4. LUBRICATION SYSTEM

4-0

Mongoose/KXR 90/50

4

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

LUBRICATION SYSTEM

__________________________________________________________________________________

SERVICE INFORMATION (Mongoose/KXR 90)-------------------- 4- 3

SERVICE INFORMATION (Mongoose/KXR 50)-------------------- 4- 4

ENGINE OIL/OIL FILTER (Mongoose/KXR 90)-------------------- 4- 5

OIL PUMP BLEEDING (Mongoose/KXR 50)------------------------ 4- 9

OIL TANK (Mongoose/KXR 50)--------------------------------------- 4-10

OIL PUMP (Mongoose/KXR 50)--------------------------------------- 4-11

OIL FILTER CLEANING (Mongoose/KXR 50) --------------------- 4-12

4

4. LUBRICATION SYSTEM

4-1

Mongoose/KXR 90/50

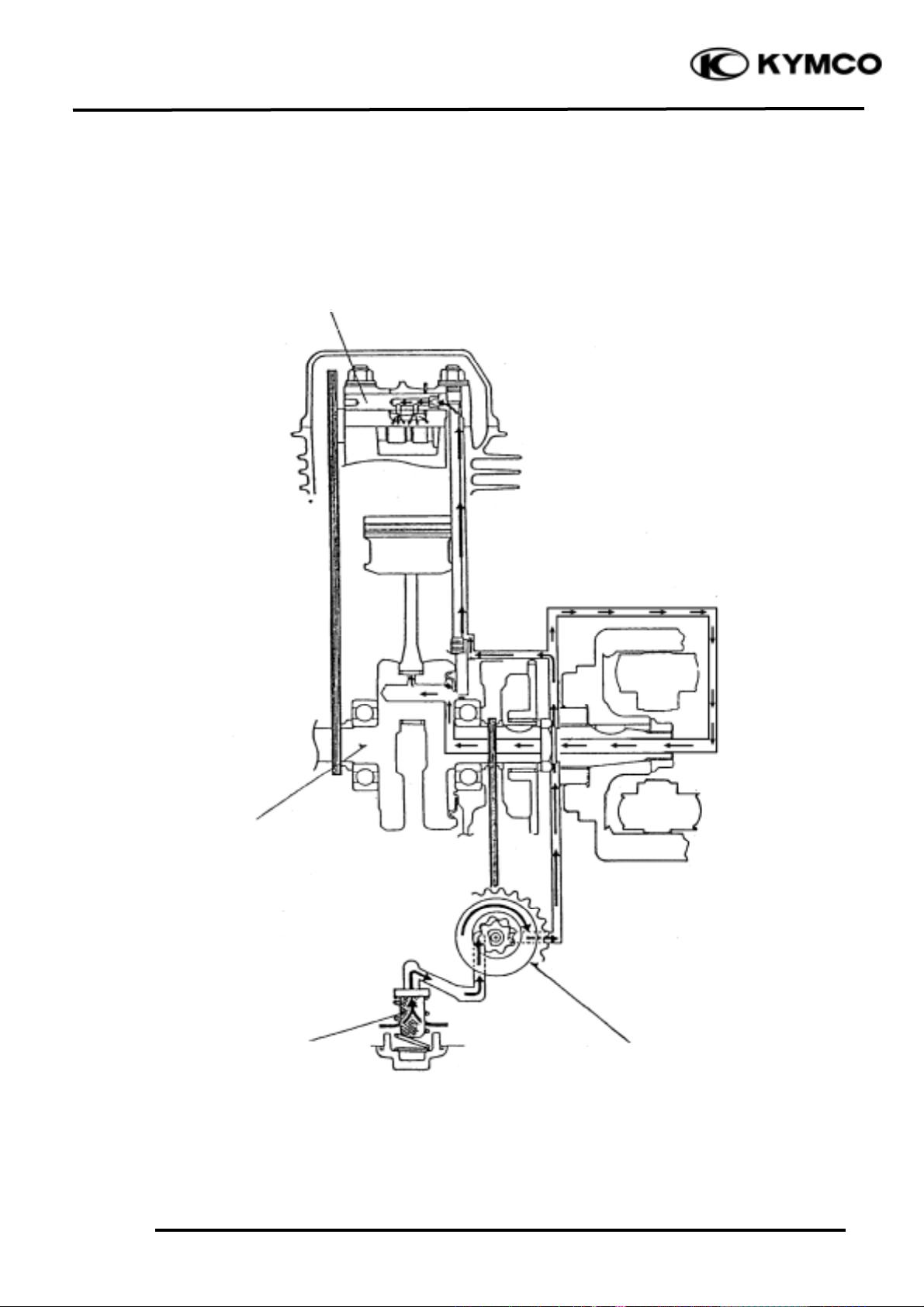

LUBRICATION SYSTEM (Mongoose/KXR 90)

Oil Pump

Oil Filter Screen

Crankshaft

Rocker Arm Shaft

4. LUBRICATION SYSTEM

4-2

Mongoose/KXR 90/50

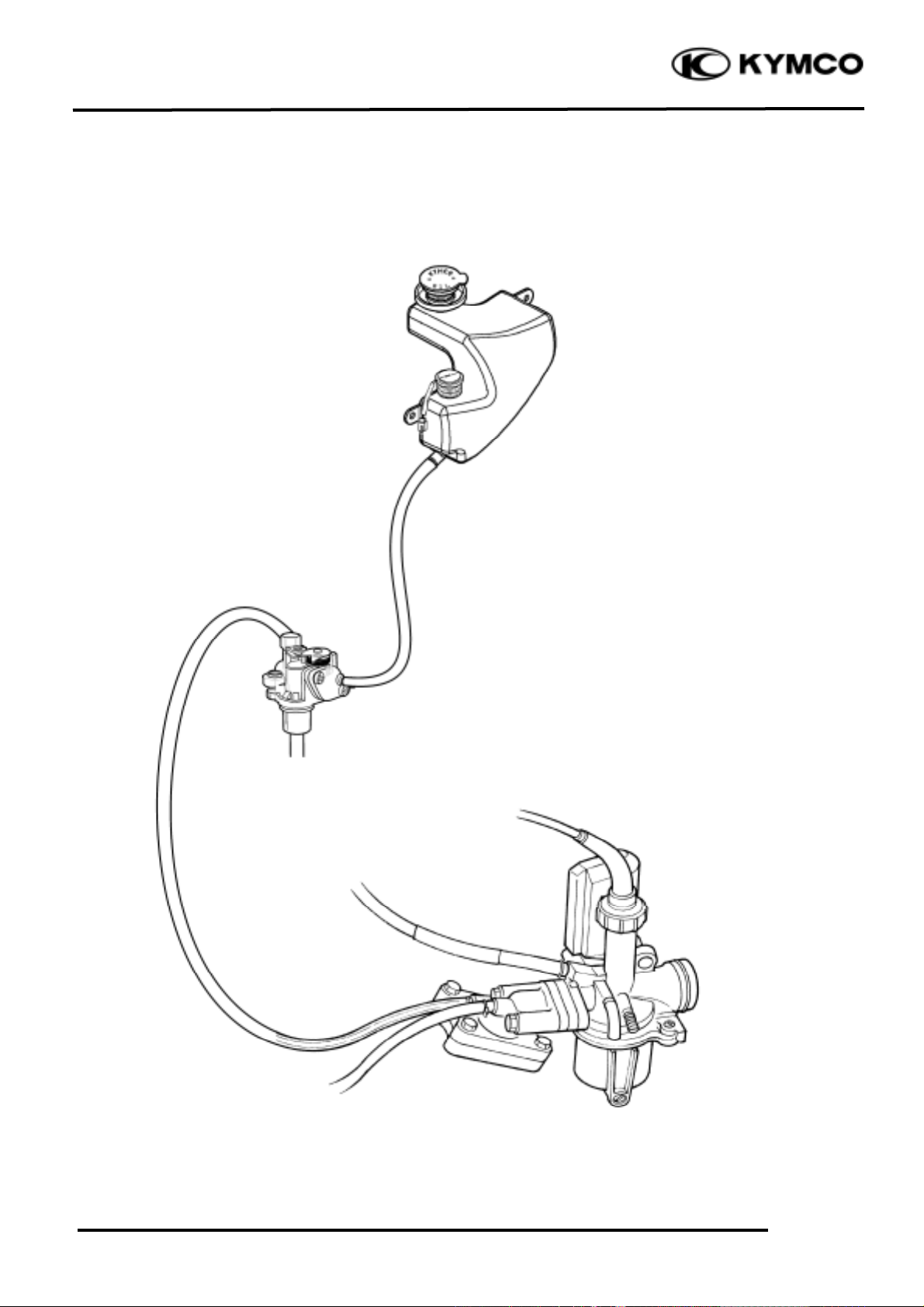

LUBRICATION SYSTEM (Mongoose/KXR 50)

4. LUBRICATION SYSTEM

4-3

Mongoose/KXR 90/50

SERVICE INFORMATION (Mongoose/KXR 90)

GENERAL INSTRUCTIONS

• The maintenance of lubrication system can be performed with the engine installed in the frame.

• Use care when removing and installing the oil pump not to allow dust and foreign matters to enter

the engine and oil line.

• Do not attempt to disassemble the oil pump. The oil pump must be replaced as a set when it

reaches its service limit.

• After the oil pump is installed, check each part for oil leaks.

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

Inner rotor-to-outer rotor clearance

0.15

0.20

Oil pump

Outer rotor-to-pump body clearance

0.15_ 0.20

0.25

Rotor end-to-pump body clearance

0.04_ 0.09

0.12

TROUBLESHOOTING

Oil level too low Poor lubrication pressure

• Natural oil consumption • Oil level too low

• Oil leaks • Clogged oil filter or oil passages

• Worn or poorly installed piston rings • Not use the specified oil

• Worn valve guide or seal

4. LUBRICATION SYSTEM

4-4

Mongoose/KXR 90/50

SERVICE INFORMATION (Mongoose/KXR 50)

GENERAL INSTRUCTIONS

• Use care when removing and installing the oil pump not to allow dust and dirt to enter the engine

and oil line.

• Do not attempt to disassemble the oil pump.

• Bleed air from the oil pump if there is air between the oil pump and oil line.

• If the oil is disconnected, refill the oil line with motor oil before connecting it.

SPECIFICATIONS

• Recommended Motor Oil: SAE20W20# 2-stroke Motor Oil

• Oil Capacity : 1.0 liter

Light comes on : 0.25 liter

TROUBLESHOOTING

Excessive white smoke or carbon deposits on spark plug

• Oil pump not properly synchronized (excessive oil)

• Poor quality oil

Engine overheating

• Oil pump not properly adjusted (insufficient oiling)

• Poor quality oil

Seized piston

• No oil in tank or clogged oil line

• Oil pump not properly adjusted (insufficient oiling)

• Air in oil line

• Faulty oil pump

Oil not flowing out of tank to engine

• Clogged oil tank cap breather hole

• Clogged oil filter

4. LUBRICATION SYSTEM

4-5

Mongoose/KXR 90/50

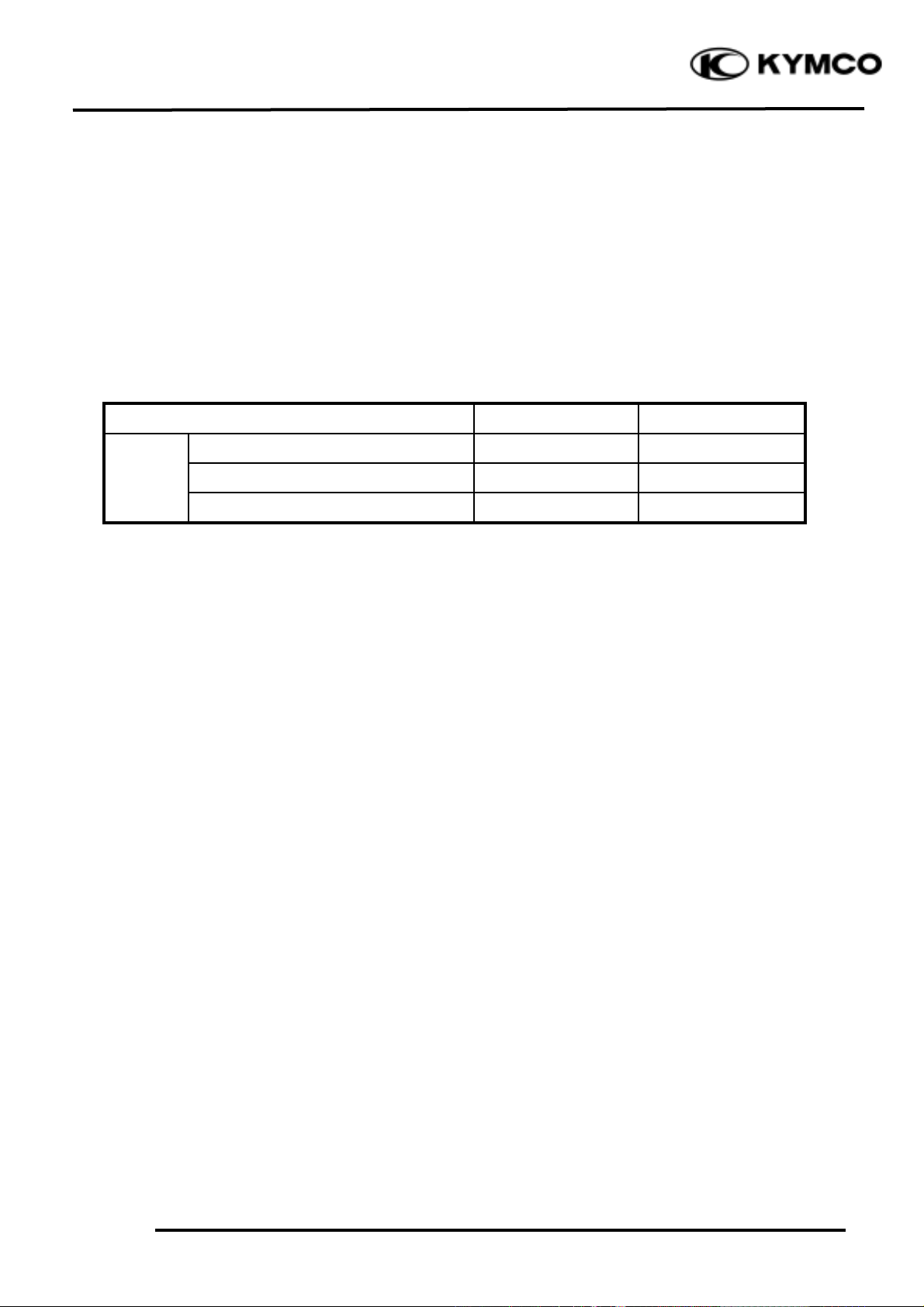

Bolts

Right Crankcase Cover

Nut

Bolts

Oil Separator Cover

ENGINE OIL/OIL FILTER

(Mongoose/KXR 90)

OIL LEVEL AND OIL CHANGE

Refer to the “ENGINE OIL” section in the

chapter 3 to check the oil level and

replacement and oil filter cleaning.

OIL PUMP

REMOVAL

Place a container under the engine.

Remove the drain plug to drain the oil. (!3-

9)

Remove the A.C. generator flywheel. (!14-

8)

Remove the A.C. generator stator and pulsar

coil. (!14-8)

Remove the eight right crankcase cover bolts

and the right crankcase cover.

Remove the two bolts and oil separator

cover.

Remove the oil pump driven gear nut.

Remove the oil pump driven gear and drive

chain.

Oil Pump Driven Gear

Drive Chain

4. LUBRICATION SYSTEM

4-6

Mongoose/KXR 90/50

Oil Pump

Bolts

Outer Rotor

Oil Pump Body

Screws

Remove the two oil pump mounting bolts

and the oil pump.

DISASSEMBLY

Remove the screw and disassemble the oil

pump.

INSPECTION

Measure the pump body-to-outer rotor

clearance.

Service Limit: 0.25mm

Oil Pump Body

4. LUBRICATION SYSTEM

4-7

Mongoose/KXR 90/50

Outer Rotor

Inner Rotor

Inner Rotor

Pump Cover

Outer Rotor

Measure the inner rotor-to-outer rotor

clearance.

Service Limit: 0.2mm

Measure the rotor end-to-pump body

clearance.

Service Limit: 0.12mm

ASSEMBLY

Install the outer rotor, inner rotor and pump

shaft into the pump body.

Install the dowel pin.

Install the pump cover by aligning the hole

in the cover with the dowel pin.

Insert the pump shaft by aligning the flat

on the shaft with the flat in the inner

rotor.

*

4. LUBRICATION SYSTEM

4-8

Mongoose/KXR 90/50

Screws

Oil Pump

Arrow Mark

Pump Shaft

Tighten the screw to secure the pump cover.

Make sure that the pump shaft rotates

freely without binding.

INSTALLATION

Reverse the “OIL PUMP REMOVAL”

procedures.

Make sure that the pump shaft rotates

freely without binding.

Install the oil pump with the arrow on

the pump body facing up and fill the oil

pump with engine oil before installation.

*

4. LUBRICATION SYSTEM

4-9

Mongoose/KXR 90/50

OIL PUMP BLEEDING

(Mongoose/KXR 50)

OIL INLET LINE/OIL PUMP BLEEDING

Fill the oil tank with recommended oil.

Place a shop towel around the oil pump.

Disconnect the oil inlet tube from the oil

pump and clip it.

Fill the oil pump with oil by squirting clean

oil through the joint. (About 3cc)

Fill the oil line with oil and connect it to the

oil pump.

OIL OUTLET LINE BLEEDING

1. Disconnect the oil outlet tube and bend it

into U shape. Force air out of the tube by

filling it with oil.

2. Start the engine and allow it to idle with

the oil control lever in the fully open

position. Visually check the oil flow.

3. If there is no oil flowing out within 1

minute, bleed air from the oil inlet tube

and oil pump.

• Air in the oil tubes will block oil flow

and result in severe engine damage.

• Bleed air from the oil tubes and oil

pump whenever the oil tubes or pump

have been removed or there is air in the

oil tubes.

°Ø

Bleed air from the oil inlet tube first,

then bleed air from the oil outlet line.

°Ø

• Never run the engine in a closed area.

• Do not increase the engine speed at

will.

°Ø

Oil Outlet Line

Oil Pump

Oil Outlet Line

4. LUBRICATION SYSTEM

4-10

Mongoose/KXR 90/50

OIL TANK (Mongoose/KXR 50)

OIL TANK REMOVAL

Remove the oil level switch connector.

Remove the two bolts attaching the oil tank.

Disconnect the oil inlet tube.

Drain the oil inside the oil tank into a clean

container.

Remove the oil tank.

The installation sequence is the reverse of

removal.

• Connect the oil tube properly.

• Bleed air from the oil pump after

installation. (See page 4-9)

• The oil tube clip (at the oil tank side)

must be locked from inside of the oil

tube joint.

°Ø

Oil Level Switch Connector

Bolts

Oil Inlet Tube

4. LUBRICATION SYSTEM

4-11

Mongoose/KXR 90/50

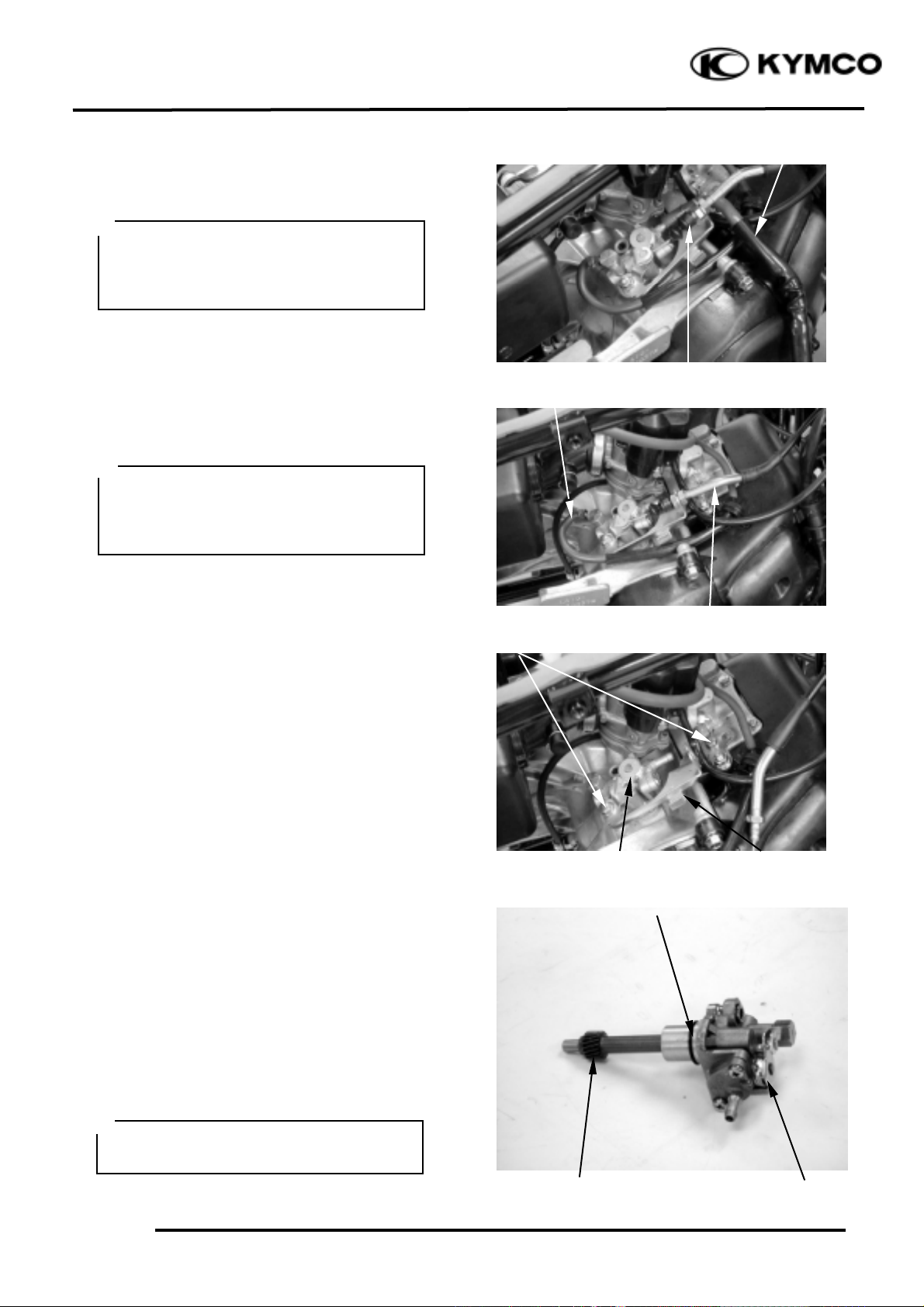

OIL PUMP (Mongoose/KXR 50)

REMOVAL

Disconnect the oil outlet tube from the oil

pump.

Disconnect the oil pump control cable from

the pump body.

Disconnect the oil inlet tube.

Remove the oil pump control cable plate

bolts.

Remove the oil pump from the crankcase.

OIL PUMP INSPECTION

Remove the oil pump and inspect the

following items:

• Weakened O-ring

• Damage to crankcase mating surface

• Damage to pump body

• Control lever operation

• Oil leaks through oil seals

• Worn or damaged pump pinion

Do not allow foreign matters to enter the

crankcase. Before removing the oil

pump, clean the oil pump and crankcase

surfaces.

°Ø

Do not disassemble the oil pump which

cannot be used after disassembly.

°Ø

O-ring

Gear

Control Lever

Oil Inlet Tube

Oil Pump Control Cable

Oil Pump Control Cable

Oil Outlet Tube

Before disconnecting the oil line, clip

the oil line to avoid oil flowing out and

then plug the oil line after it is

disconnected.

°Ø

Bolts

Oil Pump

Oil Pump Control

Cable Plate

4. LUBRICATION SYSTEM

4-12

Mongoose/KXR 90/50

OIL PUMP INSTALLATION

Install the oil pump into the crankcase.

Install the oil pump control cable plate.

Connect the oil inlet line and oil outlet tube

properly.

Connect the oil pump control cable.

Bleed air from the oil pump. (See page 4-9)

OIL FILTER CLEANING

(Mongoose/KXR 50)

Disconnect the oil tube at the oil pump side

and allow oil to drain into a clean container.

Remove the tube clip at the oil tank side and

disconnect the oil tube.

Remove the oil filter.

Clean the oil filter screen with compressed

air.

Install the oil filter in the reverse order of

removal and fill the oil tank with specified

oil up to the proper level.

Bleed air from the oil pump and oil lines.

• Lubricate the O-ring with grease or

engine oil before installation.

• Make sure that the oil pump is

inserted into the crankcase.

• Apply molybdenum disulfide or grease

to the pump pinion.

°Ø

Grease or Engine Oil

• Connect the oil tube properly.

• Bleed air from the oil pump after

installation.

• The oil tube clip (at the oil tank side)

must be locked from inside of the oil

tube joint.

°Ø

Filter Screen

Oil Filter

Clip

• Connect the oil tubes securely.

• Install the tube clip at the oil tank side

and also install the clip to the lower oil

tube that goes to the oil pump.

• Check for oil leaks.

°Ø

Loading...

Loading...