Page 1

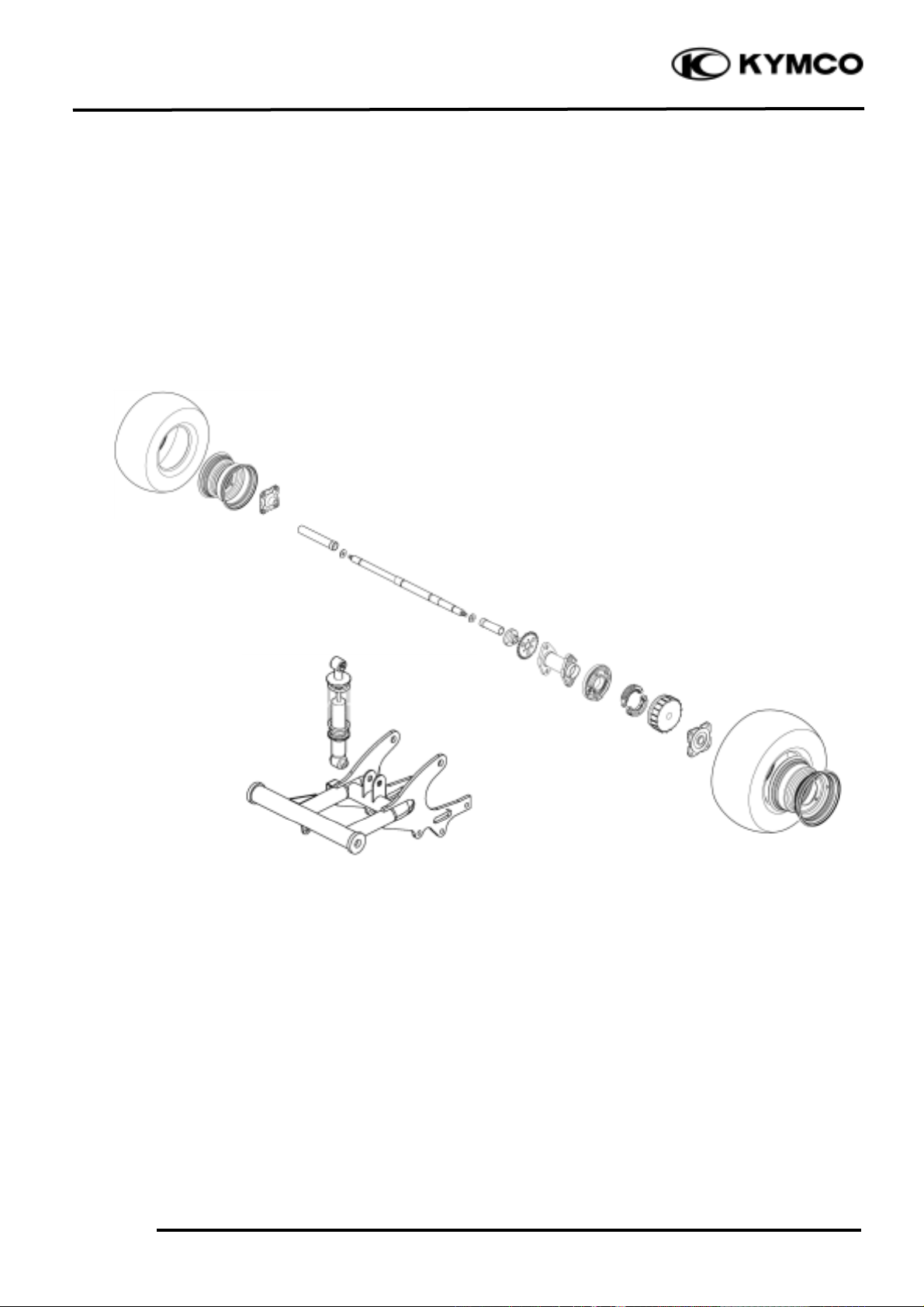

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-0

Mongoose/KXR 90/50

13

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 13- 2

REAR WHEEL ---------------------------------------------------------- 13- 4

REAR SWING ARM ---------------------------------------------------- 13-10

HYDRAULIC BRAKE -------------------------------------------------- 13-15

BRAKE PAD/DISK ----------------------------------------------------- 13-16

BRAKE MASTER CYLINDER ----------------------------------------- 13-17

BRAKE CALIPER------------------------------------------------------- 13-20

DRUM BRAKE ---------------------------------------------------------- 13-22

13

Page 2

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-1

Mongoose/KXR 90/50

Page 3

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-2

Mongoose/KXR 90/50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• During servicing, keep oil or grease off the brake drum and brake linings.

• During servicing, keep oil or grease off the brake disk and brake pads.

• Drain the brake fluid from the hydraulic brake system before disassembly.

• Contaminated brake disk or brake pads reduce stopping power. Clean the contaminated brake

disk with high-performance brake degreaser and replace the brake pads.

• Do not use brake fluid for cleaning.

• Bleed air from the brake system if the brake system is removed or the brake is soft.

• Do not allow any foreign matters entering the brake reservoir when filling the brake reservoir with

brake fluid.

• Brake fluid will damage painted, coated surfaces and plastic parts. When working with brake

fluid, use shop towels to cover and protect painted, rubber and plastic parts. Wipe off any splash

of brake fluid with a clean towel. Do not wipe the motorcycle with a towel contaminated by

brake fluid.

• Make sure to use recommended brake fluid. Use of other unspecified brake fluids may cause

brake failure.

• Inspect the brake operation before riding.

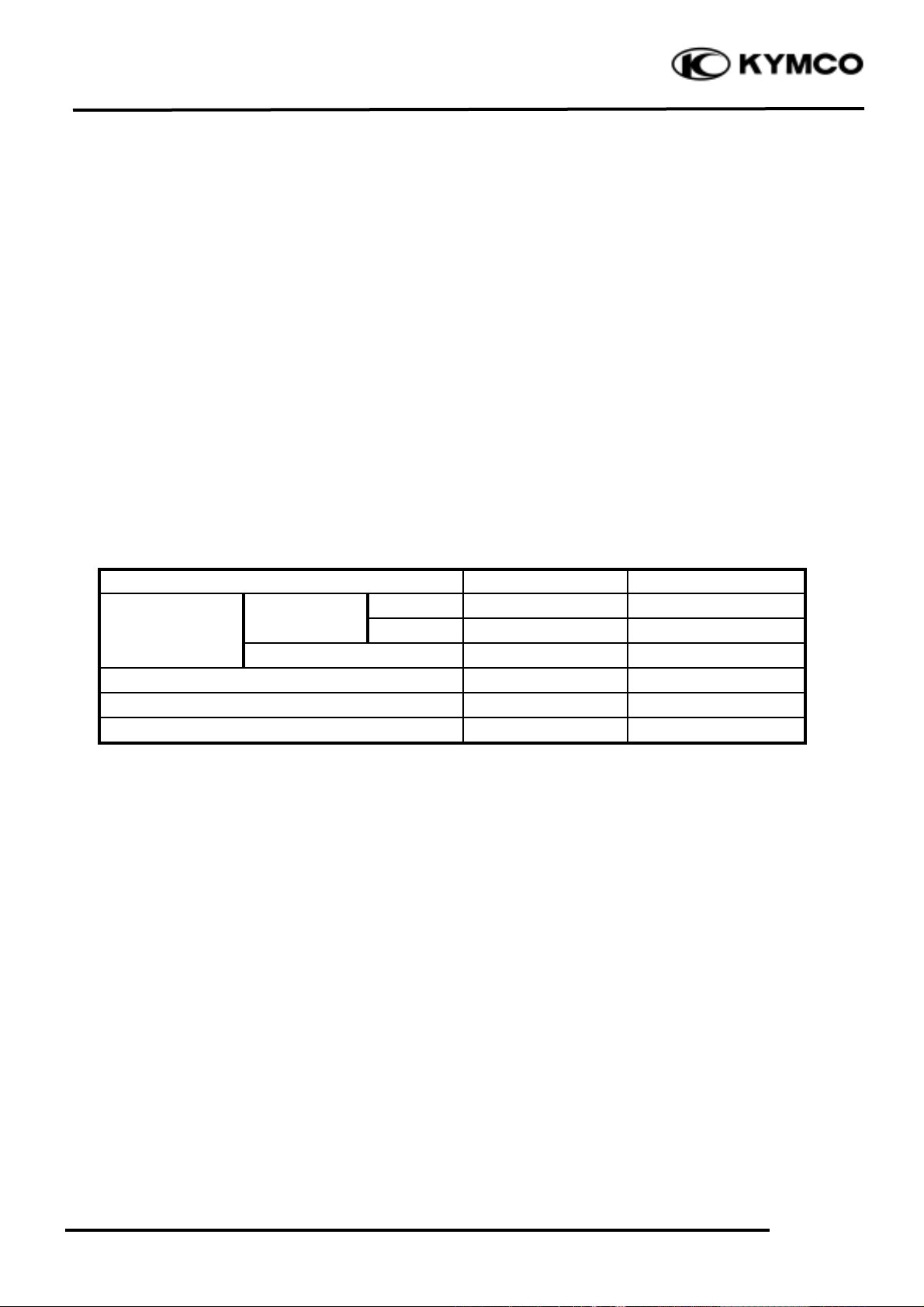

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

Radialæ2.0

Rear wheel

Axialæ2.0

Rear brake drum I.D

130_ 130.2

131

Brake disk thickness (disk brake)

3.8_ 4.2

3.0

Brake disk runout (disk brake)

°–

0.3

Rear brake lining thickness (drum brake)

4.5

2.0

TORQUE VALUES

Rear wheel nut 4.0_ 5.0kgf-m

Rear shock absorber upper mount bolt 3.5_ 4.5kgf-m

Rear shock absorber lower mount bolt 3.5_ 4.5kgf-m

Rear swing arm axle 6.0_ 8.0kgf-m

Rear wheel hub nut 6.0_ 8.0kgf-m

Brake arm bolt 1.8_ 2.5kgf-m

Caliper holder bolt 2.9_ 3.5kgf-m

Brake fluid tube bolt 3.0_ 4.0kgf-m

Caliper bleed valve 0.4_ 0.7kgf-m

Master cylinder bolt 1.0_ 1.4kgf-m

Rim run out

Page 4

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-3

Mongoose/KXR 90/50

TROUBLESHOOTING

Rear wheel wobbling Poor brake performance (Drum Brake)

• Bent rim • Brake not adjusted properly

• Faulty tire • Worn brake linings

• Axle not tightened properly • Worn brake shoes at cam contacting area

• Worn brake cam

Soft rear shock absorber • Worn brake drum

• Weak shock absorber spring

• Faulty damper

Loose brake lever (Disk Brake) Tight brake lever (Disk Brake)

• Air in hydraulic brake system •Seized piston

• Brake fluid level too low •Clogged hydraulic brake system

• Hydraulic brake system leakage •Smooth or worn brake pad

Hard braking (Disk Brake) Poor brake performance (Disk Brake)

• Seized hydraulic brake system Contaminated brake pad surface

• Seized piston

Brake noise (Disk Brake)

• Contaminated brake pad surface

• Excessive brake disk run out

• Incorrectly installed caliper

• Brake disk or wheel not aligned

Poor brake performance (Disk Brake)

• Air in brake system

• Deteriorated brake fluid

• Contaminated brake pads and brake disk

• Worn brake pads

• Worn brake master cylinder piston oil seal

• Clogged brake fluid line

• Deformed brake disk

• Unevenly worn brake caliper

Page 5

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-4

Mongoose/KXR 90/50

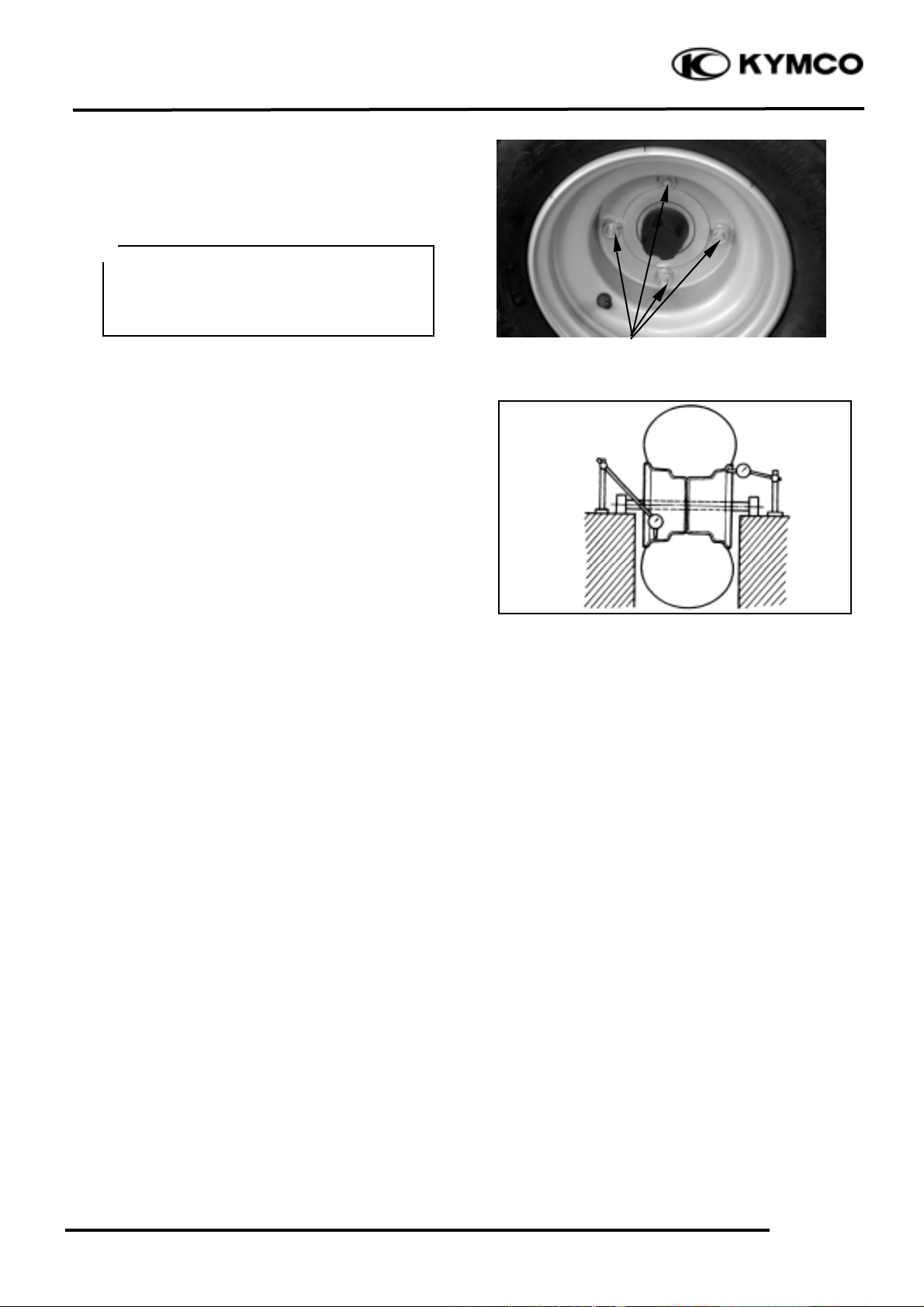

REAR WHEEL

REAR WHEEL REMOVAL

Place the machine on a level place.

Remove four nuts attaching the wheel.

Remove wheel.

INSPECTION

Measure the wheel runout.

Service Limit:

Vertical: 2.0 mm

Lateral: 2.0mm

Replace wheel if out of specification.

INSTALLATION

Install the rear wheel and tighten the nuts

(wheel).

Torque: 4.0_ 5.0kgf-m

Nuts

Elevate the rear wheels by placing a

suitable stand under the rear of frame.

Support the machine securely so there is

no danger of it falling over.

°Ø

Page 6

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-5

Mongoose/KXR 90/50

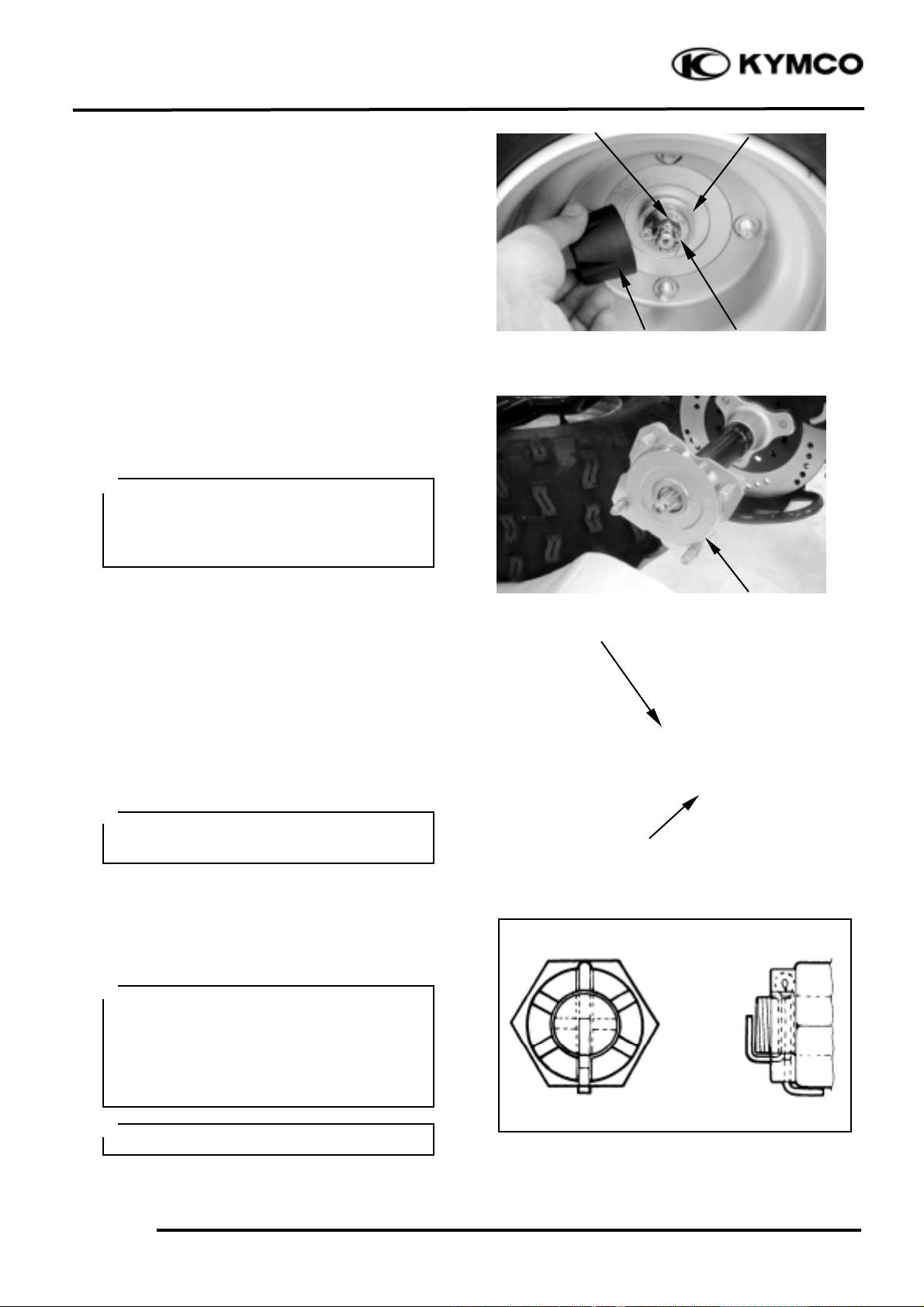

REAR WHEEL HUB REMOVAL

Remove rear wheel nuts. (See page 13-4)

Remove the wheel hub nut cover and cotter

pin.

Loosen nut attaching the wheel hub.

Remove rear wheel. (See page 13-4)

Remove wheel hub nut, washer and wheel

hub.

INSPECTION

Replace it if the wheel hub is cracks or

damage.

Replace it if splines of the wheel hub is

wear or damage.

INSTALLATION

Install wheel hub, washer and wheel hub

nut.

Torque: 6.0_ 8.0kgf-m

Install the cotter pin and band ends of cotter

pin.

Nut Cover

Cotter Pin

Washer

Nut

Wheel Hub

Splines

Wheel Hub

Do not loosen the axle nut after torque

tightening. If the axle nut groove is not

aligned with the cotter pin hole, align

groove with the hole by tightening up on

the axle nut.

°Ø

Always use a new cotter pin.

°Ø

Apply grease onto the splines of the

wheel hub.

°Ø

Elevate the rear wheels by placing a

suitable stand under the rear of frame.

Support the machine securely so there is

no danger of it falling over.

°Ø

Page 7

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-6

Mongoose/KXR 90/50

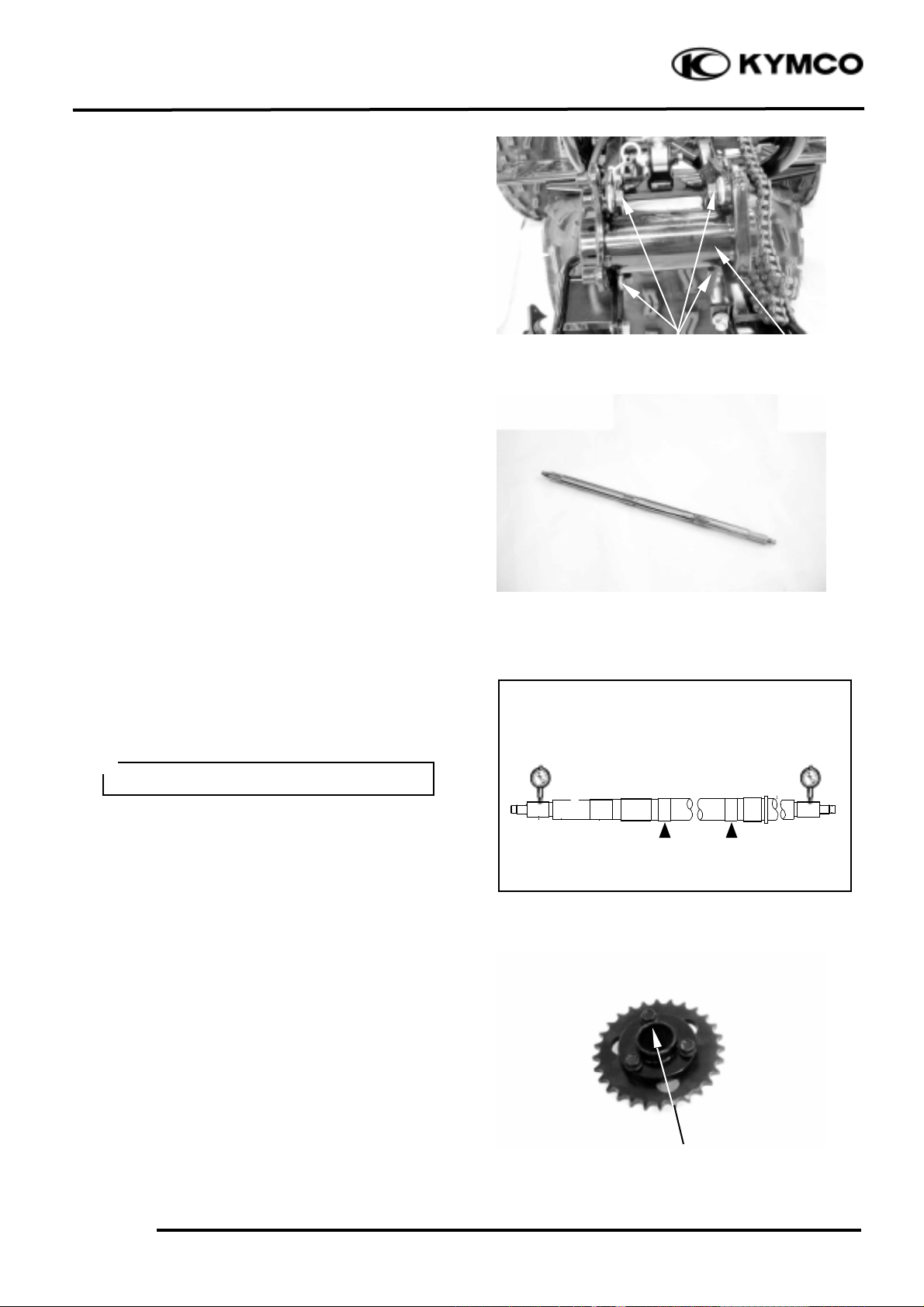

REAR AXLE REMOVAL

Remove the rear wheel hub of the both rear

wheels. (See page 13-5).

Remove the collars on the rear axle right and

left side.

Relax the drive chain. (Refer to the “DRIVE

CHAIN SLACK ADJUSTMENT” section

in chapter 3.)

Remove driven sprocket.

Remove the rear axle from right side.

Remove the two bolts and caliper and then

remove brake disk.

Collars

Driven Sprocket

Rear Axle

Bolts

Brake Disk

Bolts

Drive Chain

Caliper

Page 8

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-7

Mongoose/KXR 90/50

Remove the four bolts and rear axle hub.

INSPECTION

Replace it if the rear axle is scratched

(excessively) or damage.

Replace if splines and threads of the rear

axle is wear or damage.

Measure the rear axle run out.

Service limit: less than 1.5mm

Replace if it is out of specification.

Replace it if the driven sprocket is cracks or

damage.

Replace it if splines of the driven sprocket

is wear or damage.

Splines

Do not attempt to straighten a bent axle.

°Ø

Bolts

Axle Hub

Page 9

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-8

Mongoose/KXR 90/50

Inspect the driven sprocket.

Replace sprocket if more than 1/4 teeth

wear or bent teeth.

Replace it if the brake disk is cracks or

damage.

Replace it if splines of the brake disk is

wear or damage.

Inspect rear axle hub.

Replace it if bearing allow play in the axle

hub or the bearing turns roughly.

Replace it if oil seal is wear or damage.

Replace it if rear axle hub is cracks, bend or

damage.

Bearing and oil seal replacement steps:

Clean the outside of the rear axle.

Remove the oil seal by a flat-head screw

driver.

Remove the bearing by a general bearing

puller.

Install the new bearings and oil seal by

reversing the previous steps.

Brake Drum Cover

Splines

Oil Seal

Place a wood block against the outer

edge to protect this edge.

°Ø

Do not strike the center race or balls of

the bearing.

Contact should be made only with the

outer race.

°Ø

Distance Collar

Bearings

Oil Seal

Page 10

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-9

Mongoose/KXR 90/50

INSTALLATION

Reverse the “REMOVAL” procedures.

Install the rear axle hub.

Install the rear axle.

Install brake disk, driven sprocket and

collars.

Install wheel hub (see page 13-5) and rear

wheel (see page 13-4).

Adjust drive chain slack. (Refer to the

“DRIVE CHAIN SLACK

ADJUSTMENT” section in chapter 3.)

Approximately: 10~20 mm

At this time, the rear axle hub should not

be tightened completely.

Final tightening is done after the chain

slack adjustment.

°Ø

Apply grease onto the oil seal lips,

bearings and bushes.

°Ø

Page 11

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-10

Mongoose/KXR 90/50

REAR SWING ARM

REMOVAL

Place the machine on a level place.

Elevate the rear wheels by placing a suitable

stand under the rear of frame.

Remove the rear wheels, rear hubs, rear axle

and axle hub. (Refer to the “REAR

WHEEL” section in chapter 13.)

Remove the lower bolt attaching the rear

shock absorber.

Remove the upper bolt and then remove the

shock absorber.

INSPECTION

Check the tightening torque of the pivot

shaft (swing arm) securing nut.

Torque: 6.0_ 8.0kgf-m

Lower Bolt

Support the machine securely so there is

no danger of it falling over.

°Ø

When removing the lower bolt, hold the

swing arm so that it does not drop

downwards when the bolt is removed.

°Ø

Upper Bolt

Securing Nut

Page 12

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-11

Mongoose/KXR 90/50

Check the swing arm side play by moving it

from side to side.

If side play noticeable, check the inner

collar, bushing and thrust cover.

Check the swing arm vertical movement by

moving it up and down.

If vertical movement is tight, binding or

rough, to check the inner collar, bushing and

thrust cover.

INSPECTION

Inspect the shock absorber rod.

Replace the shock absorber assembly if

bends or damage.

Inspect the shock absorber.

Replace the shock absorber assembly if oil

leaks

Inspect the spring.

Replace the shock absorber assembly if

fatigue.

Move the spring up and down.

Page 13

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-12

Mongoose/KXR 90/50

REAR SWING ARM REMOVAL

Remove the nut and pivot shaft, then

remove swing arm.

Remove the three bolts and chain guard.

Remove the drive chain.

Remove thrust covers and collar.

Nut

Thrust Covers

Swing Arm

Bolts

Drive Chain

Chain Guard

Page 14

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-13

Mongoose/KXR 90/50

INSPECTION

Roll the axle on a flat surface to inspect the

pivot shaft.

Replace it if bends.

Inspect the swing arm.

Replace it if crack, bend or damage.

Inspect the thrust cover, chain guide, collar

and bush.

Replace them if wear or damage.

Inspect the drive chain stiffness.

Clean and lubricate or replace it if stiff.

CLEAN

Place it in kerosene, and brush off as much

dirt as possible. Then remove the chain from

the kerosene and dry the chain.

Do not attempt to straighten a bent axle.

°Ø

Bushes

Thrust Covers

Thrust Covers

Collar

Chain Guide

Page 15

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-14

Mongoose/KXR 90/50

INSTALLATION

Reverse the “REMOVAL” procedure.

Apply grease onto the collar, bush, pivot

shaft and thrust cover.

Install the swing arm and tightening the nut.

Torque: 6.0_ 8.0kgf-m

Install the shock absorber and tightening the

bolts.

Torque: 3.5_ 4.5kgf-m

This machine has a drive chain with small

rubber O-rings between the chain plates.

Steam cleaning, high-pressure washes,

and certain solvent can damage these Orings. Use only kerosene to clean the

drive chain.

°Ø

O-ring

Page 16

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-15

Mongoose/KXR 90/50

HYDRAULIC BRAKE

BRAKE FLUID CHANGE

Place the machine on a level place and set

the handlebar upright.

Remove the two screws attaching the brake

fluid reservoir cap.

Connect a transparent hose to the brake

caliper bleed valve and then loosen the bleed

valve nut.

Use a syringe to draw the brake fluid out

through the hose.

BRAKE FLUID REFILLING

Connect a transparent hose and syringe to

the brake caliper bleed valve and then loosen

the bleed valve nut.

Fill the brake reservoir with brake fluid and

use the syringe to draw brake fluid into it

until there is no air bubbles in the hose.

Then, tighten the bleed valve nut.

Torque: 0.4_ 0.7kg-m

Recommended Brake Fluid: DOT-4

Bleed Valve

Brake Reservoir

Bleed Valve

• When drawing brake fluid with the

syringe, the brake fluid level should be

kept over 1/2 of the brake reservoir

height.

• Use only the recommended brake fluid.

*

Screw

Use shop towels to cover plastic parts

and coated surfaces to avoid damage

caused by splash of brake fluid.

*

Page 17

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-16

Mongoose/KXR 90/50

BRAKE SYSTEM BLEEDING

Connect a transparent hose to the bleed

valve and fully apply the brake lever after

continuously pull it several times. Then,

loosen the bleed valve nut to bleed air from

the brake system. Repeat these steps until

the brake system is free of air.

BRAKE PAD/DISK

BRAKE PAD REPLACEMENT

Remove the two bolts attaching the brake

caliper holder.

Remove the brake caliper.

Push the brake caliper holder and then

remove brake pad.

Remove the other brake pad.

ASSEMBLY

Assemble the brake pads in the reverse

order of removal.

Brake Lever

Bleed Valve

Brake Caliper Holder

Pad Spring

Bolts

Brake Bad

Brake Bad

Make sure the pad spring has fitted.

*

When bleeding air from the brake system,

the brake fluid level should be kept over

1/2 of the brake reservoir height.

*

The brake pads can be replaced without

removing the brake fluid tube.

*

Page 18

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-17

Mongoose/KXR 90/50

BRAKE DISK

Measure the brake disk thickness.

Service Limit: 3.0mm

Measure the brake disk run out.

Service Limit: 0.3mm

BRAKE MASTER CYLINDER

REMOVAL

Drain the brake fluid from the hydraulic

brake system.

Remove the two master cylinder holder

bolts and remove the master cylinder.

Do not splash brake fluid onto any

rubber, plastic and coated parts. When

working with brake fluid, use shop

towels to cover these parts.

*

When removing the brake fluid tube bolt,

be sure to place towels under the tube

and plug the tube end to avoid brake fluid

leakage and contamination.

*

Fluid Tube Bolt

Bolts

Page 19

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-18

Mongoose/KXR 90/50

Master Cylinder

Spring

Snap Ring Pliers

Main

Piston

Snap Ring

DISASSEMBLY

Remove the piston rubber cover and snap

ring from the brake master cylinder.

Remove the washer, main piston and spring

from the brake master cylinder.

Clean the inside of the master cylinder and

brake reservoir with brake fluid.

I INSPECTION

Check the cylinder inside wall, and spring

for scratch, corrosion or other abnormal

condition.

If any abnormal condition is found, replace

the inner parts or master cylinder.

Page 20

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-19

Mongoose/KXR 90/50

Fluid Tube Bolt

Sealing Washer

“UP” Mark

ASSEMBLY

Before assembly, apply brake fluid to all

removed parts.

Install the main piston and snap ring.

Install the rubber cover.

Install the brake lever.

Install the brake fluid tube with the bolt and

two sealing washers.

Fill the brake reservoir with recommended

brake fluid to the upper level.

Bleed air from the hydraulic brake system.

(See page 13-15.)

Place the brake master cylinder on the

handlebar and install the master cylinder

holder with the “UP” mark facing up,

aligning the tab on the holder with the hole

in the handlebar.

First tighten the upper bolt and then tighten

the lower bolt.

Torque: 1.0_ 1.4kg-m

• During assembly, the main piston and

spring must be installed as a unit

without exchange.

• When assembling the piston, soak the

cups in brake fluid for a while.

• Install the cups with the cup lips facing

the correct direction.

°Ø

Page 21

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-20

Mongoose/KXR 90/50

Brake Caliper Holder

Piston Oil Seals

BRAKE CALIPER

DISASSEMBLY

Remove the brake caliper, brake pads and

pad spring. (See page 13-16)

Place a clean container under the brake

caliper and disconnect the brake fluid tube

from the brake caliper.

DISASSEMBLY

Remove the brake caliper holder from the

brake caliper.

Remove the pistons from the brake caliper.

Use compressed air to press out the pistons

through the brake fluid inlet opening and

place a shop towel under the caliper to

avoid contamination caused by the removed

pistons.

Push the piston oil seals inward to remove

them.

Clean each oil seal groove with brake fluid.

Be careful not to splash brake fluid on

any coated surfaces.

*

Be careful not to damage the piston

surface.

*

Page 22

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-21

Mongoose/KXR 90/50

INSPECTION

Inspect the caliper cylinder wall and piston

surface for scratch, corrosion or other

damages.

If any abnormal condition is noted, replace

the caliper.

ASSEMBLY

Clean all removed parts.

Apply silicon grease to the pistons and oil

seals. Lubricate the brake caliper cylinder

inside wall with brake fluid.

Install the oil seals and then install the brake

caliper pistons with the grooved side facing

out.

Wipe off excessive brake fluid with a clean

shop towel. Apply silicon grease to the

brake caliper holder pin and caliper inside.

Install the brake caliper holder.

Install the piston with its outer end

protruding 3_ 5mm beyond the brake

caliper.

*

Page 23

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-22

Mongoose/KXR 90/50

Washers

Fluid Tube Bolt

Aligning The Fluid Tube With Groove

Brake Drum

Brake Shoes

INSTALLATION

Connect the brake fluid tube to the brake

caliper, aligning the fluid tube with groove in

the caliper and tighten the fluid tube bolt.

Torque: 3.0_ 4.0kg-m

Add the recommended brake fluid into the

brake reservoir and bleed air from the brake

system. (

Refer to 13-15.

)

Install the brake caliper onto rear axle hub

and tighten the bolts.

Torque: 2.9_ 3.5kg-m

DRUM BRAKE

REMOVAL

Remove wheel hub and axle hub. (See page

13-5)

Remove brake drum.

Remove brake shoes.

Page 24

13. REAR WHEEL/SWING ARM/

HYDRAULIC BRAKE

13-23

Mongoose/KXR 90/50

INSPECTION

Inspect the inner surface of the brake drum

is scratches, polish brake drum lightly and

evenly with emery cloth.

Measure the inside diameter of the brake

drum.

Service limit: 131mm

Replace it if it is out of specification.

Measure the front brake lining thickness

(A).

Service limit: 2.0mm replace it if below

INSTALLATION

Reverse the “REMOVE” procedures.

Loading...

Loading...