Page 1

DF-30 Service Manual

V. 1.0

Page 2

Notices

Document Finisher DF-30/DF-31 Service Manual ©Kyocera Corporation 1998, 1999 All rights re served.

Notices

The information in this manual is subject to change without notification. Additional pages may be inserted in future editions. The user is asked to excuse any

technical inaccuracies or typographical errors in the present edition.

No responsibility is assumed if accidents occur while the user is following the

instructions in this manual. No responsibility is assumed for defects in the product's firmware.

The contents of this manual are protected by copyright. No part of this manual

may be reproduced or copied by any means without the permission of the copyright holder. The product's firmware (contents of its read-only memory) is similarly protected by copyright.

T rade mark Notice

Prescribe is a registered trademark of Kyocera Corporation. Prescribe IIe, KIR,

Kyocera Image Refinement, Ecosys, and Ecotone are trademarks of Kyocera Corpo-

ration.

Warning

This equipment has been certified to comply with the limits for a Class B computing device, pursuant to Subpart J of Part 15 of FCC Rules. Only peripherals (computer input/output devices, terminals, etc.) certified to comply with the Class B

limits may be attached to this equipment. Operation with non-certified peripherals is likely to result in interference to radio and TV reception.

Conventions

Throughout this manual, the following conventions are used:

Color is available when viewed online to emphasize important notices.

CAPITAL letters are used to name parts and assemblies.

Italic letters refer related chapters or sections or documentations.

Bold letters are also used for emphasis wherever italics may cause a confuse.

This symbol followed by

graph(s) includes precautions which, if ignored, could result in personal injury,

and/or irrevocable damage to the equipment.

When followed by

include the precautions which, if ignored, could result in damage to the equipment.

Caution

Warning

this symbol denotes that the following paragraph(s)

denotes that the following para-

DF-30

ii

Page 3

REVISION HISTORY

Version Date Replaced Pages Remarks

1.0 20-April-98 — Rel. 1

1.1 7-July-98

1.11

1.12 31-Aug-99

15-Aug-98

Conventions

VISIT US AT OUR INTERNET HOME PAGE (JAPAN):

FOR AVAILABILITY OF PRINTER DRIVERS AND UTILITIES, ACCESS TO YOUR LOCAL KYOCERA INTERNET SITE.

http://www.kyocera.co.jp

iii

DF-30

Page 4

Chapter 1 FEATURES

Contents

Features 2

Large-volume paper ejection 2

Job offset 2

Stapler function 2

Specifications 3

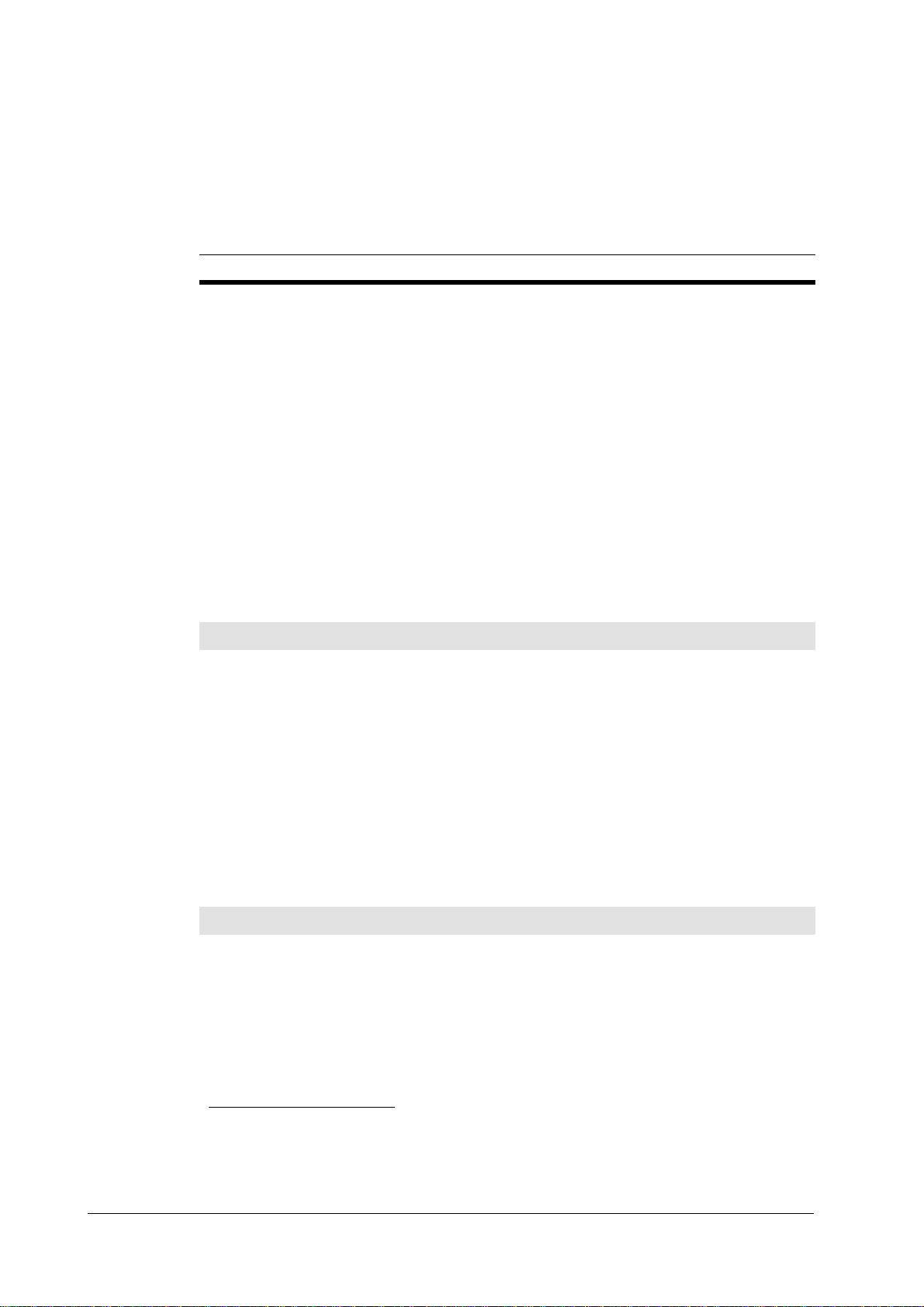

Part names 4

External diagram 4

Internal Component 6

Installation 7

Precautions during installation 7

Location of installation 7

Power supply 7

Operating environment 7

Installation spac e 8

Procedures for unpacking and installation 8

Unpacking the finisher 8

Removing paper jams 9

Paper jammed in the inversion assembly 9

Paper jammed in the feeder assembly 11

Paper jammed in the paper ejection assembly 12

Staples jammed in the Staple assembly 12

Customer maintenance and inspections 14

Replacing the staple cartridge 14

Page 5

1.1 Features

Large-volume paper ejection

FEATURES

Features

Tray No.1 has a capacity large enough to hold approximately 600 pieces of paper

(64g/m

No.2 and No.3.

Job offset

The printer is equipped with a job offset function. The first page only or whole set

of pages (default) of each job is placed aside during ejection, and the paper loaded

into the trays can be separated into groups.

Stapler function

A control signal transmitted from an external source enables staples to be set at

two locations in the center o f the paper, at one location at the left-hand co rner or at

one location at the right-ha nd corner depending on the size of the paper.

2

), and anything up to 700 pieces of paper (64g/m2) can be loaded into trays

1-2

Page 6

FEATURES

Specifications

1.2 Specifications

Table 1.1 Specifications

Ejection method 3-tray elevation type

Number of trays 3

Loading method Face-down: Normal loading, job offset, staple

Paper types

Item Specification

Face-up: Normal loading

a

Normal paper, colored paper, thick paper, labels, OHP film and

envelopes.

Paper sizes A3, B4, A4, A4 (vertical), ledger, legal, letter, B5, A5 and normal

2

executive size paper (64g/m

—128g/m2 recommended); Normal

paper with a size of 98.4mm X 190.5mm (smallest) to 297mm X

432mm (largest) (64g/m

2

—128g/m2 recommended); Monarch,

Com-10, DL, B5, C5, Western No.4 and envelopes with a size of

98.4 mm by 190.5 mm (smallest) to 176mm by 250mm (largest)

Capacity

Tray No.1: Approximately 600 pieces of 64g/m

Tray No.2: Approximately 700 pieces of 64g/m

Tray No.2: Approximately 700 pieces of 64g/m

2

paper

2

paper

2

paper

Staples

Staple type Special staples

Staple exchange method Cartridge

Staple capacity 2,000 staples per cartridge

Number of pages that can

be stapled together

Between 2 and 20 pages of 64g/m

mum 30 sets, 300 pages, stacking height: whichever comes first

2

paper for each tray (Maxi-

out of 188mm or 48mm for tray No.1, or 395mm for trays No.2

and 3.)

Staple location One location at an angle (left-hand corner or right-hand corner),

one horizontal location (right-hand side), two horizontal locations (center)

DF-30/DF-31

Paper size A3, B4, A4, A4 (vertical), ledger, legal and letter

Miscellaneous

Maximum electrical consumption

Dimensions

b

Approximately 100W or less (with a room temperature of 20

degrees Celsius and at a rated voltage input)

654 (width) X 641 (depth) X 1158 (height) mm

Weight Approximately 28kg

Power supply (Within a

110-120V (50/60Hz) or 220-240V (50Hz)

permissible voltage rate

of ±10%)

a. Paper ejection for labels, OHP films and envelopes is only possible in the face-up mode

from tray No.3.

b. 1338mm when extended to the maximum.

1-3

Page 7

FEATURES

Specifications

The details outlined in this manual are subject to modification in accordance with

product improvements.

1-4

Page 8

FEATURES

Part names

1.1 Part names

External diagram

DF-30/DF-31

1-5

Page 9

Table 1.2 External Component

FEATURES

Part names

Item (See

above)

1

2

3

4

5

6

7

8

9

10

11

Component

Upper door

Trays

Interface connector

Power supply receptacle

Upper guide

Lower guide

Staple reset switch (Not used)

Right side cover

Guide rail

Staple unit

Front door

1-6

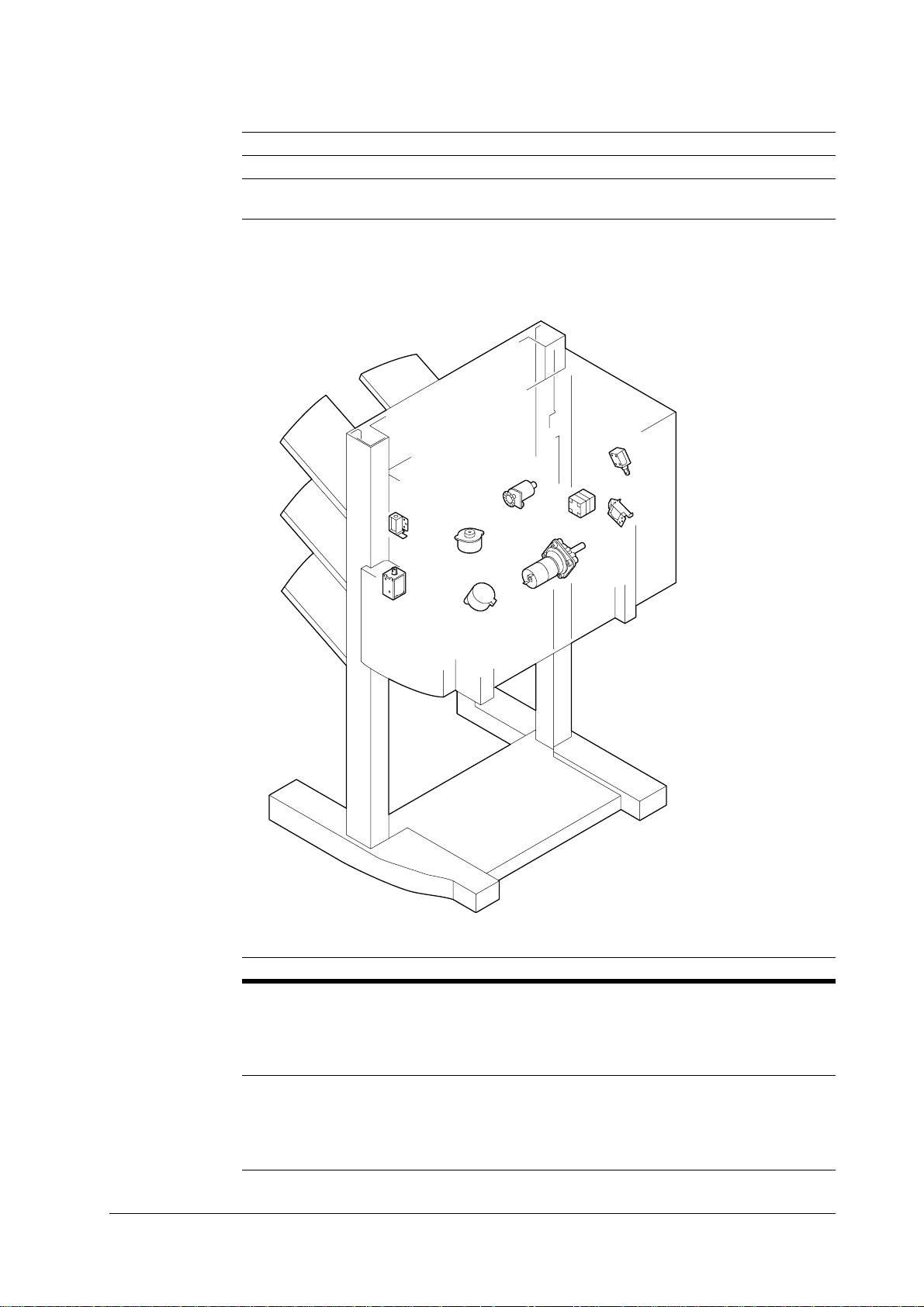

Page 10

FEATURES

Part names

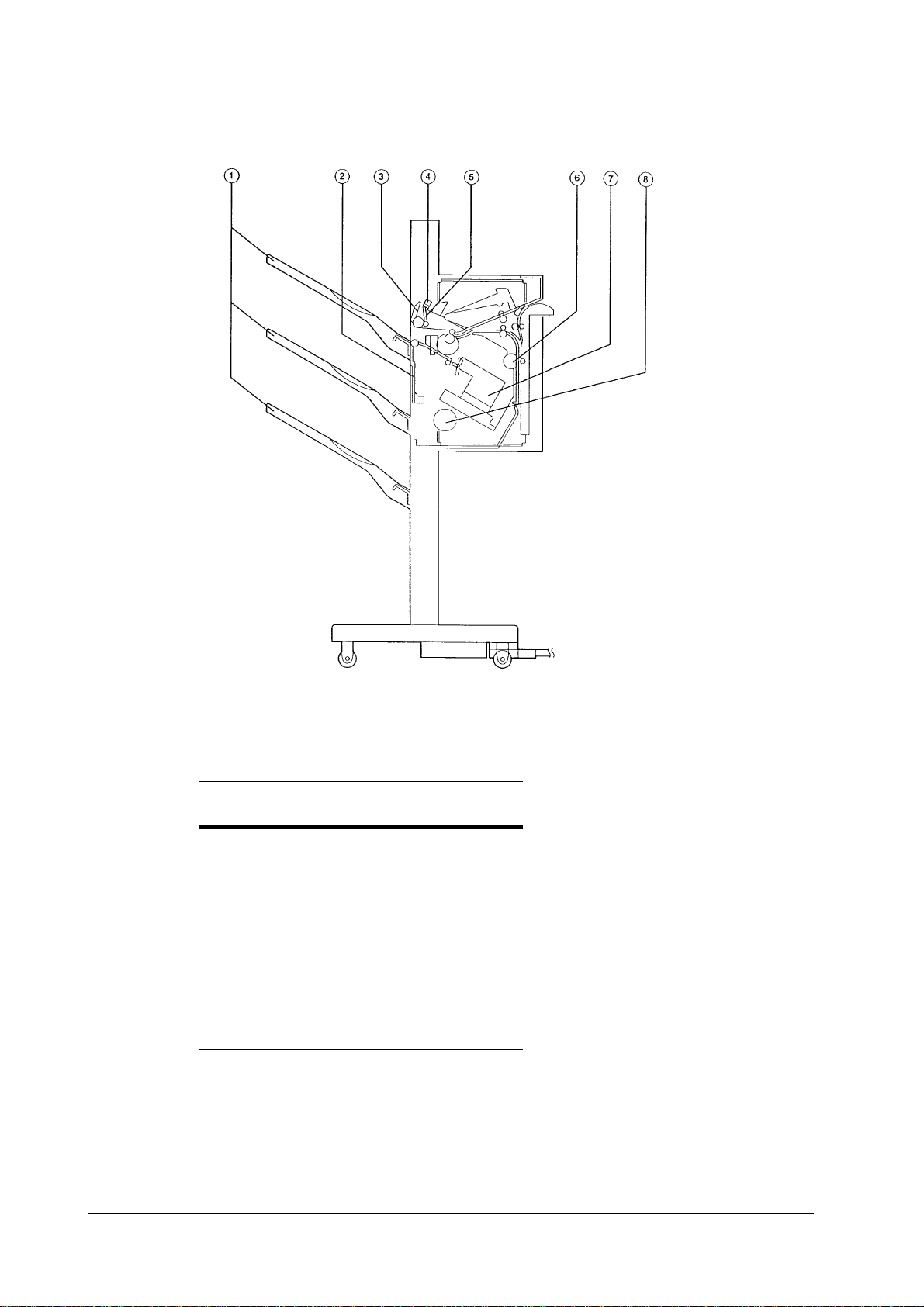

Internal Compone n t

Table 1.3 Internal Component

Item (See

above)

1

2

3

4

5

6

7

8

Trays

Shutter

Swing guide

Distance sensor

Paddle

Inversion roller

Staple unit

Tray elevation motor

Component

DF-30/DF-31

1-7

Page 11

1.1 Installation

Precautions during installation

All important adjustments were made to this equipment prior to it being packed

and shipped from the fa ctor y, and it has als o bee n su bj ect to a thoroug h i nsp ect ion.

The installation procedure is extremely important to ensure that the equipment

performs mechanically in accordance with the ratings acquired during the inspection process after it has been unpacked by the customer.

The service engineers must therefore have a full understa nding of the mechanical

capabilities of this equipment, and it must be installed in a favorable environment

in accordance with correct procedures.

Location of installation

Ensure that the location of installation satisfies the following conditions. It is recommended that an area that meets these conditions is determined prior to the unit

being delivered to the customer.

Power supply

FEATURES

Installation

Prepare a power supply that conforms to the following:

•

Current (AC)

•

Supply frequency

Operating environment

Ensure that the location of installation conforms to the following:

A flat and horizontal surface

•

Temperature and humidity ranges must be within the following:

•

•

Surrounding temperature

•

Surrounding humidity

tion

Areas which are well-ventilated and not subject to steam.

•

• Avoid installation in the following locations.

Areas where the device will be subject to direct sunlight.

•

If this is unavoidable and the device must be installed in an area where it is subject

to direct sunlight, ensure that a thick curtain or other form of protection is used to

deflect the sunlight.

Areas near magnets or wher e magnetic fields exist.

•

Areas that are subject to vibrations.

•

Areas in which dust collects.

•

Near to open flames and moisture.

•

. Rated current ±10%

. 50/60Hz ±2Hz

. 10 to 32.5 degrees Celsius

. 20 to 80% RH (relativ e humidity ) without cond ensa-

1-8

Page 12

FEATURES

Installation

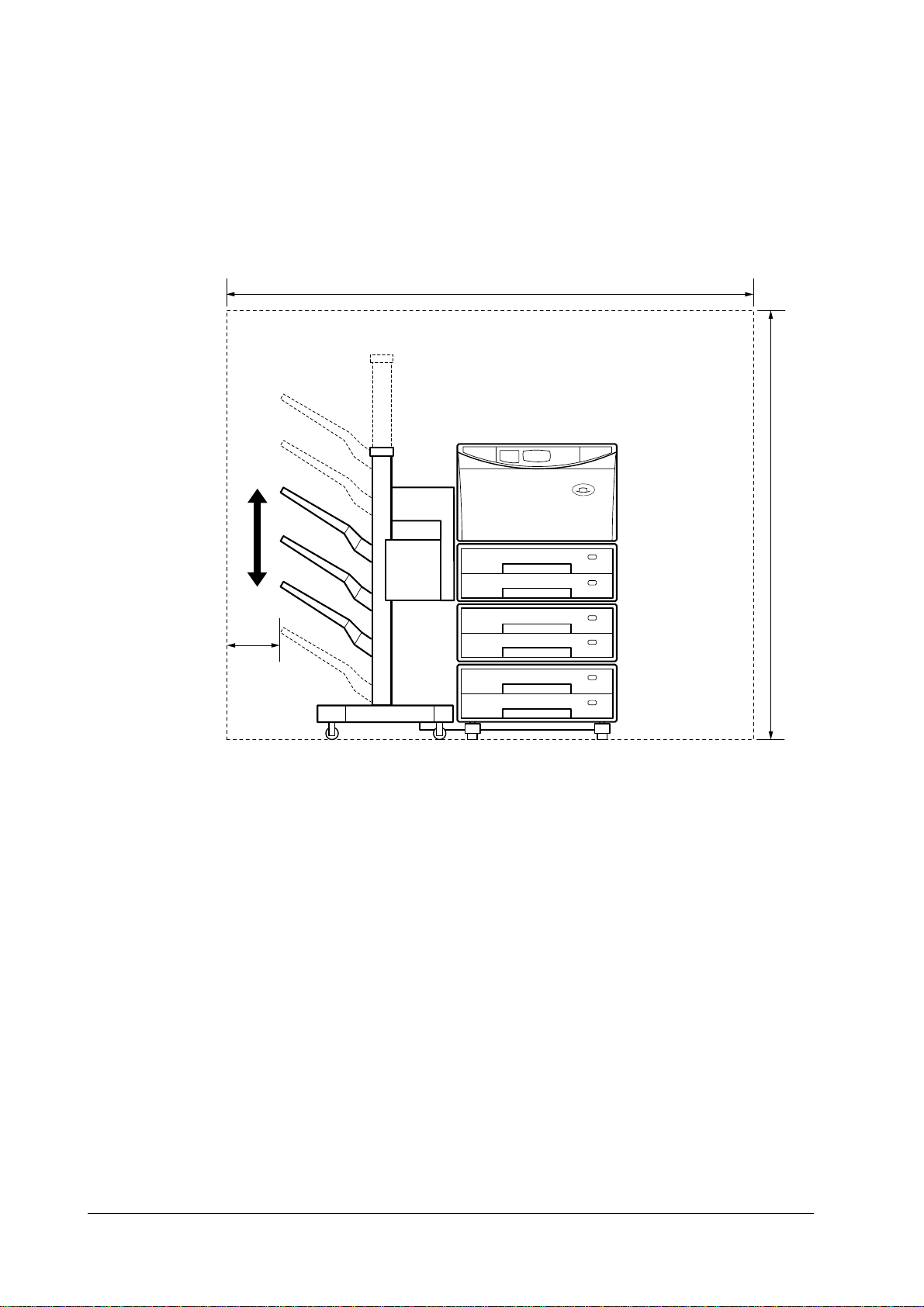

Installation space

Install the device at a suitable distance from walls and other obstructions, and

secure enough space to enable easy operations.

Figure 1.1

Installation space

2680 mm

1380 mm

630 mm

Procedures for unpacking and installation

There are cases where water droplets will form on the surface of metal fittings

when brought into warm places from cold places. This is known as condensation,

and using equipment on which condensation has formed may result in faults arising with the feeder assembly. To avoid this, do not unpack the device for at least

one hour after it has been brought in from a cold place to allow it to become accustomed to room temperature.

Unpacking the finisher

Remove the outer box in which the finisher is packed.

1

Remove the accessories. Confirm that the accessories include the power sup-

2

ply cord, the manual, the guide rails, the trays, the earth adapter and the

interface cable.

Remove the upper pads (left and right) and lift the finisher out of the box.

3

Remove the vinyl bag in which the finisher is packed and then peel off the

4

tape that holds each part in place. Verify that the covers were not scratched,

bent or otherwise damaged during transportation.

Open the front cover and remove the two spacers.

5

Attach the trays to the finisher with the screws.

6

DF-30/DF-31

1-9

Page 13

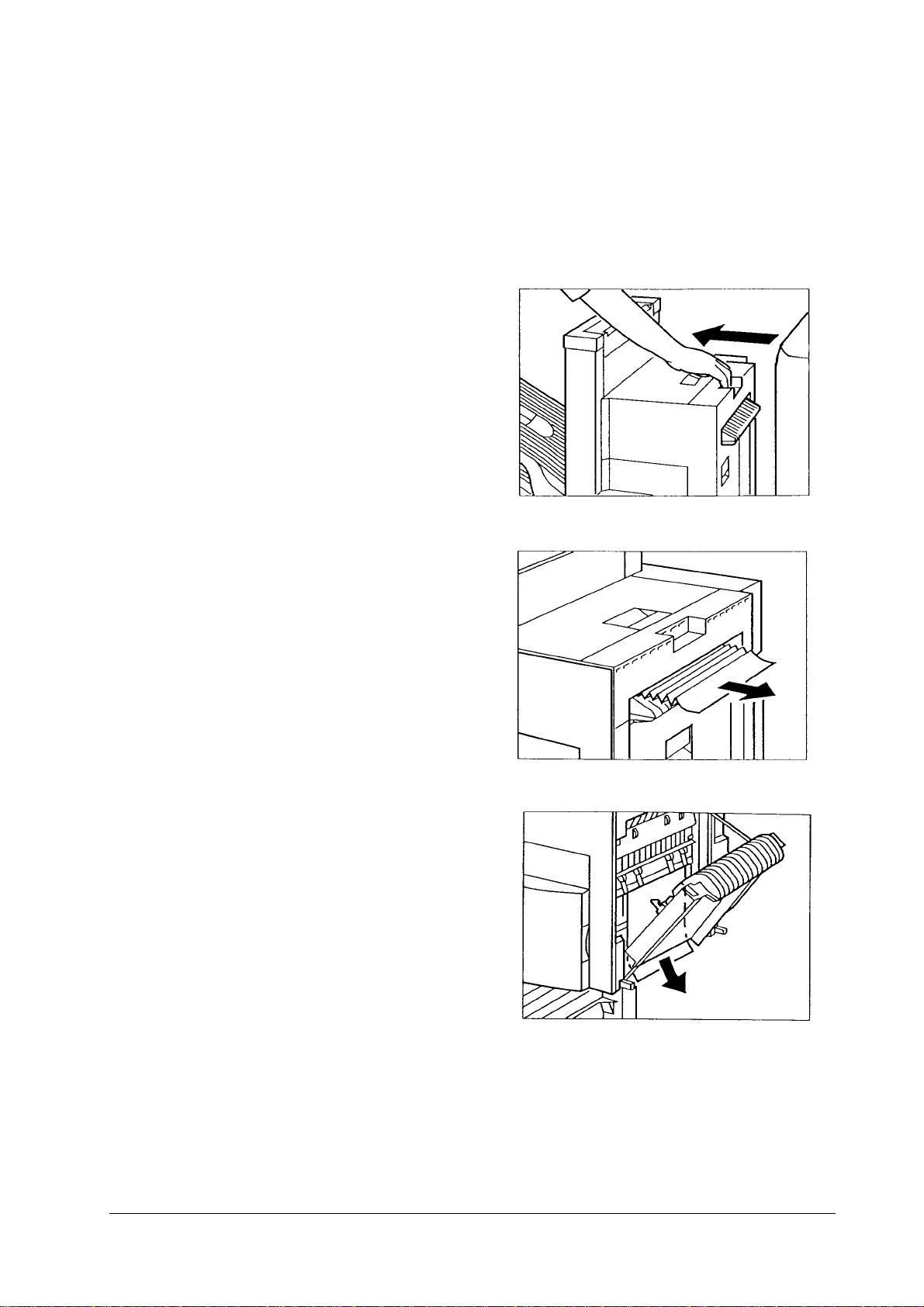

1.2 Removing paper jams

When jams occur, removing the jammed paper from the inside of the machine in

accordance with the following procedures.

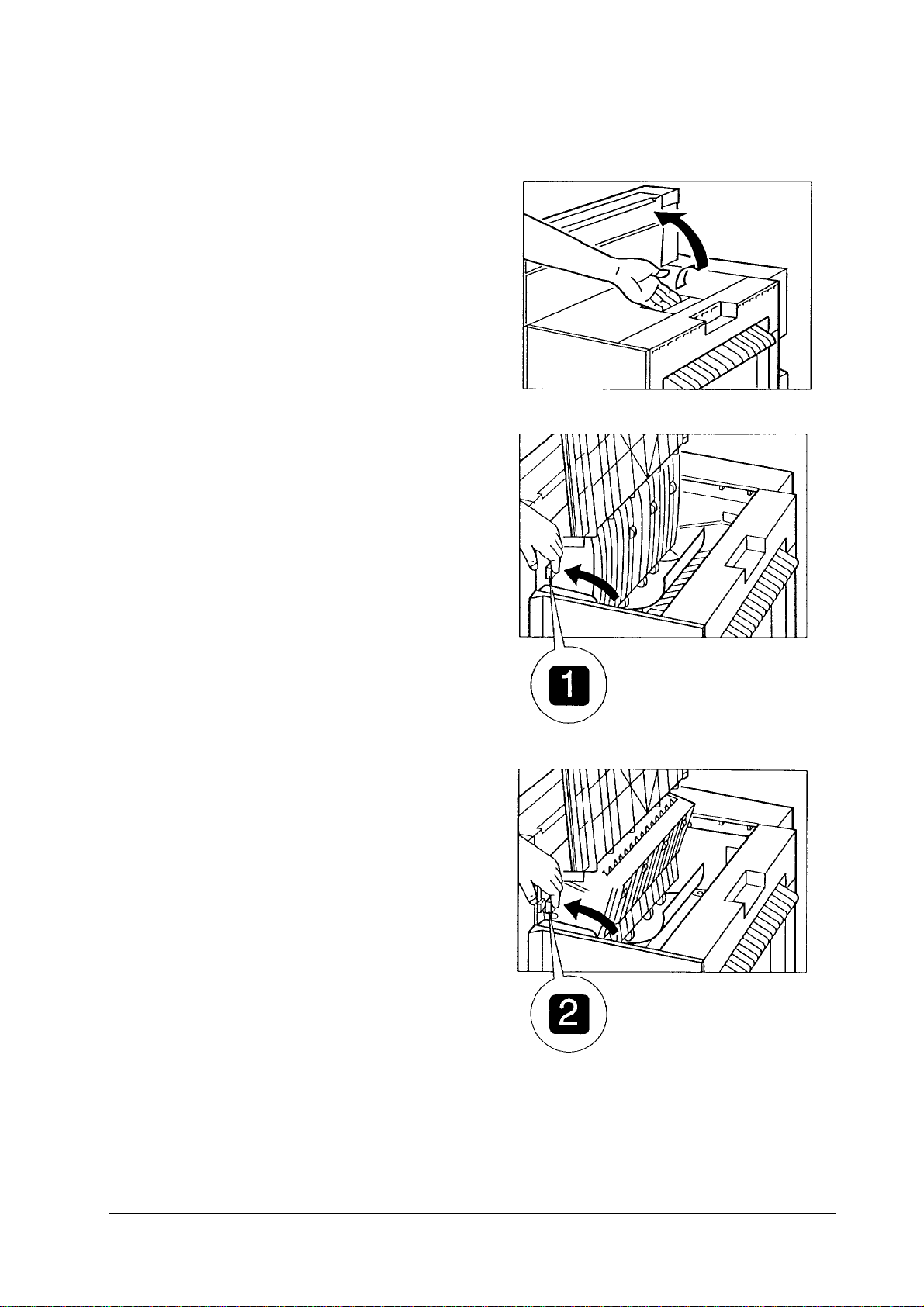

Paper jammed in the inversion assembly

Separate the finisher from

1

the printer.

FEATURES

Removing paper jams

Remove any jammed paper

2

that can be se en.

If the jammed paper cannot

3

be removed, open the inversion cover assembly and

remove the jammed paper

then.

1-10

Page 14

FEATURES

Removing paper jams

DF-30/DF-31

1-11

Page 15

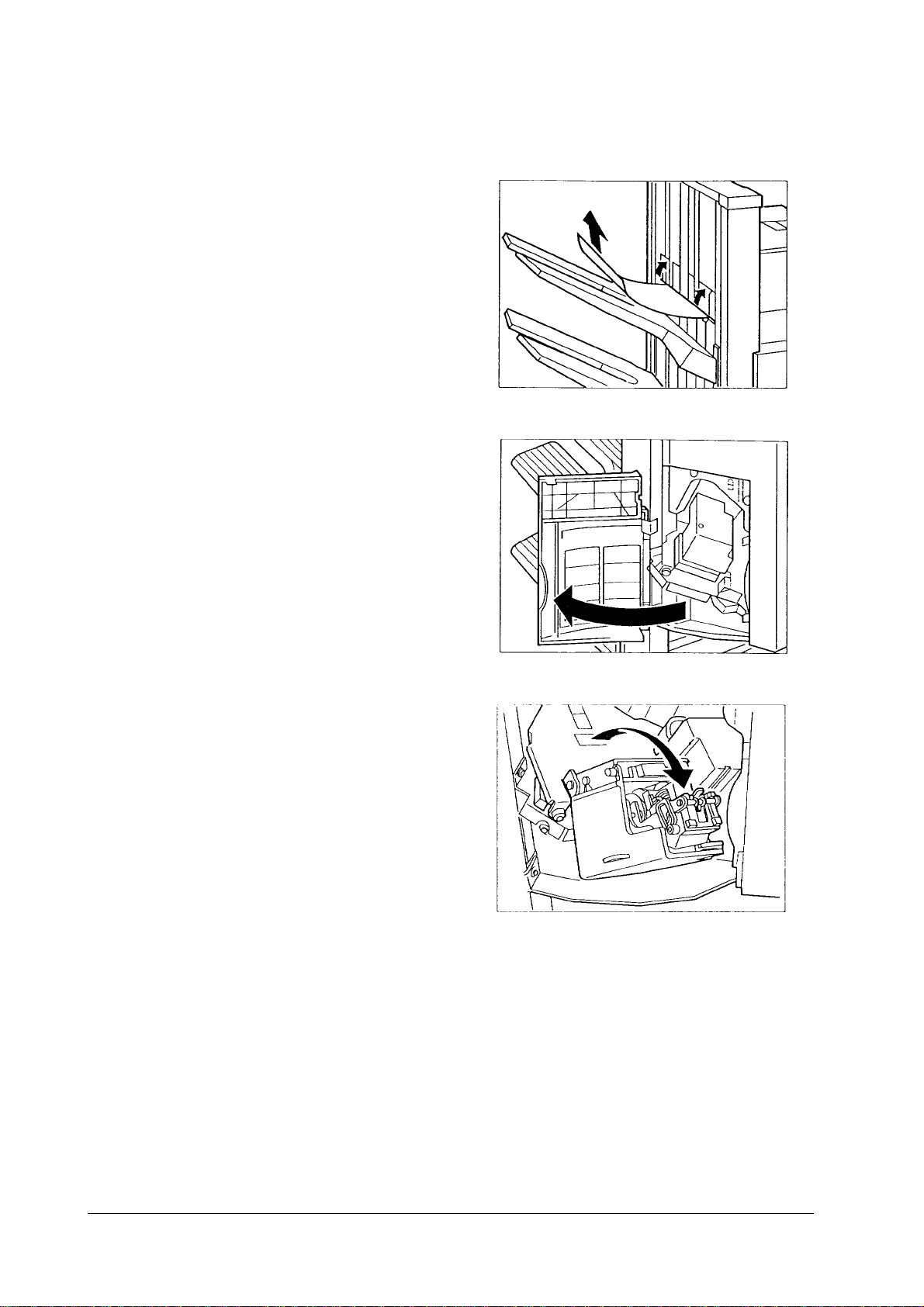

Paper jammed in the feeder assembly

Open the top cover.

1

Grip the knob and open the

2

upper guide.

Remove any jammed paper

3

that can be se en.

If the jammed paper cannot

4

be removed, grip the knob

and open the lower guide.

FEATURES

Removing paper jams

Remove any jammed paper

5

that can be se en.

1-12

Page 16

FEATURES

Removing paper jams

Paper jammed in the paper ejection assembly

Raise the paper guid e and

1

remove any jammed paper.

Open and close the front

2

cover, the upper cover and

the inversion cover.

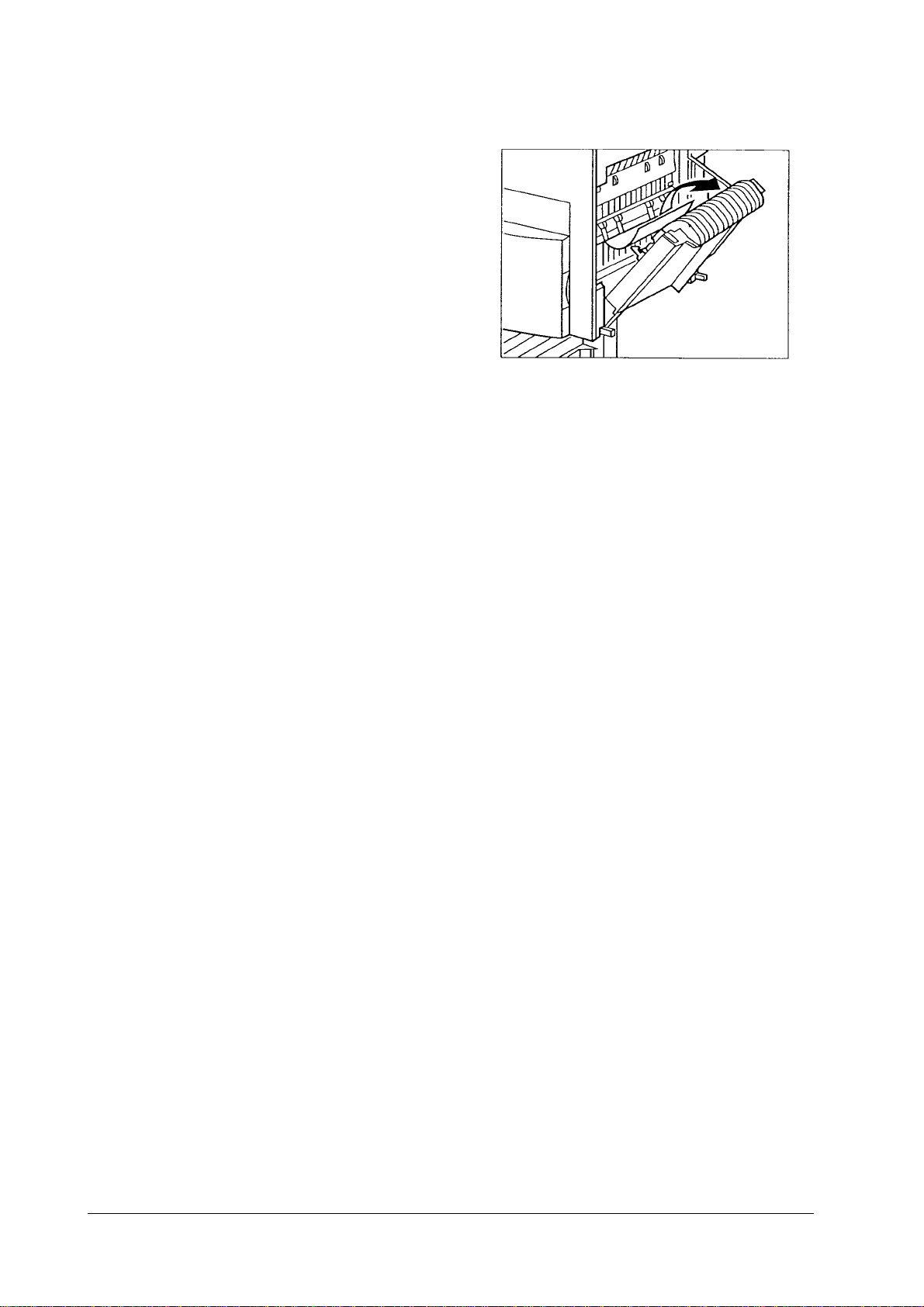

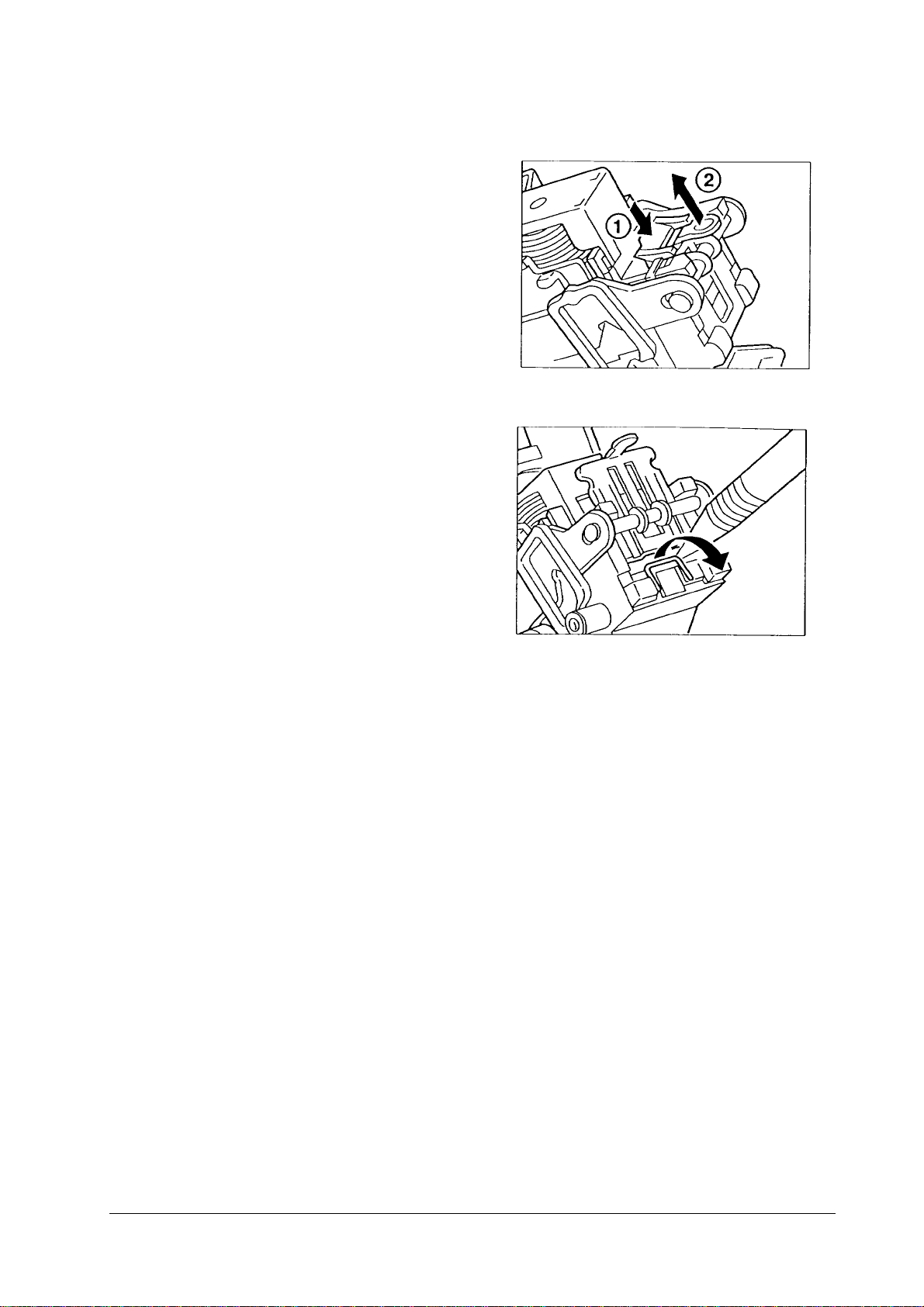

Staples jammed in the Staple

assembly

Open the front cover.

1

Pull out the staple assembly.

2

DF-30/DF-31

1-13

Page 17

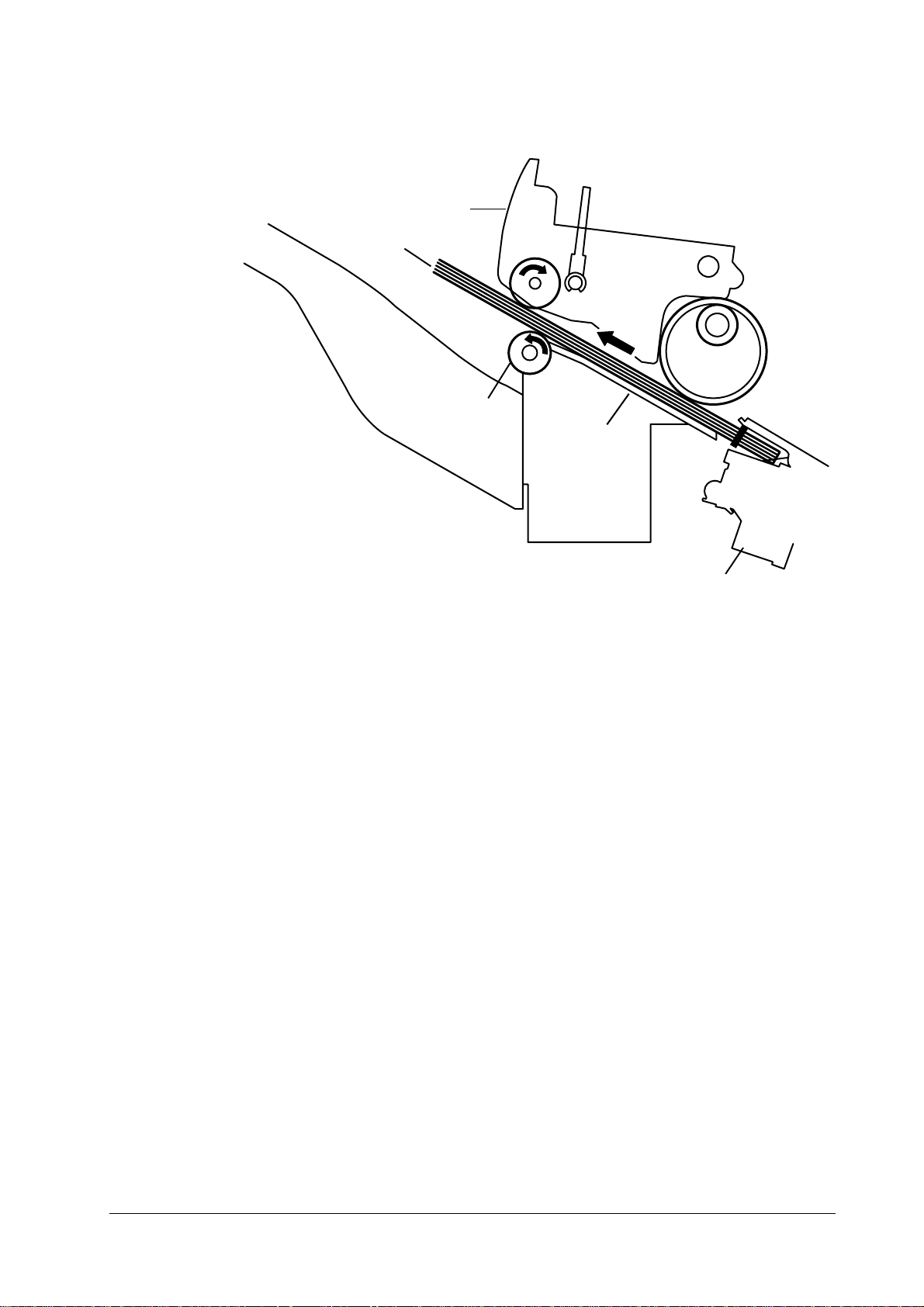

Grip the knob while apply-

3

ing pressure to the green

lever (¨) and pull out the

Staple guide.

Remove the jammed staple

4

with a poin ted object.

Grip the knob and replace

5

the staple guide.

FEATURES

Removing paper jams

1-14

Page 18

FEATURES

Customer maintenance and inspections

1.3 Customer maintenance and inspections

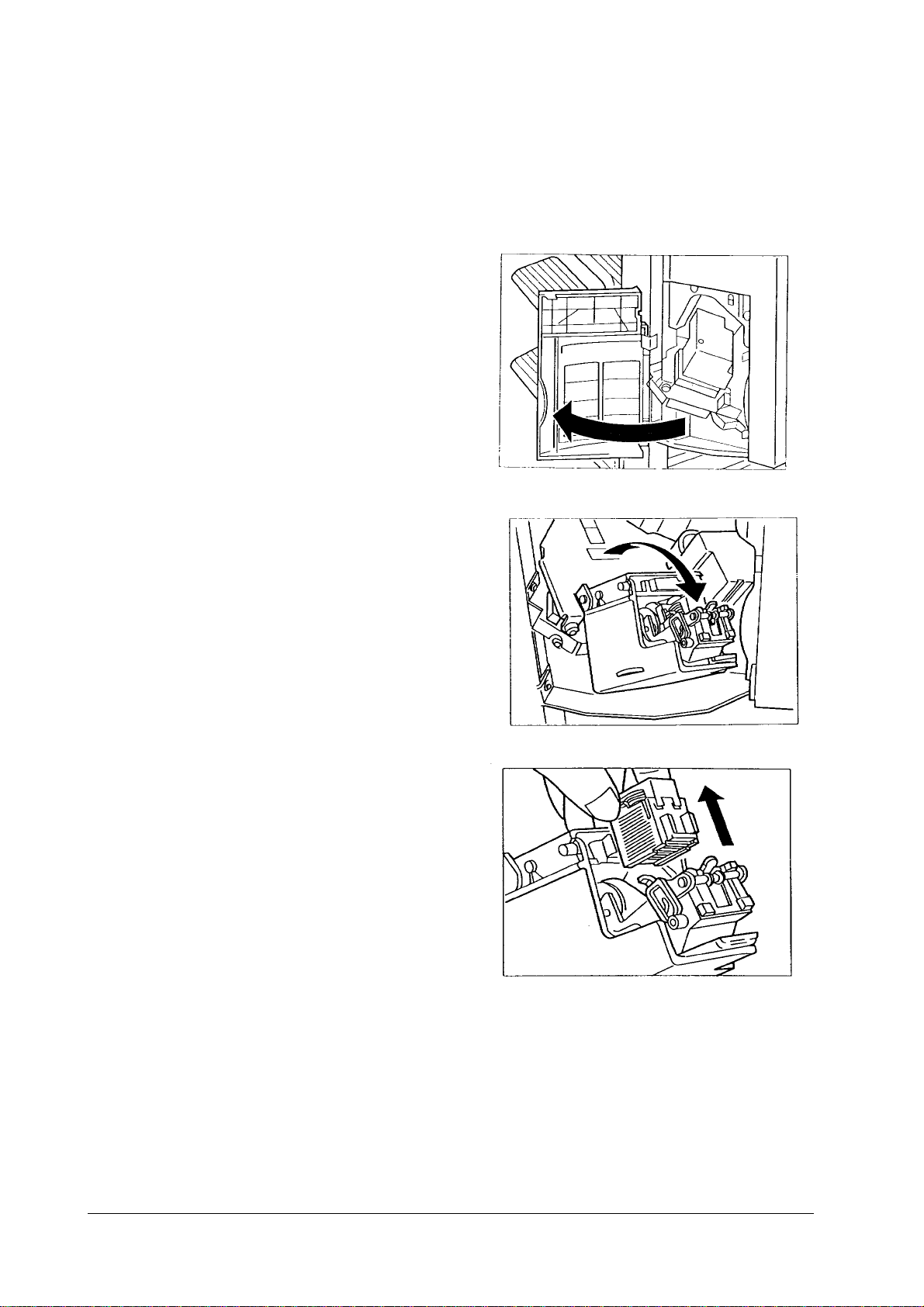

Replacing the staple cartridge

Replace the staple cartridge in accordance with the following procedure.

Open the front cover.

1

Pull out the staple assembly.

2

Remove the staple cartridge.

3

DF-30/DF-31

1-15

Page 19

Insert the staple cartridge

4

until it catches on the clip.

Return the staple assembly

5

to its original position.

FEATURES

Customer maintenance and inspections

1-16

Page 20

FEATURES

Customer maintenance and inspections

DF-30/DF-31

1-17

Page 21

Chapter 2 OPERATION THEORY

Contents

General 2

Basic operations 3

Outline 3

Outline of electrical circuits 3

Finisher driver input/output 5

Feed and drive systems 9

Outline 9

Face-down paper ejection 1 0

Normal stacking 10

Job offset 10

Stapling 11

Face-up paper ejection 12

Normal stacking 12

Feeding and ejection 13

Outline 13

Face-down feeder (inversion operations)/paper ejection operations 16

Face-up feeder, paper ejection operations 16

Job offset 16

Staple operations 18

Outline 18

First page operations 19

Second and subsequent page operations 21

Last page operations 22

Tray operations 23

Stapler unit 25

Tray loading volume detection 26

Stacking mode details 26

Jam detection 27

Power supply 30

Outline 30

Protection functions 30

Page 22

OPERATION THEORY

General

2.1 General

This chapter provides explanations on the purpose, role and mechanical system of

each function, as well as providing an outline of the operational timing of each part

by function.

The descriptions of the digital circuits for this device include signals names without slashes (“/”) for H and PSNS electrical signal levels, and signal names with

slashes, such as L and /SCNON.

H and other signal names without slashes (“/”) are true (indicating that the signal

has been output) at the supply voltage level and false (indicating that the signal

has not been output) at the G ND leve l. L and other s ignal s name s wit h sla she s are

true at the ND level and false at the supply voltage level.

This device uses a microcomputer. However, as it is impossible to run an internal

operation check on a microcomputer, the explanation for the microcomputer operations has been omitted.

Also, as it is a pre-requisite for the internal printed circuit board to be untampered

with by the customer, simple summaries with the use of block diagrams have been

used in this manual to cover the descriptions of these printed circuit boards. Owing

to this, the explanations for circuits only cover the two areas from the sensors to

the input areas of the main substrates and from the output area of the main substrates to the load, and block diagrams are used to explain each function.

DF-30/DF-31

2-2

Page 23

2.2 Basic operations

Outline

The finisher performs the face-down ejection and face-up ejection of paper fed

through from the printer. The job offset and stapling functions are available with

face-down ejection.

These operations are controlled by the finisher driver’s circuit board.

OPERATION THEORY

Basic operations

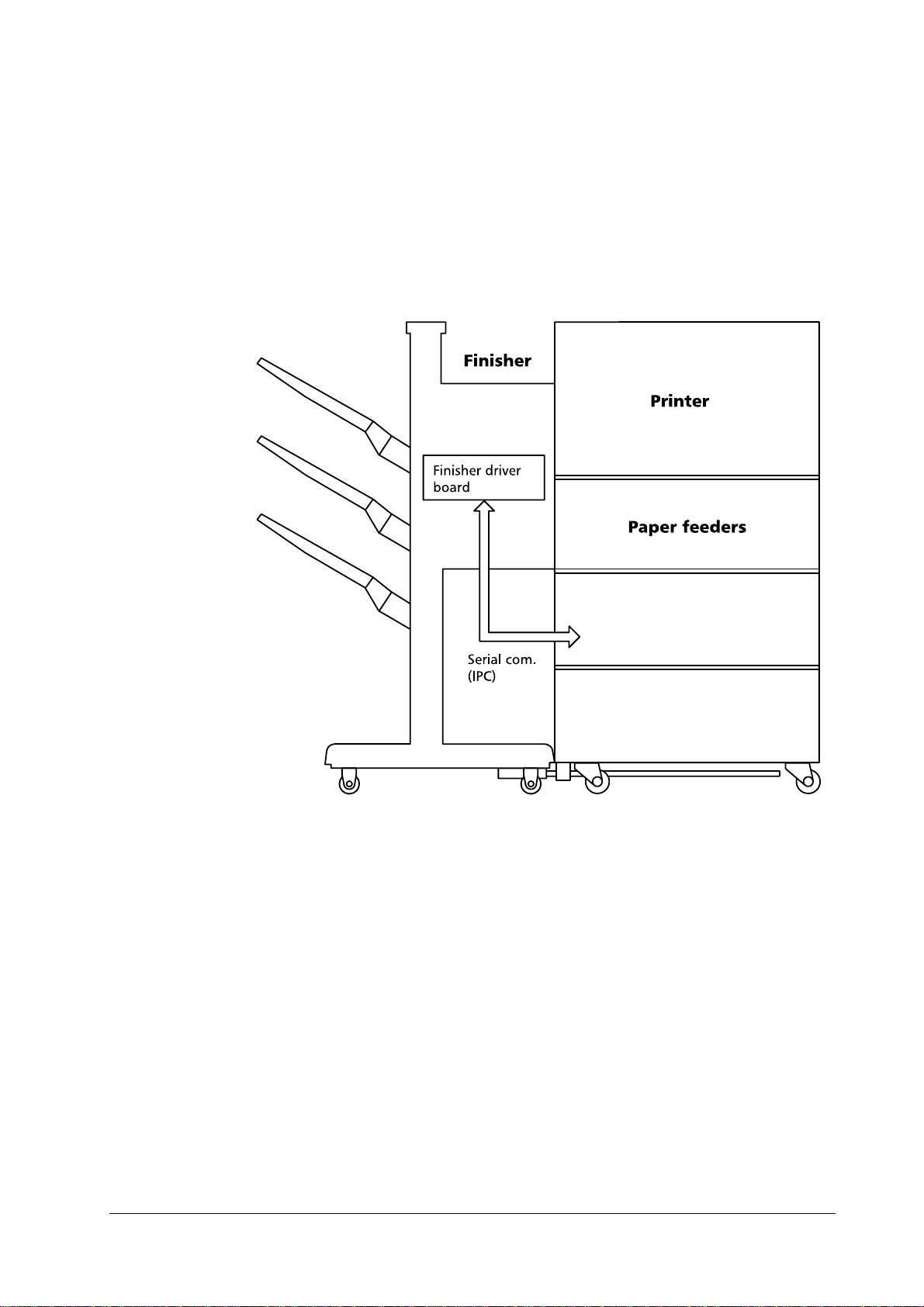

Figure 2.1

Outline of the finisher

Outline of electrical circuits

The finisher’s operational sequence is controlled by the finisher driver’s circuit

board. A 16-bit microcomputer (CPU) is used in the finisher driver’s circuit board,

and this performed serial communications with the sequential control.

The finisher driver operates the solenoids and motors, etc., in accordance with the

various commands that are transmitted from the option controller via the serial

communications line. The finisher driver also notifies the option controller of sensor and switch information via the serial communications line.

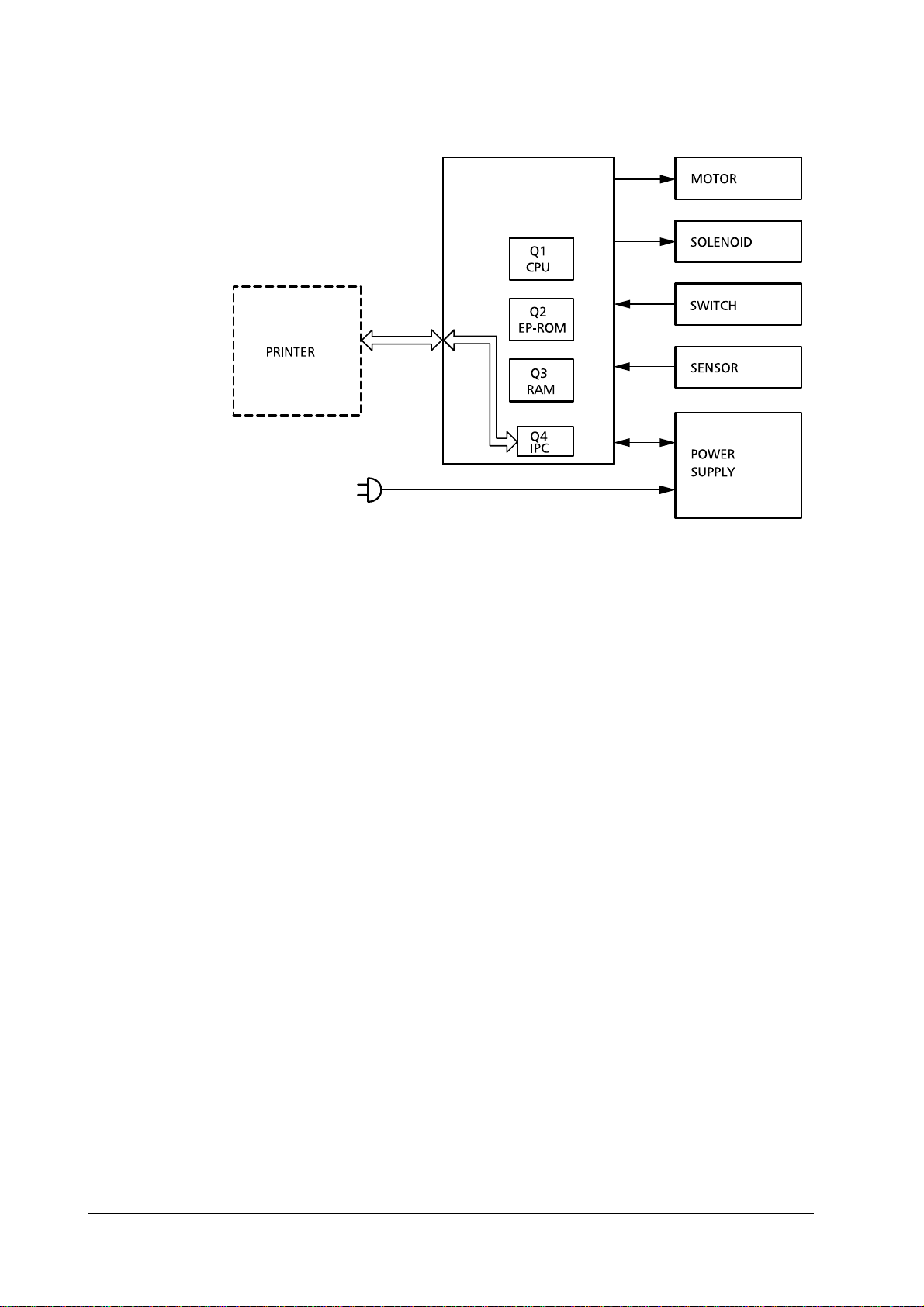

The major roles of the ICs mounted in the finisher driver are as follows.

Q1 (CPU). Sequential control.

•

Q2 (EP-ROM). Sequential programs built in.

•

Q3 (RAM). Used for backing up the initial data.

•

Q4 (IPC). Used for communications control.

•

The diagram below shows the signal flow between the finisher and the printer.

2-3

Page 24

OPERATION THEORY

Basic operations

Figure 2.2

Signal flow between the finisher and the printer

DF-30/DF-31

2-4

Page 25

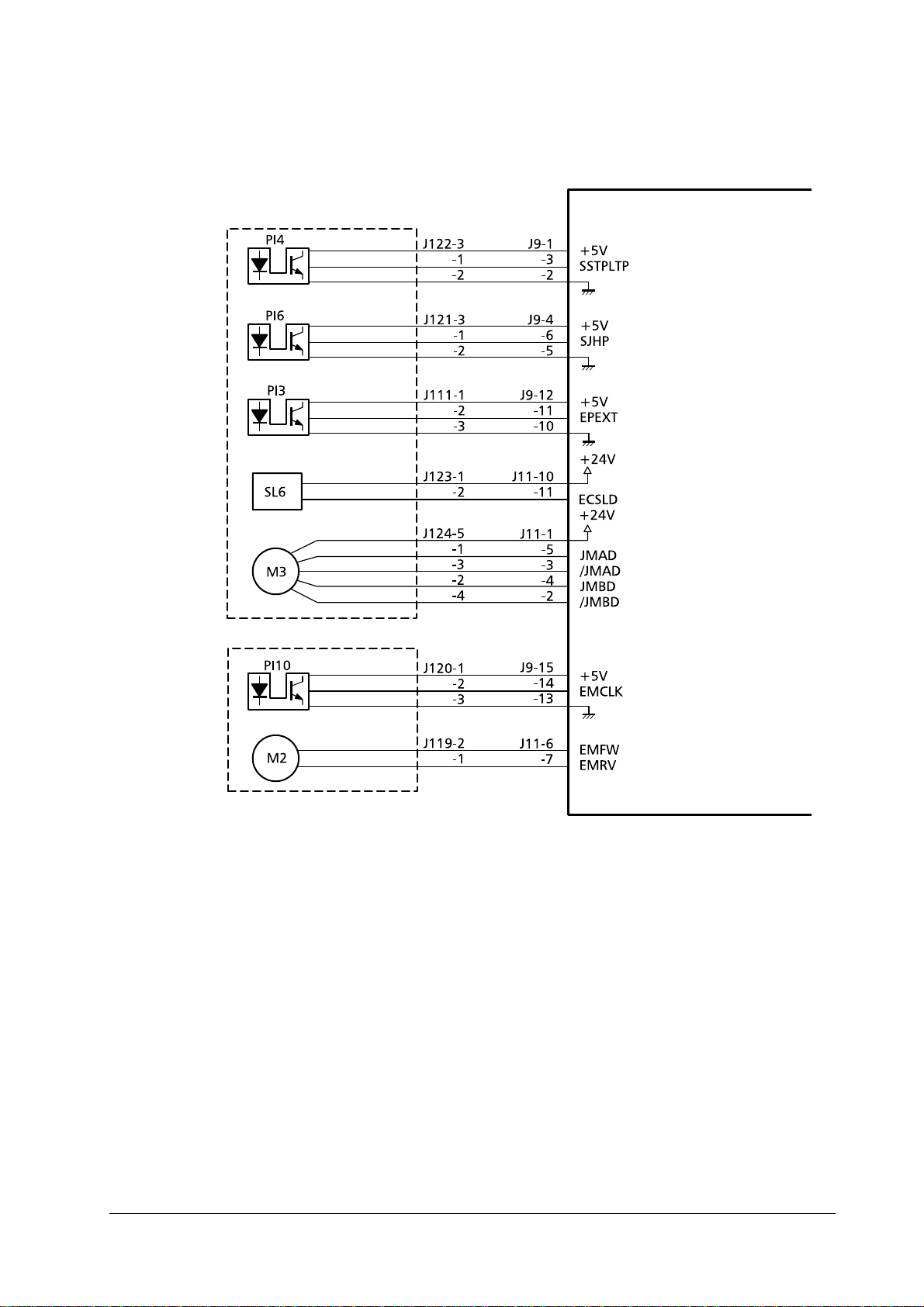

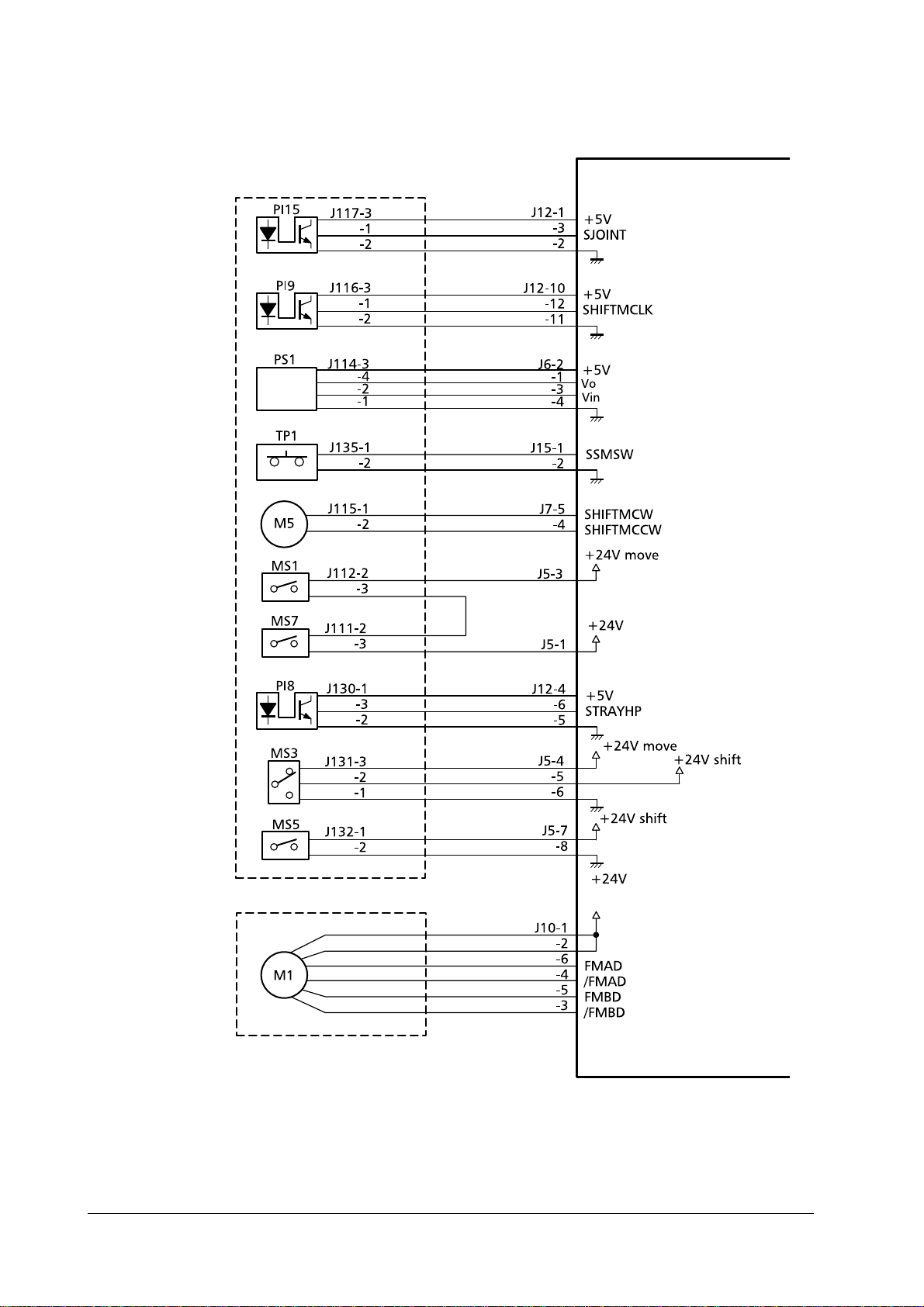

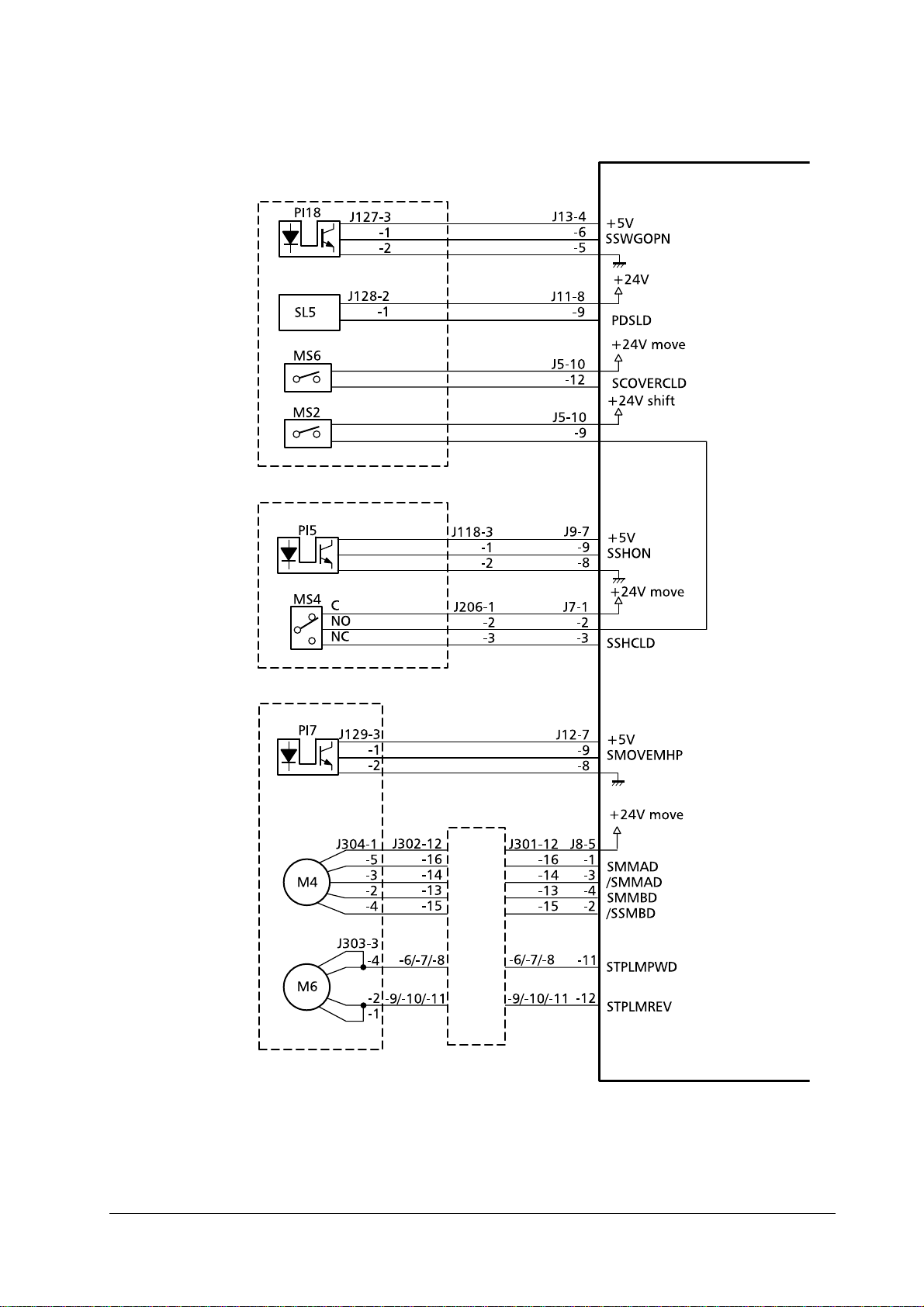

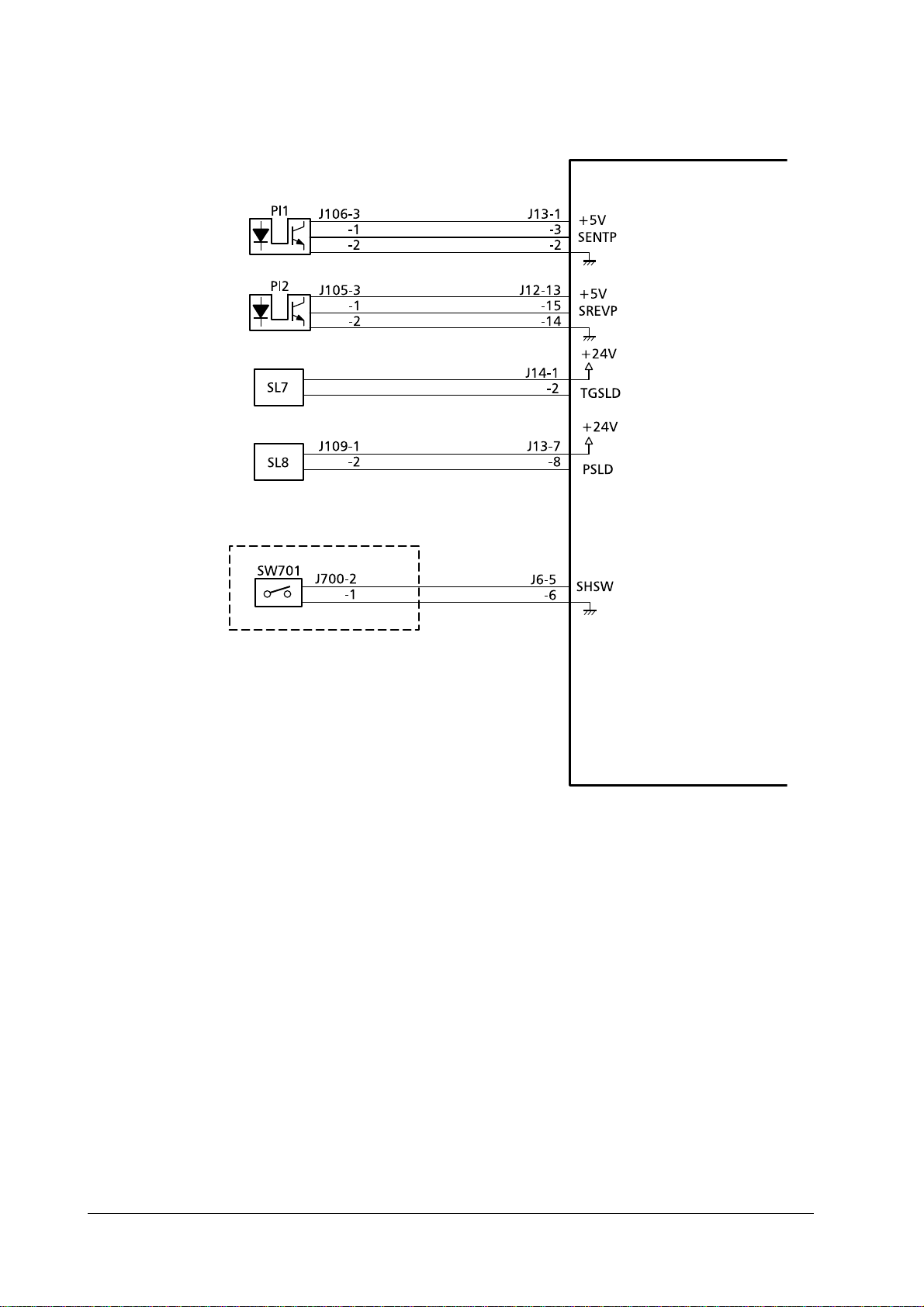

Finisher driver input/output

OPERATION THEORY

Basic operations

Staple tray paper

detection sensor

Matching board

home position

detection sensor

Paper ejectio n

detection sensor

Base board

shelter solenoi d

Matching board

movement mo tor

Staple tray assembly

Finisher driver circuit board

"L" when the sensor

detects paper.

"L" when the sensor

detects the matchi n g

board’s home position.

"L" when the sensor

detects paper.

The base board is

sheltered when "L".

Control signals for

the matching board

movement mo tor

Paper ejection

motor clock

detection sensor

Paper ejection

motor

Pulse emitted in

accordance with the

revolution speed of

the ejection motor

Control signals for

the paper ejection motor

2-5

Page 26

OPERATION THEORY

Basic operations

Frame assembly

Joint sensor

Tray elevation

motor clock

detection sensor

Distance sensor

Tray elevation

motor temperature sensor

Tray elevation

motor

Top cover open/

close detection

switch

Front cover open/

close detection

switch

Tray home position detection

sensor

"L" when connected to the

printer.

Pulse emitted in

accordance with

the revolution

speed of the tray

elevation motor.

Control signal for

the distance sensor

"L" when the

temperature of

the tray elevation

motor is high.

Control signals for

the tray elevation

motor.

"L" when the sensor detection the

tray’s home position.

Safety area

detection switch

Tra y uppe r limit

detection switch

Feeder motor

Control signal for

the feeder mot o r.

DF-30/DF-31

2-6

Page 27

OPERATION THEORY

Basic operations

Swing guide

assembly detection sensor

Paddle drive solenoid

Swing guide

open/close detection switch

Swing guide

open/close detection switch

Shutter close

detection sensor

Shutter open

detection sensor

Swing guide assembly

Shutter guide assembly

Finisher driver circuit board

"L" when the

swing guide is

open.

Paddle revolves

when "L".

"H" when the

shutter is

closed.

"H" when the

shutter is closed

Stapler home

position detection sensor

Intermediate circuit board

Stapler move ment motor

Staple motor

Staple unit

"L" when the stapler’s home position is detected.

Liaision

board

Control signals for

the stapler movement motor.

Control signals

for the stapler

motor

2-7

Page 28

OPERATION THEORY

Basic operations

Finisher driver circuit board

Inlet paper

detection sensor

Inversion paper

detection sensor

Inversion roller

drive solenoid

Face-up flapper

solenoid

Staple exchange

completion

switch

"L" when the sensor detects

paper.

"L" when the sensor detects

paper.

Inversion roller

revolved when

"L".

Paper fed face-up

when "L".

Staple exchange completion

switch circuit board

Staple operations

started when "H".

DF-30/DF-31

2-8

Page 29

OPERATION THEORY

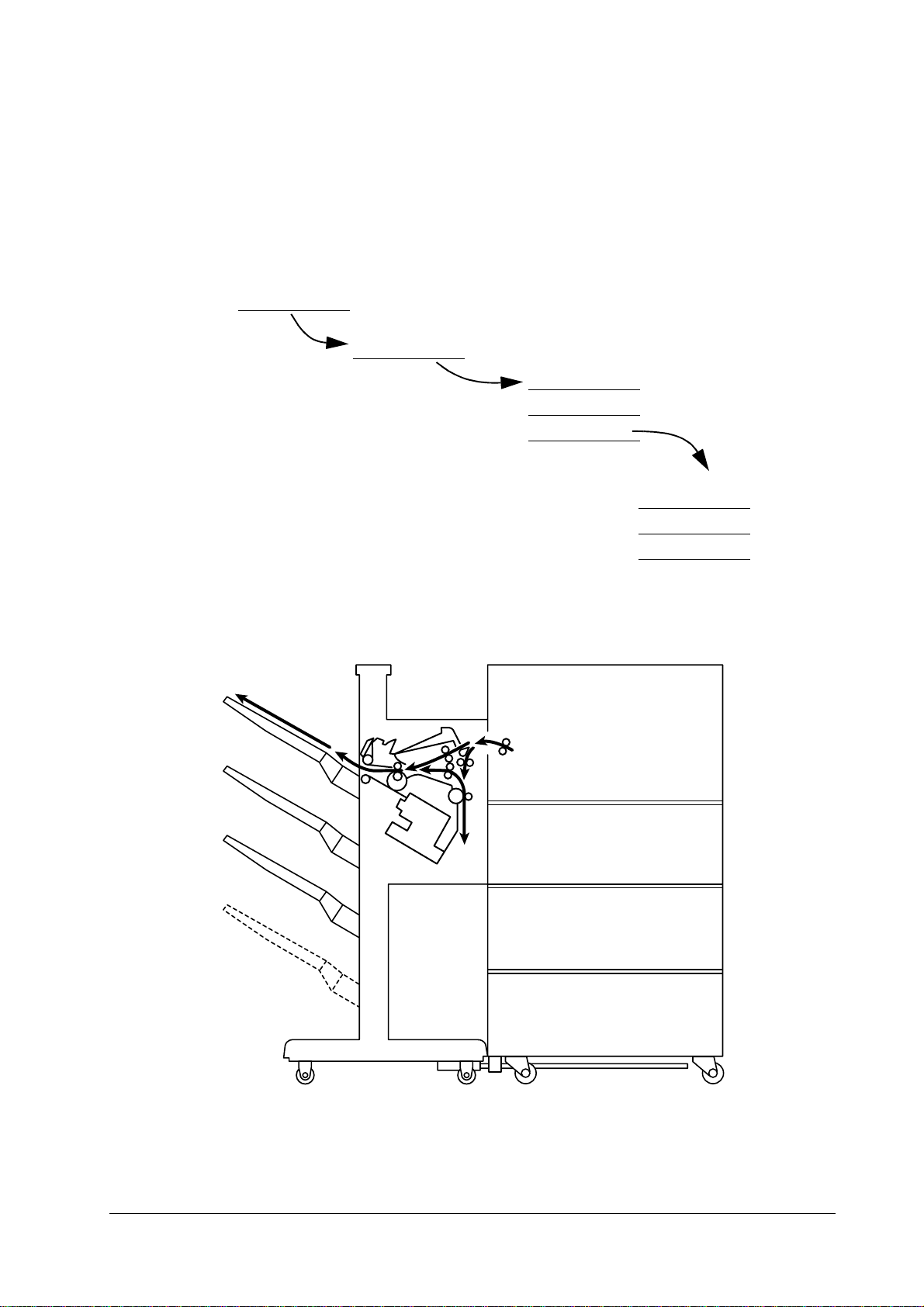

2.3 Feed and drive systems

Outline

This device stacks, shifts, staples and ejects paper to the tray in accordance with

the commands transmitted from the printer.

The four different methods of paper ejection are explained below.

Paper ejection methods

Face-down ejection

Feed and drive systems

Normal stacking

Job offset

Staple

One on the left-hand side

One on the right-hand side

Two in the center

Figure 2.3

Feed and drive sys tem

2-9

Page 30

OPERATION THEORY

Feed and drive systems

Face-down paper ejection

Normal stacking

The paper is ejected to the tray face down after being inverted.

Tray

Printed output

Top guide

Face-up tra nsport

roller

Eject roller #1

Eject roller #2

Bottom guide

Tr ansport roller #2

Face-up

diverter

Transport

roller #1

Job offset

The job offset operates in two ways: First-page-only mode and whole-set-of-pages

mode.

In the first-page-only mode, the first piece of paper is inverted and fed through to

the staple tray . The piece of paper is then shifted forward by approximately 30mm,

and ejected face down to the tray.

The second and subsequent pieces of paper are inverted and ejected to the tray

without being fed into the staple tray.

DF-30/DF-31

•

First page

Tray

Swing guide

Paper ejection roller #1

Stopper

Feed roller #2

Paper ejection

roller #2

Staple tray

2-10

Page 31

•

Second and subsequent pages

Tray

Second and subsequent pages

First page

Swing guide

OPERATION THEORY

Feed and drive systems

Paper ejection roller #1

Tray

Stopper

Staple tray

Feed roller #2

In the whole set of pages mode (defa ult), the whole page of a print jo b is fed into the

staple tray so that the jop is shifted forward. The subsequent job as a whole is not

shifted but delivered in a normal manner, allowing every other job is shifted to

each other.

Stapling

The pages are inverted, stacked in the staple tray, stapled and then ejected to the

tray.

Tray

Paper

Staple

Swing guide

Tray

Stopper

Staple tray

2-11

Page 32

OPERATION THEORY

Feed and drive systems

Figure 2.4

One staple on the le ft-hand side (1)

One staple on the right-hand side (2, angled)

Positions of stapling

Paper width/2

Two staples in the center (3)

One staple on the right-hand side (2, horizontal)

Face-up paper ejection

Normal stacking

The paper is ejected face-up to the tray without being inverted.

Tray

Paper

1

2

3

Upper guide

Paper ejection roller #1

Paper ejection roller #2

Face-up feed roller

Lower guide

Test staples (Not used)

Feed roller #2

1

2

3

Face-up

diverter

Feed roller #1

DF-30/DF-31

Inversion roller

2-12

Page 33

OPERATION THEORY

Feed and drive systems

Feeding and ejection

Outline

When the paper fed through from the printer is to be laid face down in the tray, the

inversion operation is performed.

The feed motor (M1) is a stepping motor, and the paper ejection motor (M2) is a DC

motor. The forward and reverse operation for these motors is controlled by the

microcomputer (CPU) in the finisher driver’s circuit board.

Three photo-interrupters, the inlet paper detection sensor (P11), the inversion

detection sensor (P12) and the paper ejection detection sensor, are situated along

the paper’s feed route, and these check whether the paper has reached its destination or is still in transit.

The finisher driver will judge that a paper jam has occurred if the paper does not

reach or pass each sensor within a pre-determined period of time. In this event,

operations are halted and notification of the jam is sent to the printer.

2-13

Page 34

OPERATION THEORY

Feed and drive systems

Finisher driver circuit board

Table 2.1 Detection signals

(1)

(2)

(3)

(4)

(5)

PS1:

PI1:

P12:

P13:

P14:

DF-30/DF-31

Staple tray pap er detection signal

T ray stacking volume dete ct ion signal

Paper ejection detection signal

Inverted paper detection signal

Inlet paper detection signal

Distance senso r

Inlet paper detection sensor

Inverted paper detection sensor

Paper ejection detection sensor

Staple tray paper detection sensor

2-14

Page 35

OPERATION THEORY

Finisher driver circuit board

Feed and drive systems

Table 2.2 Motors/solenoids— (1 / 2)

M1:

M2:

M3:

M4:

M5:

SL5:

SL7:

SL8:

(1)

(2)

(3)

2-15

Feed motor

Paper ejection motor

Matching board’s movement motor

Stapler movement motor

Tray elevation motor

Paddle drive solenoid

Inversion roller driver solenoid

Face-up flapper drive solenoid

Stapler movement motor drive signal

Tray elevation motor drive s ignal

Matching board movement motor drive signal

Page 36

OPERATION THEORY

Feed and drive systems

Table 2.2 Motors/solenoids— (2 / 2)

(4)

(5)

(6)

(7)

(8)

Paper ejectio n m o to r dr ive signal

Paddle solenoid drive signal

Feed motor drive signal

Inversion solenoid drive signal

Face-up flapper solenoid drive signal

Face-down feeder (inversion op erations)/paper ejection operations

The feeder motor (M1) and paper ejection motor (M2) are started up when the finisher driver receives a paper ejection signal from the printer, and feeder roller #1,

feeder roller #2, paper ejection roller #1 and paper ejection roller #2 are put into

motion. By starting up fee der ro lle r #1 , a si ngle s heet of pap er is t rans fe rred t o the

inverter . A paper detection s ensor (P11) located at the inlet detects the bottom edge

of the paper, and after transferring it to the prescribed position, the inversion roller

driver’ s solenoid (SL7) is activated and the M1 driver starts up the inversion roller.

This conveys the paper through to an inverted position. On ce the paper has been

inverted, it is passed through to the feeder guide by the inversion roller operating

in the reverse direction. The paper is then fed and ejected by feeder roller #1,

feeder roller #2, paper ejection roller #1 and paper ejection roller #2.

Face-up feeder, paper ejection operations

When the paper trans ferred fr om the printer t o the tray is to b e ejec ted face up, the

feeder motor (M1) and th e paper ejecti on motor (M2) a re put into mo tion by a p aper

ejection signal received by the finisher driver from the printer, and the face-up

feeder roller, paper ejection roller #1 and pap er e jecti on ro ller #2 are st ar ted up. At

the same time, the face-up flapper driver solenoid (SL8) is activated, and the flapper is switched across to the face-up side. This enables the paper to be fed and

ejected without being inverted.

Job offset

Shift operations move only the first piece of p aper or whole set of paper (default) fo r

each job, and eject the second and subsequent pieces of paper without moving

them.

The paper is moved with the matching board, and the matching board home position detection sensor (P16) detects whether this board is at the home position or

not.

The matching board movement motor (M3) is activated when the power supply is

switched on in order for the finisher driver to return the matching board to the

home position. If the matching board is already in the home position, the system

enters the stand-by mode. As the distance for moving the matching board is

extended when paper other tha n A3 and A4 (horizonta l) is us ed, the fi nisher dr iver

moves the matching board to the stand-by position.

1

The finisher driver hal ts the operation of the paper ejection motor (M2) after the

first piece of paper has passed the far end of paper ejection roller #1. The gear is

1. The stand-by position is 5mm outside of the paper’s edge.

DF-30/DF-31

2-16

Page 37

OPERATION THEORY

Feed and drive systems

then moved to the swing guide drive assembly after the M2 motor has been put into

reverse. This transmits the operation of M2 across to the gear and raises the swing

guide. The swing guide is raised until it is detected by the swing guide open detection sensor (PI18) and then halted.

The paper is returned to the staple tray by the rubber surface fitted to paper ejection roller #1 when the sw ing gui de is rais ed. Th e paper retu rned to the st aple tray

is then detected by the staple tray paper detection sensor (PI4).

The matching board movement motor (M3) is then activated and the paper moved

by 30mm. Depending on the size of the paper, there are cases where it cannot be

moved by 30mm as it will interfere with the left-hand edge. In this event, the base

board shelter solenoid (SL6) is set at ON, and the paper is moved 30mm after the

left-hand base board has been sheltered.

The finisher driver activates M3 in the reverse direction and moves the matching

board to the stand-by position after the paper has been moved.

The finisher driver then activates M2 in the reverse direction to lower the swing

guide. M2 is run in the forward direction when the swing guide open/close detection switch (MS2) is set at ON, and paper ejection roller #2 is activated. This ejects

the paper to the tray. The second and subsequent pieces of paper for each job are

ejected to the tray without shift movement.

Left-hand base board

Base board shelter solenoid

Matching

board

Matching board

home position

detection sensor

Matching board

movement motor

Paper

For information on modes of stapling available, see page 2-12.

2-17

Page 38

OPERATION THEORY

Feed and drive systems

Staple operations

Outline

The staple operations staple together a specified quantity of paper in the stapler

unit.

The position of the staples will differ in accordance with the stapler motor and the

size of the paper. Refer to table 2-2-1 for further details.

The stapler home position detection sensor (PI7) detects whether the stapler unit is

at the home position or not.

The finisher driver activates the stapler movement motor (M4) after receiving the

start signal from the printer, and moves the stapler unit to the central stand-by

position (note).

Note

Table 2.3 Positions of staples

The central stand-by position is the location where the stapler unit is situated prior to the

paper being returned to the stapler tray in order to prevent the stapler operations being rendered impos sible owing to the paper curling up inside the staple t r ay.

Staple mode A3 A4R

One, on left-hand side

One, on right-hand side

Two, centered

Test (Not used)

Refer to page 12, table 2.4 on (1) to (5) for details.

B5/

B4

(2) (3)

(4)

Ldg

(1)

(5)

Ltr/

Ltr A4 Lgl Otrs

R

DF-30/DF-31

2-18

Page 39

Stapler home

position sensor

OPERATION THEORY

Feed and drive systems

Paper

Stapler

movement

motor

Stapler unit

First page operations

The finisher driver halts the operation of the paper ejection motor (M2) after the

first piece of paper has passed the far end of paper ejection roller #1. The ge ar is

then moved to the swing guide drive assembly after the M2 motor has been put into

reverse. The swing guide is raised by M2 until it is detected by the swing guide

open detection sensor (PI18) and then halted. The paddle drive solenoid is then set

at ON, and the feed motor drive operates the paddle.

The paper is returned to the staple tray by the rubber surface fitted to paper ejection roller #1 when the swing guide is opened where it is detected by the staple tray

paper detection sensor (PI4).

The matching board movement motor (M3) is activated and the pieces of paper are

matched up.

2-19

Page 40

OPERATION THEORY

Feed and drive systems

Swing guide

Swing guide open

detection sensor

Swing guide open

detection switch

Paper ejection

roller #2

Swing guide

Fist page of paper

Paper ejection

roller #2

Tray

Feed m otor cl ock

detection sensor

Paper eject io n motor

Paper ejection roller #1

Rubber roller

Staple tray

DF-30/DF-31

Stapler unit

2-20

Page 41

OPERATION THEORY

Feed and drive systems

Second and subsequent page operations

The finisher driver halts the operation of the paper ejection motor (M2) when the

bottom edge of the second and subsequent pieces of paper have passed 20mm

through paper ejection roller #1. The paddle drive solenoid is then set at ON, and

the feed motor (M1) drive ope rates the paddle. This returns the pa per to the s tapler

tray, activates the matching board movement motor (M3) and matches up the

pieces of paper.

Paddle

Paddle driver

solenoid

piece of pape r

Second and subsequent

pieces of paper

Swing guideSecond or the subsequent

First piece of paper

Stopper

Stapler unit

Paddle

Paper ejection roller #1

Rubber roller

Tray

Paper ejectio n

roller #2

Staple tray

Stapler unit

2-21

Page 42

OPERATION THEORY

Feed and drive systems

Last page operations

The finisher driver sta rts up M3 once again after the matching process has been

completed for the last piece of paper in order to move the matching board to the

staple matching position (note #1). The multiple sheets of paper are then matched

up and the motor halted. The finisher driver then activates M2 in the reverse direction and lowers the swing guide.

The finisher driver activates the stapling process in accordance with the specified

staple mode transmitted from the printer (refer to fig.2-2-12 on page 2-19) and staples the pages together.

The finisher driv er activat es M3 when t he stapli ng process has been completed an d

moves the matching bo ar d to t he shel ter p osi ti on ( not e #2 ) whe n t he p aper i s being

ejected. The paper ejection mot or (M2) is then ac tiva ted i n the forwa rd dir ectio n to

operate ejection ro ller #2 and eject th e stapled pages to the tray.

Swing guide

Note

Paper ejection roller #2

Paper ejection motor

1. The staple matching position is 0.5mm inside the horizontal width of the paper. 2. The shelter position during paper ejection is 5.0mm outside of the horizontal width of the paper.

DF-30/DF-31

2-22

Page 43

Swing guide

Paper

Paper ejection

roller #2

OPERATION THEORY

Feed and drive systems

Staple tray

Stapler unit

Tray operations

The finisher driver is equip ped wit h three trays , and pa per can be eject ed to ei ther

of these trays. The trays are moved upwards and downwards with the tray elevation motor (M5). The position of each tray is detected by the tray elevation motor

clock detection sensor (PI9) with the amount of encoder pulses fitted to M5. The

tray home position detection sensor (PI8) detects whether the trays are at their

home positions or not.

2-23

Page 44

OPERATION THEORY

Feed and drive systems

Tr ay #1

Tr ay #2

Tray guide

T r ay upp er lim it detection

switch

Tr ay #3

Tray elevation motor

Safe area detection switch

The finisher driver raises and lowers the tray guide until it is aligned with the

paper ejection outlet specified by the printer.

The upper limit for the tray is detected by the tray upper limit detection switch

(MS5). The tray elevation motor (M5) is halted when the finisher driver sets MS5

to ON.

Tray elevation motor clock

detection sensor

Encoder

Tray home position sensor

DF-30/DF-31

The height of the paper eje c ted t o t he tray i s detect ed by t he d ista nce se nsor (PS1 ).

The tray is lowered when the height of the paper reaches the stipulated value.

The 24V power supply to the tray elevation motor is cut off and the finisher driver

operations halted if the safe area detection switch (MS3) is set at ON when the

shutter and swing guide are open.

The finisher driver will noti fy the printer that a fault has occurred with the tray

elevation motor in the following cases:

2-24

Page 45

OPERATION THEORY

Feed and drive systems

When the home position detection process does not end within 16.5 seconds of it starting.

1

When the tray elevation motor clock detection sensor (PI9) does not detect the tray eleva-

2

tion motor clock detection signal (SHIFTMCLK) within 0.2 seconds of tray elevation

starting.

When the tray upper limit detection switch (MS5) is set at ON during tray elevation.

3

Stapler unit

Staple operations are performed by the staple motor (M6), and stapling is completed for each revolution of the cam.

The home position for the cam is detected by the staple operation home position

detection sensor (PT2) being set at ON.

The forward and reverse operations of the staple motor (M6) are controlled by a

microcomputer (CPU) situated on the finisher driver circuit board.

The staple operations are returned to the initial status by the finisher driver operating M6 in the reverse direction when PT2 is OFF and continuing to operate until

PT2 is ON.

The staple detection sensor (PT1) detects where staples exist within the staple cartridge.

The staple motor (M6) cannot be operated unless the swing guide close detection

switches (MS2, MS6) are ON (with the swing guide closed). This is a safety protection function to prevent the stapler from operating when f ingers are inside.

The finisher driver will notify the option controller of a fault with the staple motor

in the following cases:

When the home position detection process does not end within 0.5 seconds of it starting.

1

When the staple operation home position detection sensor (PT2) is not set at ON within

2

0.5 seconds of staple operations being started.

Also, the finisher driver will judge a staple jam if the staple operation home position detection sensor (PT2) is not se t at ON within 0.5 seconds of it being set at

OFF after staple operations have been started, and the staple motor (M6) will be

operated in the reverse direction until PT2 is set at ON. The printer will also be

notified of the jam.

Staple cartridge

Staple ejection

plate

Staple anvil

Staple sensor

Staple motor

Staple operation home position sensor

2-25

Page 46

OPERATION THEORY

Feed and drive systems

Cam

Tray loading volume detection

The number of pages and stacks (staple number) of paper ejected to the tray is

recorded by the finisher driver, and the height of the paper surface is detected by

the distance sensor (PS1). The maximum amount of paper that can be stacked in

each tray is shown in the table below.

The finisher driver will halt operations when the conditions outlined in the table

have been satisfied, and the printer will be notified that the tray is full.

Table 2.4 Loding capacities

Tray #

Tray #1 88mm 88mm, 300 pages or 30 stacks 48mm, 300 pages or 30 stacks

Tray #2 95mm 95mm, 300 pages or 30 stacks 48mm, 300 pages or 30 stacks

Tray #3 95mm 95mm, 300 pages or 30 stacks 48mm, 300 pages or 30 stacks

Stacking mode details

Mode #1.

For the normal stacking of pages of the same size, of small sizes1 or dur-

ing job offset.

Mode #2.

When height, number of pages and number of stacks are relevant for sta-

ples only.

Tray mode (See

12 3

details

below.)

(note #3)

(note #3)

(note #3)

Mode #3.

sizes

Note

1. Small sizes include A4 vertical/horizontal, letter vertical/horizontal, B5 and A5

2. Large sizes include A3, B4, legal and ledger

DF-30/DF-31

Number of pages and stacks are only relevant for stapled paper.

Other cases (cross-mode stacking and cross-s ize stacking, including large

2

).

2-26

Page 47

OPERATION THEORY

Feed and drive systems

Distance sensor

Paper

Jam detection

The printer is equipped with the fol lowing paper detection sen sors to determine the

existence of paper and to determine that the paper is being fed correctly:

•

- Inlet paper detection sensor (PI1)

•

- Paper inversion detection sensor (PI2)

•

- Paper ejection detection sensor (PI3)

A jam is determined by detecting if the paper has been fed through to the sensor at

a certain time pre-set in the microcomputer (CPU) located on the finisher driver.

The finisher’s paper ejection operations are halted if the CPU determines that a

jam has occurred, and this is notified to the printer.

Delayed jam (delayed jam at the inlet sens or).

The CPU determines a delayed jam if the

paper does not arrive at the inlet’ s de tection sens or despite b eing fed the prescribed

distance (approximately 300mm) after the paper ejection signal is received from

the printer.

L1 = approximately 300mm

PINT

L1

Jam check

PINT

L1

Paper ejection signal

Inlet paper detection sensor (PI1)

Feeder motor (M1)

2-27

Normal

Abnormal

Page 48

OPERATION THEORY

Feed and drive systems

Accumulated jam #1 (inlet sensor accumulated jam).

lated jam has occurred when the inlet paper d etection sensor (PI1) detects t he front

edge of the paper but not the back edge after the paper has been fed the stipulated

distance.

Jam check

Inlet paper detection sensor (PI1)

Feed motor (M1)

L2 = the approximate size of the paper X 2mm

Accumulated jam #2 (paper ejection detection sensor delayed jam).

an accumulated jam has occurred when the inlet paper detection sensor (PI1)

detects the front edge of the paper but the paper does not arrive at the paper ejection detection sensor (PI3 ) even after the paper has been fed the stipulated distance.

PINT

L

L

Normal

The CPU judges that an accumu-

PINT

L

L

Abnormal

The CPU judges that

Inlet paper detection sensor (PI1)

Jam check

Paper ejection detection sensor (PI3)

Feed motor (M1)

L3 = approximately 360mm (for straight paper ejection), approximately 340mm (for inverted

paper ejection)

Accumulated jam #2 (paper ejection detection sensor delayed jam).

an accumulated jam has occurred when the paper ejection detection sensor (PI3)

detects the front edge of the paper but not the back edge after the paper has been

fed the stipulated distance.

PINT

L

Normal

PINT

L

Abnormal

The CPU judges that

DF-30/DF-31

2-28

Page 49

OPERATION THEORY

Feed and drive systems

Jam check

Inlet paper detection sensor (PI3)

Feed motor (M1)

L4 = the approximate size of the paper X 2mm

Power on jam.

The CPU judges that a po wer on jam ha s occurred if paper i s det ected

by either the inlet paper detec tion sensor (PI1 ), the inverted pa per detectio n sensor

(PI2) or the paper ejection detection sensor (PI3) when the power supply to the finisher is switched on.

PINT

L

Normal

PINT

L

Abnormal

2-29

Page 50

OPERATION THEORY

Power supply

2.4 Power supply

Outline

This devices uses a remote switch system for the power supply.

The printer outputs a power on signal (PWRON-IN) to the power supply assembly

when the power switch to the printer is turned on, and the power supply is

switched on. The power supply circuit supplies +24V to the finisher driver when

the PWRON-IN signal is "H".

This +24V is used to drive the feed motor , paper ejection motor, solenoids and other

elements. The finisher driver generate +5V, which is used for the sensors and the

integrated circuits in the finisher driver’s circuit board.

A block diagram is provided below.

Protection functions

The +24V power supply circuit is equipped with an excess current protection circuit

to automatically cut off the output voltage when short circuits or other trouble is

triggered and excess currents flow in order to prevent the power supply circuit

from being damaged.

Consequently, the power switch to the printer is switched off when the excess current protection function is activated and no DC voltage is output from the power

supply circuit, and the power is switched on again after the trouble with the load

has been repaired.

DF-30/DF-31

2-30

Page 51

Chapter 3 MECHANICAL SYSTEM

Contents

General 2

External control 2

External cover 2

Front door assembly 3

Rear cover 3

Upper door assembly 4

Right-hand cover assembly 4

Upper cover 5

Front cover 6

Tray assembly 7

Slat upper guide 7

Slat lower guide 8

Feeder 9

Staple tray unit 9

Removing the staple tray unit from the main unit 9

Dismantling and assembly 10

Boards 21

Finisher driver circuit board 21

Lithium battery 22

Power supply unit 23

Interface circuit board 24

Staple exchange completion switch circuit board 25

Page 52

MECHANICAL SYSTEM

General

3.1 General

This chapter explains the mechanical features, operations and procedures for dismantling and assembling the finisher driver. Ensure that the following precautions

are observed when proceeding with these tasks.

Caution Always disconnect the power supply from the socket when dismantling or reas-

sembling the device.

Unless otherwise stated, assembly procedures should be performed in the reverse

sequence to dismantling.

Care must be taken not to use the wrong screws (length, diameter) du ring assembly.

Never attempt to operate the device with parts removed.

Discharge static electricity from the body by touching a metal part of the printer

prior to removing or replacing circuit boards to prevent them from being damaged through static electricity.

External control

External cover

DF-30/DF-31

1. Tray

2. Upper door assembly

3. Upper cover assembly

4. Rear cover

5. Left-hand cover assembly

6. Front cover

7. Front door assembly

3-2

Page 53

MECHANICAL SYSTEM

Front door assembly

Open the front door assembly.

1

Remove the single screw.

2

Lift off the door assembly after removing the bearings.

3

General

Rear cover

Open the upper door assembly

1

Remove the three screws

2

Lift out the rear cover.

3

3-3

Page 54

MECHANICAL SYSTEM

General

Upper door assembly

Open the upper door assembly.

1

Undo the two clips and remove the upper door assembly.

2

Right-hand cover assembly

Open the right-hand cover assembly.

1

Remove the hinge.

2

DF-30/DF-31

3-4

Page 55

MECHANICAL SYSTEM

Remove the right-hand cover by pulling it out from the front.

3

General

Upper cover

Open the upper cover assembly

1

Remove the rear cover assembly

2

Open the left-hand cover assembly

3

Undo the two clips (➊ below) and lift the upper cover (➋ below) out.

4

3-5

Page 56

MECHANICAL SYSTEM

General

Front cover

Remove the three screws (➊ below) that secure the front cover (➋ below).

1

Undo the three c lips (➊ below) and remove the front cover (➋ below).

2

DF-30/DF-31

3-6

Page 57

Tray assembly

Remove the slide guide assembly

1

Remove the stopper

2

Lift out the tray assembly

3

MECHANICAL SYSTEM

General

Slat upper guide

Remove the slide guide (➊ below).

1

Remove the five screws (➋, 4M, below).

2

Remove the single screw (➌, 3M, below) and remove the slat upper guide (➍

3

below).

3-7

Page 58

MECHANICAL SYSTEM

General

Slat lower guide

Remove the slide guide.

1

Remove the three screws (4M).

2

Remove the three screws (3M) and pull the slat lower guide forward.

3

Remove the flux lines (➋ below) from the flux line fa stener (➊ below).

4

Remove the two connectors (➌ below) and remove the slat lower guide (➍

5

below).

DF-30/DF-31

3-8

Page 59

3.2 Feeder

Staple tray unit

Removing the staple tray unit from the main unit

Remove the rear cover.

1

Remove the slat upper guide and the slat lower guide.

2

Remove the two connectors (➊ below).

3

MECHANICAL SYSTEM

Feeder

Remove the flux lines (➋ below) from the flux li ne fastener (➊ below).

4

Remove the two connectors (➌ below).

5

3-9

Page 60

MECHANICAL SYSTEM

Feeder

Remove the three screws and then the staple tray unit

6

Dismantling and assembly

Paper ejection motor

Remove the single screw (➊ below) and then remove the motor cover (➋

1

below).

Remove the two screws (➌ below) and then remove the paper ejection motor

2

(➍ below).

DF-30/DF-31

3-10

Page 61

MECHANICAL SYSTEM

Matching board movement motor

Remove the single connector (➊ below).

1

Remove the two screws (➋ below) and then remove the matching board move-

2

ment motor (➌ below).

Feeder

Paper ejection roller #1

Undo the clip and remove the arm.

1

Remove the two rollers.

2

Remove the two screws and then remove the staple guide.

3

Remove the E-shaped fastening ring (➊ below) and then remove the single

4

bearing (➋ below).

Slide them in the direction of the arrow and then remove the paper ejection

5

roller (➌ below).

3-11

Page 62

MECHANICAL SYSTEM

Feeder

Remove the single E-shaped fastening ring (➋ below) from the paper ejection

6

roller (➊), and then remove the single cam (➌), the single gear (➍), the single

horizontal pin and the single bearing (➎).

Remove the single E-shaped fastening ring (➋ below) from the paper ejection

7

roller (➊), and then remove the single horizontal pin (➌) and the single gear

(➍).

DF-30/DF-31

3-12

Page 63

MECHANICAL SYSTEM

Feeder

Face-up flapper solenoid

Remove the face-up flapper sol enoid (➋ below) from the main unit:

Remove the rear cover and the upper cover.

1

Remove the power supply assembly in accordance with the procedures

2

explained between 1) and 4) on page 3-23,

Remove the single connector (➊ below).

3

Power supply unit

.

Remove the two screws (➊ below) from inside the unit, and then remove the

4

face-up flapper solenoid (➋).

3-13

Page 64

MECHANICAL SYSTEM

Feeder

Staple assembly

Remove the staple assembly from the device:

Remove the rear cover.

1

Remove the single screw (➋) and then remove the circuit board cover (➊).

2

DF-30/DF-31

Remove the single connector (J8 finisher driver, ➊). Detach the flexib le cable

3

from the guide.(➋=circuit board cover)

3-14

Page 65

MECHANICAL SYSTEM

Feeder

4) Perform the procedure explained between 1) and 6) on page 3-6 to remove

4

the staple tray unit.

5) Remove the flux line fastener and the flux line band, and then remove the

5

single connector.

6) Remove the tw o screws

6

Remove the two screws and then remove the staple assembly

7

3-15

Page 66

MECHANICAL SYSTEM

Feeder

Tray drive assembly

Remove the tray driver assembly from the device:

Perform the procedure explained on page 3-9,

1

Staple tray unit

staple tray unit.

Remove the E-shaped fastener ring (➊) and then remove the bearing (➋).

2

Remove the two screws (➌) and then remove the cover (➍).

3

to remove the

DF-30/DF-31

Remove the two connectors (➊).

4

3-16

Page 67

MECHANICAL SYSTEM

Feeder

Remove the flux line fastener (➊).

5

Remove the four connectors (➋).

6

Remove the three screws (➊) and then remove the tray drive assembly (➋).

7

3-17

Page 68

MECHANICAL SYSTEM

Feeder

Feed motor

Remove the feed motor from the device:

Perform the procedure explained on page 3-23,

1

Power supply unit

the power supply unit.

Remove the C-shaped fastener ring and then remove the single gear.

2

Remove the two screws and then remove the feed motor from inside the unit.

3

, to remove

DF-30/DF-31

3-18

Page 69

MECHANICAL SYSTEM

Inversion roller

Remove the inversion roller from the device:

Perform the procedure explained on page 3-23,

1

Power supply unit

the power supply unit.

Remove the single screw (➊) and then remove the inversion solenoid (➋).

2

Remove the single spring (➌).

3

Remove the E-shaped fastener ring (➍) and then remove the two gears (➎).

4

Feeder

to remove

Remove the single bearing

5

Remove the single spring restraint (➊) and then remove the single spring (➋).

6

Remove the E-shaped fastening ring (➌) and the single bearing (➍), and then

7

remove the inversion roller (➎).

3-19

Page 70

MECHANICAL SYSTEM

Feeder

DF-30/DF-31

3-20

Page 71

3.3 Boards

Finisher driver circuit board

Remove the finisher driver circuit board from the devi ce:

Remove the rear cover.

1

Remove all the connectors.

2

Remove the four screws (➊) and then remove the finisher driver circuit board

3

(➋).

MECHANICAL SYSTEM

Boards

3-21

Page 72

MECHANICAL SYSTEM

Boards

Lithium battery

Caution Replace the lithium battery with SONY Lithium Cell CR2450 only. Use of another

battery may pres ent a risk of fire or explosion.

The lithium battery includes lithium, an organic catalyst and other flammable sub-

stances. The battery may present a fire or chemical burn hazard if misteated. Do

not recharge, disassemble, or dispose of in fire.

Caution Keep the battery out of reach of children and discard used battery promptly.

When disposing the lithium battery, observe the applicable local lows and ordinances.

The package of lithium battery includes a se al (➌) in order to prevent short-circuit.

When you replace the batte ry (➋), be sure to seal the new battery after you set it on

the board (➊).

DF-30/DF-31

3-22

Page 73

MECHANICAL SYSTEM

Power supply unit

Remove the power supply unit from the device:

Perform the procedure explained between 1) and 4) on page 3-14 to remove the

1

finisher driver circuit board.

Remove the single 3M screw (➊) and the three 4M screws (➋), and then

2

remove the power supply unit (➌).

Boards

Remove the flux line fastener (➋) from the power supply unit (➊) and then

3

remove the single connector (➌).

Remove the three screws (➋) from the power supply unit (➊) and then remove

4

the cover (➌).

3-23

Page 74

MECHANICAL SYSTEM

Boards

Interface circuit board

Remove the interface circuit board from the device:

Remove the rear cover.

1

Remove the three connectors (➊).

2

Remove the two screws (➋) and then remove the interface circuit board (➌).

3

DF-30/DF-31

3-24

Page 75

MECHANICAL SYSTEM

Boards

Staple exchange completion switch circuit board

Remove the staple exchange completion switch circuit board from the device:

Remove the front cover.

1

Remove the single connector (➊).

2

Remove the single screw (➋) and then remove the staple exchange completion

3

switch circuit board (➌).

3-25

Page 76

MECHANICAL SYSTEM

Boards

This page left intentionally blank

DF-30/DF-31

3-26

Page 77

Chapter 4 TROUBLESHOOTING

Contents

General 2

Maintenance and inspections 3

Regular replacement parts 3

Life-expectancy chart for consumable parts 3

Regular servicing 3

Tools 4

Standard tools 4

Special tools 4

Ratings and adjus tments 5

Mechanical adjustments 5

Electrical adjus tm ents 5

Distance sensor adjustment 5

Initial inspections 6

Confirming the installation environment 6

Confirm the paper to be used 6

Others 6

Handling operation defects 7

Mechanical defects 7

The power supply will not switch on 7

Distance sensor defects 8

Shutter defects 8

Swing guide defects 8

Abnormal tray height 9

Inversion roller will not operate 9

Printer error messages 10

Stapler movem en t motor defects 10

Staple motor defects 10

Matching board movement motor defects 11

Tray elevation motor defects 11

Feed motor defects 11

Paper ejection motor defects 12

Wiring and function of electrical parts 13

Switches 13

Sensors 13

Solenoids and motors 14

Printed circuit board 15

Connectors 15

List of solvents and lubricants 16

Page 78

TROUBLESHOOTING

General

4.1 General

This section explains on the following topics:

•

Maintenance and inspections

•

•

•

•

•

•

on page 4-4

Tools

Ratings and adjustments

Initial inspections

Handling operation defects

Wiring and function of electrical parts

List of solvents and lubricants

on page 4-6

on page 4-3

on page 4-5

on page 4-7

on page 4-19

on page 4-13

DF-30/DF-31

4-2

Page 79

Maintenance and inspections

4.2 Maintenance and inspections

Regular replacement parts

There are no parts that require regular replacement on the main unit.

TROUBLESHOOTING

Note

Regular replacement parts are the parts that must be replaced regularly without fail to ensure

a constant standard of functionality with the product (parts which have a great effect during

malfunctions despite there being no visible changes or damage to the outsi de of t he devic e.) It

is recommended that the stipulated parts are replaced during the earliest regular service.

Life-expectancy chart for co ns umable parts

There are certain parts that may require replacement owing to deterioration or

damage at least once during the period of product warranty. The expected average

life span for parts that may require replacement owing to defects is shown below.

Table 4.1 Consumable parts

Part name Part number Qty

Stapler kit 3 100,000 staples As of April, 1998

The above list is only for reference purposes. Expected life spans may differ

Note.

Expected

average life span

Remarks

in accordance with experimental test data.

Regular servicing

There are no areas that require regular servicing.

4-3

Page 80

TROUBLESHOOTING

Tools

4.3 Tools

Standard tools

The standard tools require d for serv ic ing the finishe r are the sa me as tho se fo r the

printer.

Special tools

There are no special tools required for servicing the finisher.

DF-30/DF-31

4-4

Page 81

4.4 Ratings and adjustments

Mechanical adjustments

There are no mechanical adjustment required for the finisher.

Electrical adjustments

Distance sensor adjustment

The distance sensor must be adjusted when the finisher driver’s circuit board or

the distance sensor is replaced, and when an error occurs in the back-up RAM.

The distance sensor is adjusted prior to leaving the factory. It is therefore not necessary to make these adjustments at the time of installation, but they must be corrected if the finisher driver circuit or distance sensor is replaced after this. Initial

corrections must also be made when an error occurs in the back-up RAM. The procedure for this is as follows:

Confirm that the voltage of the lithium battery in the finisher driver circuit board is 2.7V

1

or more.

Set the finisher driver circuit board’s dip switch (SW1) #1 to OFF, #2 to OFF, #3 to OFF

2

and #4 to ON.

Insert one sheet of white paper in each of the trays.

3

Press the push switch (SW2). (To start adjustment)

4

Move the trays to each distance adjustment position and load the distance data.

5

LED2 will blink during the adjustment process, and will be illuminated when adjustment

6

is complete. If correct adjustment cannot be performed, LED2 will be extinguished and

the system will shut down in that position.

TROUBLESHOOTING

Ratings and adjustments

4-5

Page 82

TROUBLESHOOTING

Initial inspections

4.5 Initial inspections

Confirming the installation environment

Confirm that the environment in which the device is to be used conforms to the following standards:

a

b

c

d

e

f

Confirm the paper to be used

a

b

Confirm that the power supply is within +/-10% of the rated voltage.

Ensure that the device is install on a flat surface.

Ensure that the surrounding temperature is between 10 and 32.5 degrees Cel-

sius, and the surrounding humidity is between 20 and 80% RH.

Avoid areas when the device may be exposed to ammonia gas, high tempera-

tures and humidity (nearby water supply faucets, water boilers and humidifiers,) excessive coldness, naked flames or excessive dust.

Avoid areas where the device will be exposed to direct sunlight. If this is

unavoidable, ensure that the device is prot ected by a curtain or some other

form of screen.

Ensure the area is well ventilated.

Is the paper recommended for use with the finisher being used?

Is the paper damp?

Check the above points by inserted a new pack of paper and performing a test run.

Others

If the finisher is stored in a cold area, such as a warehouse during the winter

months, and then brought into a warm room, condensation may build up on the

various parts and lead to a wide range of trouble. Either dry off all parts of the

device or leave it to stand with the electricity on for between 10 to 20 minutes when

condensation has built up.

DF-30/DF-31

4-6

Page 83

Handling operation defects

4.6 Handling operation defects

Take note of the following precautions when implementing the measures for handling operational defects outlined in this section.

When measuring the voltage of the specified connector terminals, check to ensure

that there are no contact defects in the connector.

Discharge static electricity from the body by touching a metal part of the printer

prior to handling circuit boards to prevent them from being damaged through

static electricity.

Mechanical defects

The power supply will not switch on

Possible causes Suggested remedy

The socket is not supplied with the

rated voltage

The power supply plugs are not correctly inserted in the printer, finisher or socket.

A defective contact in the interface

connector is preventing the poweron signal from being input.

The power-on signal is not being

output.

Blown fuse.

Defective power supply unit Switch off the printer’s power supply and

Wiring, DC load, finisher driver circuit board

Inform the user that the rated voltage is

not being supplied to the socket.

Correctly plug in the power supply cables.

Reconnect the interface connector.

Switch on the power supply switch to the

printer. Measure the voltage between

JS3-5 (PWRON-IN) and JS3-3 (GND) on

the intermediate substrate connector.

Check the printer if the measured value is

approximately 5V.

Disconnect the power supply unit and

replace the fuse.

disconnect the J1 and J2 connectors from

the finisher driver circuit board.

Plug the power supply cable into the power

supply unit and switch on the printer’s power

supply. Then measure the DC power output

between the J1 and J2 connectors. Take care

not to short the circuit when doing this.

Replace the power supply unit if the rated

value is not being output.

Switch off the printer’s power supply and

check the end of the wiring and leading

from the finisher driver circuit board and

the DC load. If there are no problems with

the wiring and DC load, replace the finisher driv er circuit board.

TROUBLESHOOTING

4-7

Page 84

TROUBLESHOOTING

Handling operation defects

Distance sensor defects

Possible cause Suggested remedy

A contact defect exists in the distance

sensor’s signal line connector.

Distance sensor defective Measure the voltage between the J6-4 (GND)

Finisher driver circuit board defective Replace the finisher driver circuit board.

Shutter defects

Possible cause Suggested remedy

Faulty connector contact Reconnect the J7, J9 and J10 connectors on

Shutter close detection switch defective Disconnect the J7 connector from the finisher

Shutter open detection switch defective Measure the voltage between the J9-8 connec-

Finisher driver circuit board defective Replace the finisher driver circuit board.

Reconnect the J6 co nnector on the finisher

driver circuit board.

connector and the J6-2 (Vcc) and J6-3 (Vin)

connectors on the fini sher driv er ci rcuit board.

Replace the distance sensor if 5V does not exist

between J6-4 and J6-2, and if approximately

3V does not exist between J6-4 and J6-3.

the finisher driver circuit board.

driver circuit board. Meas ure the resistance

between the J7-1 connector on the switch and

the J7-2 connector. Replace the shutter close

detection switch if the value is not 0 ohms

when the shutter is raised and oo ohms when

the shutter is lowered.

tor and the J9-9 connector on the finisher

driver circuit board. Replace the shutter open

detection switch if the value is not 0V when

the shutter is raised and approximately 5V

when the shutter is lowered.

DF-30/DF-31

Swing guide defects

Possible cause Suggested remedy

Faulty connector contact Reconnect the J5, J11 and J6 connectors on

the finisher driver circuit board.

Swing guide close detecti on switch

(MS2) defective

Swing guide close detecti on switch

(MS6) defective

Disconnect the J5 connector from the finisher

driver circuit board. Meas ure the resistance

between the J5-9 connector on the switch and

the J5-10 connec tor. Replac e the swing guide

close detect ion swi t ch (M S2) i f the value is not

0 ohms when the swing guide is raised and oo

ohms when the swing guide is lowered.

Disconnect the J5 connector from the finisher

driver circuit board. Meas ure the resistance

between the J5-11 connector on the switch and

the J5-12 connec tor. Replac e the swing guide

close detect ion swi t ch (M S6) i f the value is not

0 ohms when the swing guide is raised and oo

ohms when the swing guide is lowered.

4-8

Page 85

TROUBLESHOOTING

Handling operation defects

Possible cause Suggested remedy

4) Swing guide open detection switch

defective

5) Finisher driver circuit board defective

Abnormal tray height

Possible cause Suggested remedy

Faulty connector contact Reconnect the J5, J7 and J12 connecto rs on

Tray home position detection sensor

defective

Tray upper limit detection switch defective

Safe area detection switch defective Measure the voltage between GND (CP1) and

Finisher driver circuit board defective Replace the finisher driver circuit board.

Recovery: Measure the voltage betw een the J610 connector and the J6-9 conne cto r on th e finisher driver circuit board. Replace the swing

guide open detection switch if the value is not

0V when the swing guide is raised and approximately 5V when the swing guide is lowered.

Recovery: Replace the finisher driver circuit

board.

the finisher driver circuit board.

Measure the voltage between the J12-5 c on-

nector and the J12 -6 connector on the finisher

driver circuit board. Replace the tray home

position detection sensor if the value is not

approximately 5V when the tray is in the home

position and 0V when in any other position.

Disconnect the J5 connector from the finisher

driver circuit board. Meas ure the resistance

between the J5-7 connector on the switch and

the J5-8 connector. Replace the tray upper

limit detection switch if the value is not 0

ohms.

the J5-5 and J5-6 connectors on the finisher

driver circuit bo ard. Replace the safe area

detection switch if the voltage is not between

approximately 25V to 0V when tray assemblies #2 and #3 are mov ed, or betwee n 18V and

approximately 24V.

Inversion roller will not operate

Possible cause Suggested remedy

Damaged gear Replace the gear if it is damaged.

Inversion solenoid defective Disconnect the inversion solenoid’s J4 connec-

tor. Measure the resistance between the J4-1

connector on the solenoid and the J4-2 connector. Replace the inversion solenoid if the value

is not approximately 125 ohms.

Feed motor defective Press the SW3 push switch with dip switch #3

(SW1) on the finisher driver circuit board set

to ON and perform a mechanical check.

Replace the feed moto r if it cannot be oper ate d

during this.

Finisher driver circuit board defective Replace the finisher driver circuit board.

Paper deck driver circuit board defec-

tive

Replace the paper deck driver circuit board.

4-9

Page 86

TROUBLESHOOTING

Handling operation defects

Possible cause Suggested remedy

Option controller circuit board defective Replace the option controller circuit board.

Video controller circuit board defective Replace the video controller circuit board.

Printer erro r mess a g es

The following errors are reported by a message on the printer’s message display.

The printer is not operative until the defect is corrected.

Call service person C8

Stapler movement motor defects

Possible cause Suggested remedy

A contact defect exists in the stapler

movement motor drive’s signal line connector.

Stapler movement motor defective Disconnect the J8 conne ctor from the finisher

Finisher driver circuit board defective Replace the finisher driver circuit board.

Reconnect the J8 co nnector on the finisher

driver circuit board.

driver circuit board. Meas ure the resistance

between the J8-5 connector on the motor and

the J8-4, J8-3, J8-2 and J8-1 connectors.

Replace the stapler movement motor if the

value is not approximately 16.5 ohms.

Call service person C9

Staple motor defects

Possible cause Suggested remedy

A contact defect exists in the staple

motor drive’s signal line connector.

Staple motor defective Disconnect the J8 connector from the finisher

Finisher driver circuit board defective Replace the finisher driver circuit board.

Reconnect the J8 co nnector on the finisher

driver circuit board.

driver circuit board. Meas ure the resistance

between the J8-11 connector on the motor and

the J8-12 connector. Replace the staple motor

if the value is not between 6 and 8 ohms.

Call service person CA

DF-30/DF-31

4-10

Page 87

TROUBLESHOOTING

Handling operation defects

Matching board movement motor defects

Possible cause Suggested remedy

A contact defect exists in the matching

board movement motor drive’s signal

line connector.

Matching board movement motor defective

Finisher driver circuit board defective Replace the finisher driver circuit board.

Call service person CB

Tray elevation motor defects

Reconnect the J11 connector on the finisher

driver circuit board.

Disconnect the J11 connector from the finisher

driver circuit board. Meas ure the resistance

between the J11-1 connector on the motor and

the J11-2, J11-3, J11-4 and J11-5 connector s.

Replace the matching board move ment motor

if the value is not approximately 16 ohms.

Possible cause Suggested remedy

A contact defect exists in the tray elevation motor drive’s signal line connector.

Tray elevation motor defective Disconnect the J7 connector from the finisher

Finisher driver circuit board defective Replace the finisher driver circuit board.

Reconnect the J7 connector on the finisher

driver circuit board.

driver circuit board. Meas ure the resistance

between the J7-4 and J7-5 conn ec t ors on th e

motor. Replace the tray elevation motor if th e

value is not approximately 5.5 ohms.

Call service person CC

Feed motor defects

Possible cause Suggested remedy

A contact defect exists in the feed motor

drive’s si gnal line connector.

Feed motor defective Disconnect the J10 c onnector from the finisher

Finisher driver circuit board defective Replace the finisher driver circuit board.

Reconnect the J10 connector on the finisher

driver circuit board.

driver circuit board. Meas ure the resistance

between the J10-1, J10-4 and J10 -6 connector s