Kyocera DF-600 Service Bulletin AS 118

1 / 2

Service Bulletin

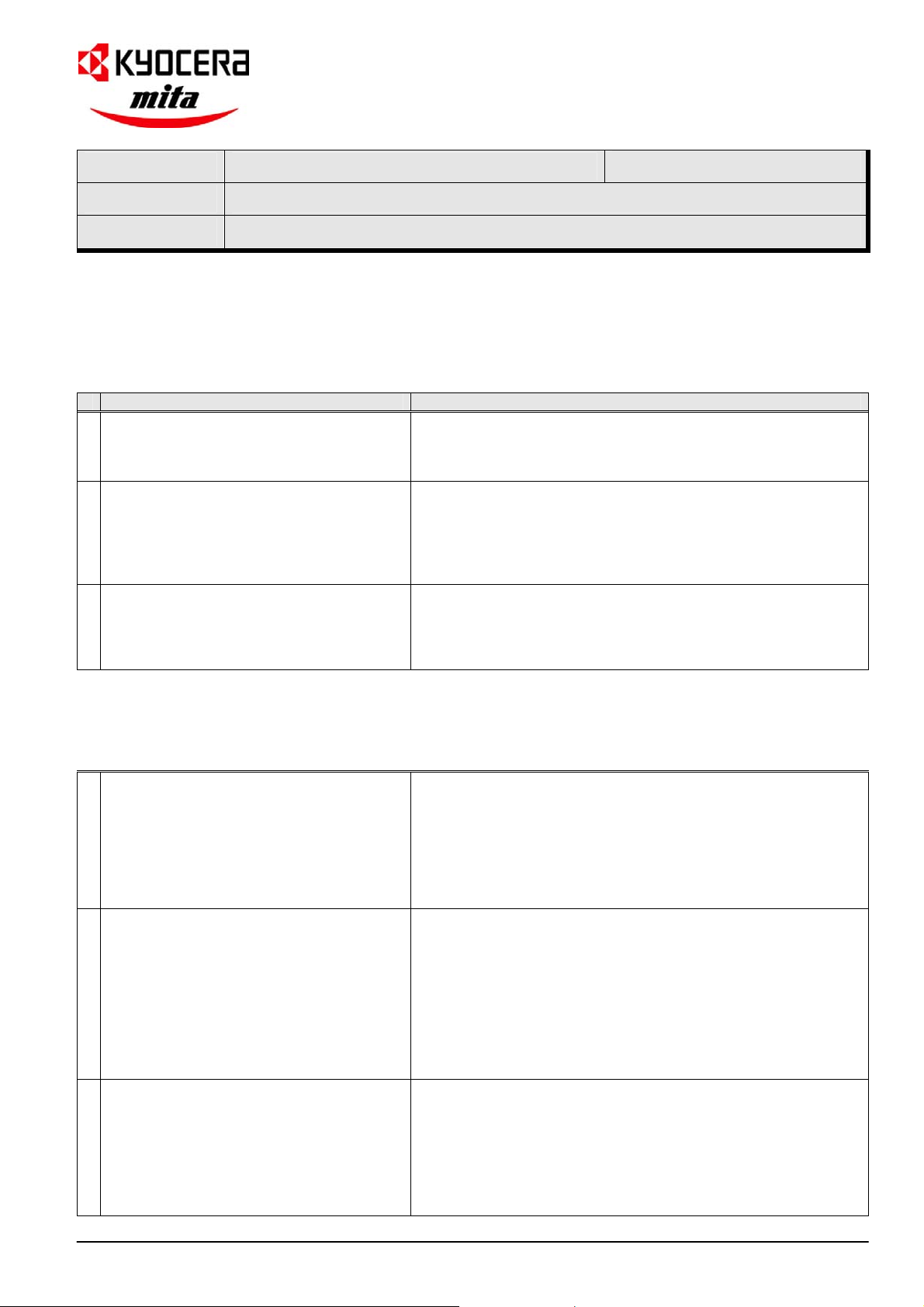

SB Number:

SB AS-118

Issue Date: 01/03/2003

Subject: Firmware upgrade (for KM-6330 support)

Model:

Please be informed that the firmware for the DF-600 / 610 has been upgraded as follows.

CONTENTS OF CHANGES

3B829524F → 5G

Item Remarks

1 Malfunction when both front and rear staple

cartridges are empty.

2 Paper misalignment when ejected paper is

stacked on main tray.

3 Mylar of ejection guide in contact with paper

edge when B4 size paper is moved for stapling.

3B829525G → 6H

KM-6330 support: when installing DF-610 in KM-6330, please use this software version!

4 Staple error at 2 points binding

5 Paper jam occurs in feed-in section

6 Jam position is not indicated when staple jam

occurs.

DF-600 / 610 (KM-4530 / 5530, KM-6330)

If both front and rear staple cartridges are empty and one of these two

cartridges is exchanged with a full one, the empty status for the

remaining empty staple cartridge is not detected anymore and user

does not know the one remaining cartridge needs to be filled.

Phenomenon

When A4 or letter size paper is stapled askew at one or two positions,

the ejected bundle may not align properly.

Correction

The ‘OFF’ timing of the ‘SOLENOID, EJECT GUIDE’ has been

changed from 80 msec. to 200 msec. after eject switch is turned on.

When B4 size paper is moved for stapling, the paper edge may catch

behind the ejection guide mylar.

Correction

When B4 size paper is stapled askew at one position on front or rear,

the length of moving is changed from 15 mm. to 18 mm.

Phenomenon

In case of 2 locations stapling, the 2nd location is stapled 100 msec.

after the 1st staple. The 2nd staple may break however due to an

incomplete stapling process because the timing of 2nd stapling is

during the peak of electric current (from staple motor).

Correction

Software has been changed so that the 2nd point is stapled 200 msec

after the 1st point is stapled.

Phenomenon

In below situation, any jammed paper on the middle tray cannot be

removed because main tray is not going down.

Situation

- The 2nd sheet of paper jams between the copier and finisher when

using the job tray.

- Although the jammed paper can and is removed according to the

steps indicated on operation panel, the main tray will not go down.

Correction

Software has been changed so that the main tray goes down normally.

Phenomenon

In case of staple copy, before the start of stapling, if the connector of

stapler comes off, and consequently a paper jam occurs, the position of

jammed paper and guidance may not be indicated.

Correction

Software has been changed so that the position of jammed paper and

guidance are indicated normally on operation panel.

KMIS Service Team, Kyocera Mita Europe 5570 / SB AS-118

2 / 2

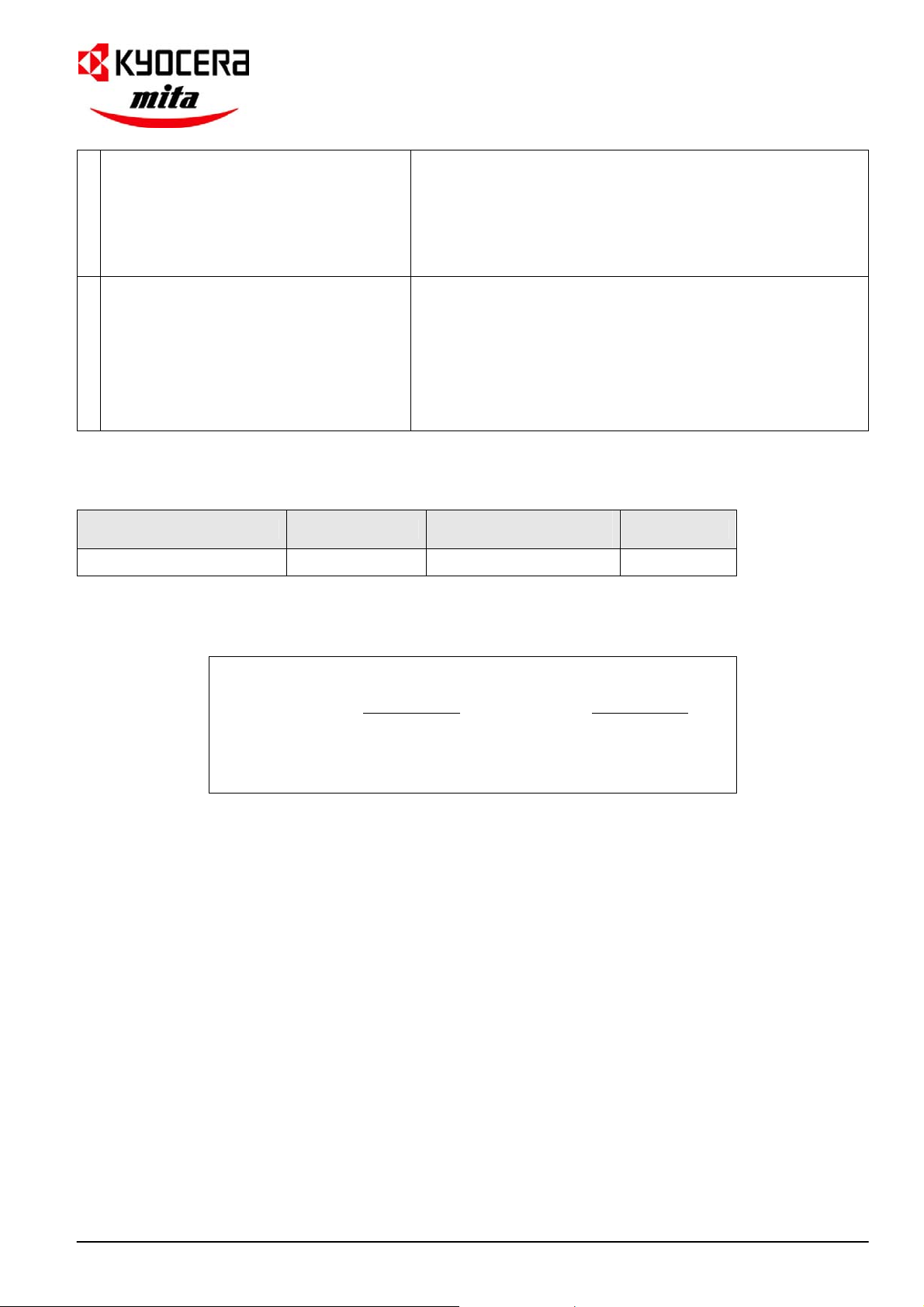

Service Bulletin

7 Letter size paper may catch behind standard

plate (P/N: 3B80713/0714) (no-stapling setting)

8 Staple cartridge is inserted halfway.

Firmware information

Program no.

Software Main (finisher) 3B829526H P3B82952.6H0 6FD7

Phenomenon

In no-stapling setting, Letter size paper / metric may catch behind the

standard plate.

Correction

Software has been changed so that in case of A4R, LETTER R,

8.5"x14" and LETTER (metric), the standard plate will not move when

paper bundle is lifted.

Phenomenon

When machine performs initializing movement while staple cartridge is

inserted only halfway, the stapler motor may catch behind the cartridge

and locks. After that, JAM00 may not be indicated and the cartridge

cannot be released.

Correction

Stapler motor is reversed so that it does not lock if ‘time out’ occurs

during the waiting time of stapler motor home sensor "ON". If home

sensor is returned to "ON", the message of "Staple empty" is indicated.

File Name

(after decompressing)

Checksum

Please make sure to use above version or later when installing the finisher to the KM-6330.

Affected Machine Serial Numbers:

‘3B829525G’ ‘3B829526H’

DF-600: G3001919 and later G3005214 and later

DF-610: F3003555 and later F3004975 and later

KMIS Service Team, Kyocera Mita Europe 5570 / SB AS-118

Loading...

Loading...