Page 1

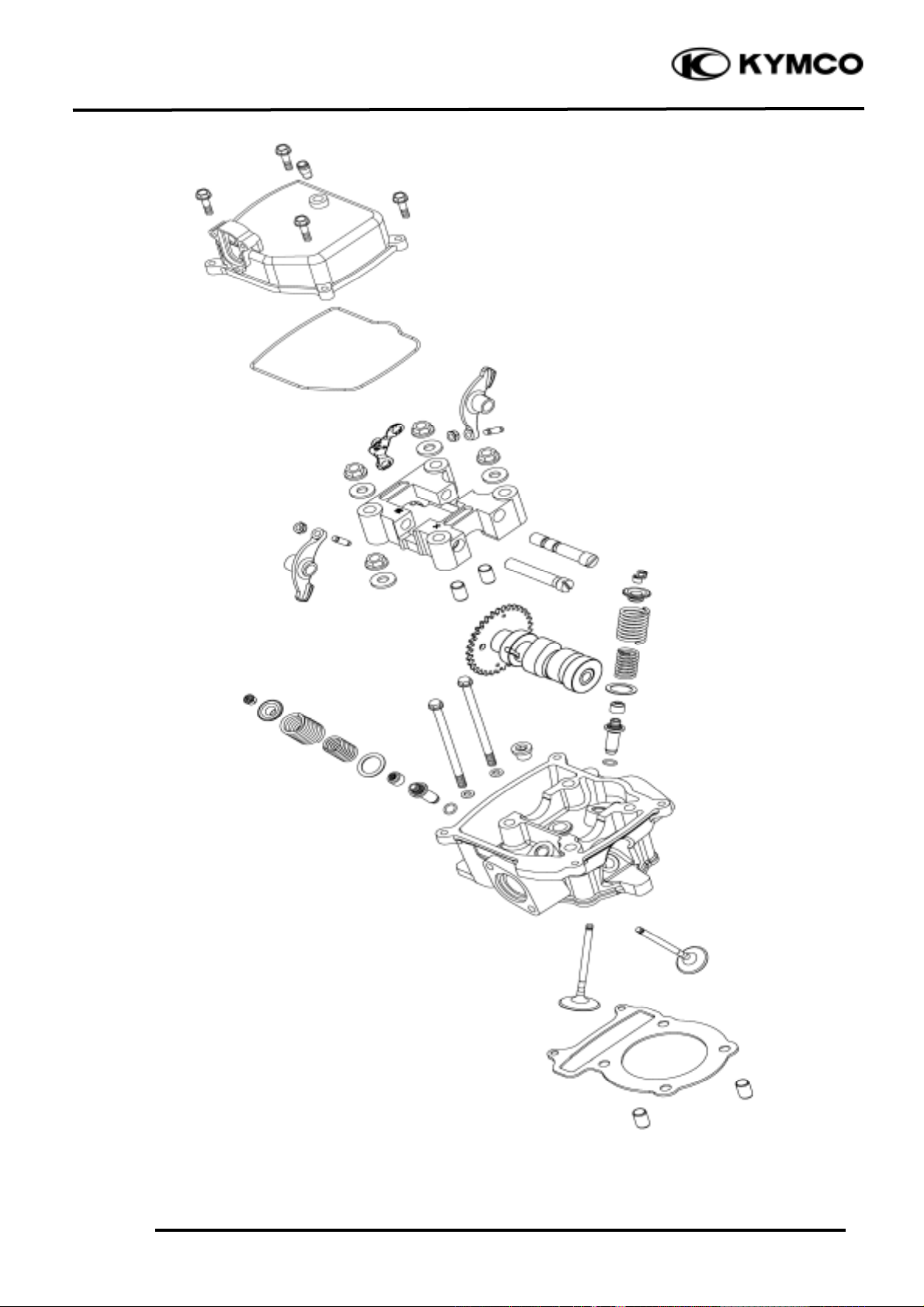

7. CYLINDER HEAD/VALVES

7-0

Mongoose/KXR 250

7

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

CYLINDER HEAD/VALVES

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 7- 2

TROUBLESHOOTING ------------------------------------------------- 7- 3

CYLINDER HEAD COVER-------------------------------------------- 7- 4

CAMSHAFT/CAMSHAFT HOLDER --------------------------------- 7- 4

CYLINDER HEAD------------------------------------------------------ 7- 9

7

Page 2

7. CYLINDER HEAD/VALVES

7-1

Mongoose/KXR 250

Page 3

7. CYLINDER HEAD/VALVES

7-2

Mongoose/KXR 250

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The cylinder head can be serviced with the engine installed in the frame.

• When assembling, apply molybdenum disulfide grease or engine oil to the valve guide movable

parts, valve arm and camshaft sliding surfaces for initial lubrication.

• The camshaft is lubricated by engine oil through the cylinder head engine oil passages. Clean and

unclog the oil passages before assembling the cylinder head.

• After disassembly, clean the removed parts and dry them with compressed air before inspection.

• After removal, mark and arrange the removed parts in order. When assembling, install them in the

reverse order of removal.

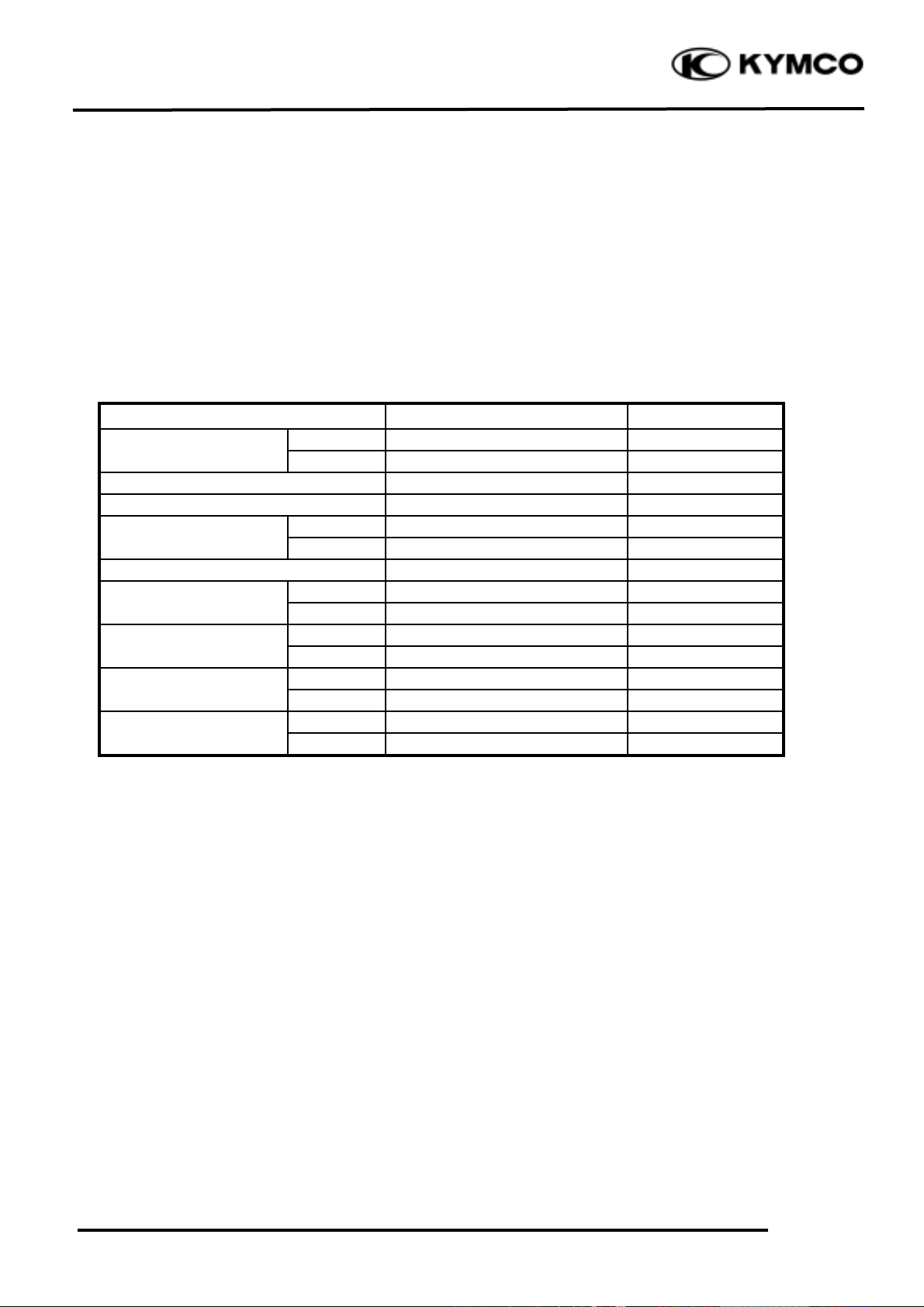

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

IN

0.1

æ

EX

0.1

æ

Cylinder head compression pressure

15±2kg/cm_

Cylinder head warpage

æ

0.05

IN

34.287

34.15

EX

34.1721

34.05

Valve rocker arm to shaft clearance

0.034_ 0.09

0.1

Valve stem-to-guide

IN

0.010_ 0.037

0.06

clearance

EX

0.025_ 0.052

0.08

IN

30.9

29.4

Valve spring free length

EX4139

IN

10.20_ 11.84kg(at 18.05mm)

æ

Valve spring

compressed force

EX

19.14_ 22.02kg(at 21.5mm)

æ

IN

0.8

æ

Valve spring tilt

EX

1.07

æ

Valve clearance (cold)

Camshaft cam height

Page 4

7. CYLINDER HEAD/VALVES

7-3

Mongoose/KXR 250

TORQUE VALUES

Cylinder head cover bolt 0.8_ 1.2kgf-m

Cam shaft hold nut 2.3_ 2.7kgf-m Apply engine oil to threads

Tappet adjusting nut 0.7_ 1.1kgf-m

SPECIAL TOOLS

Valve spring compressor E040

Tappet adjuster E012

TROUBLESHOOTING

• The poor cylinder head operation can be diagnosed by a compression test or by tracing engine

top-end noises.

Poor performance at idle speed White smoke from exhaust muffler

• Compression too low • Worn valve stem or valve guide

• Damaged valve stem seal

Compression too low

• Incorrect valve clearance adjustment Abnormal noise

• Burned or bend valves • Incorrect valve clearance adjustment

• Incorrect valve timing • Sticking valve or broken valve spring

• Broken valve spring • Damaged or worn camshaft

• Poor valve and seat contact • Worn cam chain guide

• Leaking cylinder head gasket • Worn camshaft and rocker arm

• Warped or cracked cylinder head

• Poorly installed spark plug

Compression too high

• Excessive carbon build-up in combustion

chamber

Page 5

7. CYLINDER HEAD/VALVES

7-4

Mongoose/KXR 250

CYLINDER HEAD COVER

REMOVAL

Remove fuel tank. (Refer to the chapter 5)

Disconnect the oil recycle tube at the

cylinder head cover.

Remove the four bolts at the cylinder head

cover, then remove the cylinder head cover.

INSTALLATION

Install a new cylinder head cover O-ring and

install the cylinder head cover.

Install and tighten the cylinder head cover

bolts.

Torque: 0.8_ 1.2kgf-m

CAMSHAFT/CAMSHAFT

HOLDER

REMOVAL

Remove the cylinder head cover. (Refer to

the cylinder head cover removal)

Remove the cam chain tensioner cap bolt

and the O-ring.

Turn the cam chain tensioner screw

clockwise to tighten it.

Cylinder Head Cover

Oil Recycle Tube

Bolts

O-ring

Be sure to install the O-ring into the

groove properly.

°Ø

Bolt

Tensioner Screw

Page 6

7. CYLINDER HEAD/VALVES

7-5

Mongoose/KXR 250

Remove the four camshaft holder nuts and

washers.

Remove the camshaft holder and dowel

pins.

Remove the camshaft gear from the cam

chain and remove the camshaft.

CAMSHAFT HOLDER DISASSEMBLY

Take out the valve rocker arm shafts.

Remove the valve rocker arms, arm shafts

and stop plate.

Diagonally loosen the cylinder head nuts

in 2 or 3 times.

°Ø

Nuts and Washers

Camshaft Holder

Camshaft

Stop Plate

Rocker Arms

Rocker Arm Shafts

Page 7

7. CYLINDER HEAD/VALVES

7-6

Mongoose/KXR 250

CAMSHAFT HOLDER INSPECTION

Inspect the camshaft holder for wear or

damage.

Inspect the rocker arm shaft for blue

discoloration or grooves.

If any defects are found, replace the rocker

arm shaft with a new one, then inspect

lubrication system.

Inspect the rocker arm bore, cam lobe

contact surface and adjuster surface for

wear/pitting/scratches/blue discoloration.

If any defects are found, replace the rocker

arm shaft with a new one, then inspect

lubrication system.

Measure each rocker arm shaft O.D.

Measure the I.D. of each valve rocker arm.

Measure arm to shaft clearance.

Replace as a set if out of specification.

Service limits: 0.10mm

Camshaft Holder

Rocker Arm Shafts

Rocker Arm Bore

Contact Surface

Adjuster Surface

Page 8

7. CYLINDER HEAD/VALVES

7-7

Mongoose/KXR 250

CAMSHAFT HOLDER ASSEMBLY

Reverse the “CAMSHAFT HOLDER

DISASSEMBLY” procedures.

CAMSHAFT INSPECTION

Check each camshaft bearing for play or

damage. Replace the camshaft assembly

with a new one if the bearings are noisy or

have excessive play.

Inspect camshaft lobes for

pitting/scratches/blue discoloration.

Measure the cam lobe height.

Service Limits:

IN : 34.15mm replace if below

EX: 34.05mm replace if below

If any defects are found, replace the

camshaft with a new one, then inspect

lubrication system.

Camshaft Bearings

Align the cross cutout on the exhaust

valve rocker arm shaft with the bolt of

the camshaft holder.

°Ø

Page 9

7. CYLINDER HEAD/VALVES

7-8

Mongoose/KXR 250

INSTALLATION

Reverse the “CAMSHAFT REMOVAL”

procedures.

Note the following points:

1. Turn the flywheel so that the “T” mark

on the flywheel aligns with the index

mark on the crankcase.

Keep the round hole on the camshaft gear

facing up and align the punch marks on

the camshaft gear with the cylinder head

surface (Position the intake and exhaust

cam lobes down.) and install the camshaft

onto the cylinder head. (Refer to the

“VALVE CLEARANCE” section in the

chapter 3)

Install the camshaft dowel pins and

holder.

Torque:

Cam shaft hold nut: 2.3_ 2.7kgf-m Apply engine oil to threads

2. Turn the cam chain tensioner screw

counter-clockwise to release it.

Apply engine oil to a new O-ring and

install it.

Tighten the cam chain tensioner cap bolt.

3. Adjust the valve clearance. (Refer to the

“VALVE CLEARANCE” section in the

chapter 3)

• Apply engine oil to the threads

of the cylinder head nuts.

• Diagonally tighten the cylinder

head nuts in 2_ 3 times.

°Ø

Be sure to install the O-ring into the

groove properly.

°Ø

Dowel Pins

Page 10

7. CYLINDER HEAD/VALVES

7-9

Mongoose/KXR 250

CYLINDER HEAD

REMOVE

Remove the camshaft. (Refer to the

“camshaft remove” section in the chapter 7)

Remove the carburetor. (Refer to the

“carburetor remove” section in the chapter

5)

Remove the exhaust muffler. (Refer to the

“exhaust muffler remove” section in the

chapter 2)

Remove the two bolts and then remove the

carburetor intake manifold.

Remove the bolt and disconnect the

thermostat.

Remove the two cylinder head bolts.

Remove the cylinder head.

CYLINDER HEAD DISASS EMBLY

Remove the valve spring cotters, retainers,

springs, spring seats, oil seals and valves

using a valve spring compressor.

Valve Spring Compressor E040

Bolts

Intake Manifold

Bolt

Bolt

Bolts

Valve Cotter

Retainer

Springs

Springs Seat

Oil Seal

Valve

Spring Compressor

• Be sure to compress the valve

springs with a valve spring compressor.

• Mark all disassembled parts to

ensure correct reassembly.

°Ø

Special

Page 11

7. CYLINDER HEAD/VALVES

7-10

Mongoose/KXR 250

VALVE /VALVE GUIDE INSPECTION

Inspect each valve for bending, burning,

scratches or abnormal stem wear.

If any defects are found, replace the valve

with a new one.

Check valve movement in the guide.

Measure each valve stem O.D.

Measure each valve guide I.D.

Subtract each valve stem O.D. from the

corresponding guide I.D. to obtain the stemto-guide clearance.

Service limits: IN : 0.06mm replace if over

EX: 0.08mm replace if over

CYLINDER HEAD INPECTION

Check the spark plug hole and valve areas

for cracks.

Check the cylinder head for warpage with a

straight edge and feeler gauge.

Service Limit: 0.05mm repair or replace if

over

VALVE SPRING INSPECTION

Measure the free length of the inner and

outer valve springs.

Service Limit:

Inner: 29.4mm replace if below

Outer: 39mm replace if below

If the stem-to-guide clearance exceeds the

service limits, replace the cylinder head

as necessary.

°Ø

Page 12

7. CYLINDER HEAD/VALVES

7-11

Mongoose/KXR 250

Measure compressed force (valve spring)

and installed length.

Replace if out of specification.

Service limits:

IN : 10.20_ 11.84kg(at 18.05mm)

EX : 19.14_ 22.02kg(at 21.5mm)

Measure the spring tilt.

Replace if out of specification.

Service limits: IN : 0.8mm

EX : 1.07mm

Page 13

7. CYLINDER HEAD/VALVES

7-12

Mongoose/KXR 250

ASSEMBLY

Install the valve spring seats and oil seal.

Lubricate each valve with engine oil and

insert the valves into the valve guides.

Install the valve springs and retainers.

Compress the valve springs using the valve

spring compressor, then install the valve

cotters.

Valve Spring Compressor E040

Tap the valve stems gently with a plastic

hammer for 2_ 3 times to firmly seat the

cotters.

INSTALLATION

Install the dowel pins and a new cylinder

head gasket.

Reverse the “CYLINDER HEAD

REMOVAL” procedures.

Torque:

Cylinder head bolt: 0.8_ 1.2kgf-m

Dowel Pins

Gasket

• When assembling, a valve spring

compressor must be used.

• Install the cotters with the

pointed ends facing down from the

upper side of the cylinder head.

°Ø

Special

Be sure to install new oil seal.

°Ø

Be careful not to damage the valves.

°Ø

Loading...

Loading...