Page 1

A

UPDATE 10/12/04: Parts info added on page 6

1 / 6

Service Bulletin

SB Number:

SB AS-131

Subject: DF-600 / DF-610 and PH-3A/3C change for KM-7530

Model:

DF-600: KM-4530 / DF-610: KM-4530/5530/6330/7530

Please be informed that a number of parts on the DF-610 have been changed and improved in order to use

this finisher perfectly in combination with the KM-7530. (DF-600 is also affected by these changes as some

parts are shared with the DF-610.)

Attention:

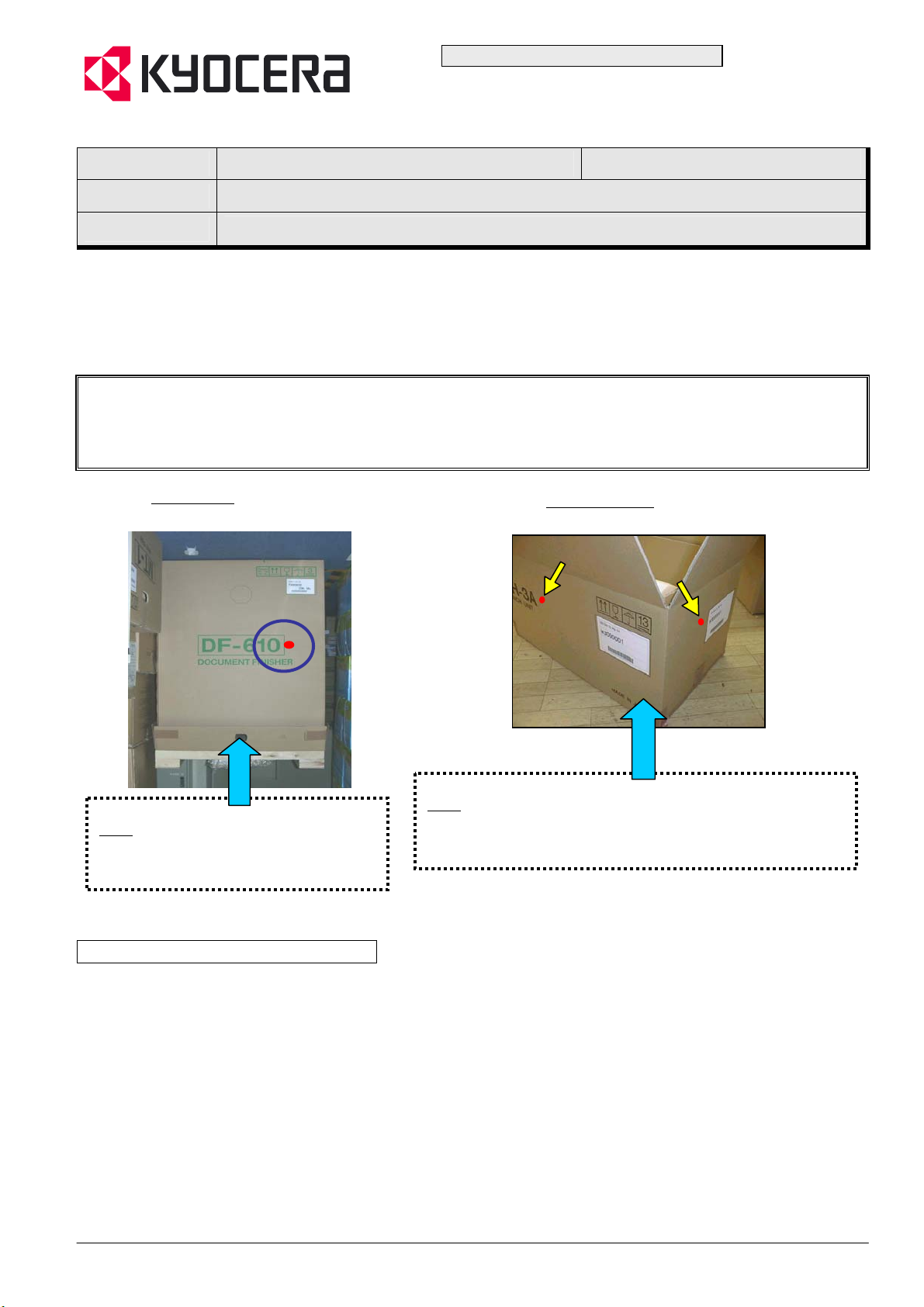

When installing the DF-610 to the KM-7530, please check if it is the new / slightly modified DF-610.

When installing the punch unit (PH-3A/PH-3C) to the KM-7530, please check if the punch unit is the new / modified type..

A distinction can be made between old and new type by a marking seal, which has been added to the outer packaging of the

new types.(see photos below.)

A round red seal is attached next to DF-610.

Note:

As for the DF-610 that supports the

KM-6330, a green seal is attached instead.

DF-610 CONTENTS OF CHANGES

CHANGE 1.: Noise reduction at paper conveying

Paper conveying noise may increase because the usage frequency of the siding drum goes up.

In order to prevent any noise, if present, the following change has been done.

• ‘RIGHT GUIDE, SUB CONVEYING’: ribs were added.

• ‘GUIDE, FEED SHIFT SUB EJECT’: shape of claw changed.

• ‘SHAFT, CONVEYING DRUM’: fixation pin for drum and gear is changed from ∅2 spring pin to ∅2.5 parallel

pin to create a more stable fixation of drum and gear. In compliance with change of pin, the size of the hole

in the shaft also needed to be changed.

• ‘SHAFT, CONVEYING DRIVE’: size of hole in the shaft has been changed.

CHANGE 2.: Improving tolerance for clutch locking

• ‘CLUTCH 33, CONVEYING’: ‘spring clutch’ has been changed to ‘electromagnetic clutch’ in order to

improve tolerance against clutch locking due to the unsuccessful recovery of spring,

NEW DF-610 for KM-7530

DF-600 / 610, PH-3A / 3C

marking seal

round red seal is attached next to the Punch unit’s name.

Note:

As for the DF-610 that supports the KM-6330, a green seal is

attached instead. (see SB 2CJ-004)

Creation Date: 22/09/2004

NEW punch unit for KM-7530

marking seal

KMIS Service Team, Kyocera Mita Europe 5794 / SB AS-131

Page 2

N

UPDATE 10/12/04: Parts info added on page 6

2 / 6

Service Bulletin

CHANGE 3.: Measures for the erroneous operation

‘MAIN PCB’ has been changed to prevent PI (photo interrupter) erroneous operation and to improve tolerance

due to the increase of processing number of the sheets.

New version Main PCB mentions ‘VER 3’ (REV 3).

• ‘MAIN PCB ASS'Y’: Q30 is removed and the number of relay poles has been changed from 1 to 2.

In order to secure good operation, the number of the elements (transistor) has been changed from 4 to 6.

(staple motor drive circuit is changed.)

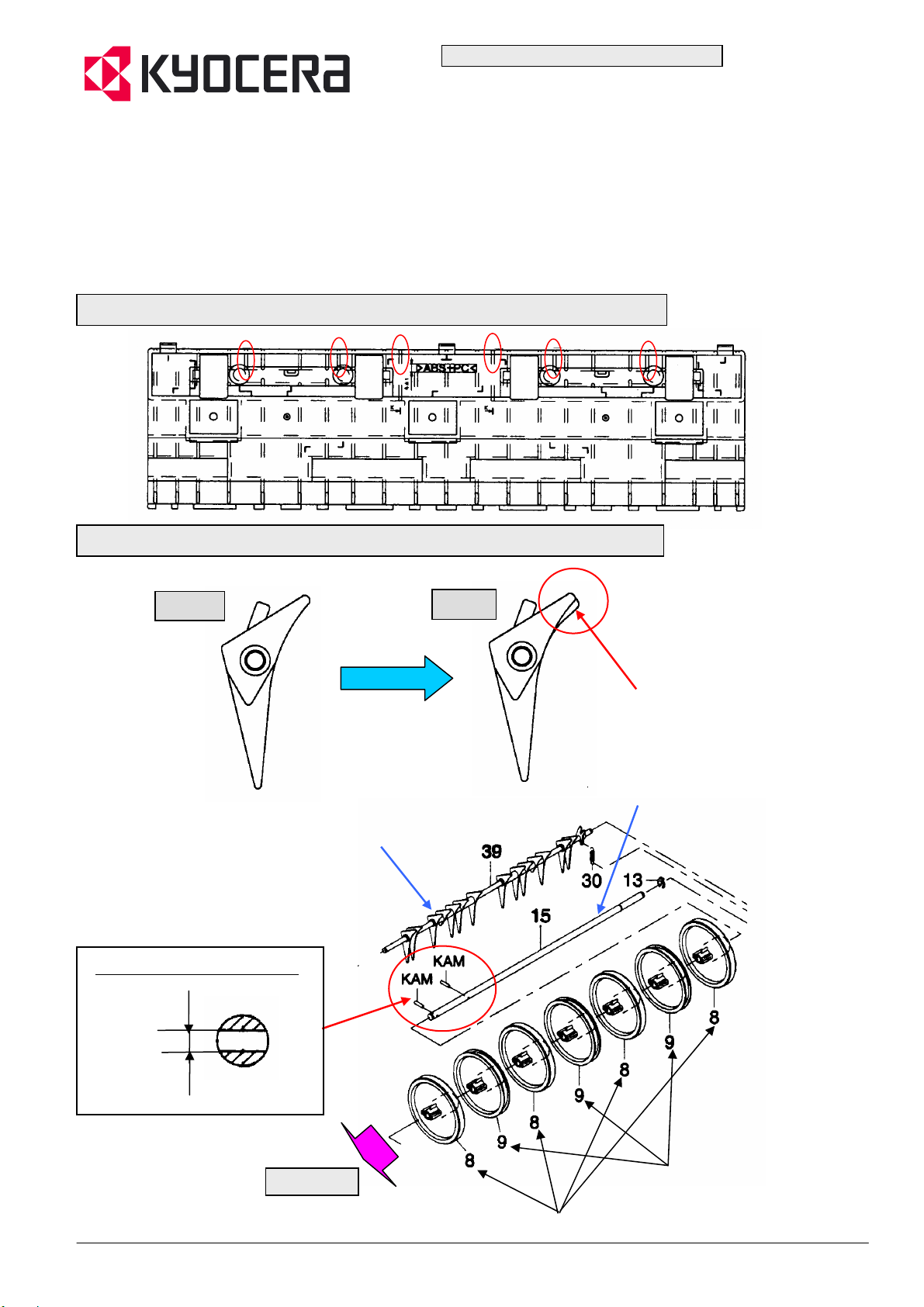

‘RIGHT GUIDE, SUB CONVEYING’: ribs are added as circled below for noise reduction

‘GUIDE, FEED SHIFT SUB EJECT’: shape of claw has been changed for noise reduction.

OLD

EW

‘SHAFT, CONVEYING DRUM’

‘GUIDE, FEED SHIFT SUB EJECT’

By changing the fixation pin from ∅2 spring

pin to

∅

the shaft is also changed.

2.5 parallel pin, the size of hole in

Dimension change of hole for pin

2.3 → 2.5

Gear side

‘GUIDE A, DRUM’

point of claw widened.

‘GUIDE B, DRUM’

KMIS Service Team, Kyocera Mita Europe 5794 / SB AS-131

Page 3

g

UPDATE 10/12/04: Parts info added on page 6

3 / 6

Service Bulletin

Gear and ‘FRONT FRAME’ side

By changing the fixation pin from “

to “

∅

2.5 parallel pin”, the size of hole on the shaft

is also changed.

‘SHAFT, CONVEYING DRIVE’

‘CLUTCH 33, CONVEYING’: ‘spring clutch’ is changed to ‘electromagnetic clutch’

OLD

‘MAIN PCB ASS'Y’ chan

e

Q30 removed and number of relay pole changed from 1 to 2.

∅

2 spring pin”

Dimension change of hole for pin

2.3 → 2.5

NEW

Number of elements (digital transistor)

changed from 4 to 6.

KMIS Service Team, Kyocera Mita Europe 5794 / SB AS-131

Page 4

UPDATE 10/12/04: Parts info added on page 6

Service Bulletin

Version indication: REV 2 → REV 3

CHANGE 4.: Finisher software upgrade

F/W information Program No. File Name

DF-610 with

KM-7530

Software Main (Finisher) 3B829527J P3B82952.7J0 E1A7

Please upgrade finisher to above level or later when using in combination with KM-7530.

CONTENTS OF SOFTWARE UPGRADE

Item Remarks

Stack count for centerfold is cleared

1

when paper jam occurs.

(this only occurs on DF-610)

Message of main tray overflow for

2

1500 sheets detection appears and

disappears at straight ejection

(both DF-610 and DF-600)

Adding the tray full count when the

3

paper is ejected to the main tray

after saddle stitching.

(DF-610 only)

When paper with centerfold is stacked, the set count should be cleared if there is

no more paper on the tray. However, if the centerfold unit is pulled out at that time

(when there is for example a paper jam), the communication between the finisher

and the centerfold unit is interrupted. Then, if the communication task restarts the

receiving buffer is cleared and ‘paper empty’ on the tray is detected. As a result,

the stack count for centerfold is cleared.

→ Software has been changed so that the counter is not cleared when there is

paper on the stack tray for centerfold, even if the centerfold unit is pulled out and

put back.

When the centerfold unit is installed, ‘main tray overflow’ is detected at 1,500

sheets. However, the main tray goes up and down at every straight ejection and

the tray detection sensor for 1,500 sheets is hereby turned on and off. Because of

this, the message ‘main tray overflow’ appears and disappears repeatedly.

→ S/W has been changed to solve this.

Phenomenon

In the main tray ejection mode, when the paper is ejected with saddle stitch and

staple, if the number of the stacked paper is increased, paper may jam at the

ejection side.

Change

Software is changed as follows.

• Count the sets of ejected paper with saddle stitch and staple to the main tray,

and give the notice of the main tray full to the copier at 50 sets count so that the

copier stops the operation.

Enlarged photo: Q30 removal section / relay pole section

Change of relay: number of poles changed from 1 to 2.

Check SUM Software for

(After decompression)

4 / 6

Q30 removed

KMIS Service Team, Kyocera Mita Europe 5794 / SB AS-131

Page 5

N

UPDATE 10/12/04: Parts info added on page 6

5 / 6

Service Bulletin

4 Addition of Sim. 237 (= ‘Setting

the number of stacked sheets on

the main tray’)

This simulation is added for both

DF-610 and DF-600.

Presently this simulation is

supported in combination with

KM-7530 only. In future, this

simulation will be also supported

with KM-6330, KM-4530 and KM-

5530. Details will follow later.

PUNCH UNIT CONTENTS OF CHANGES

CHANGE 1.

In order to prevent the paper from twisting / bending due to the increase of peripheral speed, the number of

rotation for punch cam shaft has been increased. Additionally, in order to secure the stopping accuracy of the

cam shaft, the structure of ‘UNIT, PUNCH’ (= component part of ‘PUNCH ASS’Y’) has been changed.

• ‘SPRING, STOPPER’:

Dimensions have been slightly changed to prevent the stapling from being performed twice and for

reinforcement due to increase of the rotation numbers for punch.

• ‘SPONGE, STOPPER SUB’:

The thickness is changed from 4mm to 5 mm to reduce noise.

CHANGE 2.

The clutch has been changed to secure proper rotation of the ‘CLUTCH, PUNCH’ due to the raise in

temperature.

• ‘CLUTCH, PUNCH’: shape change

• ‘BUSHING, PUNCH CLUTCH’: newly added.

SPRING, STOPPER

CLUTCH, PUNCH

OLD

Paper might jam or fall due to the paper curl around the time that 3,000 sheets of

paper are stacked without stapling.

Software has been changed so that the number of stacked sheets without stapling

is adjustable to 1,500 sheets or 3,000 sheets by simulation 237.

Sim 237: Setting [0] → Present state

Setting [1] → 1,500 sheets/1,000 sheets support

The following change is made in case of using the small size (*) paper without

stapling.

DF-610: possible to change to 1,500 sheets / 3,000 sheets

DF-600: possible to change 1,000 sheets / 2,000 sheets

* As for larger size, originally, the upper limit is 1,500 sheets or 1,000 sheets.

Ø11 →11.2mm

38.6 → 35.6 mm.

POM

Load: 1.47N → 2.64N

EW

Iron sintering (black)

POM

copper sintering (black)

KMIS Service Team, Kyocera Mita Europe 5794 / SB AS-131

Page 6

UPDATE 10/12/04: Parts info added on page 6

6 / 6

Service Bulletin

Parts Table

No.

Part No.

OLD

1 3B816030 3B816031 RIGHT GUIDE,SUB CONVEYING 1 1 X O

2 3B816520 3B816521 GUIDE,FEED SHIFT SUB EJECT 1 1 X O DF-610 only

3 3B816680 3B816681 SHAFT,CONVEYING DRUM 1 1 X X

4 E0020120 E5125120 PARALLEL PIN H7A 2.5X12 SUS 2 2 X X Used for No.3

5 3B822070 3B822071 SHAFT,CONVEYING DRIVE 1 1 X X

6 E0020120 E5125100 PARALLEL PIN H7A 2.5X10 SUS 1 1 X X Used for No.5

7 3B822191 3B822192 CLUTCH 33, CONVEYING 1 1 X O DF-610 only

8 3B801015 3B801016 MAIN PCB ASS'Y 1 1 X O For DF-610

9

3B901010 3B901011 MAIN PCB ASS'Y 1 1 X O

PH-3A/PH-3C

3B860011 3B893041

10

NOTES:

• Please use the old parts for DF-610 that has not undergone these changes or for a DF-610 used for

KM-4530/5530/6330.

• As for part no. 4 and 6, please use the old pin for the old shaft and use the new pin for the new shaft.

Affected Machine Serial Numbers:

DF-610/DF-600: F3011094 to F3011322, F3011460 and later

PH-3A/PH-3C: W3006228 to W3006833

Part No.

NEW

PARTS, UNIT PUNCH, METRIC (SP)

Description

from W3006863 to W3007024, W3007139 and later

Q’ty

old-new

1 1 X O

Interchange-

ability

For DF-600

Remarks

KMIS Service Team, Kyocera Mita Europe 5794 / SB AS-131

Loading...

Loading...