Page 1

1 / 4

Service Bulletin

SB Number:

SB AS-119 Issue Date: 30/04/2003

Subject: Supply of ‘Special Tool, Stapler’ for field service

Model:

DF-600: KM-4530 / 5530 * / 6330 * (* = with special adjustment only: see SB AS-116)

DF-610: KM-4530 / 5530 / 6330

Please be informed that a part number for the ‘SPECIAL TOOL, STAPLER’ is available.

Please order the ‘SPECIAL TOOL, STAPLER’ with below part number if required.

Purpose

The ‘SPECIAL TOOL, STAPLER’ is a jig that is used when replacing a stapler unit or when a stapling

malfunction occurs. Please refer to page 2 and later of this service bulletin for more details.

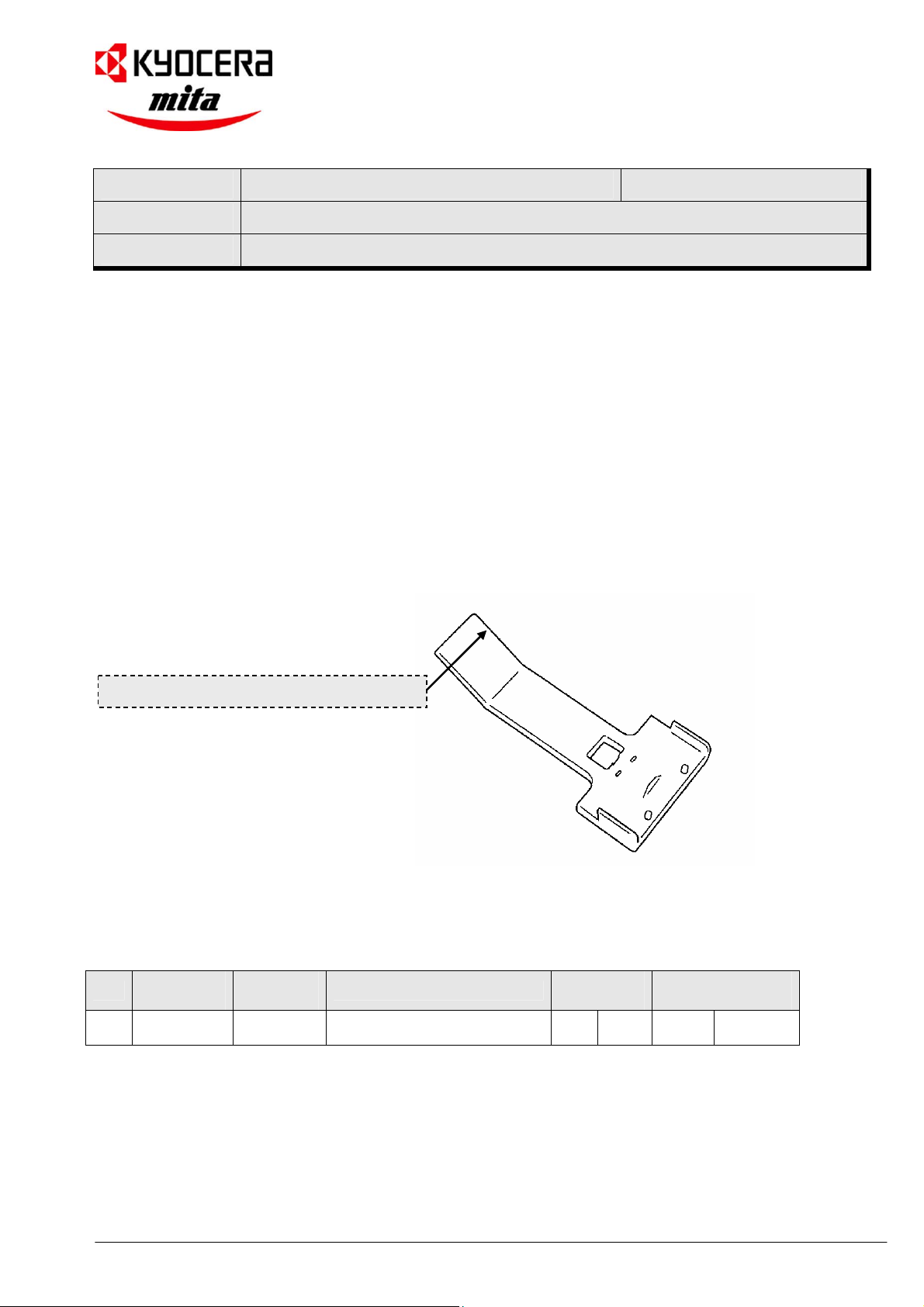

‘SPECIAL TOOL, STAPLER’ (P/N: 3B868010)

Parts Table

No.

Part No.

OLD

DF-600 / DF-610

Part No.

NEW

Description

Q’ty

old-new

Interchange-

ability

1 --------- 3B868010 SPECIAL TOOL, STAPLER - 1

KMIS Service Team, Kyocera Mita Europe 5490 / SB AS-119

- O

Page 2

3B8/9-2

(3) Adjusting the stapler unit mounting position

Perform this operation when replacing a stapler unit or when a stapling malfunction occurs.

* Since the front stapler and the rear stapler in the finisher have the same construction, only the procedure for the front

stapler is described below. Use similar procedure for adjusting the rear stapler.

Tool required for adjustment

• SPECIAL TOOL, STAPLER (P/N 3B868010)

Stapler cartridge

Procedure

1. Pull out the intermediate tray and remove the

Staple cover

stapler cartridge.

2. Open the staple cover and remove a staple

sheet.

Staple sheet

Figure 1-5-6-1

3. Remove the stapler adjustment metal from the

stapler adjustment tool.

4. Attach the stapler adjustment metal to the

stapler cartridge and close the staple cover.

* Attach the stapler adjustment metal by

inserting its projections into the grooves of the

stapler cartridge.

5. Reattach the stapler cartridge into the stapler.

Stapler adjustment tool

Figure 1-5-6-2

Stapler cartridge

Stapler adjustment metal

Staple cover

Projections

Grooves

Figure 1-5-6-3

Stapler adjustment

metal

1-5-31-5-2-1

Page 3

3B8/9-2

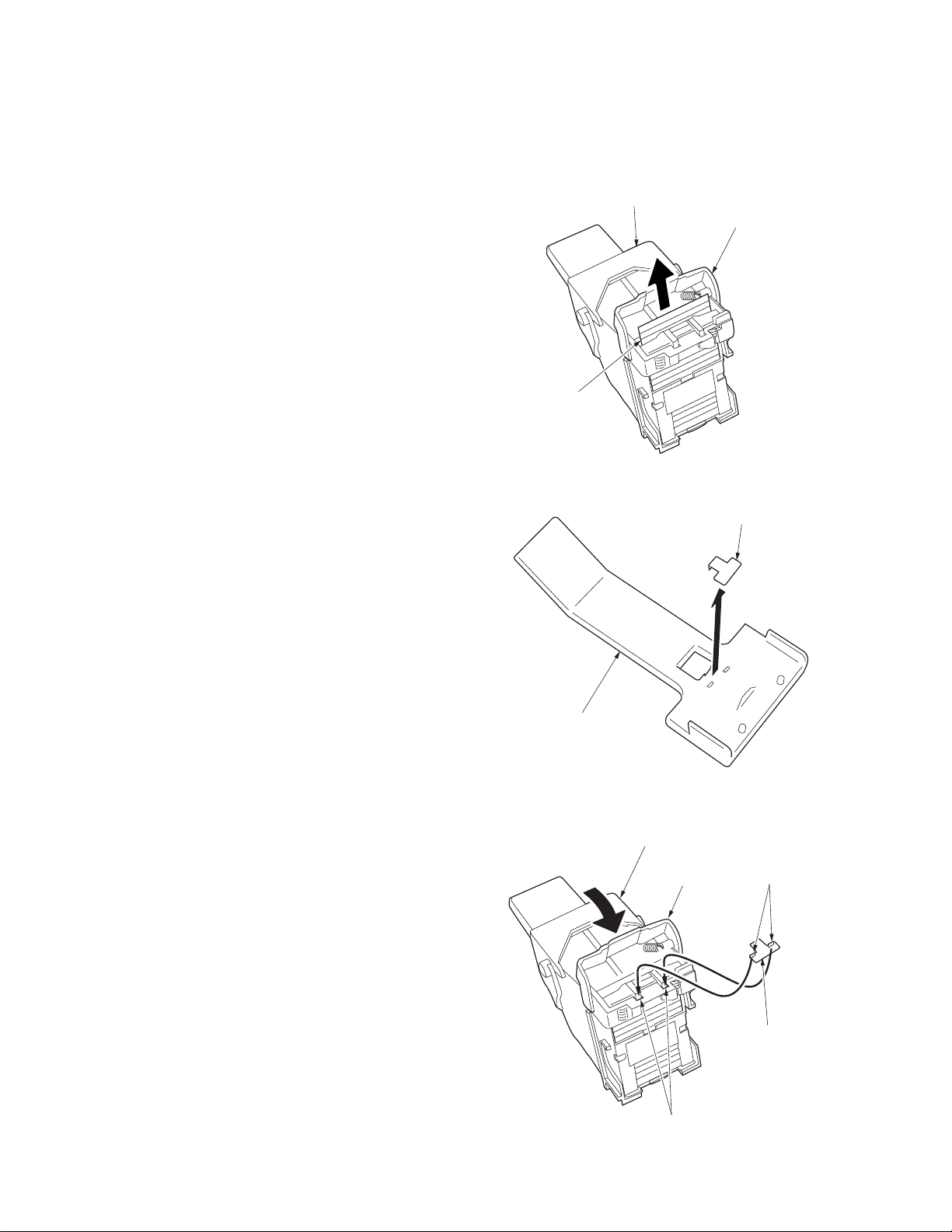

6. Open the intermediate tray and attach the

stapler adjustment tool to the stapler.

* Attach the stapler adjustment tool by inserting

its projections into the stapler holes. In

addition, be careful not to get the film caught

when attaching the tool.

7. Close the intermediate tray.

* Do not carry out step 8 with the intermediate

tray open because the stapler may be

damaged.

8. Turn the gear manually to push the stapler into

the inner part and ensure that the stapler

adjustment metal is inserted smoothly into the

adjustment hole of the stapler adjustment tool.

Stapler adjustment tool

Projections

Figure 1-5-6-4

Stapler

Holes

Film

Stapler

1-5-41-5-2-2

Gear

Figure 1-5-6-5

Stapler adjustment tool

Adjustment hole

Stapler adjustment metal

Figure 1-5-6-6

Page 4

3B8/9-2

9. If the stapler adjustment metal is not inserted

into the adjustment hole, loosen the four

adjustment screws on the intermediate tray

and adjust the stapler unit mounting position

so that the metal is inserted into the hole.

* At this time, turn the gear manually

furthermore and ensure that the stapler is

securely pushed into the inner part.

10. Tighten the adjustment screws in the order

shown below.

1

Tighten the upper two screws loosely.

2

Tighten the lower two screws loosely.

3

Finally tighten the upper two screws.

4

Finally tighten the lower two screws.

11. Turn the gear manually to pull back the stapler

to its original position and then remove the

stapler cartridge.

12. Remove the stapler adjustment metal and the

stapler adjustment tool.

13. With the stapler cartridge removed, return the

intermediate tray to its original position and

mount the finisher to the copier. Turn the

copier main switch on (to detect the noncartridge status).

14. Pull out the intermediate tray again and attach

the stapler cartridge. Mount the finisher to the

copier and turn the main switch on.

Intermediate tray

Adjustment screws

Adjustment screws

Figure 1-5-6-7

15. Select the staple mode (mode specifying the

stapler that has been adjusted) and carry out

this mode.

* After the staples in the cartridge are

automatically fed in test stapling, the staple

mode will be carried out.

16. Check the shape of the staples on the rear

side that have been used in the test stapling

and the staple mode above.

* If the shape is defective, perform the

adjustment again.

Shape of staples on the rear side

Normal Defective

> 0.5mm

a

a

<

0.5mm

=

a

a

1-5-5

1-5-2-3

Loading...

Loading...