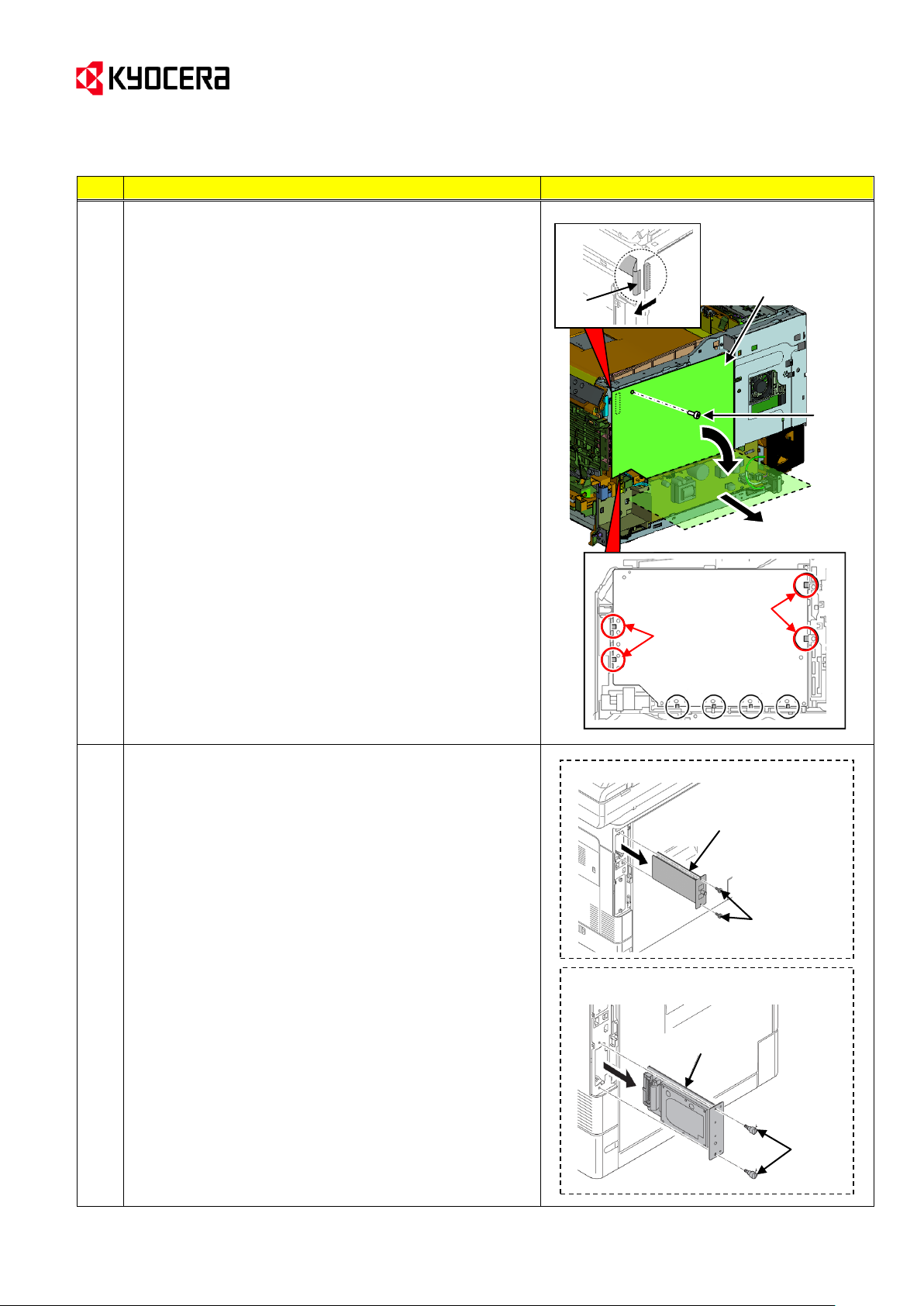

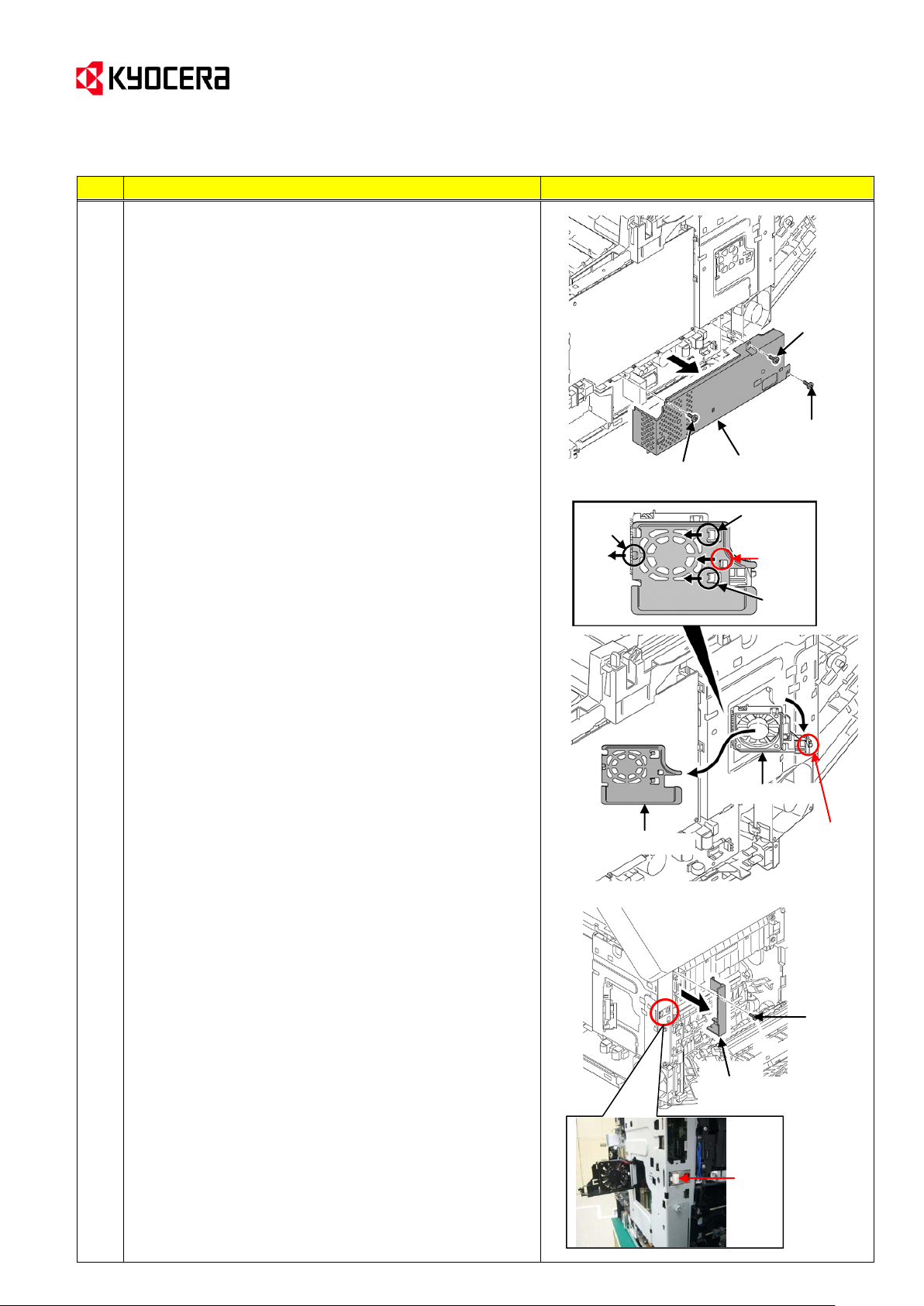

5

Detach the high voltage PWB.

(Details)

5-1. Remove the screw.

5-2. Release the hook (x4) of the upside of the PWB

circled with red in the right figure and slant the upside

of the high voltage PWB like opening it, and then

remove the FFC.

5-3. After the high voltage PWB is tilted till 90 degrees,

pull it out toward the machine right side. (Note)

(Note) If trying to pull out the PWB on the way of

slanting till 90 degrees, the hooks securing the

PWB’s low side might be damaged. (The

hooks are circled with black in the figure to the

right.)

6

Detach the main PWB.

* These procedures are described in the Service Manual 1-

5-8 [(3) Detaching and refitting the main PWB].

(Details)

<For the machine with FAX>

6-1. Remove the screw (x2) and then remove the FAX

control PWB.

<For the machine with the hard disk or the network

interface card>

6-1. Remove the pin (x2) and then pull out the hard disk or

the network interface card.

* As for the machine without FAX, go to

the Procedure 6-2.

(Machine with FAX)

Screw

FAX control PWB

HVU PWB

FFC

Hook

Hook

Screw

(Machine with the hard disk or the

network interface card)

Pin

Hard disk

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 13

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

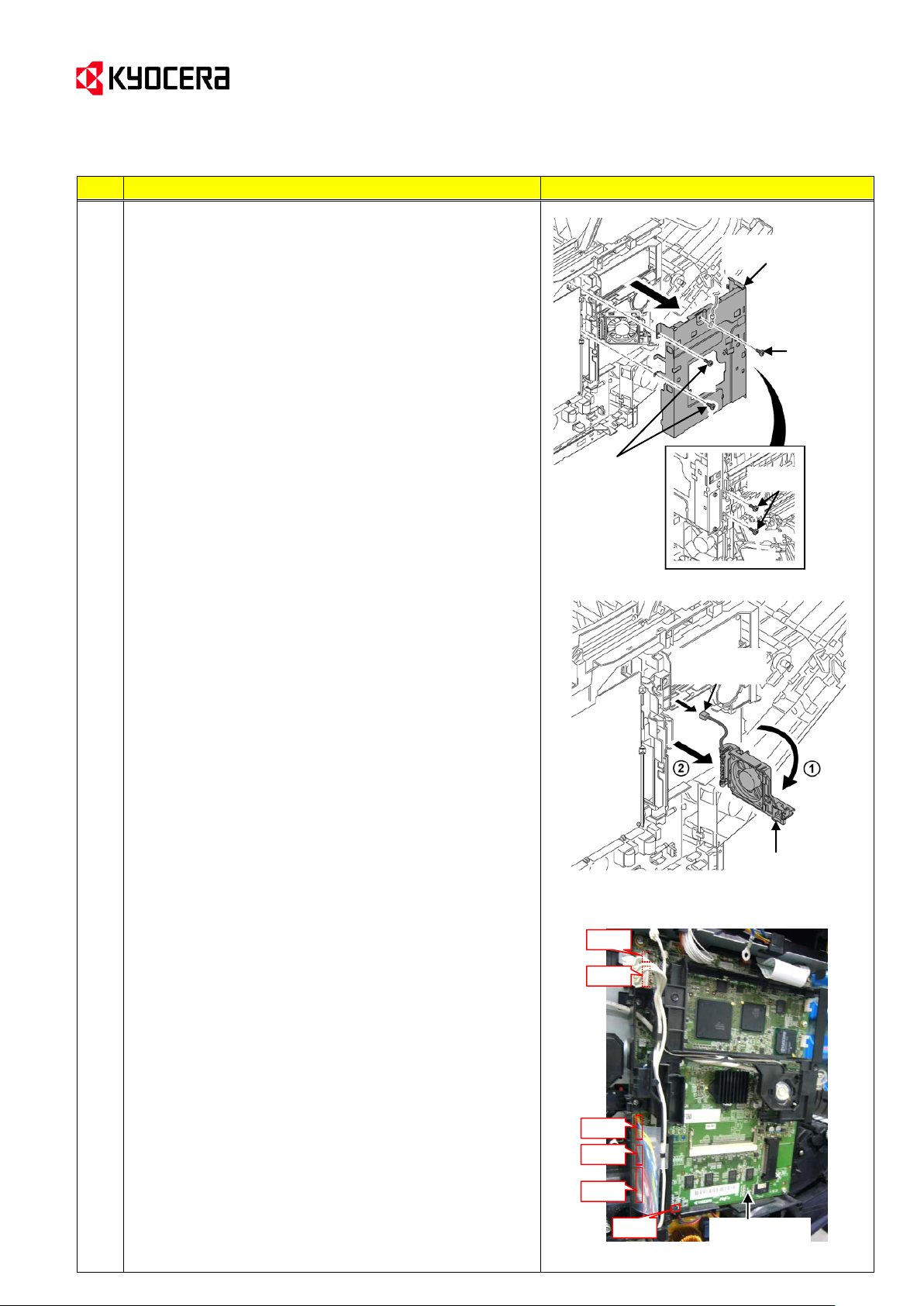

6

6-2. Remove the screw (x3) and then remove the power

source shield.

(Note) The screws A and B are different.

Please do not mix them up when refitting.

6-3. Pick up the hook A ant then open the fan bracket (the

bracket*).

6-4. Release the hook B and slide the fan plate (the

plate*). Release the remaining the hook (x3) and then

remove it.

* The part names in the Procedure 6-3 and 6-4 are

described as “Bracket” and “Plate” in the Service

Manual for the printer model. (The fan is not used.)

6-5. Remove the screw and then remove the fuser wire

cover.

6-6. Remove the cap.

Power source

shield

Screw A

Screw A

Screw B

Fan plate

Fan bracket

Hook

Hook

Hook

Hook B

Hook A

Fuser wire cover

Screw

Cap

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 13/45)

Page 14

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

6

(For the MFP model)

6-7. Remove the screw (x5) and then remove the

controller shield.

(For the Printer model)

6-7. Remove the screw (x4) and then remove the

controller shield.

6-8. Remove the connector (YC41) of the controller fan

motor.

(The Procedure 6-8 is unnecessary for the printer

model without the fan.)

6-9. Open the fan bracket (bracket) and then remove it.

(The procedure afterwards differs between the MFPs and

printers.

For the MFP model, go to the Procedure 6-M10 below,

For the Printer model, go to Procedure 6-P10 on the page

12.)

[For the MFPs]

6-M10. Remove the connectors YC15, YC37, YC40, YC38,

YC39 and YC42 from the main PWB.

Controller shield

Screw

(MFP only)

Screw

Screw

Main PWB

YC15

YC37

YC40

YC38

YC39

YC42

Fan bracket

Connector

(YC41)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 14/45)

Page 15

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

6

6-M11. Remove the wires aligned in the wire holder.

6-M12. Remove the screw (x2).

6-M13. Release the hook (x3) and then remove the wire

holder.

6-M14. Remove the connectors YC36, YC32, YC12 and

then FFC wires YC8, YC43 from the main PWB.

(Note) Reconnect the connectors and FFC wires

above before reattaching the wire holder

which was removed in the Procedure 6M13.

6-M15. Remove the screw (x5) and then remove the main

PWB.

--> Go to the Procedure (A) on the page 13.

Main PWB

Wire holder

Screw

Hook

Screw

Screw

Main PWB

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 15/45)

Page 16

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

6

[For the printers]

6-P10. Remove all connectors and FFC from the main

PWB.

6-P11. Remove the wires aligned in the wire holder.

6-P12. Remove the screw (x2) and then remove the wire

holder.

6-P13. Remove the screw (x3) and then remove the main

PWB.

--> Go to Procedure (A) in page 13.

Wire holder

Screw

Screw

Main PWB

Main PWB

Main PWB

Screw

Screw

Screw

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 16/45)

Page 17

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

(A)

[Check the contact state between the drum and the

high voltage PWB] / [How to attach the CASE SPACER]

Execute the following when abnormal image (full-page solid

image or leak image) appears.

[Samples of the abnormal image]

[Check the contact state between the drum and the high

voltage PWB (Work from the machine inside)]

(A)-1.

Check if the leading edge of the drum ground springs (4

pcs.) is sufficiently inserted in the inner part of the resin

guide hole on the inner right side of the machine. (Refer

to the normal state in the photo to the right.)

If the leading edge contacts the wall around the hole like

the wrong state in the photo to the right, release its

contact using a flathead screw driver, and insert the

leading edge into the hole of the resin guide.

[Attachment of the CASE SPACER

(Work from the machine right side)]

Attach the CASE SPACER (302KV02E5_)(x4) to the

aperture of the guide behind the high voltage PWB by

following the procedures below. 連サービスブリテン No.2KV-

0004 (B296)

<CASE SPACER (302KV02E5_)>

(Inner right side of the machine)

(Machine right side)

(Leak image: Cyan and yellow

high voltage contact failure)

Drum ground spring (x4)

(Normal state)

(Wrong state)

Waste toner guide

Aperture (x4)

(Full-page solid image:

Cyan high voltage contact failure)

Leak mark

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 17/45)

Page 18

(Page 18/45)

No.

Procedure

Illustration/Remarks

(A)

(A)-2. Insert the T-shape part of the CASE SPACER into

the aperture aslant.

(First, insert the X side of the T-shape.)

(A)-3. Attach the CASE SPACER so that the rib on the

bottom of the CASE SPACER can be inserted into

the groove of the aperture (on the upside of the

center spring).

(A)-4. Attach the CASE SPACER to the remaining section

(x3) as well.

X

Rib

[Aperture]

CASE SPACER

Groove

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 19

(Page 19/45)

No.

Procedure

Illustration/Remarks

7

<For MFPs only>

Detach the scanner unit with Document Processor.

(Details)

7-1. Close the RFID holder.

7-2. Remove the left and right pins by pushing the pins out

from inside while opening the top tray till the half way

of the opening angle. (After this procedure, the top

tray goes down and only the scanner unit opens.)

7-3. Release the hook (x4) and then remove the left and

right rails.

Rail

Rail

Hook

Rail

Top tray

Pin

Pin

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 20

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

7

7-4. Remove the spring (x2) from the left and right holders.

7-5. Remove the left and right holders from the scanner

unit.

(Note)

When reattaching the holders to the scanner unit,

assemble the parts so that the holders will be in

front of the triangle ribs of the ISU frame. (If the

holders are behind the triangle ribs, the scanner

unit cannot be closed.)

7-6. Release the hook (x4) and then remove the upper

middle cover.

Spring

Holder

Holder

Holder

Holder

[Attachment of the right holder]

(Normal) (Wrong)

Holder

Triangle ribs

Upper middle cover

Hook

Hook

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 20/45)

Page 21

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

7

7-7. Remove the CCD wire and the LCD wire from the wire

holder 1.

Remove the screw and then remove the wire holder 2

with DP wire/Operation wires/Ground wire/Motor wire.

7-8. Remove the spring from the right side hinge and then

pull out the pins.

7-9. Remove the scanner unit with Document Processor.

(Note)

Put the scanner unit by turning it over in order to

prevent damage of the wires after detaching.

(Machine inner right side)

電線ホルダー

Scanner unit with DP

Spring

Pin

Pin

CCD wire

DP wire/Operation wires/Ground wire/

Motor wire (The wires are fixed in the wire

holder 2 by the band.)

LCD wire

Wire holder 1

Screw

Wire holder 2

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 21/45)

Page 22

(Page 22/45)

No.

Procedure

Illustration/Remarks

8

Release each of the hooks (x4) and the claw. Then,

remove the top right cover and the top left cover.

--> For MFP model, go to the Procedure 9.

For printer model, go to the Procedure 11.

(Note)

When reattaching the top left cover and the top right cover

to MFP model, in addition to the hooks and the claw

above, attach the ribs and the hole to the ISU left and right

frames also. (The ribs and the hole are circled with red

dotted line in the figure.)

9

<For the MFPs only>

Remove the screw (x2) and then remove ISU right frame.

Remove the screw (x3) and then remove ISU left frame.

(One screw among the three screws is tightened behind

the spring.)

Top left cover

for MFP

(Top right cover for MFP) (Top right cover for Printer)

O indicate the hooks. (*) The location of each

cover is common.

Top right cover for MFP

(Top left cover for MFP) (Top left cover for Printer)

O indicate the hooks. (*) The location of each

cover is common.

Claw

Claw

Claw

Claw

Screw

Screw

ISU left frame

ISU right frame

Spring

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 23

(Page 23/45)

No.

Procedure

Illustration/Remarks

10

<For MFPs only>

Release the hook (x2) at the front side of the wire holder.

Also, release the wire holder by opening it from the claw

(x2) on the rear side to the arrow direction in the photo to

the right.

11

Disconnect the connector of the exit sensor wire

and then remove the wire from the aligning rib (x5) on the

top of the exit upper guide.

12

<For the MFPs>

Remove the screw (x3) and then remove the exit upper

guide.

<For the printers>

Remove the screw (x5) and then remove the exit upper

guide.

<Wire holder>

(Rear of this part)

Hook

Claw

Hook

Connector of the exit

sensor wire

Aligning ribs

Exit upper guide

(Top)

Exit upper guide

Screw

Screw

Screw

Screw for the printer model only

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 24

(Page 24/45)

No.

Procedure

Illustration/Remarks

13

Detach the fuser unit.

* These procedures are described in the Service

Manual 1-5-7 [(1) Detaching and refitting the fuser

unit].

(Details)

13-1. Remove the connector (x3).

13-2. Remove the screw (x2) and then remove the fuser

unit.

(Note)

Take care not to pinch the cables when refitting the fuser

unit.

14

Disconnect the connectors and the following FFC (YC23,

YC19, YC24, YC37, YC38, YC15, YC25, YC11, YC26,

YC12, YC30, YC28) from the engine PWB.

Connector

Connector

Fuser unit

Screw

Engine PWB

Engine PWB

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 25

(Page 25/45)

No.

Procedure

Illustration/Remarks

15

Remove the connector, screw and hook.

Remove the wire (white/black/red) from the wire aligning

ribs of the developer fan unit and then remove the

developer fan unit.

16

Remove the screw (x3), release the hook (x2). Then,

remove the fuser pressure drive unit.

(The wire of the fuser pressure drive unit is kept

connected with the toner motor holder even after

removing.)

Connector

Screw

Hook

Developer fan unit

Wire

aligning

ribs

(Rear of the developer fan unit)

Hook

Fuser pressure drive unit

Hook

Screw

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 26

(Page 26/45)

No.

Procedure

Illustration/Remarks

17

Release the both side fulcrum parts of the top tray by

tilting either the left or right frames outwards, and remove

the top tray forward.

(The left and right frames become movable after removing

the fuser pressure drive unit in the Procedure 16, and the

top tray can be removed without applying loads for the

fulcrum parts.)

(Note)

The shape of the fulcrum parts is same while the whole

shape of the top tray differs between the MFPs and printer

models.

18

Release the hook (x4) and then remove the exit lower

guide.

Exit lower guide

Hook

Top tray

Left and right frames

(Open to arrow direction.)

* The left and right side shapes of the

fulcrum parts of the machine/top tray are

symmetrical.

(Machine left side)

Y

X

<Fulcrum part>

X

Y

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 27

(Page 27/45)

No.

Procedure

Illustration/Remarks

19

Release the hook (x3) and then remove the exit lower

housing.

Hook

Exit lower housing

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 28

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

20

Detach the toner container right guide.

20-1. Remove the inner tray switch wire, the USB wire

and the FFC wire from the hook shapes of the

toner container right guide at the machine right

frame. (FFC wire is for the Printer model only.)

20-2. Disconnect the connector from the toner container

sensor.

20-3. Remove the interlock switch fixed by the claw (x2).

20-4. Release the hook (x4) on the upside using the flat-

blade screw driver, and remove the toner container

detection holder by opening it in the arrow direction

as shown in the figure.

20-5. Remove the screw fixing the toner container right

guide.

(Right frame viewed from outside)

(Right frame viewed from inside)

Toner container detection holder

Hooks on the upside

:Hooks on the HOLDERJOINT in the

HOLDER JOINT ASSY.

゙

USB wire

゙

Inner tray switch wire

FFC wire

Interlock switch

Claw

Toner container

sensor

Connector

Screw

Toner container right guide

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 28/45)

Page 29

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

20

20-6. Release the hook (x5) of the toner container right

guide.

20-7. Release the hooks A and B inside of the machine by

following the procedures below.

[Note]

Take care not to damage the hooks A and B during

this release process.

1) Release the hook A (x3) from the front side while

pushing the protrusion (1) of outside of the right

frame to the inner direction.

When releasing the hook, insert a flathead screw

driver with thin leading edge lengthwise into the

inner part of the section where the hooks are

fixed and then rotate the hook A

counterclockwise (Note1) to remove it. (Fig.1)

2) While pushing the protrusion (2) to the inner

direction, insert a flathead screw driver lengthwise

into the inner part of the section where the hook B

is fixed and then rotate the hook B clockwise

(Note1) to remove it. (Fig.2)

3) Pull the LEVER INTERLOCK of the rear side of

the toner container right guide forward and

remove the toner container right guide. (Fig.3)

(Note1)

The directions of rotating the hooks A and B are the one

from inside of the machine.

If technician stands at the machine right side, the rotating

direction becomes counter direction.

Rotate the hooks A and B in the arrow direction shown in

Fig.1 and Fig.2.

(Right frame viewed from outside)

* The arrows above indicate the direction for

pushing the protrusions in the Procedure 20-7.

(Right frame viewed from inside)

Fig.2

Square hole of

the right frame

Hook B

Protrusion (1)

Protrusion (2)

Hook

Hook

Toner container right guide

Hook A

(Front)

(Back)

Hook B

Fig.1

Square hole of

the right frame

Hook A

Fig.3

LEVER INTERLOCK

Toner container right guide

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 29/45)

Page 30

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

(B)

[How to replace the HINGE LID R]

If the HINGE LID R is damaged on FSC2026MFP/C2126MFP, replace the HINGE LID R with the

new one (302KV0254_: the part with material change).

※ サービ

(B)-1. Remove the HOLDER JOINT ASSY, RATCHET

SHUTTER, HOLDER JOINT ASSY, the gear (X),

the rack and HINGE LID R fitted on the toner

container right guide.

(B)-2. Reattach the new HINGE LID R with the angle of

closing the top tray. (Fully rotate the HINGE

clockwise as shown in the figure to the right.)

(B)-3. Shift the rack to the HINGE side till the hole of the

new HINGE LID R is visible from the hole of the rack.

Hook the upside of the rack on the claw (x4) of the

toner container right guide and then reattach the rack.

(The shape to push the LEVER of the rack runs over

the rib attaching the HOLDER JOINT ASSY by the

shifting work. (Fig.4) This state should be kept until

the HOLDER JOINT ASSY. is reattached.

Even if the rack runs over the rib, it does not affect

the operation since it will be released by the HINGE

rotation or the rack's sliding operation.)

(B)-4. Reattach the gear (X) when the HINGE LID is at the

angle of closing the top tray and the rack is fully

shifted to the HINGE side.

After reattaching, check if the teeth of the gear (X)

are engaged in the teeth of the HINGE and of the

rack. (Fig.5)

--> Go to the next procedure.

<Toner container right guide>

Rack

New HINGE LID R

Hole

Shift the HINGE side

Shape pushing LEVER

HOLDER JOINT ASSY

HINGE LID R

Rack

Gear (X)

RATCHET SHUTTER

Fig.4

Part where the rack runs

over the rib.

Rack

(It is translucently

indicated in the figure.)

Gear (X)

Gear (X)

HINGE LID R

Rac

Fig.5

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 30/45)

Page 31

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

(C)

[How to replace the RATCHET SHUTTER]

Replace the RATCHET SHUTTER with the new one

(302KV0250: The part with 1 or later as the last digit) in

order to improve the operability when fully opening the top

tray.

<New RATCHET SHUTTER>

(C)-1. If the HOLDER JOINT of HOLDER JOINT ASSY is

contaminated by toner, clean it or replace it with the

new one (302KV0251_).

Afterwards, reassemble the HOLDER JOINT ASSY

by following the procedures below.

1) Install the spring into the center shaft of the

HOLDER JOINT.

2) Insert the JOINT into the HOLDER JOINT while

aligning the keyhole of the JOINT with the

convex part of the center shaft of the HOLDER,

and rotate the JOINT to fix it. (Fig.6)

3) Check if the flanges of the JOINT pass over

upside of the ribs of the HOLDER JOINT by

rotating JOINT. Also, check if the opening shape

at the engaging rib of the JOINT is horizontal.

<Attachment of the RATCHET and the HOLDER JOINT

ASSY.>

(C)-2. Align the notch of the new RATCHET SHUTTER to

the bending part of the toner container right guide

and then install RATCHET. Also, engage the first

tooth of the new RATCHET and the first tooth of the

rack (first tooth from the machine front side).

(Fig.7)

(C)-3. Attach the HOLDER JOINT ASSY to the section

where the new RATCHET is installed in the

Procedure (C)-2. (Insert the both claws and both

protrusions of the HOLDER JOINT ASSY into the

holes of the toner container right guide.)

(C)-4. Check if only two teeth of the rack are visible from

the backside hole. (If three teeth or more are visible,

the part should be reassembled.)

(C)-5. Repeat the procedures (C)-2 to (C)-4 for the

remaining sections (x3).

(Note)

Execute (C)-2 and (C)-3 above when pushing the rack

to the HINGE LID R side.

A distinction rib was added

to the new part.

(Fig.7)

New RATCHET SHUTTER

HOLDER JOINT ASSY

(Note)

<HOLDER JOINT ASSY>

HOLDER JOINT

(302KV0251_)

Fig.6

<HOLDER JOINT

with the spring>

<JOINT>

Keyhole shape

Convex part

Insert

Lock JOINT's

position by

rotating it.

Flange

Flanges of JOINT should pass over

upside of the rib of HOLDER.

Rack

Positioning part (RATCHET's notch and

the guide's bending part)

Rack

New

RATCHET

Engage 1st

tooth each

other.

Protrusion

Claw

Claw

Protrusion

: Opening shape

Only 2

teeth of

the rack

are

visible.

JOINT

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 31/45)

Page 32

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

(D)

[How to replace the LEVER INTERLOCK]

If the message "REAR COVER OPEN" is frequently

displayed after slowly closing the top tray while the rear

cover is closed, replace the LEVER INTERLOCK with the

new one (302KV0252: 1 or later as the last digit).

<New LEVER INTERLOCK>

(D)-1. Remove the spring (Y).

(D)-2. Replace the LEVER INTERLOCK with the new one.

Hook the rib (x2) of the guide to the holes of the new

LEVER and insert the fulcrum shaft into the LEVER.

(D)-3. Hook the spring (Y) to the hook of the toner

container right guide and to the hole of the LEVER

INTERLOCK in the arrow direction as shown in the

figure to the right. (Refer to the normal and wrong

states.)

(D)-4. Check LEVER INTERLOCK can normally return

by pushing the rear edge of LEVER horizontally.

<Toner container right guide>

Distinction rib added to the

new LEVER

LEVER INTERLOCK

Spring (Y)

Rib

Fulcrum shaft

Rib

LEVER INTERLOCK

(Normal state) (Wrong state)

Spring (Y)

The spring should

not run over the

corner of the

guide.

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 32/45)

Page 33

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

21

Reattach the toner container right guide to the machine.

Then, reconnect and realign the connectors and the wires

that were removed in the Procedure 20-1 to 20-4.

Also, reattach the toner container detection holder.

After reattaching, check the following points.

1) Check if the HINGE LID R is at the same angle as the

one for closing the top tray.

(The rib of the HINGE LID R should not be higher than

the upside of the toner container right guide. Please

refer to the figure to the right.)

2) Check if two teeth of the rack are visible from every

JOINT section.

3) Check if the opening shape at the engaging rib of the

JOINT is horizontal as shown in the figure to the right.

HINGE LID R

Toner container

right guide

Correct Wrong

HINGE's rib

Upside of the toner container right guide

2 teeth of

the rack

JOINT

: Opening shape

<Angle of the opening shape>

(Other than 5150DN)

(Correct) (Wrong)

<Angle of the opening shape>

(5150DN only)

(Correct) (Wrong)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 33/45)

Page 34

(Page 34/45)

No.

Procedure

Illustration/Remarks

21

4) Check if the actuator to switch the toner container

sensor contacts the front side of the toner container

detection holder after the toner container detection

holder with the hook (x8) was reattached.

(Right frame viewed from outside)

(Front side)

Toner container detection holder

The parts should contact.

Actuator to switch the toner container

sensor

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 35

(Page 35/45)

No.

Procedure

Illustration/Remarks

22

Detach the toner motor holder from the machine left side.

22-1. Remove the duplex motor wire connected to the

connector YC37 on the engine PWB from the

aligning ribs of the low side of the toner motor

holder.

22-2. Remove the FFC wire connected to the connector

YC12 on the engine PWB from the aligning rib of

the front side of the toner motor holder.

22-3. Remove the screw fixing the front side of the toner

motor holder.

(Left frame viewed from the machine left side)

Duplex motor

Toner motor holder

Aligning ribs

Screw

Aligning

rib

FFC wire

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 36

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

22

22-4. Disconnect the connector from the PWB of the

intermediate transfer drive unit and remove the

screw fixing the toner motor holder.

22-5. Release the hook (x6).

22-6. Open the toner motor holder to the machine left side

and then remove the ID sensor holder from inside

the toner motor holder.

22-7. Remove the toner motor holder.

22-8. Clean the jointing hole (x4) with dry cloth from the

machine left side.

Screw

Connector

Intermediate transfer drive unit

Toner motor holder

Toner motor holder

O indicates 6 hooks.

ID sensor holder

Jointing holes

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 36/45)

Page 37

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

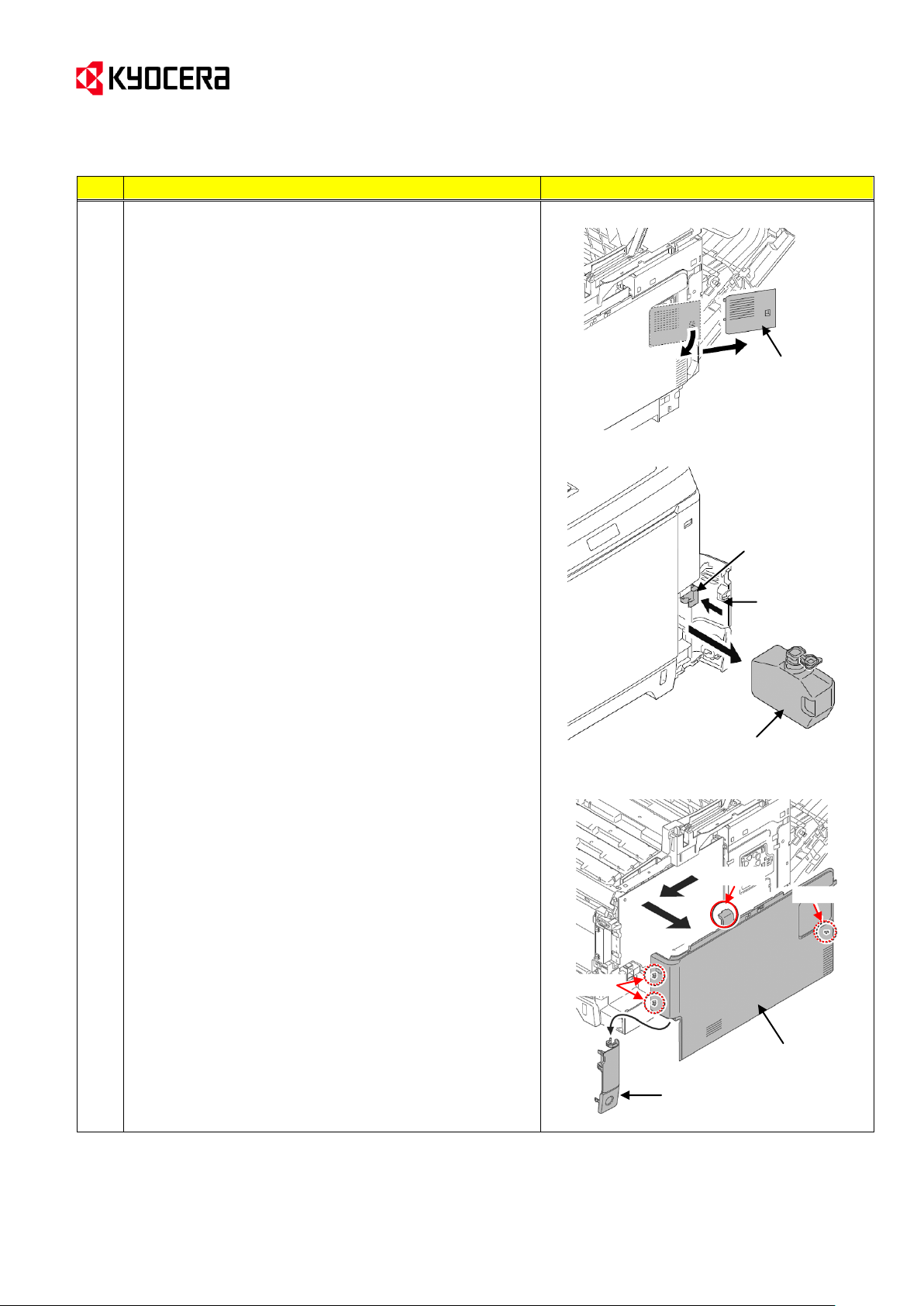

(E)

[How to replace the HINGE LID L]

Replace the HINGE LID L with the new one (302KV0253_:

the parts changing its material) by following the

procedures below if the HINGE of FSC2026MFP/C2126MFP is damaged.

(市場供給品は全て新材料品)

(E)-1. Remove the screw and release the hook (x9).

Then, remove the toner container left guide from

the left frame.

(E)-2. Remove the old left hinge gear and the gear (X)

from the toner container left guide.

(E)-3. Install the new left hinge gear at the angle for

closing the top tray. (It contacts the rib of the toner

container left guide at the state of the right figure.)

(E)-4. Slide the rack at the toner container left guide

backward (the left hinge gear side).

(E)-5. Rotate the gear (Y) clockwise by one tooth.

* Confirm that there is space of approx. 3 mm

between the rib of the guide and the claw of the

rack lower part.

(E)-6. Refit the gear (X).

(E)-7. Refit the toner container left guide to the left frame.

O indicates 9 hooks.

HINGE LID L

Gear (X)

Gear (Y)

About 3mm

Rack

Screw

Toner container left guide

HINGE LID L

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 37/45)

Page 38

(Page 38/45)

No.

Procedure

Illustration/Remarks

(E)

(E)-8. Check if the rib edge of the rack is invisible from

the aperture of the left frame after reassembling.

(If it is visible, the angle of the HINGE LID L is not

same as the state when closing the top tray. In

this case, reassemble the parts after checking the

toner container left guide.)

Left frame

(Normal) (Wrong)

<Rack>

Rib edge

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 39

(Page 39/45)

<Joint part>

CAM

Groove

Groove

No.

Procedure

Illustration/Remarks

(F)

[How to replace the CAM TONER SUPPLY]

When the toner can be supplied and the message for

instructing the toner replacement frequently appears due

to the engaging failure between the toner motor joint at the

machine left side and the joint gear of the toner container,

replace 4 pcs of CAM TONER SUPPLY with the new parts

(302KV0246: 1 or later of the last digit parts number) by

the following procedures.

(F)-1. Remove 4 pcs. of the old CAM TONER SUPPLY

from the toner motor holder.

(F)-2. Attach the new CAM TONER SUPLY on the toner

motor joint by inserting the claw (x2) into the

grooves of the guide.

(F)-3. Check if the toner motor joint does not idle by

rotating. (At that time, the convex part of CAM faces

the lower right direction.)

(F)-4. Reattach the toner motor holder by tightening the

screw (x2) and hooking the hook (x6).

<Toner motor holder>

(Left frame side)

(View from backside)

[Attachment]

CAM TONER SUPPLY

Claw

Claw

Claw

Claw

CAM's convex part

(Normal state is in the

photo on the next

page.)

Toner motor joint

(Different shape

according to the

model and spec)

<New CAM TONER SUPPLY>

The edge of the new

part is cut for

distinction.

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 40

Service Bulletin Ref. No. 2KT-0019 (D012)

No.

Procedure

Illustration/Remarks

(F)

[Note]

Check the following points when refitting the toner motor

holder.

1) Check all convex parts of the cam at the toner motor

joint face the lower right at the angle of the HINGE LID

L at the state of closing the top tray. (Please refer to

the figure.)

2) Check if all hooks (x6) of the toner motor holder are

surely hooked the left frame.

(Note)

If the hook is insufficiently hooked, toner supply failure

might occur.

3) Check if the film (x2) affixed at the upside of the

engine PWB are not pinched between the toner motor

holder and the left frame.

2 films

Engine PWB

Toner motor holder

O indicates hooks.

Toner motor holder

Convex part of

CAM at the toner motor joint

HINGE LID L

(Angle when the top tray

is closed.)

Normal

Wrong

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

(Page 40/45)

Page 41

(Page 41/45)

No.

Procedure

Illustration/Remarks

(F)

4) Check if the film to clean the ID sensor installed inside

of the toner motor holder does not twist at the aligning

rib. Then, slide the switch of the ID sensor back and

forth to see if it be can be normally slid.

23

Reassemble all parts and the unit detached in the reverse

order of the disassembly.

24

After reassembling, affix the LABEL SET ISU to the right

holder of the scanner unit if necessary.

<LABEL SET ISU (302KW3404_)>

* This is the label to clearly indicate the scanner unit's

lock position when the top tray is fully opened.

(The lock position is where the corner of the triangle

shape of the right holder comes to the engraving on

the right upper cover.)

<Procedures>

1) Open the top tray.

2) Clean the triangle shape of the fulcrum part of the

scanner unit's right holder with alcohol.

3) Affix the LABEL SET ISU according to the alignments

shown in the figure.

[Alignments]

Engraving to

indicate the

lock position

when opening

the top tray

Right holder

Align to the rib

Rib

Align to the edge of the holder

0.5mm

0.5mm

LABEL SET ISU

(302KW3404_)

ID guide

Switch of the ID sensor

Film to clean ID

sensor

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 42

(Page 42/45)

No.

Procedure

Illustration /Remark

1

Remove the cassette.

2

Release the hook (x4) indicated by the

triangle engravings and remove the cover

from the cassette right rear side.

3

Release the hook (x2) and remove the

bottom plate from the side of the hooks.

Cassette

250-sheets cassette

Hook

Cover

Bottom plate

Hook

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

G: [How to attach the new STOPPER HOOK and the SPRING STOPPER HOOK only for the machine with

250 sheets cassette]

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 43

(Page 43/45)

No.

Procedure

Illustration /Remark

4

Lift up the center hook using a flathead

screwdriver and remove the stop ring in

the direction of the arrow as shown in the

figure.

5

Pull out the shaft and remove the old

STOPPER HOOK.

250-sheets cassette

<Stop ring>

Lift up the center hook

Shaft

(Cassette rear side)

Old STOPPER HOOK

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 44

(Page 44/45)

No.

Procedure

Illustration /Remark

6

Attach the SPRING STOPPER HOOK

(No.4) to the new STOPPER HOOK

(No.3). At that time, put the edge of the

SPRING (hooking shape) on the bottom

side of the new STOPPER.

<New STOPPER HOOK ASSY>

7

Attach the new STOPPER HOOK ASSY

to the cassette rear side.

At that time, put the edge of the SPRING

on the cassette’s base.

8

Reinsert the shaft removed in the Step 5

and fix the new STOPPER HOOK ASSY.

Note the following points when reinserting

the shaft.

1) Confirm that the gear attached to the

shaft’s right edge is engaged with the

bottom plate drive gear.

(Backside of the left figure:

Bottom)

SPRING STOPPER HOOK (No.4)

Put the edge of the SPRING.

New STOPPER HOOK

(No.3)

New STOPPER HOOK ASSY

Put the edge of the SPRING on the base.

Gear Bottom plate drive gear

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Page 45

(Page 45/45)

No.

Procedure

Illustration /Remark

8

2) Pass the shaft over the ground spring.

3) Reinsert the shaft’s left end (oval

shape) into the plate’s square hole

while aligning it to its directions.

9

Reassemble other parts in the reverse

order of disassembly.

Ground spring

Shaft

New STOPPER HOOK ASSY

Plate square hole

(It is located sideward.)

<Shaft>

Left end (Oval shape)

Service Bulletin Ref. No. 2KT-0019 (D012)

[Service Information] <Date> April 8, 2013

KYOCERA Document Solutions Europe

Customer Services & Support Division (CSSD)

Loading...

Loading...