Page 1

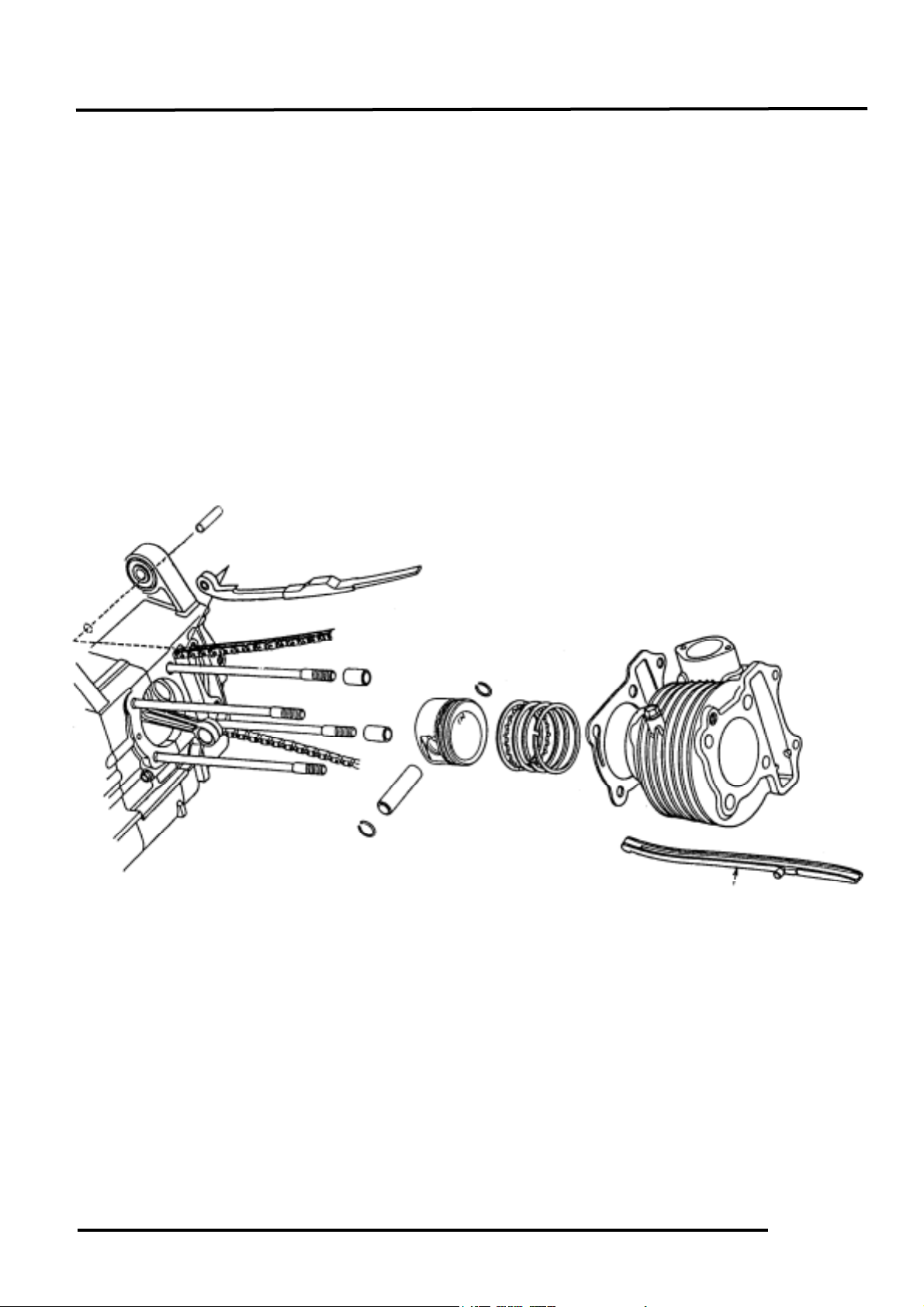

8. CYLINDER/PISTON

8-0

8

Do not bend

Page 2

8. CYLINDER/PISTON

8-1

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The cylinder and piston can be serviced with the engine installed in the frame.

• After disassembly, clean the removed parts and dry them with compressed air before inspection.

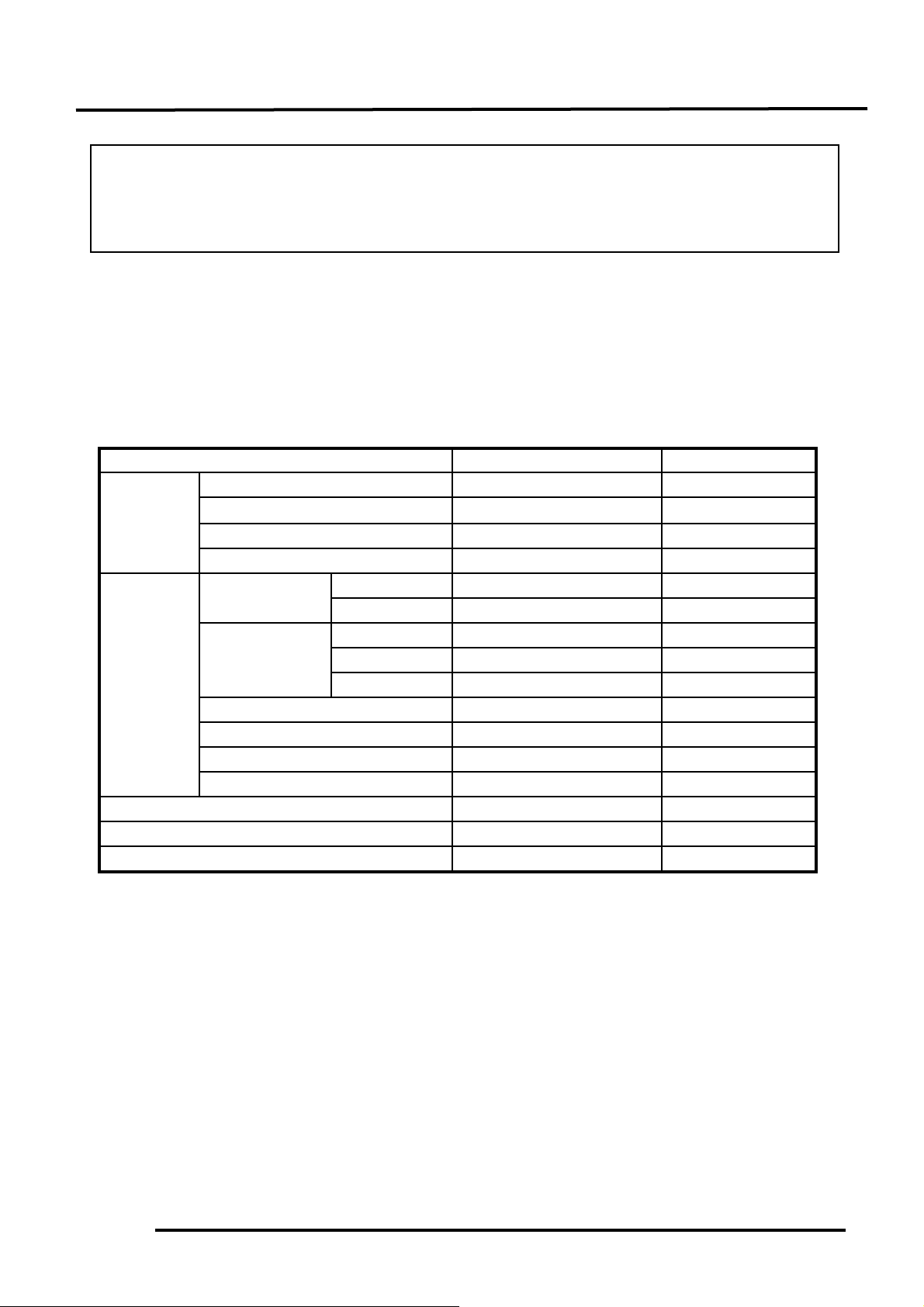

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

I.D.

52.400_ 52.410

52.50

Warpageæ0.05

Cylindricity

æ

0.05

True roundness

æ

0.05

Ring-to-groove

Top

0.015_ 0.055

0.09

clearance

Second

0.015_ 0.055

0.09

Top

0.10_ 0.25

0.5

Piston,

Ring end gap

Second

0.10_ 0.25

0.5

piston ring

Oil side rail

0.2_ 0.7

æ

Piston O.D.

52.370_ 52.390

52.3

Piston O.D. measuring position

9mm from bottom of skirt

æ

.

Piston-to-cylinder clearance

0.010_ 0.040

0.1

Piston pin hole I.D.

15.002_ 15.008

15.04

Piston pin O.D

14.994_ 15.000

14.96

Piston-to-piston pin clearance

0.002_ 0.014

0.02

Connecting rod small end I.D. bore

15.016_ 15.034

15.06

TROUBLESHOOTING

• When hard starting or poor performance at low speed occurs, check the crankcase breather for

white smoke. If white smoke is found, it means that the piston rings are worn, stuck or broken.

Compression too low or uneven

compression Excessive smoke from exhaust muffler

• Worn, stuck or broken piston rings • Worn or damaged piston rings

• Worn or damaged cylinder and piston • Worn or damaged cylinder and piston

Compression too high Abnormal noisy piston

• Excessive carbon build-up in combustion • Worn cylinder, piston and piston rings

chamber or on piston head

• Worn piston pin hole and piston pin

Cylinder

SERVICE INFORMATION

......................

8-1 PISTON REMOVAL

.................................

8-3

TROUBLESHOOTING

.............................

8-1 PISTON INSTALLATION

.......................

8-6

CYLINDER REMOVAL

............................

8-2 CYLINDER INSTALLATION

.................

8-6

Page 3

8. CYLINDER/PISTON

8-2

CYLINDER REMOVAL

Remove the cylinder head. (!7-6)

Remove the cam chain guide.

Remove the cylinder base bolts.

Remove the cylinder.

Remove the cylinder gasket and dowel pins.

Clean any gasket material from the cylinder

surface.

PISTON REMOVAL

Remove the piston pin clip.

Press the piston pin out of the piston and

remove the piston.

Dowel Pins

Gasket

Cylinder

Piston

Piston Rings

Place a clean shop towel in the crankcase

to keep the piston pin clip from falling

into the crankcase.

*

Page 4

8. CYLINDER/PISTON

8-3

Inspect the piston, piston pin and piston

rings.

Remove the piston rings.

Clean carbon deposits from the piston ring

grooves.

Install the piston rings onto the piston and

measure the piston ring-to-groove clearance.

Service Limits: Top: 0.09mm replace if over

2nd: 0.09mm replace if over

Remove the piston rings and insert each

piston ring into the cylinder bottom.

Measure the piston ring end gap.

Service Limit: 0.5mm replace if over

Measure the piston pin hole I.D.

Service Limit: 15.04mm replace if below

Take care not to damage or break the

piston rings during removal.

*

Use the piston head to push each piston

ring into the cylinder.

*

Page 5

8. CYLINDER/PISTON

8-4

Measure the piston pin O.D.

Service Limit: 14.96mm replace if below

Measure the piston O.D.

Service Limit: 52.3mm replace if below

Measure the piston-to-piston pin clearance.

Service Limit: 0.02mm replace if over

CYLINDER INSPECTION

Inspect the cylinder bore for wear or damage.

Measure the cylinder I.D. at three levels of

top, middle and bottom at 90° to the piston

pin (in both X and Y directions).

Service Limit: 52.50mm repair or replace if

below

Measure the cylinder-to-piston clearance.

Service Limit: 0.1mm repair or replace if

below

The true roundness is the difference between

the values measured in X and Y directions.

The cylindricity (difference between the

values measured at the three levels) is subject

to the maximum value calculated.

Service Limits:

True Roundness: 0.05mm repair or replace

if over

Cylindricity: 0.05mm repair or replace if over

Take measurement at 9mm from the

bottom and 90° to the piston pin hole.

*

Middle

Bottom

Top

Page 6

8. CYLINDER/PISTON

8-5

Inspect the top of the cylinder for warpage.

Service Limit: 0.05mm repair or replace if below

Measure the connecting rod small end I.D.

Service Limit: 15.06mm replace if below

PISTON RING INSTALLATION

Install the piston rings onto the piston.

Apply engine oil to each piston ring.

Second

Side Rail

Top

• Be careful not to damage or break

the piston and piston rings.

• All rings should be installed with

the markings facing up.

• After installing the rings, they

should rotate freely without sticking.

*

Second

Top

Side Rail

Oil Ring

Page 7

8. CYLINDER/PISTON

8-6

PISTON INSTALLATION

Remove any gasket material from the

crankcase surface.

Install the piston, piston pin and a new

piston pin clip.

CYLINDER INSTALLATION

Install the dowel pins and a new cylinder

gasket on the crankcase.

Coat the cylinder bore, piston and piston

rings with clean engine oil.

Carefully lower the cylinder over the piston

by compressing the piston rings.

Gasket

Cylinder

Be careful not to drop foreign matters

into the crankcase.

*

• Position the piston “IN” mark

on the intake valve side.

• Place a clean shop towel in the

crankcase to keep the piston pin clip

from falling into the crankcase.

*

• Be careful not to damage or break

the piston rings.

• Stagger the ring end gaps at 120°

to the piston pin.

*

Piston Pin

Piston Pin Clip

Piston

Page 8

8. CYLINDER/PISTON

8-7

Loosely install the cylinder base bolts.

Install the cam chain guide.

Install the cylinder head. (!7-13)

Tighten the cylinder base bolts.

Insert the tab on the cam chain guide into

the cylinder groove.

*

Cylinder Base Bolt

Cam Chain Guide

Loading...

Loading...