Page 1

1 / 3

Service Bulletin

SB Number:

SB AS-138

Creation Date: 25/02/2005

Subject: Change of sub ejection section

Model:

DF-600: finisher for KM-4530, FS-C8026N, KM-C2630/C2630D

DF-610: finisher for KM-4530/5530/6330/7530, FS-C8026N,KM-C2630/C2630D

Please be informed that the following changes have been implemented to the DF-600/610 sub ejection section.

Field Action

When replacing any of the involved parts in this modification, please mind to use the old parts for former finisher

(before

on page 3).

CONTENTS OF CHANGES

1) Improving the efficiency of assembly work

a. The fixation method of the ‘RIGHT GUIDE SUB CONVEYING’ to the ‘MOUNT, CONVEYING GUIDE’ has been

changed from 3 pieces of ‘BINDING SCREW BVM4X6 (BLACK)’ to 1 piece.

b. The fixation method of ‘UPPER GUIDE, SUB CONVEYING’ to the ‘MOUNT, CONVEYING GUIDE’ has been

c. Hook parts have been added and holes have been created to the ‘RIGHT GUIDE SUB CONVEYING’, ‘UPPER

GUIDE, SUB CONVEYING’ and ‘MOUNT, CONVEYING GUIDE’.

2) Reduction of deterioration of the shaft for ‘PULLEY EXIT’

d. So far, for fixation, the ‘PULLEY EXIT’ was fitted into the ‘PLATE SPRING, SUB EJECT’. The fixation method

has been changed so that the ‘PULLEY EXIT’ is put through the ‘SHAFT SUB EJECT PULLEY’.

3) Protecting the wires

e. In order to protect the wires of ‘SOLENOID PADDLE’ from the edge of ‘MOUNT, CONVEYING GUIDE’ (used for

DF-610), the ‘EDGING, EDS-17L (KITAGAWA)’ has been added as wire protection. In addition, the hole shape

for the wires on ‘MOUNT, CONVEYING GUIDE’ has been changed in order to attach the ‘EDGING, EDS-17L

(KITAGAWA)’.

4) Common use of certain parts with next new models

f. A screw hole has been created into the ‘MOUNT, CONVEYING GUIDE’.

Please refer to Fig. 1 on next page

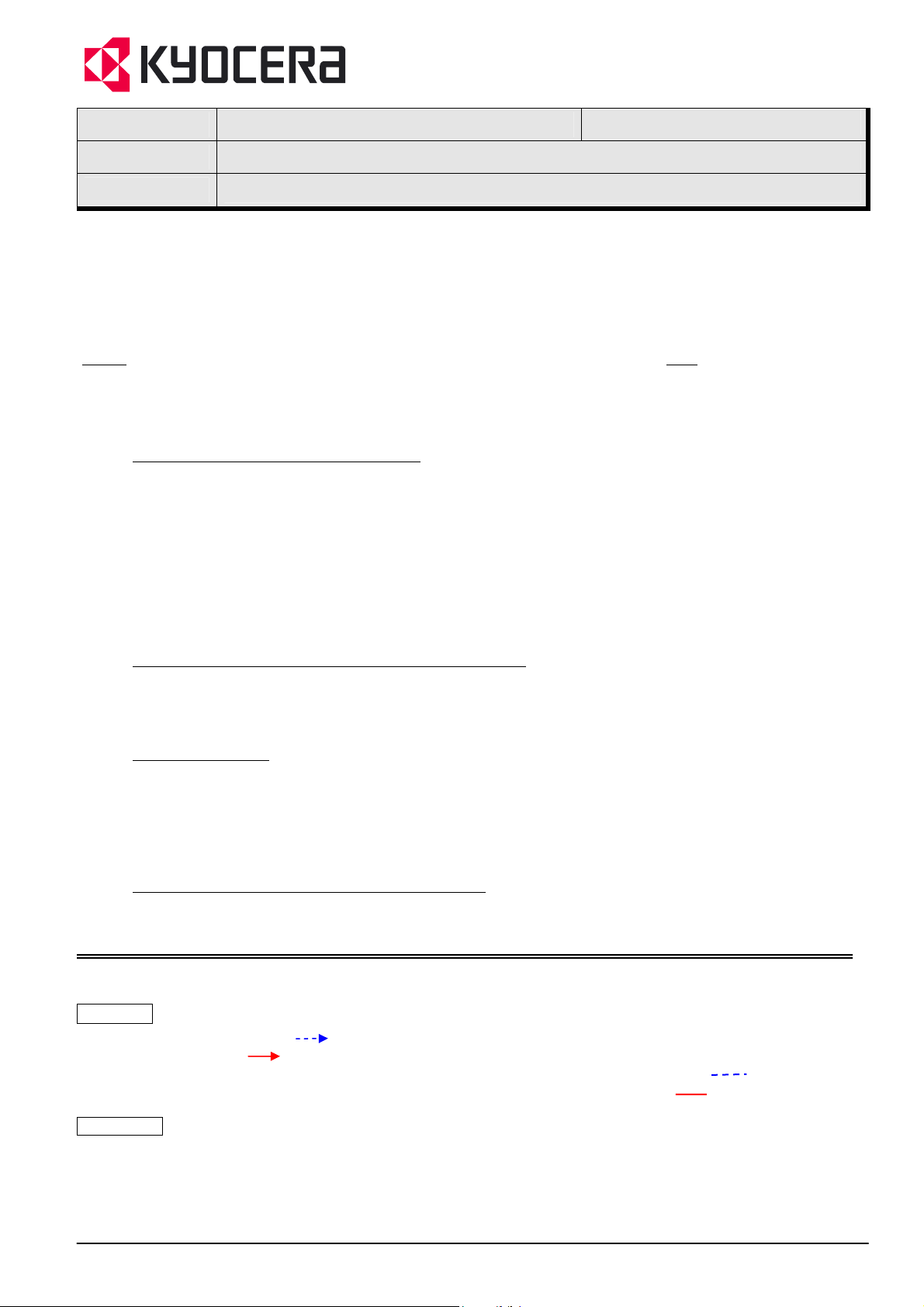

Change 1

a. See dotted arrows in Fig.1.

b. See red arrows in Fig 1.

c. The hook parts of ‘RIGHT GUIDE SUB CONVEYING’: dotted blue circled section

Change 2-d

• In order to put the ‘PULLEY EXIT’ through the ‘SHAFT SUB EJECT PULLEY’, the ‘PULLEY SUB EJECT’ and

‘PLATE SPRING SUB EJECT’ have been changed. In addition, the ‘SHAFT SUB EJECT PULLEY’ has been

added.

• By the above changes, the shape of the ‘UPPER GUIDE, SUB CONVEYING’ and ‘MOUNT, CONVEYING

GUIDE’ has been changed. (For details, please refer to new shape on page 2.)

affected serial number on page 3) and the new parts for the modified finisher (after affected serial number

changed from 4 pieces of ‘BINDING SCREW BVM4X6 (BLACK)’ to 2 pieces.

The hook parts of ‘UPPER GUIDE, SUB CONVEYING’: red circled section

DF-600, DF-610

KMIS Service Team, Kyocera Mita Europe 6849 / SB AS-138

Page 2

N

A

Change 3-e, 4-f: See ‘A’ section below.

OLD

Fix with 4 screws

No.2

Fix with 3 screws

OLD ‘PULLEY EXIT’:

For fixation, the shaft of ‘PULLEY EXIT’ is fitted into

the shaft support part of ‘PLATE SPRING, SUB

EJECT’. Due to the rubbing against the shaft support

part of ‘PLATE SPRING, SUB EJECT’, the shaft of

the ‘PULLEY EXIT’ tends to wear down.

hole of the wires for ‘SOLENOID PADDLE’

(new shape)

Service Bulletin

o.3

Fix with 2 screws

No.4

No.5

No.4

NEW

No.6

New ‘PULLEY EXIT’:

For fixation, put ‘PULLEY SUB EJECT’ (No.5) through the

‘SHAFT SUB EJECT PULLEY’.

‘A’ section

created hole

No.9

2 / 3

No.1

KMIS Service Team, Kyocera Mita Europe 6849 / SB AS-138

Page 3

Service Bulletin

3 / 3

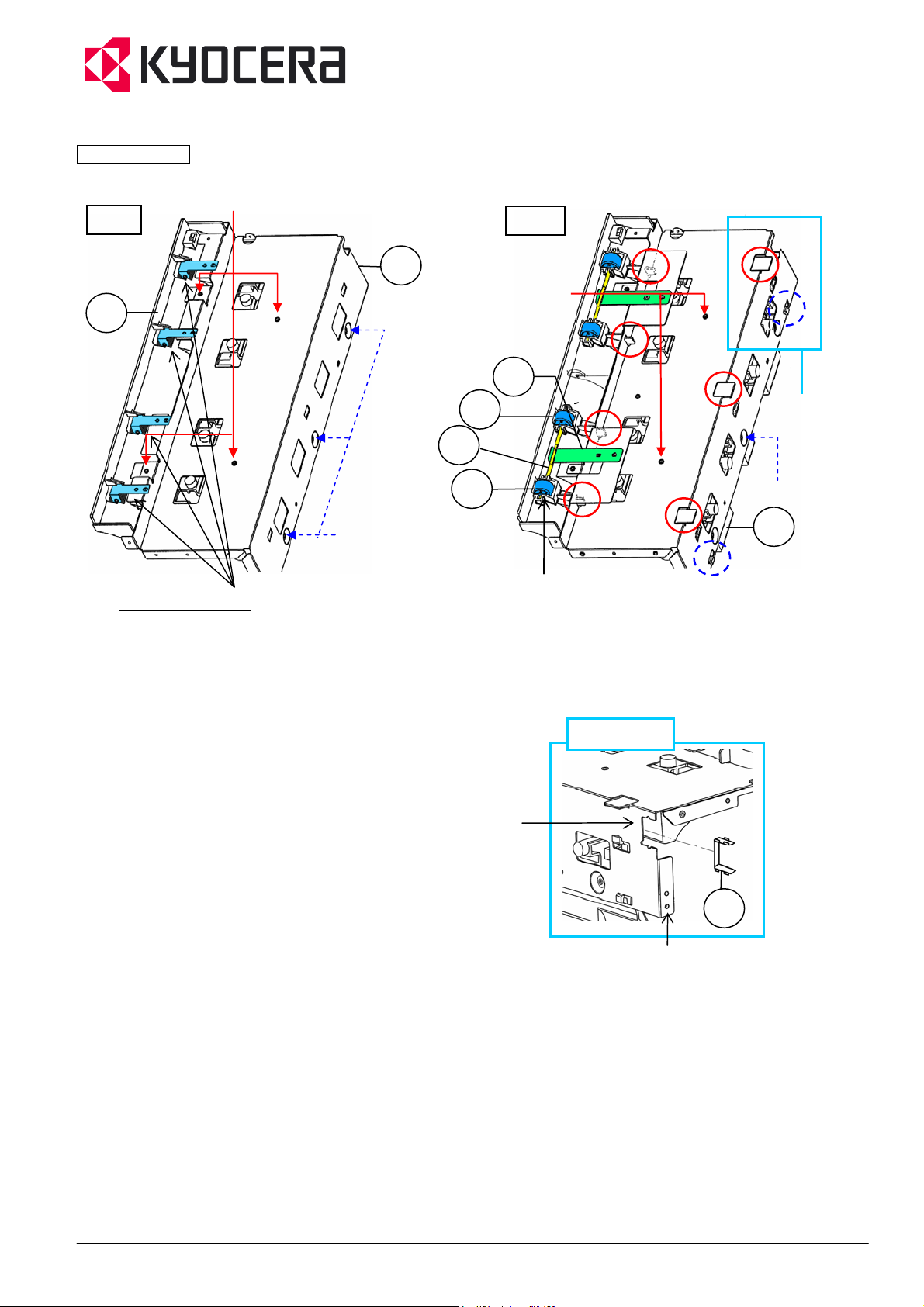

Parts Table

No Part No.

OLD

Part No.

NEW

Description

Q’ty Interchang

e

Remarks

Old New ability

1 3B816031

2 3B816700

3 3B816710

4 -----------5 -----------6 ------------

7 3B816571 ------------ PLATE SPRING,SUB EJECT 4 -

8 5MVB888CB002 ------------ PULLEY EXIT 4 -

9 ------------ M2104250 EDGING,EDS-17L(KITAGAWA) - 1

10 B1304060 B1304060

11 B4303050 B4303050 TRIPLE SCREW M3X5 (BLACK) 4 2

303B816032

3B816032

303B816701

3B816701

303B816711

3B816711

303B817020

3B817020

303B817030

3B817030

303B817040

3B817040

RIGHT GUIDE,SUB CONVEYING 1 1

UPPER GUIDE,SUB CONVEYING 1 1

MOUNT,CONVEYING GUIDE 1 1

PULLEY SUB EJECT - 4

SHAFT SUB EJECT PULLEY - 2

PLATE SPRING SUB EJECT - 2

BINDING SCREW BVM4X6

(BLACK)

7 2

X X

X X

X X

- X

- X

- X

X X -

- X

O O

O O

DF-610

DF-610

DF-610

DF-610

DF-610

* 1

DF-610, * 2

* 1: Fixation screw for ‘RIGHT GUIDE SUB CONVEYING’, ‘UPPER GUIDE, SUB CONVEYING’ and ‘MOUNT,

CONVEYING GUIDE’.

* 2: Fixation screw for ‘PLATE SPRING SUB EJECT’.

Affected Machine Serial Numbers:

DF-600: G3012762 and later

DF-610: F3027791 and later

KMIS Service Team, Kyocera Mita Europe 6849 / SB AS-138

Loading...

Loading...