Page 1

15. IGNITION SYSTEM

15-0

Mongoose/KXR 90/50

15

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

IGNITION SYSTEM

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 15- 3

CDI UNIT INSPECTION----------------------------------------------- 15- 5

IGNITION COIL -------------------------------------------------------- 15- 7

PULSER COIL----------------------------------------------------------- 15- 8

IGNITION TIMING INSPECTION ----------------------------------- 15- 8

15

Page 2

15. IGNITION SYSTEM

15-1

Mongoose/KXR 90/50

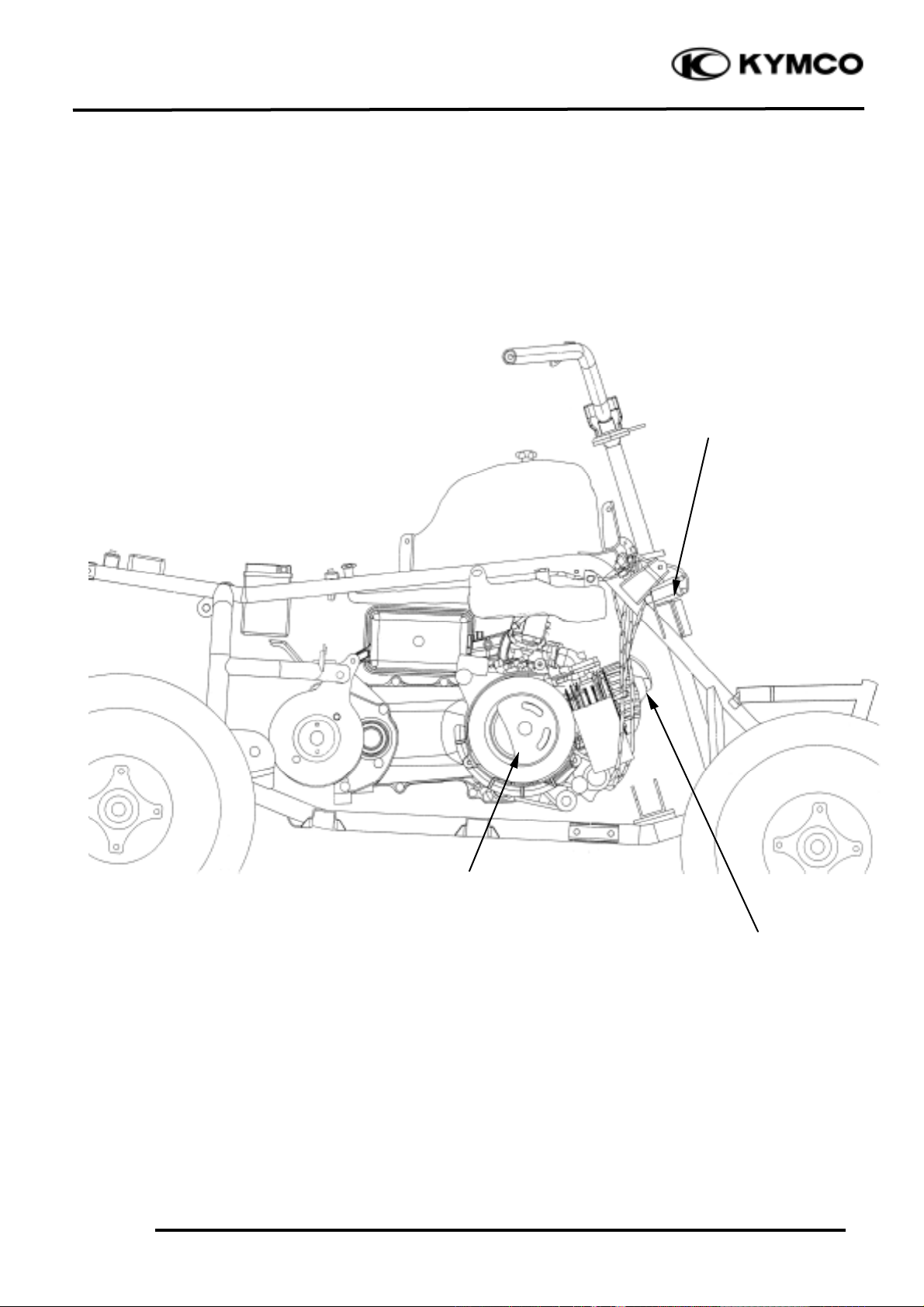

A.C. Generator/ Pulser Coil

Spark Plug

Ignition Coil

Page 3

15. IGNITION SYSTEM

15-2

Mongoose/KXR 90/50

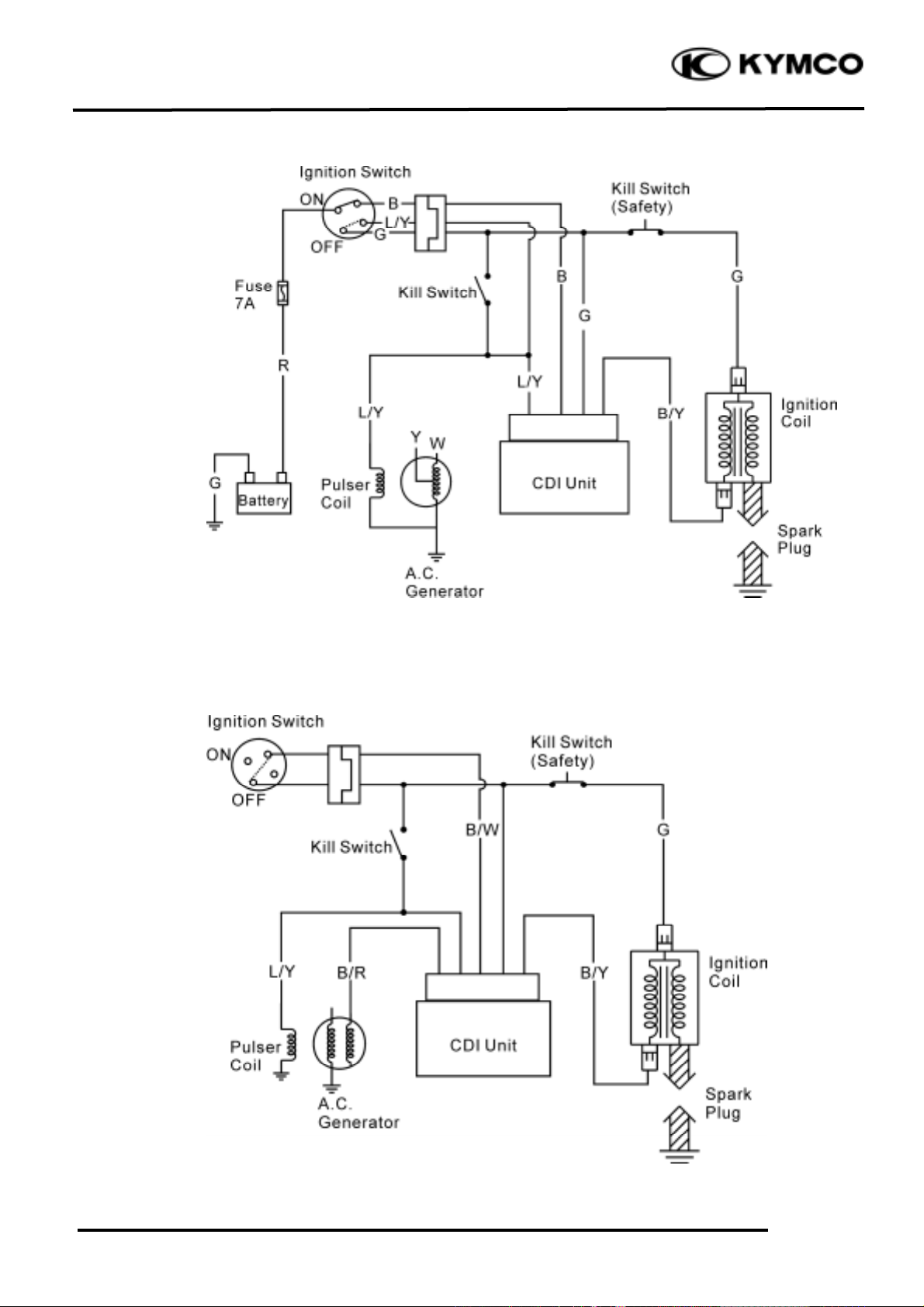

IGNITION CIRCUIT (Mongoose/KXR 90)

IGNITION CIRCUIT (Mongoose/KXR 50)

Page 4

15. IGNITION SYSTEM

15-3

Mongoose/KXR 90/50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• Check the ignition system according to the sequence specified in the Troubleshooting.

• The ignition system adopts ignition unit, change gear control and the ignition timing cannot be

adjusted.

• If the timing is incorrect, inspect the ignition unit, A.C. generator, change gear control and replace

any faulty parts. Inspect the ignition unit with a ignition unit tester

• Loose connector and poor wire connection are the main causes of faulty ignition system. Check

each connector before operation.

• Use of spark plug with improper heat range is the main cause of poor engine performance.

• The inspections in this section are focused on maximum voltage. The inspection of ignition coil

resistance is also described in this section.

• Inspect the spark plug referring to chapter 3.

SPECIFICATIONS (Mongoose/KXR 90)

Item

Standard

Spark plug

Standard type

NGK-C7HSA

Spark plug gap

0.6_ 0.7mm

Ignition timing

“F” mark

Full advance

28º±1ºBTDC/4000RPM

Primary coil

2.2_ 2.6W

Ignition coil resistance (20¢J)

Secondary

without plug cap

3.14KW

coil

with plug cap

8.39KW

Pulser coil resistance (20¢J)

121.1W

SPECIFICATIONS (Mongoose/KXR 50)

Item

Standard

Spark plug

Standard type

BR8HAS

Spark plug gap

0.6_ 0.7mm

Ignition timing

“F” mark

Full advance

15ºBTDC/1700±100rpm

Primary coil

3.7_ 15.2W

Ignition coil resistance (20¢J)

Secondary

without plug cap

3.51KW

coil

with plug cap

8.81KW

Pulser coil resistance (20¢J)

80_ 160W

Page 5

15. IGNITION SYSTEM

15-4

Mongoose/KXR 90/50

TROUBLESHOOTING

High voltage too low No high voltage

• Weak battery or low engine speed • Faulty ignition switch

• Loose ignition system connection • Faulty ignition unit

• Faulty ignition unit • Poorly connected or broken ignition unit

ground wire

• Faulty ignition coil •Dead battery or faulty regulator/rectifier

• Faulty pulser coil • Faulty ignition coil connector

Normal high voltage but no spark at plug • Faulty pulser coil

• Faulty spark plug

• Electric leakage in ignition secondary circuit

• Faulty ignition coil

Good spark at plug but engine won‘t start

• Faulty ignition unit or incorrect ignition timing

• Faulty change gear control unit

• Improperly tightened A.C. generator flywheel

Page 6

15. IGNITION SYSTEM

15-5

Mongoose/KXR 90/50

CDI UNIT INSPECTION

Remove seat. (!2-3)

Disconnect the CDI coupler and remove the

CDI unit.

Measure the resistance between the

terminals using the electric tester.

Mongoose/KXR 90(OFF ROAD) Unit:

MW

Probe⊕

(-)Probe

Black

Black/

Yellow

Blue/

Yellow

Green

Black

°¤°¤°¤

Black/

Yellow

°¤°¤°¤

Blue/

Yellow

°¤°¤°¤

Green

4.9~5.5

4.9~5.5

4.9~5.5

Note: The readings in this table are taken

with a YF-3501 Tester.

CDI Unit

Green

Black

Black/Yellow

Blue/Yellow

• Due to the semiconductor in circuit, it is

necessary to use a specified tester for

accurate testing. Use of an improper

tester in an improper range may give

false readings.

• Use a YF-3501 Electric Tester.

• In this table, “Needle swings then

returns” indicates that there is a charging

current app lied to a condenser. The needle

will then remain at “°¤ ” unless the

condenser is discharged.

*

Page 7

15. IGNITION SYSTEM

15-6

Mongoose/KXR 90/50

KXR 90(ON ROAD) Unit: MW

Probe⊕

(-)Probe

Black

Black/

Yellow

Blue/

Yellow

Green

Black

°¤°¤°¤

Black/

Yellow

°¤°¤°¤

Blue/

Yellow

°¤°¤°¤

Green

6.1~6.8

6.1~6.8

6.1~6.8

Note: The readings in this table are taken

with a YF-3501 Tester.

Mongoose/KXR 50(OFF ROAD) Unit:

MW

Probe⊕

(-)Probe

Black/

Yellow

Black/

Red

Black/

White

Blue/

Yellow

Green

Black/

Yellow

°¤°¤°¤

°¤

Black/

Red

°¤°¤15.73

4.63

Black/

White

°¤

8.52°¤°¤

Blue/

Yellow

°¤°¤°¤

°¤

Green

°¤°¤°¤

8.07

Note: The readings in this table are taken

with a YF-3501 Tester.

KXR 50(ON ROAD) Unit: MW

Probe⊕

(-)Probe

Black/

Yellow

Black/

Red

Black/

White

Blue/

Yellow

Green

Black/

Yellow

°¤°¤°¤

°¤

Black/

Red

°¤°¤°¤

9.98

Black/

White

°¤

10.2°¤°¤

Blue/

Yellow

°¤°¤°¤

°¤

Green

°¤°¤°¤

6.91

Note: The readings in this table are taken

with a YF-3501 Tester.

Blue/Yellow

Green

Black/Yellow

Black/ Red

Black/White

Green

Black

Black/Yellow

Blue/Yellow

Blue/Yellow

Green

Black/Yellow

Black/ Red

Black/White

Page 8

15. IGNITION SYSTEM

15-7

Mongoose/KXR 90/50

IGNITION COIL

REMOVAL

Remove the spark plug cap.

Disconnect the ignition coil wires and

remove the ignition coil bolt and ignition

coil.

INSPECTION

CONTINUITY TEST

Measure the resistance between the ignition

coil primary coil terminals.

Resistance:

Mongoose/KXR 90) : 2.2_ 2.6W/20°C

Mongoose/KXR 50) : 3.7_ 15.2W/20°C

Measure the secondary coil resistances with

and without the spark plug cap.

Resistances:

(Mongoose/KXR 90)

(with plug cap) : 8.39KW/20°C

(without plug cap) : 3.14KW/20°C

Mongoose/KXR 50)

(with plug cap) : 8.81KW/20°C

(without plug cap) : 3.51KW/20°C

Note: The readings in this table are taken

with a YF-3501 Tester.

The CDI unit is not adjustable. If the

timing is incorrect, inspect the CDI unit,

pulser coil and A.C. generator and

replace any faulty parts.

*

Correctly operate the tester following the

manufacturer‘s instructions.

*

Ignition Coil

Page 9

15. IGNITION SYSTEM

15-8

Mongoose/KXR 90/50

PULSER COIL

INSPECTION

Disconnect the A.C. generator connector.

Measure the pulser coil resistance between

the blue/yellow and green wire terminals.

Resistance:

Mongoose/KXR 90): 121.1W/20°C

Mongoose/KXR 50): 80_ 160W/20°C

Note: The readings in this table are taken

with a YF-3501 Tester.

REMOVAL

Refer to chapter 14 for the A.C. generator

removal.

IGNITION TIMING INSPECTION

Remove the fan cover.

Warm up the engine and check the ignition

timing with a timing light.

When the engine is running at the ignition

timing is correct if the “F” mark aligns with

the index mark within ±2°.

Ignition Timing:

Mongoose/KXR 90): BTDC28°/4000rpm

Mongoose/KXR 50): BTDC15°/1700rpm

Advance Mark

“F” Mark

This test is performed with the stator

installed in the engine.

*

Pulser Coil Lead

The CDI unit is not adjustable. If the

ignition timing is incorrect, inspect the

CDI unit, pulser coil and A.C. generator

and replace any faulty parts.

*

Loading...

Loading...