Kymco MO Movie125, MO Movie 150 Service Manual - chap 18 (emissioni)

18. EVAPORATIVE EMISSION CONTROL

SYSTEM

18-0

18

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

EVAPORATIVE EMISSION CONTROL SYSTEM

__________________________________________________________________________________

SCHEMATIC DRAWING ............................................................ 18- 1

EVAPORATIVE EMISSION CONTROL SYSTEM FUNCTION..... 18- 2

TROUBLESHOOTING ................................................................ 18- 2

EVAPORATIVE EMISSION CONTROL SYSTEM

MAINTENANCE SCHEDULE ..................................................... 18- 3

SERVICE INFORMATION .......................................................... 18- 4

MOTORCYCLE ENGINE EVAPORATIVE EMISSION

CONTROL SYSTEM TEST ......................................................... 18- 5

PURGE CONTROL VALVE ........................................................ 18- 6

CHARCOAL CANISTER ............................................................. 18- 8

PCV (POSITIVE CRANKCASE VENTILATION) SYSTEM .......... 18- 9

EXHAUST EMISSION RELATED SYSTEM INSPECTION .......... 18-10

EXHAUST EMISSION TEST AND ADJUSTMENT...................... 18-10

18. EVAPORATIVE EMISSION CONTROL

SYSTEM

18-1

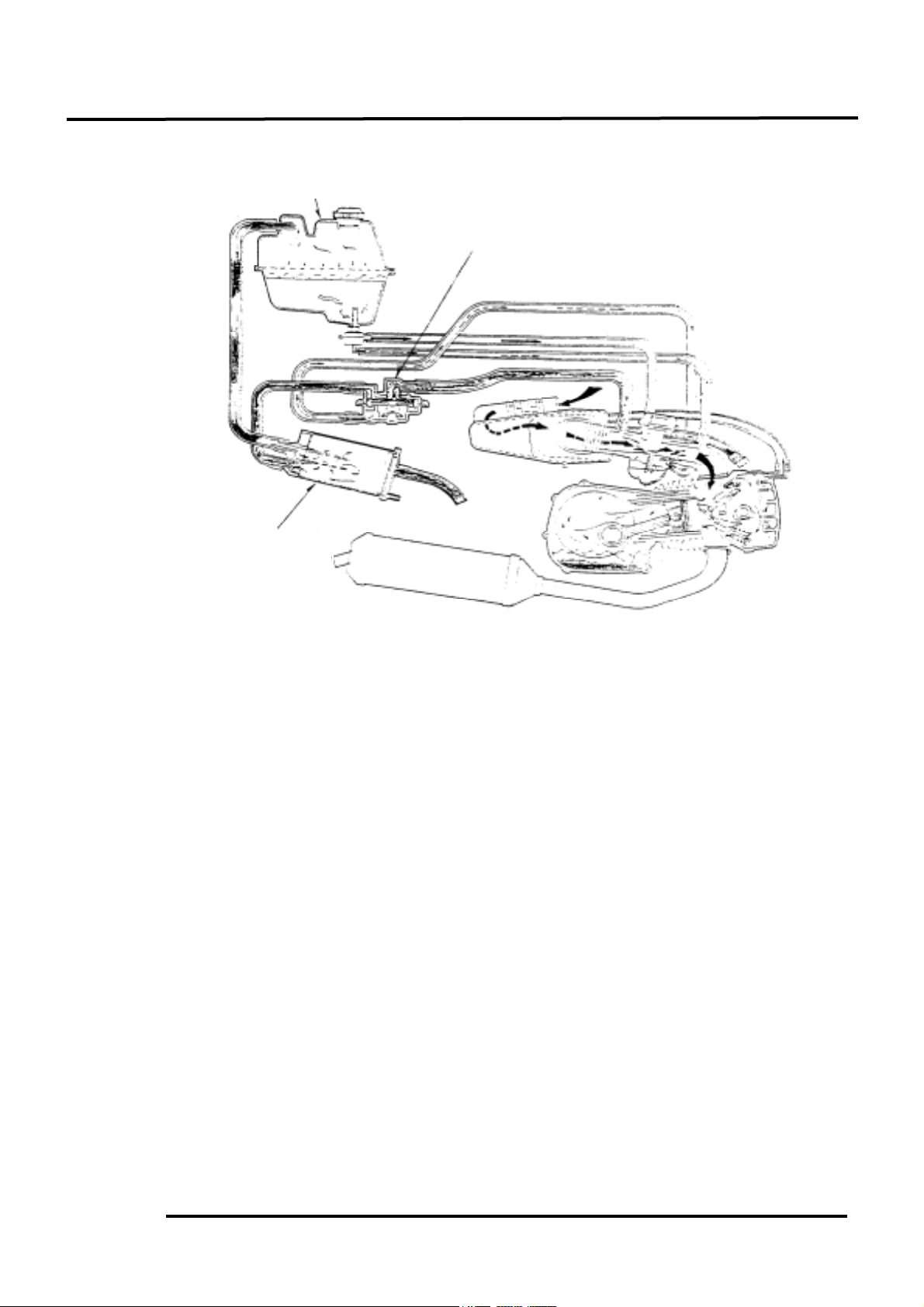

SCHEMATIC DRAWING

S EVAPORATIVE EMISSION CONTROL SYSTEM LOCATION

Charcoal Canister

Purge Control Valve

Fuel Tank

18. EVAPORATIVE EMISSION CONTROL

SYSTEM

18-2

EVAPORATIVE EMISSION CONTROL SYSTEM FUNCTION

FOREWORD:

The Evaporative Emission Control System is abbreviated to E.E.C. System. This device collects

the fuel vapor from the carburetor and fuel tank and then the fuel vapor is drawn into the engine for

re-burning to avoid air pollution caused by the fuel vapor diffused into the air.

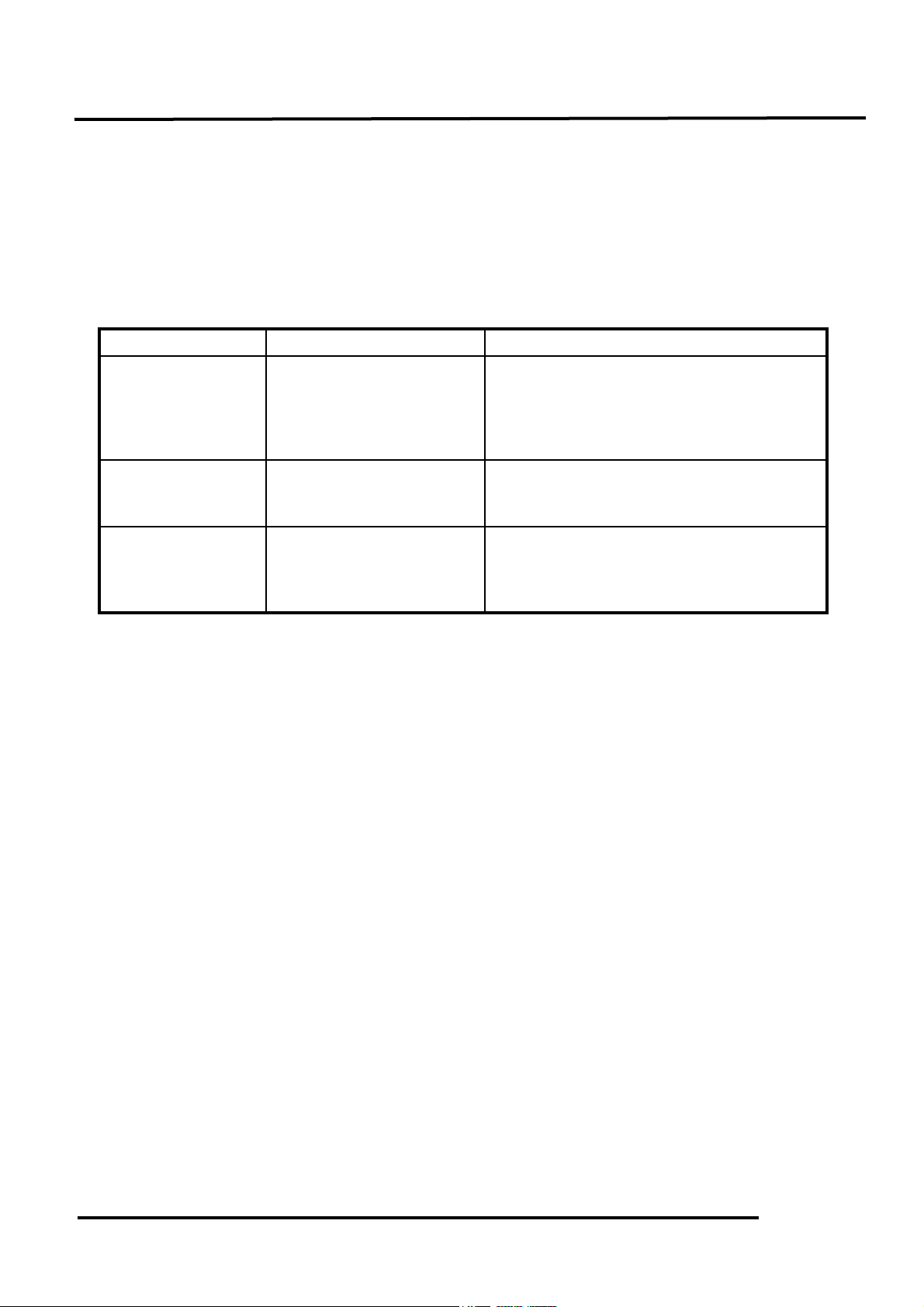

FUNCTION

Item

Purpose

Function

Purge Control Valve

Control vaporized HC from

fuel tank not to diffuse into

the air.

The charcoal canister absorbs vaporized HC

from the fuel tank. When the engine is

running and the purge control valve is open,

the fuel vapor in the charcoal canister is

drawn into the engine for re-burning.

Charcoal Canister

Absorb and store the

vaporized HC from the fuel

tank and carburetor.

The vaporized HC is absorbed in the

charcoal canister and the specified volume of

HC in the emission should not exceed 2g.

P.C.V.

Completely recover the HC

of blow-by gas in the

crankcase for re-burning.

Through the P.C.V. system, the blow-by

gas from the crankcase is separated into fuel

vapor and fuel and then drawn into the

cylinder for re-burning.

TROUBLESHOOTING

Engine loses power or runs erratic at idle speed

1. Clogged P.C.V. system

2. Clogged air cleaner

3. Faulty purge control valve

4. Loose or broken E.E.C. system tubes or connectors

Engine idles or accelerates roughly

1. Faulty fuel cut-off valve

2. Faulty purge control valve

3. Clogged or faulty charcoal canister

18. EVAPORATIVE EMISSION CONTROL

SYSTEM

18-3

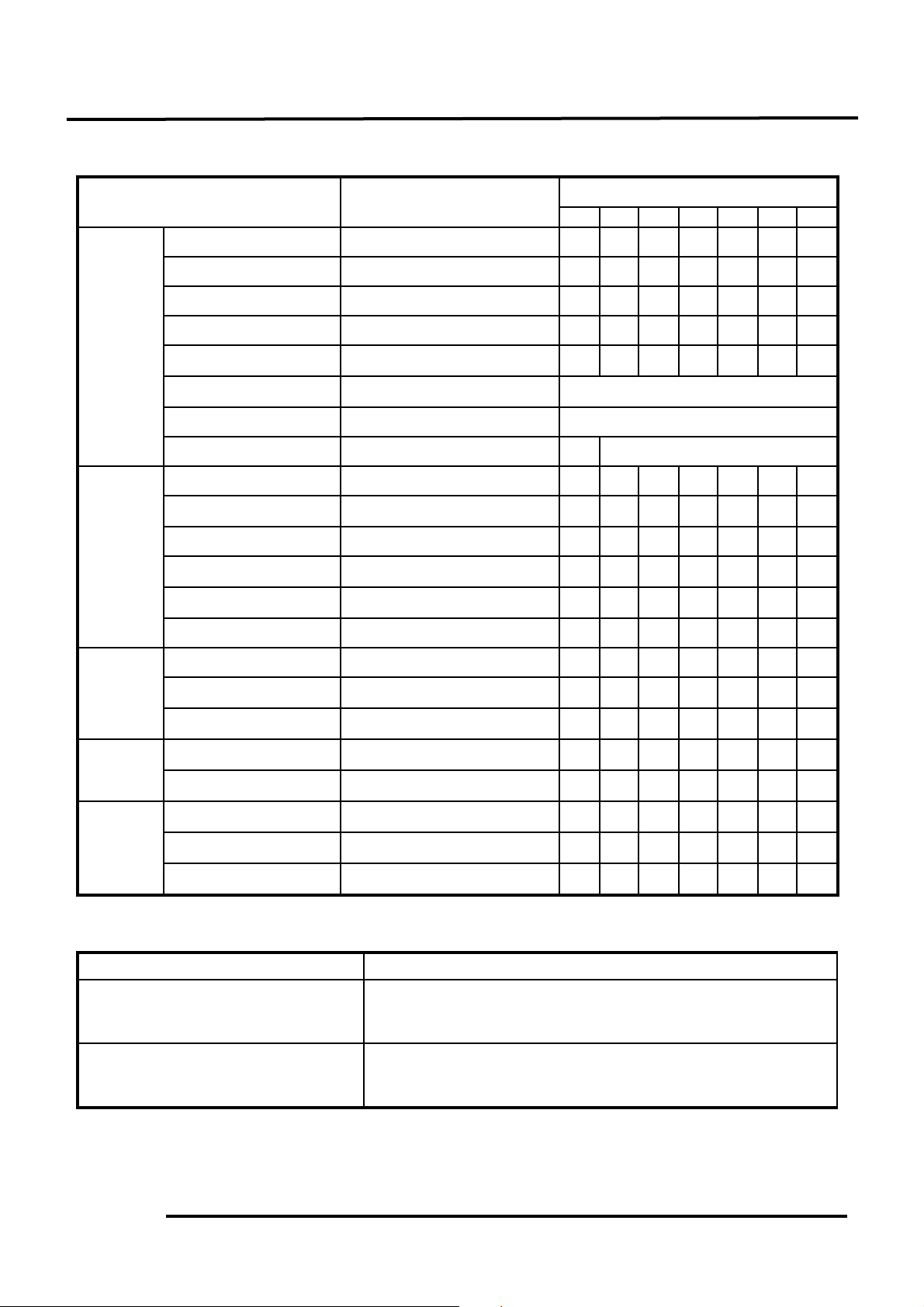

1. EMISSION CONTROL SYSTEM MAINTENANCE SCHEDULE:

Item

Inspection

Service Mileage (KM)

300

1000

3000

5000

7000

9000

1100

Drive belt

Belt thickness

○

Drive chain

Chain tension & length

○○○○○

○

Cam chain

Chain length

○○○

○

Engine

Valve clearance

IN/EX clearance

○○○○○

Parts

Manifold & cylinder

head bolts

Lock bolt

○

○

Air Cleaner

Clean or replace air cleaner

element

Clean at every 3000km and replace if

necessary

Cooling water

Check for engine cooling

Replace at every 10000km or every

Engine oil

Engine lubrication

○

Replace at every 1000km

Gear oil

Inspect or add gear oil

Fuel filter

Clean or replace fuel filter

screen

○○○

○

Fuel

Choke system

Check for proper operation

○○○

System

Fuel line connectors

Check for leaks, block or

breakage

○○○○○

○

Carburetor idle speed

Inspect, clean or adjust

○○○

Oil filter

Clean filter screen

○○○

Ignition timing

Inspect ignition timing

○○○○○

○

Ignition

Spark plug

Clean, inspect or replace

○○○○○

○

Ignition system wire

connection

Check wire connectors

○○○○○

○

Exhaust

Secondary air inlet line

Check for leaks, clogged or

loose pipe connection

○○○

Control

Intake manifold bolt

Check manifold connector

and replace if necessary

○○○○○

○

Evaporative

Engine compartment

pipe connection

Check for leaks, clogged or

loose pipe connection

○○○○○

○

Emission

Control

Charcoal canister

Check air vent hole for

damage and clean it

○○○○○

○

System

Purge control valve

Check for loose or broken

tube connectors

○○○○○

○

2. EMISSION CONTROL SYSTEM IRREGULAR MAINTENANCE:

Item

Contents

*Burned crankshaft bearing

Before riding, inspect the engine for engine oil leaks to avoid

crankshaft bearing burning during riding.

*Burned cylinder or piston

Long-time or severe use may cause worn or seized cylinder or

piston. Clean or replace them with new ones.

Loading...

Loading...