Page 1

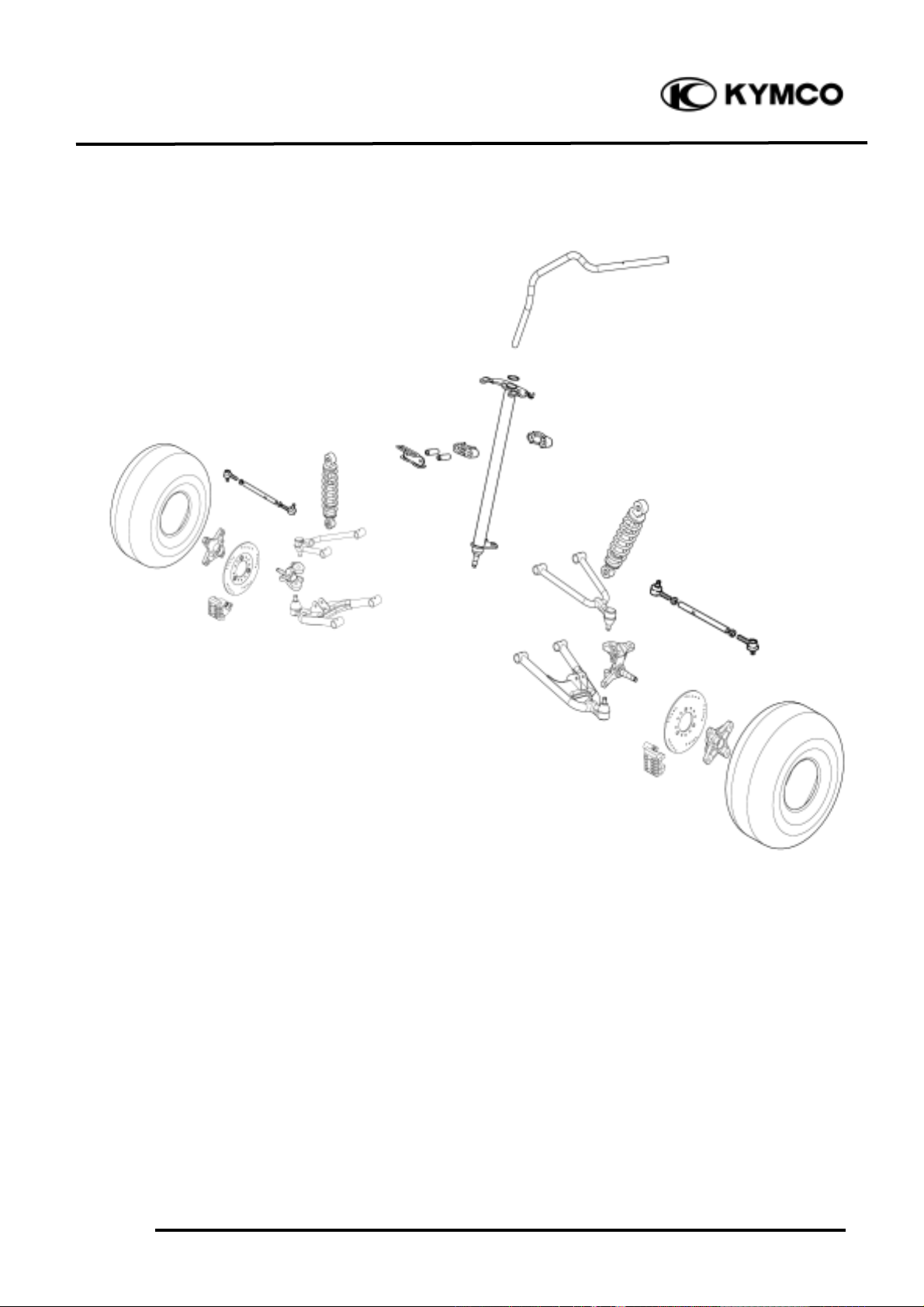

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-0

Mongoose/KXR 250

14

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

FRONT WHEEL/

FRONT SUSPENSION\STEERING SYSTEM

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 14- 2

TROUBLESHOOTING ------------------------------------------------- 14- 2

FRONT WHEEL--------------------------------------------------------- 14- 3

FRONT WHEEL HUB -------------------------------------------------- 14- 4

FRONT SUSPENSION ------------------------------------------------- 14- 7

TIE-ROD ----------------------------------------------------------------- 14-11

HANDLEBAR ----------------------------------------------------------- 14-13

STEERING COLUMN -------------------------------------------------- 14-15

14

Page 2

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-1

Mongoose/KXR 250

Page 3

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-2

Mongoose/KXR 250

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• Jack the machine front wheel off the ground and be careful to prevent the machine from falling

down.

• During servicing, keep oil or grease off the brake disk

• Inspect the brake system before riding.

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

Radialæ2.0

Axialæ2.0

Tie rod length

299.5±0.5

æ

Rod-end (tie rod) angle

180ºæ

TORQUE VALUES

Steering stem nut 6.0_ 8.0kgf-m

Front swing arm nut 4.0_ 5.0kgf-m

Front wheel nut 5.0_ 6.0kgf-m

Front wheel hub nut 6.0~8.0kgf-m

Steering knuckle nut 3.0_ 4.0kgf-m

Front shock absorber upper

mount bolt 3.5_ 4.5kgf-m

Front shock absorber lower

mount bolt 3.5_ 4.5kgf-m

SPECIAL TOOLS

Oil seal and bearing install E014

TROUBLESHOOTING

Hard steering (heavy) Front wheel wobbling

•Insufficient tire pressure • Bent rim

• Excessive wheel bearing play

• Bent spoke plate

• Faulty tire

Steers to one side or does not track straight • Improperly tightened axle nut

• Uneven front shock absorbers Soft front shock absorber

• Bent front arm • Weak shock springs

• Bent steering knuckle • Insufficient damper oil

Front shock absorber noise

• Slider bending

• Loose arm fasteners

• Lack of lubrication

Front wheel rim run out

Page 4

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-3

Mongoose/KXR 250

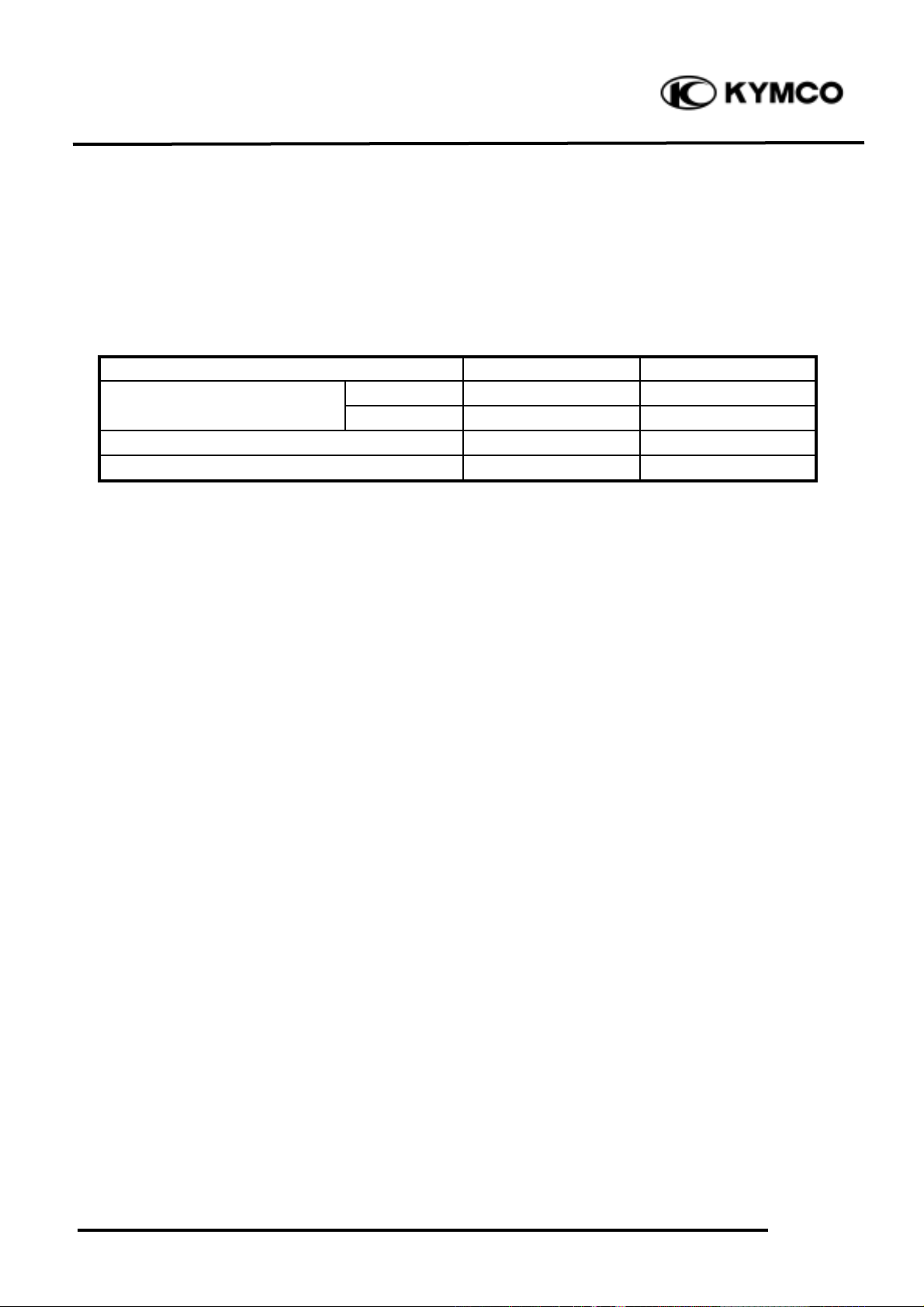

FRONT WHEEL

REMOVAL AND INSPECTION

Place the machine on a level place.

Remove four nuts attaching the front wheel

hub and front wheel.

Elevate the front wheels by placing a

suitable stand under the frame.

Measure the wheel run out.

Replace wheel or check bearing play if out

of specification

Rim run out limits:

Vertical: 2.0mm

Lateral: 2.0mm

INSTALLATION

When reinstalling a wheel, tighten the wheel

nuts in a crisscross (rather than a circular)

pattern.

Torque: 5.0_ 6.0kgf-m

Support the machine securely so

there is no danger of it falling over.

°Ø

Be sure the tapered side of the wheel

nuts face the wheel rim.

°Ø

Nuts

Page 5

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-4

Mongoose/KXR 250

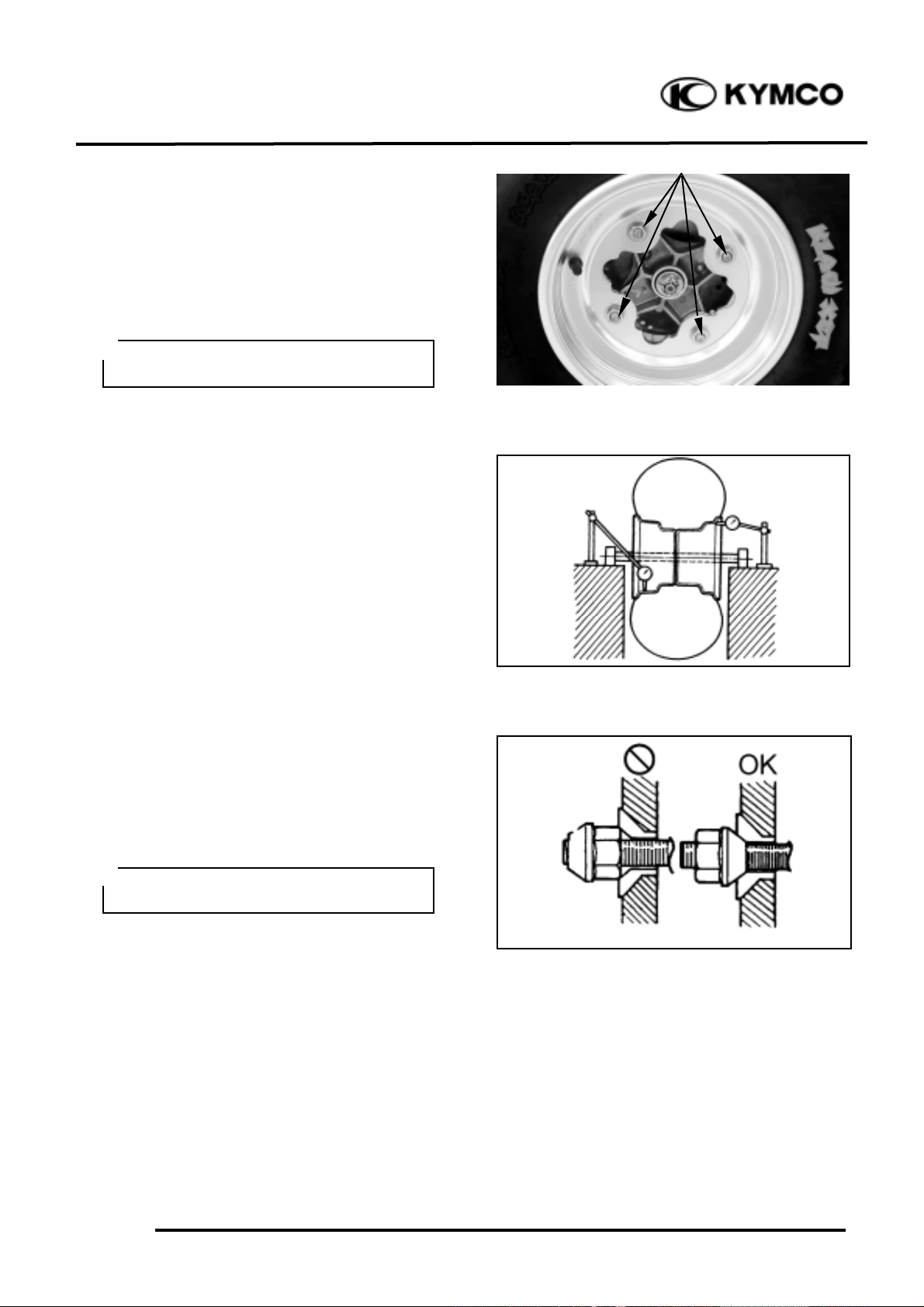

FRONT WHEEL HUB

REMOVAL AND INSPECTION

Place the machine on a level place.

Remove the front wheel (!14-3) and

caliper. (!13-8)

Elevate the front wheels by placing a

suitable stand under the frame.

Remove the cotter pin.

Remove nut attaching the front wheel hub

and then remove front wheel hub.

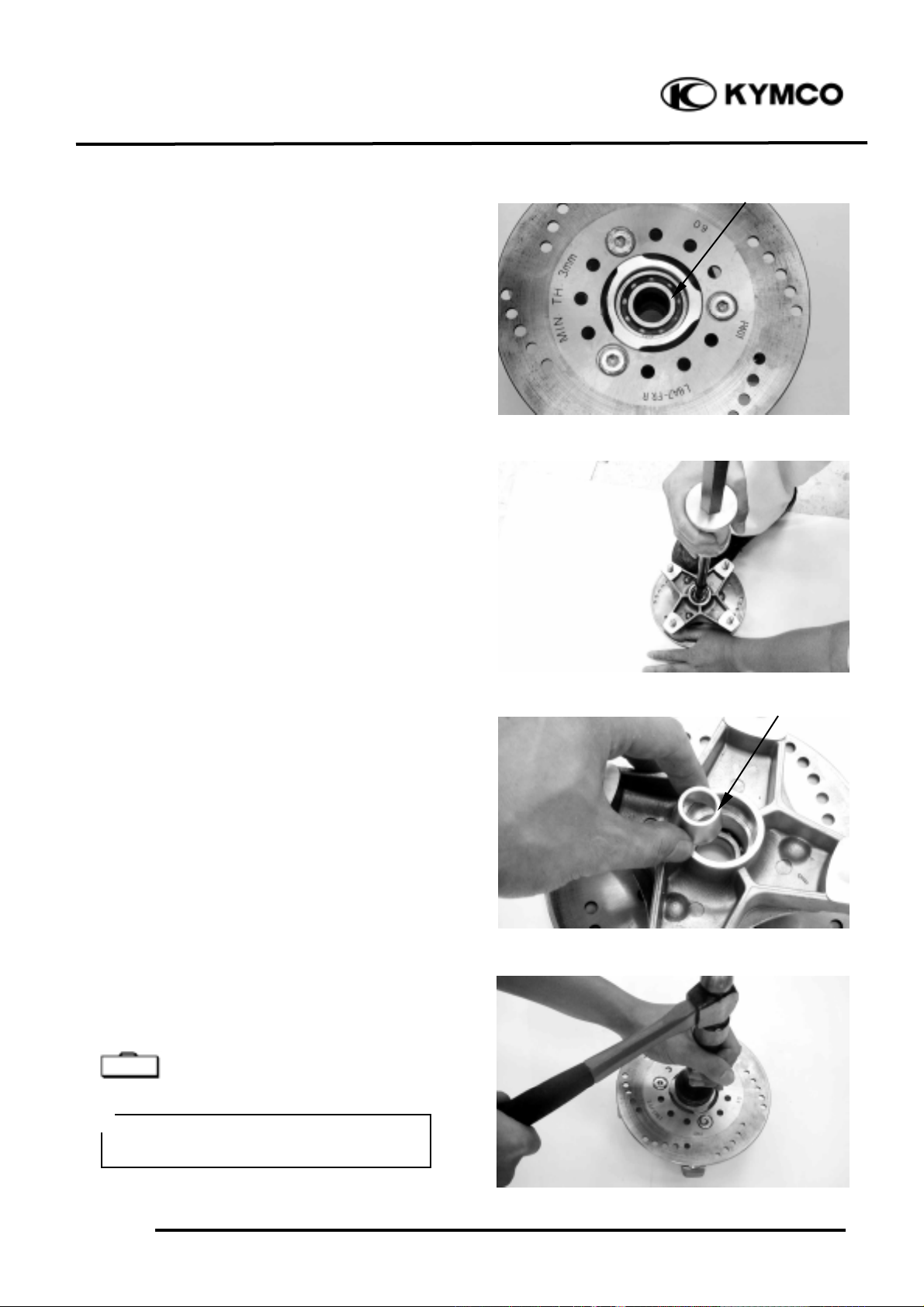

DISASSEMBLY

Remove the outside collars.

Inspect the dust seals for wear or damage.

If any defects are found, replace the dust

seal with a new one.

Remove the dust seals by a flat-head screw

driver.

Inspect the bearings for allow play in the

front wheel hub or the wheel turns roughly.

Support the machine securely so

there is no danger of it falling over.

°Ø

Place a wood block against the outer

edge to protect this edge.

°Ø

Nuts

Cotter Pin

Outside Collar

Dust Seal

Outside Collar

Dust Seal

Bearing

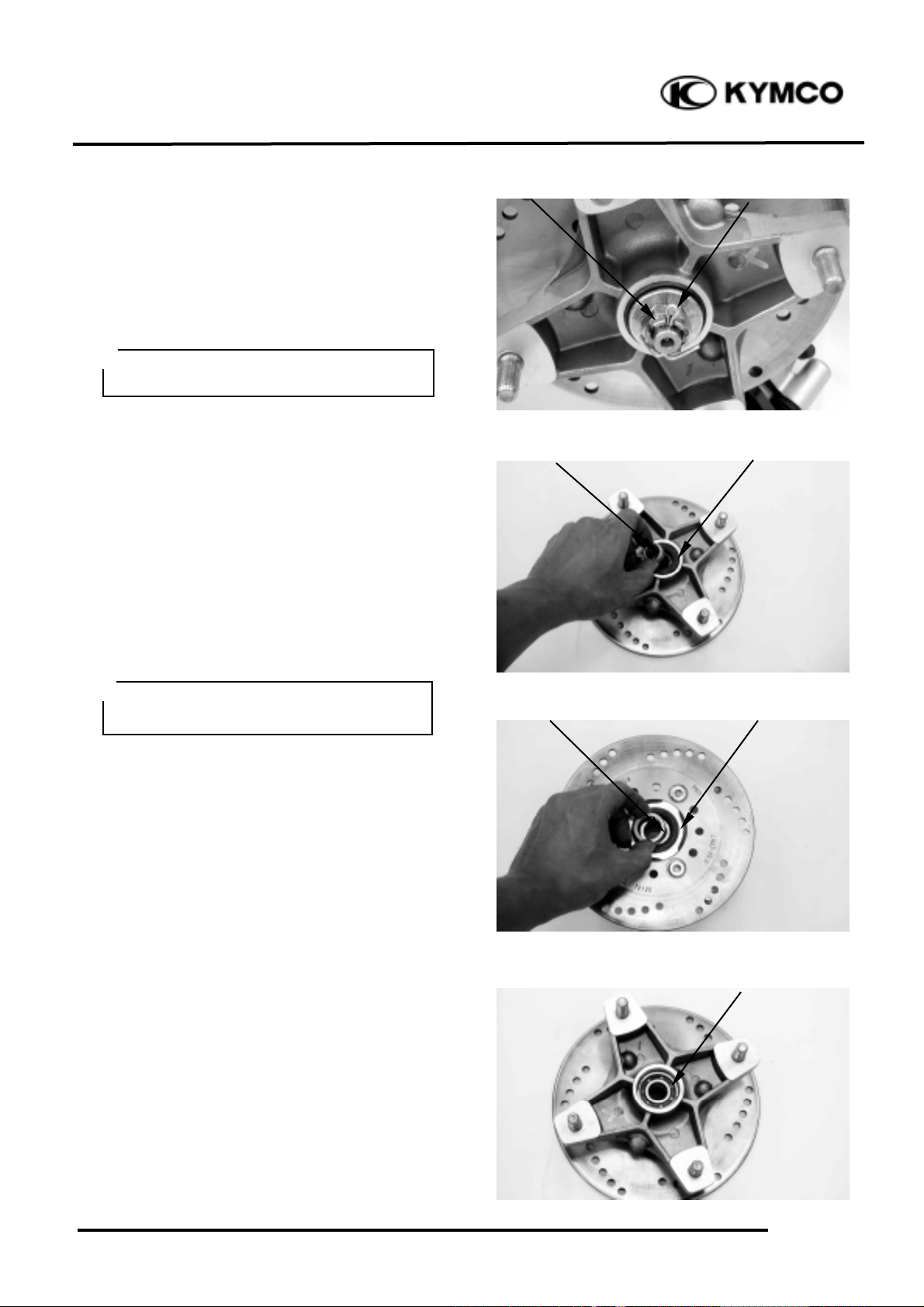

Page 6

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-5

Mongoose/KXR 250

If any defects are found, replace the bearings

Remove the bearings using a general bearing

puller.

Remove the distance collar from the front

wheel hub.

ASSEMBLY

Install the left new bearing and dust seal into

the front wheel hub.

Oil seal and bearing install E014

Special

Apply the grease onto the oil seal lips,

bearing.

°Ø

Bearing

Distance Collar

Page 7

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-6

Mongoose/KXR 250

Install the distance collar.

Install the right new bearing and dust seal

into the front wheel hub.

Oil seal and bearing install E014

INSTALLATION

Reverse the “FRONT WHEEL HUB

REMOVAL AND INSPECTION”

procedures.

Tighten the front wheel hub nut.

Torque: 5.0_ 6.0kgf-m

Install the cotter pin and band ends of cotter

pin.

Be sure the tapered side of the distance

collar face the wheel.

°Ø

Apply the grease onto the oil seal lips,

bearing.

°Ø

• Do not allow the bearings to tilt

while driving them in.

• Do not strike the center race or

balls of the bearing. Contact should be

made only with the outer race.

• Pack all bearing cavities with

grease.

• Drive in the bearing squarely

°Ø

Special

Apply grease onto the bearing and dust

seal lips of the wheel panel.

°Ø

Always use a new cotter pin.

°Ø

Distance Collar

Page 8

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-7

Mongoose/KXR 250

FRONT SUSPENSION

REMOVAL AND INSPECTION

Elevate the front wheels by placing a

suitable stand under the frame.

Remove the front wheel (!14-3), caliper

(!13-8) and front wheel hub. (!14-4)

Remove the cotter pins, washer and nuts

attaching tie-rod, upper and lower front arm.

Disconnect the upper front arm from the

steering knuckle.

Remove the front shock absorber upper mount

and lower mount bolts, then remove the front

shock absorber and bush.

Disconnect the tie-rod and lower front arm

from steering knuckle, then remove steering

knuckle.

Inspect the steering knuckle for cracks,

pitting or damage.

If any defects are found, replace the steering

knuckle with a new one.

Support the machine securely so there is

no danger of it falling over.

°Ø

Nut

Cotter Pin

Nuts

Cotter Pin

Upper Front Arm

Upper Front Arm

Bolts

Lower Front Arm

Tie-rod

Page 9

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-8

Mongoose/KXR 250

Inspect the shock absorber rod.

Bends/damage _Replace the shock absorber

assembly.

Inspect the shock absorber.

Oil leaks _Replace the shock absorber

assembly.

Inspect the spring of the shock absorber by

move the spring up and down.

Fatigue _Replace the shock absorber

assembly.

Inspect bush.

Wear/damage _Replace.

Check the upper front arm brackets of the

frame.

If bent, cracked or damaged, repair or

replace the frame.

Check the tightening torque of the front

arms securing nuts.

Torque: 40_ 5.0kgf-m

Check the upper front arm side play by

moving it from side to side.

If side play noticeable, replace the inner

collars and bushes as a set. as a set.

Check the front arm vertical movement by

moving it up and down.

If vertical movement is tight, binding or

rough, replace the inner collars and bushes

as a set.

Remove the band and then disconnect the

front brake fluid tube from the upper front

arm.

Remove the two nuts and two bolts

attaching the upper front arm, then remove

the upper front arm and bushes.

Bush

Shock Absorber

Band

Front Brake Fluid Tube

Bolts

Page 10

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-9

Mongoose/KXR 250

Inspect the front arm.

Cracks/bends/damage _Replace.

Inspect bushes.

Wear/damage _Replace.

Check the lower front arm brackets of the

frame.

If bent, cracked or damaged, repair or

replace the frame.

Check the tightening torque of the front

arms securing nuts.

Torque: 4.0_ 5.0kgf-m

Check the lower front arm side play by

moving it from side to side.

If side play noticeable, replace the inner

collar and bushes as a set.

Check the lower front arm vertical

movement by moving it up and down.

If vertical movement is tight, binding or

rough, replace the inner collar and bushes as

a set.

Remove the two nuts and two bolts

attaching the lower front arm, then remove

the lower front arm and bushes.

Do not attempt to straighten a bent arm,

this may dangerously weaken the arm.

°Ø

Bushes

Bolts

Page 11

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-10

Mongoose/KXR 250

Inspect the lower front arm.

Cracks/bends/damage _Replace.

Inspect bushes.

Wear/damage _Replace.

INSTALLATION

Reverse the “FRONT SUSPENSION

REMOVAL AND INSPECTION”

procedures.

Install the lower and upper front arms nuts

onto the frame and tighten the nuts.

Torque: 4.0_ 5.0kgf-m

Install the steering knuckle onto the upper

and lower front arms and tighten the nuts.

Torque: 3.0_ 4.0kgf-m

Install the tie-rod and washer onto the

steering knuckle and tighten the nut.

Torque: 3.0_ 4.0kgf-m

Install the all cotter pins and band ends of

cotter pins.

Apply the grease onto the bush, then install

the shock absorber and tighten the upper

mount and lower mount bolts.

Torque: 3.5_ 4.5kgf-m

Install the front wheel hub (!14-6), caliper

(!13-10) and front wheel. (!14-3)

Do not attempt to straighten a bent arm,

this may dangerously weaken the arm.

°Ø

Apply the grease onto the bushes and

inner collars

°Ø

Always use a new cotter pin.

°Ø

Bushes

Page 12

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-11

Mongoose/KXR 250

TIE-ROD

REMOVAL AND INSPECTION

Remove the cotter pin and nut attaching the

tie-rod and steering column.

Remove the cotter pin and nut attaching the

tie-rod and steering knuckle.

Then remove tie-rods.

Inspect the tie-rod.

Bend/damage _Replace.

Check the tie-rod end movement.

Tie-rod end exists free play or turns

roughly _Replace.

Check the tapered surface of the tie-rod end.

Pitting/wear/damage _Replace.

Adjust the tie-rod length.

Adjustment steps:

(The following procedures are done on both

tie-rods, right and left.)

Loosen the lock nuts.

Adjust the tie-rod length by tuning both tie-

rod ends.

Tie rod length: 299.5±0.5mm

Lock Nut

Lock Nut

Indentation Surface

Nut

Cotter Pin

Nut

Cotter Pin

Page 13

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-12

Mongoose/KXR 250

Set the rod-end (steering column side) in an

angle where the indentation surface of the

tie-rod is parallel to the rod-end shaft, and

then tighten the lock nut.

Torque: 2.5_ 3.5kgf-m

Set the other rod-end (knuckle arm side) in

an angle as shown (right-hand tie-rod and

left-had tie-rod), and then tighten the lock

nut.

Rod-end (tie rod) angle: 180

º

Torque: 2.5_ 3.5kgf-m

INSTALLATION

Reverse the “REMOVAL AND

INSPECTION” procedures.

Install the tie-rod and washer onto the

steering knuckle and steering column, then

tighten the nuts.

Torque: 3.0_ 4.0kgf-m

Install the all cotter pins and band ends of

cotter pins.

After making adjustment on both tie rods

be sure to mark them R and L for

identification.

°Ø

The threads on both rod-end must be of

the same length.

°Ø

To Steering Column

To Knuckle Arm

Always use a new cotter pin.

°Ø

Be sure that the rod-end on the

indentation surface side is connected to

the steering knuckle.

°Ø

Indentation Surface

Page 14

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-13

Mongoose/KXR 250

HANDLEBAR

REMOVAL AND INSPECTION

Remove the following parts:

Seat, front cover, center cover, front fender

and handlebar cover.

Refer to the “FENDERS” section in the

CHAPTER 2

Remove the right and left master cylinder

and remove bands then disconnect the rear

and front fluid tube from the handlebar.

Remove the two screws and remove the

handlebar switch.

Remove the two screws and remove throttle

unit.

Remove the four handlebar holder bolts and

remove the handlebar.

INSPECTION

Inspect the handlebar.

Cracks/bends/damage _Replace.

Bolts

Brake Fluid Tube

Screws

Screws

Bolts

Page 15

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-14

Mongoose/KXR 250

INSTALLATION

Install handlebar and handlebar holder, then

tighten the four bolts.

Torque: 1.8_ 2.5kgf-m

Install the handlebar switch by aligning the

pin on the handlebar switch with the hole in

the handlebar and then tighten the two

screws.

Place the right and left brake master cylinder

on the handlebar and install the master

cylinder holder with the “UP” mark facing

up, aligning the punch mark on the

handlebar with the holder joint seam. First

tighten the upper bolt and then tighten the

lower blot.

Torque: 0.8 ~ 1.2kg-m

• Align the mark on the handlebar

with the lower handlebar holder surface.

• Be sure the upper handlebar

holder mark face to front.

• Fist tighten the bolts on the front

side of the handlebar holder, and then

tighten the bolts on the rear side.

°Ø

Mark

Holder Surface

Forward Mark

Hole

Pin

Joint Seam

Punch Mark

“UP” Mark

Page 16

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-15

Mongoose/KXR 250

Install the throttle unit by aligning the upper

holder lip with the mark in the handlebar

and then install the lower holder and tighten

the two screws.

STEERING COLUMN

REMOVAL AND INSPECTION

Remove handlebar. (!14-13)

Remove the two bolts and remove the cable

holder, steering brackets, collars and dust

seal.

Mark

Upper Holder Lip

Bolts

Collars

Steering Bracket

Steering Bracket

Dust Seal

Page 17

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-16

Mongoose/KXR 250

Remove the cotter pins and nuts attaching

the tie-rods, then disconnect the tie-rods

from the steering column.

Remove the cotter pin and nut attaching the

steering column under the frame body, then

remove steering column and collar.

Inspect the collar, dust seals, snap ring

(under the dust seal) and bearing.

Wear/damage _Replace.

Cotter Pin

Nut

Cotter Pin

Nut

Dust Seal

Collar

Bearing

Dust Seal

Snap Ring

Page 18

14. FRONT WHEEL/FRONT SUSPENSION/

STEERING SYSTEM

14-17

Mongoose/KXR 250

Inspect the steering column.

Bends/damage _Replace.

Inspect the steering brackets and oil seal.

Wear damage _Replace.

INSTALLATION

Reverse the “REMOVAL” procedures.

Install the steering column and collar, then

tighten the nut under the frame body.

Torque: 6.0_ 8.0kgf-m

Install the cotter pin and band ends of cotter

pin.

Assembly the steering column and tighten

the two bolts.

Torque: 1.8_ 2.5kgf-m

Install the tie rods and washer, then tighten

the nut.

Torque: 3.0_ 4.0kgf-m

Install the cotter pins and band ends of

cotter pins.

Refer to the “TOE-IN ADJUSTMENT”

section in the CHAPTER 3 to adjust toe-in.

Do not attempt to straighten a bent

shaft, this may dangerously weaken the

°Ø

Apply the grease onto the collar, dust

seals, and bearing.

°Ø

Always use a new cotter pin.

°Ø

Always use a new cotter pin.

°Ø

Loading...

Loading...