Page 1

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-0

Mongoose/KXR 90/50

14

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

BATTER/CHARGING SYSTEM/

A.C. GENERATOR

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 14- 2

BATTERY REMOVAL ------------------------------------------------- 14- 4

CHARGING SYSTEM -------------------------------------------------- 14- 6

REGULATOR/RECTIFIER -------------------------------------------- 14- 7

A.C. GENERATOR CHARGING COIL-------------------------------- 14- 8

A.C. GENERATOR LIGHTING COIL-------------------------------- 14- 8

RESISTOR INSPECTION---------------------------------------------- 14- 8

A.C. GENERATOR ----------------------------------------------------- 14- 8

14

Page 2

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-1

Mongoose/KXR 90/50

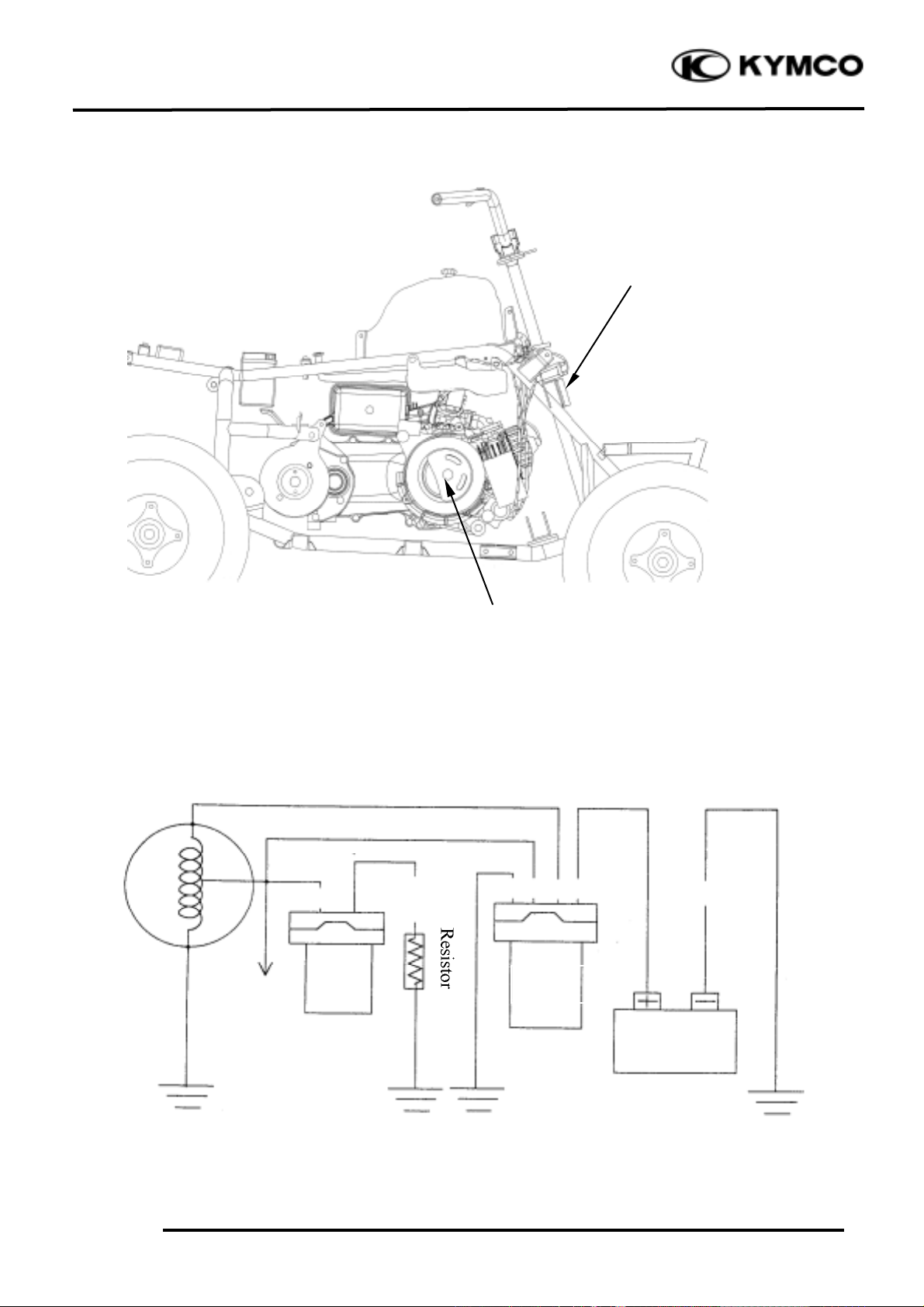

CHARGING CIRCUIT

Regulator/Rectifier

A.C. Generator

Regulator/

Rectifier

A.C. Generator

Headlight Switch

YRG

Battery

12V4AH

Y

Auto

Bystarter

G/B

W

G

90cc:

12W5W

50cc:

10.2W5W

Page 3

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-2

Mongoose/KXR 90/50

SERVICE INFORMATIONN

GENERAL INSTRUCTIONS

• The battery can be charged and discharged repeatedly. If a discharged battery is not used for a

long time, its service life will be shortened. Generally, the capacity of a battery will decrease after

it is used for 2_ 3 years. A capacity-decreased battery will resume its voltage after it is recharged

but its voltage decreases suddenly and then increases when a load is added.

• When a battery is overcharged, some symptoms can be found. If there is a short circuit inside the

battery, no voltage is produced on the battery terminals. If the rectifier won‘t operate, the

voltage will become too high and shorten the battery service life.

• If a battery is not used for a long time, it will discharge by itself and should be recharged every 3

months.

• A new battery filled with electrolyte will generate voltage within a certain time and it should be

recharged when the capacity is insufficient. Recharging a new battery will prolong its service life.

• Inspect the charging system according to the sequence specified in the Troubleshooting.

• Do not disconnect and soon reconnect the power of any electrical equipment because the electronic

parts in the regulator/rectifier will be damaged. Turn off the ignition switch before operation.

• It is not necessary to check the MF battery electrolyte or fill with distilled water.

• Check the load of the whole charging system.

• Do not quick charge the battery. Quick charging should only be done in an emergency.

• Remove the battery from the motorcycle for charging.

• When replacing the battery, do not use a traditional battery.

• When charging, check the voltage with an voltmeter.

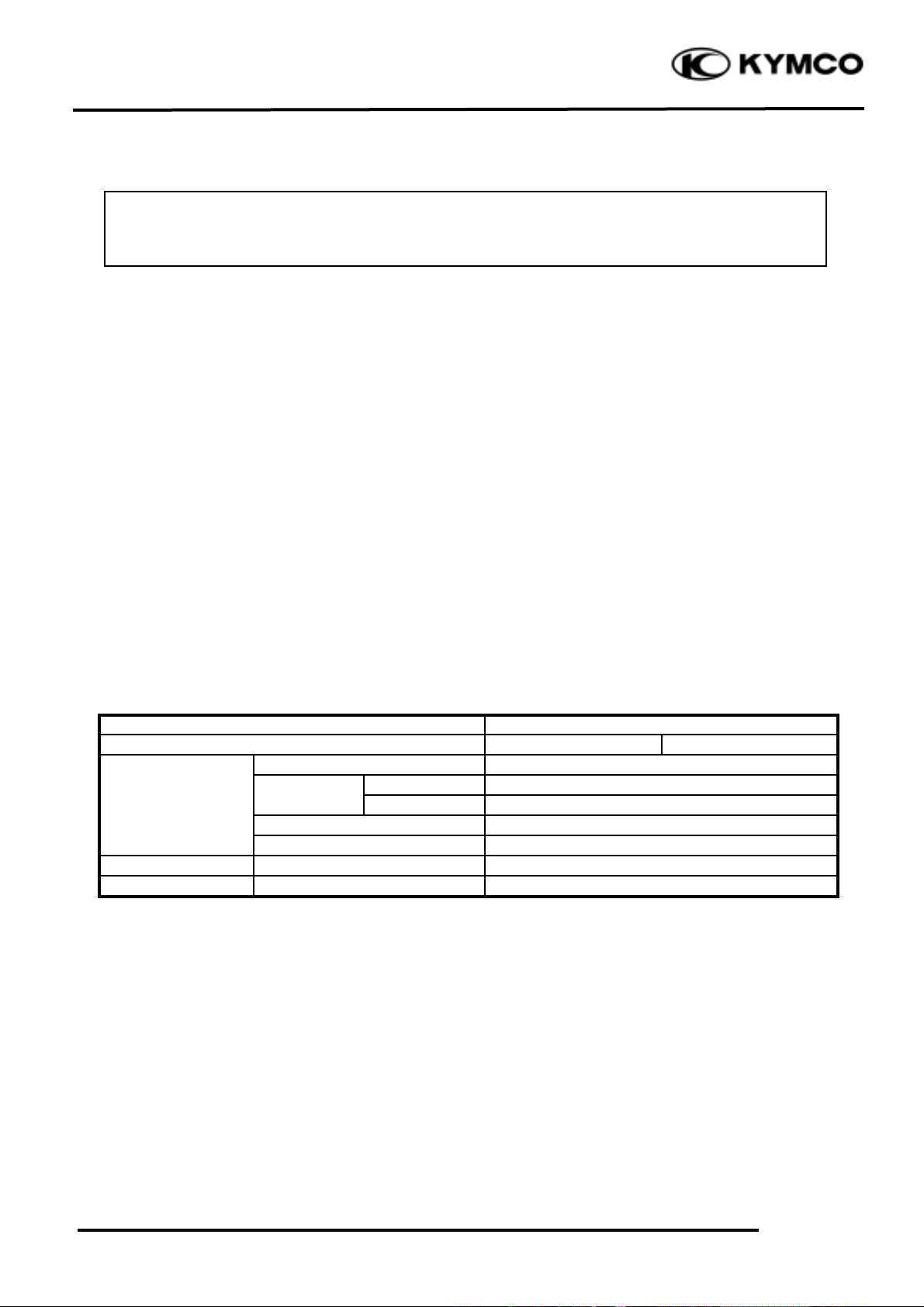

SPECIFICATIONS

Item

Standard

ATV Name &Type

Mongoose/KXR 90

Mongoose/KXR 50

Capacity/Model

12V4AH

Voltage

Fully charged

13.1V

Battery

(20¢J )

Undercharged

12.3V

Charging current

STD: 0.4A Quick: 4.0A

Charging time

STD: 5_ 10hr Quick: 30min

A.C. Generator

Capacity

150W

Charging

14.5±0.5V

Regulator/Rectifier

The battery electrolyte (sulfuric acid) is poisonous and may seriously damage the skin and

eyes. Avoid contact with skin, eyes, or clothing. In case of contact, flush with water and get

prompt medical attention

Page 4

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-3

Mongoose/KXR 90/50

TESTING INSTRUMENTS

Electric tester: YF-3051

TROUBLESHOOTING

No power Intermittent power

• Dead battery • Loose battery cable connection

• Disconnected battery cable • Loose charging system connection

• Fuse burned out • Loose connection or short circuit in

• Faulty ignition switch

lighting system

Low power Charging system failure

• Weak battery • Loose, broken or shorted wire or connector

• Loose battery connection • Faulty regulator/rectifier

• Charging system failure • Faulty A.C. generator

• Faulty regulator/rectifier

Page 5

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-4

Mongoose/KXR 90/50

BATTERY REMOVAL

Remove seat. (See page 2-3)

Remove the battery cover, by removing the

mount bolts. (Make sure the ignition switch

is OFF)

Remove the battery by removing the bolts.

First disconnect the battery negative (-)

cable and then the positive (+) cable.

The installation sequence is the reverse of

removal.

BATTERY VOLTAGE (OPEN CIRCUIT

VOLTAGE) INSPECTION

Remove the seat. (See page 2-3)

Disconnect the battery cables.

Measure the voltage between the battery

terminals.

Fully charged : 13.1V

Undercharged : 12.3V max

Bolts

Negative (-) Cable

Positive (+) Cable

Battery charging inspection must be

performed with a voltmeter.

°Ø

Battery Cover

When disconnecting the battery positive

(+) cable, do not touch the frame with

tool; otherwise it will cause short circuit

and sparks to fire the fuel.

First connect the positive (+) cable and then

negative (-) cable to avoid short circuit.

Page 6

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-5

Mongoose/KXR 90/50

CHARGING

Connect the charger positive (+) cable to the

battery positive (+) terminal.

Connect the charger negative (-) cable to the

battery negative (-) terminal.

Charging current : Standard : 0.4A

Quick : 4.0A

Charging time : Standard : 5_ 10 hours

Quick : 30 minutes

After charging: Open circuit voltage: 12.8V min.

• Keep flames and sparks away

from a charging battery.

• Turn power ON/OFF at the

charger, not at the battery terminals to

prevent sparks near the battery to avoid

explosion.

• Charge the battery according to

• Quick charging should only be done in

an emergency.

• Measure the voltage 30 minutes after

the battery is charged.

°Ø

Power Lamp (Red)

Charging Lamp

(Green)

Red

Black

Page 7

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-6

Mongoose/KXR 90/50

CHARGING SYSTEM

SHORT CIRCUIT TEST

Disconnect the ground wire from the battery

and connect an ammeter across the battery

negative (-) terminal and the ground wire.

Turn the ignition switch OFF and check for

short circuit.

If any abnormality is found, check the ignition

switch and wire harness for short circuit.

CURRENT TEST

This inspection must be performed with an

electric tester when the battery is fully

charged.

Warm up the engine for inspection.

Connect the electric tester across the battery

terminals. Disconnect the red wire from the

fuse terminal and connect an ammeter

between the red wire lead and the fuse

terminal as shown.

Attach a tachometer to the engine.

Start the engine and gradually increase the

engine speed to measure the limit voltage

and current.

Limit Voltage/Current:

13.5_ 15.5V/0.5

A max. (5000rp m

max.)

If the limit voltage is not within the

specified range, check the regulator/rectifier.

Connect the electric tester positive (+)

terminal to ground wire and the tester

negative (-) terminal to the battery

negative (-) terminal.

°Ø

Page 8

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-7

Mongoose/KXR 90/50

REGULATOR/RECTIFIER

MAIN HARNES S CIRCUIT INS PECTION

Remove the front covers. (!2-2)

Remove the regulator/rectifier 4P coupler

and check for continuity between the wire

harness terminals according to the following

:

Item (Wire Color)

Judgment

Between battery (red)

and engine ground

Battery has

voltage

Between ground (green)

and engine ground

Continuity exists

Between lighting wire

(yellow) and engine

ground (Remove the

resistor coupler and auto

bystarter coupler and

turn the lighting switch

OFF for inspection)

A.C. generator

stator has

resistance

Between charging coil

(white) and engine

ground

A.C. generator

stator has

resistance

REGULATOR/RECTIFIER INS PECTION

If the main harness terminals are normal,

check the regulator/rectifier coupler for loose

connection and measure the resistances

between the regulator/rectifier terminals.

Replace the regulator/rectifier if the readings

are not within the specifications in

the table.

Probe⊕

Probe(-)

White

Yellow

Red

Green

White°¤°¤

°¤

Yellow

°¤°¤10.75M

Red

6.62M

°¤

°¤

Green

°¤

11.17M

°¤

• Do not touch the tester probes with

your finger because human body has

resistance.

• Use the following specified testers for

accurate testing. Use of an improper

tester in an improper range may give

false readings.

Testing instrument

YF-3501

• If the dry battery in the tester is weak,

the readings will be incorrect. In this

case, check the dry battery.

*

Regulator/Rectifier

Yellow

Red

Green

White

Page 9

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-8

Mongoose/KXR 90/50

A.C. GENERATOR CHARGING

COIL

INSPECTION

Disconnect the A.C. generator 2P connector.

Measure the resistance between the A.C.

generator white wire and engine ground with

an electric tester (YF-3501 tester).

Standard: 2.2W(at 20¢J)

Replace the A.C. generator charging coil if

the reading is not within the specifications.

A.C. GENERATOR LIGHTING

COIL

INSPECTION

Disconnect the A.C. generator 2P connector.

Measure the resistance between the A.C.

generator yellow wire and engine ground

with an electric tester (YF-3501 tester).

Standard: 3.1W (20¢J)

Replace the A.C. generator lighting coil if

the reading is not within the specifications.

RESISTOR INSPECTION

Remove the front covers. (!2-2)

Measure the resistance between the resistor

lead and engine ground.

Resistances:

Mongoose/KXR 90: 5W12W

30W7.5W

Mongoose/KXR 50: 5W10.2W

30W5.9W

A.C. GENERATOR

REMOVAL

Remove the four bolts attaching the cooling

fan cover.

Remove the fan cover.

The inspection of A.C. generator charging

coil can be made with the engine installed.

*

The inspection of A.C. generator lighting

coil can be made with the engine installed.

*

Charging Coil Wire

Lighting Coil Wire

Resistor

Fan Cover

Bolts

Page 10

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-9

Mongoose/KXR 90/50

Remove the cooling fan by removing the

four cooling fan attaching bolts.

Hold the flywheel with an universal holder.

Remove the flywheel nut.

Universal Holder E017

Remove the A.C. generator flywheel using

the flywheel puller.

Flywheel Puller E001

Remove the pulser coil bolts.

Remove the A.C. generator wire rubber

sleeve and pulser coil from the right

crankcase.

Remove the two bolts and A.C. generator

stator.

Special

Special

Cooling Fan

Universal Holder

Flywheel Puller

Bolts

Bolts

Bolts

Page 11

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-10

Mongoose/KXR 90/50

A.C. GNERATOR INSTALLATION

Reverse the A.C. GENERATOR

REMOVE” procedures.

Install the A.C. generator stator and pulser

coil onto the right crankcase.

Install the A.C. generator wire rubber sleeve.

Tighten the stator and pulser coil bolts.

Torques: Pulser Coil : 0.45~0.6kgf-m

Stator: 0.8~1.2kgf-m

Connect the A.C. generator wire connector.

Clean the taper hole in the flywheel off any

burrs and dirt.

Install the woodruff key in the crankshaft

keyway.

Install the flywheel onto the crankshaft with

the flywheel hole aligned with the

crankshaft woodruff key.

A.C. Generator

Wire Rubber

Sleeve

Woodruff Key

Flywheel

Cooling Fan

Stator

3.5_ 4.5kgf-m

0.6_ 1.0kgf-m

The inside of the flywheel is magnetic.

Make sure that there is no bolt or nut

before installation.

*

Woodruff Key

0.45_ 0.6kgf-m

Fan Cover

Page 12

14. BATTERY/CHARGING SYSTEM/

A.C. GENERATOR

14-11

Mongoose/KXR 90/50

Hold the flywheel with the universal holder

and tighten the flywheel nut.

Torque: 3.5~4.5kgf-m

Universal Holder E017

Install the cooling fan.

Torque: 0.6~1.0kgf-m

Install the fan cover and tighten bolts.

Special

Loading...

Loading...