Page 1

3. INSPECTION/ADJUSTMENT

3-0

Mongoose/KXR 90/50

3

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

INSPECTION/ADJUSTMENT

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 3- 1

MAINTENANCE SCHEDULE ---------------------------------------- 3- 3

FUEL LINE/THROTTLE OPERATION------------------------------ 3- 4

AIR CLEANER ---------------------------------------------------------- 3- 5

SPARK PLUG/CYLINDER COMPRESSION ------------------------ 3- 7

VALVE CLEARANCE (Mongoose/KXR 90)------------------------- 3- 8

CARBURETOR IDLE SPEED ----------------------------------------- 3- 8

ENGINE OIL (Mongoose/KXR 90)------------------------------------ 3- 9

TRANSMISSION OIL -------------------------------------------------- 3-11

DRIVE BELT/BRAKE SHOES/BRAKE PADS/BRAKE FLUID -- 3-12

BRAKE LEVER FREE PLAY ----------------------------------------- 3-13

STEERING SYSTEM INSPECTION --------------------------------- 3-14

TOE-IN ADJUSTMENT------------------------------------------------ 3-15

WHEELS/TIRES -------------------------------------------------------- 3-16

DRIVE CHAIN SLACK ADJUSTMENT ----------------------------- 3-17

CABLE INSPECTION AND LUBRICATION ----------------------- 3-19

FRONT SUSPENSION LUBRICATION------------------------------ 3-19

HEADLIGHT BEAM ADJUSTMENT (ON ROAD ONLY) -------- 3-20

BRAKE PEDAL ADJUSTMENT (KXR 90 ON ROAD ONLY)---- 3-20

BRAKE FULID (KXR 90 ON ROAD ONLY)------------------------ 3-21

3

Page 2

3. INSPECTION/ADJUSTMENT

3-1

Mongoose/KXR 90/50

SERVICE INFORMATION

GENERAL

°I WARNING

•Before running the engine, make sure that the working area is well-ventilated. Never run the

engine in a closed area. The exhaust contains poisonous carbon monoxide gas which may cause

death to people.

•Gasoline is extremely flammable and is explosive under some conditions. The working area

must be well-ventilated and do not smoke or allow flames or sparks near the working area or

fuel storage area.

SPECIFICATIONS (Mongoose/KXR 90)

ENGINE

Throttle grip free play : 1_ 4mm

Spark plug gap : 0.6_ 0.7mm

Spark plug: Standard : NGK: C7HSA

Valve clearance : IN: 0.1m

EX: 0.1m

Idle speed : 1700±100rpm

Engine oil capacity:

At disassembly : 0.8 liter

At change : 0.7 liter

Gear oil capacity :

At disassembly : 120cc

At change : 110cc

Cylinder compression : 16kg/cm_

Ignition timing : BTDC 28°/4000rpm

CHASSIS

Front brake free play: 10_ 20mm

Rear brake free play: 10_ 20mm

TIRE PRESSURE

1 Rider

Front

0.22kgf/cm_

Rear

0.22kgf/cm_

TIRE SIZE:

Front : 18*7-8

Rear : 18*9-8

TORQUE VALUES

Front wheel nut 4.0_ 5.0kgf-m

Rear wheel nut 4.0_ 5.0kgf-m

Page 3

3. INSPECTION/ADJUSTMENT

3-2

Mongoose/KXR 90/50

SPECIFICATIONS (Mongoose/KXR 50)

ENGINE

Throttle grip free play : 1_ 4mm

Spark plug gap : 0.6_ 0.7mm

Spark plug: Standard : NGK: BR8HAS

Idle speed : 2000±100rpm

Gear oil capacity :

At disassembly : 120cc

At change : 110cc

Cylinder compression : 12kg/cm_

Ignition timing : BTDC 15°/1700rpm

CHASSIS

Front brake free play: 10_ 20mm

Rear brake free play: 10_ 20mm

TIRE PRESSURE

1 Rider

Front

0.22kgf/cm_

Rear

0.22kgf/cm_

TIRE SIZE:

Front : 16*8-7

Rear : 16*8-7

TORQUE VALUES

Front wheel nut 4.0_ 5.0kgf-m

Rear wheel nut 4.0_ 5.0kgf-m

Page 4

3. INSPECTION/ADJUSTMENT

3-3

Mongoose/KXR 90/50

MAINTENANCE SCHEDULE

This chapter includes all information necessary to perform recommended inspections and

adjustments. These preventive maintenance procedures, if followed, will ensure more reliable

vehicle operation and a longer service life. The need for costly overhaul work will be greatly

reduced. This information applies to vehicles already in service ad well as new vehicles that are

being prepared for sale. All service technicians should be familiar with this entire chapter.

Initial

Every

Item

Remarks

1

month

3

month

6

month

6

month

1

year

Valves

(Mongoose/KXR 50)

Check valve clearance. Adjust if

necessary.

°≥°≥°≥

°≥

Spark plug

Check condition. Clean or replace if

necessary.

°≥°≥°≥°≥°≥

Air clearance

Clean. Replace if necessary.

°≥°≥°≥

°≥

Carburetor

Check idle speed/starter operation.

Adjust if necessary.

°≥°≥°≥

°≥

Fuel line

Check fuel hose for cracks or

damage. Replace if necessary.

°≥°≥°≥

Engine oil

(Mongoose/KXR 50)

Replace (Warm engine before

draining).

°≥°≥°≥

°≥

Engine oil filter

screen

(Mongoose/KXR 50)

Clean. Replace if necessary.

°≥

°≥

Transmission oil

Check oil leakage. Replace every 12

months.

°≥

°≥

Brake system

Check operation. Adjust if

necessary.

°≥°≥°≥°≥°≥

Drive belt

Check operation/replace if damage

or excessive wear.

°≥

°≥

Wheels

Check balance/damage/runout.

Replace if necessary.

°≥°≥°≥

°≥

Wheel bearings

Check bearings assembly for

looseness/damage. Replace if

damaged.

°≥°≥°≥

°≥

Steering system

Check operation/replace if damage.

Check toe-in/adjust if necessary.

°≥°≥°≥°≥°≥

Knuckle shafts

Lubricate every 6 months.

°≥°≥°≥

Fitting/Fasteners

Check all chassis fittings and

fasteners. Correct if necessary.

°≥°≥°≥°≥°≥

• In the interest of safety, we recommend these items should be serviced only by an

authorized KYMCO motorcycle dealer.

Page 5

3. INSPECTION/ADJUSTMENT

3-4

Mongoose/KXR 90/50

FUEL LINE

Check the fuel tubes and replace any parts,

which show signs of deterioration, damage

or leakage.

THROTTLE OPERATION

Check the throttle to swing for smooth

movement.

Measure the throttle to swing free play.

Free Play: 1_ 4mm

To adjust throttle free play:

1. Slide the rubber sleeves back to expose

the throttle cable adjuster.

2. Loosen the lock nut, then turn the

adjuster to obtain the correct free play.

(1~4 mm or 0.04~0.16 in)

3. Tighten the lock nut and reinstall the

sleeve.

OIL PUMP ADJUSTMENT

(Mongoose/KXR 50)

Open the throttle valve fully and check that

the index mark on the pump body aligns

with the aligning mark on the oil pump

control lever.

Reference tip alignment within 1mm of

index mark on open side is acceptable.

Start and idle the engine, then slowly open

the throttle to increase engine rpm and check

the operation of the oil pump control lever.

If adjustment is necessary, adjust the oil

pump control cable by loosening the control

cable lock nut and turning the adjusting nut.

After adjustment, tighten the lock nut.

Fuel Filter

Fuel Tubes

Rubber Sleeves

Lock Nut

Cable Adjuster

Throttle Lever

Adjust oil pump control cable after the

throttle grip free play is adjusted.

°Ø

Control Lever Aligning Mark

Lock Nut

Adjusting Nut

Do not smoke or allow flames or sparks

in your working area.

°Ø

Page 6

3. INSPECTION/ADJUSTMENT

3-5

Mongoose/KXR 90/50

If the oil pump is not synchronized

properly, the following will occur:

• Excessive white smoke or hard starting due

to pump control lever excessively open

• Seized piston due to pump control lever

insufficiently open

AIR CLEANER

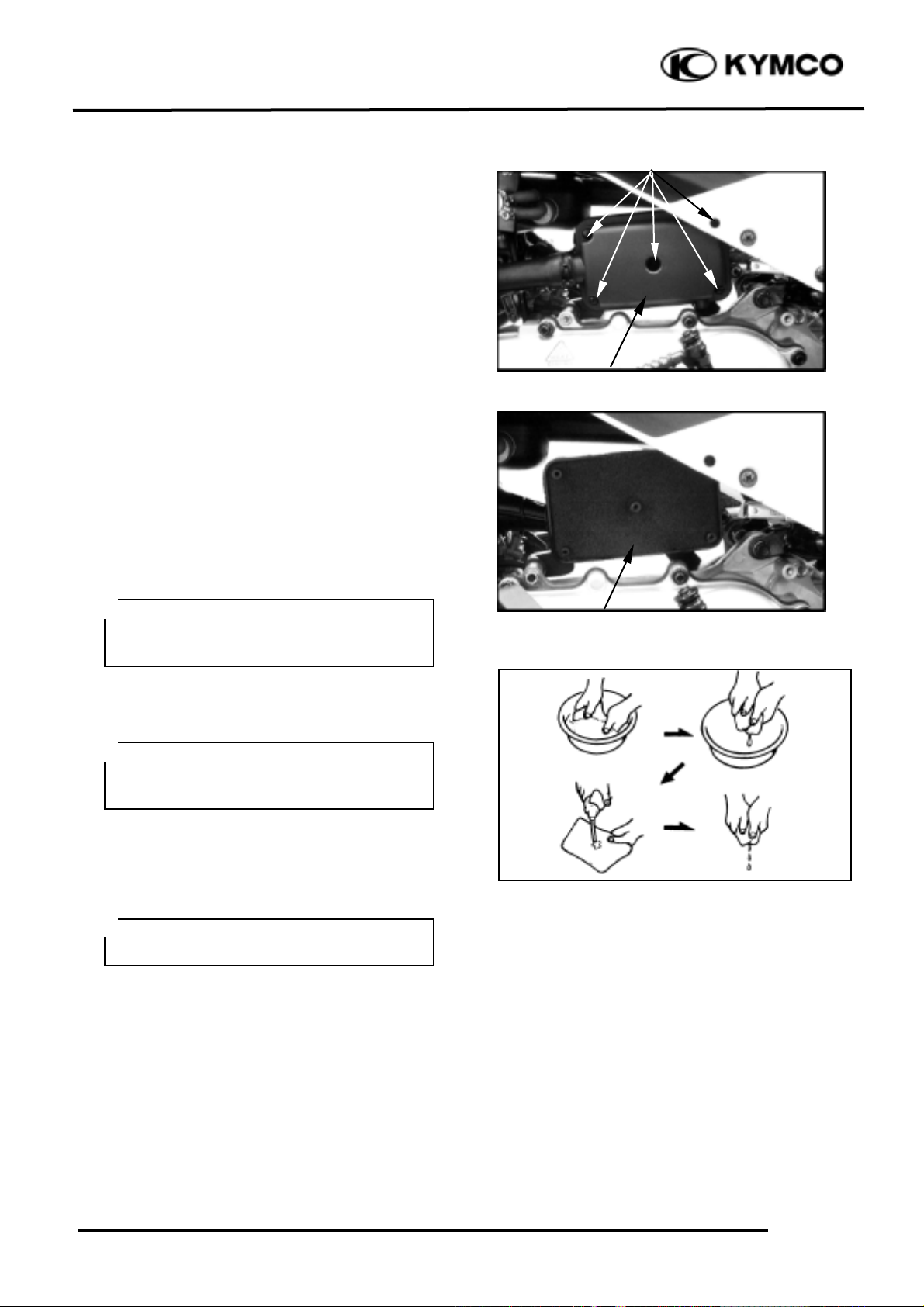

AIR CLEANER

REPLACEMENT/CLEANING

To replace the air cleaner

(Mongoose/KXR 90):

1. Remove the seat. (See page 2-3.)

2. Remove the five screws and then remove

air filter case cover.

3. Remove the air filter element, and

separate it from the box.

Screws

Air Filter Case Cover

Air Filter Element

Reference tip alignment within 1mm of

index mark on open side is acceptable.

However, the aligning mark on the

control lever must never be on the closed

side of the index mark, otherwise engine

damage will occur because of insufficient

lubrication.

°Ø

Page 7

3. INSPECTION/ADJUSTMENT

3-6

Mongoose/KXR 90/50

To replace the air cleaner

(Mongoose/KXR 50):

1. Remove the five screws and air filter case

cover.

2. Remove the air filter element, and

separate it from the box.

To clean the air filter element:

1. Wash the element gently but thoroughly

in solvent.

2. Squeeze the excess solvent out of the

filter and let it dry.

3. Inspect the element. If damaged, replace

it.

4. Apply quality foam air filter oil to the

element. If foam air filter oil is not

available, motor oil may be used.

5. Reinstall the element to the air filter case.

6. Reinstall the element assembly and parts

removed for access.

Apply the engine oil.

Squeeze out the excess oil.

CHANGE INTERVAL

More frequent replacement is required when

riding in unusually dusty or rainy areas.

Use parts cleaning solvent only. Never

use gasoline or low flash point solvents

which may lead to a fire or explosion.

°Ø

Do not twist or wring out the foam

element. This could damage the foam

material.

°Ø

The element should be wet but not

dripping.

°Ø

Air Filter Element

Screws

Air Filter Case Cover

Page 8

3. INSPECTION/ADJUSTMENT

3-7

Mongoose/KXR 90/50

Gap, Wear, and Fouling Deposits

SPARK PLUG

Remove the ignition coil cap and spark plug.

Check the spark plug for wear and fouling

deposits.

Clean any fouling deposits with a spark

plug cleaner or a wire brush.

Specified Spark Plug:

(Mongoose/KXR 90): NGK: C7HSA

(Mongoose/KXR 50): NGK: BR8HAS

Measure the spark plug gap.

Spark Plug Gap: 0.6_ 0.7mm

CYLINDER COMPRESSION

Warm up the engine before compression

test.

Remove the spark plug.

Insert a compression gauge.

Open the throttle valve fully and push the

starter button to test the compression.

Compression:

(Mongoose/KXR 90): 16kg/cm_

(Mongoose/KXR 50): 12kg/cm_

If the compression is low, check for the

following:

- Leaky valves

- Valve clearance too small

- Leaking cylinder head gasket

- Worn piston rings

- Worn piston/cylinder

If the compression is high, it indicates that

carbon deposits have accumulated on the

combustion chamber and the piston head.

Cracks, Damage

Washer Deformation

Ignition Coil Cap/Spark Plug

When installing, first screw in the spark

plug by hand and then tighten it with a

spark plug wrench.

°Ø

Compression Gauge

Page 9

3. INSPECTION/ADJUSTMENT

3-8

Mongoose/KXR 90/50

VALVE CLEARANCE

(Mongoose/KXR 90):

Disconnect the oil recycle tube at the

cylinder head cover.

Remove the four bolts and cylinder head

cover.

Remove the two screws and two bolts, then

remove the fan cover.

Turn the cooling fan clockwise so that the

“T” mark on the flywheel aligns with the

index mark on the crankcase to bring the

round hole on the camshaft gear facing up to

the top dead center on the compression

stroke.

Inspect and adjust the valve clearance.

Valve Clearance: IN: 0.1mm

EX: 0.1mm

Loosen the lock nut and adjust by turning

the adjusting nut

Tappet adjuster E012

CARBURETOR IDLE SPEED

Warm up the engine before this operation.

Start the engine and connect a tachometer.

Turn the throttle stop screw to obtain the

specified idle speed.

Idle Speed:

(Mongoose/KXR 90): 1700±100rpm

(Mongoose/KXR 50): 2000±100rpm

When the engine misses or run erratic, adjust

the air screw.

Inspect and adjust valve clearance while

the engine is cold (below 35¢J).

°Ø

• Check the valve clearance again after

the lock nut is tightened.

°Ø

Cylinder Head Cover

Special

Bolts

Cooling Fan Cover

Screws

Bolts

Round Hole

Punch Marks

Tappet Adjuster

Throttle Stop Screw

Air Screw

• The engine must be warm for accurate

idle speed inspection and adjustment.

°Ø

Page 10

3. INSPECTION/ADJUSTMENT

3-9

Mongoose/KXR 90/50

ENGINE OIL (Mongoose/KXR 90)

OIL LEVEL

Remove the two bolts and right side cover.

Place the machine on a level place.

Warm up the engine for several minutes and

stop it.

Remove the dipstick and wipe it off with a

clean rag. Insert the dipstick in the filler hole

without screwing it in.

Remove the dipstick and inspect the oil

level.

The oil level should be between the

maximum and minimum marks. If the level is

low, add oil to raise it to the proper level.

ENGINE OIL REPLACEMENT

Place the machine on a level place.

Warm up the engine for several minutes and

stop it.

Place a container under the engine.

Remove right side cover.

Remove the oil filler cap and drain plug to

drain the oil.

Reinstall the drain plug and tighten the drain

plug to specification.

Torque: 2.0_ 3.0kgf-m

Fill the engine with oil and install the oil

filler cap.

Warm up the engine for several minutes at

idle speed. Check for oil leakage while

warming up.

Oil Capacity: At disassembly: 0.8L

At change: 0.7L

Maximum Level Mark

Dipstick/Oil Filler Cap

Minimum Level Mark

Dipstick/Oil Filler Cap

Drain Plug

Be sure no foreign material enters the

crankcase.

°Ø

Run the engine for 2_ 3 minutes and

check the oil level after the engine is

stopped for 2_ 3 minutes.

°Ø

Right Side Cover

Bolts

Page 11

3. INSPECTION/ADJUSTMENT

3-10

Mongoose/KXR 90/50

ENGINE OIL REPLACEMENT AND OIL

FILTER CLEANING

A. Place the machine on a level place.

B. Warm up the engine for several minutes

and stop it.

C. Place a container under the engine.

D. Remove the oil filler cap and oil filter cap

to drain the oil.

E. Clean the oil strainer with solvent.

F. Inspect the O-ring and replace if

damaged.

G. Reinstall the O-ring, oil strainer,

compression spring and drain plug.

Tighten the drain plug to specification.

Torque: 1.0_ 2.0kgf-m

Oil Capacity: At disassembly: 0.8L

At change: 0.7L

Oil Filter Cap

°DBe sure no foreign material enters the

crankcase.

°DWhen removing the drain plug, the

compression spring, oil strainer and

O-ring will fall out. Take care not to

lose these parts.

°Ø

Before reinstalling the drain plug, be sure

to install the O-ring, compression spring

and oil strainer.

°Ø

Oil Filter Cap

Compression Spring

Oil Strainer

O-ring

Page 12

3. INSPECTION/ADJUSTMENT

3-11

Mongoose/KXR 90/50

TRANSMISSION OIL

TRANSMISSION OIL MEASUREMENT

Place the machine on a level place.

Remove the oil filler bolt and check the oil

level. It should be up to the brim of the hole.

If the level is low, add oil to raise it to the

proper level.

Reinstall the oil filler bolt and tighten to

specification.

Torque: 1.0_ 2.0kgf-m

TRANSMISSION OIL REPLACEMENT

Place the machine on a level place.

Place a container under the engine.

Remove the oil filler bolt and drain plug to

drain the oil.

Reinstall the drain plug and tighten to

specification.

Torque: 1.0_ 2.0kgf-m

Fill the engine with oil and install the oil

filler bolt.

Torque: 1.0_ 2.0kgf-m

Oil Capacity: At disassembly: 0.12L

At change: 0.11L

Start the engine and warm up for a few

minutes. While warming up, check for oil

leakage. If oil leakage is found, stop the

engine immediately and check for the cause.

Oil Filter Bolt/Measurement Hole

Drain Plug

Be sure no foreign material enters the

crankcase.

°Ø

Page 13

3. INSPECTION/ADJUSTMENT

3-12

Mongoose/KXR 90/50

DRIVE BELT

Remove the left crankcase cover.

Inspect the drive belt for cracks, scaling,

chipping or excessive wear.

Measure the V-belt width

Service limit:

Mongoose/KXR 90:16.5mm

Mongoose/KXR 50:16.5mm

Replace the drive belt if out of specification.

BRAK SHOES

The checking of brake shoes wear will

disassemble the brake. If the lining thickness

below to the wear limit (A) 2.0mm (0.08in),

to replace the shoes as a set.

BRAKE PADS

A wear indicator is provided on each brake.

The indicators allows checking of brake

pads wear. Check the position of the

indicator. If the indicator reaches the wear

limit line, to replace the pads.

BRAKE FLUID

Check if the fluid level is below the lower

level mark through the inspection window.

Drive Belt

Inspection Window

Page 14

3. INSPECTION/ADJUSTMENT

3-13

Mongoose/KXR 90/50

BRAKEN LEVER FREE PLAY

(DRUM BRAKE)

The brake lever free play (A) should be

adjusted to 10~20 mm (0.4~0.8 in) at the tip

of the brake lever.

FRONT BRAKE FREE PLAY

ADJUSTMENT

Loosen the upper lock nut and fully turn in

the adjusting bolt.

Loosen the lower lock nut.

Turn the lower adjusting bolt until specified

free play is obtained.

Tighten the lower lock nut.

While applying the front brake, turn out the

upper adjusting bolt until the upper and

lower cable lengths (A) are equal. The cable

joint will become vertical.

Tighten the upper lock nut.

REAR BRAKE FREE PLAY

ADJUSTMENT

Turn the adjusting nut on the brake hub in

direction A to decrease play, and in

direction B to increase play.

Lock Nuts

Adjusting Bolts

Page 15

3. INSPECTION/ADJUSTMENT

3-14

Mongoose/KXR 90/50

STEERING SYSTEM

INSPECTION

Place the machine on a level place.

Check the steering column bushings and

bearings:

Move the handlebar up and down, and/or

back and forth.

Replace the steering column bushings and or

bearings if excessive play

Check the tie-rod ends

Turn the handlebar to the left and/or right

until it stops completely, then slightly move

the handlebar from left to right.

Replace the tie-rod ends if tie-rod end has

any vertical play.

Raise the front end of the machine so that

there is no weight on the front wheels.

Check ball joints and/or wheel bearings.

Move the wheels lately back and froth.

Replace the front arms and/or wheel

bearings if excessive free play.

Tie-rod Ends

Make sure the cut-out on the adjusting

nut Is seated on the brake arm pin after

making final free play adjustment.

°Ø

Arm Pin

Adjusting Nut

Page 16

3. INSPECTION/ADJUSTMENT

3-15

Mongoose/KXR 90/50

TOE-IN ADJUSTMENT

Place the machine on a level place.

Measure the toe-in

Adjust if out of specification.

Toe-in measurement steps:

Mark both front tire tread centers.

Raise the front end of the machine so that

there is no weight on the front tires.

Fix the handlebar straight ahead.

Measure the width A between the marks.

Rotate the front tires 180 degrees until the

marks come exactly opposite.

Measure the width B between the marks.

Calculate the toe-in using the formula given

below.

Toe-in = B°– A

Toe-in: 0_ 15mm

If the toe-in is incorrect, adjust the toe-in

Adjust the toe-in step:

Mark both tie-rods ends.

This reference point will be needed during

adjustment.

Loosen the lock nuts (tie-rod end) of both

tie-rods

The same number of turns should be given

to both tie-rods right and left until the

specified toe-in is obtained, so that the

lengths of the rods will be kept the same.

Torque: 2.5_ 3.5kgf-m

• Be sure that both tie-rod are

turned the same amount. If not, the

machine will drift tight or left even

though the handlebar is positioned

straight which may lead to mishandling

and accident.

• After setting the toe-in to

specification, run the machine slowly

for some distance with hands placed

lightly on the handlebar and check that

the handlebar responds correctly. If

not, turn either the right or left tie-rod

within the toe-in specification.

°Ø

A

B

Tie-rod

Tie-rod End Nuts

Tie-rod

Tie-rod End Nuts

Page 17

3. INSPECTION/ADJUSTMENT

3-16

Mongoose/KXR 90/50

WHEELS/TIRES

Check the tires for cuts, imbedded nails or

other damages.

Check the tire pressure.

TIRE PRESSURE

1 Rider

Front

0.22kgf/cm_

Rear

0.22kgf/cm_

TIRE SIZE (Mongoose/KXR 90)

Front : 18*7-8

Rear : 18*9-8

TIRE SIZE (Mongoose/KXR 50)

Front : 16*8-7

Rear : 16*8-7

Check the front wheel hub nut for

looseness.

Check the rear wheel hub nut for looseness.

If the axle nuts are loose, tighten them to the

specified torque.

Torque: Front : 5.5_ 6.5kgf-m

Rear : 6.0_ 8.0kgf-m

WHEEL INSPECTION

Inspect the tire surfaces.

Replace if wear or damage.

Tire wear limit: 3.0mm

Front Axle Nut

Tire pressure should be checked when

tires are cold.

°Ø

Rear Axle Nut

It is dangerous to ride with a worn out

tire. When a tire wear is out of

specification, replace the tire

immediately.

°Ø

Page 18

3. INSPECTION/ADJUSTMENT

3-17

Mongoose/KXR 90/50

Inspect the wheel.

Replace if damage or bends

Always balance the wheel when a tire or

wheel has been changed or replaced.

DRIVE CHAIN SLACK

ADJUSTMENT

Before checking and/or adjusting, rotate the

rear wheels several revolutions and check

slack at several points to find the tightest

point. Check and/or adjust the chain slack

with the rear wheels in this “tightest”

position.

Place the machine on a level place.

Check drive chain slack (A).

Adjust if out of specification.

Drive chain slack: Approximately

10~20mm

Adjust drive chain slack:

Elevate the rear wheels by placing a suitable

stand under the rear of frame.

Loosen the upper and lower axle holding

bolts.

Bolts

• Never attempt even small repairs

to the wheel.

• Ride conservatively after

installing a tire to allow it to seat itself

properly on the rim.

°Ø

Too little of chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.

°Ø

Wheels should be on the ground without

the rider on it.

°Ø

Support the machine securely so there is

no danger of it falling over.

°Ø

Hub Stopper Nut

Page 19

3. INSPECTION/ADJUSTMENT

3-18

Mongoose/KXR 90/50

Turn the adjusting nut, to decrease or

increase chain slack.

Retighten the upper and lower axle holding

bolts.

Torque: 6.0_ 8.0kgf-m

Drive chain cleaning and lubrication

The drive chain is equipped with rubber O-

rings between the chain plates. Steam

cleaning, high-pressure washes, and certain

solvents can damage these O-rings. Use only

kerosene to clean the drive chain. Wipe it

dry, and thoroughly lubricate it with SAE

30~50 motor oil. Do not use any other

lubricants on the drive chain. They may

contain solvents that could damage the O-

rings.

Adjusting Nut

O-ring

Page 20

3. INSPECTION/ADJUSTMENT

3-19

Mongoose/KXR 90/50

CABLE INSPECTION AND

LUBRICATION

Inspect the cable sheath.

Replace if damage.

Check the cable operation.

Lubricate or replace if unsmooth operation.

LEVER LUBRICATION

Lubricate the pivoting parts of each lever.

SUSPENSION LUBRICATION

Inject grease into the nipples using a grease

gun until slight over flow is observed from

the thrust covers.

Front Swing

Arm Nipple

Damaged cable sheath may cause

corrosion and interfere with the cable

movement. An unsafe condition may

result so replace such cable as soon as

possible.

°Ø

Wipe off the excess grease.

°Ø

Hold cable end high and apply several

drops of lubricant to cable.

°Ø

Rear Swing

Arm Nipple

Page 21

3. INSPECTION/ADJUSTMENT

3-20

Mongoose/KXR 90/50

HEADLIGHT BEAM

ADJUSTMENT (ON ROAD

ONLY)

Vertical adjustment:

Turn the ignition switch ON and start the

engine.

Turn on the headlight switch.

Adjust the headlight aim by turning the

headlight aim adjusting screw.

BRAKE PEDAL ADJUSTMENT

(KXR 90 ON ROAD ONLY)

The brake pedal free play should be

adjusted to 5~10 mm (0.2~0.4 in) at the

brake pedal pivot. If the free play is

incorrect, adjust as follows:

Adjust:

1. Keep front brake lever free play at 10~20

mm (0.4~0.8 in).

2. Loosen the locknuts. (R/L front lower

brake cables)

3. Turn the adjusting bolts until the front

lower brake cables is tensed.

4. Apply the front brake lever and check

front brake cam lever to make sure that

the brake does not drag after adjusting.

5. While remove the cable joint case cover

and applying the brake pedal, make sure

the left and right front lower cable lengths

(A and B) are equal. The cable joint will

become vertical.

6. Tighten the locknuts. (R/L front lower

brake cables)

Headlight

Adjusting screw

Adjusting Bolts

Locknuts

Brake Cam Lever

R/L Front Lower Cable

Cable Joint Case Cover

Bolts

Cable Joint

Page 22

3. INSPECTION/ADJUSTMENT

3-21

Mongoose/KXR 90/50

7. Loosen the locknut. (Brake pedal cable)

8. Turn the adjusting bolt until the specified

free play is obtained.

9. Tighten the locknut. (Brake pedal cable)

BRAKE FLUID (KXR 90 ON

ROAD ONLY)

Check if the fluid level is below the lower

level mark through the inspection window.

Locknut

Adjusting Blot

Brake Pedal Cable

Loading...

Loading...